Patents

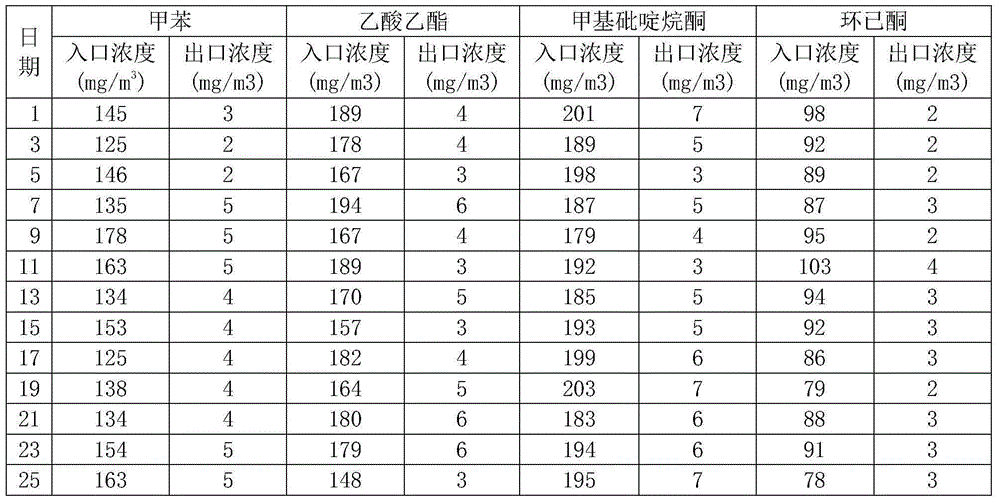

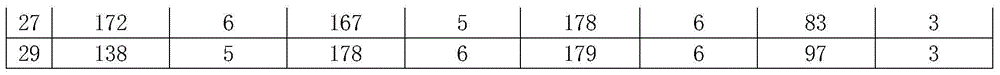

Literature

92results about How to "Efficient solid-liquid separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

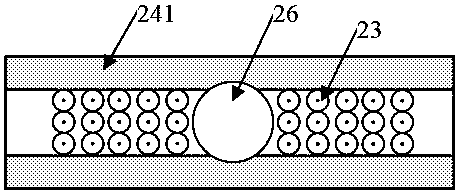

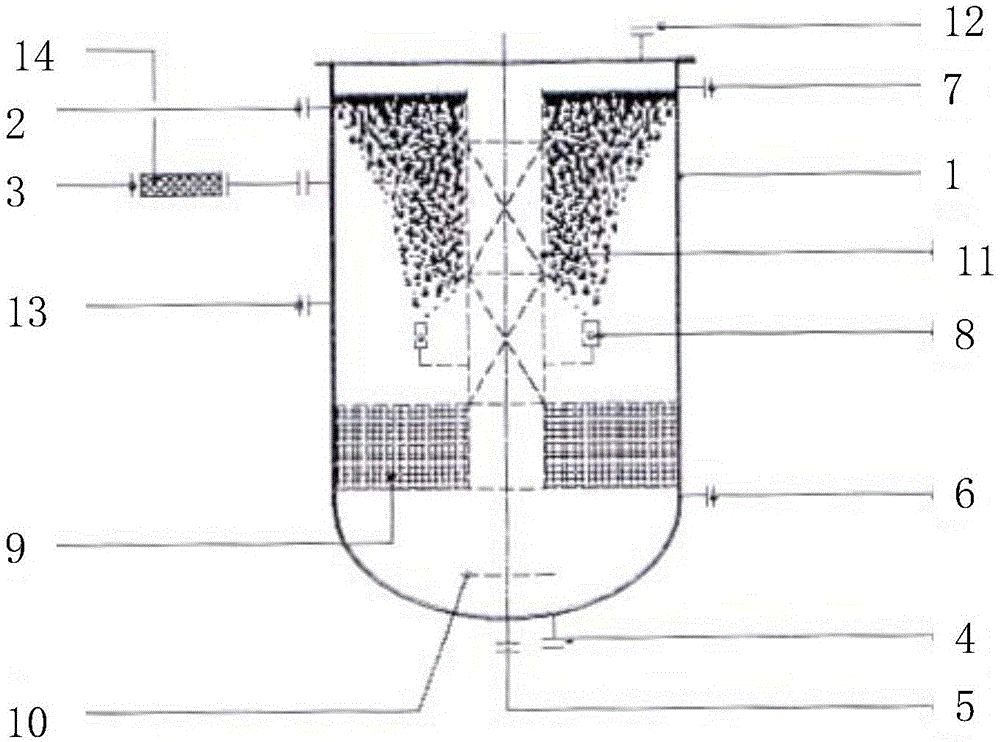

Gas-liquid-solid three-phase suspension bed reactor for fischer-tropsch synthesis and its applications

ActiveUS20100216896A1High activitySimple structureHydrocarbon from carbon oxidesPhysical/chemical process catalystsGas phaseFiltration

