Three-phase fluidized-bed reactor

A three-phase fluidized bed and reaction equipment technology, applied in the field of three-phase fluidized bed reaction equipment, can solve the problems of poor gas-water mixing effect, poor solid-liquid separation effect, unsatisfactory treatment effect, etc., and achieve low turbidity of effluent. , The effluent quality is good, and the gas-water mixing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

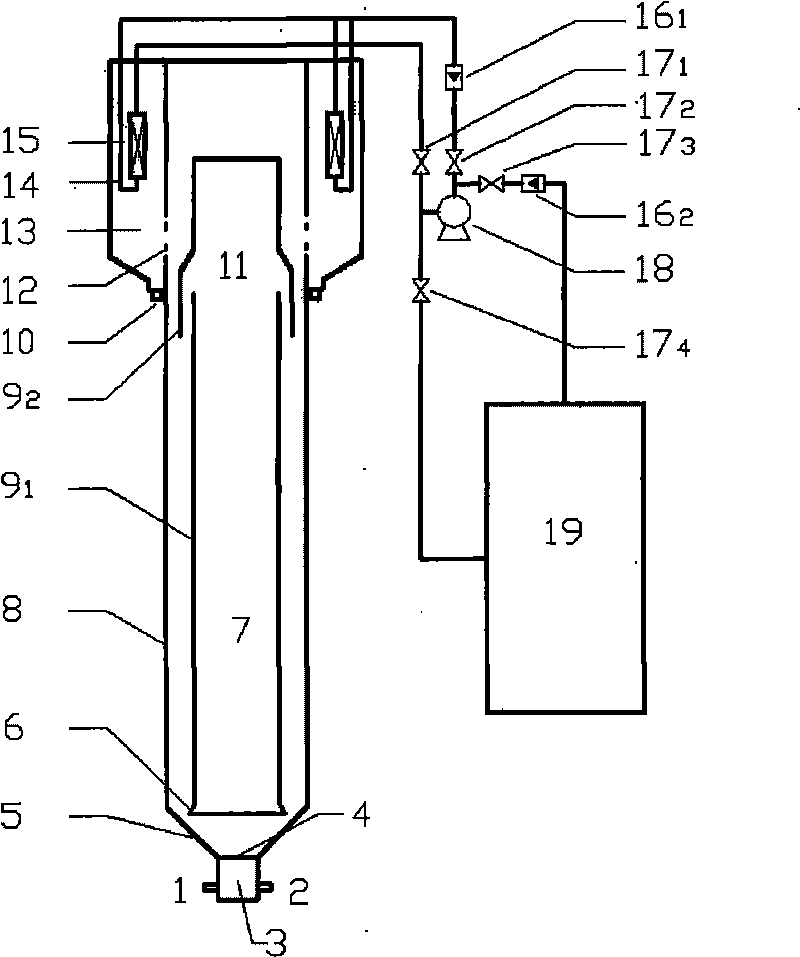

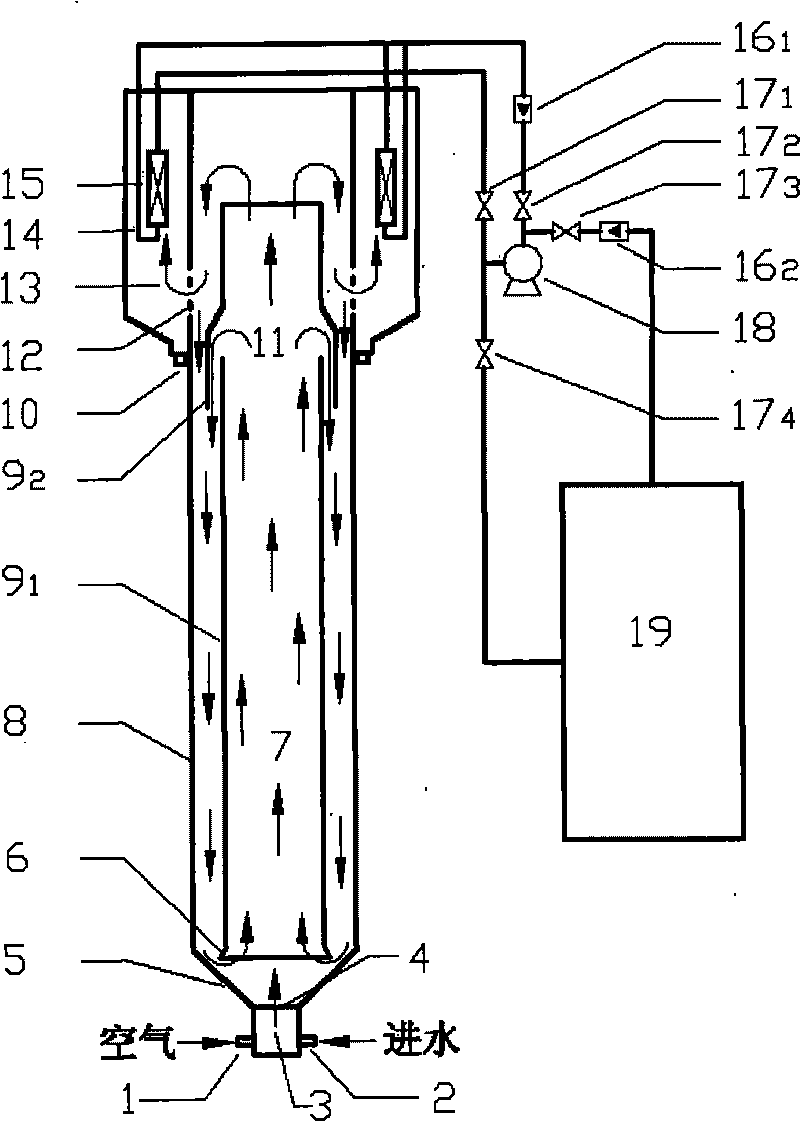

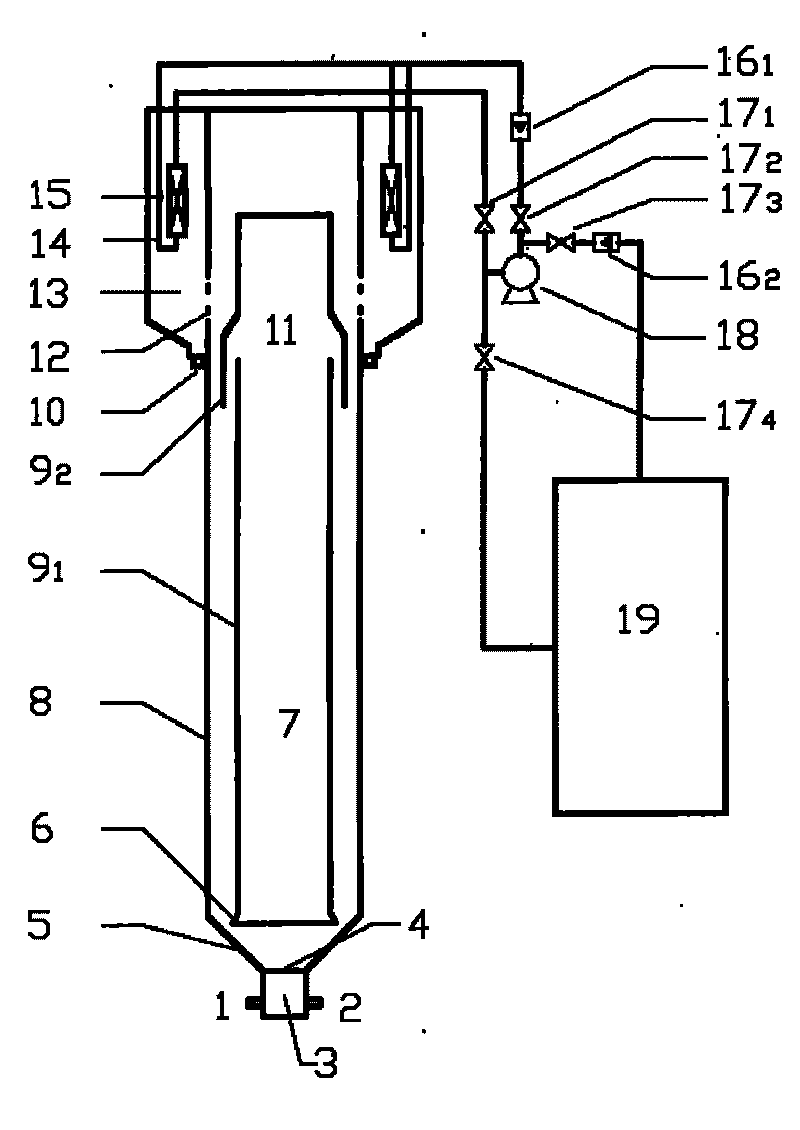

[0021] A kind of three-phase fluidized bed reaction equipment, it comprises gas-water mixing zone (3), reaction zone (7), separation zone (11), filtering zone (14); Gas-water mixing zone (3) is placed at this equipment most The lower part is provided with a water inlet (1) and an air inlet (2) at the bottom of the side; the reaction zone (7) is composed of an outer cylinder (8) and an inner cylinder (9 1 ) form; the gas-water mixing zone (3) communicates with the reaction zone (7) through the microporous gas distribution plate (4); the separation zone (11) is located at the top of the equipment, and the separation zone (11) is provided with an annular precipitation zone (13) and filtering area (14), both are connected by perforated