Patents

Literature

103results about How to "Strong turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

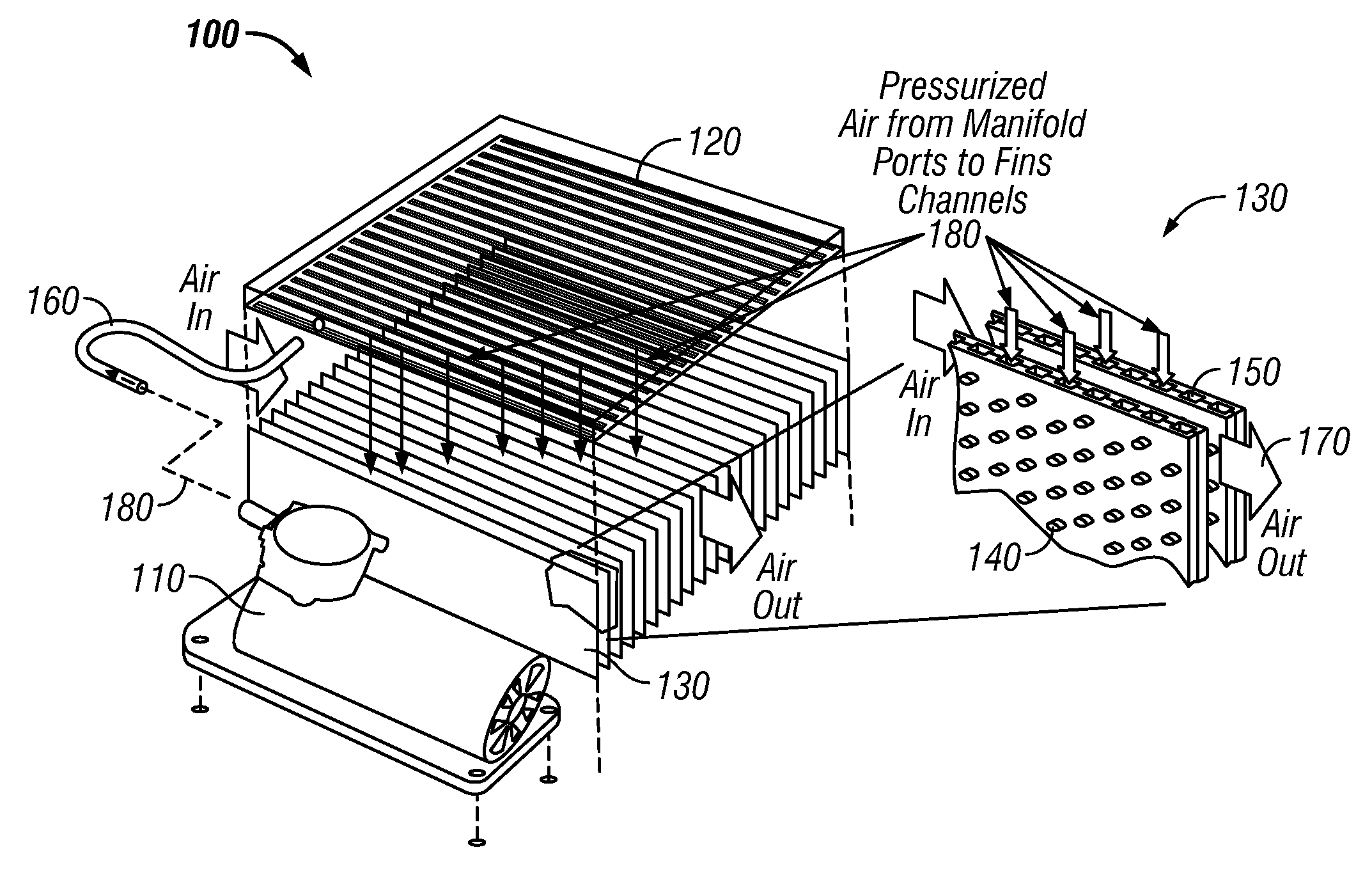

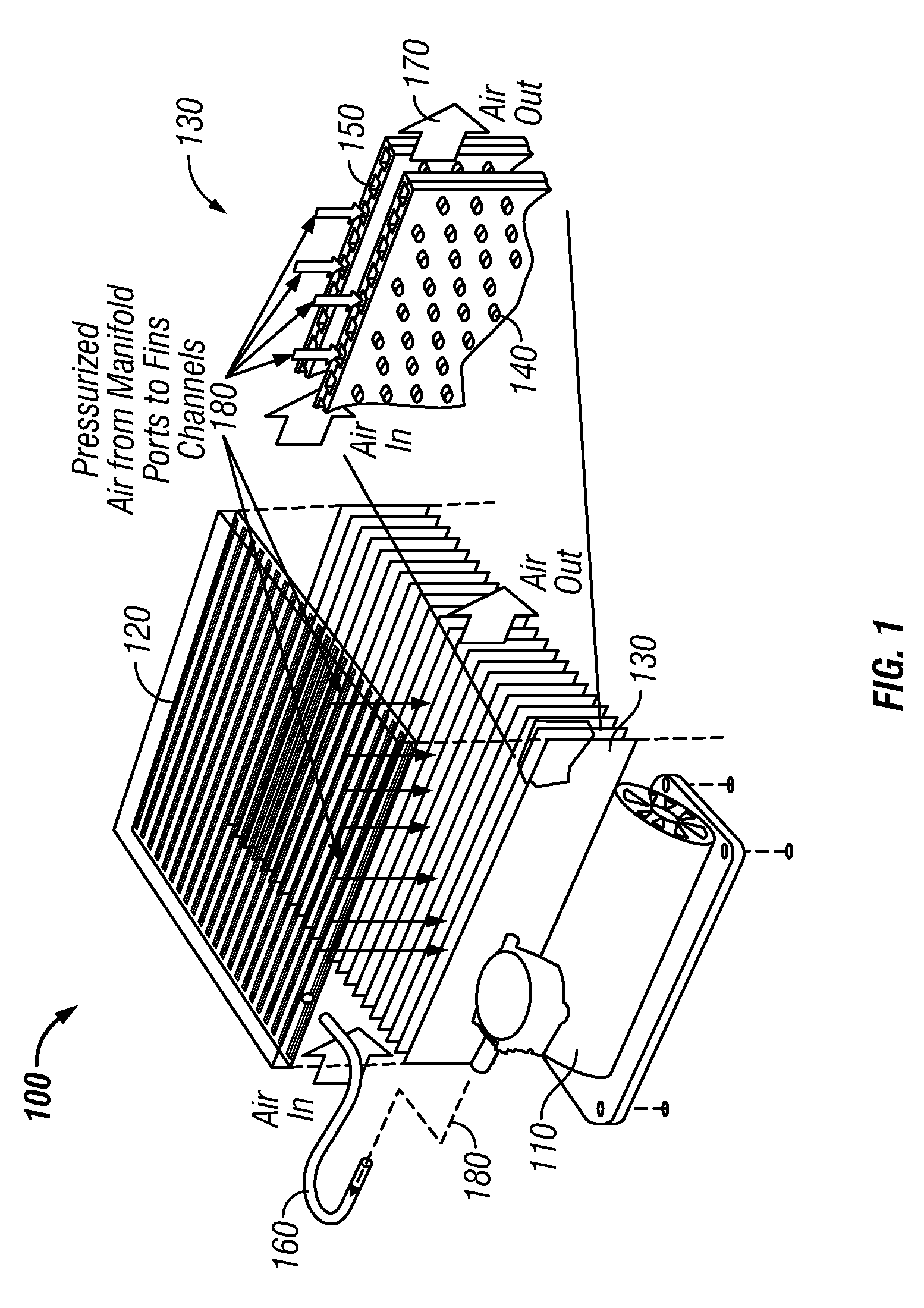

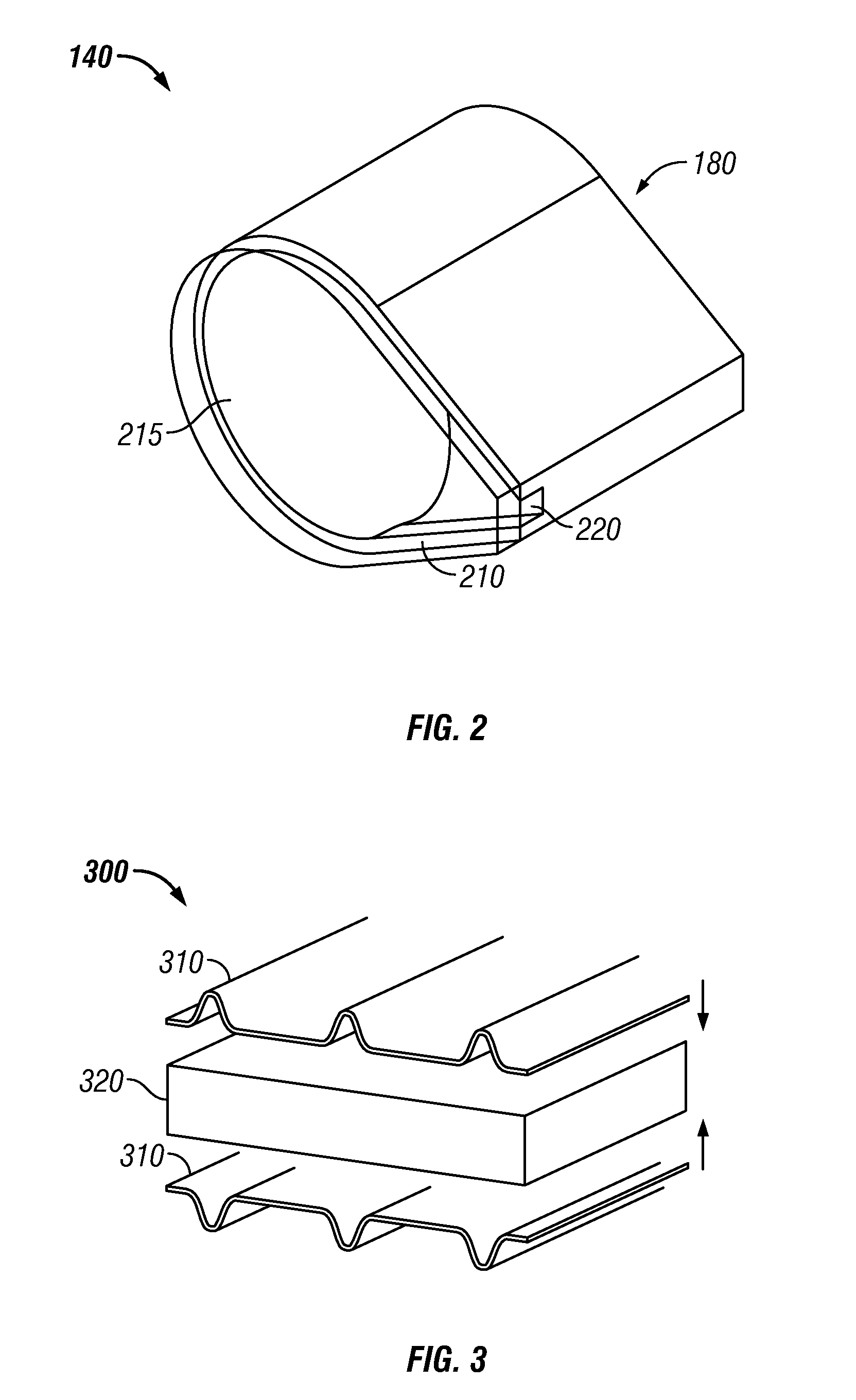

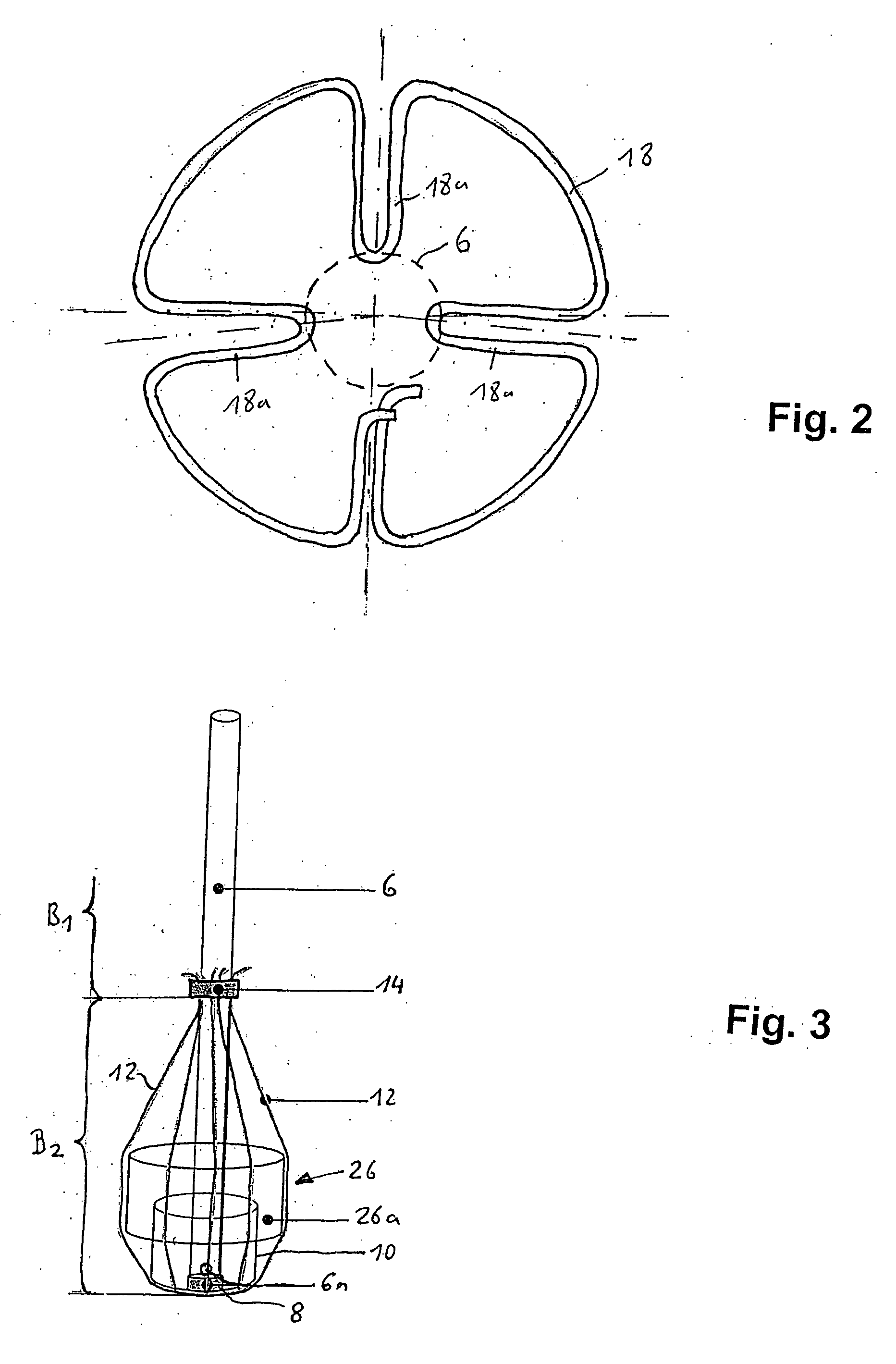

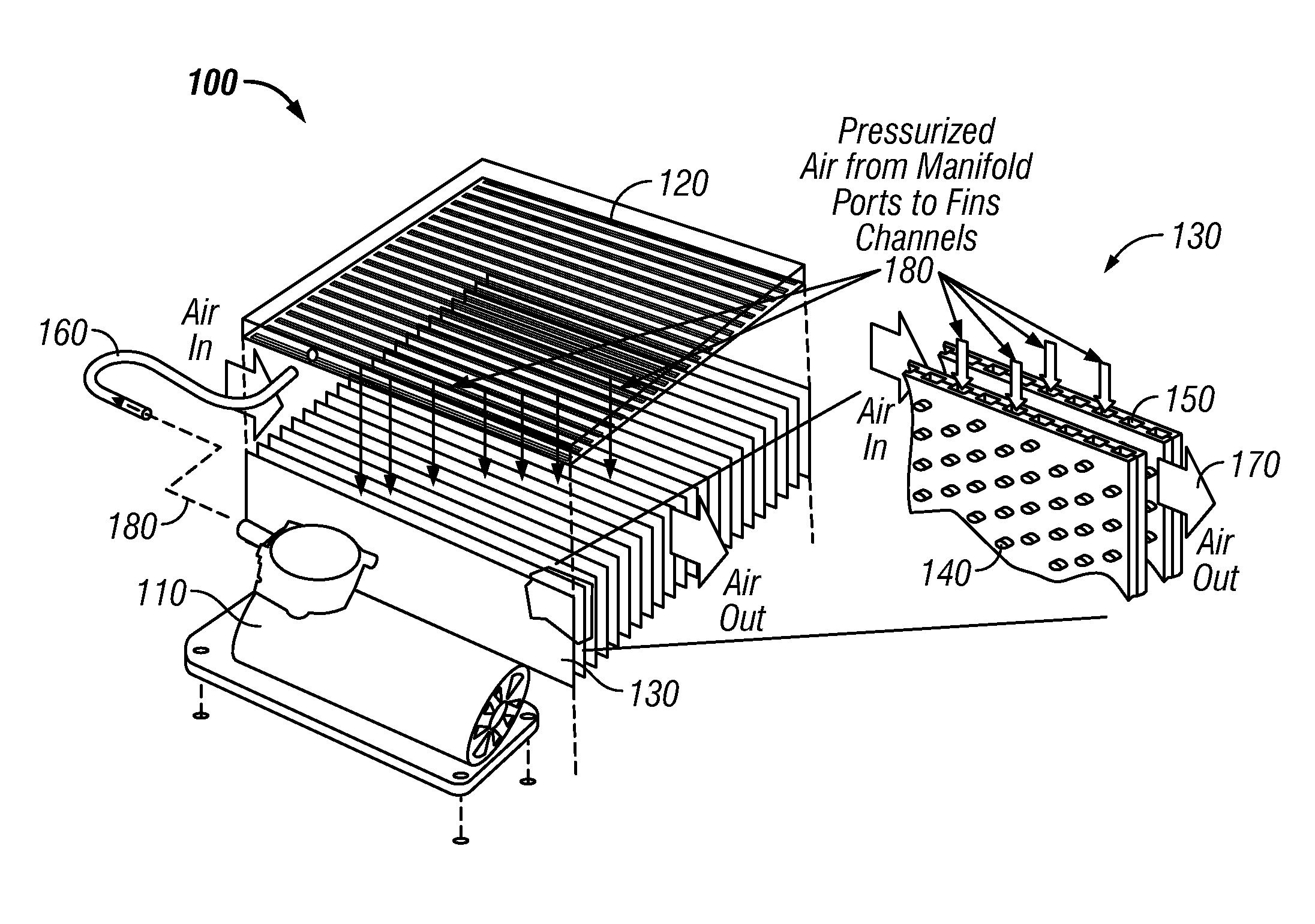

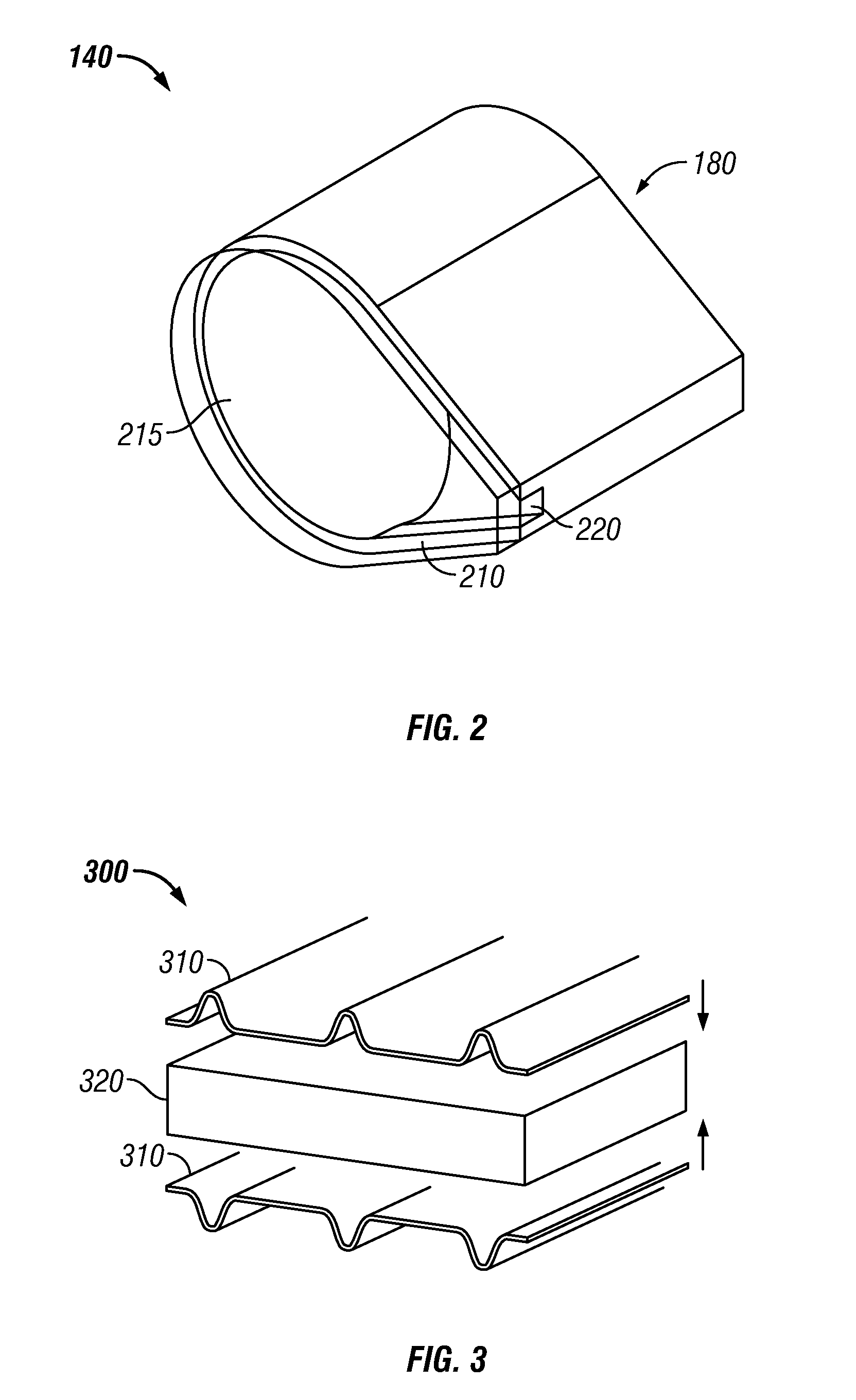

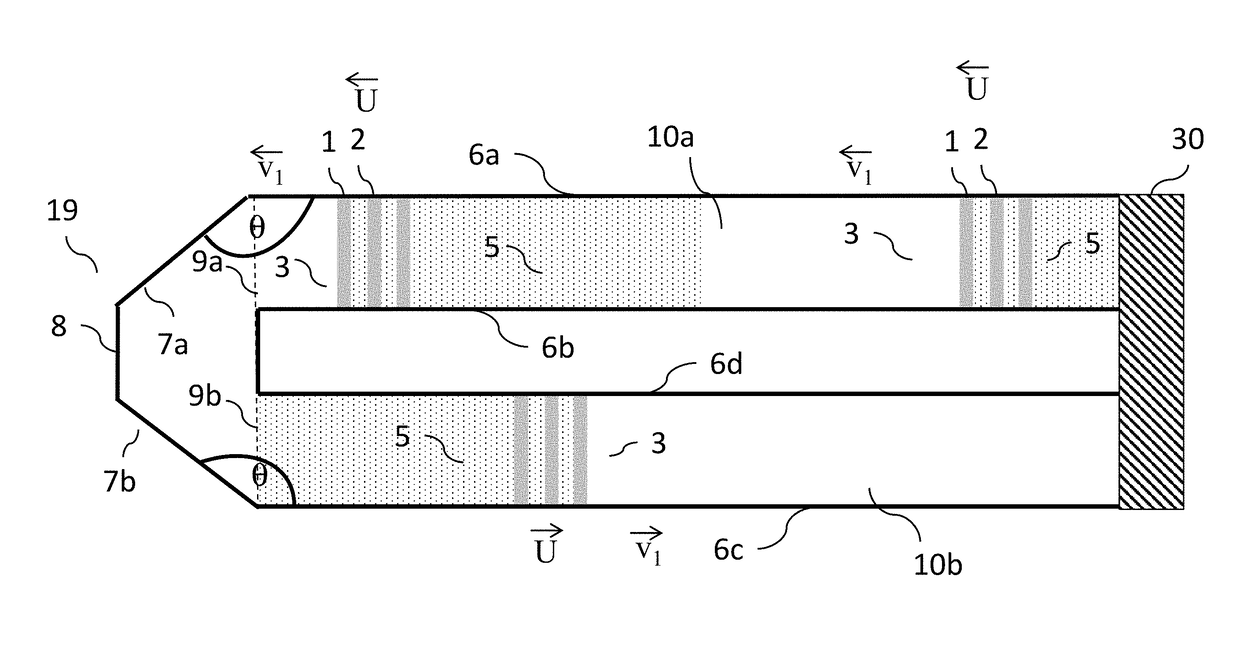

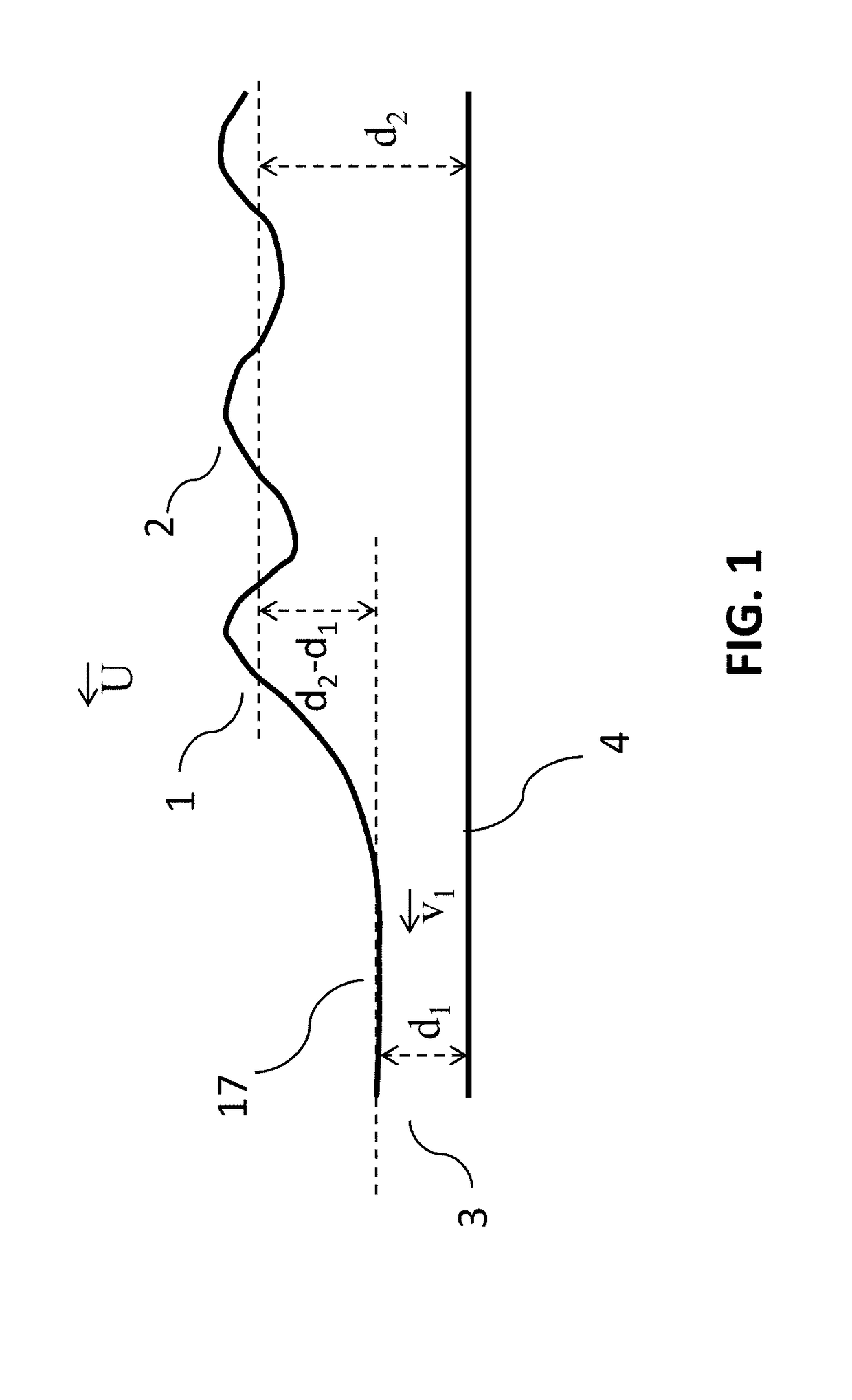

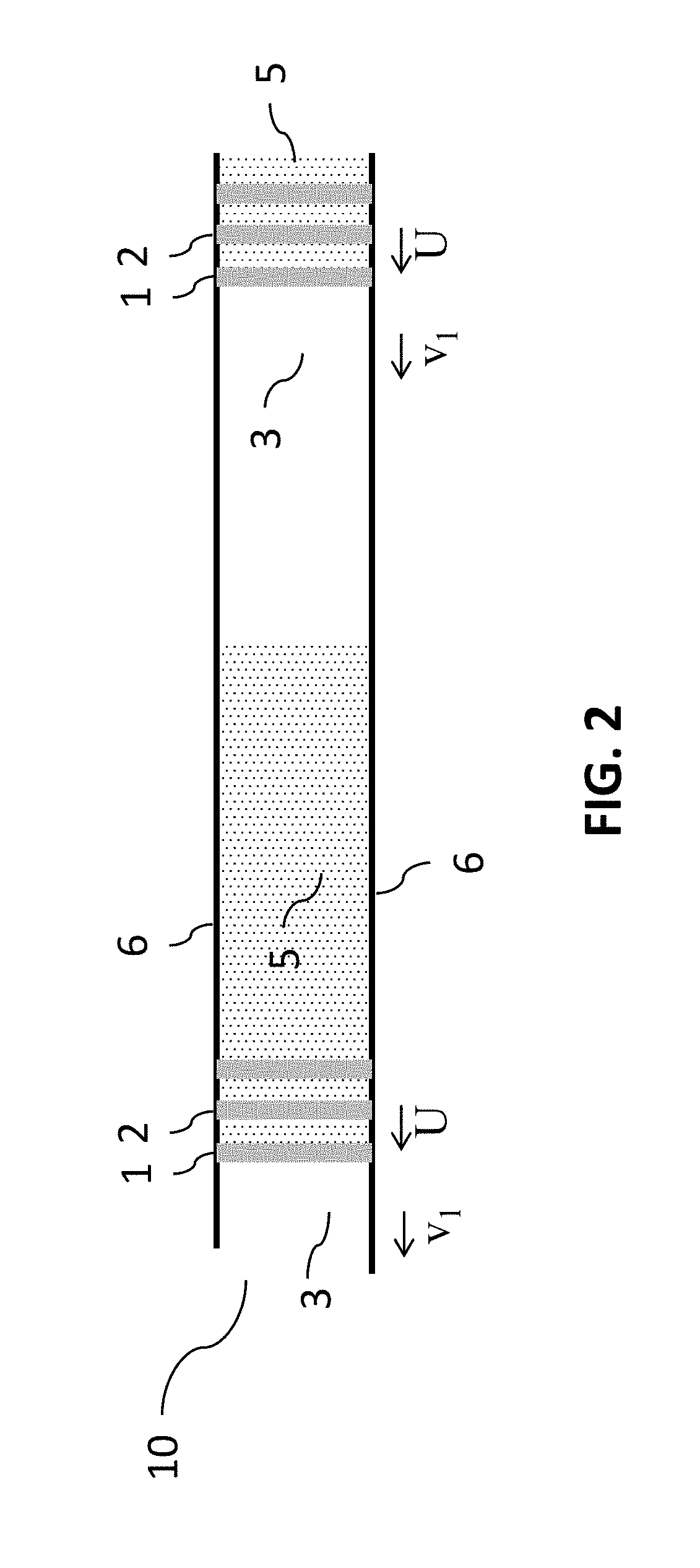

Blowerless heat exchanger based on micro-jet entrainment

ActiveUS20090288807A1Improve heat transfer performanceReduce flow resistanceSemiconductor/solid-state device detailsMetal-working apparatusAir movementEngineering

A blowerless heat exchanger apparatus based on micro-jet entrainment is disclosed. The heat exchanger apparatus incorporates a number of fins regularly spaced apart from each other and parallel to each other, thus letting air currents flow in the space defined between them. A dense array of micro-jet nozzles can be fabricated on the fins surface