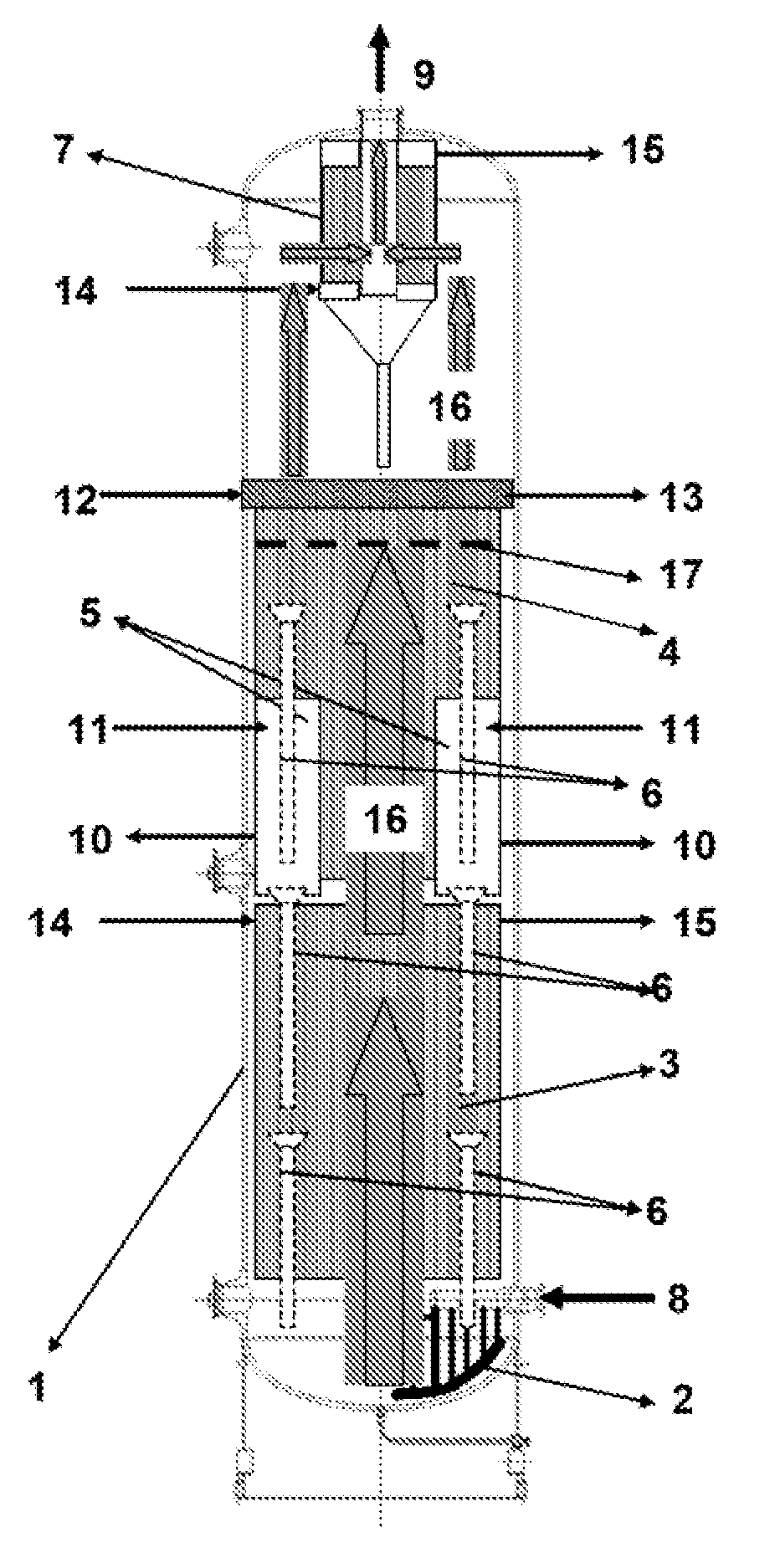

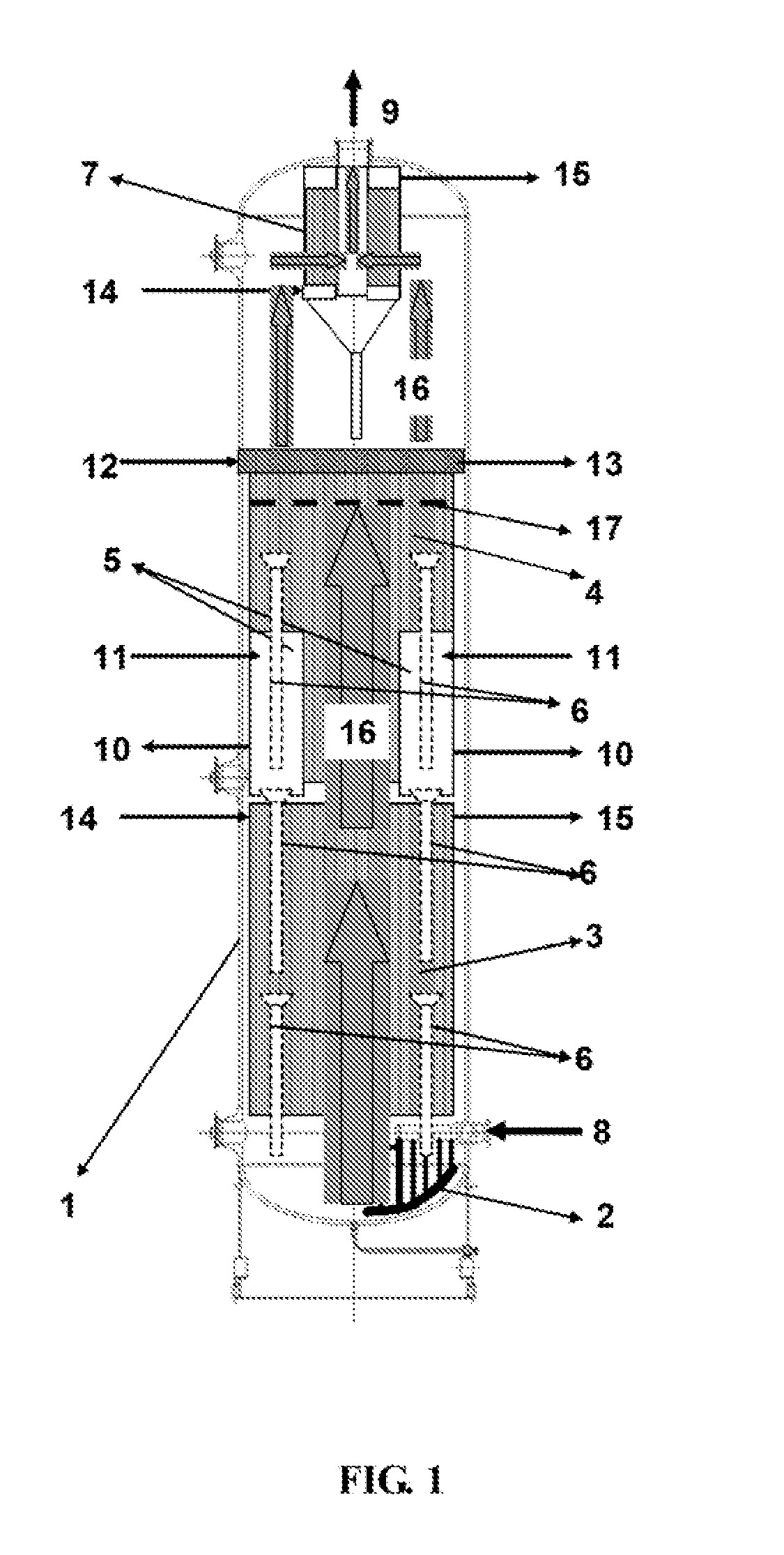

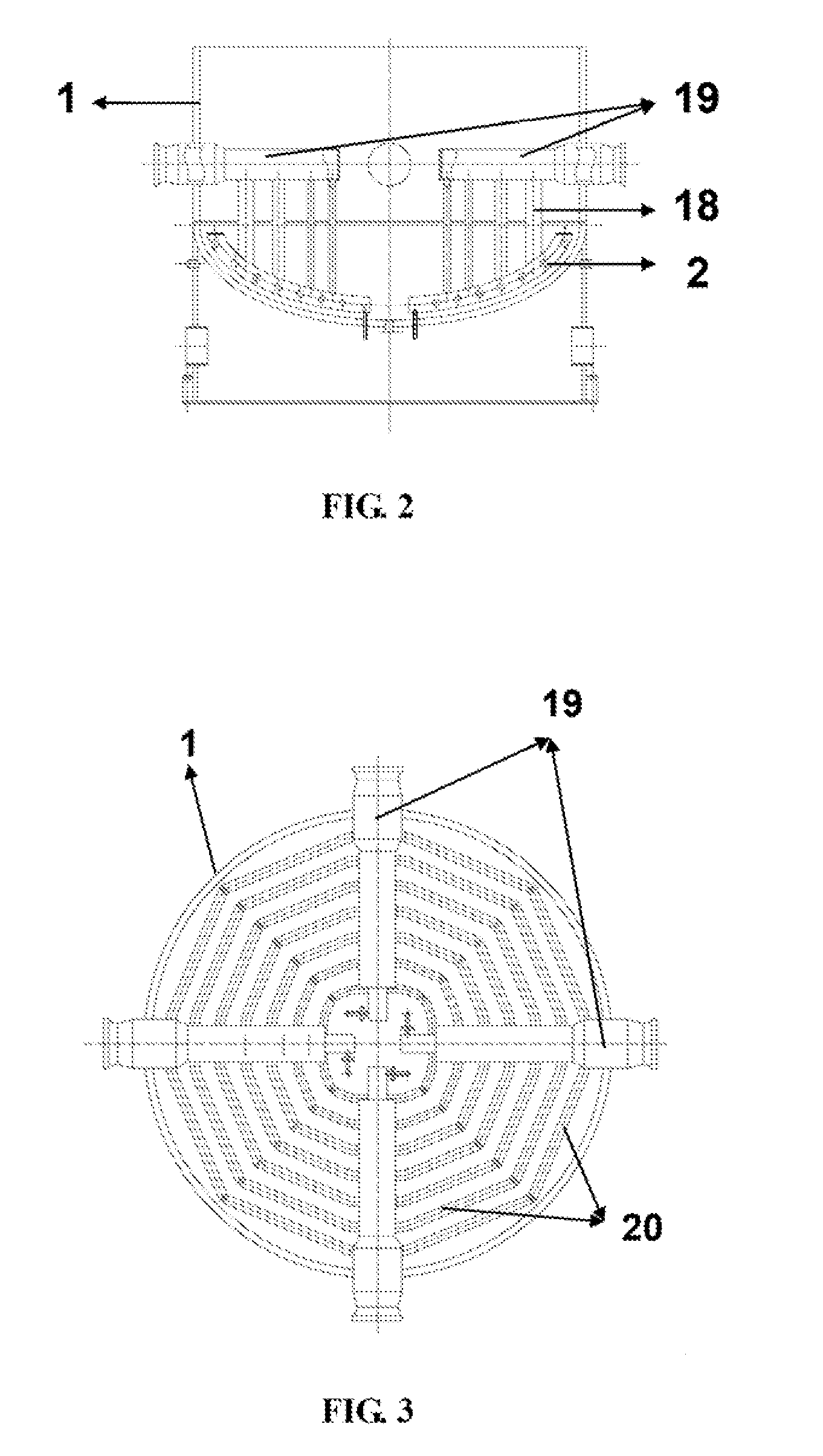

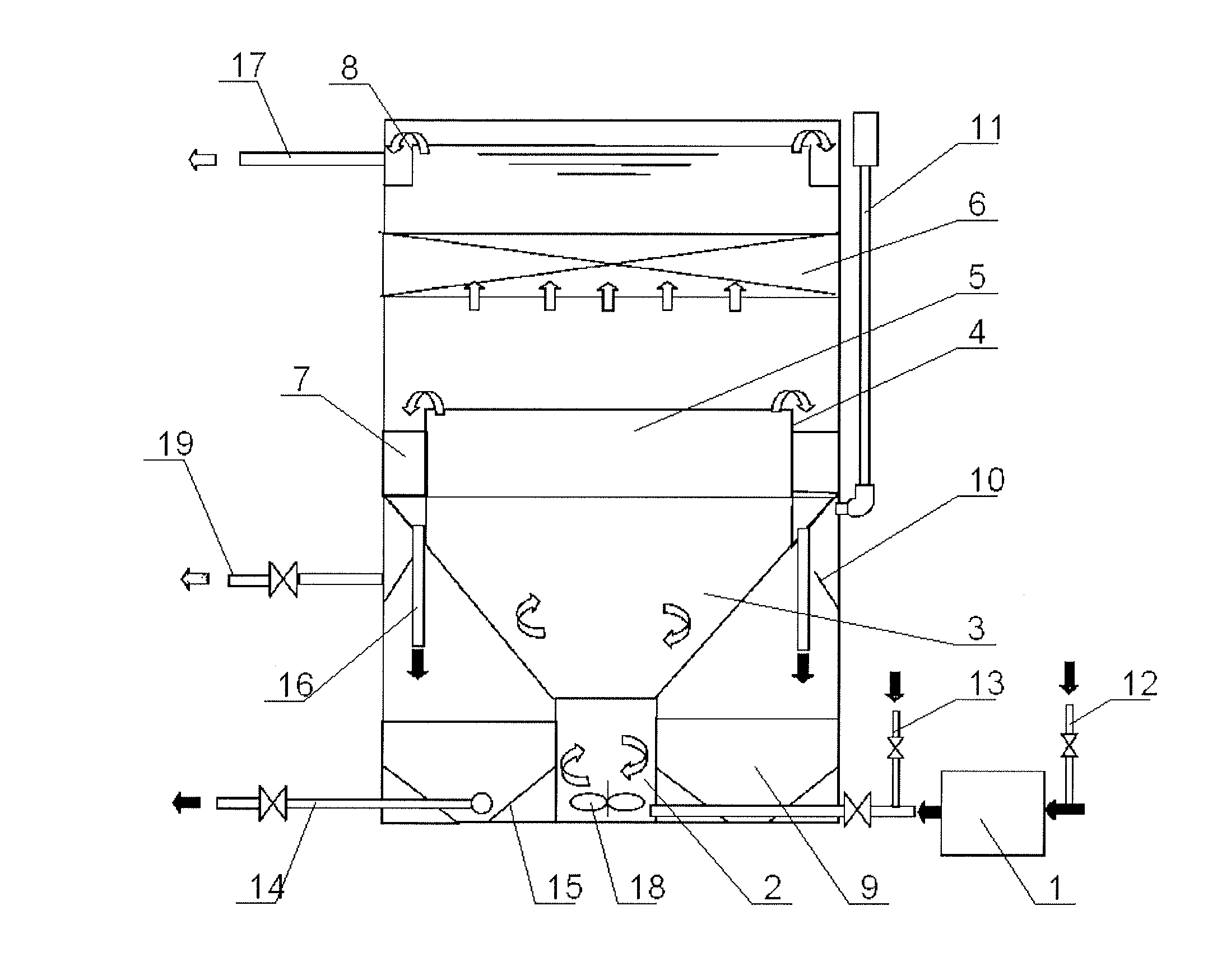

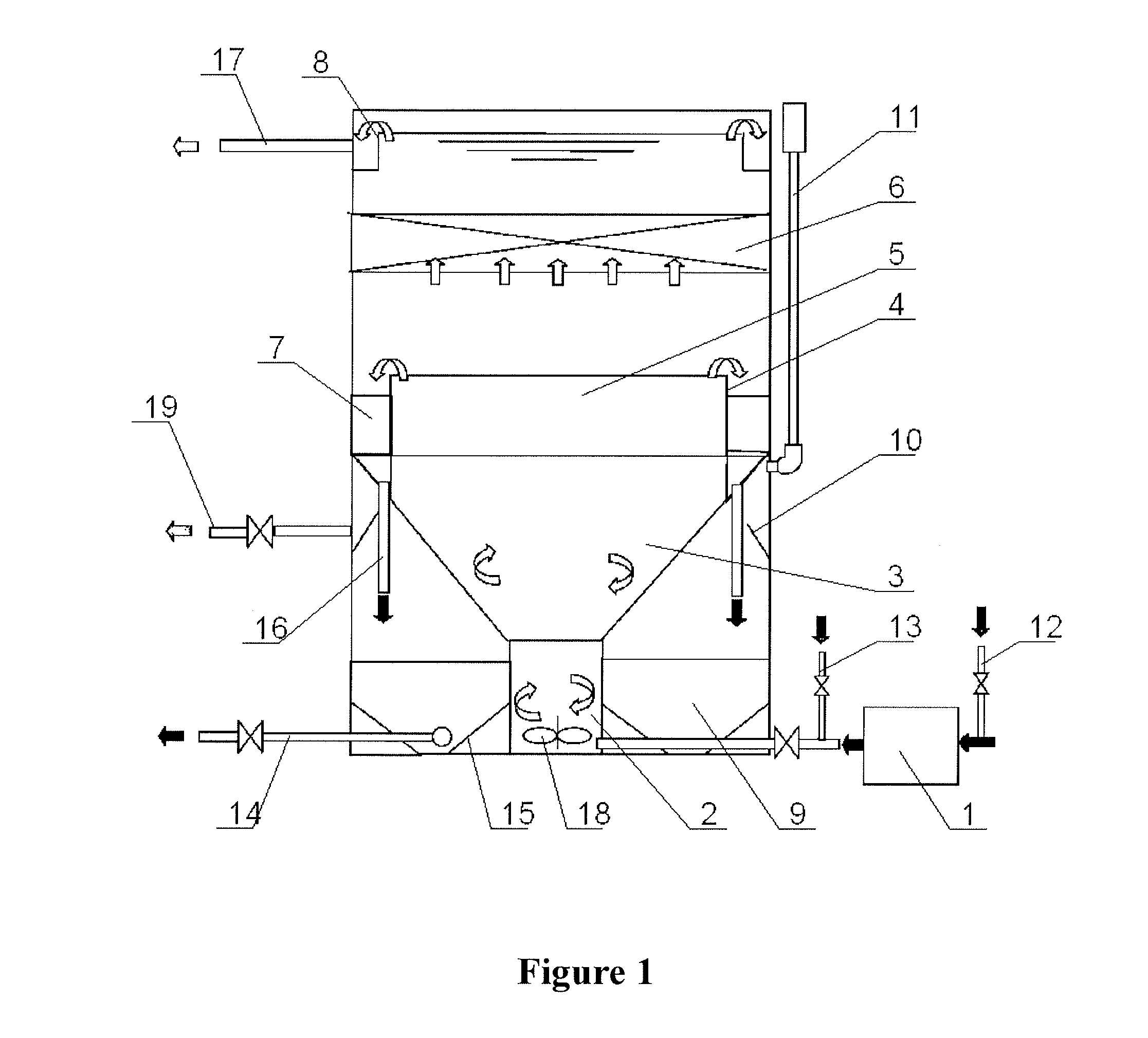

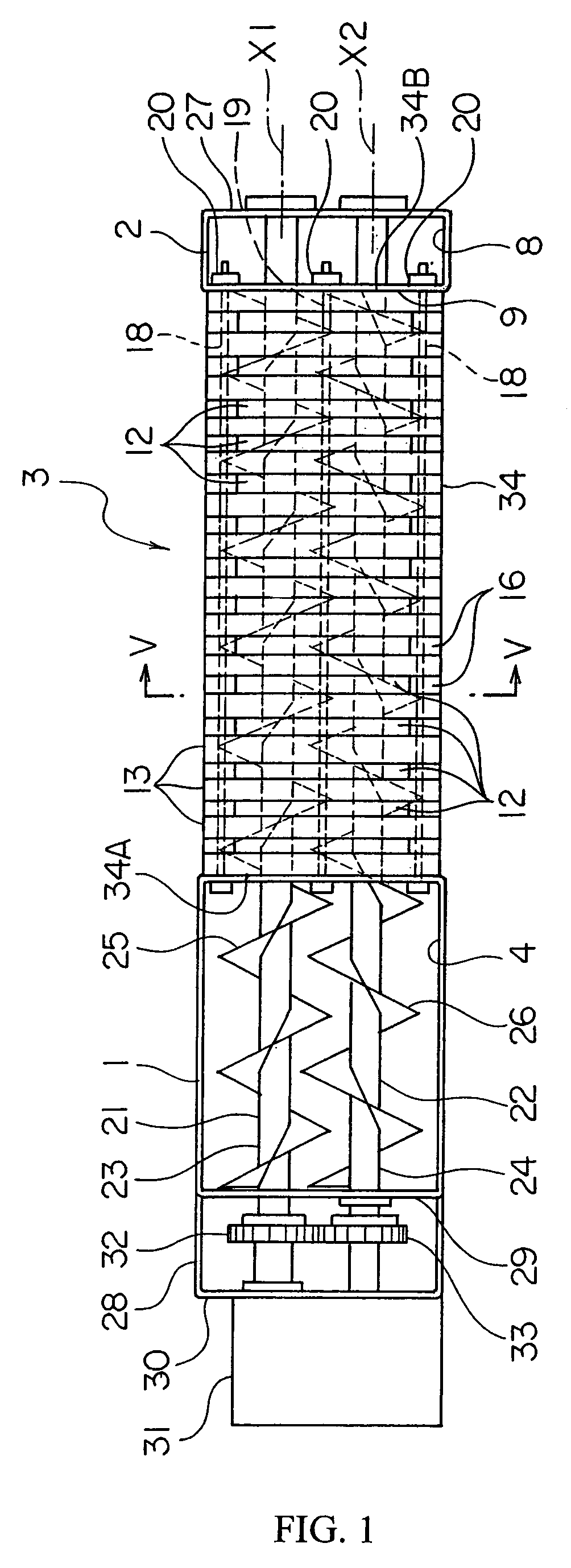

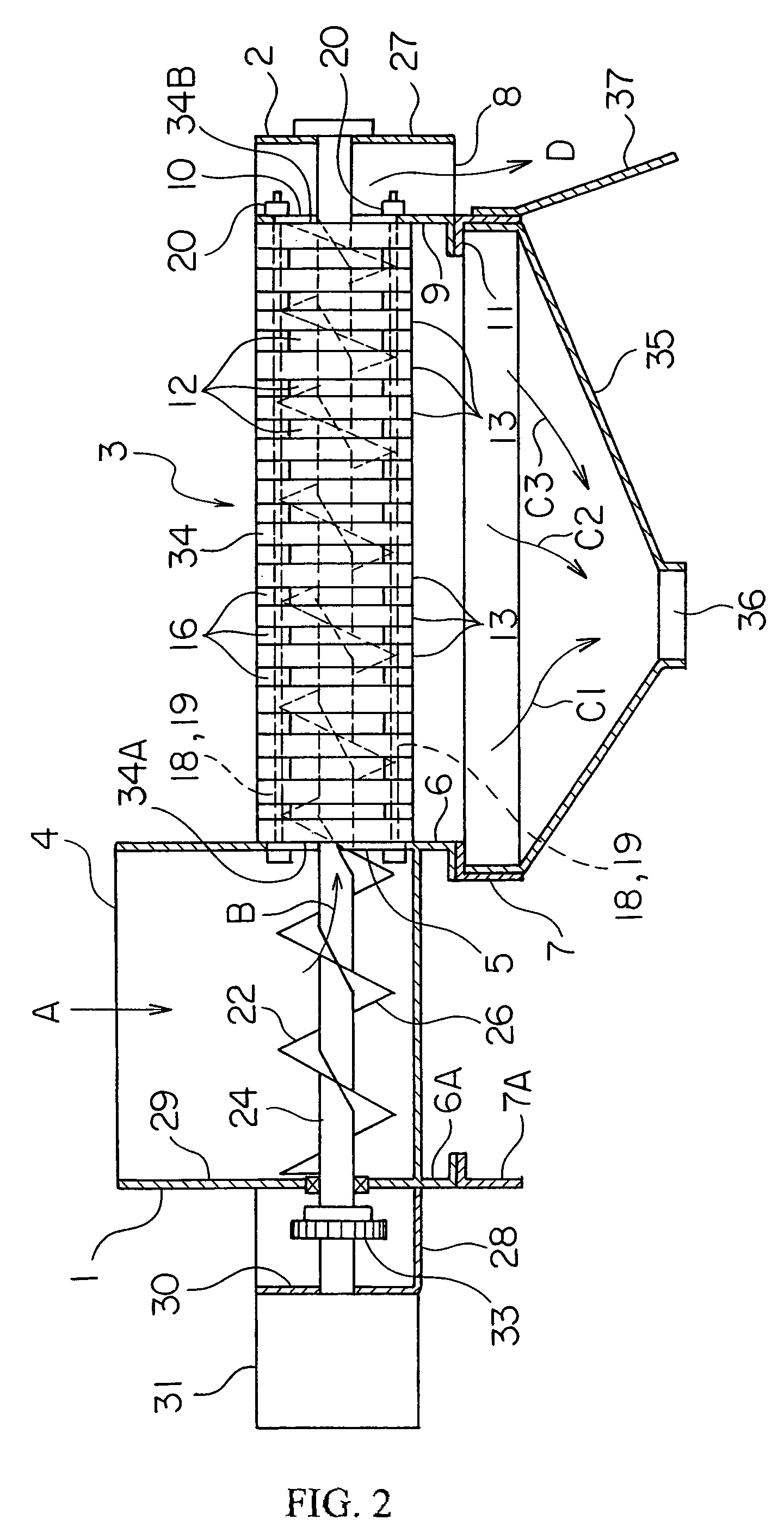

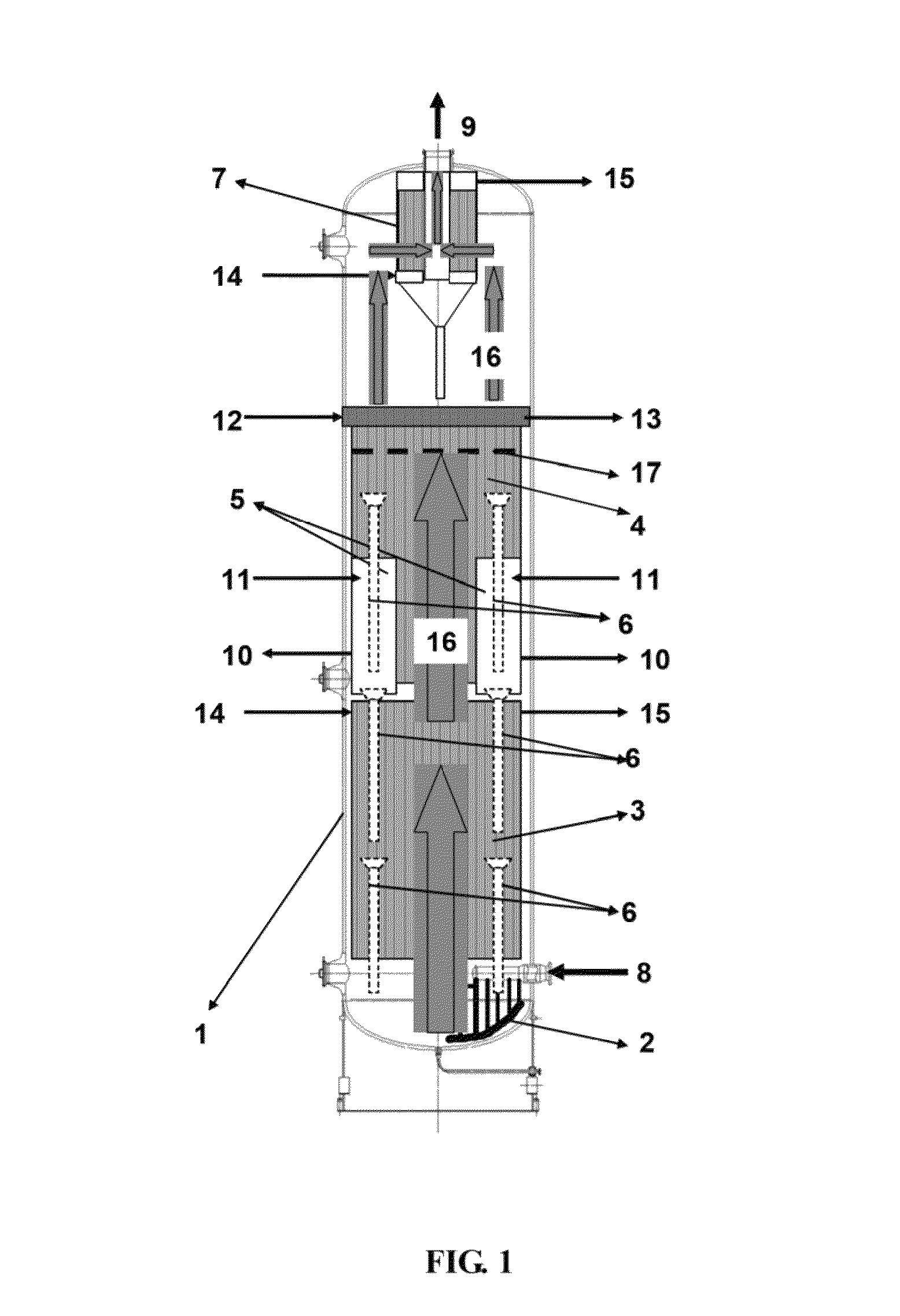

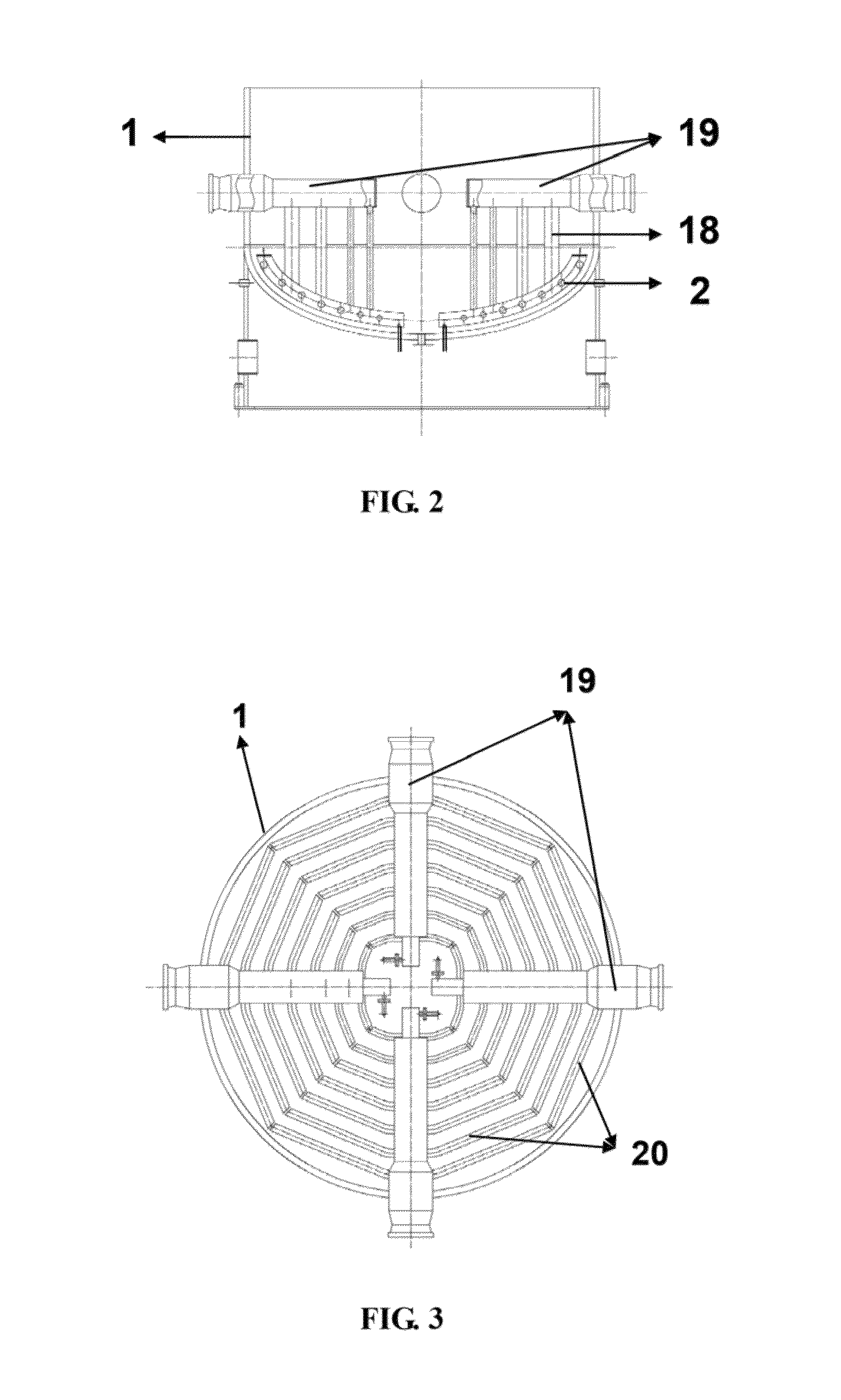

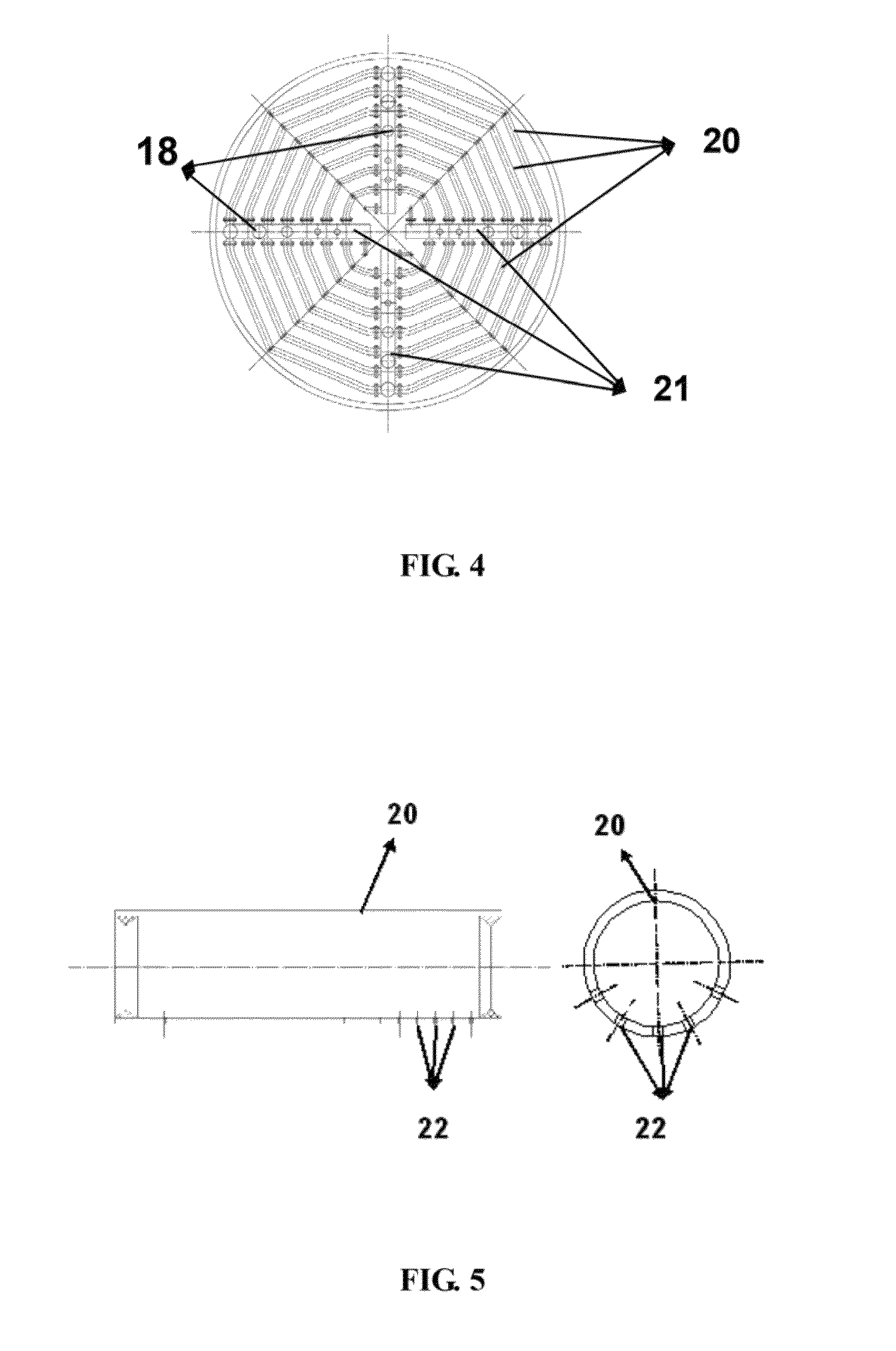

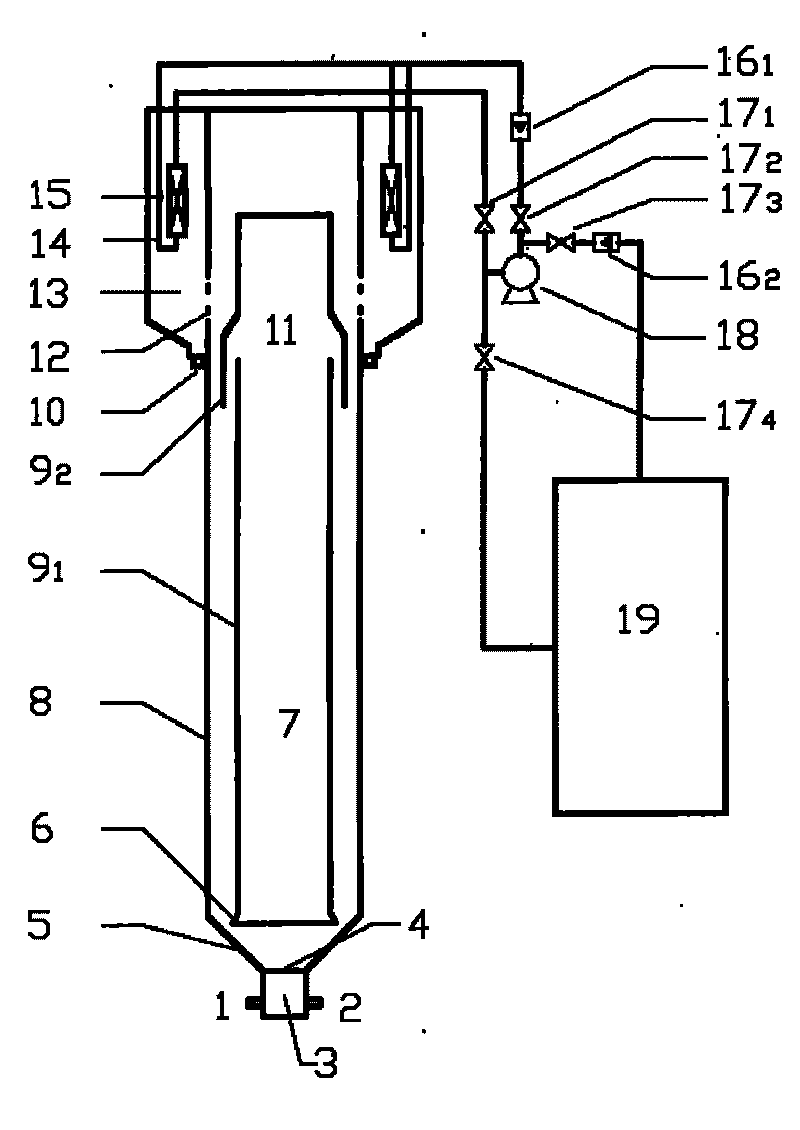

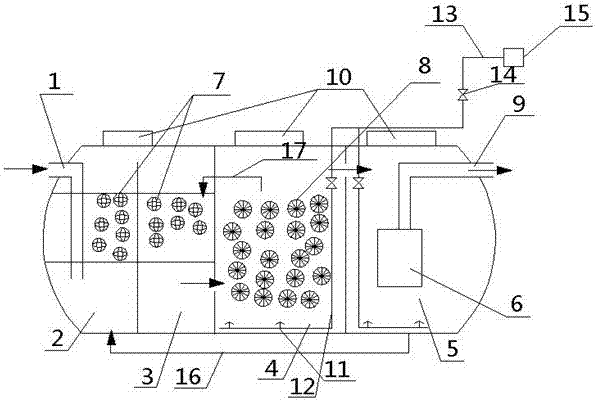

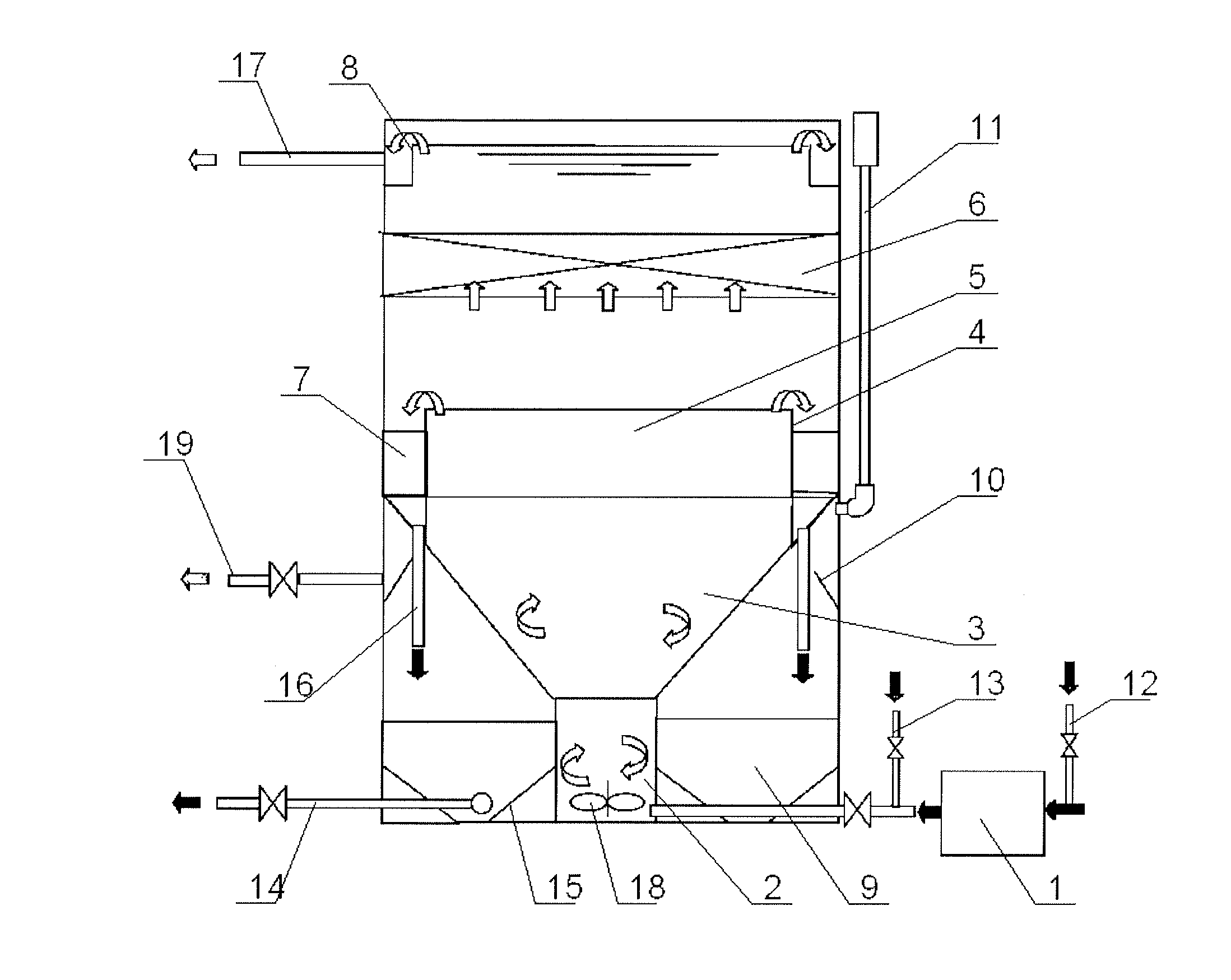

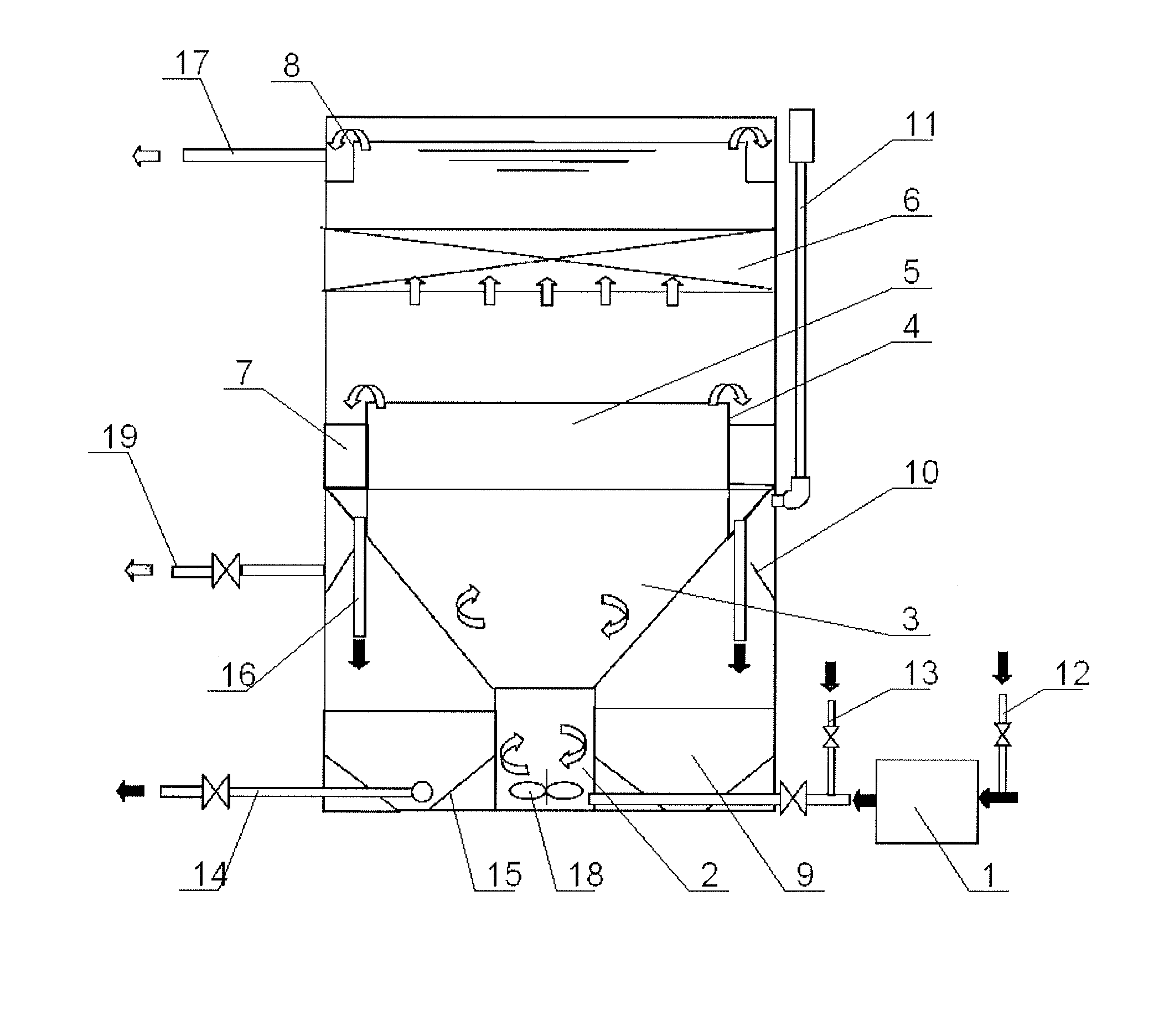

A Fischer-Tropsch synthesis three-phase suspension bed reactor (“suspension bed” also called “slurry bed”) and its supplemental systems, may include: 1) structure and dimension design of F-T synthesis reactor, 2) a gas distributor located at the bottom of the reactor, 3) structure and arrangement of a heat exchanger members inside the reactor, 4) a liquid-solid filtration separation device inside reactor, 5) a flow guidance device inside reactor, 6) a condensate flux and separation member located in the gas phase space at the top of reactor, 7) a pressure stabilizer, a cleaning system for the separation device; an online cleaning system for the gas distributor; an ancillary system for slurry deposition and a pre-condensate and mist separation system located at the outlet of upper reactor. This reactor is suitable for industrial scale application of Fischer-Tropsch synthesis.

Owner:SYNFUELS CHINA TECH CO LTD

VOC (volatile organic compound) treatment system adopting ozone and micro-nano-bubbles

InactiveCN105056726AEfficient removalImprove adsorption capacityDispersed particle separationAir quality improvementMicro nanoFiltration

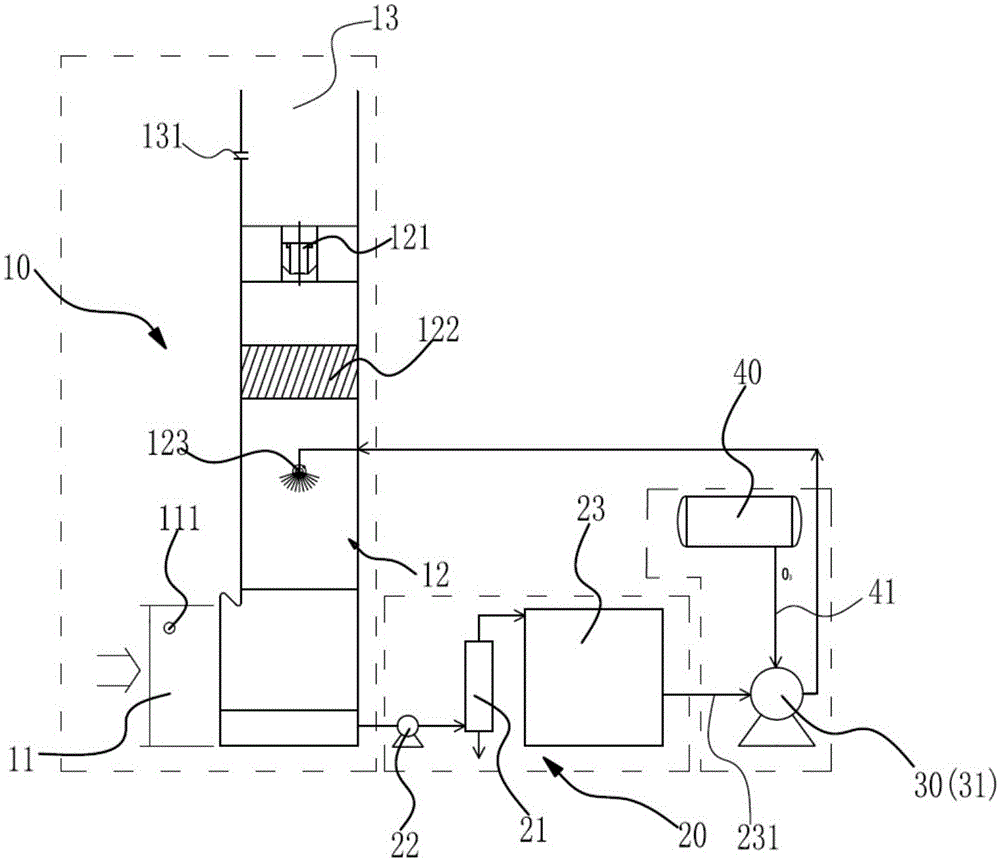

The invention discloses a VOC (volatile organic compound) treatment system adopting ozone and micro-nano-bubbles. The system comprises a waste gas treatment device, a spray liquid circulating filtration device, a micro-nano-bubble generation device and an ozone generation device, wherein the waste gas treatment device comprises a waste gas inlet, a waste gas purification chamber and a waste gas outlet; an axial flow fan, a gas-water separator and a micro-nano-bubble water mist spray nozzle are arranged in the waste gas purification chamber sequentially from top to bottom. The system adopts the ozone and the micro-nano-bubbles to degrade VOCs, a treatment method is safer than other treatment methods, the operation is convenient, and the treatment cost is low; the VOC removal rate can be higher than 96% by the aid of optimization selection of a spray liquid and mutual actions of the ozone generation device, the micro-nano-bubble generation device and the spray nozzle.

Owner:DONGGUAN BOSO ENVIRONMENTAL TECH CO LTD

Device for Purifying Oily Wastewater

InactiveUS20130062272A1Increase settling velocityStrong turbulenceWaste water treatment from quariesSludge treatmentFlocculationFiltration

