Separable toilet

A separate, toilet technology, used in flushing equipment with water tanks, sanitary equipment for toilets, flushing toilets, etc., can solve the problems of difficult cleaning, difficult to remove, and high costs, achieve high-efficiency solid-liquid separation, and prevent increase. Large, the effect of preventing transportation and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

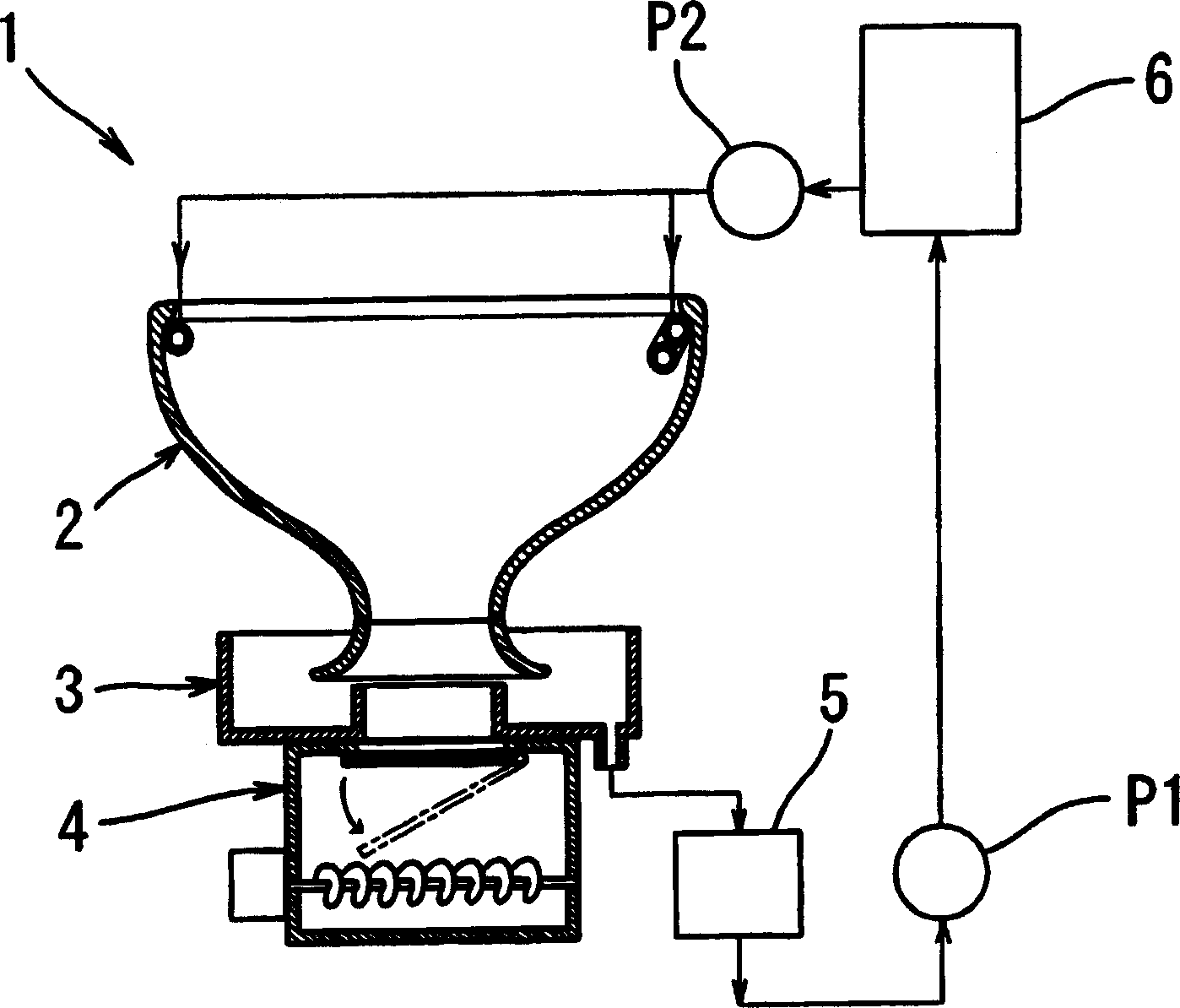

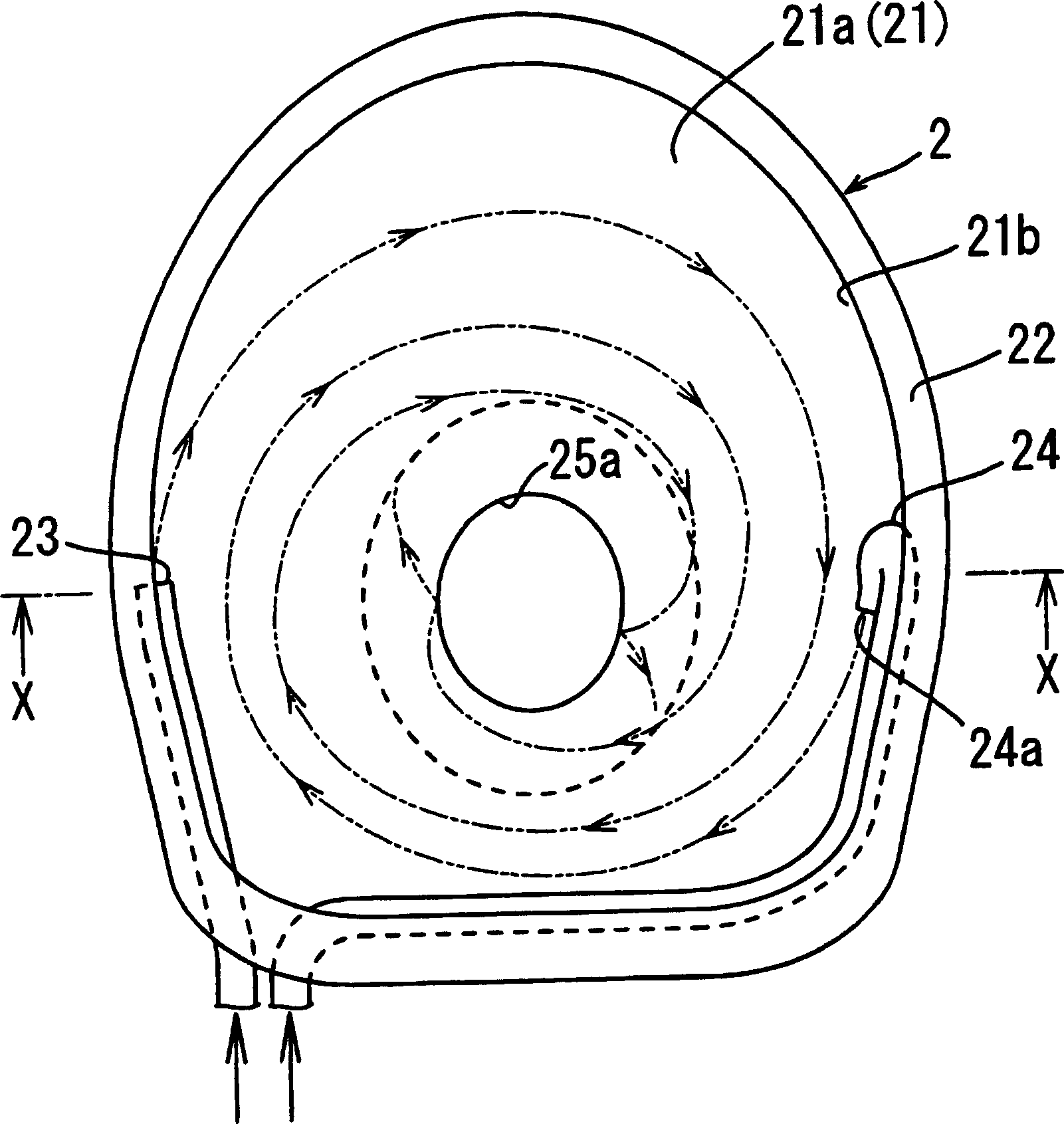