pointing to the flow direction of the air movement in order to induce increase airflow. The air from an air compressor delivers sufficient airflow on the fins surface utilizing micro-jets entrainment. The micro-jet entrainment confirms strong turbulent around the micro-jets and suggests significant heat transfer enhancement. The turbulence from the micro-jets enhance the heat transfer coefficient, potentially by an order of magnitude, therefore allowing much larger fin spacing and leads to huge reduction of flow resistance and overall power consumption.

Owner:HONEYWELL INT INC

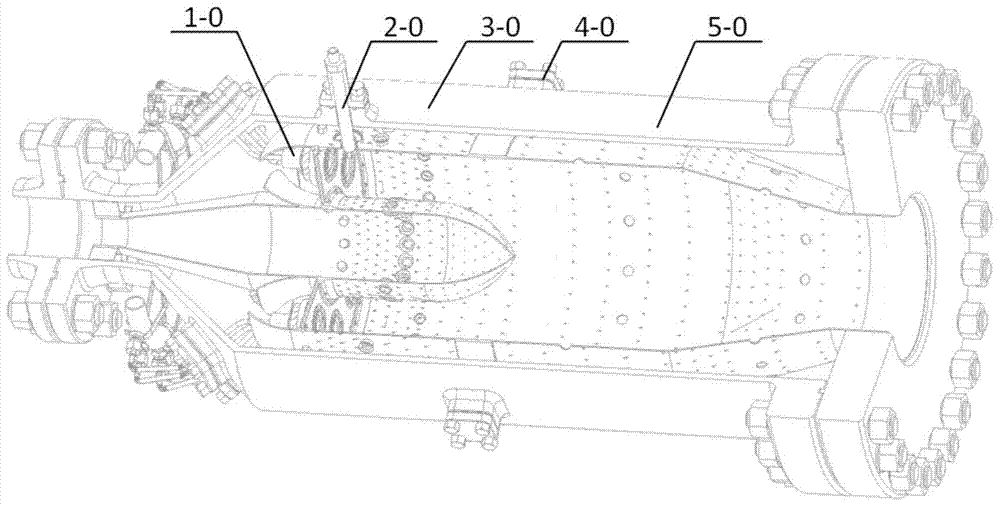

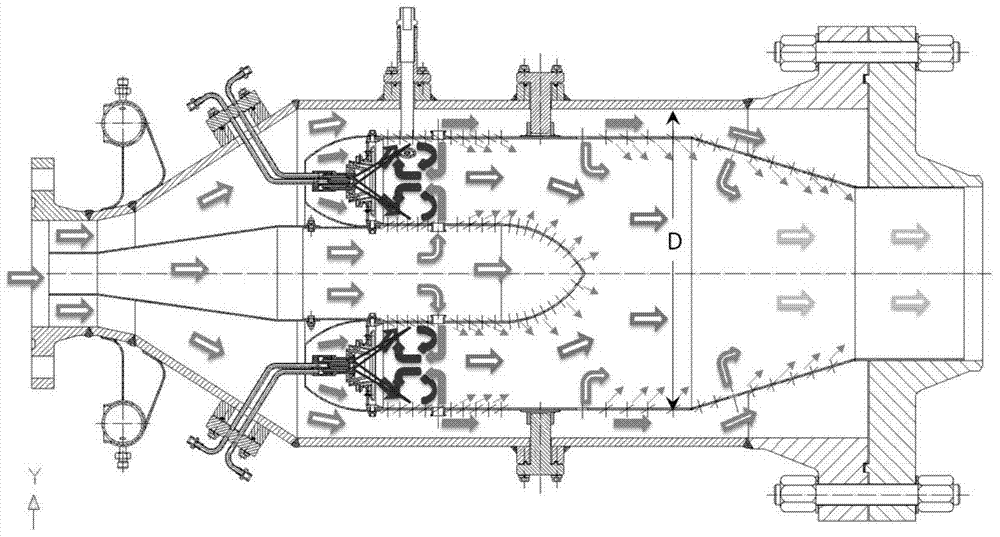

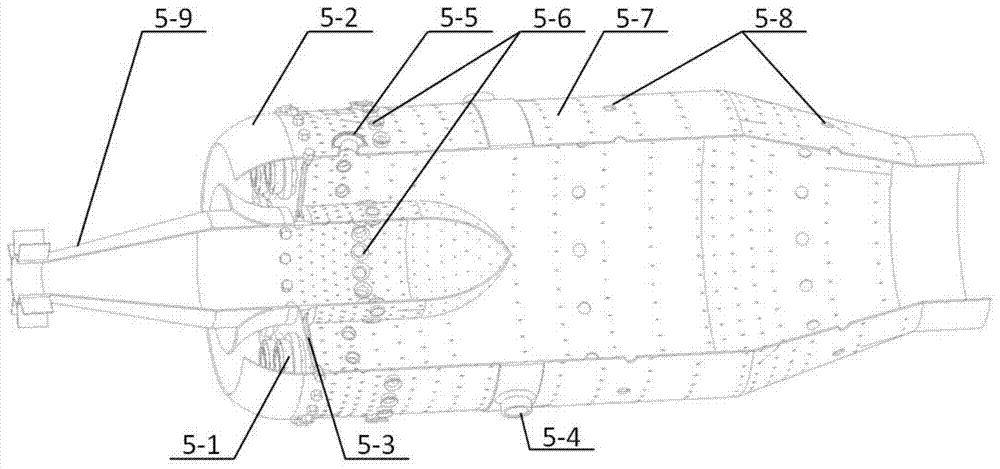

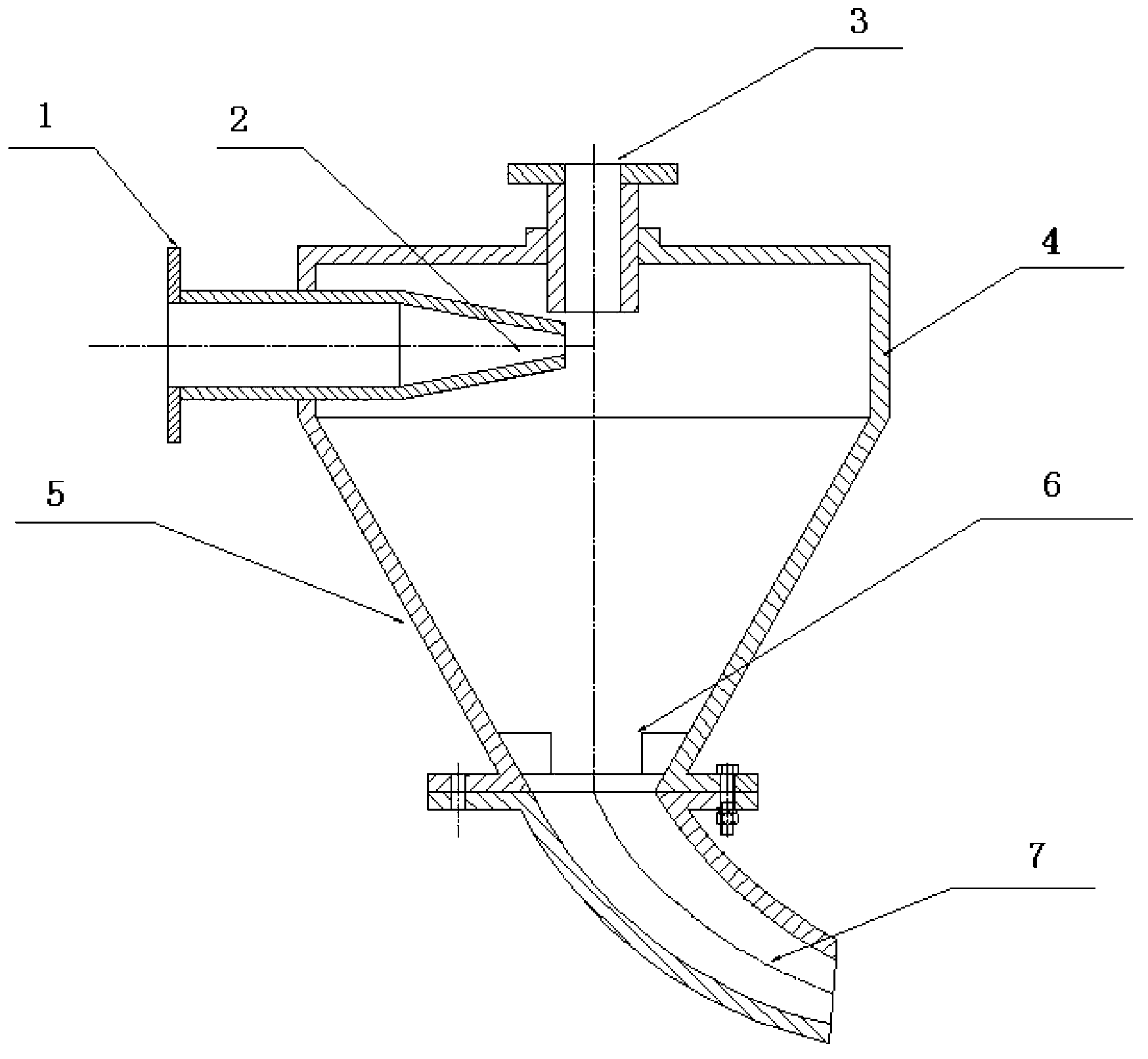

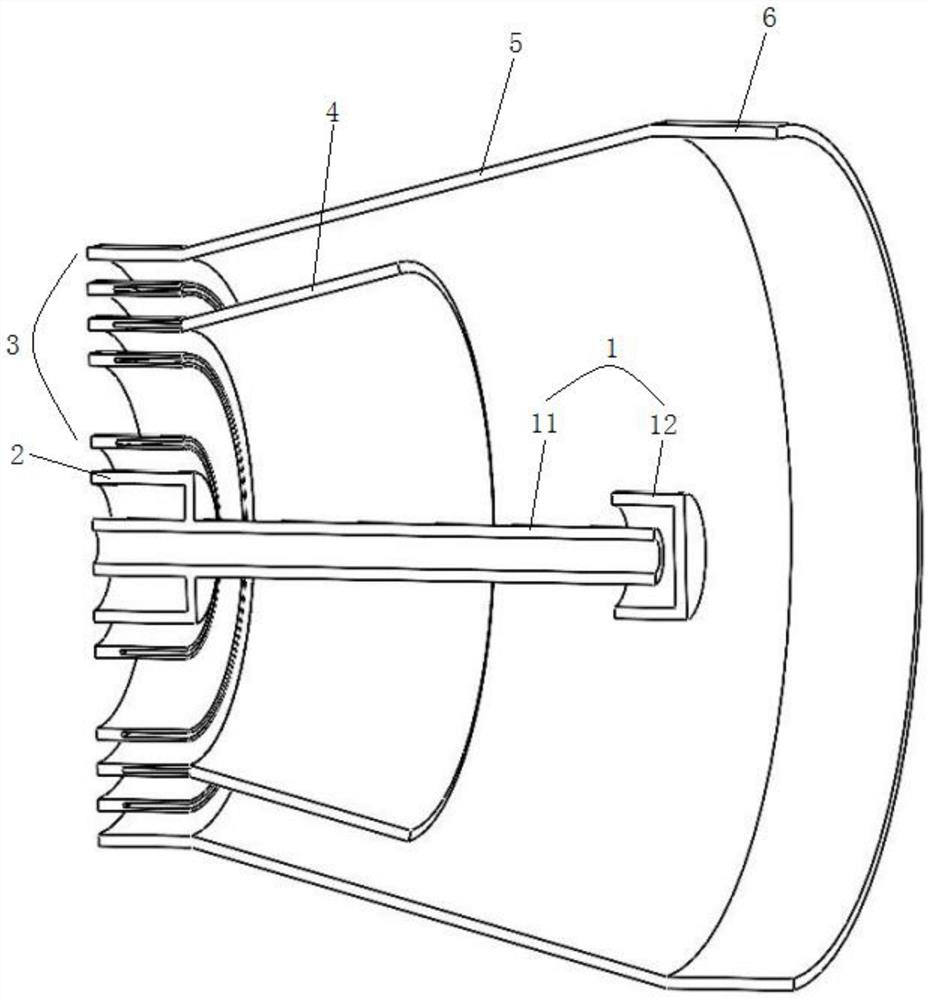

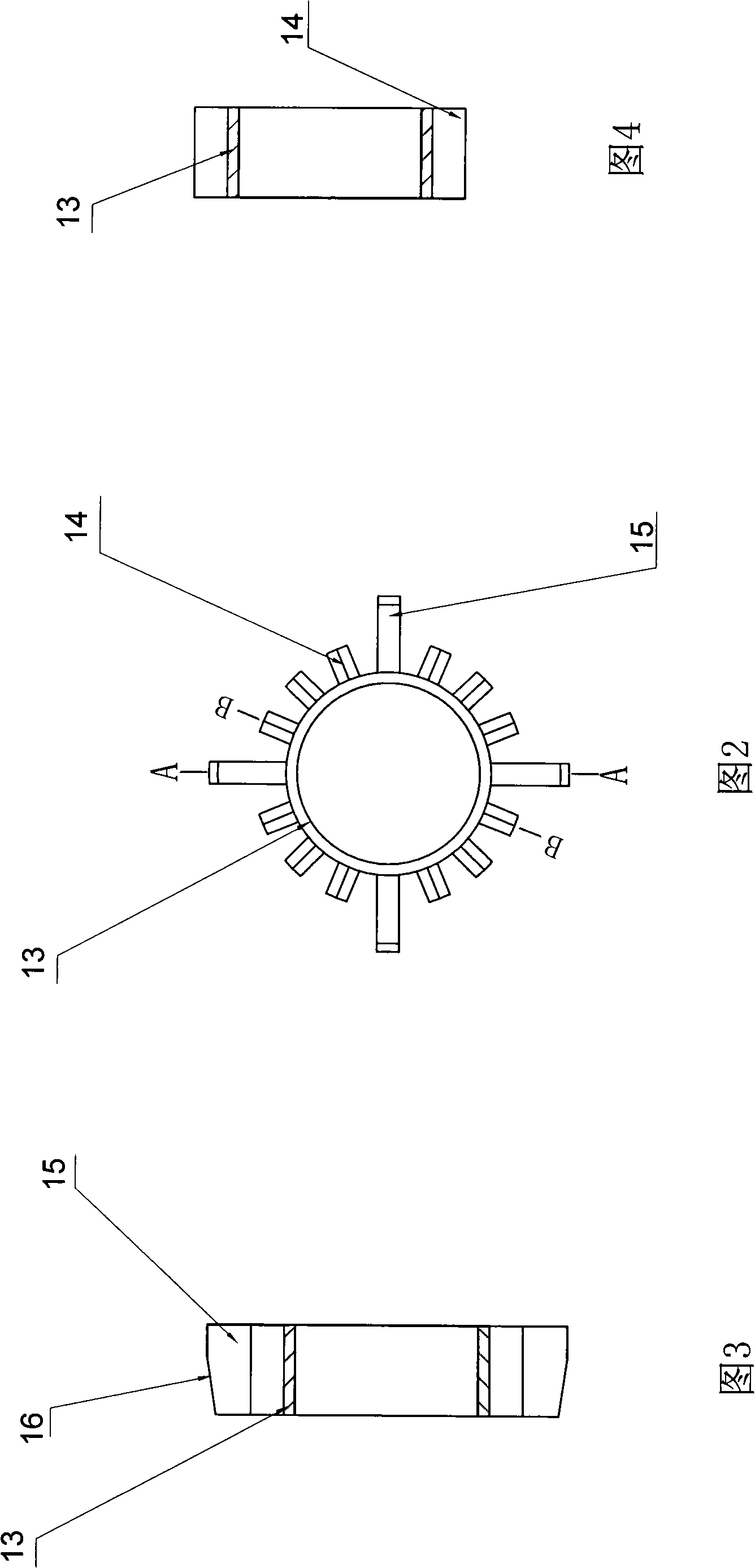

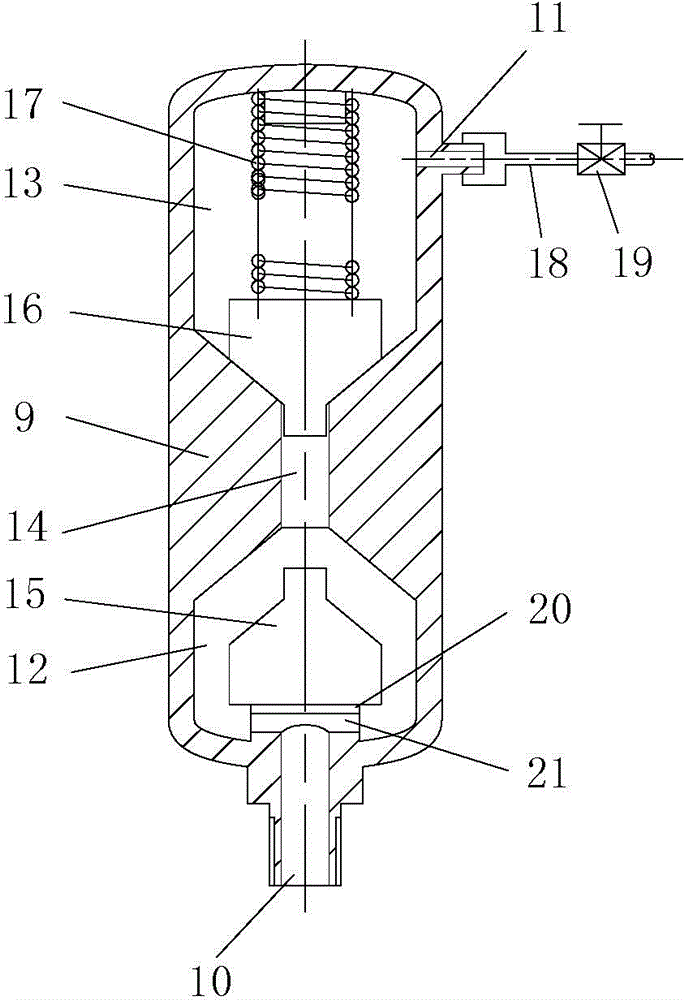

Annular combustion chamber fuel gas generator using alcohol as fuel

ActiveCN103697471AImprove atomization effectImprove ignition reliabilityBurnersAlcoholCombustion chamber

