VOC (volatile organic compound) treatment system adopting ozone and micro-nano-bubbles

A technology of micro-nano bubbles and treatment system, which is applied in the field of ozone micro-nano bubbles treatment system to achieve the effect of low treatment cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

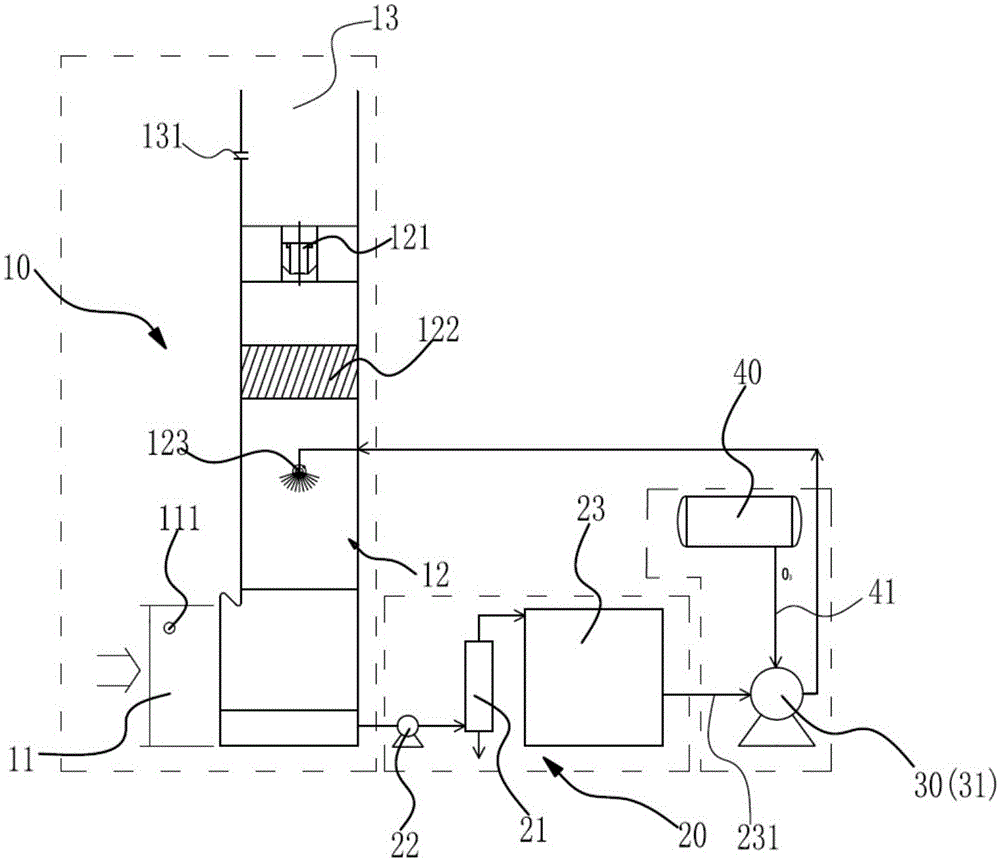

Method used

Image

Examples

Embodiment

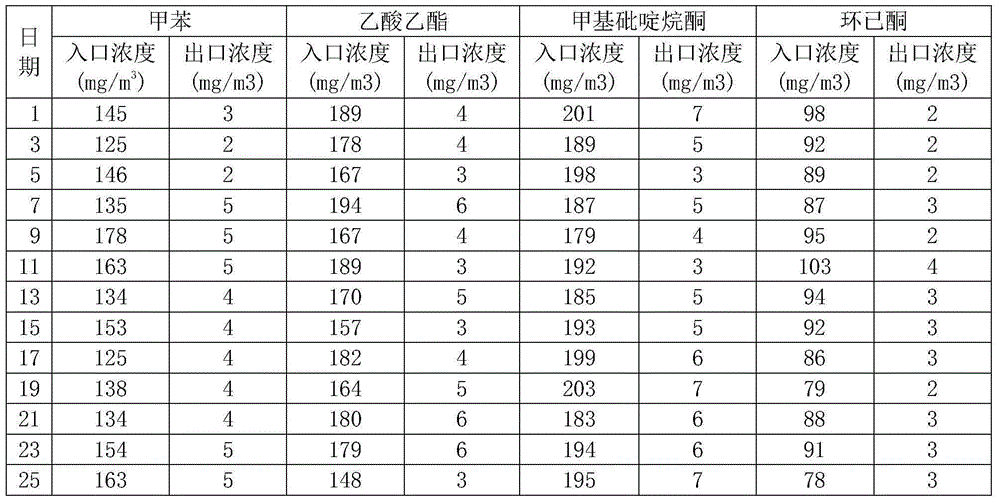

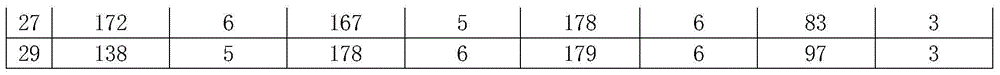

[0043] The gas-water separation device adopts a swirling plate type gas-liquid separator, and the concentration of N-formylmorpholine aqueous solution is 17 mg / L; the solid-liquid separation component adopts a membrane separation component; when the equipment is running, the flow rate of the high-pressure gas-water mixing pump is set to 0.15m 3 / h, gas flow rate 0.015m 3 / h, the mass concentration of ozone in the gas is 10%; the present embodiment tests the operating equipment of the Wood Products Co., Ltd. for one month, and the test time is once every two days; the specific test data and analysis are as follows:

[0044] Table 1 Online detection data of VOC concentration at exhaust gas inlet and exhaust gas outlet

[0045]

[0046]

[0047] Table 2 Analysis table of various VOC treatment rates

[0048]

[0049] The working principle of the present invention: this system uses ozone micro-nano bubbles to degrade VOC, which is safer than other treatment methods, easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com