Process for deeply treating rubber accelerator DCBS mother liquor wastewater and recovering BT

A rubber accelerator and advanced treatment technology, which is applied in water/sewage treatment, water/sewage multi-stage treatment, chilled water/sewage treatment, etc., can solve the problems of high operating cost, difficulty in long-term stable operation, and large investment in equipment. To achieve the effect of high biological toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

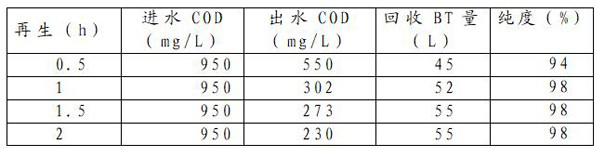

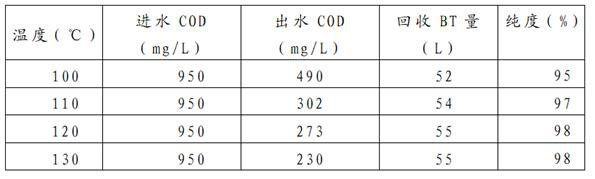

[0032] Example 1: This example provides a method for treating rubber accelerator wastewater. The method includes the following steps: (1) Under low-temperature sedimentation conditions, the rubber accelerator DCBS mother liquor wastewater (COD>50000mg / L) can be effectively removed COD, and reduce the salt content; Table 1 shows the treatment effect under cooling and sedimentation. The waste water can effectively remove the sodium sulfonate salt by cooling down, and at the same time reduce the COD, which can effectively reduce the difficulty of catalytic oxidation;

[0033] Table 1

[0034]

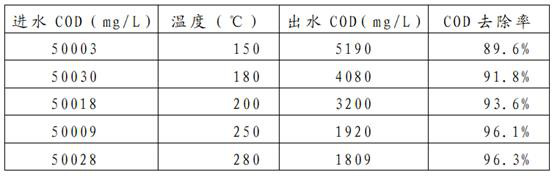

[0035] (2) Add approximately 5wt‰ copper-based catalyst copper sulfate to the wastewater (COD≈50000mg / L) to catalyze the oxidation degradation of organic matter (COD<5000mg / L) at a temperature of 250°C;

[0036] Investigate the oxidation effect under the conditions of 2MPa / 3MPa / 4MPa / 5MPa respectively; Table 2 shows the oxidation effect under different pressure conditions;

[0037] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com