There is disclosed a device for purifying oily wastewater, including a vertical tank of an atmospheric pressure, inside which a central coagulation reaction tube, a reverse cone-shaped cyclone flocculation stage, a suspended sludge filtering zone and a purified water commutation stage of inclined plates are included from bottom to top sequentially, oily wastewater is sequentially subjected to a coagulation reaction, suspended sludge filtering and a purified water commutation process and then discharged, a sludge collecting groove collects and guides the suspended sludge to a sludge concentrating zone for further sedimentation and concentration processes and then discharges it to external to the tank, in this way, the purification reaction, flocculation and fine filtration of wastewater and the sludge concentration process are integrated within the same wastewater purifying device. Thus, the device is equivalent to the existing wastewater pretreatment system plus a fine filtration system.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

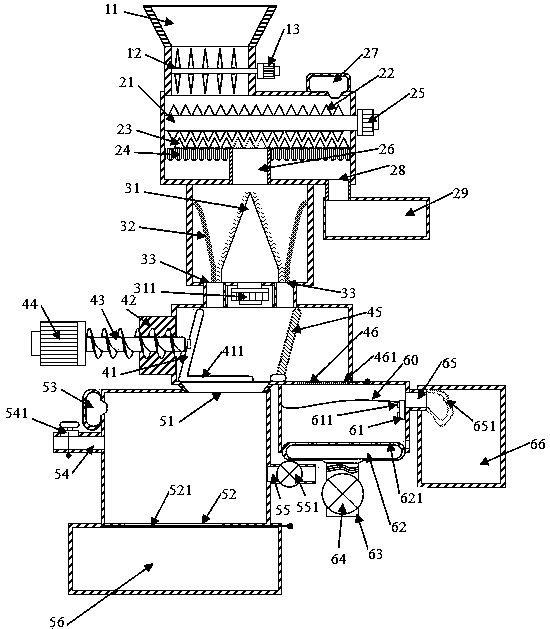

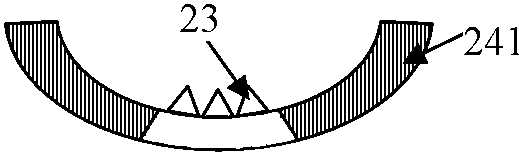

Pretreatment device for residential kitchen waste

ActiveCN110355186AImprove grinding effectAvoid mixingFatty/oily/floating substances removal devicesSolid waste disposalFertilizerPre treatment

The invention relates to a pretreatment device for residential kitchen waste. The device comprises an inlet pretreatment component, a crushing device, a grinding chamber, a solid-liquid separation chamber, a fermentation device and an oil-water separation device. According to the device, by arranging the crushing device, the grinding chamber, the solid-liquid separation chamber and the fermentation device, primary treatment of the kitchen waste subjected to classification and delivery in residential communities can be realized; and after treatment, grease and primary fermentation fertilizers can be transferred while recycled water is returned to the residential communities as recycled water for use, so that the occurrence of mass propagation of microorganisms and foul smell during the transportation process of the kitchen waste can be avoided, in this way, the harmful turns into the beneficial, and the whole environment is improved.

Owner:JINHUA MINGZHENG TECH CO LTD

Solid-liquid separator

InactiveUS7191700B2Effectively minimizedPrevent materialSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludgeEffluent

Owner:AMUKON

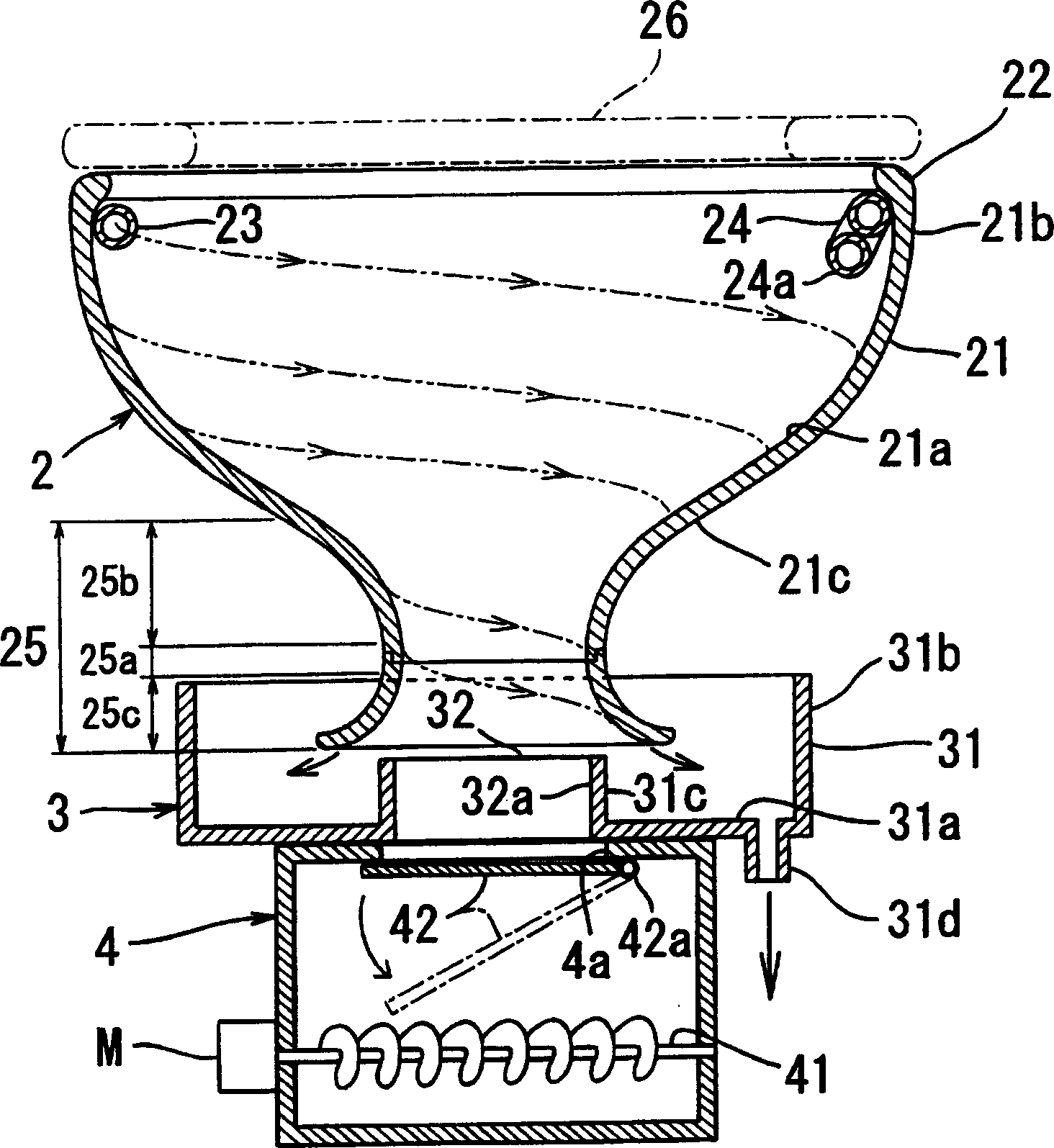

Separable toilet

InactiveCN1782243ASmall sizePrevent increase in transportation and installation costsWater closetsFlushing devicesSolid componentEngineering

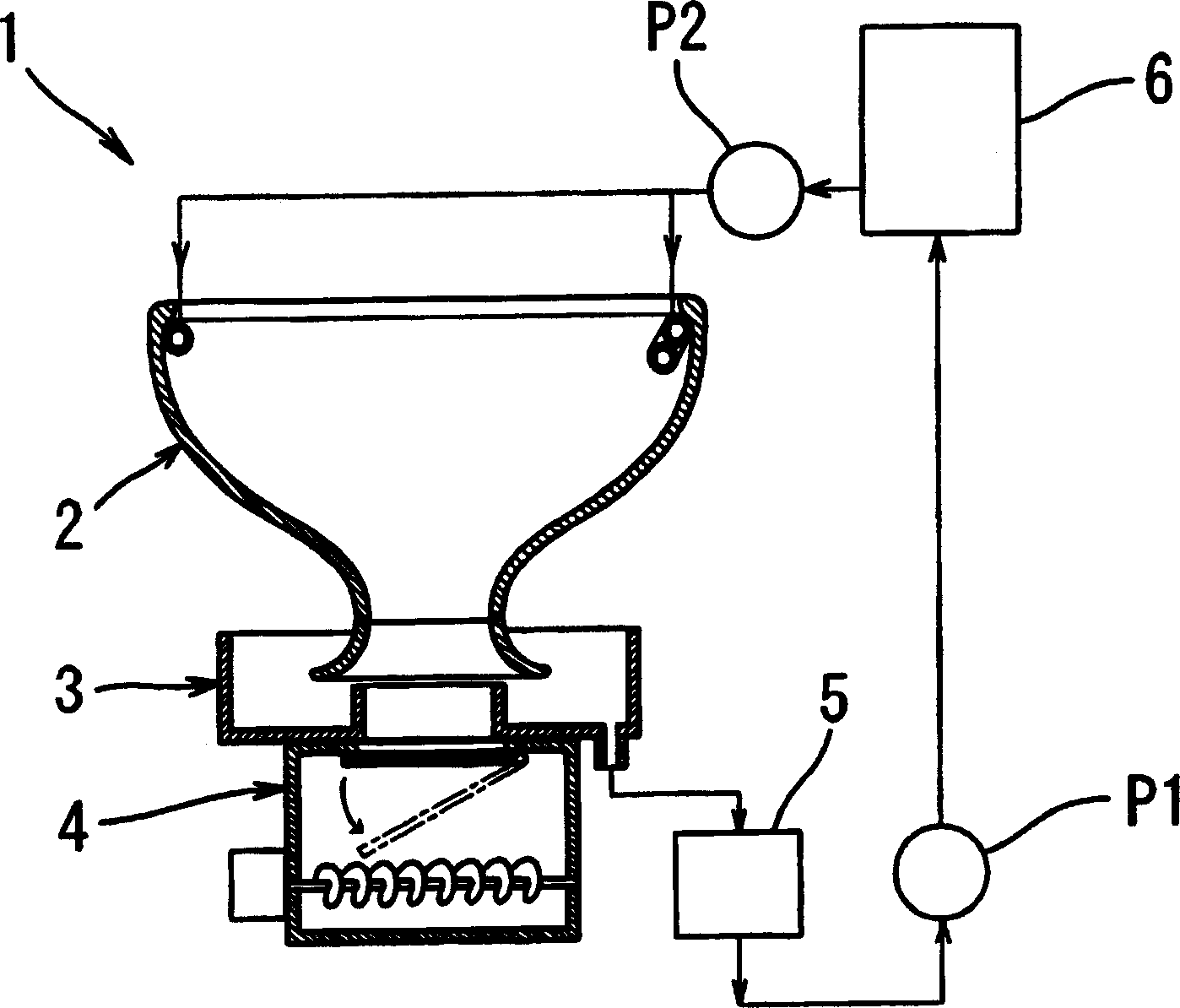

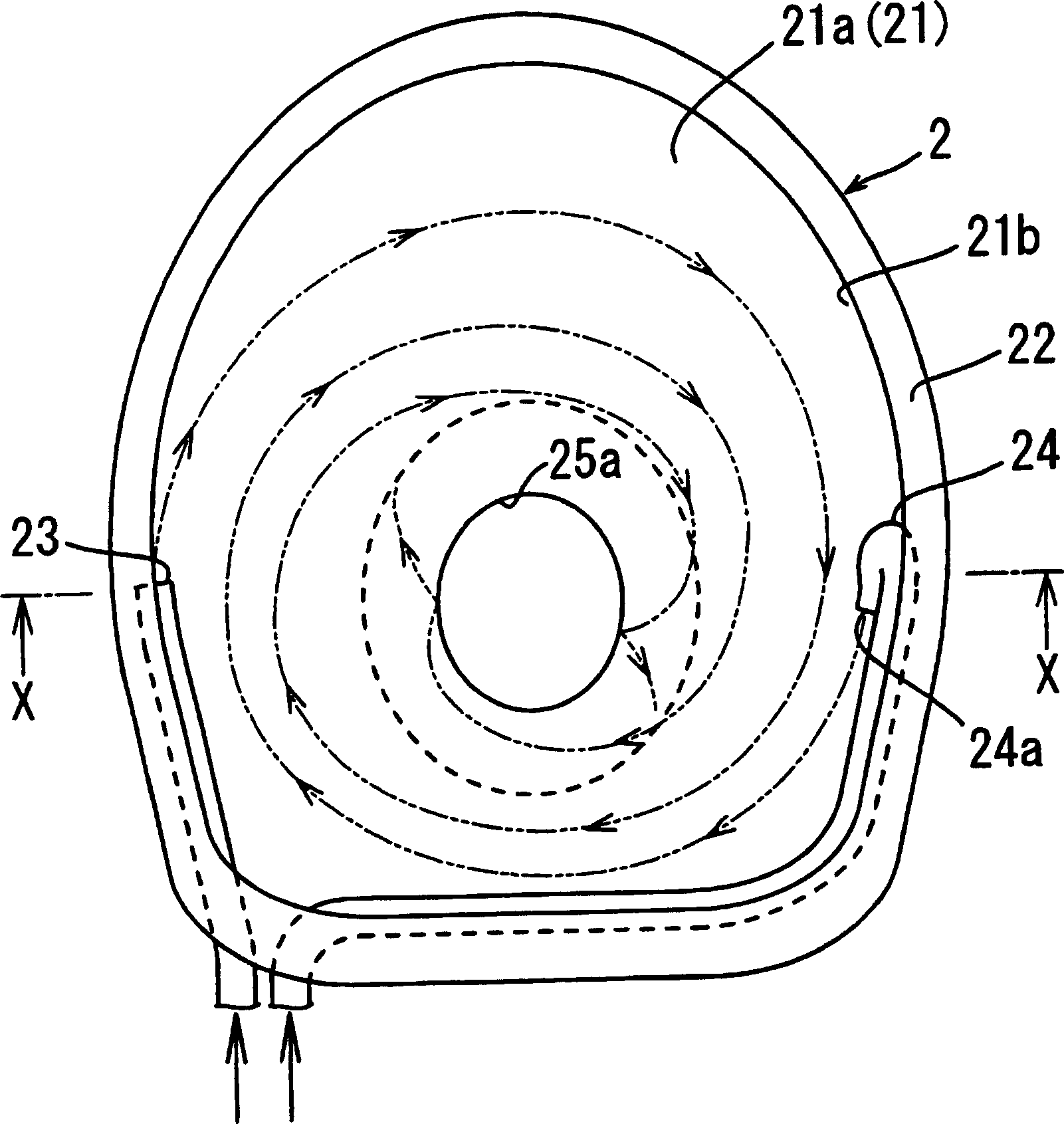

The invention discloses a separate toilet, which is composed of a throttling portion reduced to the smallest diameter, an upper expansion portion that expands from the throttle portion upward in a trumpet shape, and a lower expansion portion that expands from the throttle portion downward in a trumpet shape. The discharge pipe is integrally formed at the bottom of the toilet main body; a solid-liquid separator having a container-shaped liquid component receiving part and a cylindrical solid component receiving part penetrating up and down is provided directly below it; the solid component of excrement and urine is separated from The throttling part drops directly to the solid component receiving part, and the liquid component drops directly to the liquid component receiving part through the lower expansion part. Therefore, it is possible to suppress the height reduction from the toilet mounting surface to the toilet bowl, and even when toilet paper is attached to the piping provided below the toilet bowl, it can be easily removed.

