Method for synthesizing oxiracetam by adopting NaA type molecular film reactor

A membrane reactor and reaction technology, applied in the field of biomedicine, can solve the problems of low product yield, inability to reuse a large amount of water-containing ethanol, high separation energy consumption, and achieve the effects of high product yield, excellent dehydration performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

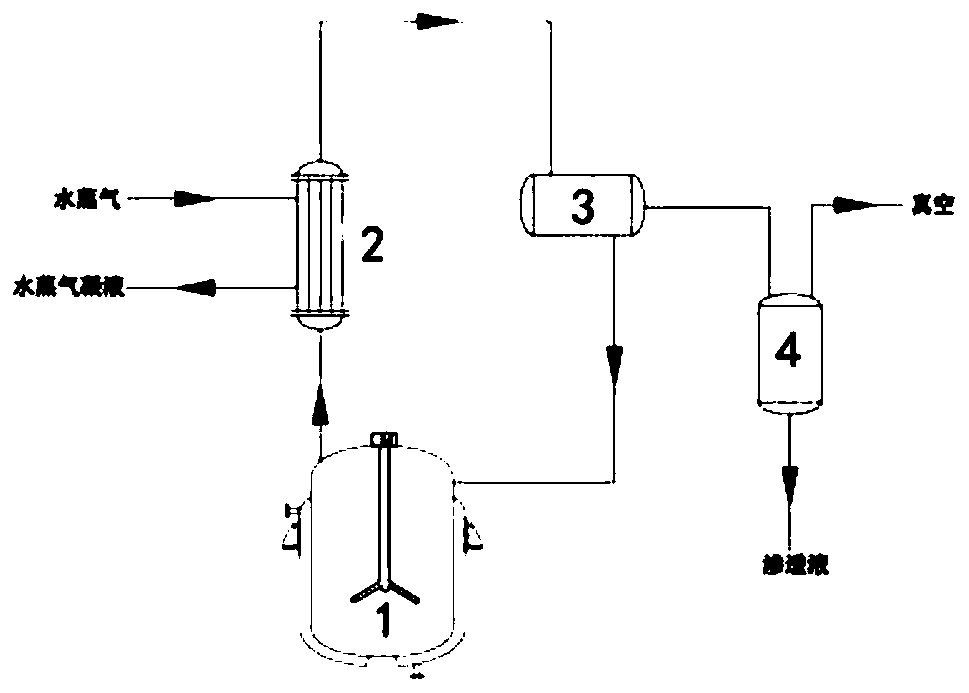

Method used

Image

Examples

Embodiment 1

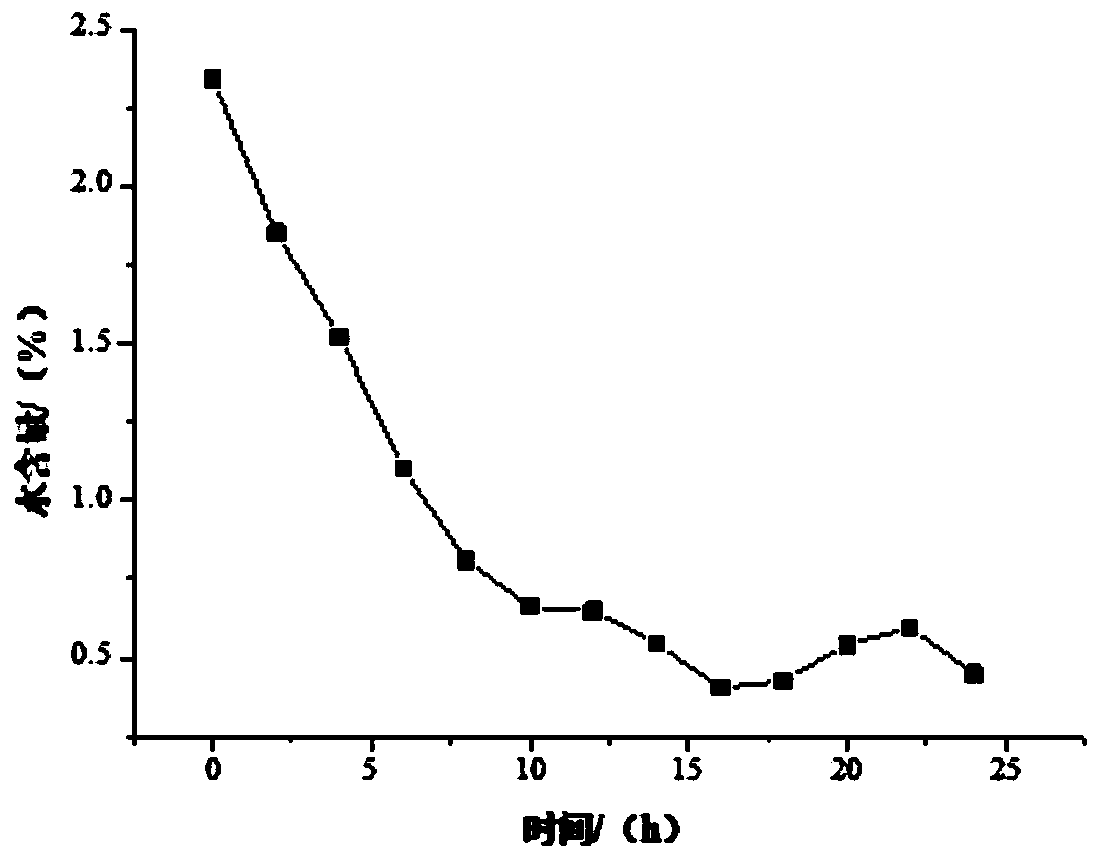

[0031] Add 480 g of absolute ethanol to the reaction flask, add 55 g of glycine hydrochloride and 85 g of sodium bicarbonate under stirring, and heat up to reflux; start to drop 90 g of 4-chloro-3-hydroxybutyrate into the reaction solution, Continue to reflux and stir; when the reflux is stable, place the NaA-type molecular sieve membrane reactor above the reaction liquid, couple with the ring-closure reaction device and turn on the vacuum, the vacuum degree is 0.05Mpa, the reaction temperature and reaction time are 80°C and 24h respectively , the ratio of membrane area to reaction solution volume is 1cm 2 / cm 3 . During the reaction process, the ethanol reflux liquid was collected every 2 hours, and its water content was detected by a Karl Fischer moisture analyzer. After the cyclization reaction was completed, the reaction product was detected by high-performance liquid chromatography, and the product yield was analyzed and calculated. The water content of ethanol is shown...