The invention belongs to the technical field of fuel gas generators, and particularly relates to an annular combustion chamber fuel gas generator. The annular combustion chamber fuel gas generator using alcohol as fuel comprises a plurality of dual-oil path centrifugal sprayers (1-0) distributed uniformly along the peripheral direction, a plasma ignition electric nozzle (2-0), a shell (3-0), a positioning pin (4-0) and a flame drum (5-0); the flame drum (5-0) is arranged in the shell (3-0) and is coaxial with the shell (3-0), and two cavity paths are formed between the flame drum and the shell; the dual-oil path centrifugal sprayers (1-0), the plasma igniter (2-0) and the positioning pin (4-0) are combined and assembled with the flame drum (5-0) by the shell (3-0). The fuel gas generator uses air as an oxidizing agent and the alcohol as the fuel, so the fuel gas has high enthalpy value. Air is very easy to obtain, and the alcohol is low in price, so the disadvantages of low enthalpy value and high operation cost of fuel gas of the existing fuel gas generator in the application field are solved.

Owner:AECC SICHUAN GAS TURBINE RES INST

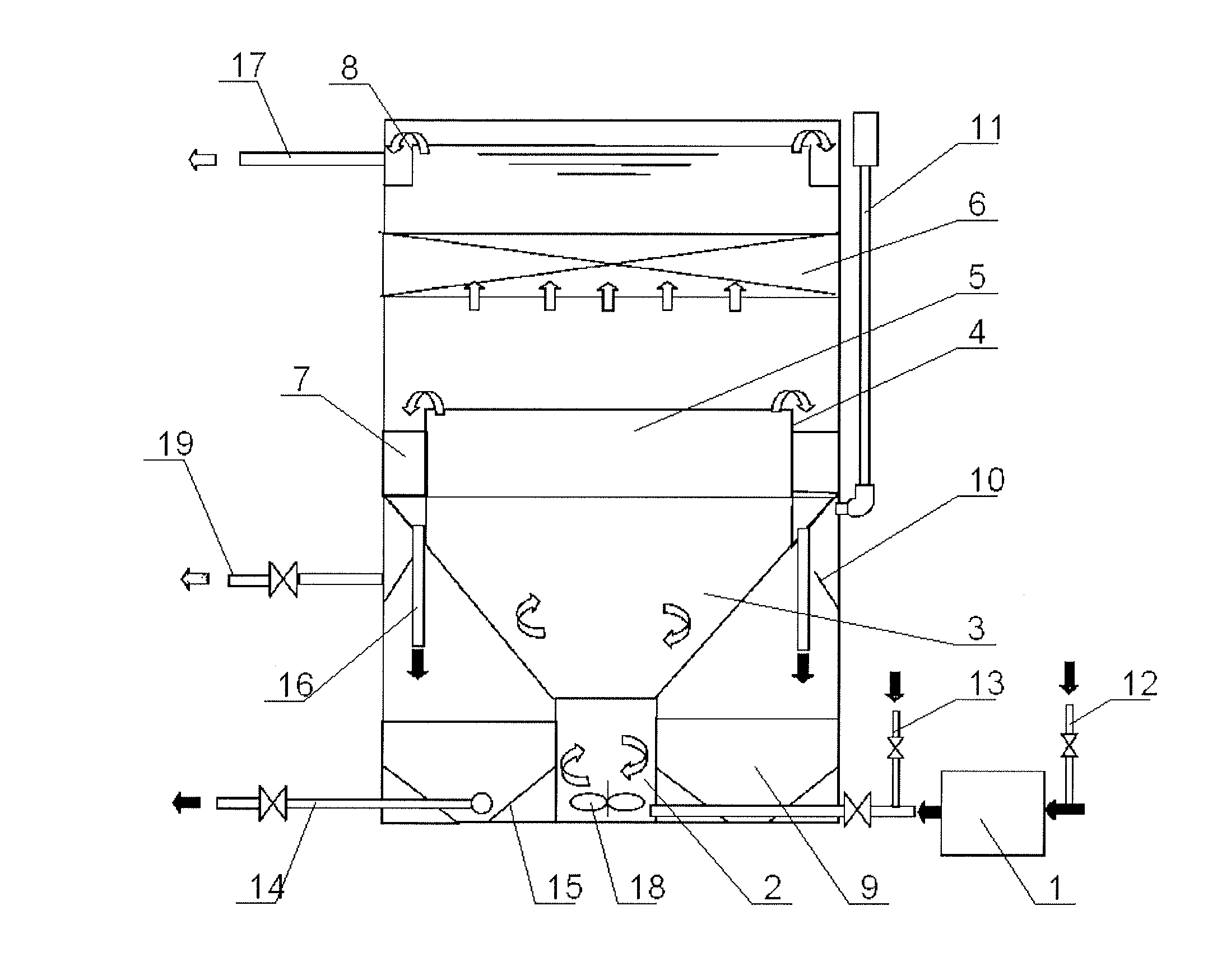

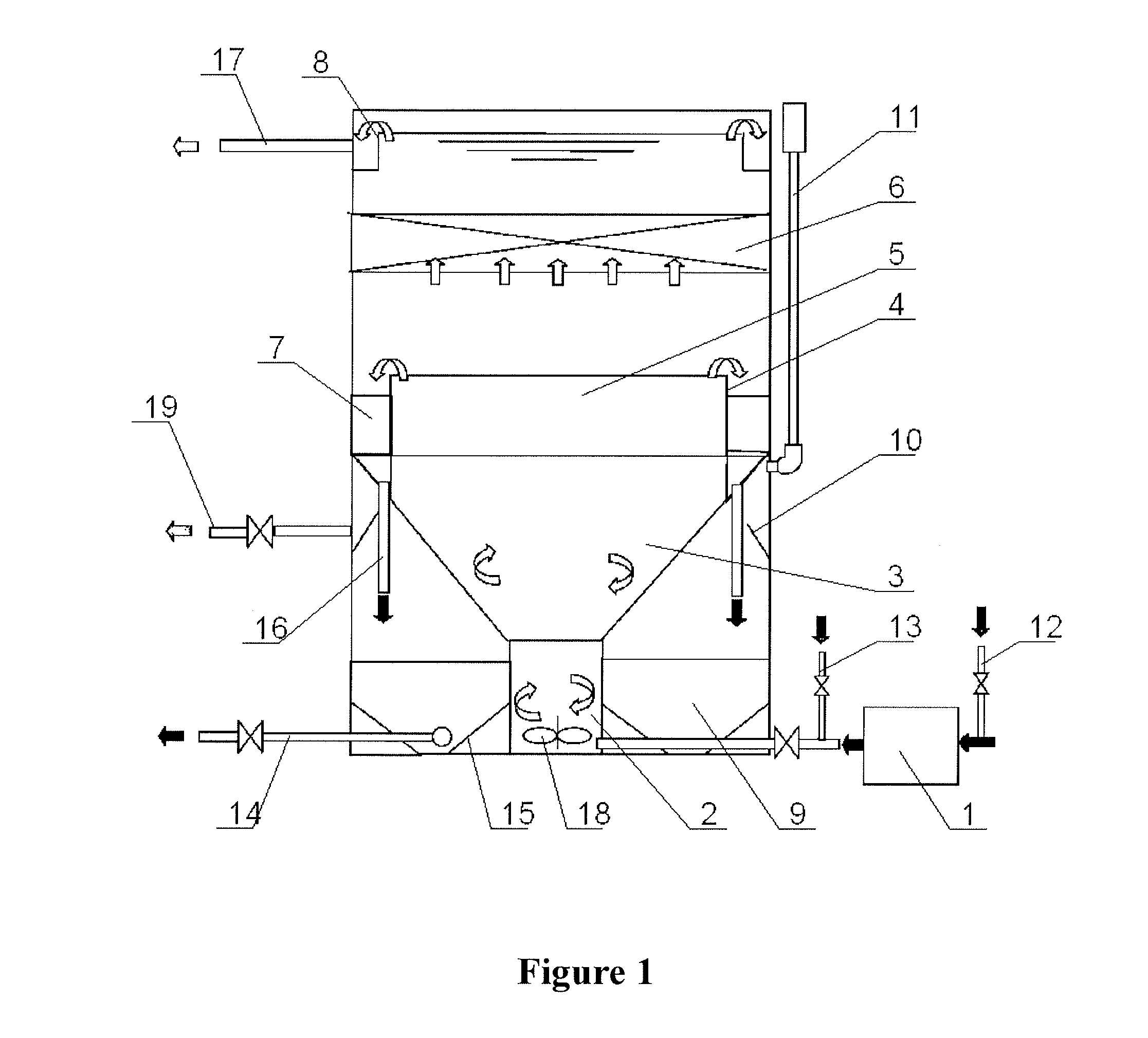

Device for Purifying Oily Wastewater

InactiveUS20130062272A1Increase settling velocityStrong turbulenceWaste water treatment from quariesSludge treatmentFlocculationFiltration

There is disclosed a device for purifying oily wastewater, including a vertical tank of an atmospheric pressure, inside which a central coagulation reaction tube, a reverse cone-shaped cyclone flocculation stage, a suspended sludge filtering zone and a purified water commutation stage of inclined plates are included from bottom to top sequentially, oily wastewater is sequentially subjected to a coagulation reaction, suspended sludge filtering and a purified water commutation process and then discharged, a sludge collecting groove collects and guides the suspended sludge to a sludge concentrating zone for further sedimentation and concentration processes and then discharges it to external to the tank, in this way, the purification reaction, flocculation and fine filtration of wastewater and the sludge concentration process are integrated within the same wastewater purifying device. Thus, the device is equivalent to the existing wastewater pretreatment system plus a fine filtration system.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

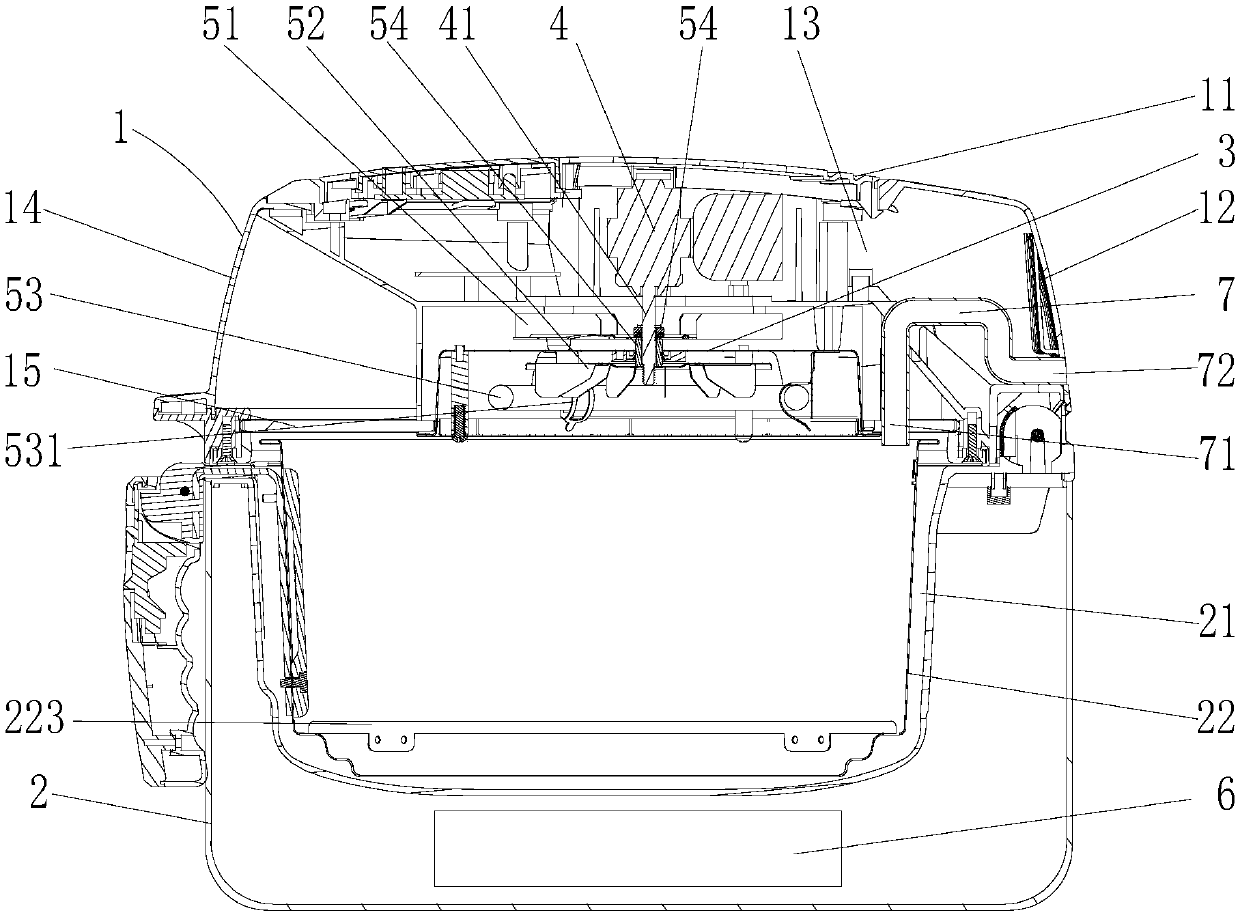

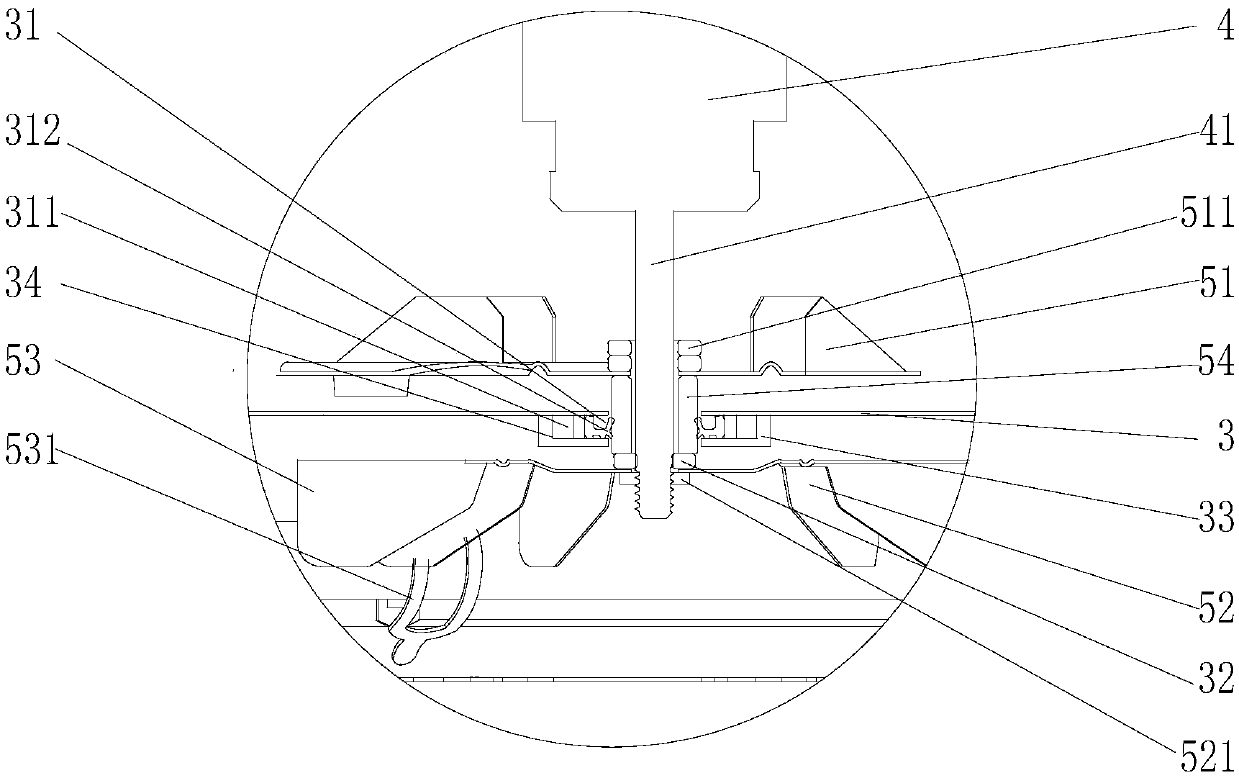

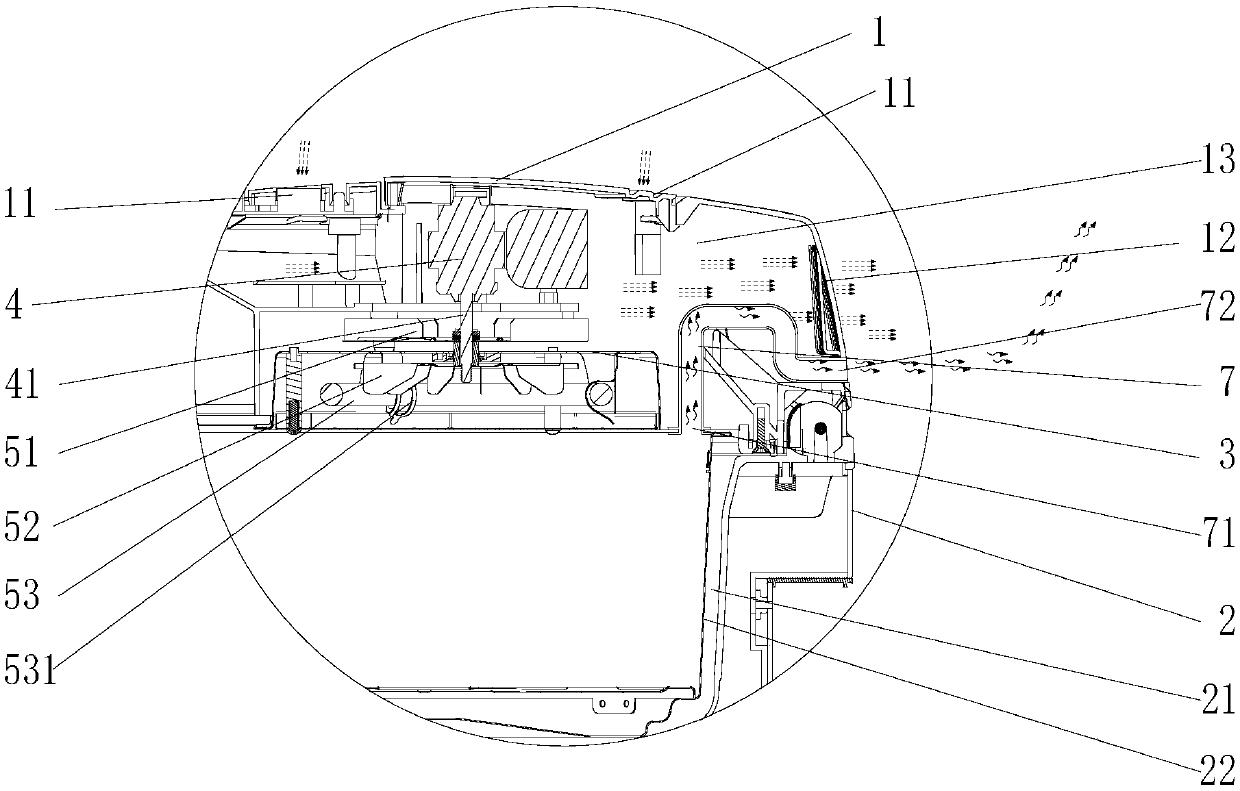

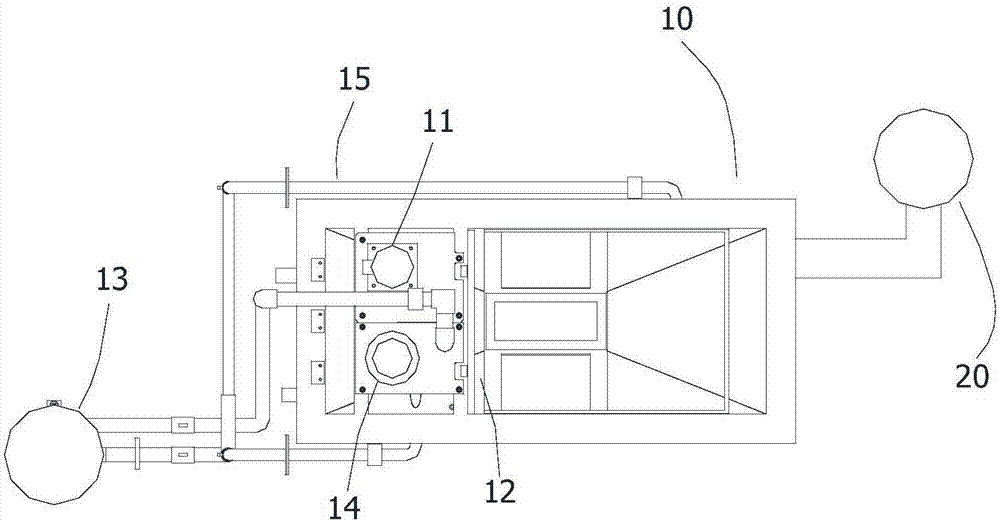

Multifunctional cooking utensil

InactiveCN110876559AExtended service lifeAvoid damageSteam cooking vesselsRoasters/grillsCold airElectric machinery

The invention discloses a multifunctional cooking utensil. The multifunctional cooking utensil comprises an upper shell and a lower shell, an air inlet and an air outlet are formed in the upper shell;a air guide cover r is arranged below the upper shell; a cold air cavity is defined between the upper shell and the air guide cover; the air inlet and the air outlet are communicated with the cold air cavity; a motor and a cold air fan are arranged in the cold air cavity; the cold air fan is fixedly connected with a motor shaft of the motor; a hot air fan and a heating element are arranged belowthe air guide cover; a motor shaft penetrates through the air guide cover and then is fixedly connected with the hot air fan; a containing cavity is formed in the lower shell body, a container is arranged in the containing cavity, the multifunctional cooking utensil further comprises a steam generation device for providing steam for the container. The cold air cavity is hermetically separated fromthe containing cavity; and a steam exhaust channel is formed in the upper shell, a first communicating opening of the steam exhaust channel communicates with the containing cavity, a second communicating opening of the steam exhaust channel communicates with the outside, and the second communicating opening is located in the upper shell and is formed in the side different from the side provided with the air inlet.