Owner:ミリオン商事

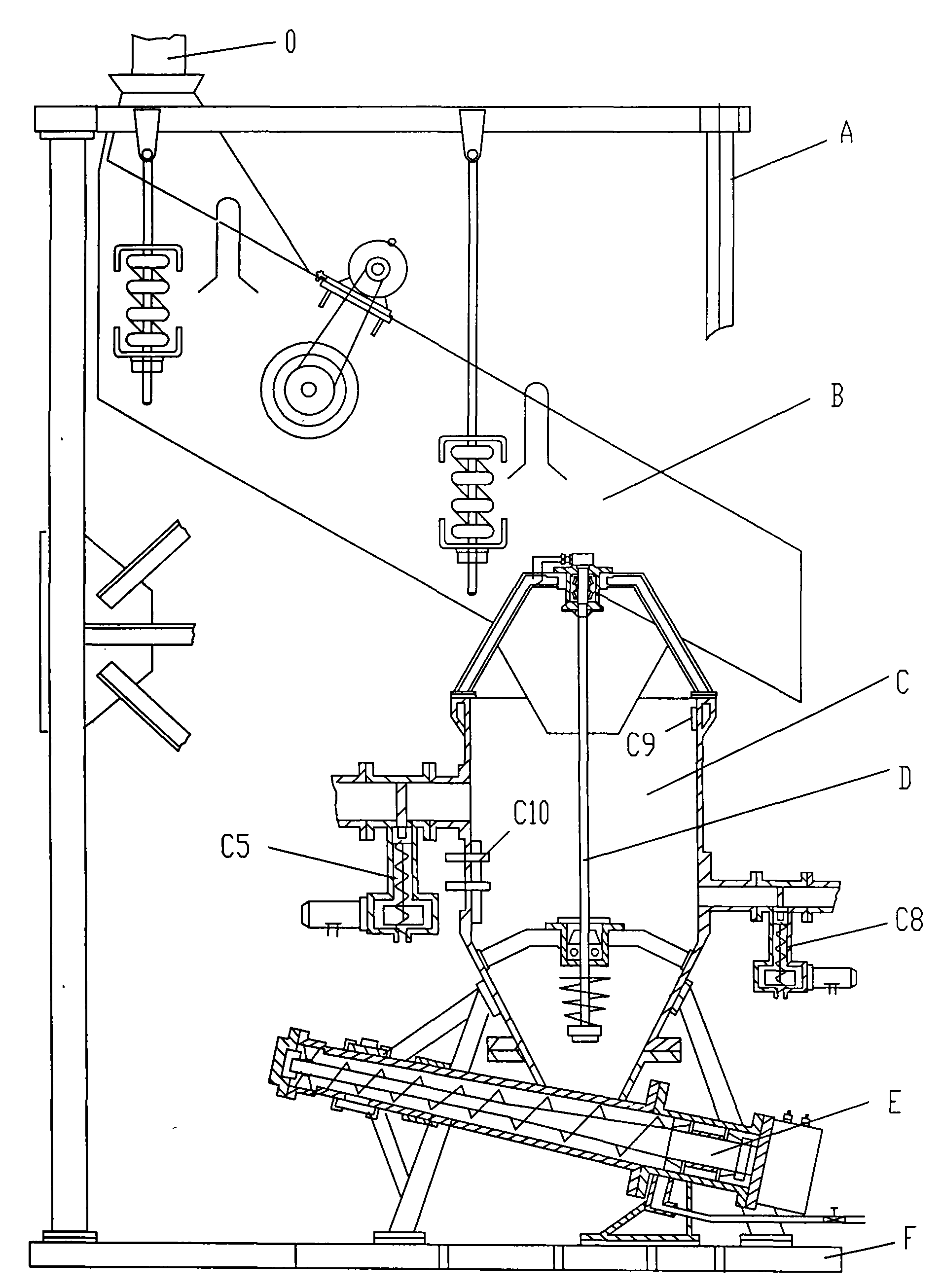

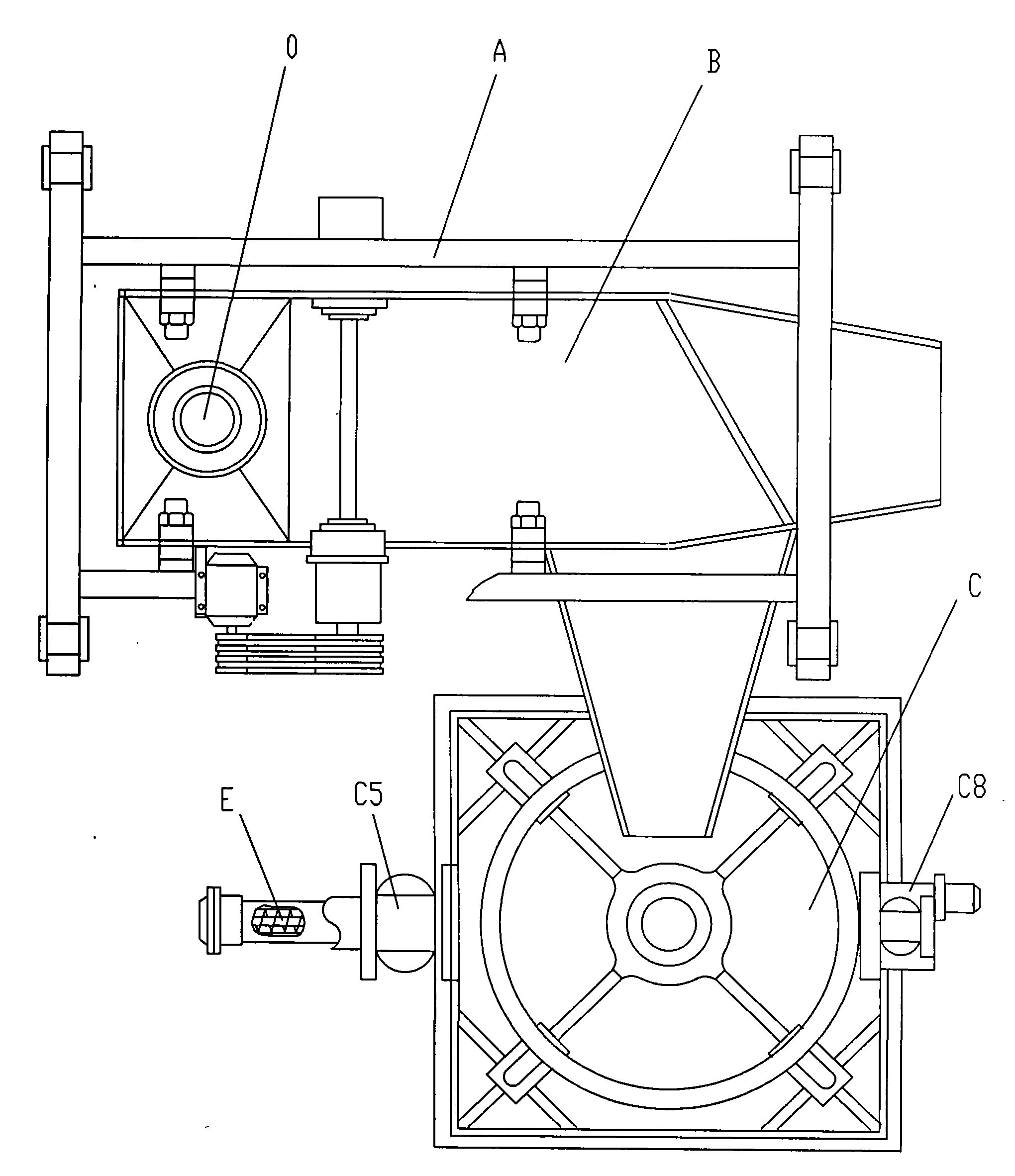

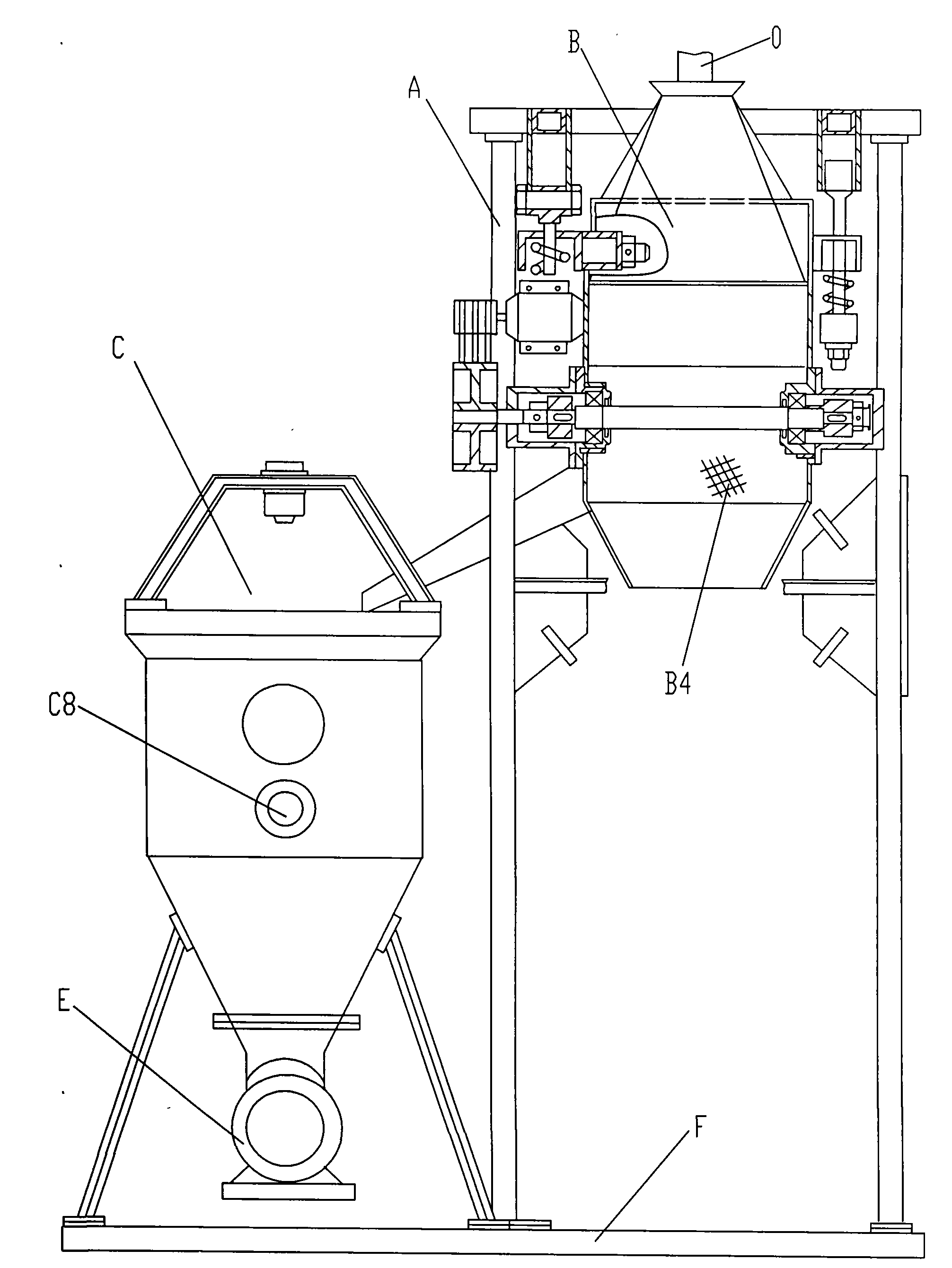

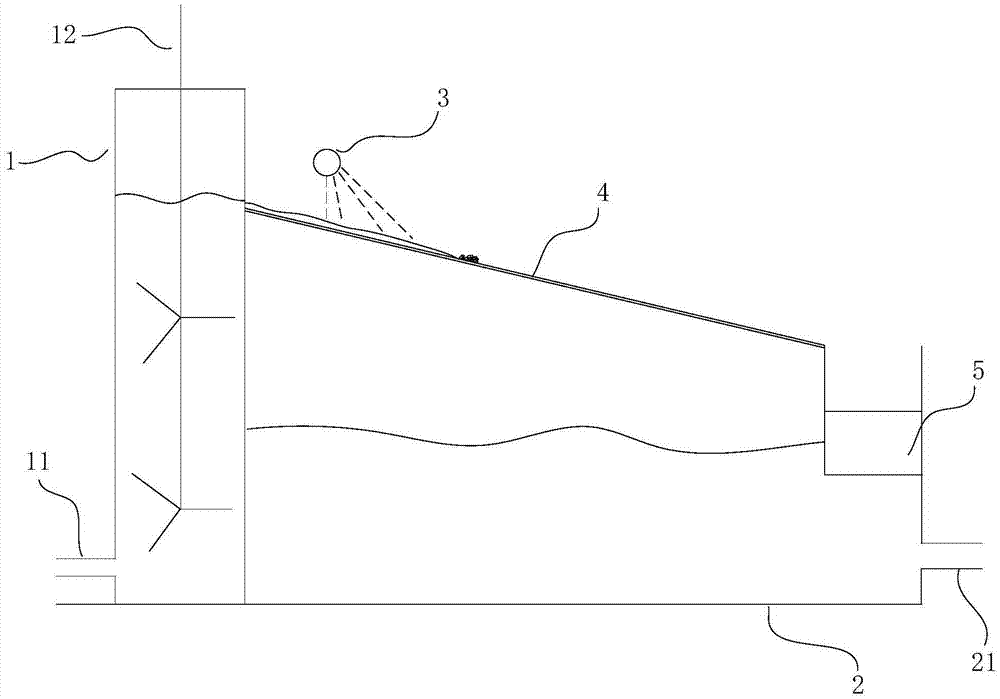

Combined type solid-liquid separation device

The invention discloses a combined type solid-liquid separation device, which comprises a slurry feed valve, a stander, an eccentric vibration residue filter, a storage sedimentation bin, a vertical screw conveyer, a reducing screw squeezing machine and a control system, wherein the wall of the storage sedimentation bin is provided with a clear solution discharge valve and a suspension discharge valve, the clear solution discharge valve is positioned above the suspension discharge valve, the stander is positioned on the lateral surface of the storage sedimentation bin, the eccentric vibration residue filter is slantwise arranged on the stander, the slurry feed valve is communicated with the eccentric vibration residue filter, the eccentric vibration residue filter is communicated with the storage sedimentation bin, the vertical screw conveyer is positioned in the center of the storage sedimentation bin, and the discharge end of the vertical screw conveyer faces to the bottom end of the storage sedimentation bin; and the reducing screw squeezing machine is slantwise arranged below the storage sedimentation bin transversely and is communicated with the bottom end of the storage sedimentation bin. The combined type solid-liquid separation device has the advantages of reasonable structure, stable equipment operation and good solid-liquid separation effect, and can quickly separate and treat various slurries containing residues with different specific gravities, different shapes and different sizes.

Owner:王雅谷 +1

Microparticle separator for water treatment

InactiveCN105435504AReduce decreaseGuaranteed to workSpecific water treatment objectivesTreatment involving filtrationMicroparticleWater treatment

The invention provides a microparticle separator for water treatment. The microparticle separator comprises a first water tank, a second water tank, a stirrer and a filter membrane structure which at least comprises a filter membrane; a water inlet of the first water tank is formed to be close to the bottom of the first water tank, the stirrer is used for stirring liquid in the first water tank, an opening formed in the upper side of the second water tank is covered with the filter membrane structure, and due to the connection or position relation between the second water tank and the first water tank, the liquid in the first water tank can overflow to the filter membrane structure arranged at the opening formed in the upper side of the second water tank from an opening formed in the upper side of the first water tank, and the liquid enters the second water tank after being filtered by the filter membrane; a water outlet of the second water tank is formed to be close to the bottom of the second water tank.

