Microparticle separator for water treatment

A technology of microparticles and water treatment, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., and can solve the problems of reduced heat transfer efficiency of heat exchange equipment, decreased pipeline flow, energy waste, etc. problems, to achieve the effect of reducing equipment failure, reducing the presence of particulate matter, and restoring normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

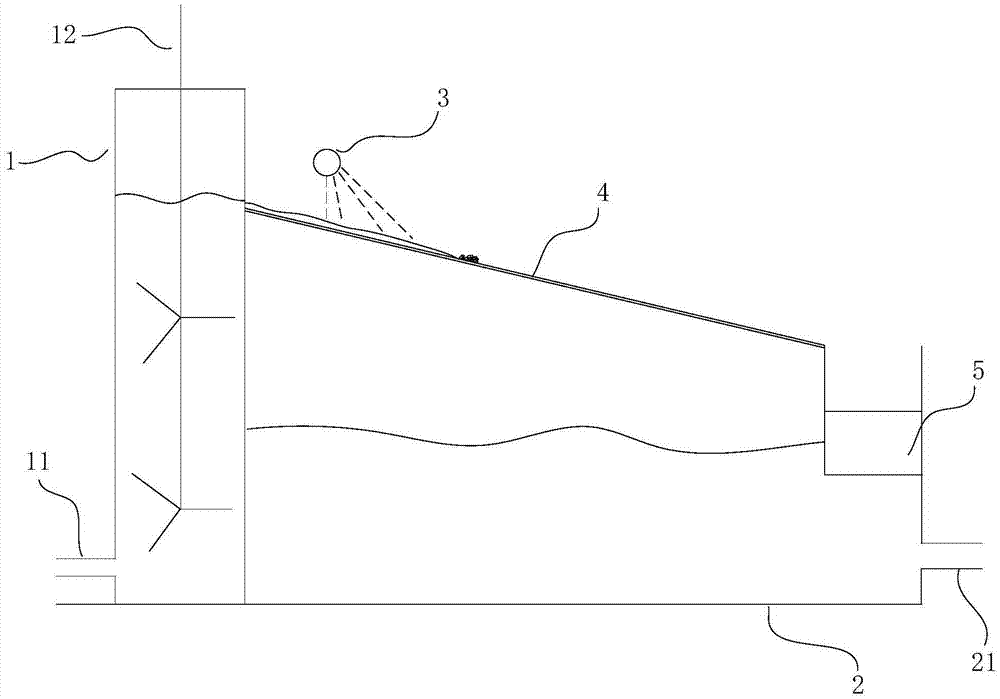

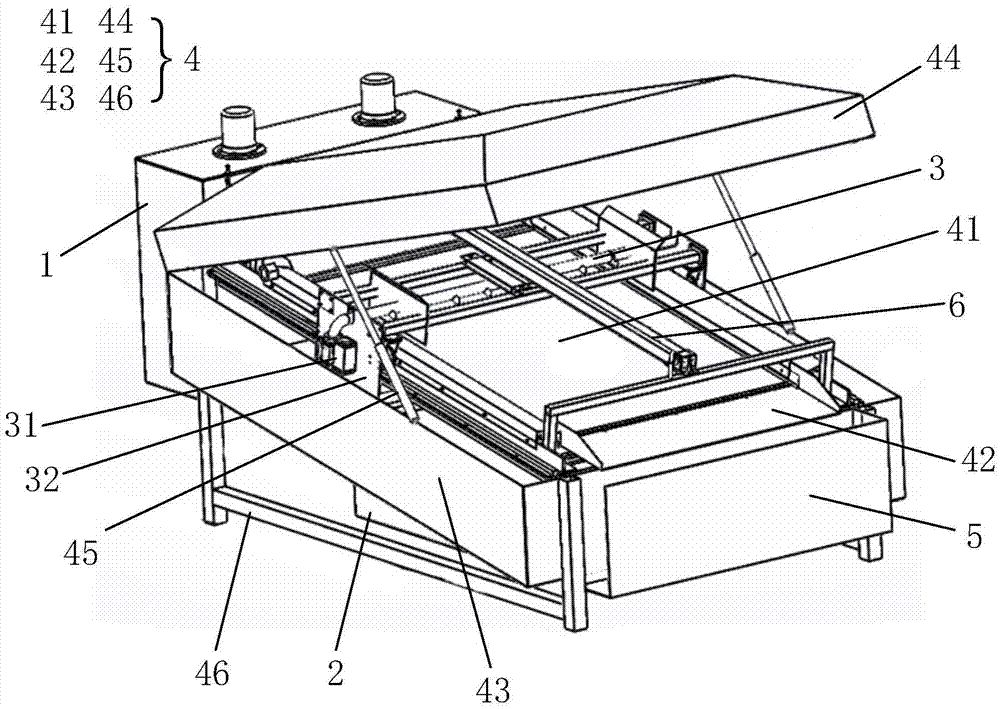

[0017] The following will combine figure 1 and figure 2 The microparticle separator for water treatment provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and modify it within the scope of not changing the spirit and content of the present invention. polish.

[0018] Please refer to figure 1 and figure 2 , the present invention provides a water treatment particulate matter separator, comprising a first water tank 1, a second water tank 2, an agitator 11 and a filter membrane structure 4, the filter membrane structure 4 at least includes a filter membrane 41, the first The water inlet of a water tank 1 is arranged close to the bottom of the first water tank 1, the agitator 11 is used to stir the liquid in the first water tank 1, and the upper opening of the second water tank 2 covers the filter The membrane structure 4, the connection or positiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com