Owner:JOYOUNG CO LTD

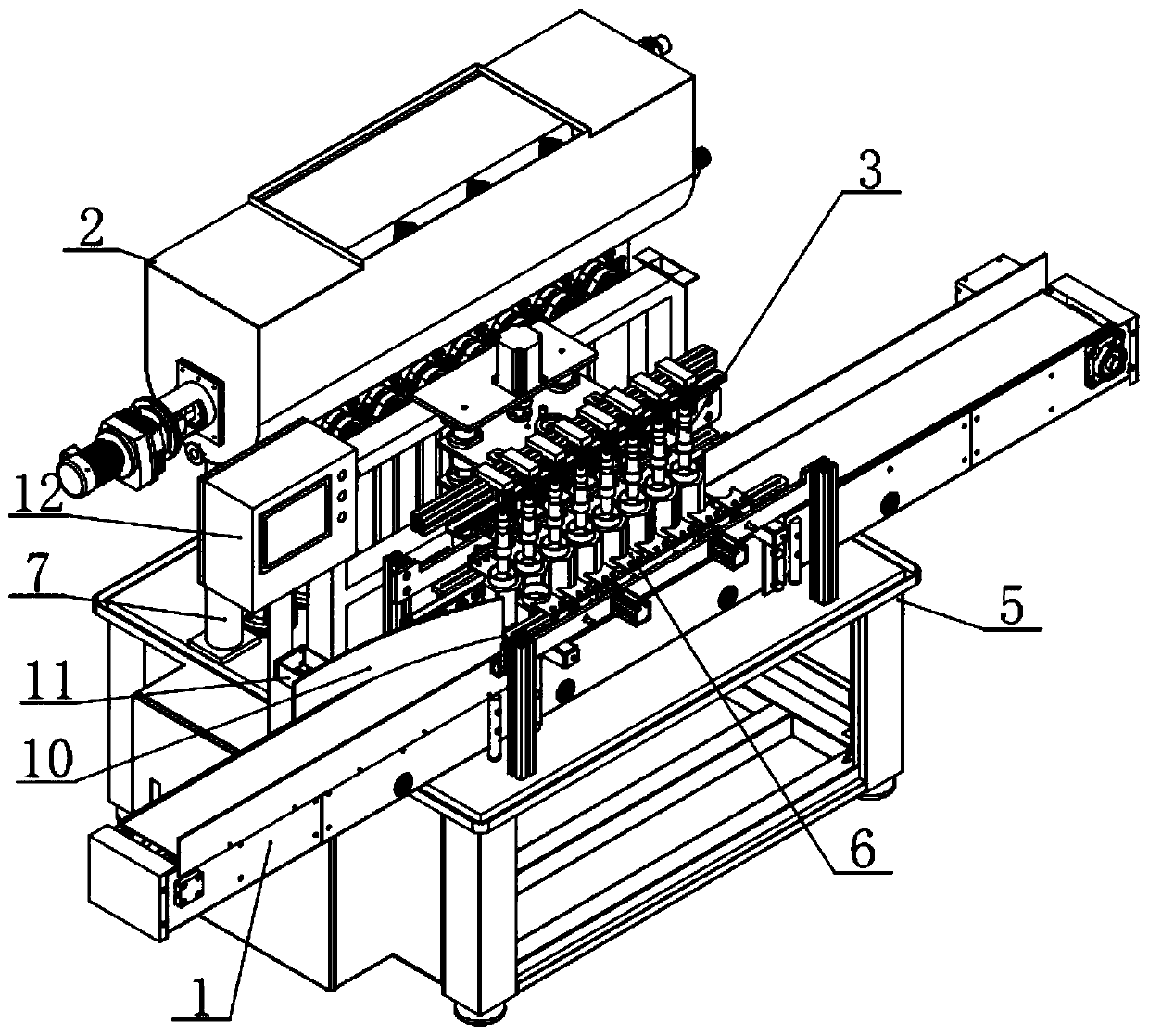

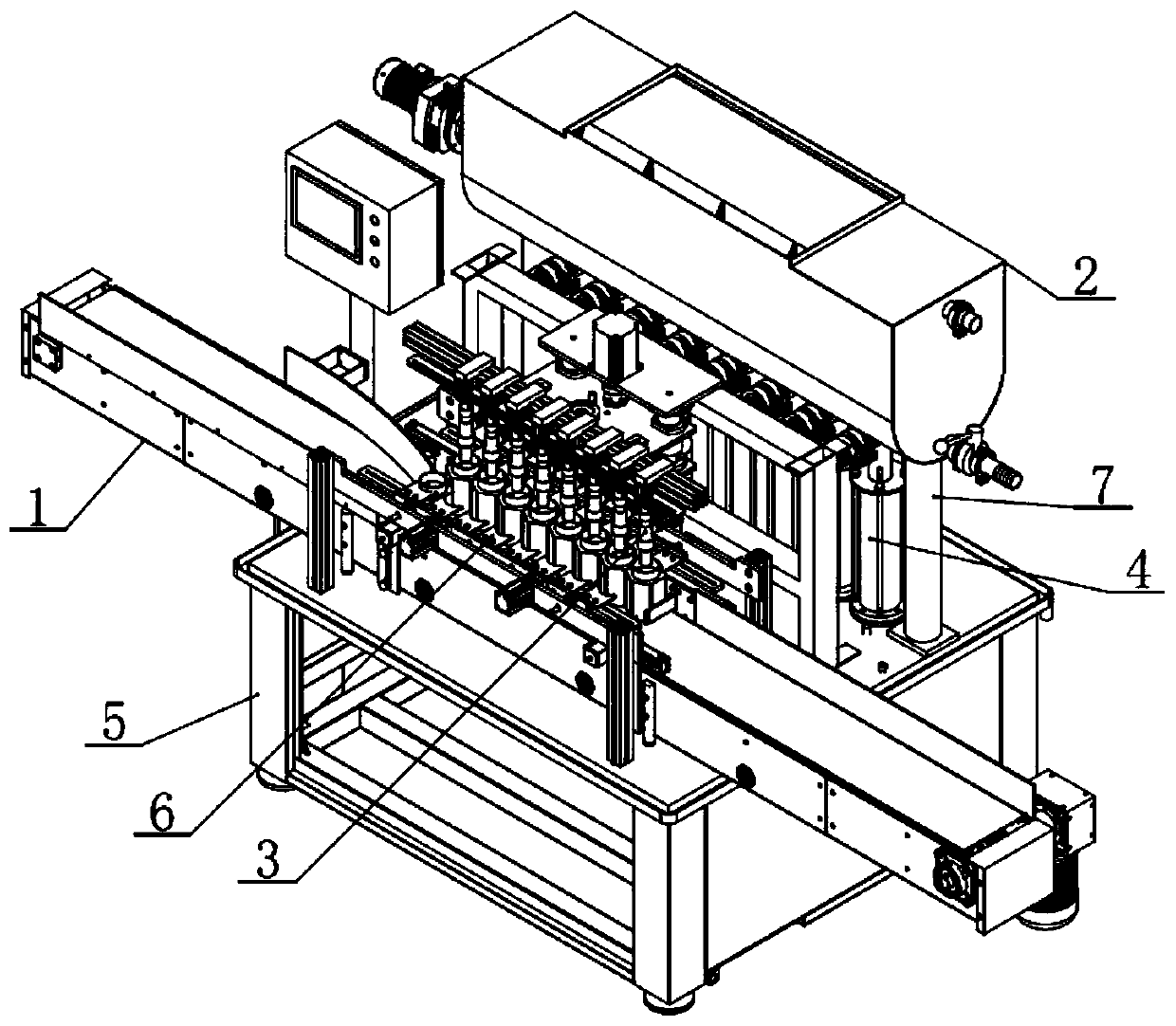

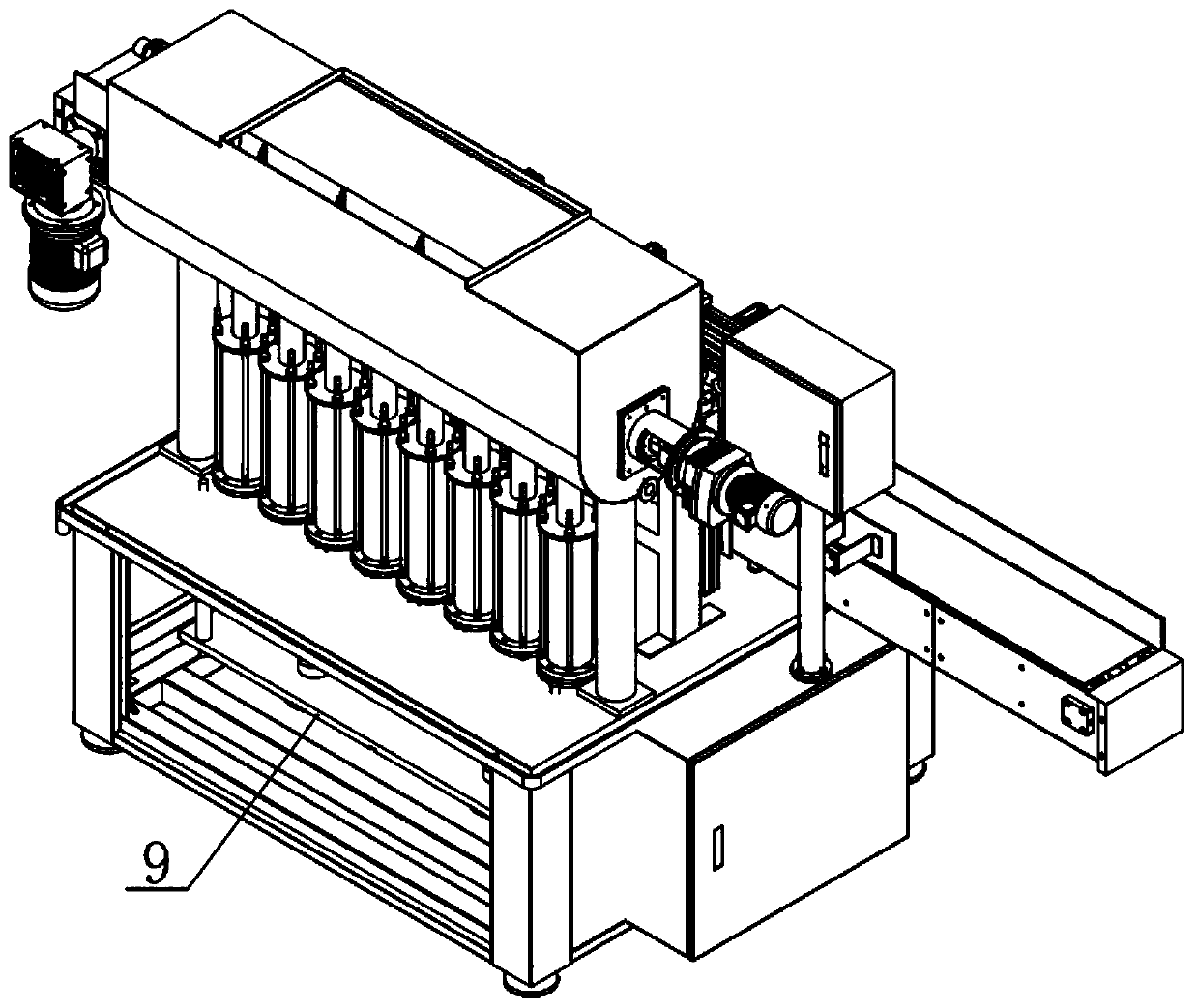

Passion fruit linear type filling machine

The invention discloses a passion fruit linear type filling machine. The passion fruit linear type filling machine comprises a conveying mechanism, a stirrer, a filling mechanism and metering cylinders. The conveying mechanism is installed on the transverse front side of the upper end of a base, and a bottle opening limiting mechanism and the filling mechanism are installed on the front side and the rear side of the middle of the conveying mechanism. The filling mechanism is connected to the discharging ends of the metering cylinders through pipelines, and the feeding ends of the metering cylinders are connected to the bottom of the stirrer. The stirrer is fixedly connected to the rear side of the base through a supporting frame, piston rods of the metering cylinders are connected with a metering adjusting mechanism, and the metering adjusting mechanism is installed on the base. The metering adjusting mechanism in the passion fruit linear type filling machine adjusts the stir uniform feeding of the stirrer and the discharging operation of the metering cylinders and controls the feeding operation of the metering cylinders, and after the metering cylinders are filled with passion fruit juice, the filling mechanism is controlled to multiple filling bottles conveyed by the conveying mechanism to conduct discharging and filling operation. The bottle opening limiting mechanism is adopted to conduct automatic quick limiting, the bottles are pushed to the filling positions to be subjected to quick filling, and therefore the bottle output waiting time is shortened, and the production efficiency is improved.