Owner:王刚

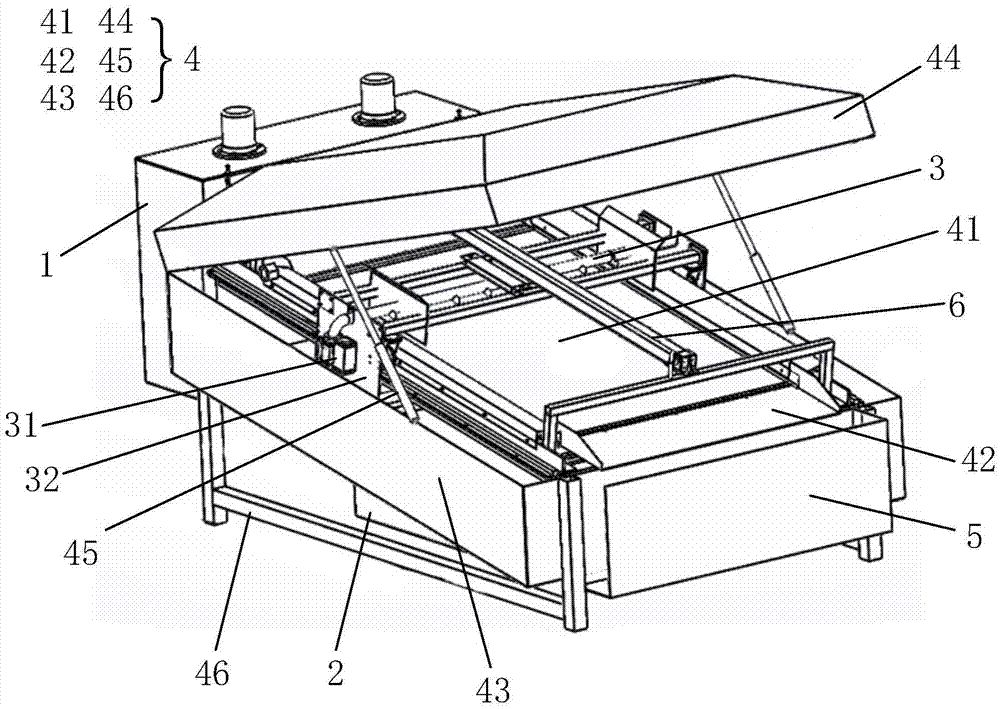

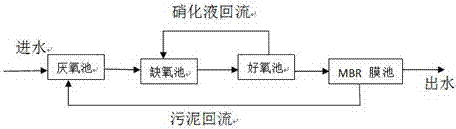

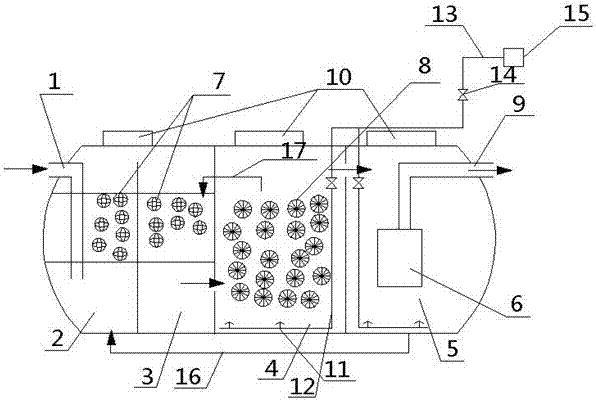

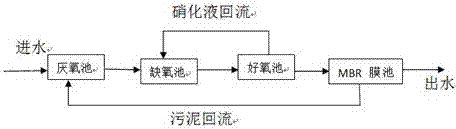

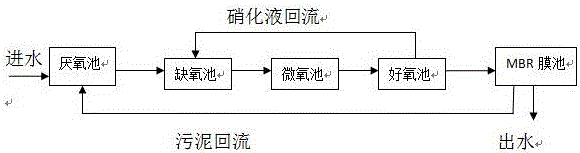

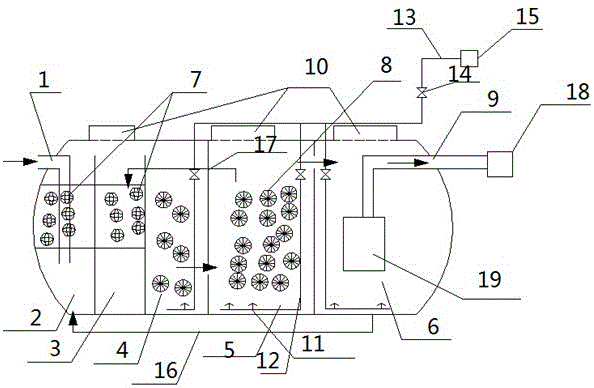

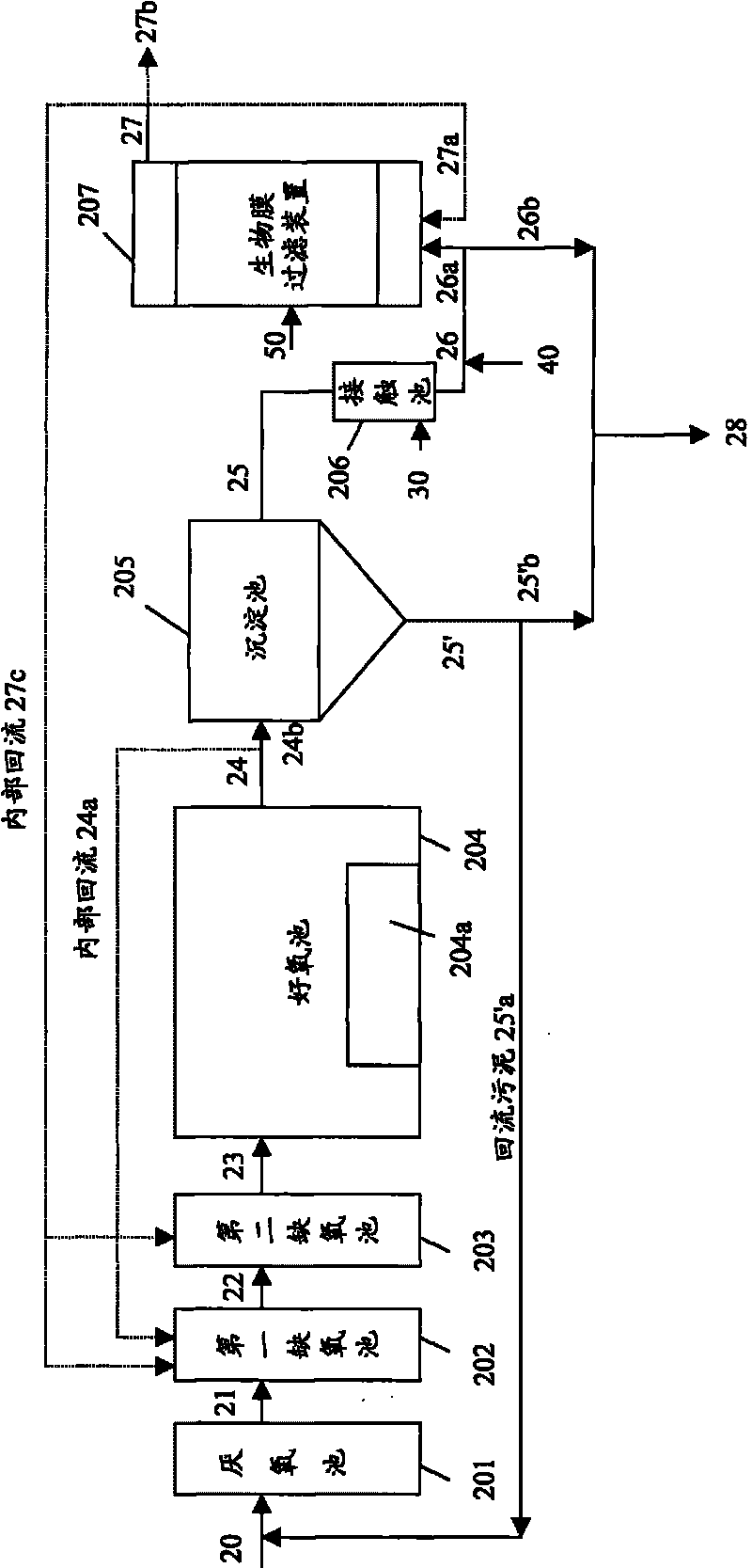

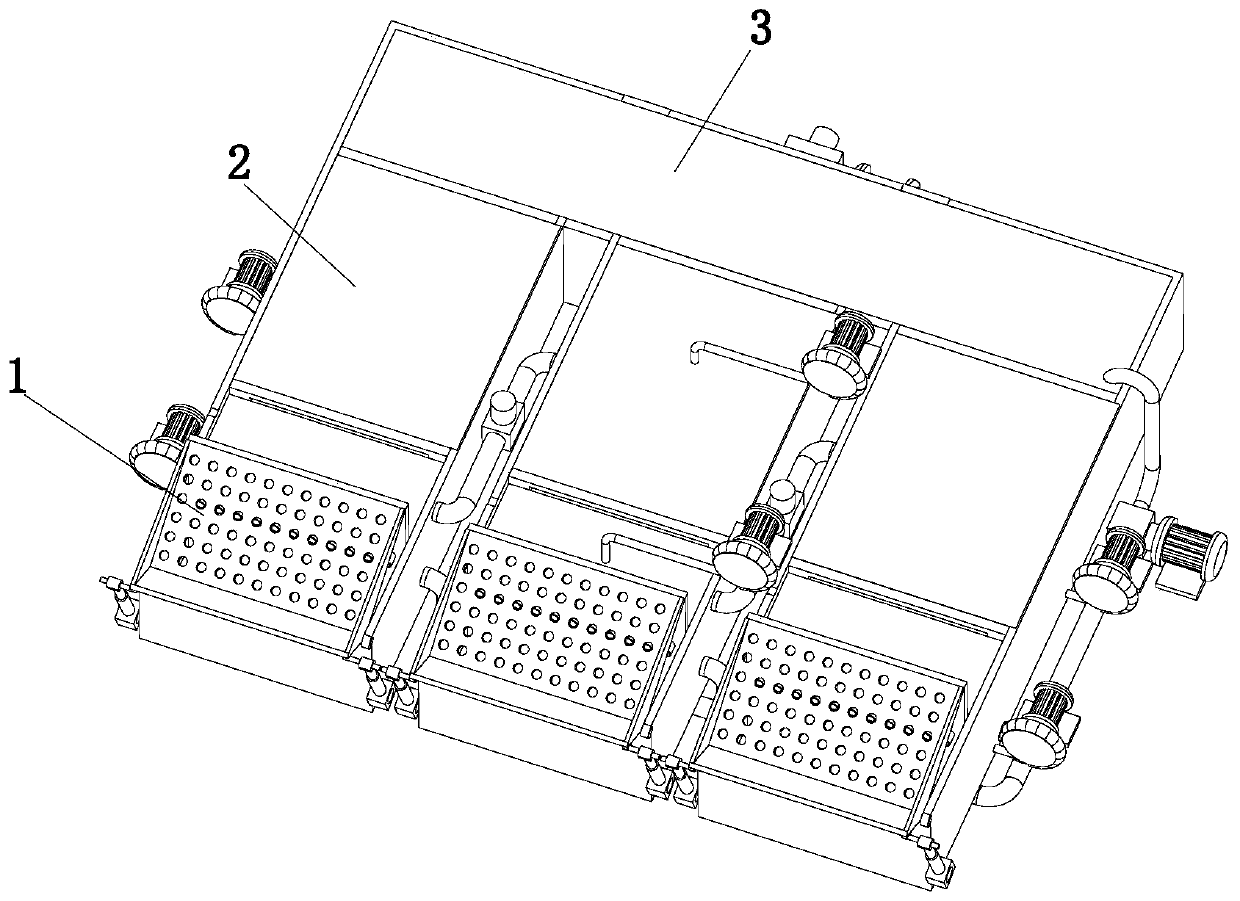

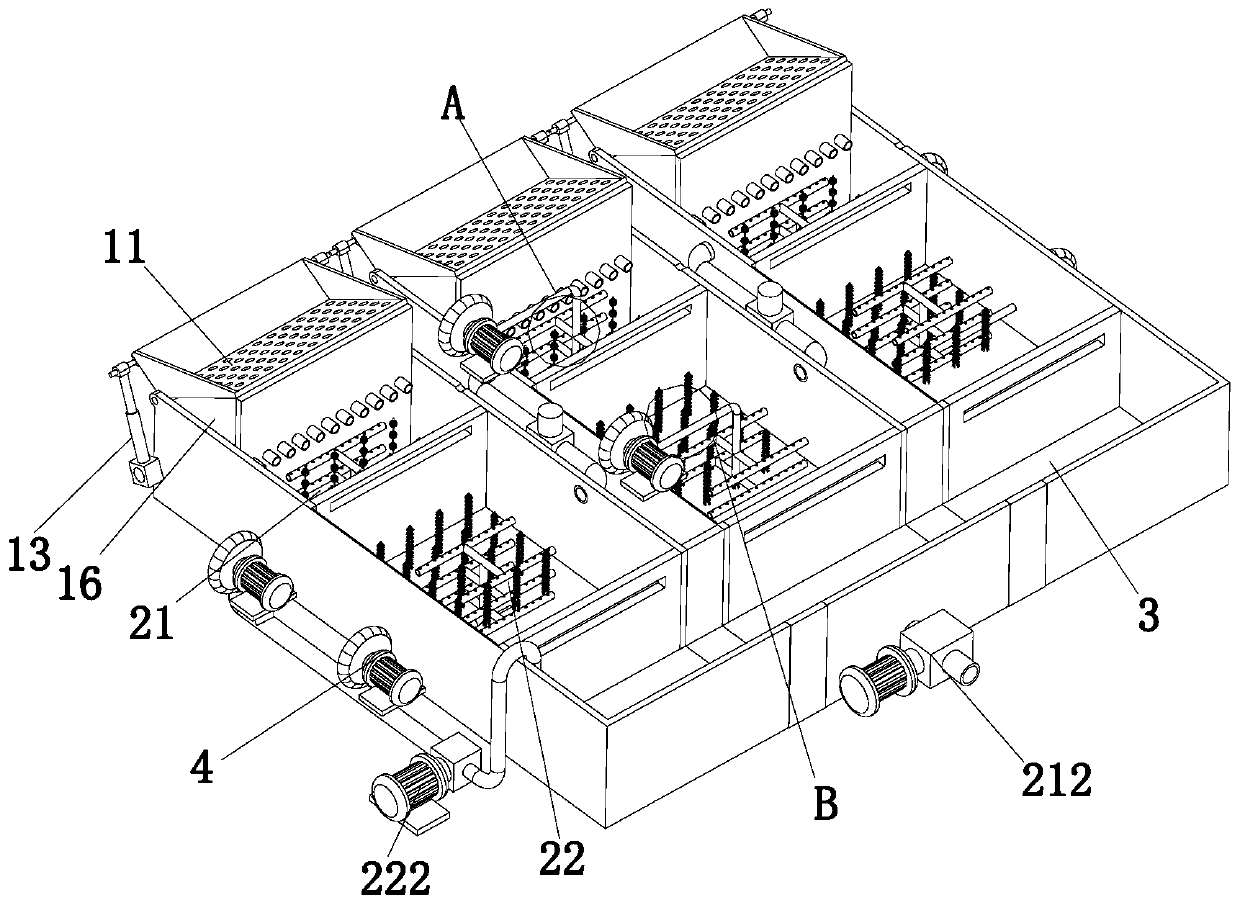

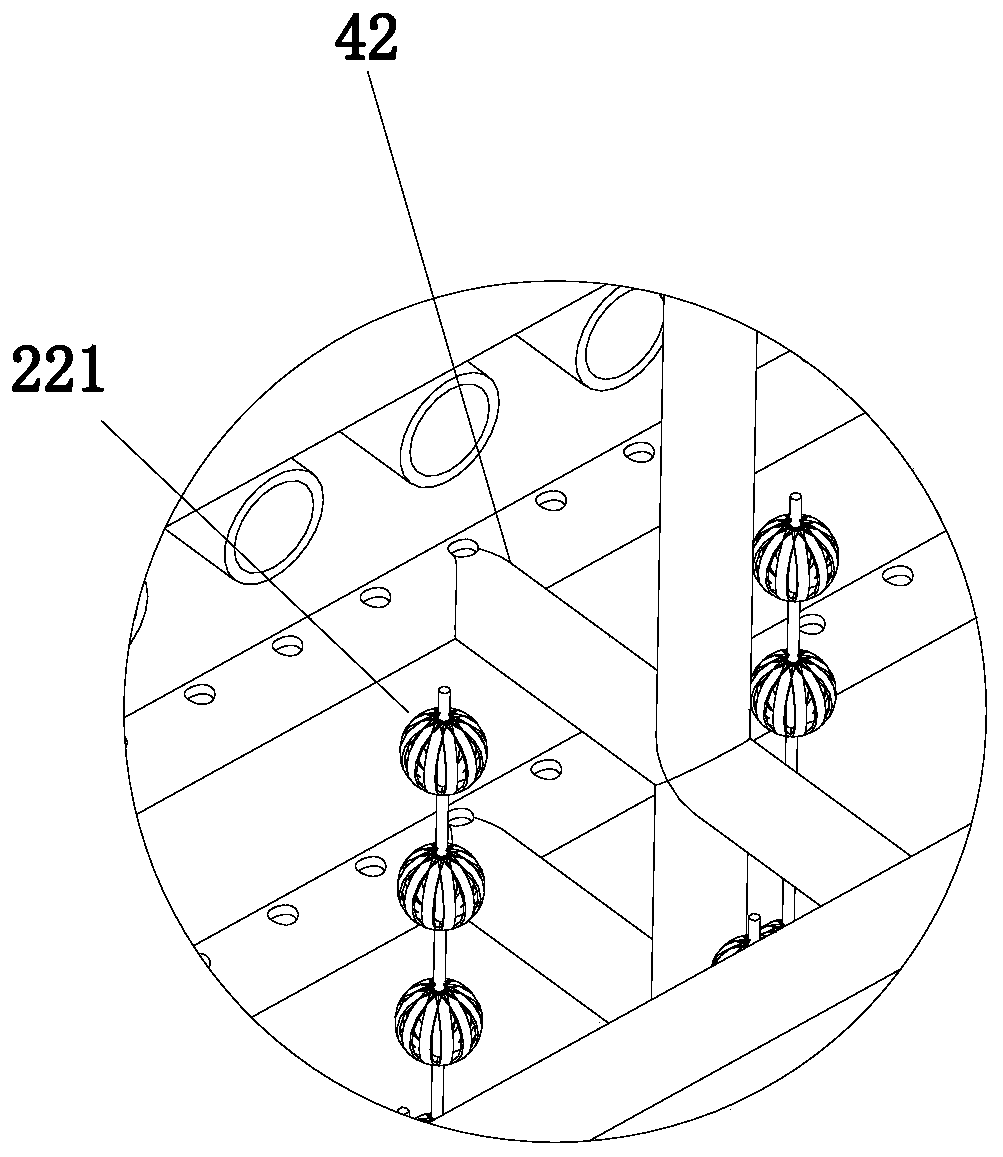

A20+MBR processing device

PendingCN107055787AOvercome the disadvantages of easy sludge bulkingEfficient solid-liquid separationTreatment with aerobic and anaerobic processesSustainable biological treatmentRefluxProcess equipment

The invention discloses an A20+MBR processing device, belongs to the field of environmental protection, and particularly relates to the field of wastewater biotreatment and reuse. The A20+MBR processing device includes an water inlet, an anaerobic pool, an anoxic pool, an aerobic pool, a membrane pool, an MBR membrane component, a spherical filler, an MBBR filler, a water outlet, an aeration head, an aeration branch pipe, an aeration main pipe, a gas adjusting valve, aeration equipment, a sludge reflux pipe, a nitrifying liquid reflux pipe, a biological flow bed; the MBR membrane component is installed in the membrane pool; the nitrifying liquid reflux pipe is installed between the upper portion of the aerobic pool and the upper portion of the anoxic pool; the sludge reflux pipe is installed between the bottom of the membrane pool and the bottom of the anaerobic pool. The A20+MBR processing device has the advantages that the efficient solid liquid separation is achieved; the effluent water quality is good and stable; the remaining sludge amount is small; the covering area is small; a secondary settling tank is not needed; process equipment is concentrated; the device can be widely used in the field of urban and rural sewage treatment.

Owner:云南傲远智能环保科技有限公司

Solid-liquid separator

InactiveUS20050193902A1Prevent materialAvoid cloggingSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludgeEffluent

A system is disclosed that provides a solid-liquid separator which can transport sludge and other material for treatment without clogging and can efficiently separator liquid from such material for treatment. The system includes movable plates and fixed plates alternatingly disposed and two screws disposed in holes formed in the movable plates and fixed plates. The screws have blades that partially overlap. As the two screws rotate, the material for treatment is transported and the effluent is discharged through the gaps between the movable plates and fixed plates.

Owner:AMUKON

Spiral scraping type vertical centrifugal machine

ActiveCN105880042AEfficient solid-liquid separationReasonable structural designCentrifugesSolid phasesSeparation process

The invention discloses a spiral scraping type vertical centrifugal machine. A rotary drum is arranged in a shell. A spiral mechanism is arranged in the rotary drum. A rotary disc of the spiral mechanism is internally provided with a storage cavity. During centrifuging, materials to be separated are distributed towards the interior of the rotary drum through the rotary disc. A liquid phase of the materials to be separated is thrown out through meshes through the high-speed rotation of the rotary drum. A fixed phase of the materials to be separated is attached to the inner wall of the rotary drum, meanwhile, the spiral mechanism rotates to scrap the solid-phase material on the inner wall of the rotary drum away, and fast and efficient solid-liquid separation is achieved. By means of the above spiral scraping type vertical centrifugal machine optimally designed, the structural design is reasonable, on one hand, in the solid-liquid separation process, a spiral blade can make the solid phase scraped from the rotary drum; on the other hand, the materials to be separated enter the rotary drum through the cavity in the rotary disc so that the materials can enter the rotary drum at the speed in the direction the same as the steering direction of the rotary drum; and therefore the solid-liquid separation effect in the rotary drum is improved.

Owner:南京振兴新能源发展有限公司

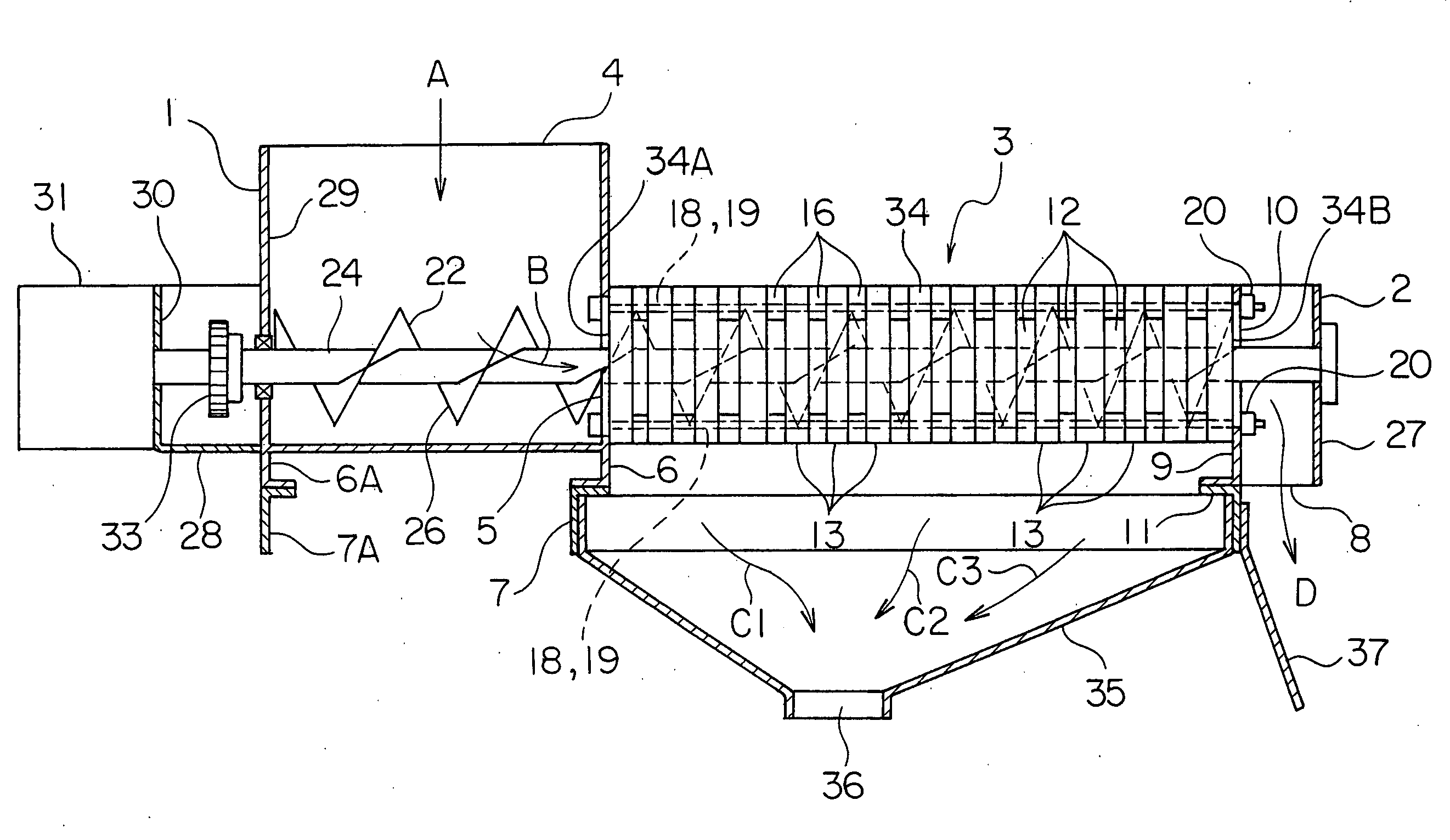

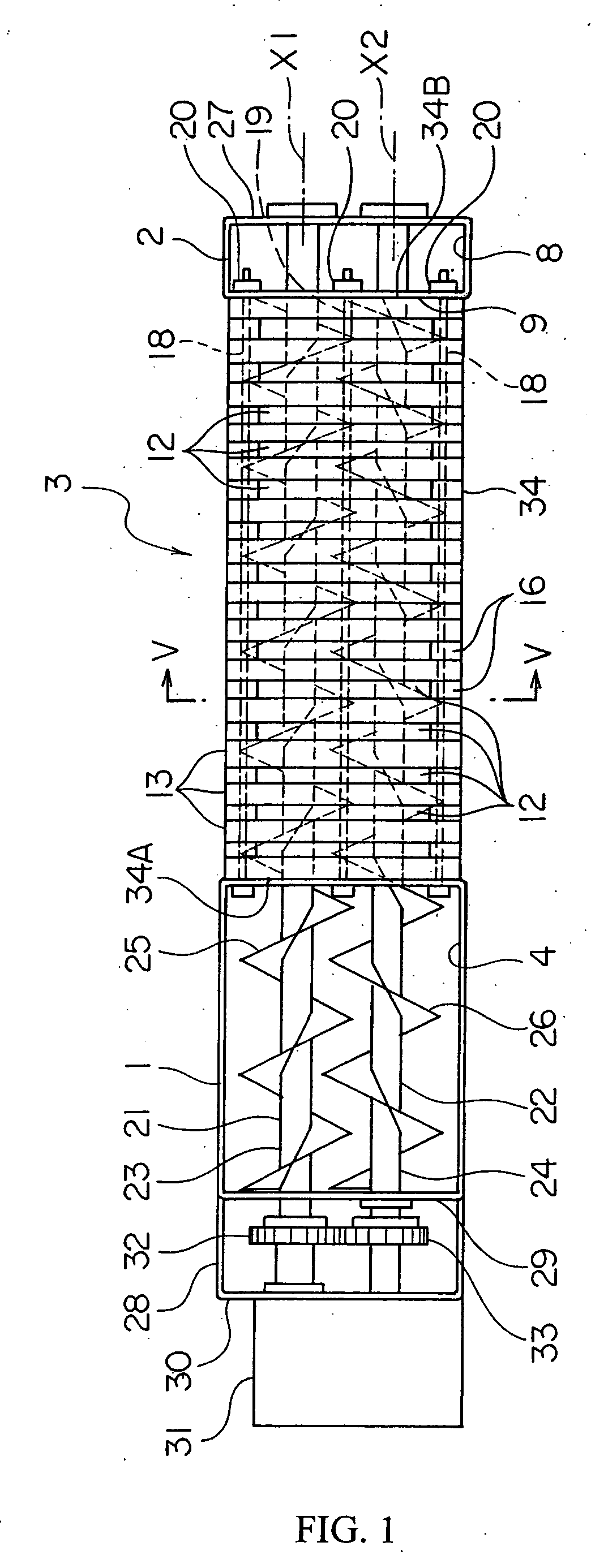

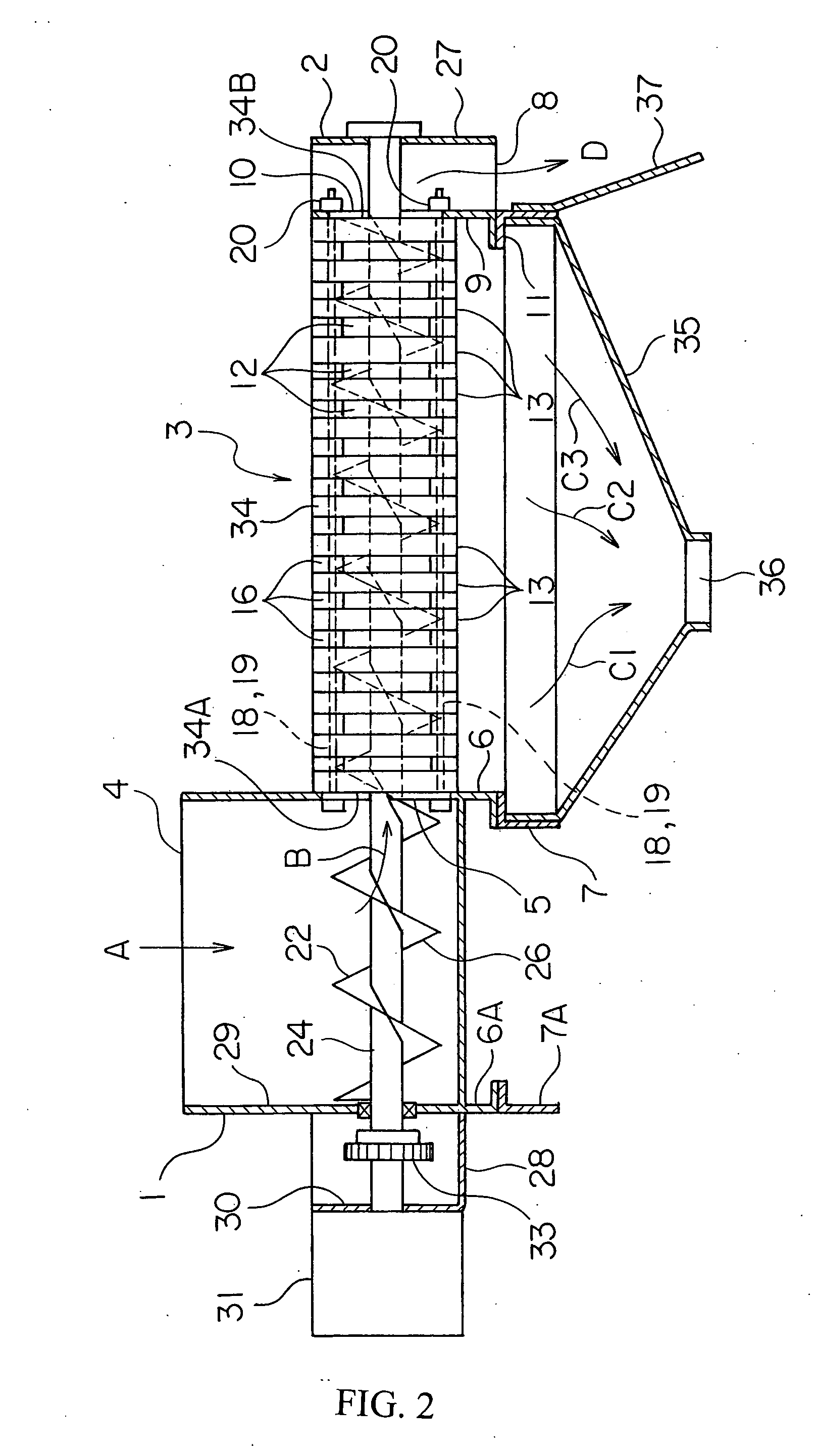

Gas-liquid-solid three-phase suspension bed reactor for fischer-tropsch synthesis and its applications

ActiveUS8506895B2Promote conversionIncrease capacityPhysical/chemical process catalystsOrganic compound preparationGas phaseFiltration

A Fischer-Tropsch synthesis three-phase suspension bed reactor (“suspension bed” also called “slurry bed”) and its supplemental systems, may include: 1) structure and dimension design of F-T synthesis reactor, 2) a gas distributor located at the bottom of the reactor, 3) structure and arrangement of a heat exchanger members inside the reactor, 4) a liquid-solid filtration separation device inside reactor, 5) a flow guidance device inside reactor, 6) a condensate flux and separation member located in the gas phase space at the top of reactor, 7) a pressure stabilizer, a cleaning system for the separation device; an online cleaning system for the gas distributor; an ancillary system for slurry deposition and a pre-condensate and mist separation system located at the outlet of upper reactor. This reactor is suitable for industrial scale application of Fischer-Tropsch synthesis.

