Method for treating and recycling fluorite beneficiation wastewater

A technology of mineral processing wastewater and treatment method, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of waste of resources, environment, pollution, etc. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Water treatment and reuse test of total tailings of fluorite beneficiation plant in Shizhuyuan Dongbo Concentrator

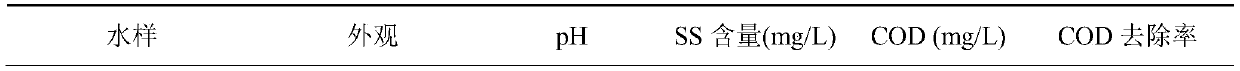

[0030] Table 1 shows the water quality analysis of the total tailings water and wastewater of each stage of fluorite beneficiation plant in Shizhuyuan Dongbo Concentrator.

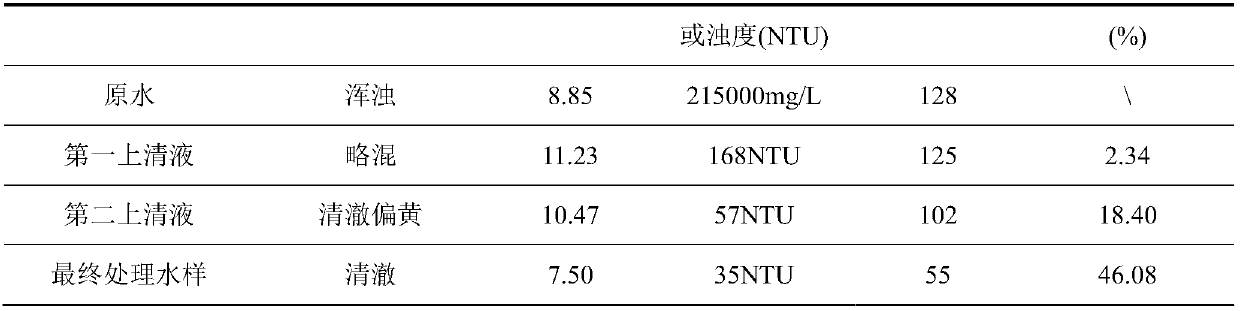

[0031] According to the technological process of the present invention, first add 500g / m3 to the total tailings water of fluorite 3 lime, stirred for 3 minutes, and settled for 30 minutes to obtain the first supernatant; then add 100g / m3 to the first supernatant 3 of polyaluminum, add 0.5g / m after stirring for 1min 3 The polyacrylamide produced a large number of flocs after stirring for 2 minutes, and the second supernatant was obtained after settling for 20 minutes; 2 SO 4 After adjusting the pH of the second supernatant to 7.5, add 200 g / m 3 Activated carbon, after adsorption for 30 minutes, was filtered to obtain the treated water sample; finally, the fluorite flotat...

Embodiment 2

[0037] Example 2: Water treatment and reuse test of fluorite low-coarse tailings in Shizhuyuan Dongbo Concentrator

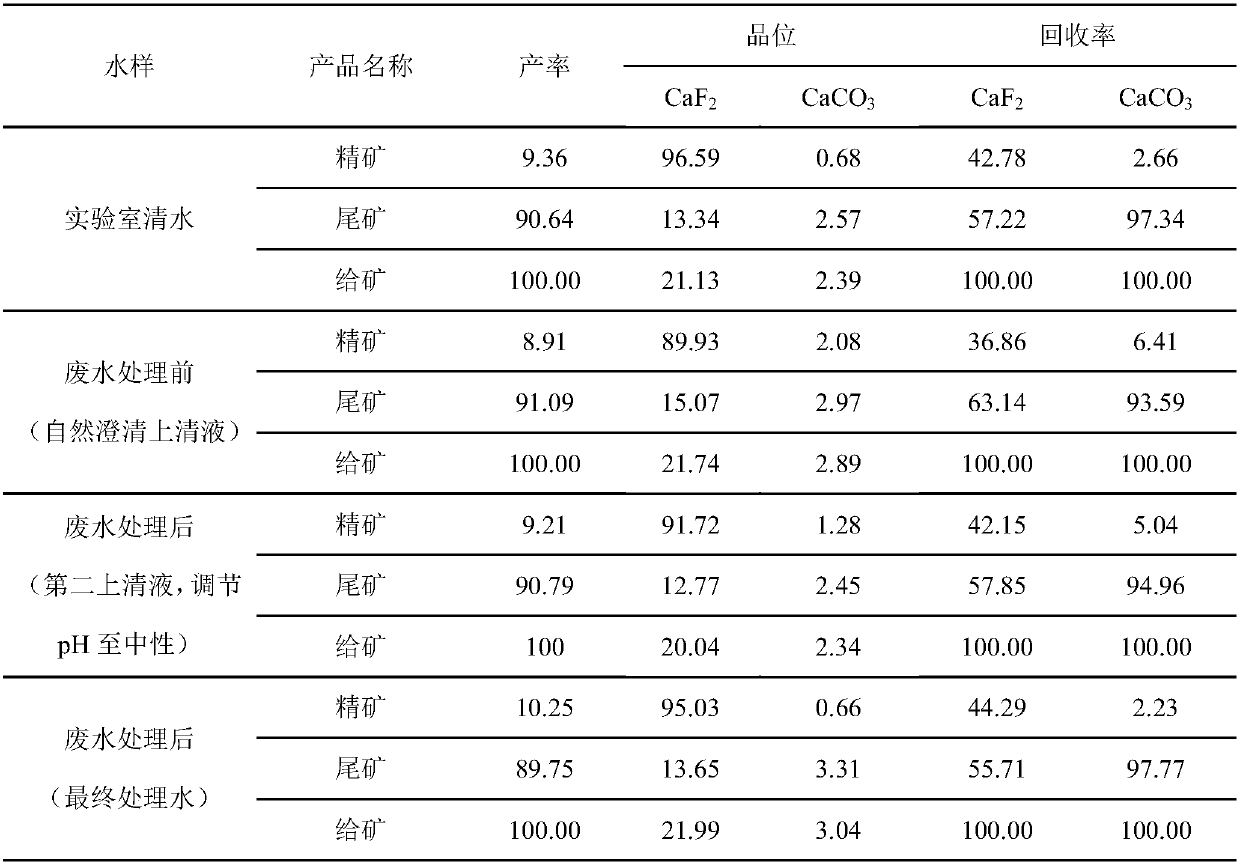

[0038] Table 3 shows the water quality analysis of fluorite low-grade roughing tailings water and wastewater at various stages in Shizhuyuan Dongbo Concentrator.

[0039] According to the technological process of the present invention, add 400g / m3 to fluorite low coarse tailings water 3 lime, stirred for 2min, and settled for 20min to obtain the first supernatant; then add 100g / m3 to the first supernatant 3 of polyaluminum, add 0.5g / m after stirring for 1min 3 The polyacrylamide produced a large number of flocs after stirring for 2 minutes, and the second supernatant was obtained after settling for 20 minutes;2 SO 4 After adjusting the pH of the second supernatant to 7.5, add 200 g / m 3 Activated carbon, after adsorption for 30 minutes, was filtered to obtain the treated water sample; finally, the fluorite flotation open-circuit verification test was carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com