Owner:GUIZHOU UNIV

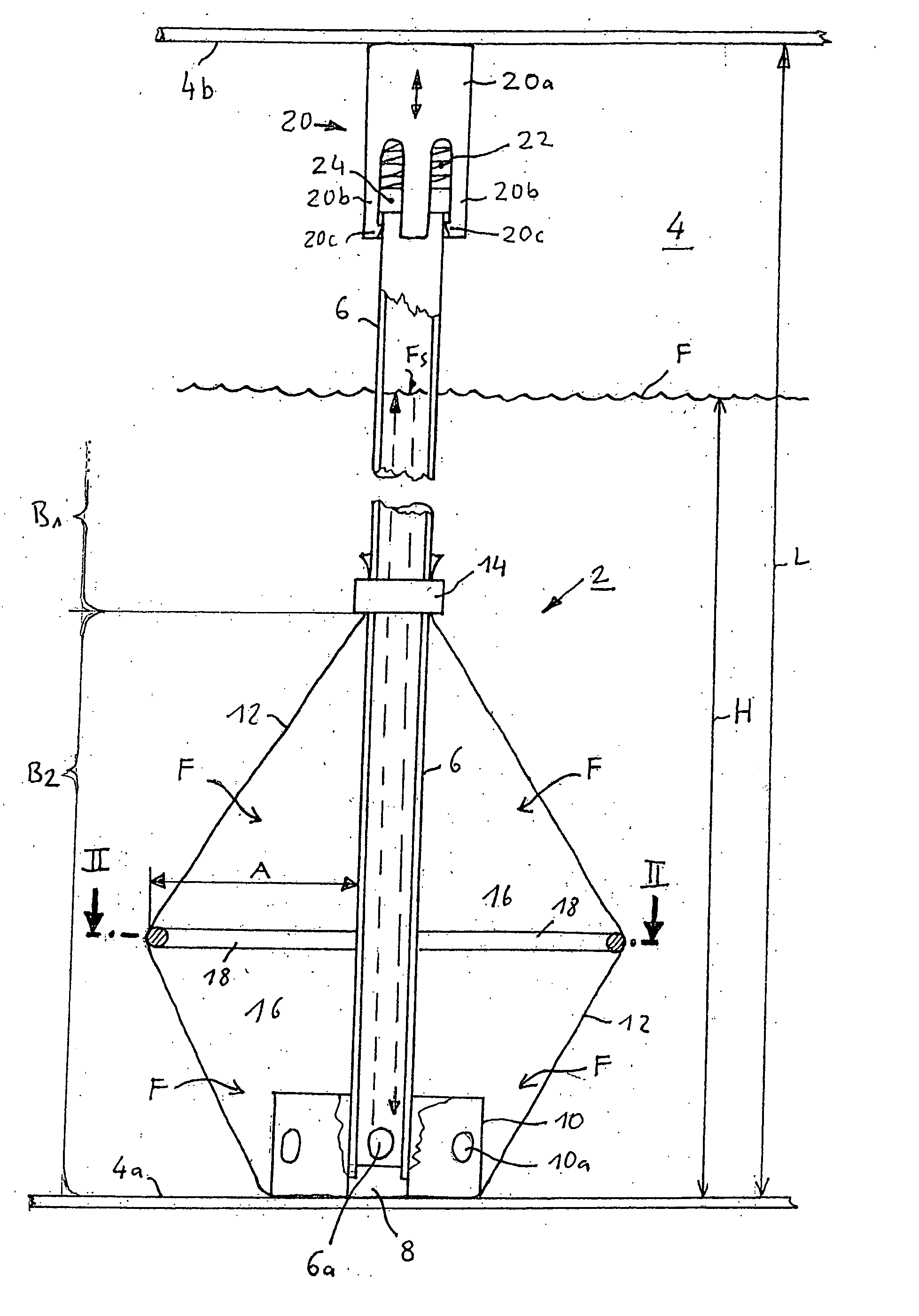

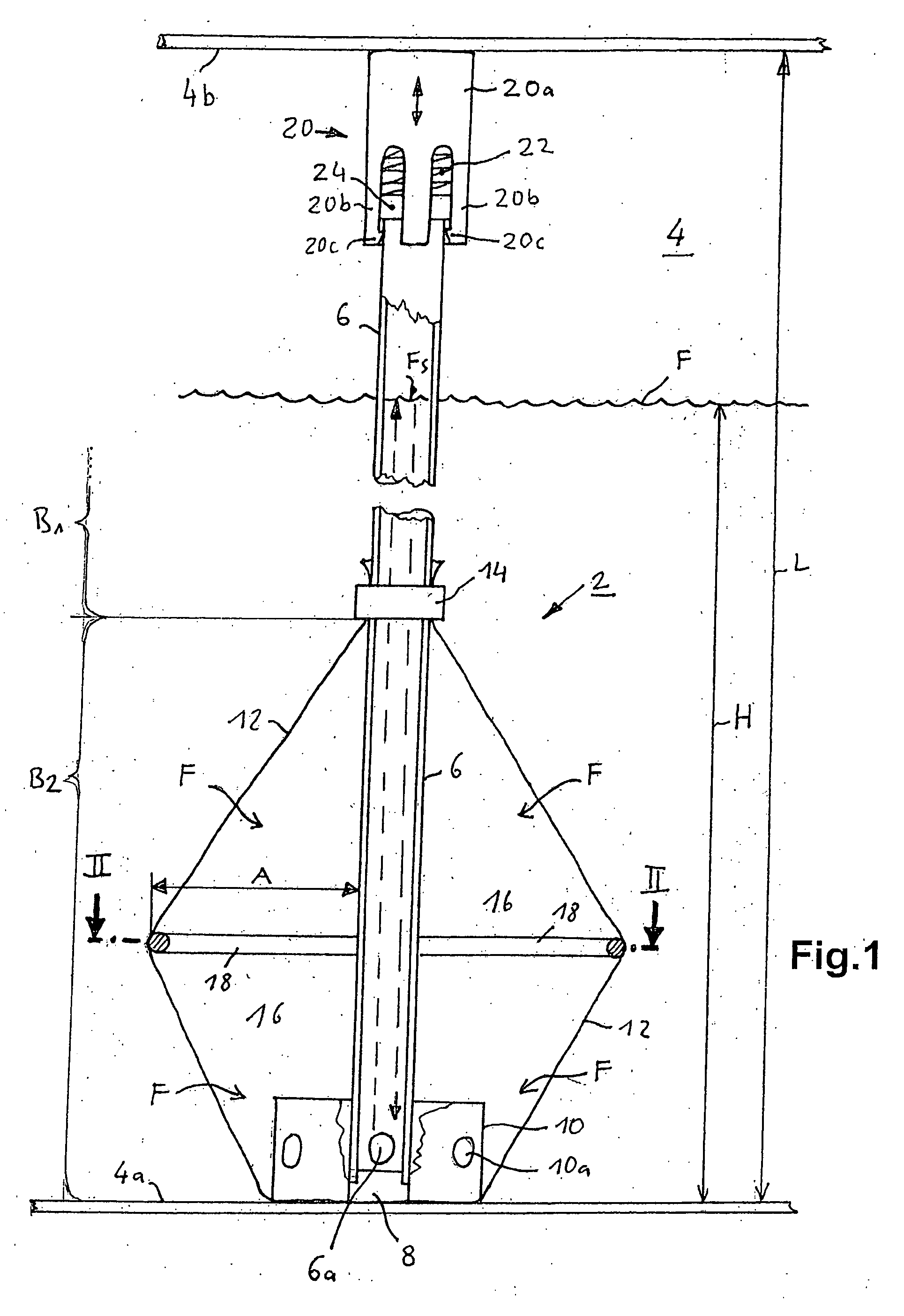

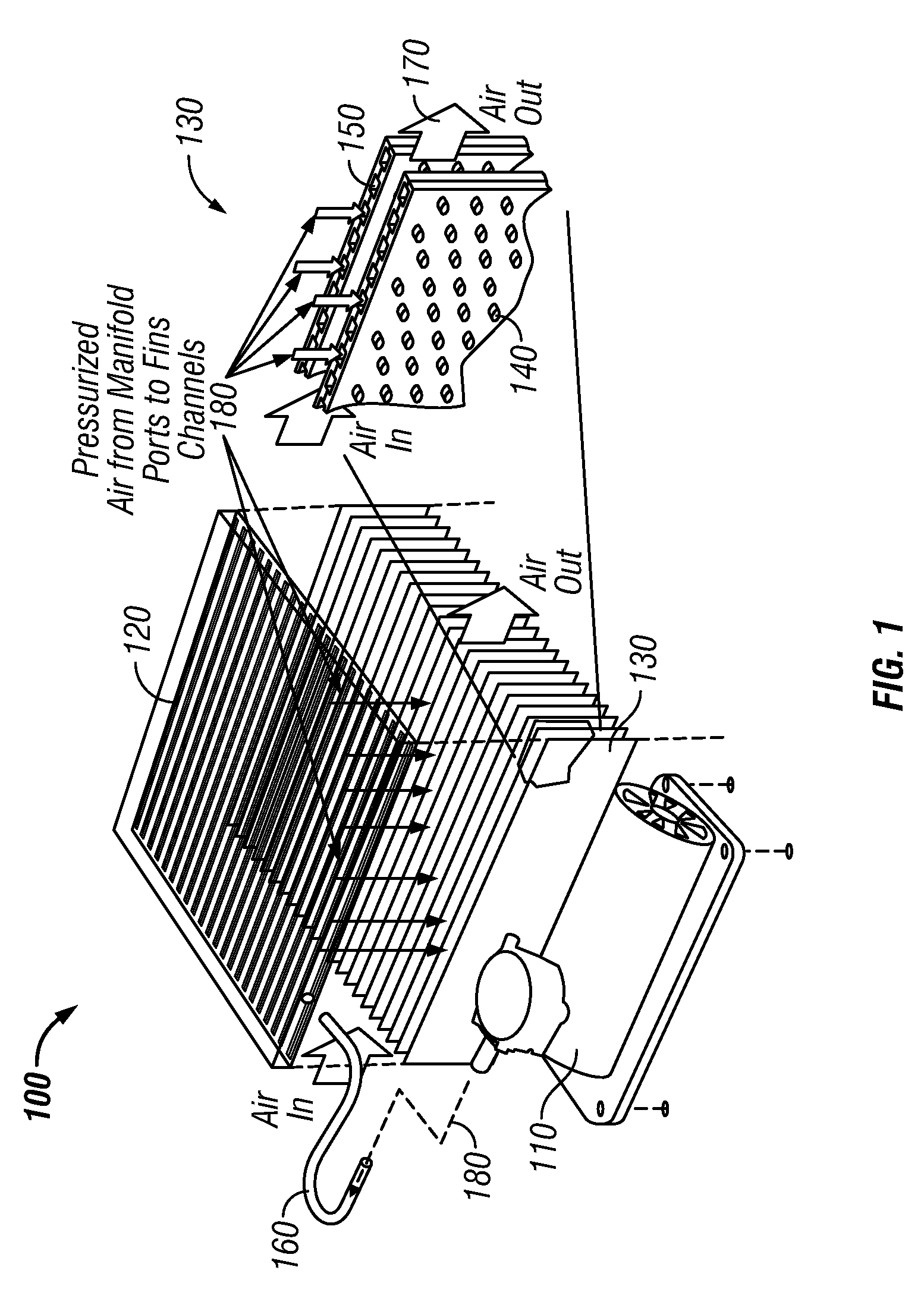

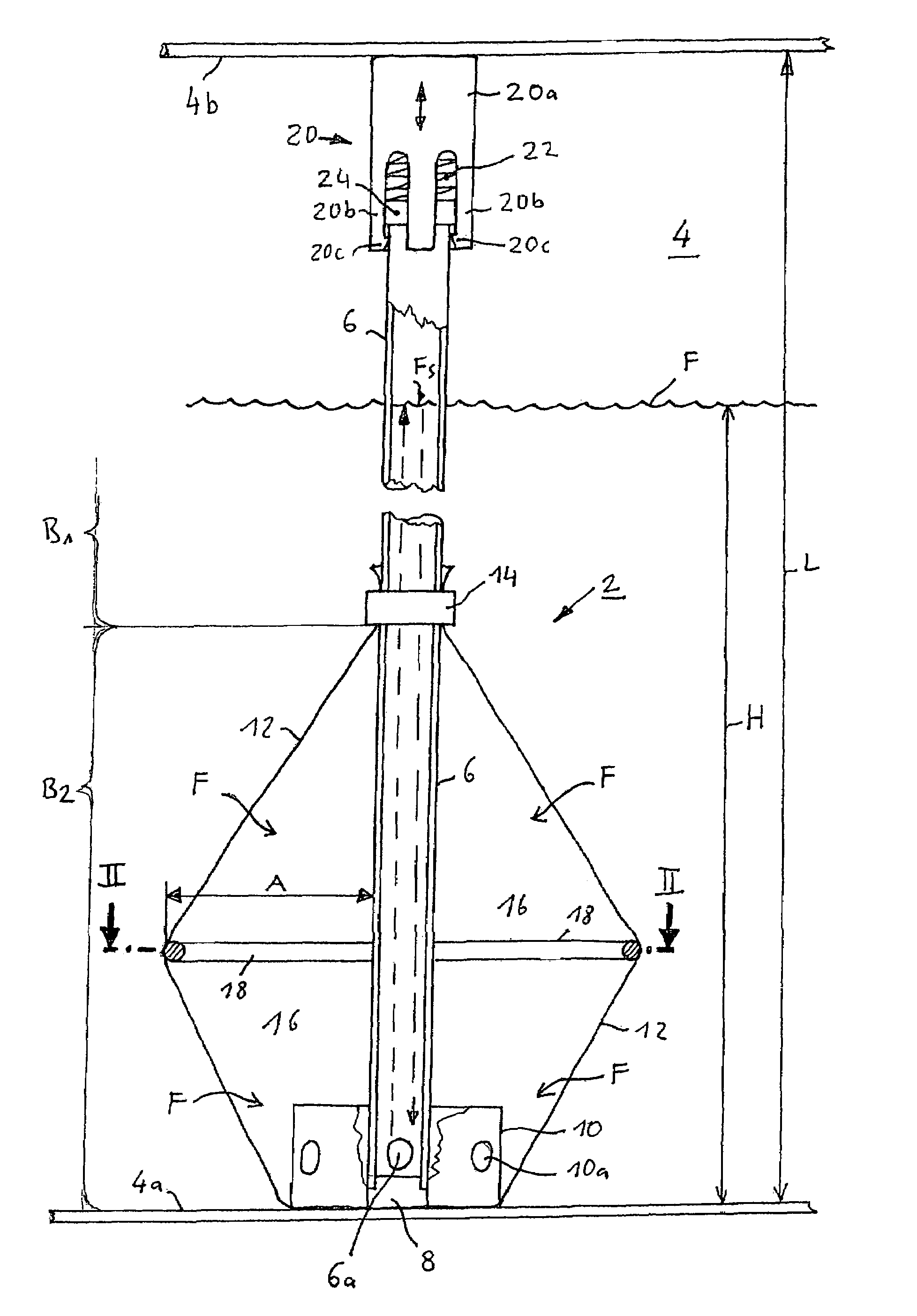

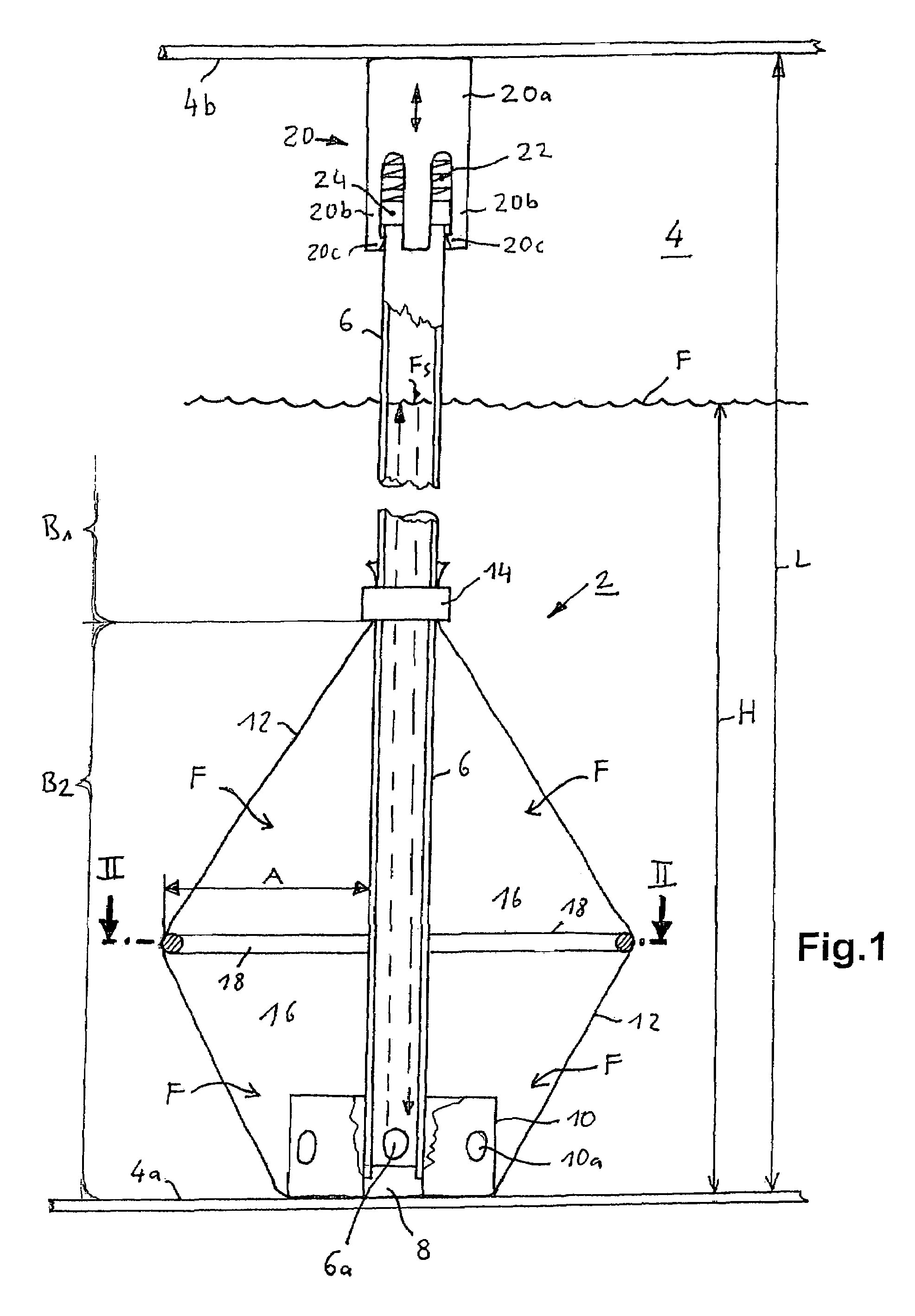

Tank system with fuel level gauge

InactiveUS20060201578A1High fault toleranceImprove reliabilityLiquid fillingMachines/enginesAntechamberLevel sensor

A fuel level gauge includes a measuring pipe configured as a riser pipe that has a fuel inlet opening at one end region defines a measuring distance. The fuel level gauge also includes a fuel level sensor associated with the measuring pipe and disposed the vicinity of the fuel inlet opening and having a measurement-sensitive sensor area for purposes of measuring the fuel filling height in the measuring pipe. A fuel-permeable, thin-walled enveloping element surrounding the measuring pipe tightly so as to seal it in a first area of the measuring pipe and enclosing a second area of the measuring pipe at a predefined distance over a large surface. The second area encompasses at least the fuel inlet opening and the measurement-sensitive area of the fuel level sensor, and forms a large-volume antechamber upstream from the fuel inlet opening in the second area between an inside of the enveloping element and an outside of the measuring pipe.

Owner:AIRBUS HELICOPTERS DEUT GMBH

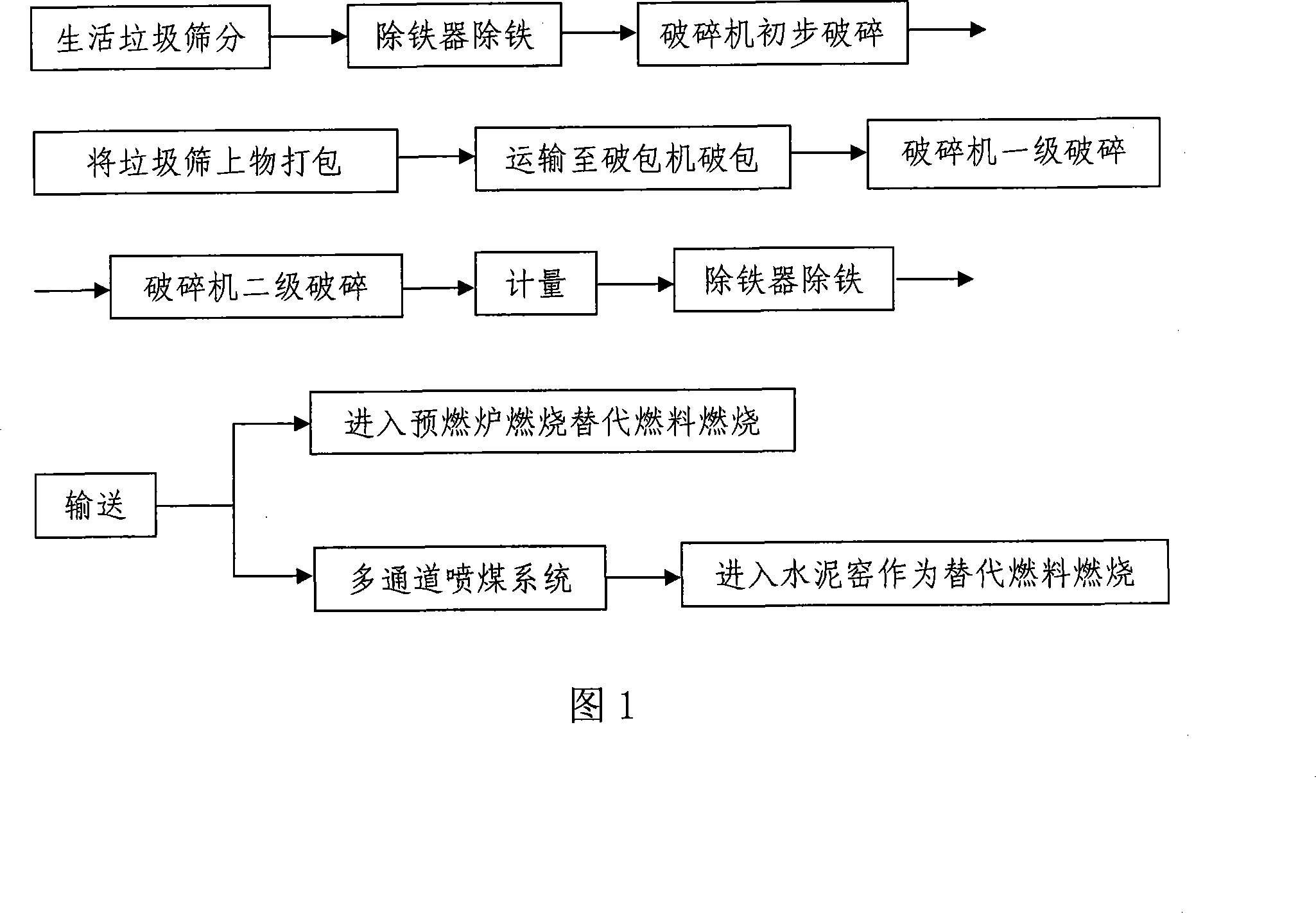

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

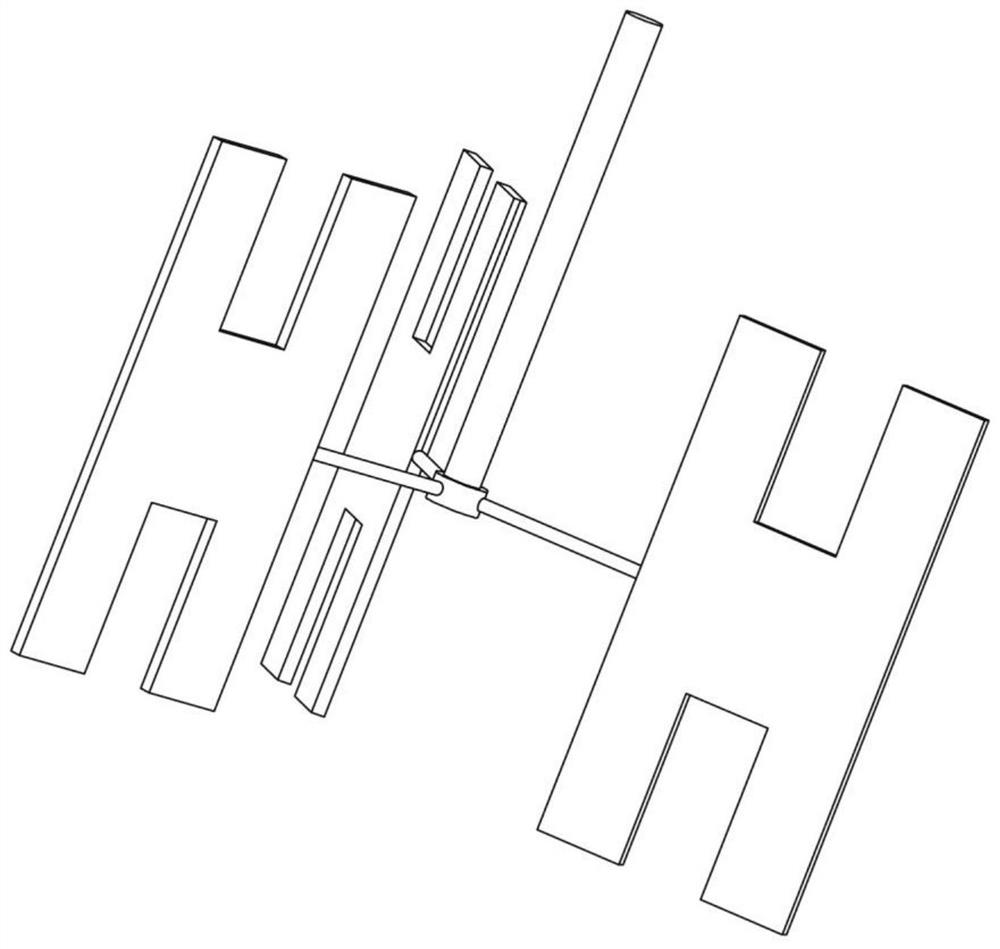

Blowerless heat exchanger based on micro-jet entrainment

ActiveUS8376031B2Improve heat transfer performanceReduce areaSemiconductor/solid-state device detailsSolid-state devicesAir movementAir entrainment

A blowerless heat exchanger apparatus based on micro-jet entrainment is disclosed. The heat exchanger apparatus incorporates a number of fins regularly spaced apart from each other and parallel to each other, thus letting air currents flow in the space defined between them. A dense array of micro-jet nozzles can be fabricated on the fins surface pointing to the flow direction of the air movement in order to induce increase airflow. The air from an air compressor delivers sufficient airflow on the fins surface utilizing micro-jets entrainment. The micro-jet entrainment confirms strong turbulent around the micro-jets and suggests significant heat transfer enhancement. The turbulence from the micro-jets enhance the heat transfer coefficient, potentially by an order of magnitude, therefore allowing much larger fin spacing and leads to huge reduction of flow resistance and overall power consumption.