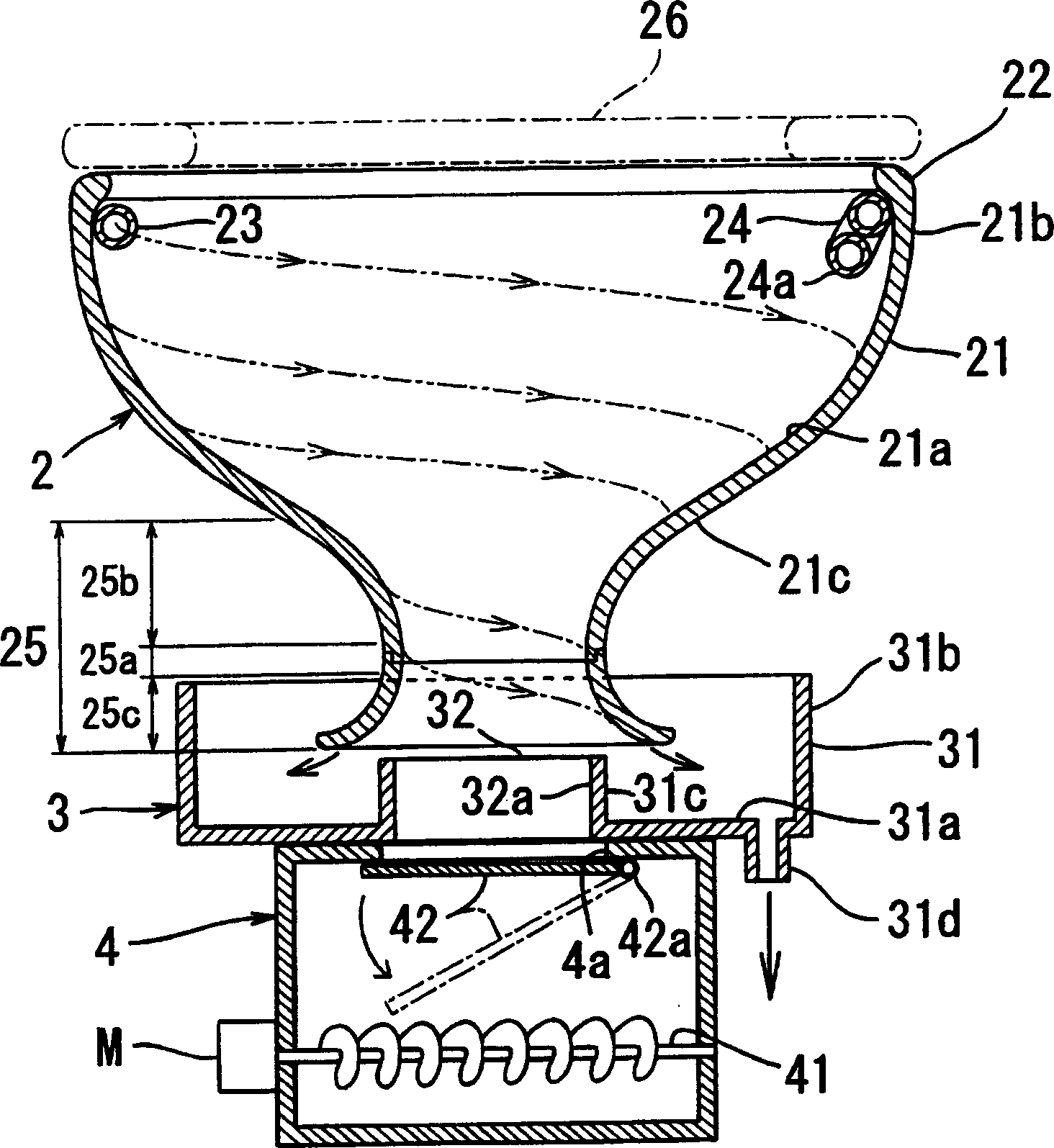

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0033] Figure 1 to Figure 5 An example of an embodiment of the invention is shown. figure 1 It is a schematic block diagram showing the separate type toilet of this embodiment. figure 2 A top view of a toilet showing a split toilet. image 3 is equivalent to figure 2 The X-X section of , showing the toilet, the solid-liquid separator and the solid component receiving part arranged below it. Figure 4 It is a figure explaining the manufacturing method of the discharge pipe formed in the bottom part of a toilet. Figure 5 It is a figure explaining the structure and manufacturing method of a solid-liquid separator. Also, in figure 1 as well as image 3 In , although the toilet is described in a suspended state, it is actually supported and fixed by an unillustrated support table and fixing tools. In addition, although the solid-liquid separator is described in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com