Owner:SYNFUELS CHINA TECH CO LTD

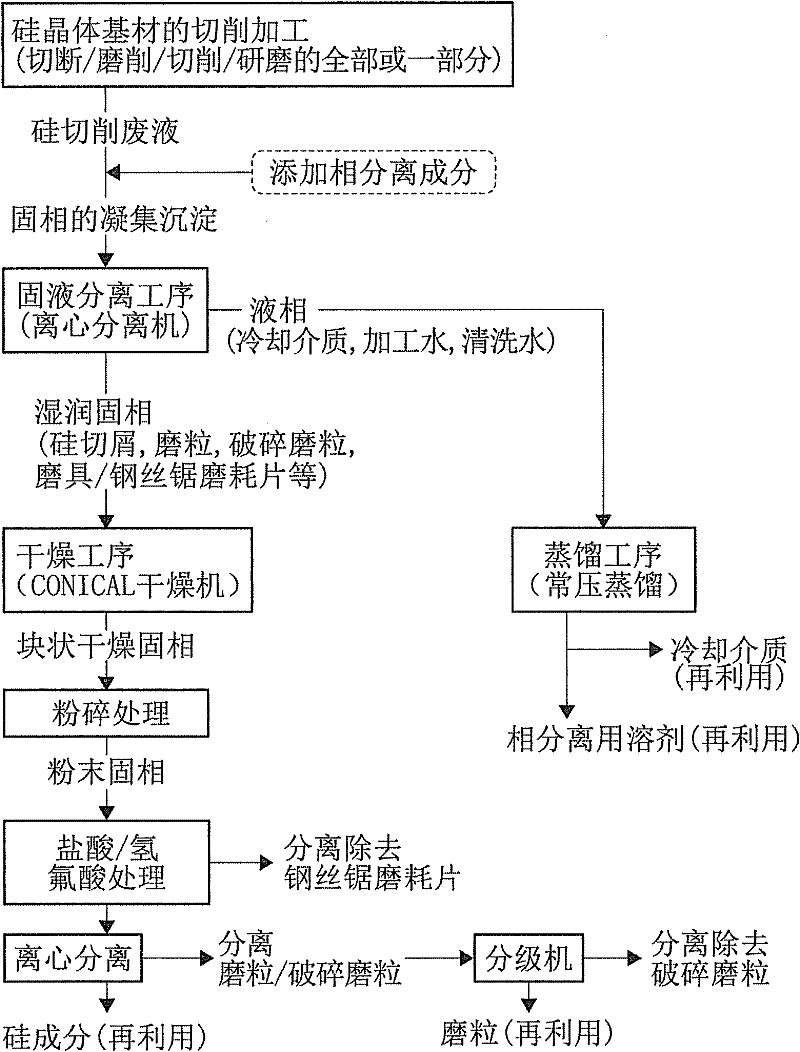

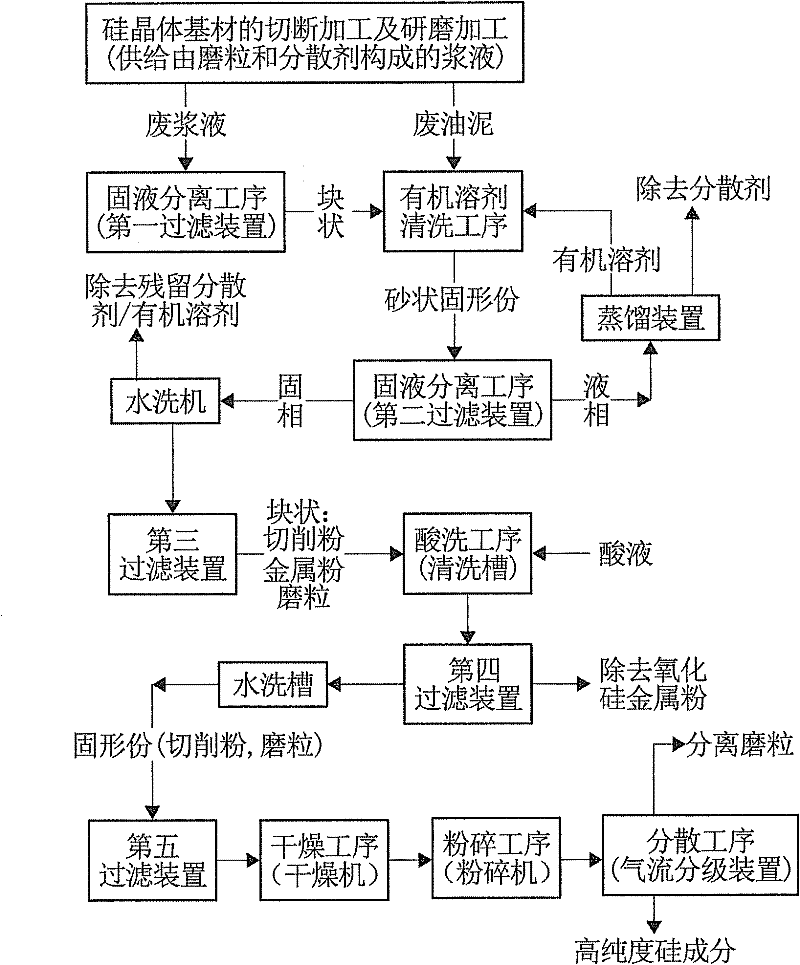

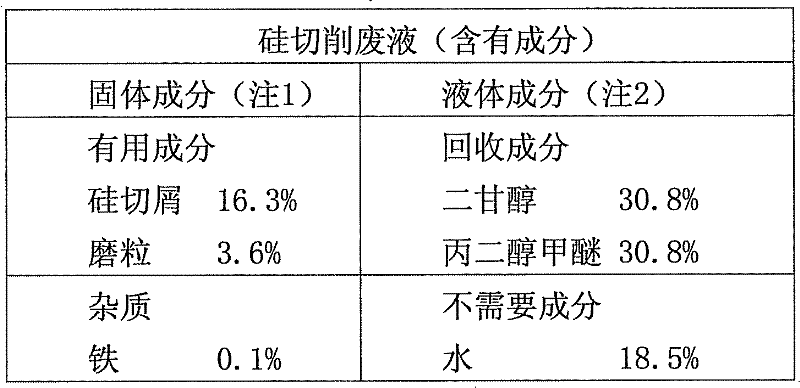

Processing Method Of Silicon Cutting Waste Liquid

InactiveCN102559361AEfficient solid-liquid separationReduce the burden onLubricant compositionSolid componentWaste treatment

The present invention relates to a processing method of a silicon cutting waste liquid. In a particle-dispersed suspension which comprises solid component, namely the silicon cutting waste liquid, separated components such as polar aprotic solvent, polar protic solvent, nonionic agglutinant, ethylenediamine polybasic acid, and salt thereof, so the solid phase in the waste liquid is agglutinated and deposited. Excellent solid-liquid separation in an earliest period of the waste liquid treatment is ensured, so as to facilitate recycling of the useful components in the waste liquid. The invention provides the processing method which causes excellent solid-liquid separation of the silicon cutting waste liquid that is discharged in the processing step in semiconductor component manufacturing wherein crystal silicon is used as the substrate and separates and recycles the useful components such as silicon chips through low load and low cost for regeneration and reuse.

Owner:サンワバイオテック +1

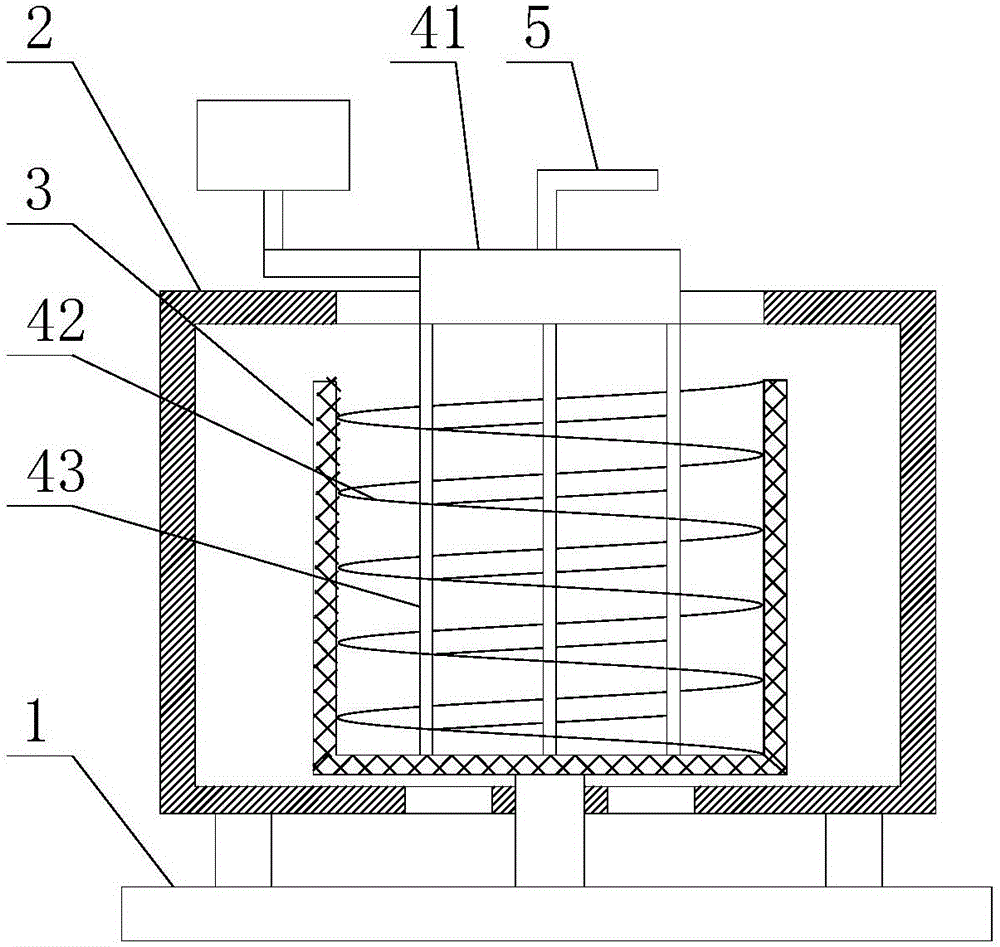

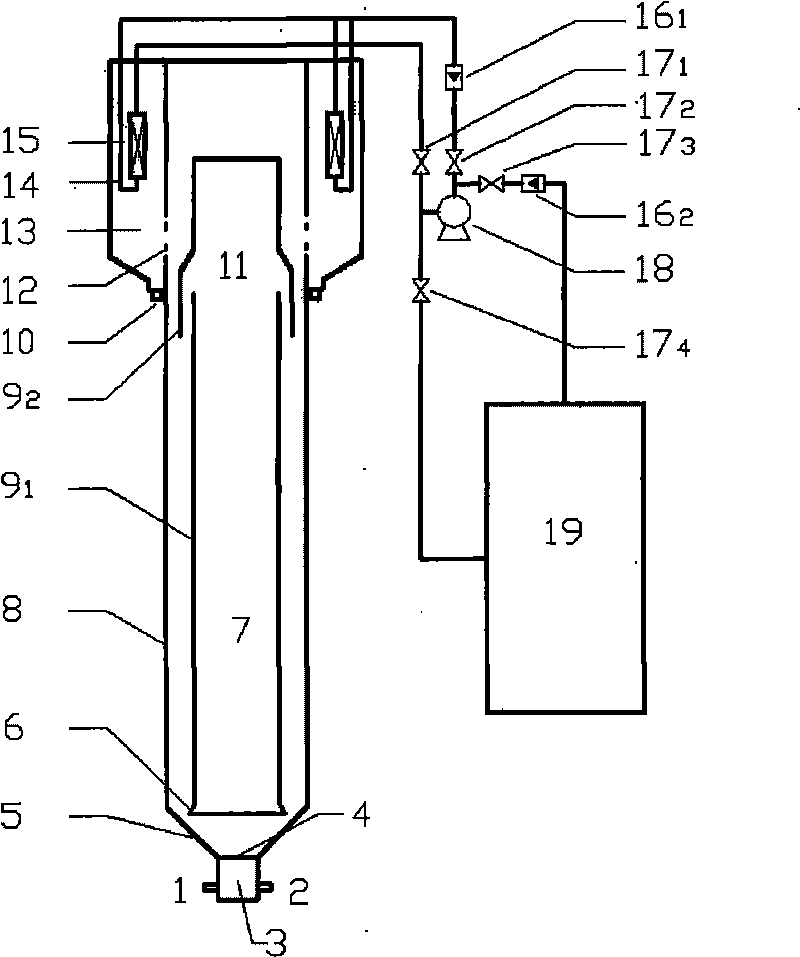

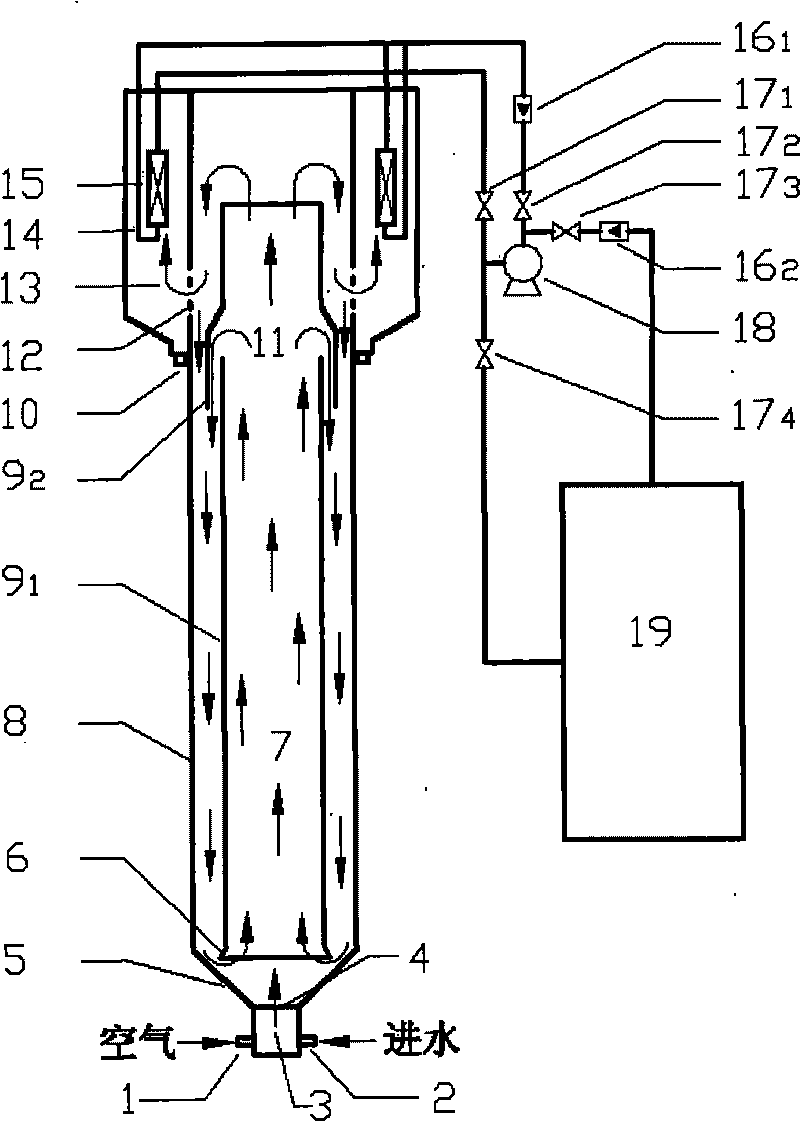

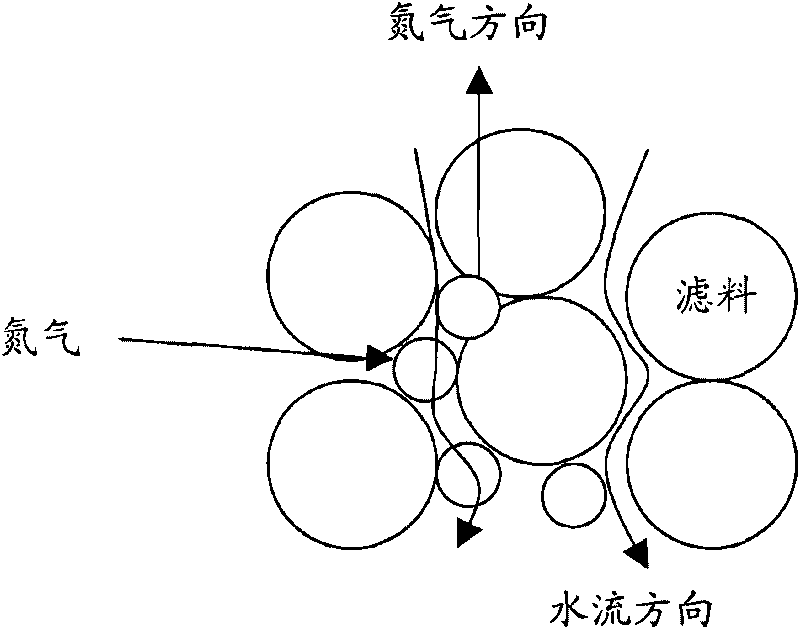

Three-phase fluidized-bed reactor

InactiveCN101733046AImprove the mixing effectEasy constructionTreatment using aerobic processesSustainable biological treatmentIndustrial effluentFluidized bed

The invention discloses a three-phase fluidized-bed reactor. The three-phase fluidized-bed reactor solves the technical problems of poor gas-water mixing, difficult operation, undesirable solid-liquid separating effect and high effluent turbidity of an internal circulating three-phase fluidized-bed reactor. The three-phase fluidized-bed reactor comprises a gas-water mixing area, a reacting area, separating area and a filtrating area; the gas-water mixing area is, through a micro-porous gas distributor, communicated with the reacting area which is formed by an outer barrel and an inner barrel; a precipitating area and the filtrating area are formed outside the separating area on the top and communicated with each other through a perforated plate; the filtrating area is provided with a filtering component; and the filtrating component is connected with a water outlet and back wash system which comprises a water pump, a plurality of valves, a plurality of flowmeters and the like. The three-phase fluidized-bed reactor is characterized in that: the gas-water mixing area is shaped as a column; and the filtering component is a film component. The three-phase fluidized-bed reactor is used for treating the domestic sewage and the industrial effluent, so the municipal sewage is recycled to meet the municipal non-drinking water quality standards.

Owner:NANJING UNIV OF SCI & TECH

Method for electrochemical preparation of hydrotalcite for in-situ treatment on strontium-containing radioactive waste liquid in power plant

ActiveCN108573762AHigh adsorption activitySmall particle sizeRadioactive decontaminationLiquid wasteElectrolysis

The invention relates to a method for electrochemical preparation of hydrotalcite for in-situ treatment on a strontium-containing radioactive waste liquid in a power plant. The method comprises the following steps: preparing simulated radioactive wastewater with Sr<2+> as electrolyte, dropping an alkali solution and an acid solution, adjusting the pH value to be 5-11, and carrying out electrolysiswith double power supplies, wherein a direct-current voltage stabilizing power supply with an aluminum piece as an anode and graphite as a cathode is adopted as one group of the power supplies, and apulse power supply with two zinc pieces as an anode and a cathode respectively is adopted as the other group of the power supplies; alternating the anodes and the cathodes through inverse electrodes,carrying out electrolysis synthesis under a constant temperature condition, after the reaction is completed, leaving the electrolyte to stand, filtering, and carrying out solid-liquid separation, soas to complete simulation waste liquid purification treatment. By adopting the method, a great amount of chemicals or absorbents are not needed, only nitrate radicals and chloride ions of certain concentrations in the waste liquid need to be controlled, no secondary pollution can be caused, efficient removal of multiple divalent radioactive metallic ions can be achieved, and the method only aims at removal of strontium ions, is capable achieving efficient solid-liquid separation, is wide in material resource, simple in process and convenient to operate.

Owner:EAST CHINA UNIV OF SCI & TECH

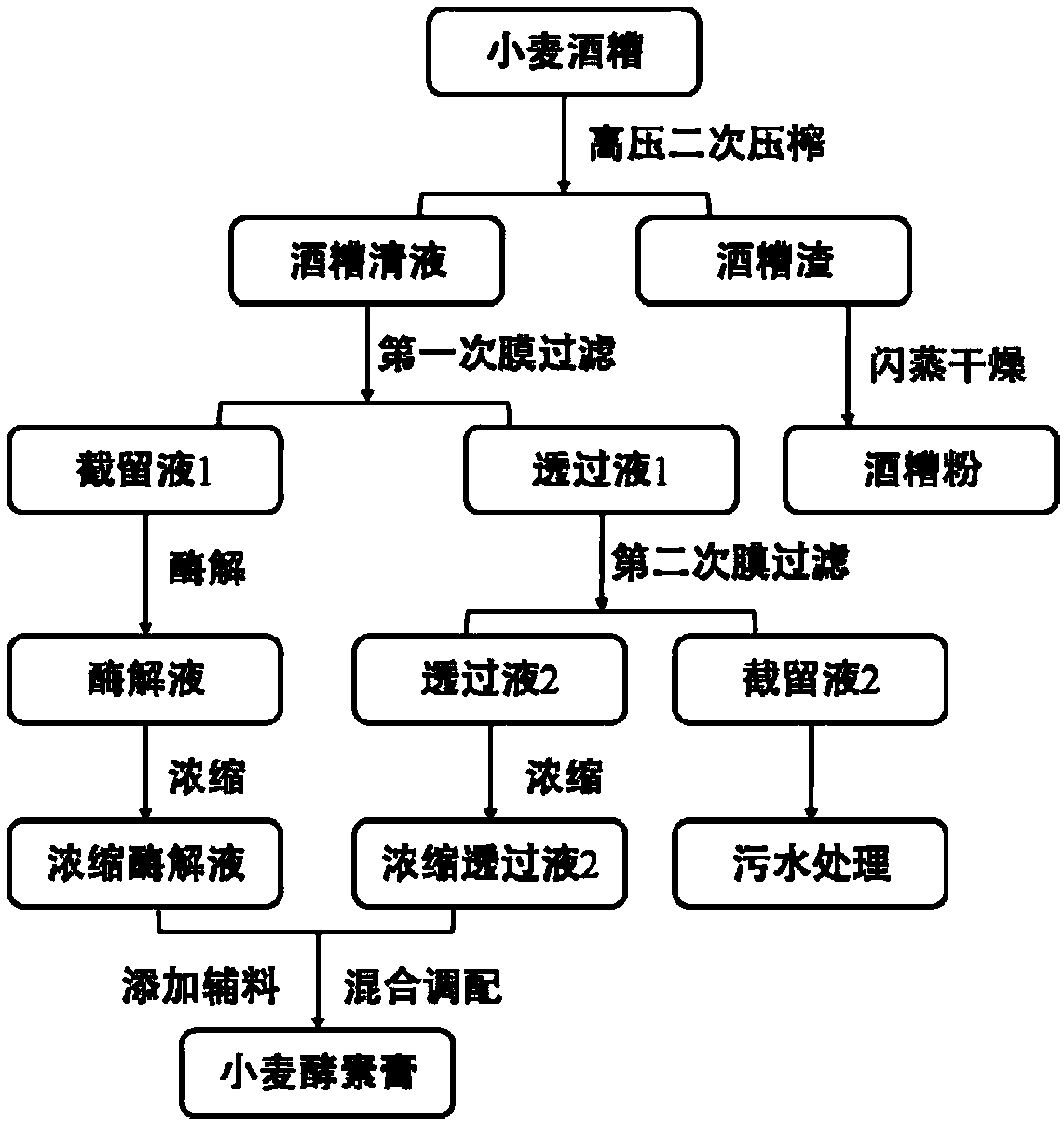

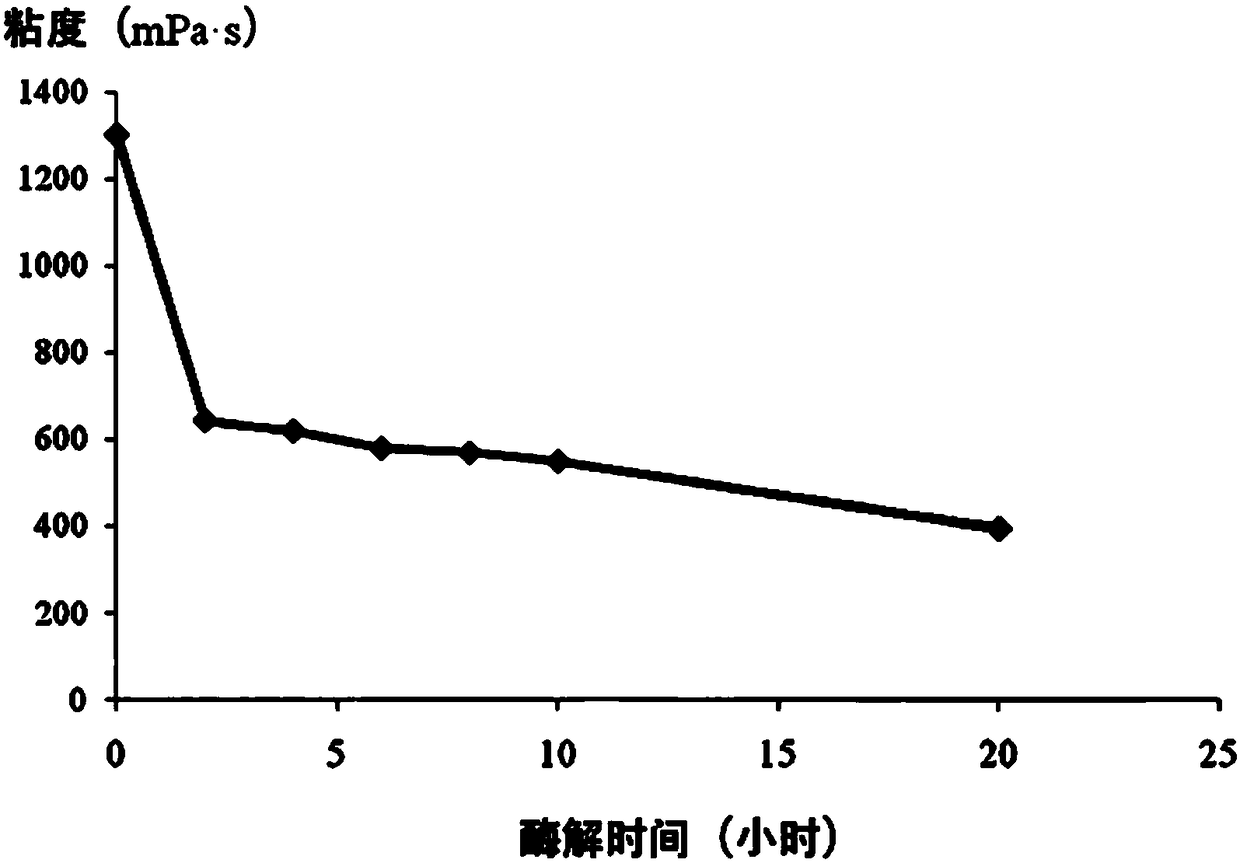

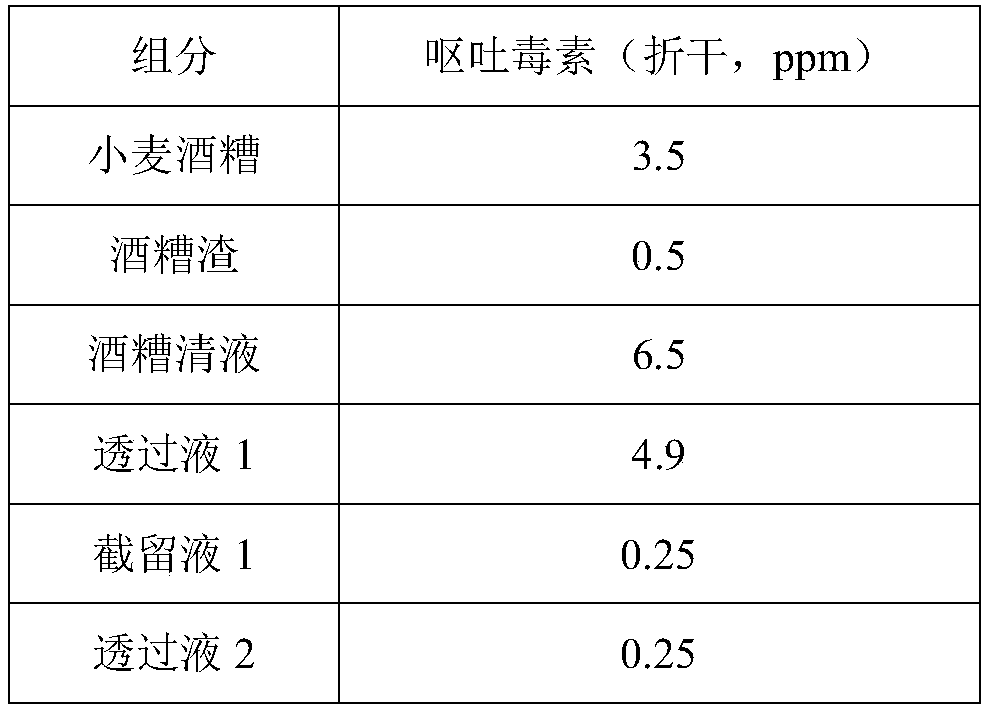

Method for producing distillers' grain powder and wheat enzyme paste by using wheat distillers' grains

