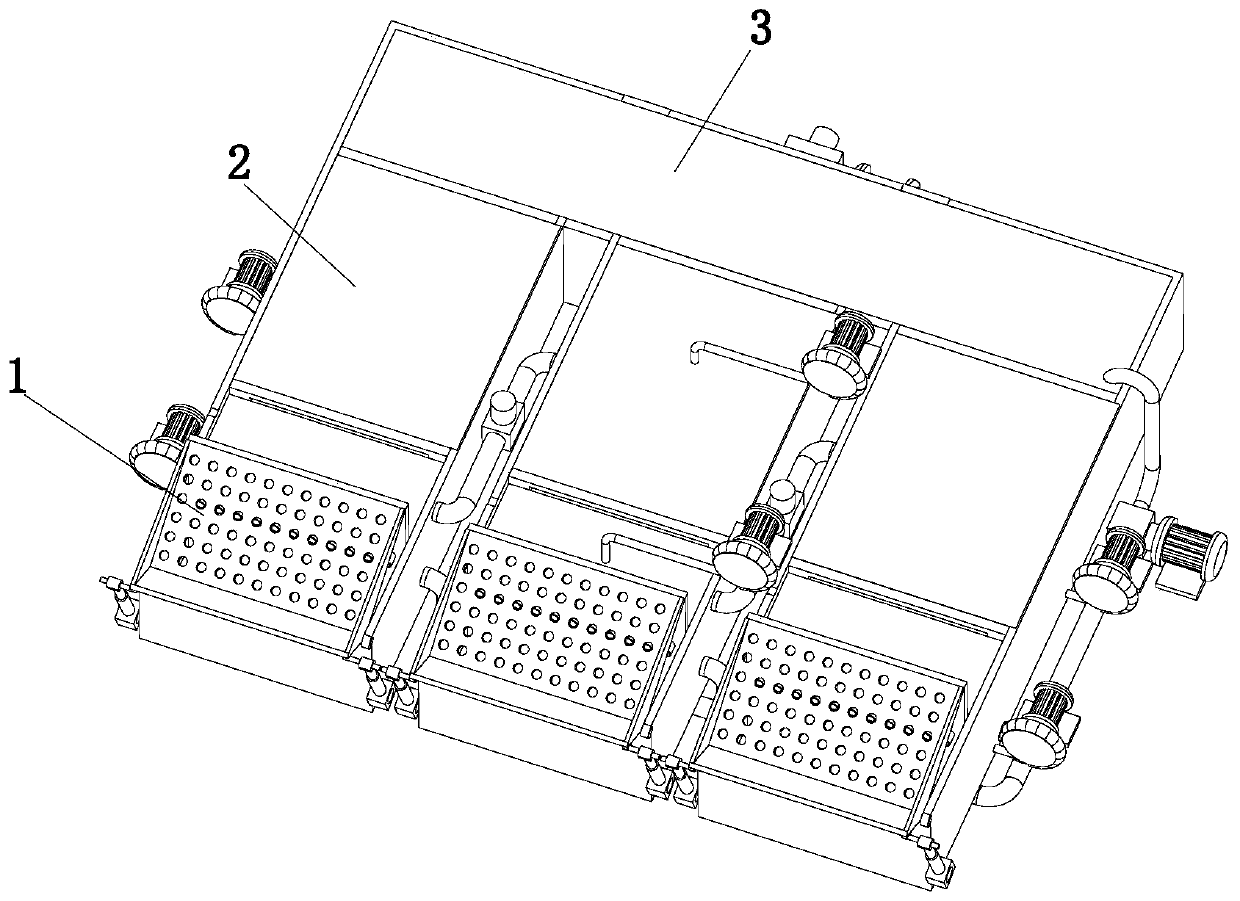

Sewage treatment equipment and treatment method combining multi-stage anoxic oxic (AO) membrane technology and membrane bioreactor (MBR) membrane technology

A technology of sewage treatment equipment and treatment equipment, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. , low nitrogen and phosphorus removal rate, etc., to achieve the effect of strong mobility and improving equipment processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