Owner:HONEYWELL INT INC

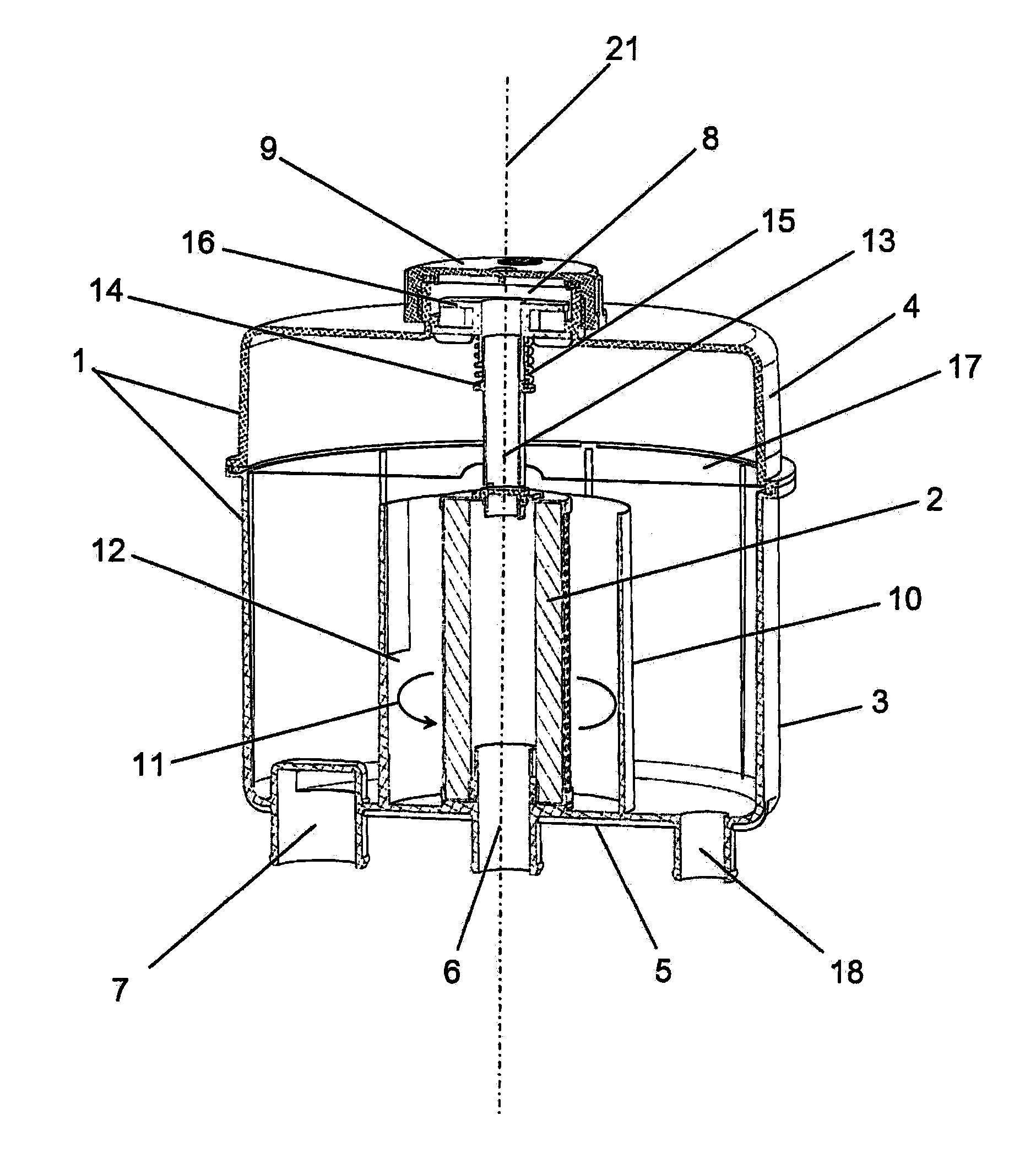

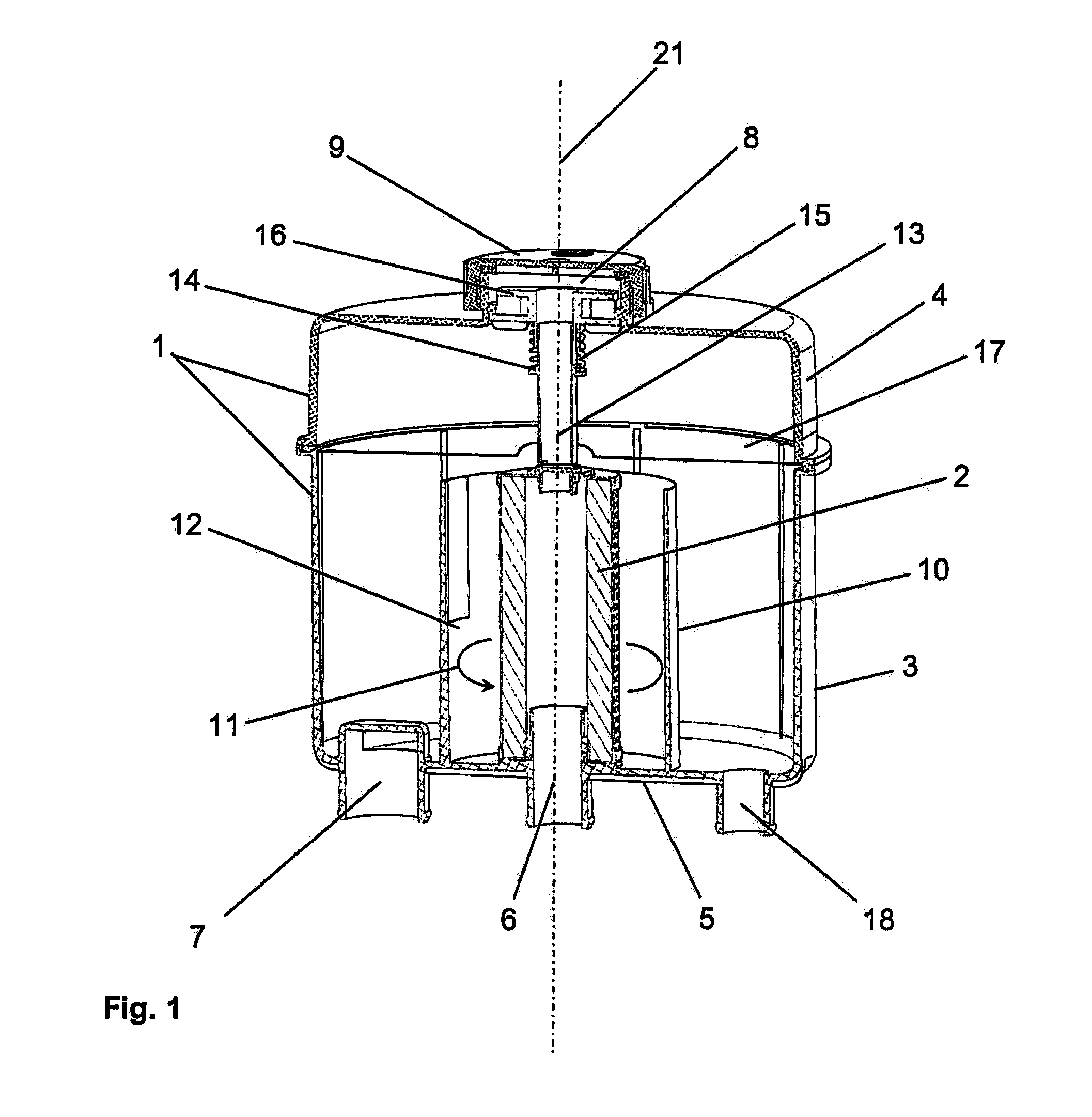

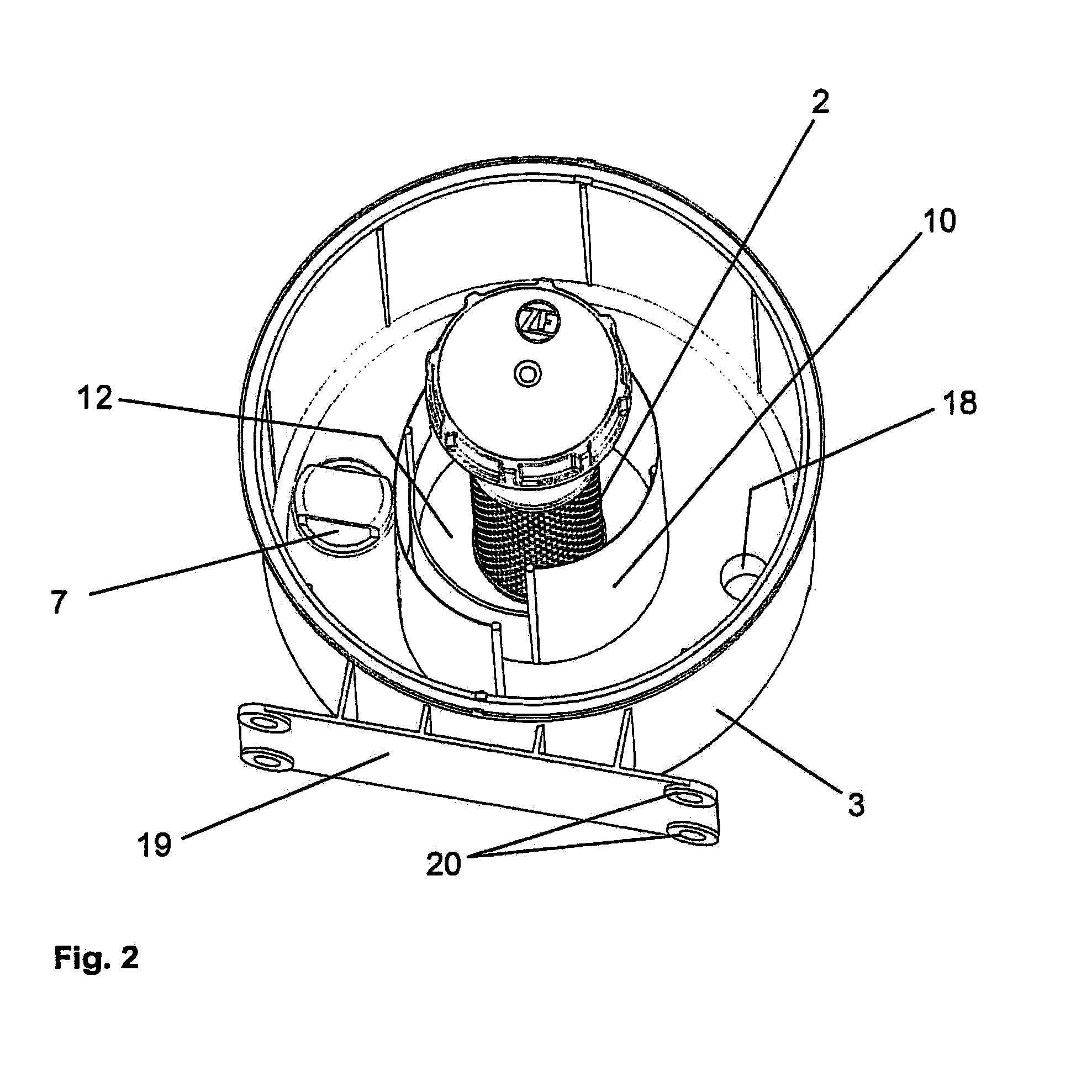

Oil reservoir comprising an oil filter

ActiveUS20120091047A1Simple designEfficient separationLiquid degasificationCartridge filtersFuel tankOil filter

An oil reservoir having an oil inlet fitting and at least one oil outlet fitting for connecting to a hydraulic system. The reservoir comprising a housing having a lower housing part and a reservoir cover which is connected to the lower housing part and includes an integrated oil filter. An oil filler neck, which can be closed by a cap, is configured on the housing cover. The reservoir housing is equipped with at least one guide element which is attached to at least one inside wall of the reservoir housing and forms a circular guidance track for the oil. This guidance track forces the oil flow in a circular manner, after entering the reservoir and passing through the oil filter but before exiting the oil reservoir, such that any air which may be present is separated from the oil and can exit the oil reservoir via an air outlet.

Owner:ROBERT BOSCH GMBH +1

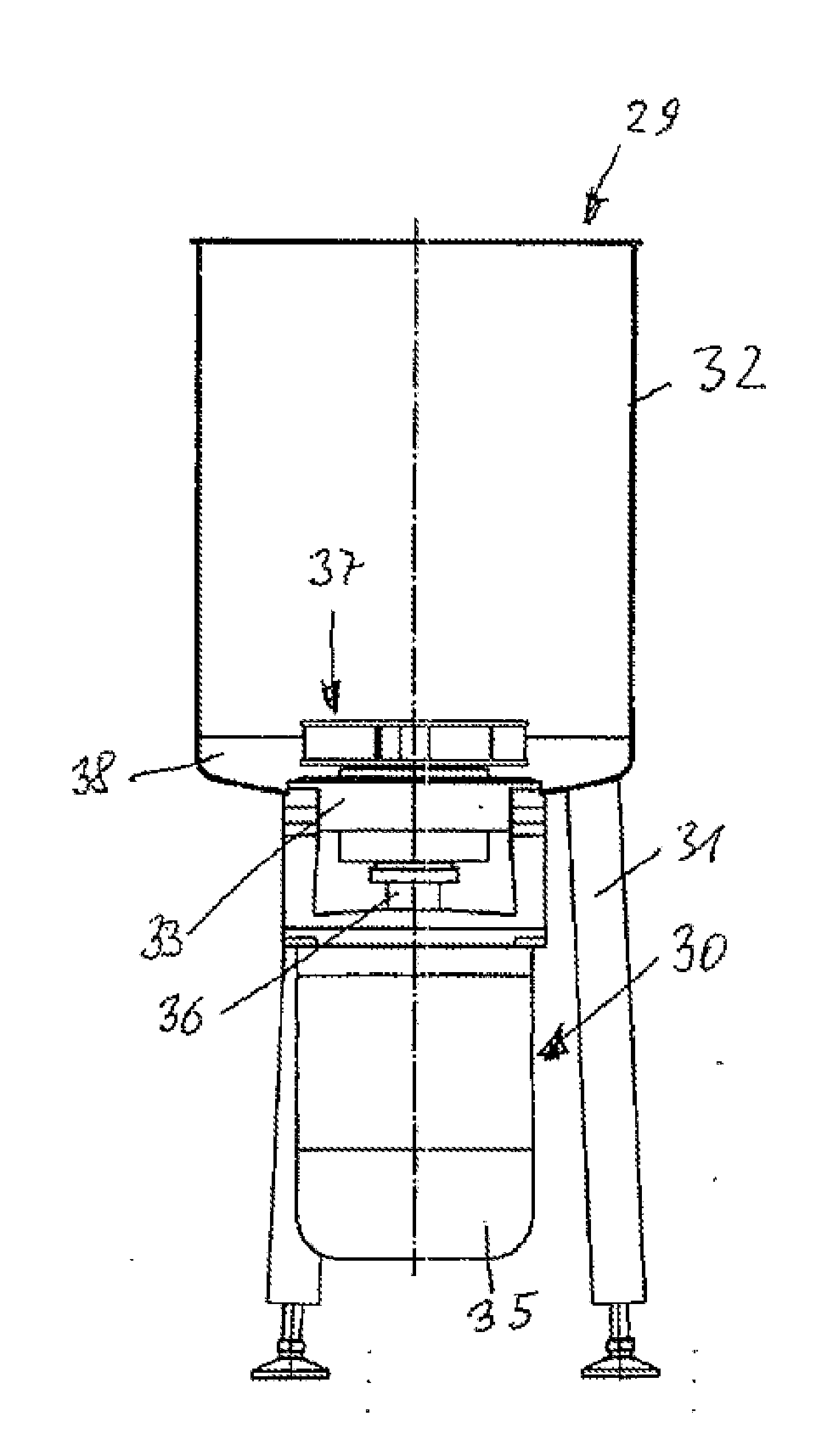

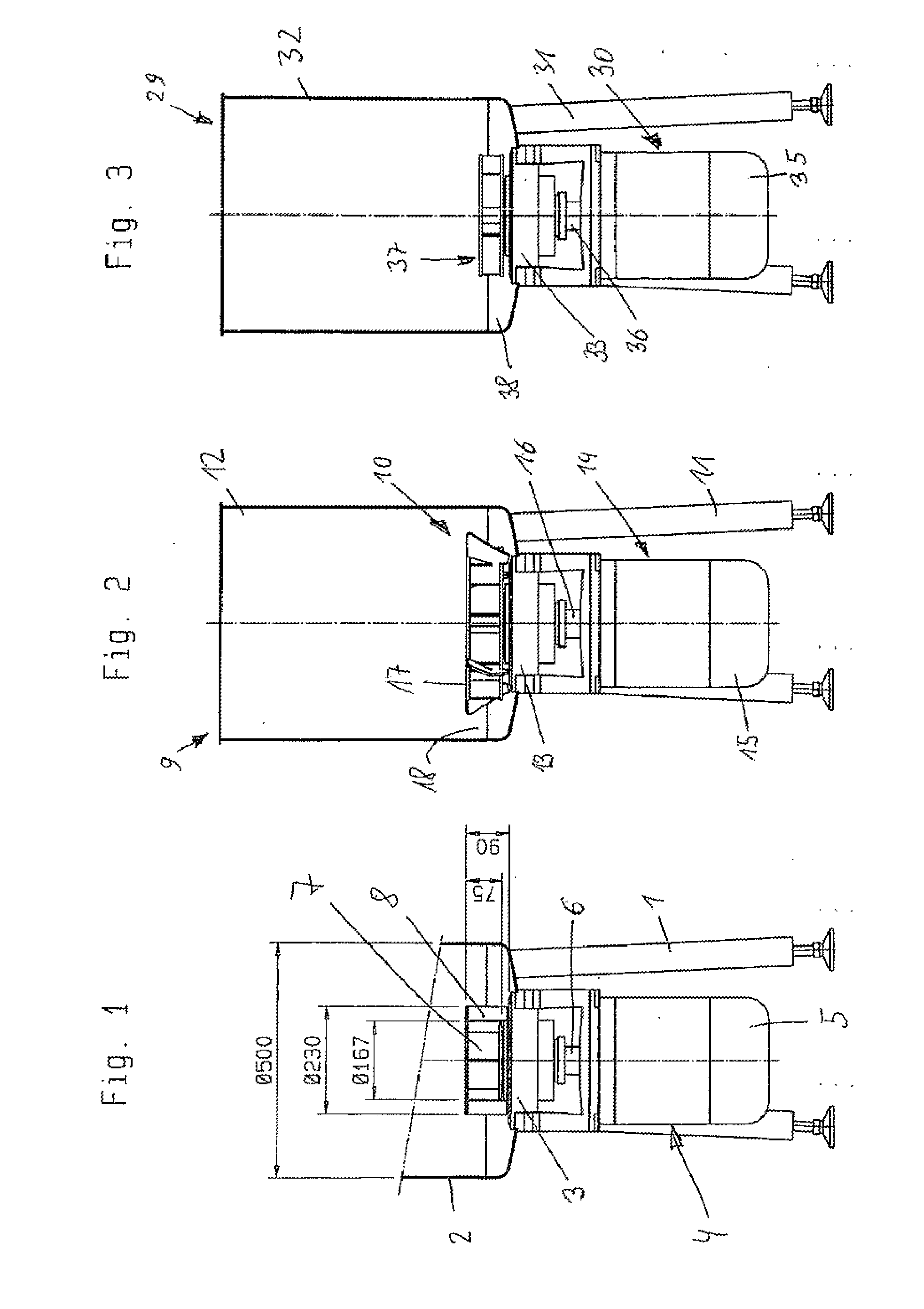

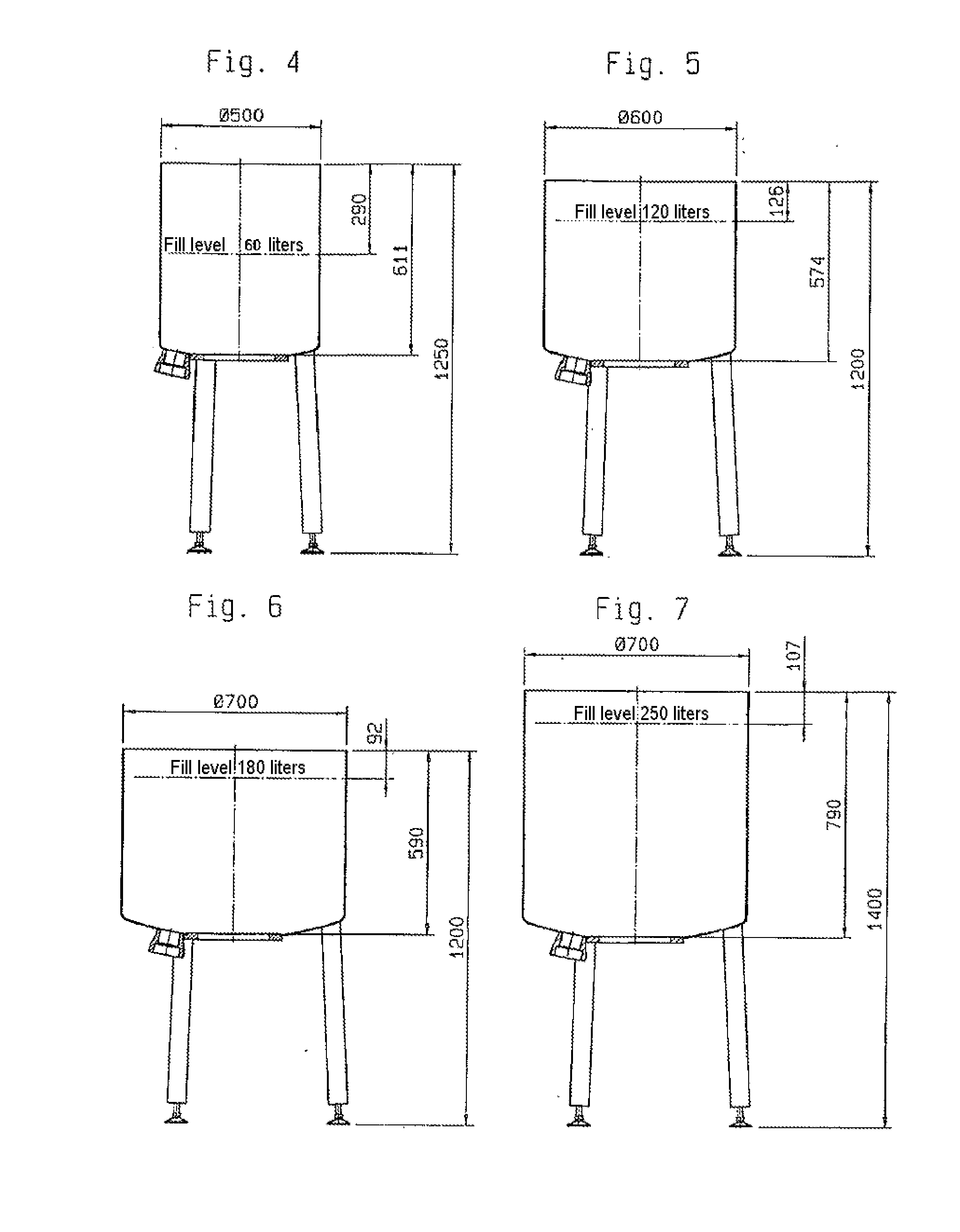

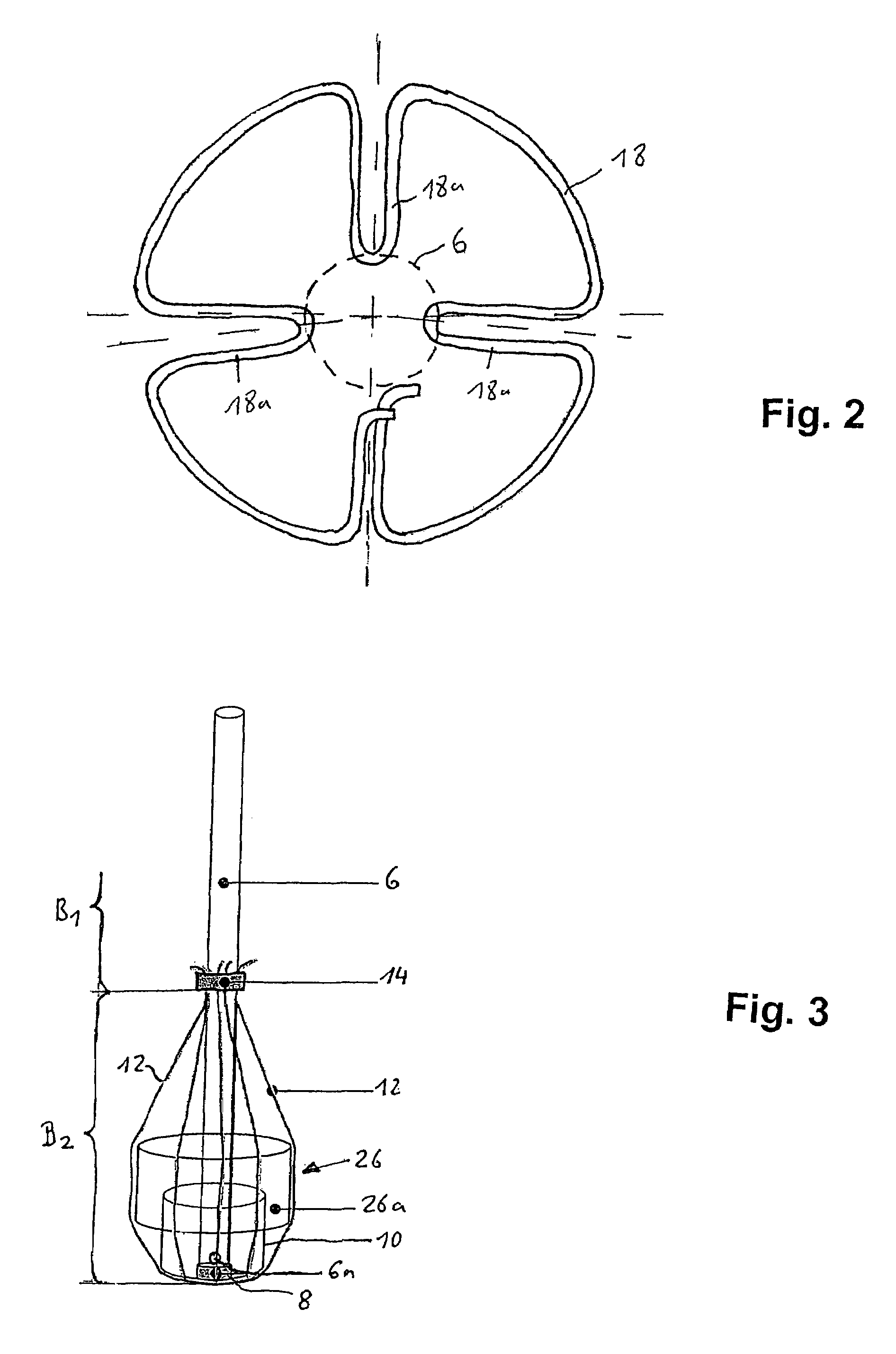

Mixing apparatus

InactiveUS20120275260A1Strong turbulenceRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

A mixing device has a frame, a cylindrical mixing container that is open toward the top, and a single-shaft agitator. A vertical agitator shaft extends into the mixing container from beneath. The agitator is an agitator without a stator and includes a rotor body arranged just above the container bottom in the mixing container. The rotor body is surrounded by a ring-shaped clearance between the rotor body and the container wall. Above the base plate fastened to the agitator shaft, the rotor body is provided with an inner clearance above the agitator shaft, mixing blades vertically arranged about the clearance, and flow channels arranged between the blades. The channels are delimited toward the top by a cover plate that is connected to the upper edges of the mixing blades. The cover plate is formed with a void arranged in the center and above the inner clearance.

