Processing Method Of Silicon Cutting Waste Liquid

A technology of cutting waste fluid and treatment method, applied in the direction of lubricating composition, etc., can solve the problems of slow treatment speed, poor treatment efficiency, and impair the purity of silicon that can be recycled, and achieve the effect of low burden and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

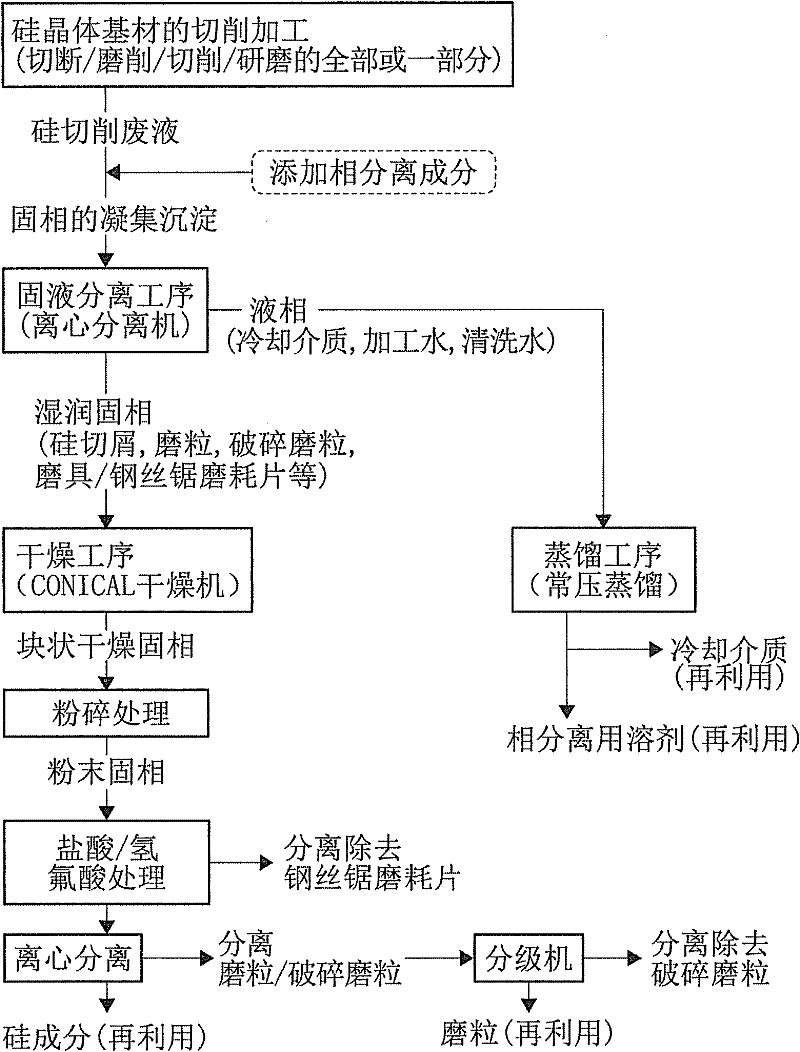

[0048] Below, refer to figure 1 , to describe an embodiment of the present invention.

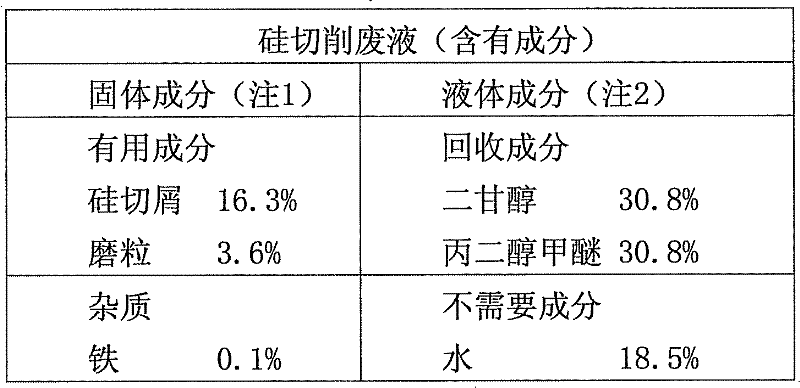

[0049] In this embodiment, the silicon cutting waste liquid as the object of treatment refers to the process of cutting single crystal silicon (slicing from silicon ingots to slices of silicon wafers to the division and cutting of semiconductor elements to form circuits) in the manufacture of semiconductor elements. Cutting into small pieces, grinding, cutting, and a series of processing of grinding) silicon chips generated from processing water (grinding water, cutting water, etc.), or waste liquid composed of cleaning water, containing the components shown in Table 1 below (It can be seen from the table that the liquid phase after the treatment of the present invention that fully separates and recovers the contained solid content can be supplied and reused), as the phase separation component added to the silicon cutting waste liquid, a polar aprotic type Butanone as one of the solvents....

Embodiment 2

[0074] This embodiment shows another example of implementing the treatment method of silicon cutting waste liquid related to the present invention. The processing object is silicon cutting waste liquid under the same conditions as in Example 1. As a phase separation component, methanol is used as a polar protic solvent. Add 2500 g of methanol to 2000 g of silicon cutting waste liquid, stir and let it stand still. After 40 minutes, the solid phase and liquid phase are clearly separated.

[0075]Next, centrifugal separation is performed under the same conditions as in Example 1, and 650 g of the clay-like separation block phase is recovered. In addition, the analysis result of the liquid phase after the separation and recovery of the solid phase shows that the total weight of the residual solids containing silicon is 0.5 g .

[0076] Methanol is the cheapest solvent. It has a low boiling point and is characterized by low cost for solid-liquid separation. However, the particle si...

Embodiment 3

[0087] This embodiment also shows another example of implementing the treatment method of the silicon cutting waste liquid related to the present invention. The processing object is the silicon cutting waste liquid under the same conditions as in Example 1. As a phase separation component, a non-ionic coagulant DIAFLOC NP800 ( (manufactured by DIANITRIX Co., Ltd.), 60 g of a 0.1% by weight aqueous solution of DIAFLOC NP800 was added to 2000 g of silicon cutting waste liquid, and the mixture was left to stand with stirring. After 120 minutes, the solid phase and the liquid phase were clearly separated.

[0088] Next, centrifugal separation is performed under the same conditions as in Example 1, and 800 g of the clay-like separation block phase is recovered. In addition, the liquid phase after separation and recovery of the solid phase is analyzed, and the total weight of the residual solids containing silicon is 0.05 g. .

[0089] Even a small amount of organic polymer coagulan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com