Crystallizing-dephosphorizing reactor

A technology of crystallization phosphorus removal and reactor, applied in the field of reactor, to achieve the effect of improving the pH of wastewater, avoiding short flow of fluid, and good solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

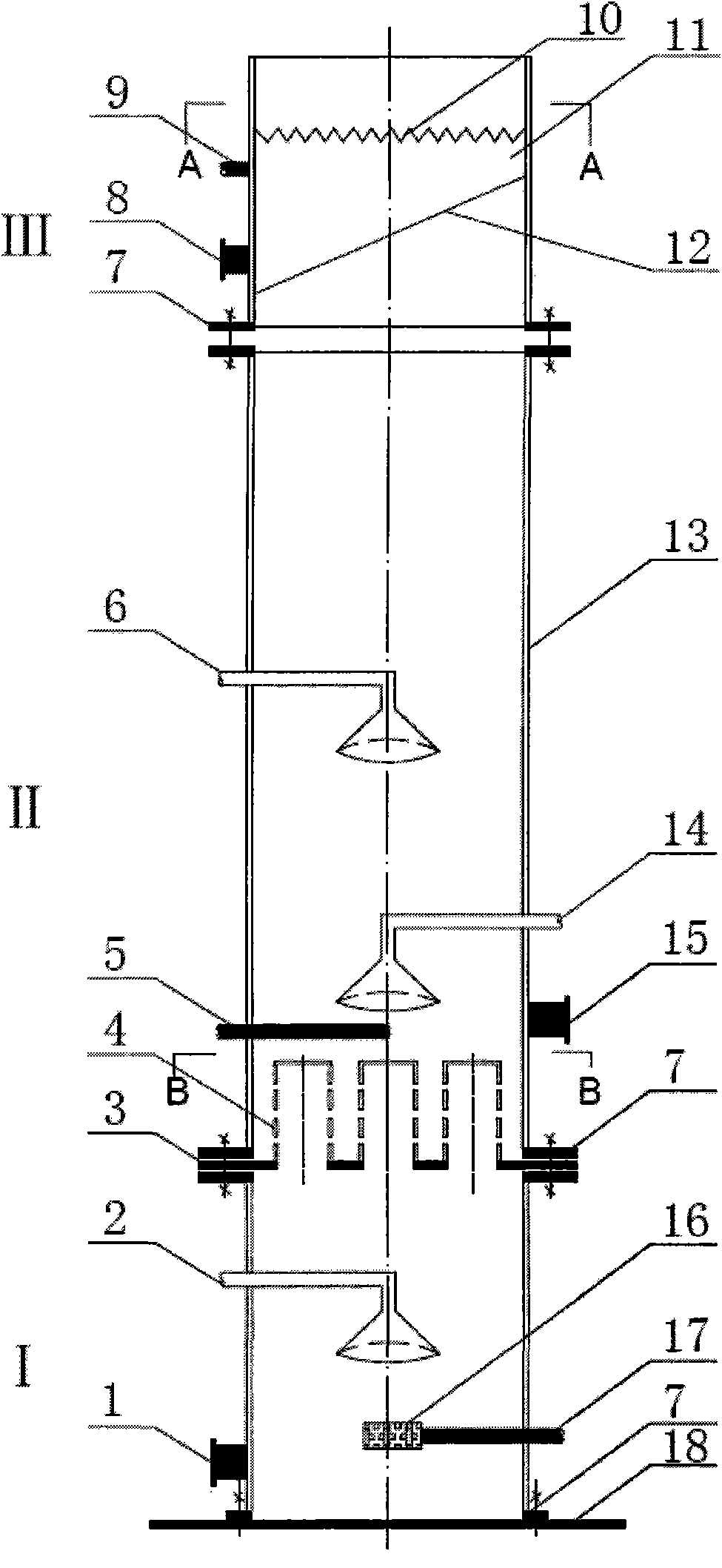

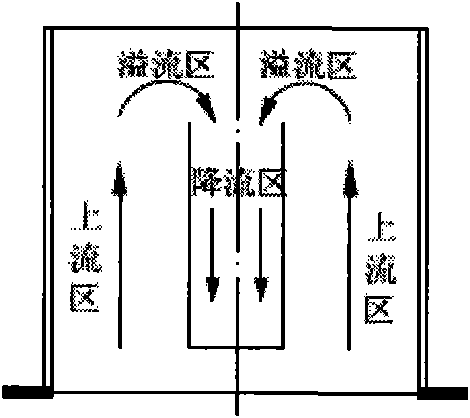

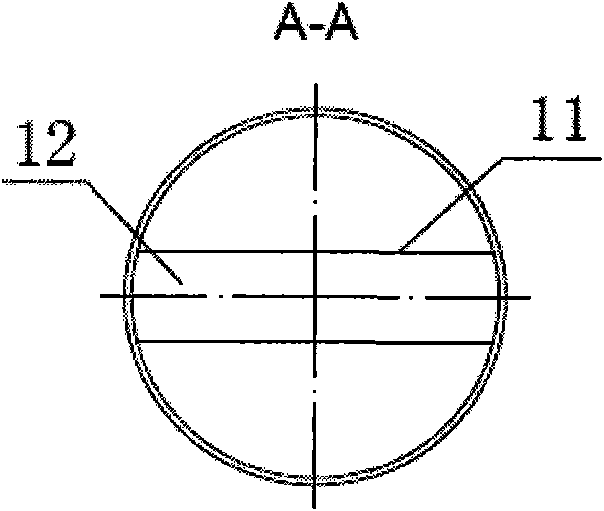

[0014] Such as figure 1 As shown, the body of the crystallization phosphorus removal reactor is equipped with water distribution area I, reaction area II and precipitation area III from bottom to top, and water distribution area I is equipped with slag discharge pipe 1, water inlet pipe 2, and upflow column disc distributor 3. Aeration device. The aeration device is composed of an aeration tube 17 and an aeration head 16. The lower part of the reaction zone II is equipped with a carrier inlet 15 and a drug feeding tube 5. The upper and lower parts of the middle part of the reaction zone II are equipped with first The return pipe 6, the second return pipe 14, the sedimentation zone III is provided with an outlet weir, an outlet pipe 9, and a discharge port 8, the upper part of the outlet weir is provided with a zigzag overflow weir 10, and the side of the outlet weir is provided with two parallel baffles 11, A sloping plate 12 is provided at the bottom of the outlet weir.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com