Owner:HAAS FOOD EQUIP

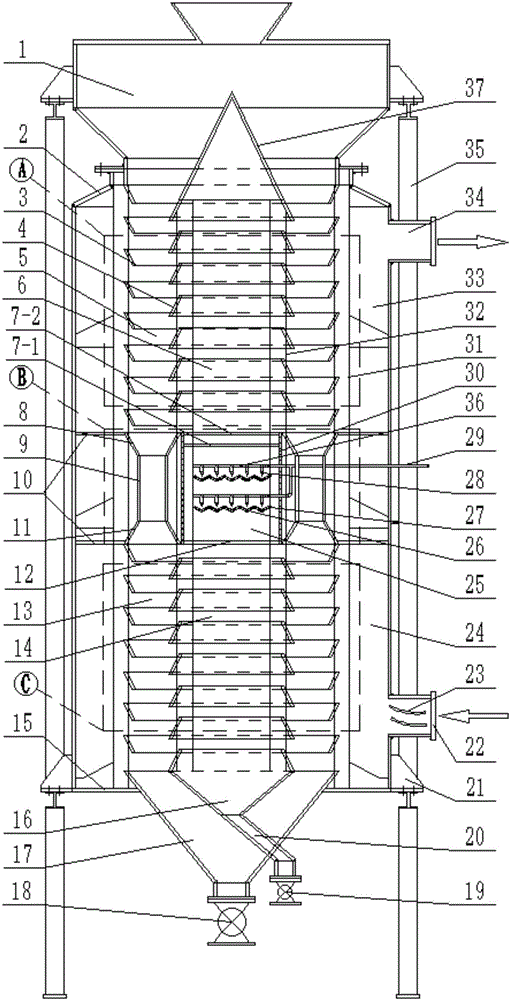

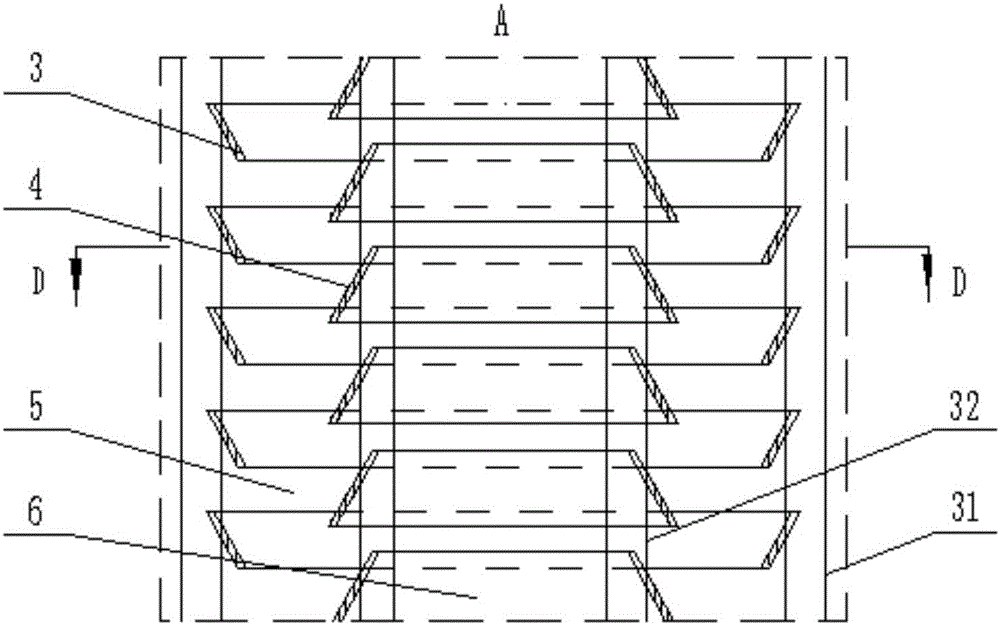

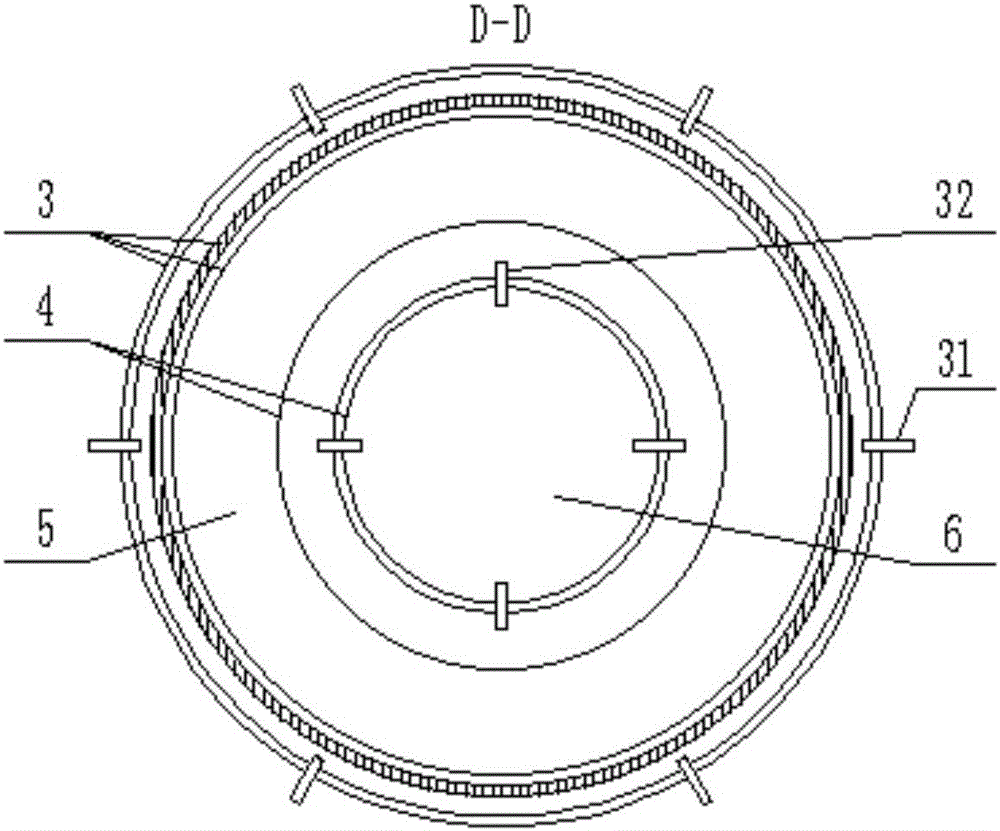

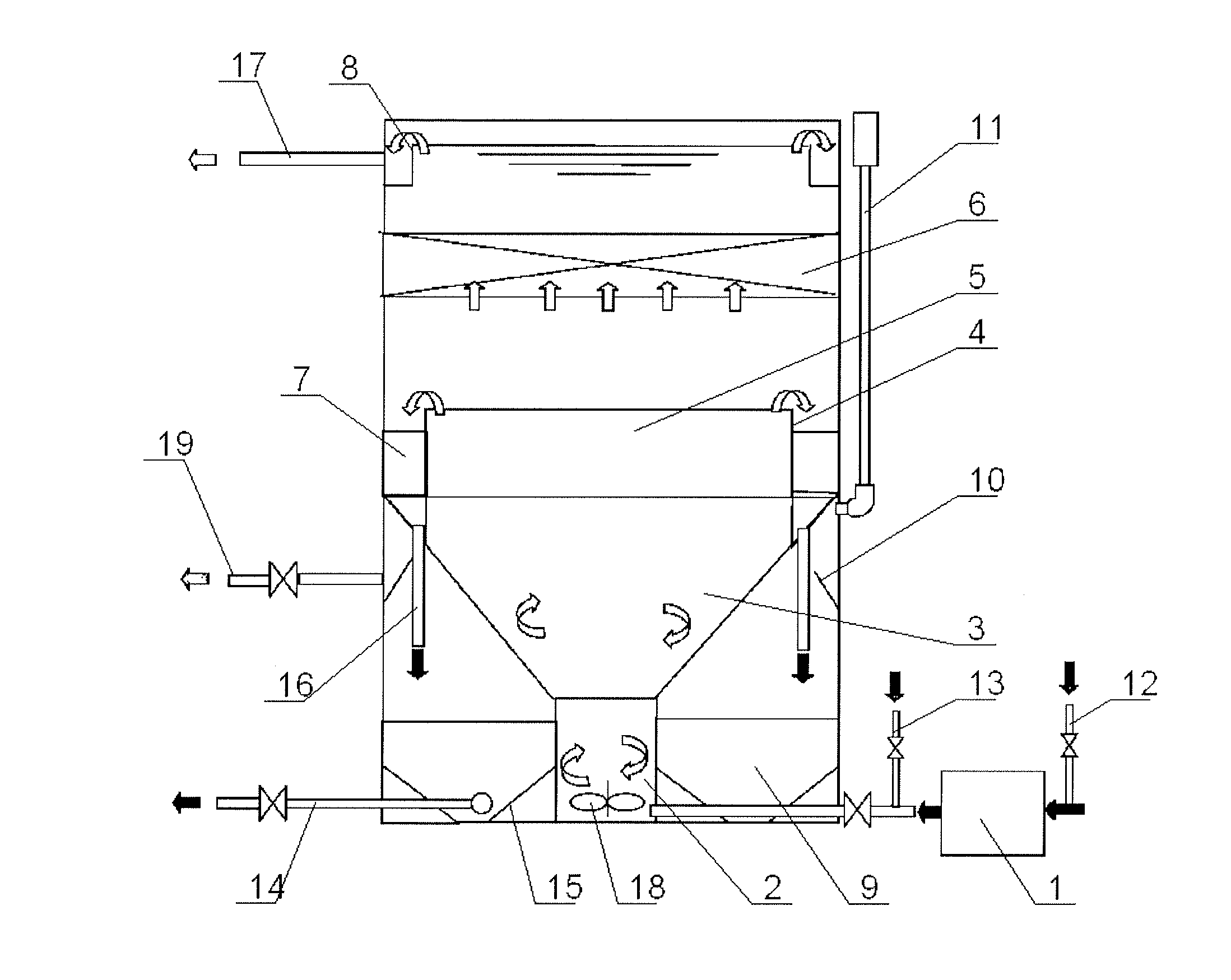

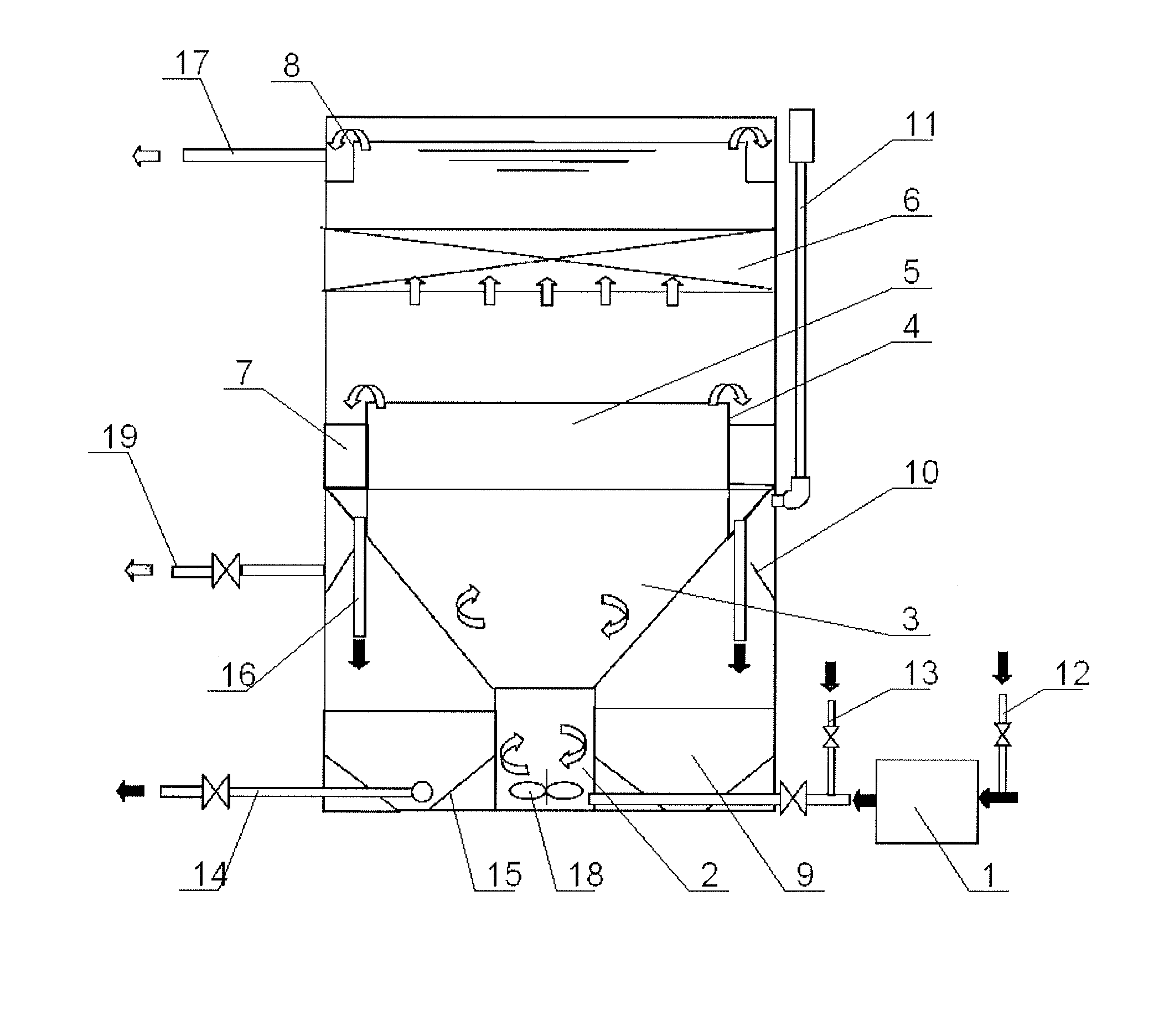

Desulfurization and denitration integrated device

ActiveCN105749748AWell mixedStrong turbulenceGas treatmentDispersed particle separationSmall footprintAmmonia

A desulfurization and denitration integrated device comprises a top bin (1), a shell (2), an ammonia spraying master pipe (29), a denitration chamber (5), a smoke inlet (22), a smoke discharging port (34), a discharging valve (18) and a support (35), wherein the shell is divided into an upper denitration region, a middle buffering region and a lower desulfurization region through upper and lower annular partitioning plates (10), the denitration region and the desulfurization region are cut into different chambers through inverted truncated hollow cones (3) and truncated hollow cones (4), and a purified smoke outlet chamber (33), the denitration chamber (5) and a denitration smoke inlet chamber (6) are sequentially arranged in the denitration region from outside to inside; a desulfurization smoke inlet chamber (24), a desulfurization chamber (13) and a desulfurization smoke outlet chamber (14) are sequentially arranged inside the desulfurization region from outside to inside; the desulfurization chamber (13) and the denitration chamber (5) are communicated through discharging pipes (9) in the buffering reigon, and the desulfurization smoke outlet chamber (14) and the denitration smoke inlet chamber (6) are communicated through an eddy ammonia mixing chamber (25) in the buffering region.The occupied area is small, smoke flow is distributed reasonably, the quantity of filled purifying agent is small, and desulfurization and denitration efficiency is high.

Owner:山西科瑞信环保工程有限公司

High-pressure rotational flow mixing device

InactiveCN102698625AIncreased turbulence areaMix well and evenlyFlow mixersMixer accessoriesWear resistantSpray nozzle

The invention provides a high-pressure rotational flow mixing device. The main mixing chamber of the high-pressure rotational flow mixing device is formed by connecting and combining a cylindrical mixing chamber and a conical mixing chamber in series; a liquid inlet pipe is connected with the cylindrical mixing chamber; the liquid inlet pipe is internally provided with a nozzle which can resist a pressure of larger than 10MPa; a solid phase charging opening is formed above the cylindrical mixing chamber; the axis of the solid phase charging opening is perpendicular to that of the nozzle; the outlet of the conical mixing chamber is provided with a mixing baffle plate; the baffle plate consists of 2-6 blades which are distributed at the outlet and have the angle from 20 degrees to 60 degrees relative to the horizontal plane; and the outlet of the conical mixing chamber is connected with the inlet of a constant-current elbow pipe; the elbow pipe is of a diameter-changing structure, wherein the elbow pipe inlet diameter D1 / the elbow pipe outlet diameter D2=1.5-1.8, and the curvature radius of the central axis of the elbow pipe R / D=3.0-3.5. The inner wall of the mixing chamber is sprayed with a wear-resistant material mixed with solid particles, so that the abrasive resistance of a chamber body can be improved, the concavity of the spraying surface can be increased, the turbulent condition in the mixing chamber can be enhanced, and the mixing efficiency can be improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

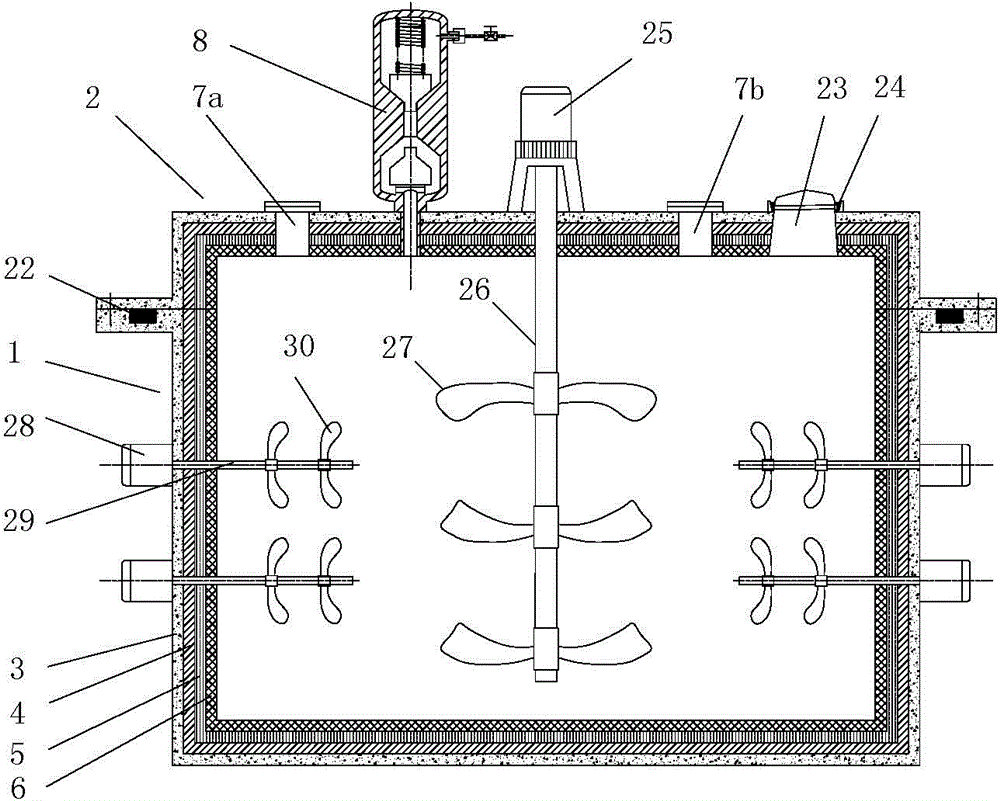

Device and method for achieving uniformity of electroless nickel plating layer

ActiveCN107955941AReduces attached crystalsStrong turbulenceLiquid/solution decomposition chemical coatingElectroless nickelCompound (substance)

The invention relates to a device and method for achieving the uniformity of an electroless nickel plating layer. The device comprises an electroless nickel plating tank, an automatic chemical addingapparatus is arranged on the outer side of the electroless nickel plating tank, a chemical adding tube of the automatic chemical adding apparatus is arranged on the side wall of the electroless nickelplating tank, and a stirrer is arranged in the electroless nickel plating tank. The method includes the following steps that 1, after the electroless nickel plating tank prepares a plating solution,the stirrer is started and a filter pump is started; 2, the tank wall of the electroless nickel plating tank is provided with an anode protection device; 3, a work piece is fed into the work area of the electroless nickel plating tank, nickel plating is started, and at the same time, the automatic chemical adding apparatus is started to maintain the concentration of the main salt of the bath solution. The device and method can provide the uniformity of the temperature and concentration in the electroless nickel plating tank so that the concentration of each component of the electroless nickelplating solution can be maintained in the normal process range, thus the uniformity of the electroless nickel plating layer is achieved.

Owner:HENGLI ELETEK

Tank system with fuel level gauge

InactiveUS7481105B2InhibitionSuppresses bubble and foam formationLiquid fillingMachines/enginesAntechamberLevel sensor

A fuel level gauge includes a measuring pipe configured as a riser pipe that has a fuel inlet opening at one end region defines a measuring distance. The fuel level gauge also includes a fuel level sensor associated with the measuring pipe and disposed the vicinity of the fuel inlet opening and having a measurement-sensitive sensor area for purposes of measuring the fuel filling height in the measuring pipe. A fuel-permeable, thin-walled enveloping element surrounding the measuring pipe tightly so as to seal it in a first area of the measuring pipe and enclosing a second area of the measuring pipe at a predefined distance over a large surface. The second area encompasses at least the fuel inlet opening and the measurement-sensitive area of the fuel level sensor, and forms a large-volume antechamber upstream from the fuel inlet opening in the second area between an inside of the enveloping element and an outside of the measuring pipe.

Owner:AIRBUS HELICOPTERS DEUT GMBH

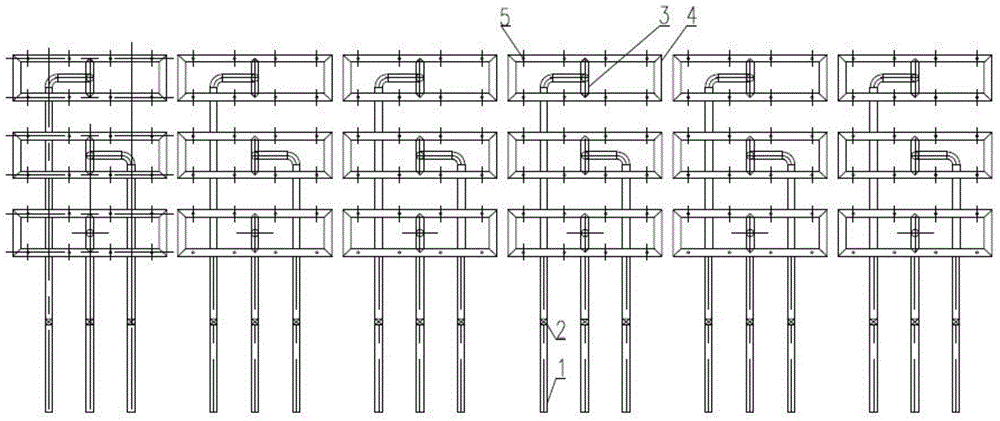

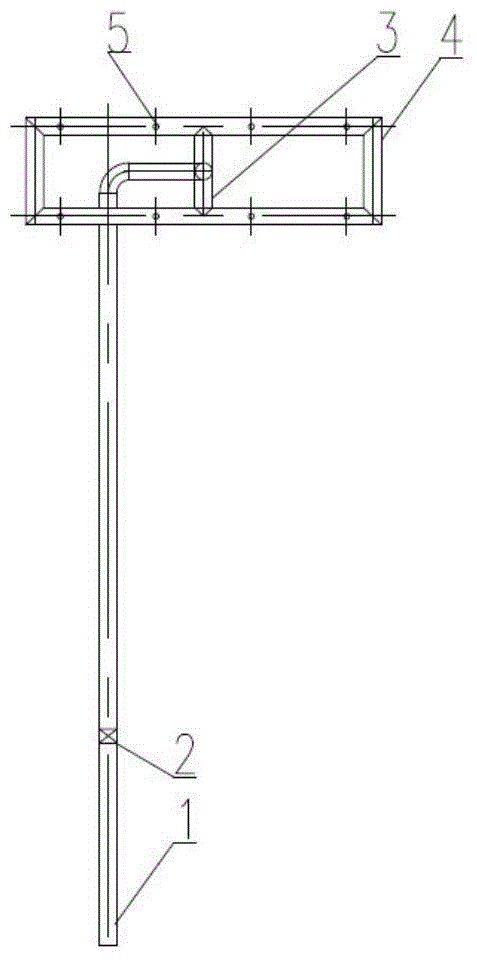

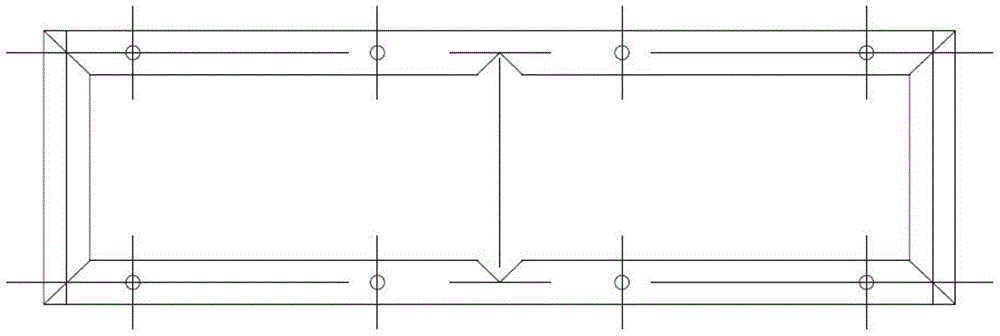

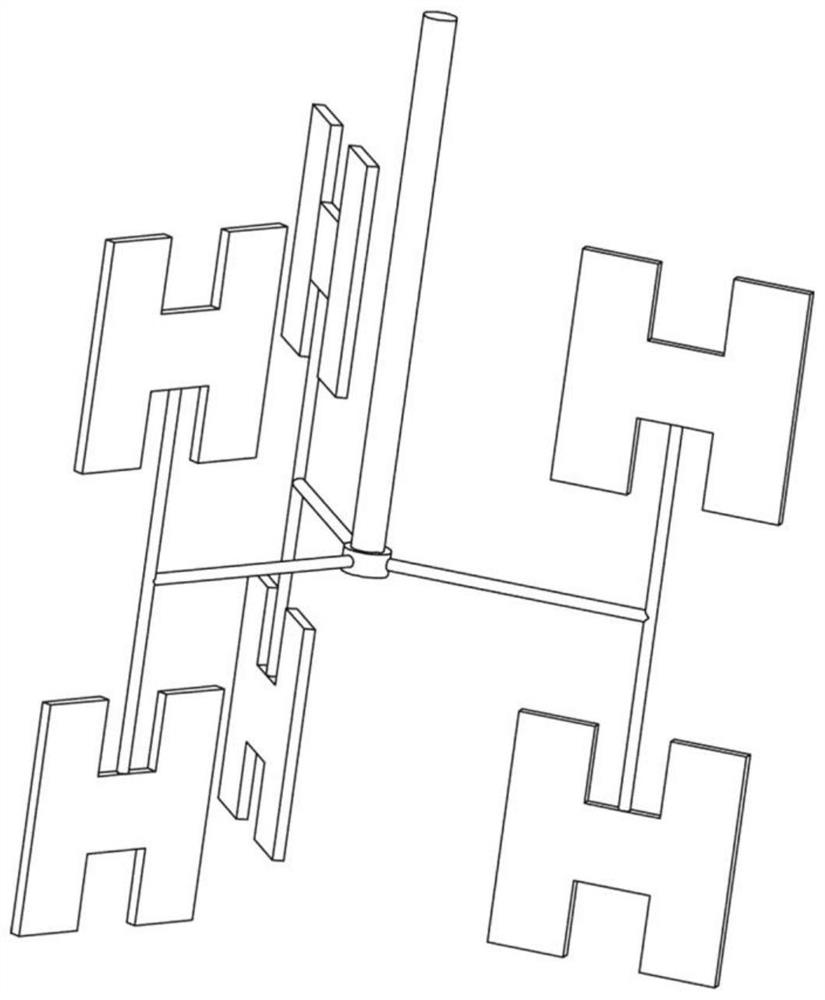

Spraying ammonia mixing system device for SCR flue gas denitrification project

ActiveCN104785103AEvenly arrangedUniform flowDispersed particle separationArray data structureFlue gas

The invention relates to a spraying ammonia mixing system device for an SCR (Selective Catalytic Reduction) flue gas denitrification project. The spraying ammonia mixing system device consists of a plurality of groups of spraying ammonia mixing units, wherein the number of the spraying ammonia mixing units is determined by section shape and size at a gas flue position where the spraying ammonia mixing system device is; all the spraying ammonia mixing units are uniformly and symmetrically mounted in a gas flue; input pipes are symmetrically and perpendicularly connected with the middle of communicated type spray pipes through branch pipes; valves are arranged on passageways by which the input pipes are connected with the branch pipes; the communicated type spray pipes adopt continuous closed tubular structures, and through holes for glue gas flow are formed in the communicated type spray pipes and uniformly, perpendicularly and symmetrically formed in the communicated type spray pipes; spray nozzles comprises spouts and spray nozzle walls and are formed in the through holes of the communicated type spray pipes; the spray nozzle walls are hermetically welded with the through holes of the communicated type spray pipes, the tops of the spray nozzle walls are sealed, and the spouts are formed in the spray nozzle walls.