plate (12); Filtering area (14) middle part is provided with filtering assembly (15), and filtering assembly (15) is connected with by water pump (18), valve (17) 1 ), valves (17 2 ), valves (17 3 ), valves (17 4 ), flowmeter (16 1 ), flowmeter ...

Embodiment 2

[0028] The structure and treatment process of a three-phase fluidized bed reaction equipment are the same as in Example 1. Wherein the air-water mixing zone (3) has a cylindrical height-to-diameter ratio of 2:1, and the gas-water mixing zone (3) and the inner cylinder (9 1 ) area ratio is 1: 5, the area ratio of inner and outer cylinders is 1: 5, the height-diameter ratio of the reaction zone (7) is 12, and the filter assembly adopts a ceramic membrane, and its effect is the same as that of Example 1.

Embodiment 3

[0030] The structure and treatment process of a three-phase fluidized bed reaction equipment are the same as in Example 1. Wherein the air-water mixing zone (3) has a cylindrical height-to-diameter ratio of 1.5:1, and the gas-water mixing zone (3) and the inner cylinder (9 1 ) area ratio is 1: 3, the area ratio of inner and outer cylinders is 1: 3, the height-diameter ratio of the reaction zone (7) is 8, and the filter assembly adopts a ceramic membrane, and its effect is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com