InactiveCN109170266AEliminate anti-nutritional factorsSolve the problems that affect the effect of animal feedingFood processingAnimal feeding stuffEnzymatic hydrolysisFiltration

The invention discloses a method for producing distillers' grain powder and wheat enzyme paste by using wheat distillers' grains. The method comprises the following steps: acquiring wheat distillers'grain raw materials; performing solid-liquid separation; performing expansion drying; performing primary filtration by a nanofiltration membrane; performing enzymatic hydrolysis; performing concentration; performing secondary filtration by a nanofiltration membrane; and acquiring the wheat enzyme paste. The method has the following beneficial effects: by using a high pressure secondary pressing technique, solid-liquid separation of the wheat distillers' grains is realized, and vomitoxin is transferred into liquid by secondary pressing deep dehydration; by an enzyme preparation technique, anti-nutritional factors in the wheat distillers' grains are eliminated, the anti-nutritional factors are transformed into prebiotics, and a wheat enzyme type product is prepared by concentration and blending; and by secondary filtration by the nanofiltration membrane, the problem of excessive vomitoxin in the wheat distillers' grains is solved. The method solves the problem of treatment of the wheat distillers' grains in starch enterprises, derives two kinds of wheat distillers' grain products for feed enterprises, realizes optimization utilization of the wheat distillers' grains, and has extensive popularization application potential and huge commercial value.

Owner:梁耀培 +3

Integrated cyclone air flotation device and sewage treatment method

PendingCN106145233ASimple structureHigh degree of integrationFatty/oily/floating substances removal devicesLiquid separationMicrobubblesSewage treatment

The invention discloses an integrated cyclone air flotation device which comprises integrated outer cylinder and inner cylinder, wherein the inner cylinder is arranged in the outer cylinder; an annular cavity is formed between the outer cylinder and the inner cylinder; the annular cavity is communicated with a water inlet and a gas inlet of the outer cylinder; a gas-water releaser for transforming a gas-water mixture in the inner cylinder into microbubbles is arranged in the annular cavity; a residue collection tank or an oil collection tank for collecting the floating residue or floating oil gathered on the annular cavity is arranged at the upper end of the inner cylinder; a residue discharge pipe or an oil discharge pipe is arranged in the inner cylinder; and the upper end of the residue discharge pipe or the oil discharge pipe is communicated with the residue collection tank or the oil collection tank, and the lower end is communicated with a residue discharge port of the outer cylinder. The invention also discloses a sewage treatment method. The integrated cyclone air flotation device disclosed by the invention has simple structure and high integration degree and can efficiently realize solid-liquid separation and wastewater purification while the energy consumption is low.

Owner:苏州孚林环保科技有限公司

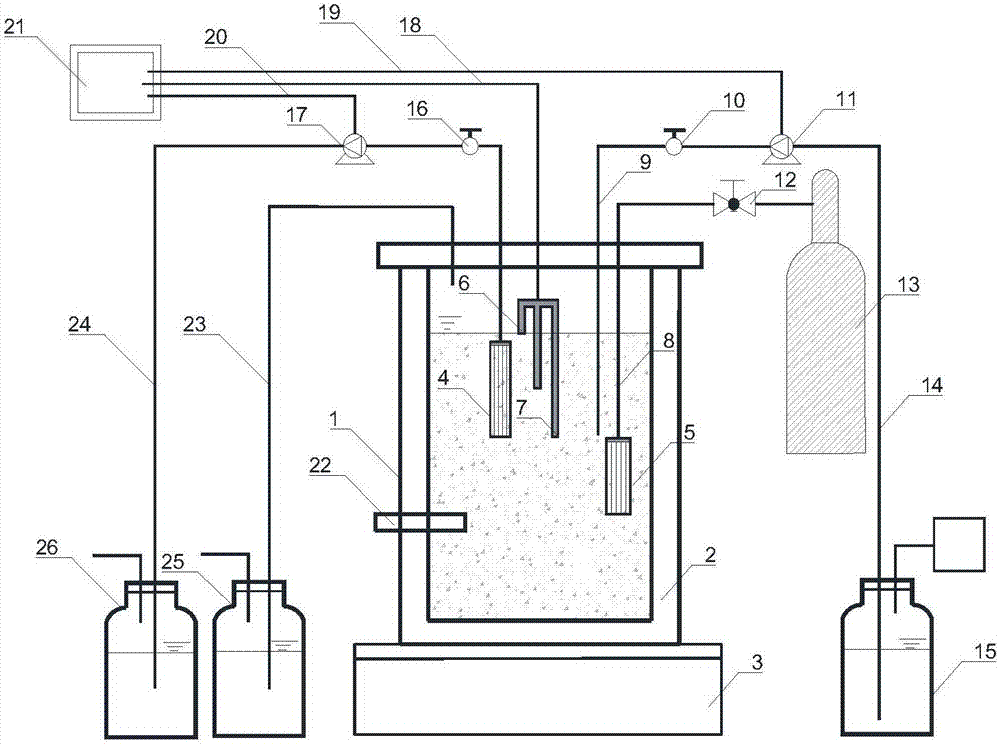

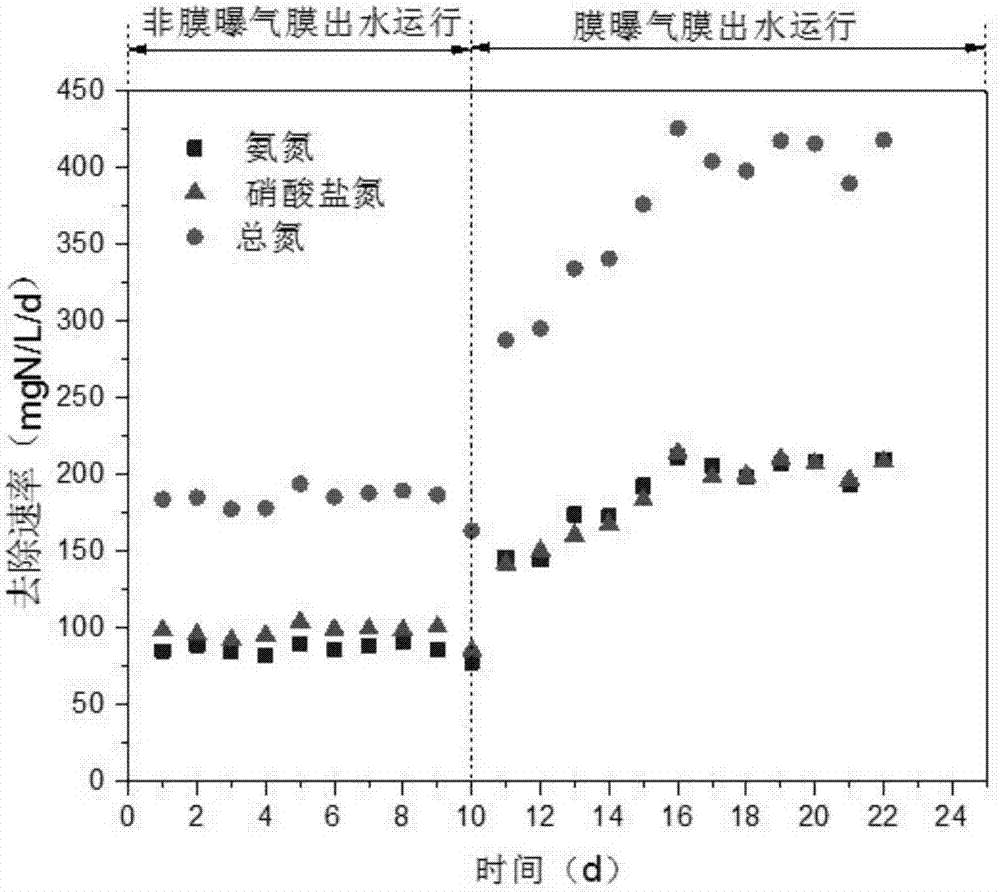

Efficient denitrification method and novel membrane aeration MBR (membrane bioreactor) for realizing method

InactiveCN108002531AGuaranteed uptimeSolve the problem of low substrate utilizationWater contaminantsTreatment with anaerobic digestion processesMembrane bioreactorSewage

The invention discloses an efficient denitrification method and a novel membrane aeration MBR (membrane bioreactor) for realizing the method, and belongs to the technical field of sewage biological denitrification. The method is characterized in that a mixed microbial flora subjected to enrichment culture is put inside a reactor main body; sewage to be treated is conveyed inside the reactor main body through a water inlet pump; meanwhile, methane gas is continuously conveyed into a mud water mixture; bubbleless aeration is performed through an aeration membrane; a stirring device stops after the hydraulic retention time is reached; the mud water mixture is subjected to static sedimentation; after the static sedimentation, solid-liquid separation and membrane discharging-out are performed.The invention also provides the novel membrane aeration MBR for realizing the method. The method has the advantages that an MBR system and membrane aeration are coupled; the biomass can be effectivelyintercepted; the gas substrate utilization rate is high; the method is applicable to efficient denitrification of denitrification anaerobic methane oxidation using methane as the substrate.

Owner:HARBIN INST OF TECH

Anaerobic-anoxic-aerobic-film component treatment method

PendingCN107200401AOvercome the disadvantages of easy sludge bulkingEfficient solid-liquid separationTreatment with aerobic and anaerobic processesFluidized bedSludge

The A20+MBR treatment method belongs to the field of environmental protection, especially the field of sewage filtration biological treatment and reuse; A20+MBR treated sewage enters the anaerobic pool through the water inlet, and the sewage is filtered through the biological fluidized bed in the anaerobic pool 2; anaerobic The pre-filtered sewage in the pool 2 enters the anoxic pool 3, and the sewage is filtered through the biological fluidized bed in the anoxic pool 3; Flow state bed filtration; the sewage filtered by the aerobic pool 4 enters the membrane pool 5, and the sewage is filtered by the MBR membrane module 6 in the membrane pool 5; the sewage filtered by the MBR membrane module 6 in the membrane pool 5 passes through under the action of negative pressure Water outlet 9 gets rid of. Realize high-efficiency solid-liquid separation, high-quality and stable effluent water quality; less residual sludge, small footprint, no need for secondary settling tanks, centralized process equipment; can be widely used in urban and rural sewage treatment fields.

Owner:云南傲远智能环保科技有限公司

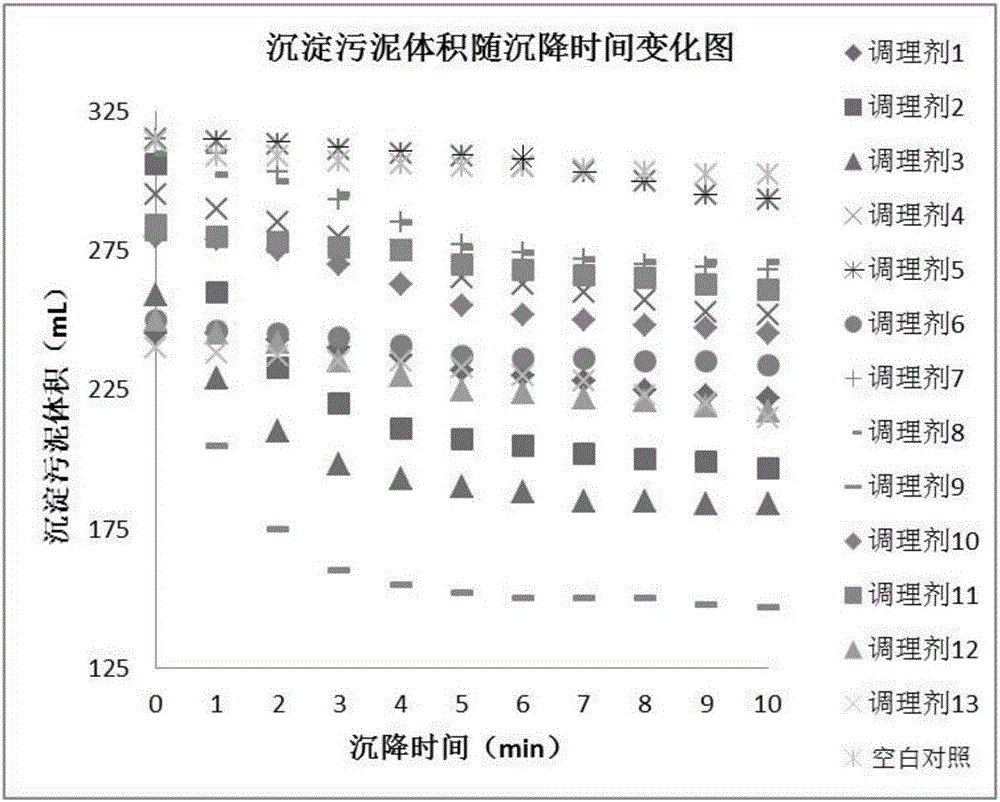

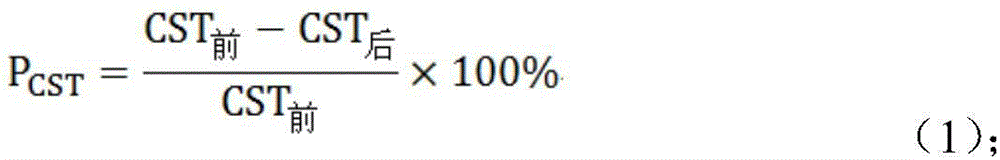

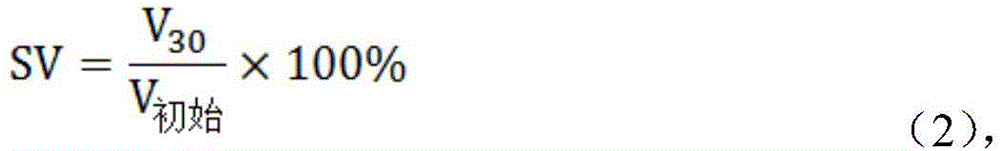

Method for evaluating comprehensive performance of sludge dewatering conditioner

PendingCN106055915AEfficient solid-liquid separationSettling fastSpecial data processing applicationsInformaticsWater qualityTurbidity

The invention discloses a method for evaluating the comprehensive performance of sludge dewatering conditioners. A set of uniform and comprehensive evaluation indexes capable of being quantitatively calculated is selected. The evaluation indexes comprises SV and SA of the sludge settling performance, SCT of the sludge filtering performance, a dewatering rate W of sludge dewatering degree, a filtrate water quality index COD, pH and turbidity, the indexes are integrated together to form an evaluation index Ecp. The performance of various conditioners can be compared through comparison of the Ecps. The vacancy of the evaluation method for the comprehensive performance of the current conditioners is filled up. New evaluation methods are defined for the evaluation indexes CST and COD capable of being quantitatively calculated. A filtering performance improving rate PCST is used for expressing the improving or baffling action degree of the conditioners to the sludge filtering performance better. A COD change rate GCOD is used for expressing the digestion or increasing degree of the conditioners to filtrate reductive substances better. The evaluation indexes Ecps for the comprehensive performance of the sludge dewatering conditioners are provided. The evaluation method is objective and quantified and has high repeatability, operability and practicability.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

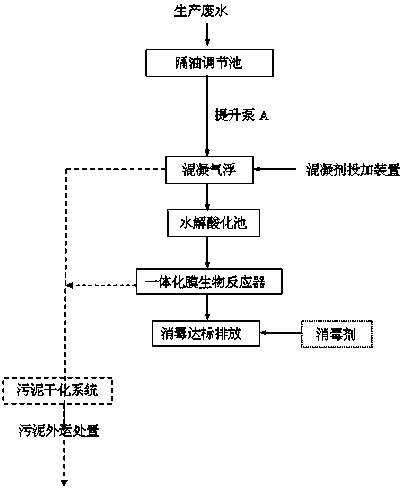

SBR (Sequencing Batch Reactor) activated sludge process for soybean lecithin production

InactiveCN108467154AAvoid siltingWell mixedFatty/oily/floating substances removal devicesSpecific water treatment objectivesSequencing batch reactorProcess equipment

The invention discloses an SBR (Sequencing Batch Reactor) activated sludge process for soybean lecithin production. The process comprises the following steps: performing pretreatment sludge fishing, pretreating floating oil, adjusting water quantity in an adjusting tank, homogenizing water quality, performing coagulation air floating treatment, performing acidification conditioning in a hydrolysisacidification tank, and performing aerobic treatment in an integral bioreactor. The process disclosed by the invention is concise in process, efficient in solid-liquid separation, excellent and stable in effluent quality, capable of removing ammonia nitrogen and refractory organic matters and overcoming defects that sludge expansion can be easily caused when a conventional activated sludge process is used, small in floor space, free of secondary sedimentation tank and centralized in process equipment.

Owner:江苏大彭环保科技有限公司

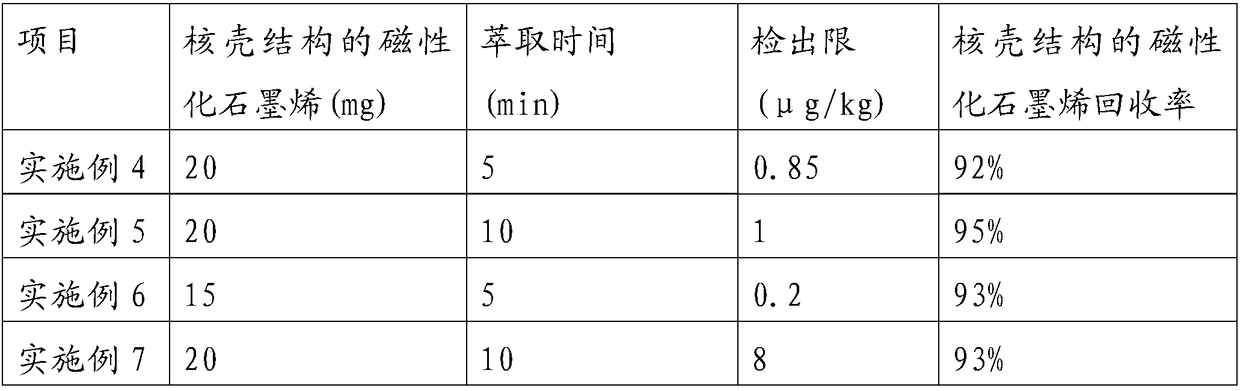

Magnetic graphene with core-shell structure, application thereof to pesticide residue detection and application method

ActiveCN109336100AExcellent magnetic propertiesEfficient solid-liquid separationCarbon compoundsComponent separationSolid phase extractionGraphene

The invention discloses magnetic graphene with a core-shell structure, application thereof to pesticide residue detection and an application method. The magnetic graphene, with the core-shell structure, is formed by coating magnetic graphene to the surface of silicon dioxide through the adhesive action of dopamine, wherein the silicon dioxide serves as a core, and the magnetic graphene serves as ashell; the magnetic graphene adopts graphene loaded with Fe3O4. The magnetic graphene is applied to pesticide residue detection, serves as a magnetic solid phase extraction adsorbent, and performs pretreatment on a target sample before purification; the special structure of the graphene is beneficial to enrichment of aromatic or hydrophobic analyte; the magnetic graphene has excellent magnetic property, can rapidly and efficiently realize solid-liquid separation under the action of external magnetic field, and can further realize recycling and reusing.

Owner:WEIFANG VOCATIONAL COLLEGE

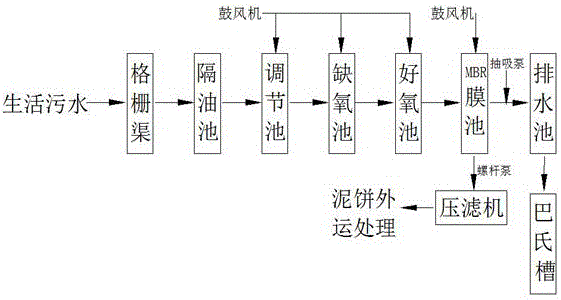

Method for treating domestic wastewater with porous multilayer hollow PTFE-MBR membrane

InactiveCN105923896AThe water is clear and transparentEfficient solid-liquid separationFatty/oily/floating substances removal devicesTreatment involving filtrationPollutantOil separation

The invention provides a method for treating domestic wastewater with a porous multilayer hollow PTFE-MBR membrane. The method comprises the steps that domestic wastewater is collected through a pipe network and then enters a wastewater treatment station, wherein gratings are arranged at the front end of the wastewater treatment station, and the gaps between the gratings is 5 mm; water out of the gratings automatically flows into an oil separation tank; water out of the oil separation tank enters a regulating tank; water out of the regulating tank is lifted to an anoxia tank through a submersible sewage pump, wherein the primary function of the anoxia tank is denitrification; water out of the anoxia tank automatically flows into an aerobic tank, wherein the aerobic tank performs the functions of making active sludge carry out aerobic respiration, further decomposing organic matter into inorganic matter and removing pollutants; water out of the aerobic tank automatically flows into a membrane bioreactor; water of the membrane bioreactor is sucked to a discharging tank through a self-priming pump and then discharged into a natural water body through a Parshall trough. According to the method, the occupied area is small, the technological process is short, the water quality of outlet water is stable, it is ensured that outlet water is clear and transparent, and high-quality produced water is obtained.