Embodiment 2

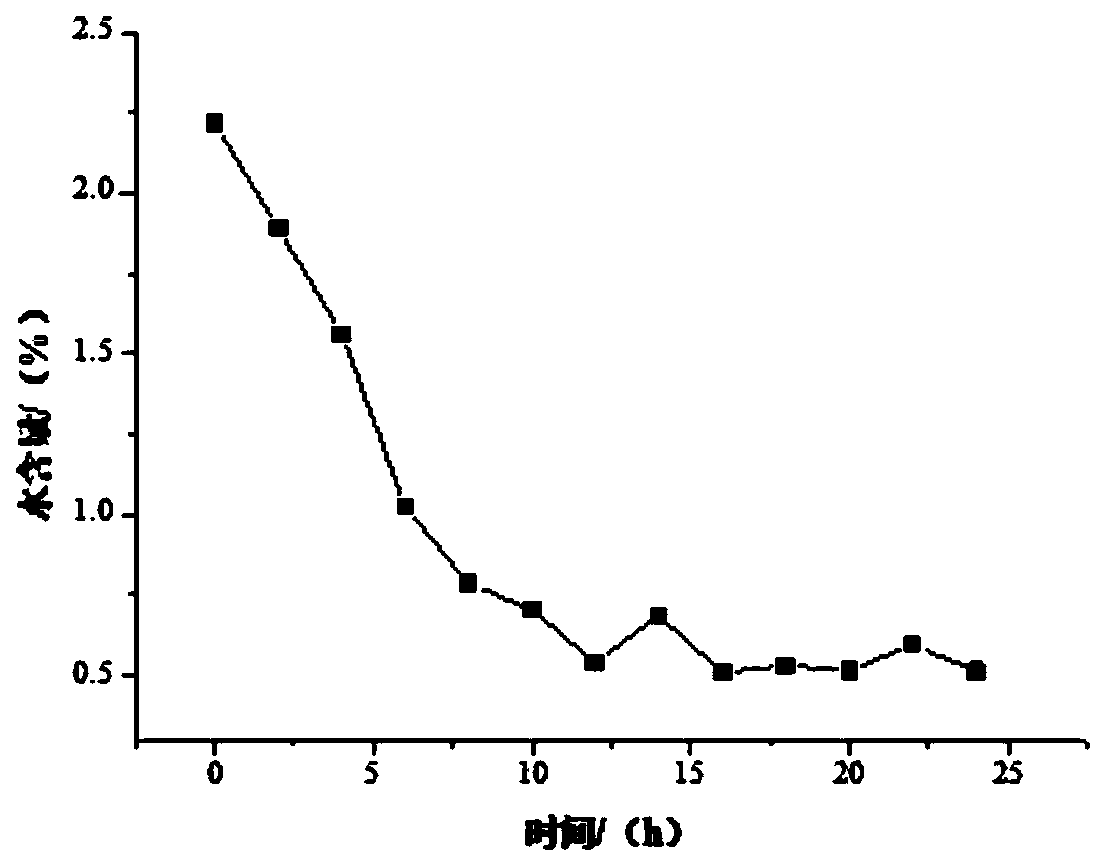

[0033] Add 500 g of absolute ethanol to the reaction flask, add 60 g of glycine hydrochloride and 90 g of sodium bicarbonate under stirring, and heat up to reflux; start to drop 95 g of 4-chloro-3-hydroxybutyrate into the reaction solution, Continue to reflux and stir; when the reflux is stable, place the NaA-type molecular sieve membrane reactor above the reaction liquid, couple with the ring-closure reaction device and turn on the vacuum, the vacuum degree is 0.05Mpa, the reaction temperature and reaction time are 85°C and 24h respectively , the ratio of membrane area to reaction solution volume is 1cm 2 / cm 3 . During the reaction process, the ethanol reflux liquid was collected every 2 hours, and its water content was detected by a Karl Fischer moisture analyzer. After the cyclization reaction, the reaction product was detected by high-performance liquid chromatography, and the product yield was analyzed and calculated. The water content of ethanol is shown in the accomp...

Embodiment 3

[0035] Add 500 g of absolute ethanol to the reaction flask, add 55 g of glycine hydrochloride and 85 g of sodium bicarbonate under stirring, and heat up to reflux; start to drop 90 g of 4-chloro-3-hydroxybutyrate into the reaction solution, Continue to reflux and stir; when the reflux is stable, place the NaA-type molecular sieve membrane reactor above the reaction liquid, couple with the ring-closure reaction device and turn on the vacuum, the vacuum degree is 0.05Mpa, the reaction temperature and reaction time are 85°C and 24h respectively , the ratio of membrane area to reaction solution volume is 1cm 2 / cm 3 . During the reaction process, the ethanol reflux liquid was collected every 2 hours, and its water content was detected by a Karl Fischer moisture analyzer. After the cyclization reaction, the reaction product was detected by high-performance liquid chromatography, and the product yield was analyzed and calculated. The water content of ethanol is shown in the accomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com