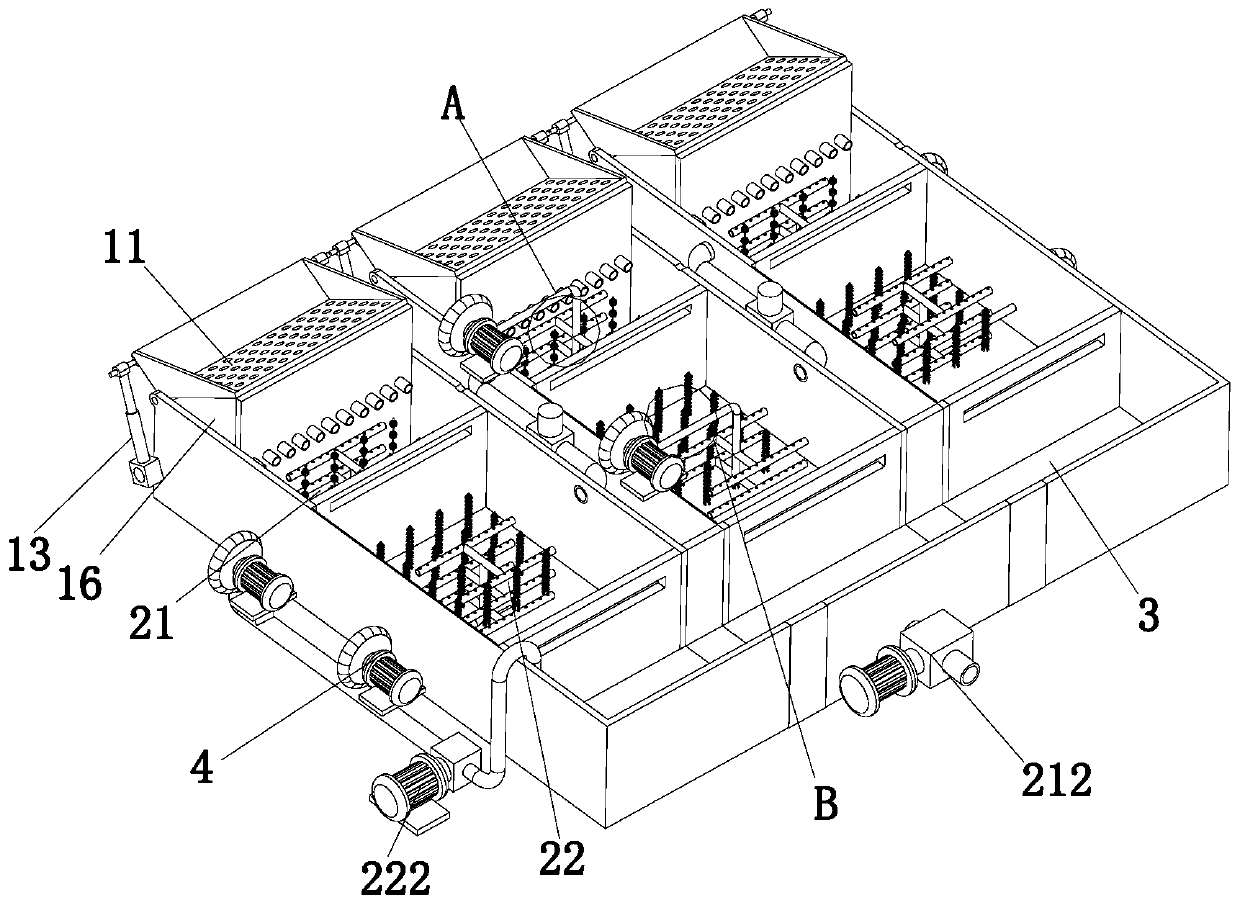

[0039] A treatment method for combining multi-stage AO and MBR membrane technology with sewage treatment equipment, comprising the following steps:

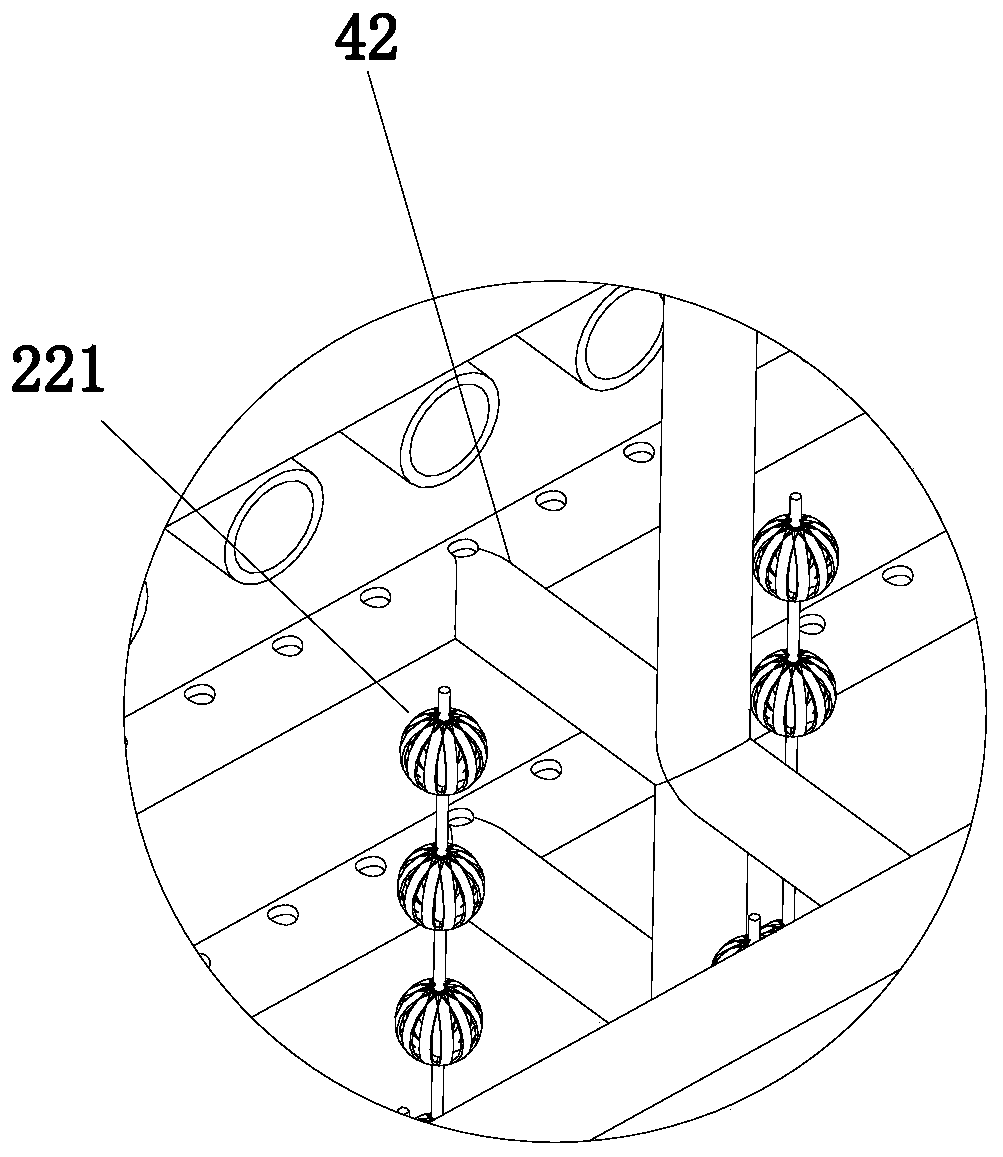

[0040] 1. Inject the sewage from all the V-shaped filter hoppers into the filter pool 16, and the V-shaped filter hoppers 11 initially filter the raw water, and filter out the undegradable impurities, and then the water flows into the corresponding anaerobic pool 21;

[0041] 2. Open the corresponding gate valves so that all the anaerobic pools 21 and all the aerobic pools 22 are connected in series and in parallel;

[0042] 3. The water passing through the AO process equipment 2 enters the membrane separation tank 3 for filtration, the water passing through the AO process treatment equipment 2 enters the membrane separation tank 3 for filtration, and the water outside the MBR membrane reactor 31 is transported back through the reflux pump 212 In the anaerobic tank 21, the AO process is carried out again.

[0043] Working princi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com