Owner:安徽洋森环保节能科技有限公司

Anaerobic-anoxic-aerobiotic-aerobiotic-membrane component treatment method

InactiveCN107176679AImprove retention efficiencyFunction increaseTreatment with aerobic and anaerobic processesSustainable biological treatmentSludgeBiological filter

The invention discloses an A2O2+MBR treatment method, and belongs to the technical field of environment friendliness, and sewage treatment reutilization. The method is characterized in that sewage enters an anaerobic pool through a water inlet, and is filtered by a biological filter bed in the anaerobic pool; preliminarily filtered sewage in the anaerobic pool enters an anoxic pool and is filtered by a biological filter bed in the anoxic pool; sewage filtered in the anoxic pool enters a micro-aerobic pool and is filtered by a biological filter bed in the micro-aerobic pool; sewage filtered in the micro-aerobic pool enters an aerobiotic pool and is filtered by a biological filter bed in the aerobiotic pool; sewage filtered by the aerobiotic pool enters a membrane pool and is filtered by an MBR membrane component in the membrane pool; and sewage filtered by the MBR membrane assembly in the membrane pool is removed through a water outlet under action of negative pressure. The method realizes efficient solid-liquid separation, water quality of outlet water is excellent and stable, amount of residual sludge is less, floor space is small, degradation-resistant organic substances are removed, and the defect that sludge expanding is easily generated by conventional active sludge is overcome. The method can be widely applied to the swage treatment field.

Owner:云南傲远智能环保科技有限公司

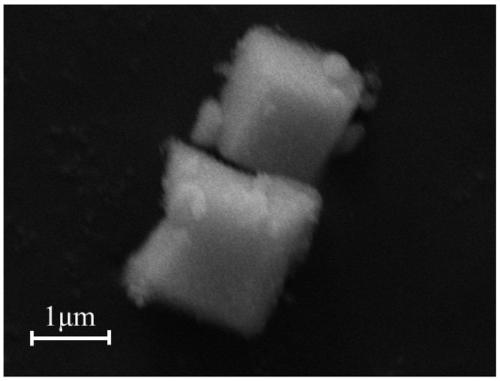

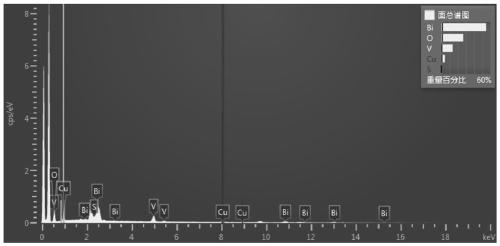

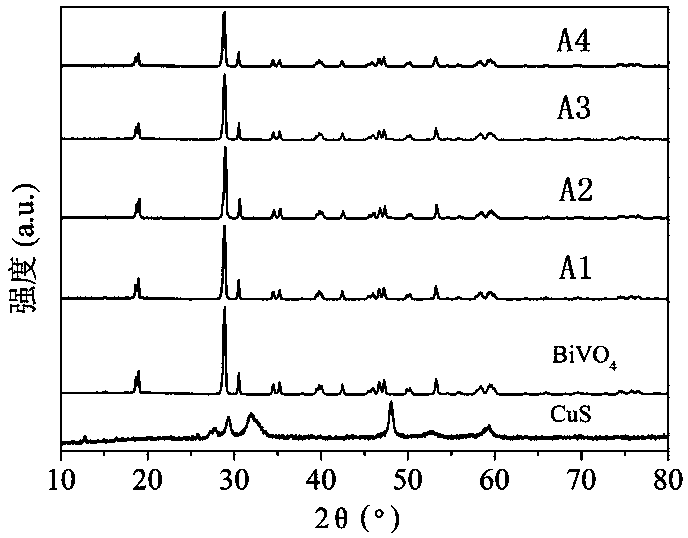

Method for removing antibiotics from water body by using copper sulfide/bismuth vanadate heterojunction photocatalyst

ActiveCN109046388AEfficient degradationEfficient solid-liquid separationPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionBismuth vanadate

The invention discloses a method for removing antibiotics from a water body by using a copper sulfide / bismuth vanadate heterojunction photocatalyst. The method treats the antibiotics in the water bodyby using the copper sulfide / bismuth vanadate heterojunction photocatalyst, wherein the copper sulfide / bismuth vanadate heterojunction photocatalyst comprises copper sulfide and bismuth vanadate, andthe copper sulfide is attached to the bismuth vanadate. The method can be carried out at normal temperature under normal pressure, can mineralize the antibiotics (such as ciprofloxacin) into water andcarbon dioxide, can effectively perform solid-liquid separation without secondary pollution, has the advantages of simple operation, no need for large equipment, low cost, wide application range, high treatment efficiency, good treatment effect, strong reusability and environmental friendliness, can efficiently degrade the antibiotics in the water body, and has good application value and application prospect.

Owner:HUNAN UNIV

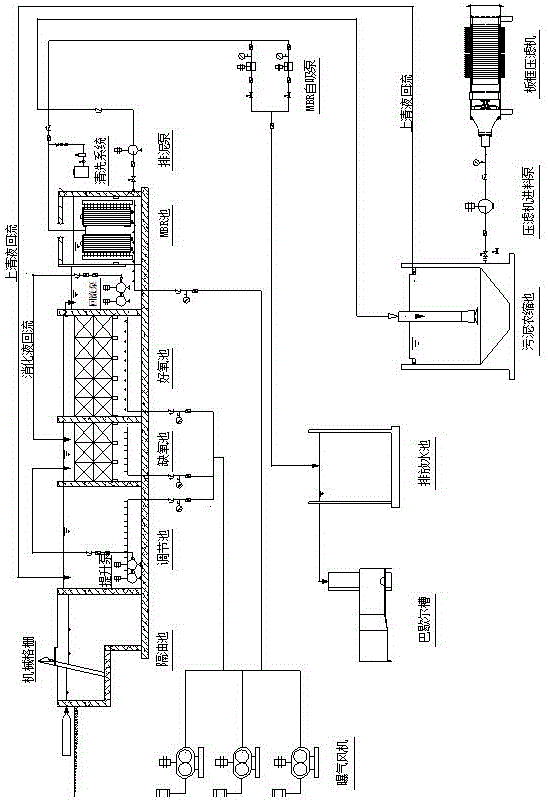

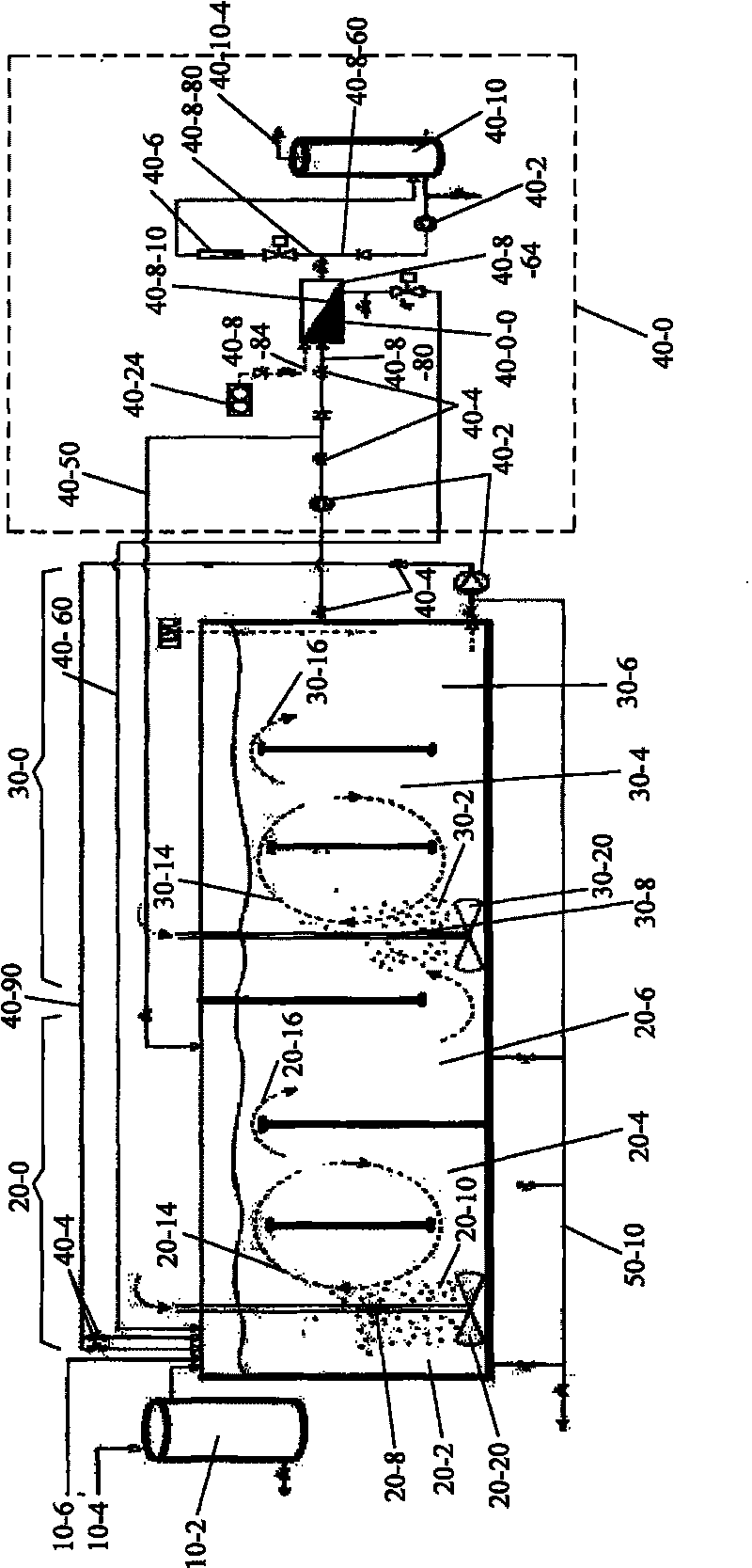

Lateral flow type membrane bioreactor device and sewage treatment method using same

InactiveCN101734794AAdvantages of side flow MBR processHigh water quality standardTreatment with aerobic and anaerobic processesFiberUltrafiltration

The invention provides a lateral flow type membrane bioreactor device and a sewage treatment method using same. The device sequentially comprises a regulating pond (10-2), at least a first bioreactor (20-0) and an ultrafiltration system (40-0), wherein the first bioreactor (20-0) comprises a first aerobic pond (20-2), a first anoxic pond (20-4) and a first anaerobic pond (20-6); the ultrafiltration system (40-0) also comprises a membrane ultrafiltration device (40-0-0) and an ultrafiltration back flush water pot (40-10-4); a gas back flush pipe (40-8-30) is arranged at the centre of a membrane cylinder (40-8-64); a filtered water collection bin (40-8-48) is arranged below the membrane cylinder (40-8-64); an impermeable clapboard is arranged between the membrane cylinder (40-8-64) and the filtered water collection bin (40-8-48); and a plurality of U-shaped hollow fibrous membranes (40-8-10) are closely arranged between the inner wall of the hollow membrane cylinder (40-8-64) and the outer wall of the gas back flush pipe (40-8-30), sealed in the membrane cylinder (40-8-64) with downward openings, and form a sewage storage bin (40-8-40) with the hollow membrane cylinder. The invention also provides a combined sewage treatment method by utilizing at least the lateral flow type membrane bioreactor device and a lateral flow type membrane ultrafiltration device comprising a gas back flush, gas-water joint back flush and chemical membrane cleaning system.

Owner:北京渭黄天安环保科技有限公司

Device for purifying oily wastewater

InactiveUS8828224B2Simple but reliable treatment processReduce investmentWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Sewage treatment equipment and treatment method combining multi-stage anoxic oxic (AO) membrane technology and membrane bioreactor (MBR) membrane technology

PendingCN109867360APrevent inflowAvoid savingTreatment with aerobic and anaerobic processesSustainable biological treatmentNitrogen removalAeration system

The invention belongs to the technical field of sewage and wastewater treatment, and particularly relates to a sewage treatment equipment and treatment method combining multi-stage anoxic oxic (AO) membrane technology and membrane bioreactor (MBR) membrane technology. The sewage treatment equipment comprises a raw water pretreatment device, an AO process treatment device and an MBR membrane mechanism; the AO process treatment device comprises an anaerobic mechanism and an aerobic mechanism, wherein the anaerobic mechanism comprises a plurality of anaerobic tanks, the aerobic mechanism comprises a plurality of aerobic tanks, and all the anaerobic tanks and the aerobic tanks are all internally provided with an aeration system; the raw water pretreatment device comprises a plurality of filterturnover mechanisms and a plurality of filter tanks; and the MBR membrane mechanism comprises a membrane separation tank, an MBR membrane reactor and a back cleaning assembly. Regulation of differentprocesses can be realized through the control of gate valves, and certain flexibility is achieved, and the plurality of aerobic tanks and anaerobic tanks can be operated in series or in parallel through the gate valves. The sewage passes through the series-connected multi-stage A / O process treatment devices and then enters an MBR membrane area, so that high-efficiency nitrogen removal is realized, and treatment efficiency of the equipment is improved.

Owner:芜湖沃泰环保科技有限公司

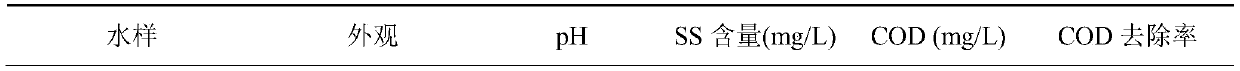

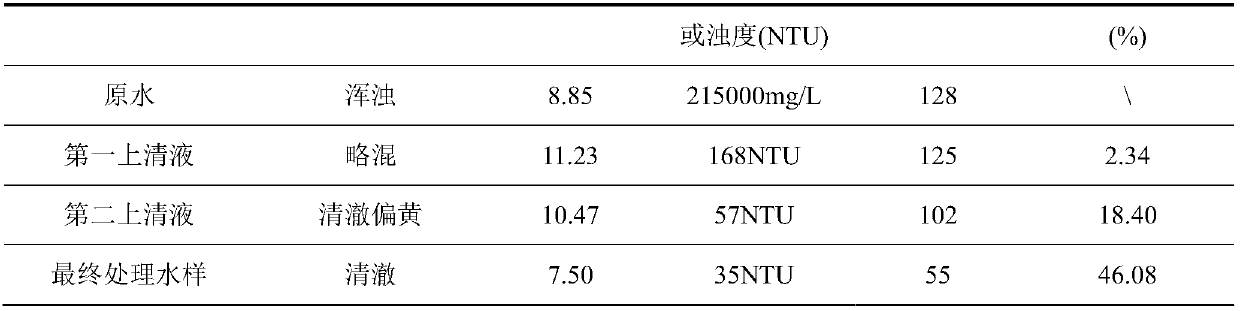

Method for treating and recycling fluorite beneficiation wastewater

InactiveCN109574263AMeet the requirements of recyclingSolve processingWaste water treatment from metallurgical processMultistage water/sewage treatmentSuspended particlesActivated carbon

The invention discloses a method for treating and recycling fluorite beneficiation wastewater. The method includes following steps: 1), adding lime into the fluorite beneficiation wastewater, sufficiently stirring, and coagulating and settling to obtain first supernate; 2), adding polyaluminum and polyacrylamide into the first supernate obtained in the step 1), stirring, and performing coagulationand sedimentation to obtain second supernate; 3), adjusting pH of the second supernate obtained in the step 2) to 6-8, adding activated carbon for adsorption, and removing the activated carbon afteradsorption is completed to obtain a final treatment water sample which can be recycled for a fluorite flotation system. The method is simple in operation; lime and polyaluminum are utilized to performcascaded coagulating and settling on suspended particles in the wastewater, and the activated carbon is utilized to selectively adsorb key impact factors in the wastewater, so that the wastewater after being treated by utilizing the method can be recycled for fluorite beneficiation, and efficient recycling of the fluorite beneficiation wastewater is realized.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

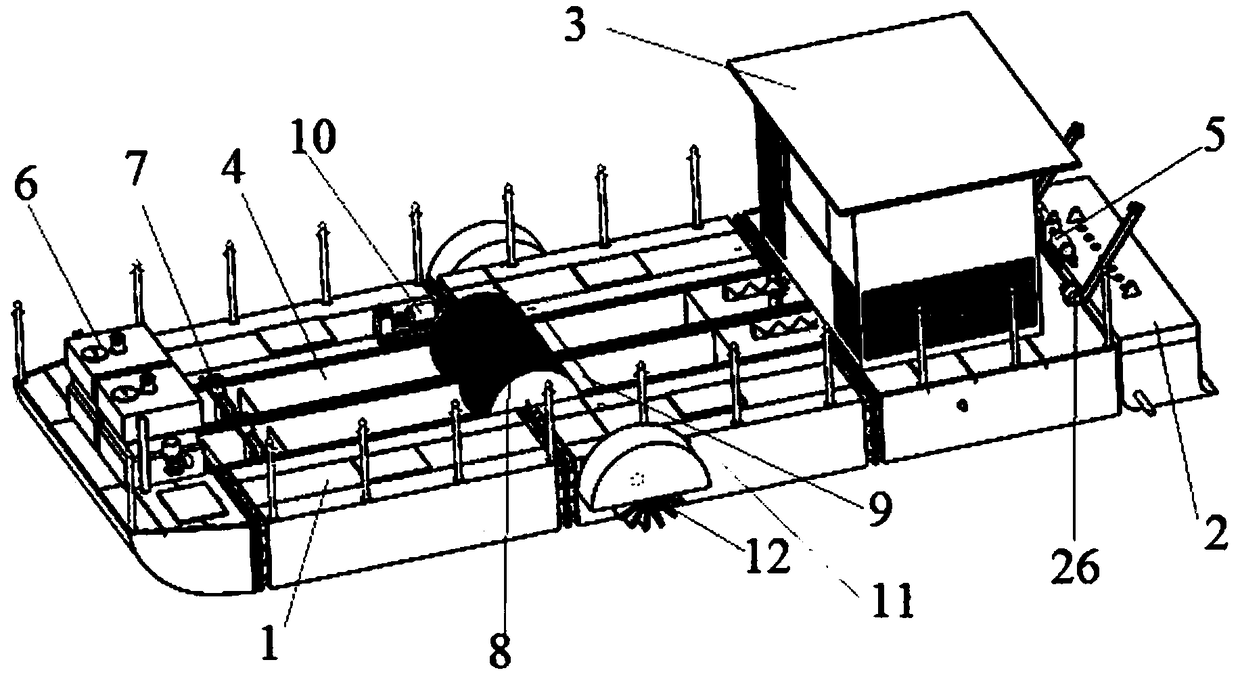

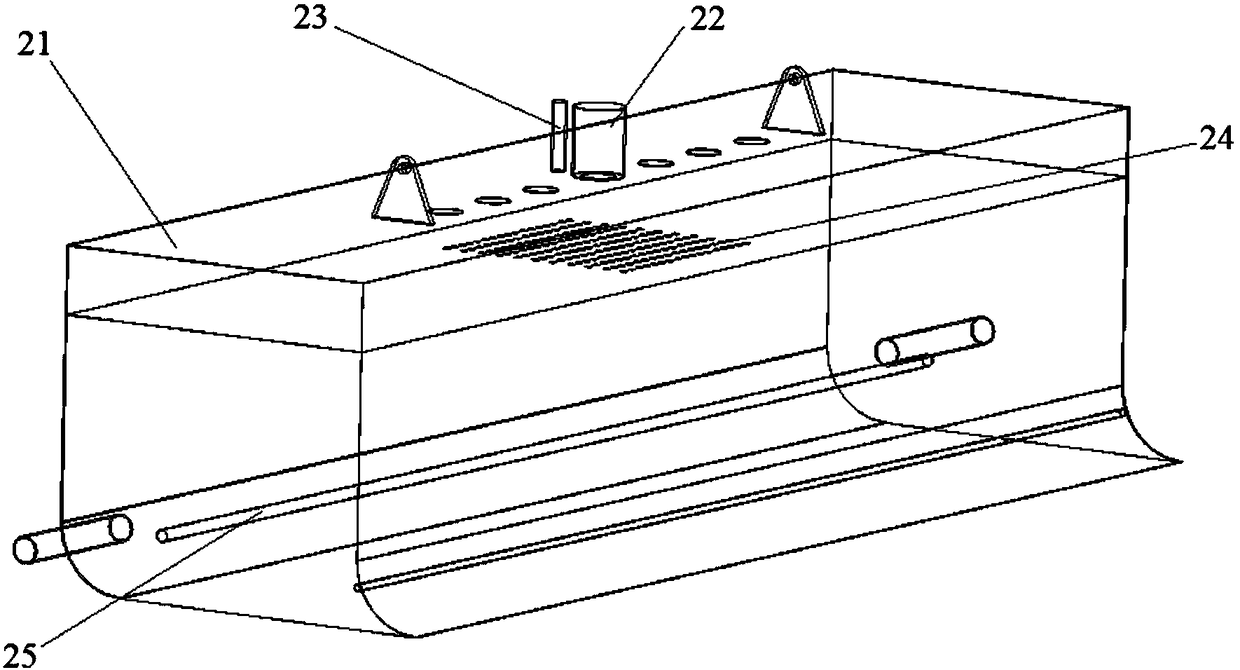

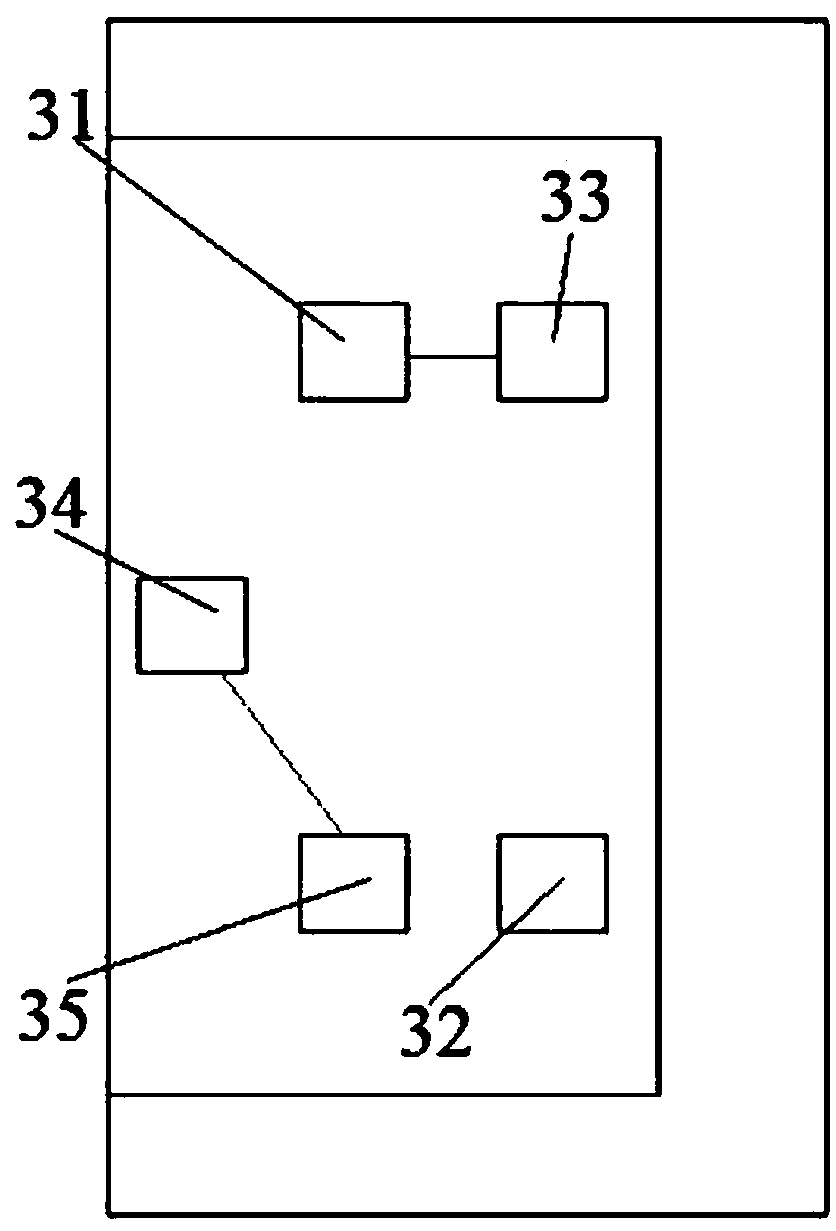

Bottom sludge elution floating platform on basis of magnetic coagulation and loading processes

PendingCN108147611AHigh transparencyImprove germination rateWater treatment parameter controlSludge treatment by de-watering/drying/thickeningSludgeElution

The invention relates to a bottom sludge elution floating platform on the basis of magnetic coagulation and loading processes. The bottom sludge elution floating platform comprises a floating platform, a magnetic coagulation and loading device, an aeration disturbance device and a control room. The bottom sludge elution floating platform has the advantages that bottom sludge elution can be carriedout on large-volume water bodies by the aid of the magnetic coagulation and loading processes, and platform structures are optimized; the magnetic coagulation and loading processes have the characteristics of compact structures, the bottom sludge elution floating platform which is a product is designed to be modular and is convenient to detach and transport, and accordingly the operation efficiency and effects can be effectively improved; the bottom sludge elution floating platform can effectively adapt to various water areas and landforms, depths and environments, magnetic seeds in separatedfloc can be recycled, filter-press is carried out on sludge deposits, the sludge deposits are bagged and transported, and accordingly secondary pollution can be prevented.

Owner:安徽雷克环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com