Efficient denitrification method and novel membrane aeration MBR (membrane bioreactor) for realizing method

A technology of membrane bioreactor and membrane aeration, applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc., can solve the problems of DAMO functional microorganism loss, low methane solubility, small mass transfer coefficient, etc. Achieve the effects of reducing the loss of DAMO functional microorganisms, improving mass transfer efficiency, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

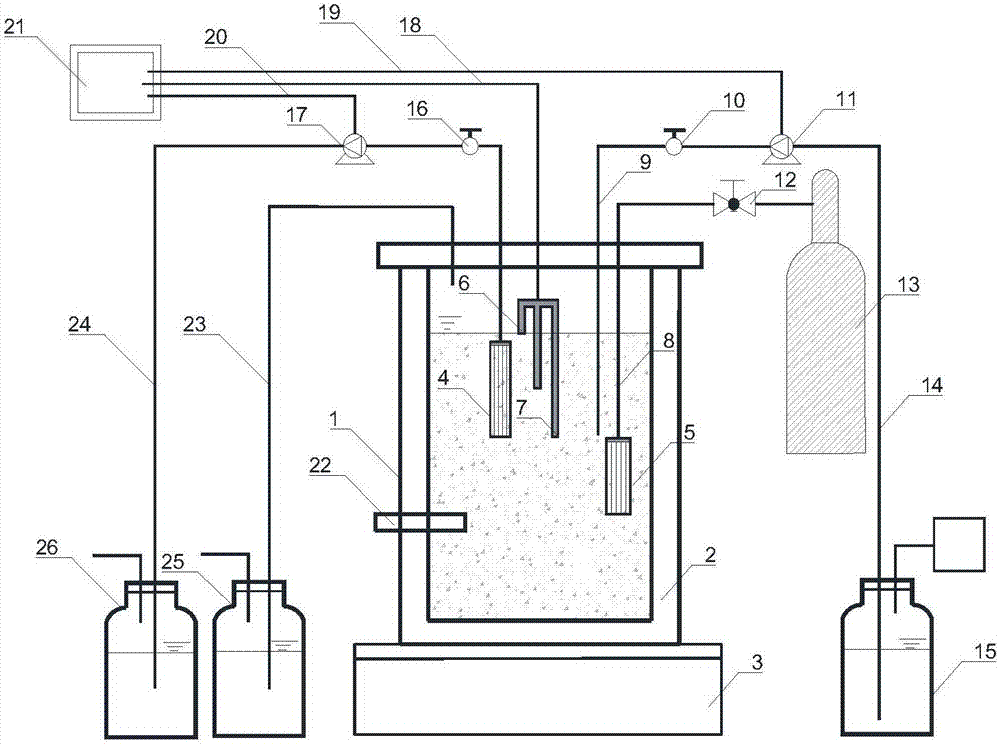

[0032] combine figure 1 Description of this embodiment, this embodiment provides a novel membrane aerated membrane bioreactor for realizing the above method, the novel membrane aerated membrane bioreactor comprises a reactor main body 1, a temperature control device 2, a magnetic stirring device 3. Solid-liquid separation membrane 4, aeration membrane 5, pH electrode 22, high-pressure methane gas storage tank 13, water inlet device 15, water outlet device 26, gas outlet pipeline 23, gas outlet liquid sealing device 25, water inlet pump 11 and water outlet pump 17; wherein: the outside of the wall of the reactor body 1 is provided with a temperature control device 2; the bottom of the reactor body 1 is provided with a magnetic stirring device 3; the inner wall of the reactor body 1 is also provided with a pH electrode 22; the inside of the reactor main body 1 is also fixed with a solid-liquid separation membrane 4 and an aeration membrane 5; the solid-liquid separation membrane...

Embodiment approach 2

[0046] This embodiment adds a technical feature liquid level sensor 21 on the basis of Embodiment 1. The liquid level sensor 21 in this embodiment includes a high liquid level sensor probe 6, a low liquid level sensor probe 7, and the first liquid level sensor signal output Line 18, the second liquid level sensor signal output line 19 and the third liquid level sensor signal output line 20; wherein: the liquid level sensor 21 communicates with the high liquid level sensor probe 6 and the low level sensor through the first liquid level sensor signal output line 18 The liquid level sensor probe 7 is connected, the liquid level sensor 21 is connected with the water inlet pump 11 through the second liquid level sensor signal output line 19, and the liquid level sensor 21 is connected with the water outlet pump 17 through the third liquid level sensor signal output line 20; The liquid level sensor probe 6 and the low liquid level sensor probe 7 are fixed inside the reactor main body...

Embodiment approach 3

[0052] This embodiment provides a novel membrane aerated membrane bioreactor efficient denitrification method, the specific method is as follows:

[0053] 1. In this embodiment, NH is added to water 4 + -N, NO 3 - -N and KH 2 PO 4 , CaCl 2 2H 2 O, MgSO 4 ·7H 2 O and trace elements to simulate the actual wastewater, so that the content of the above components in the wastewater is as follows: KH 2 PO 4 0.075g / L, CaCl 2H 2 O0.3g / L, MgSO 4 ·7H 2 O 0.2g / L, basic trace elements 0.2mL / L, acid trace elements 0.5mL / L, NH 4 + -N 200mg / L, NO 3 - -N 200mg / L.

[0054] 2. In this embodiment, the mixed flora is: a mixed flora composed of DAMO bacteria Candidatus Methylomirabilis oxyfera, DAMO archaea Methanoperedens nitroreducens and Anammox bacteria through 315 days of enrichment culture

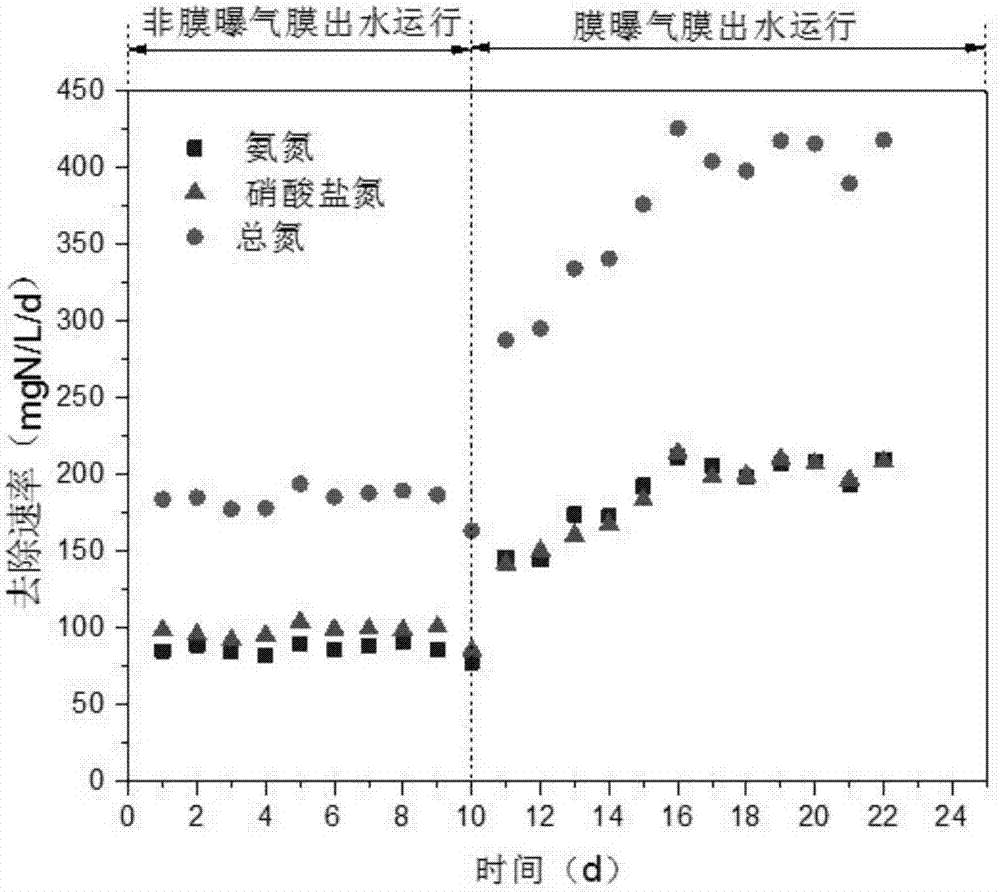

[0055] The artificial sewage configured according to the above method is used as the experimental object, and the novel membrane aerated membrane bioreactor of the second embodiment and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com