Owner:BEIJING UNIV OF TECH

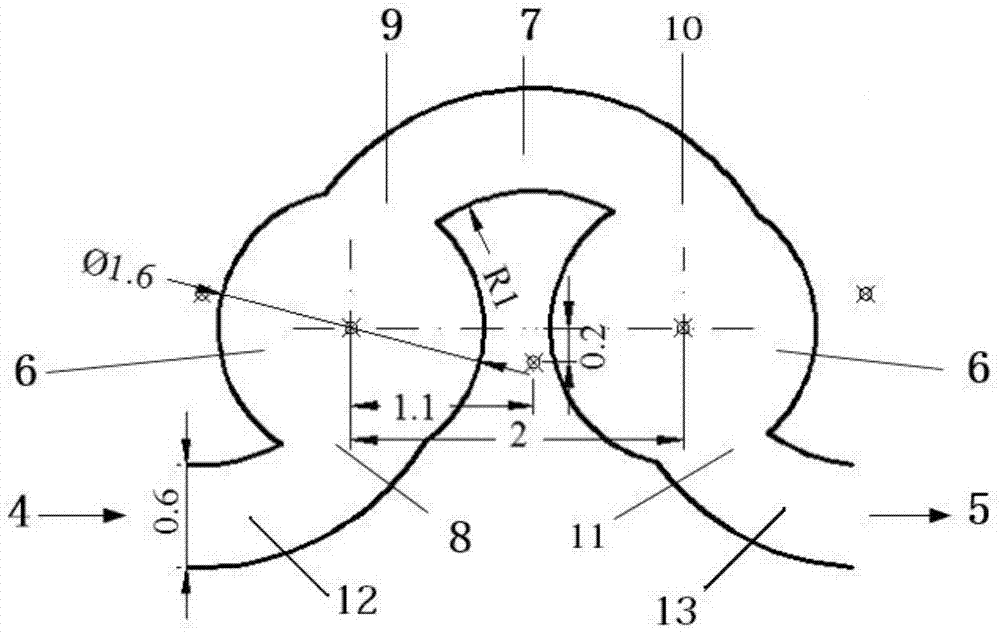

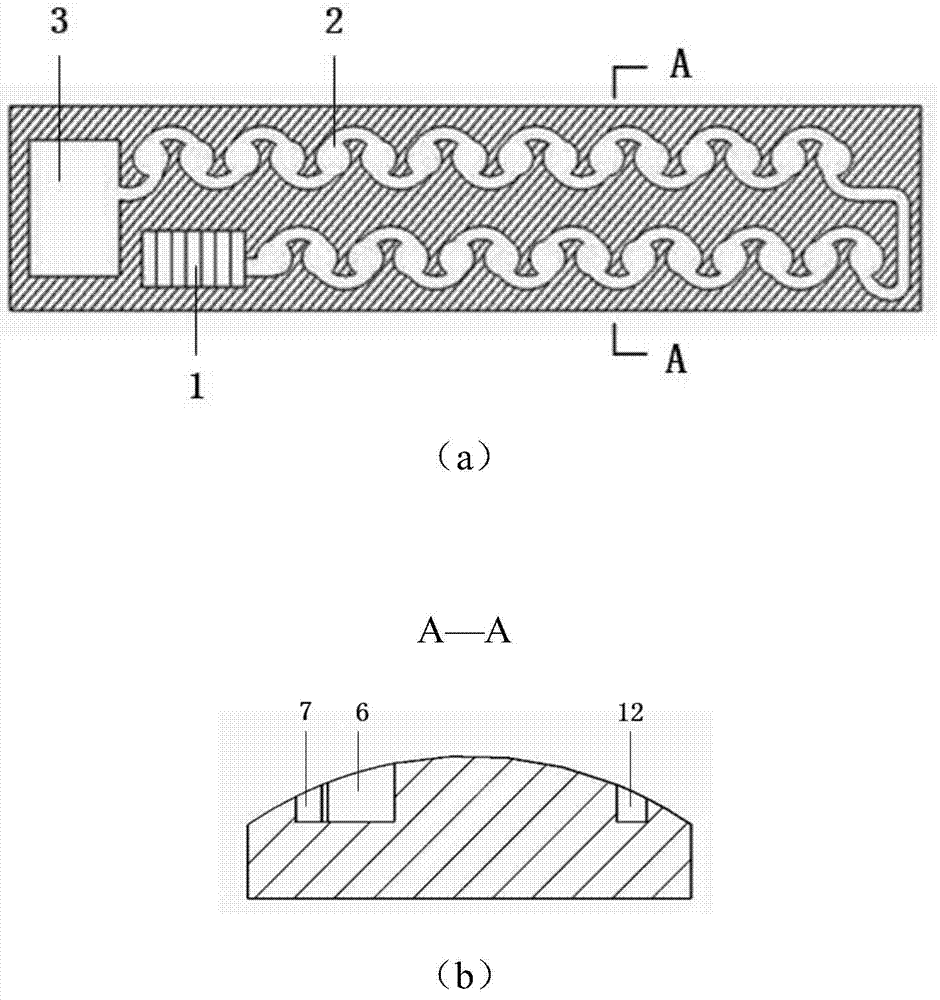

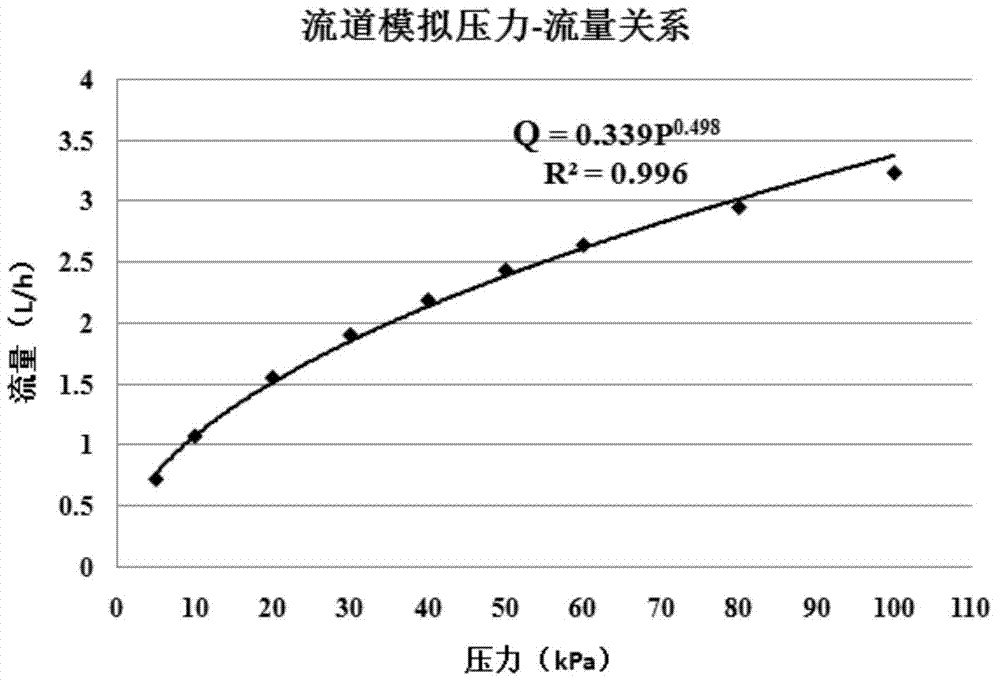

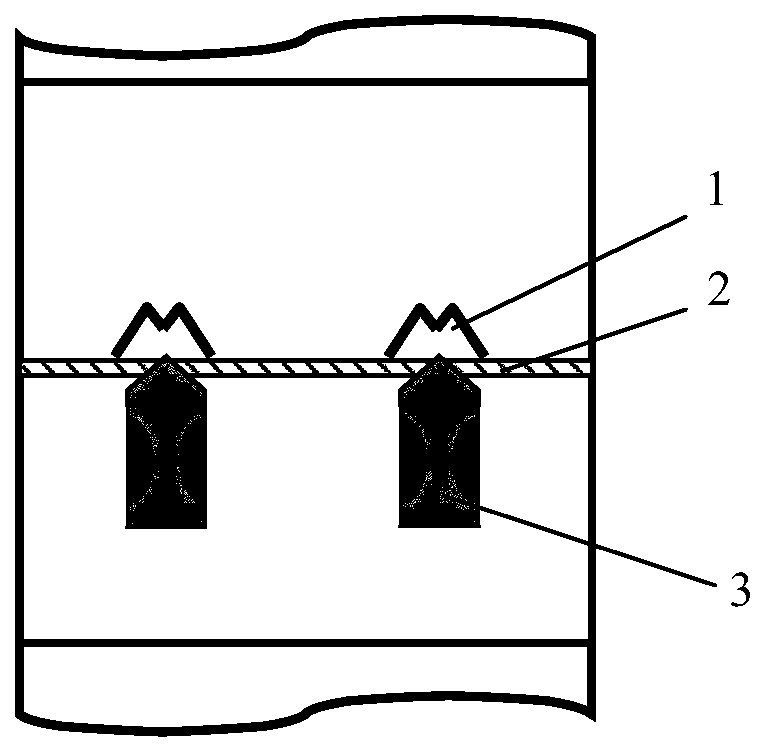

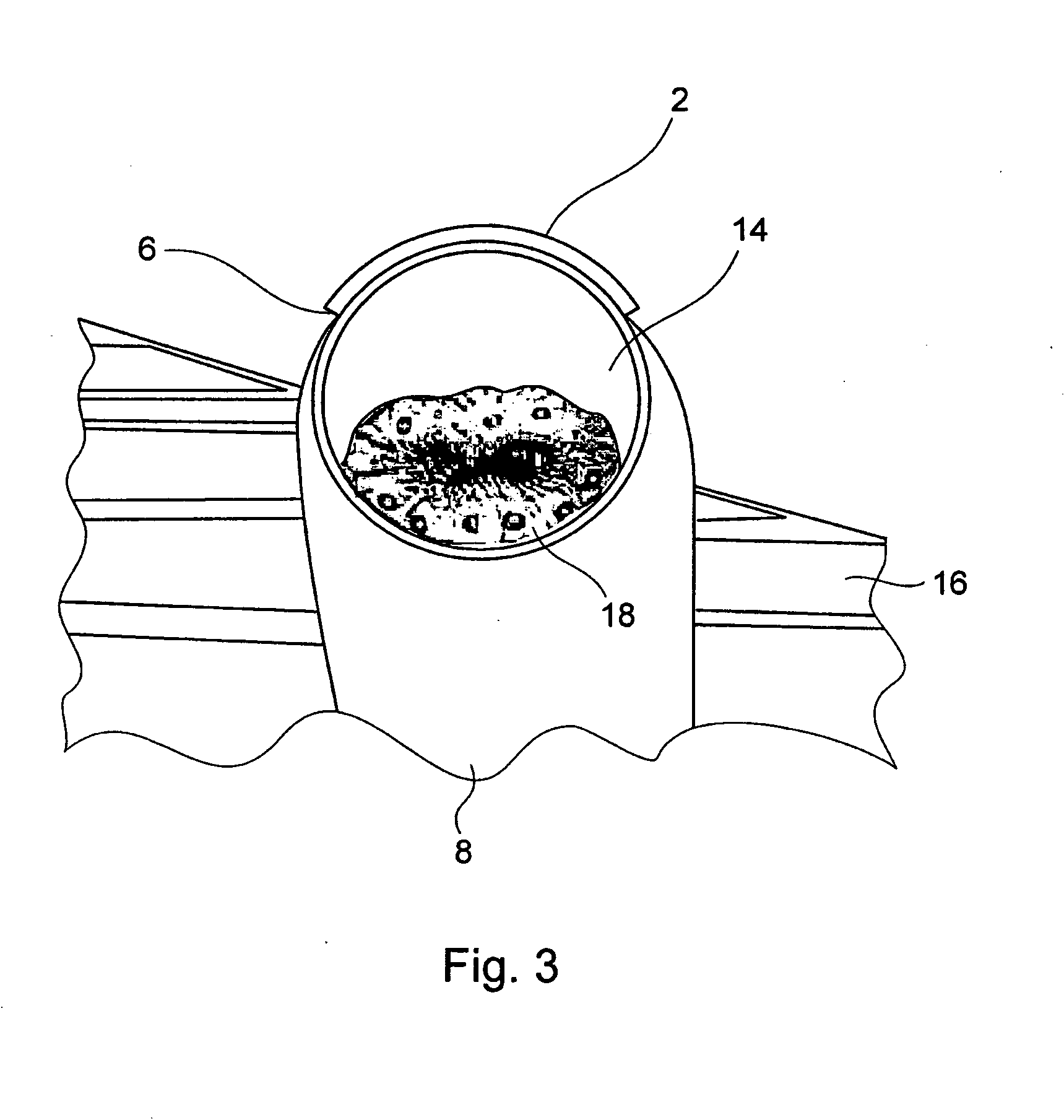

Karman vortex street shaped runner and drip irrigation emitter comprising same

InactiveCN104488665AStrong turbulenceGood blocking resistanceWatering devicesCultivating equipmentsPhysicsWater irrigation

The invention discloses a karman vortex street shaped runner and a drip irrigation emitter comprising the same, and belongs to the technical field of agricultural water-saving irrigation. The karman vortex street shaped runner consists of two or more karman vortex street shaped runner units, wherein each karman vortex street shaped runner unit comprises a first upper arc-shaped columnar channel, a first lower half-arc-shaped columnar channel, a second lower half-arc-shaped columnar channel and two columnar channels; when being fed into one karman vortex street shaped runner unit from the inlets of the karman vortex street shaped runner unit, liquid passes through a sudden expansion part, a sudden shrinkage part, a sudden expansion part and a sudden shrinkage part in sequence, and enters the next karman vortex street shaped runner unit from the outlet of the karman vortex street shaped runner unit. The drip irrigation emitter comprises a runner base body and the karman vortex street shaped runner formed in the surface of the rubber base body, wherein a water inlet groove and an irrigation emitter outlet are respectively formed in two ends of the karman vortex street shaped runner. The karman vortex street shaped runner and the drip irrigation emitter comprising the same are large in passage cross section, low in vortex energy consumption, intense in turbulent fluctuation and good in flow uniformity.

Owner:XI AN JIAOTONG UNIV

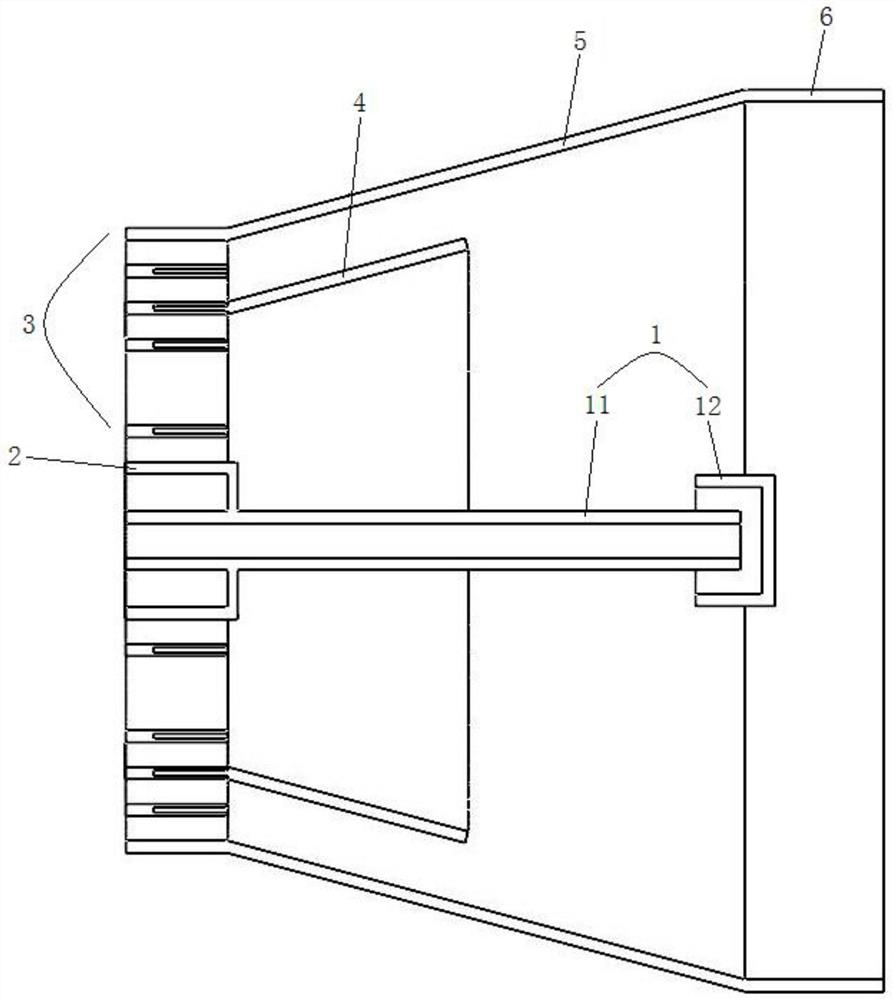

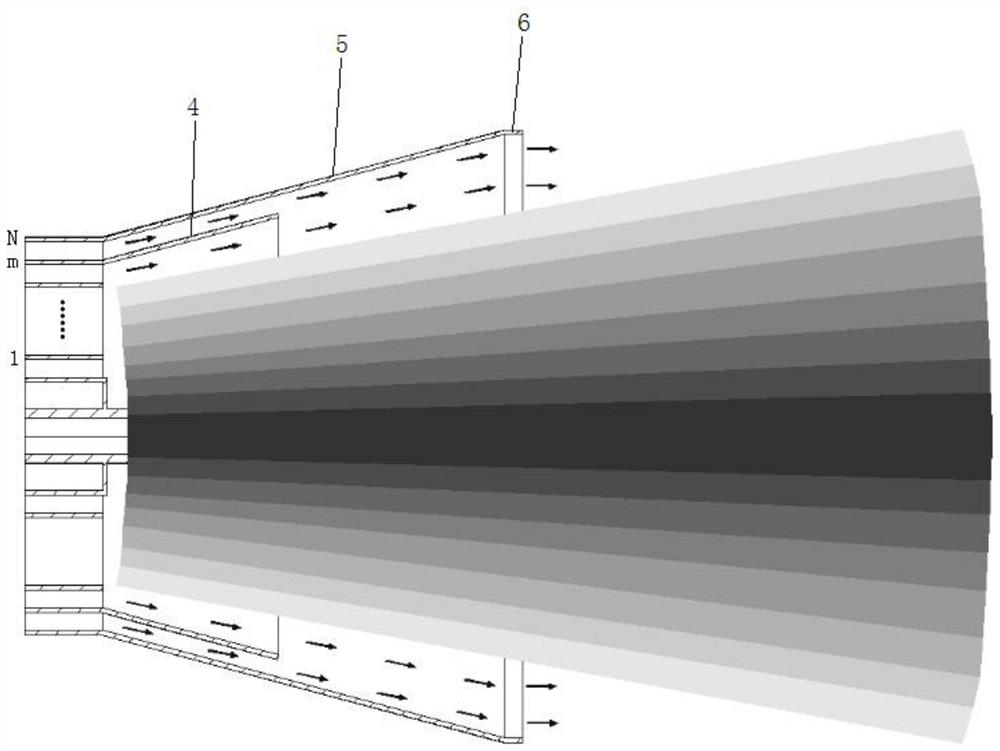

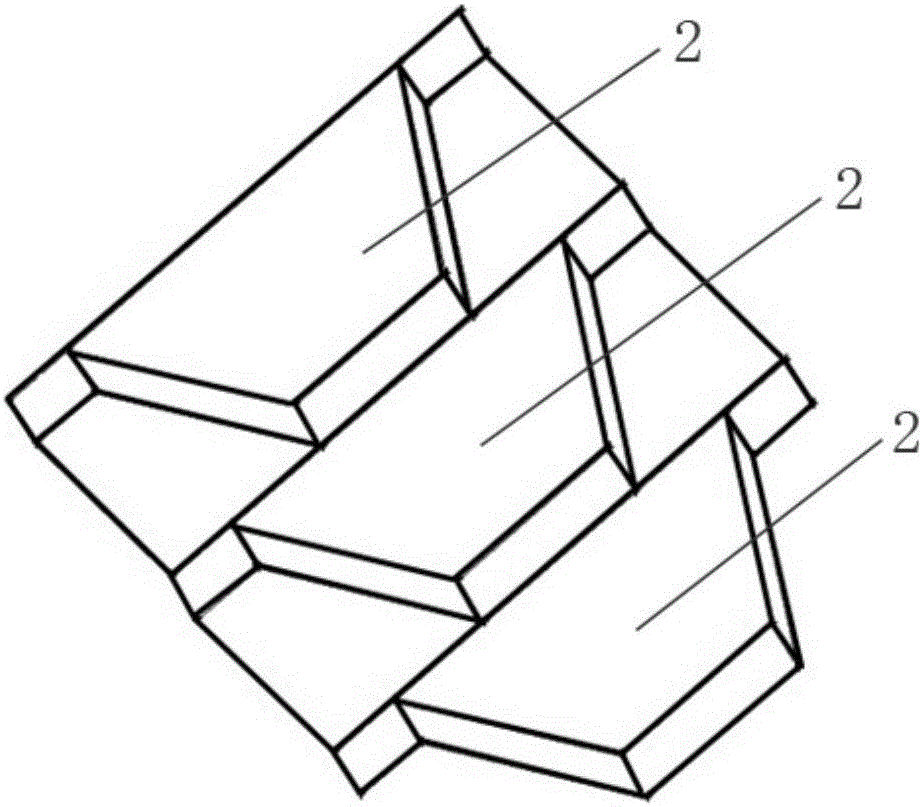

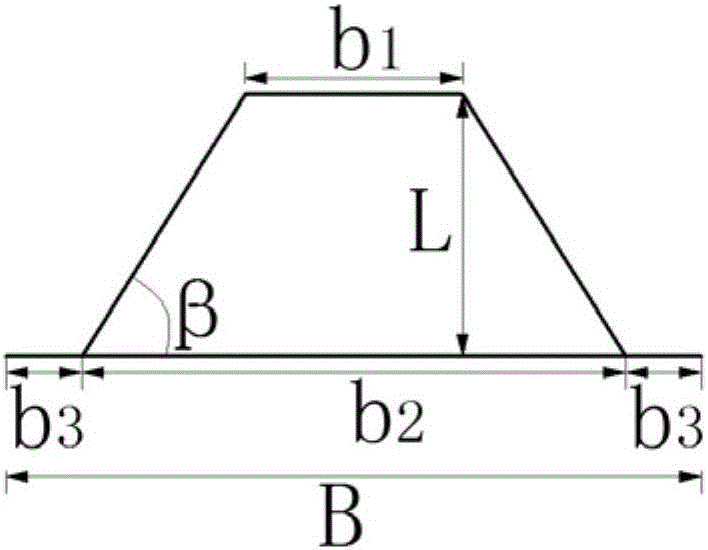

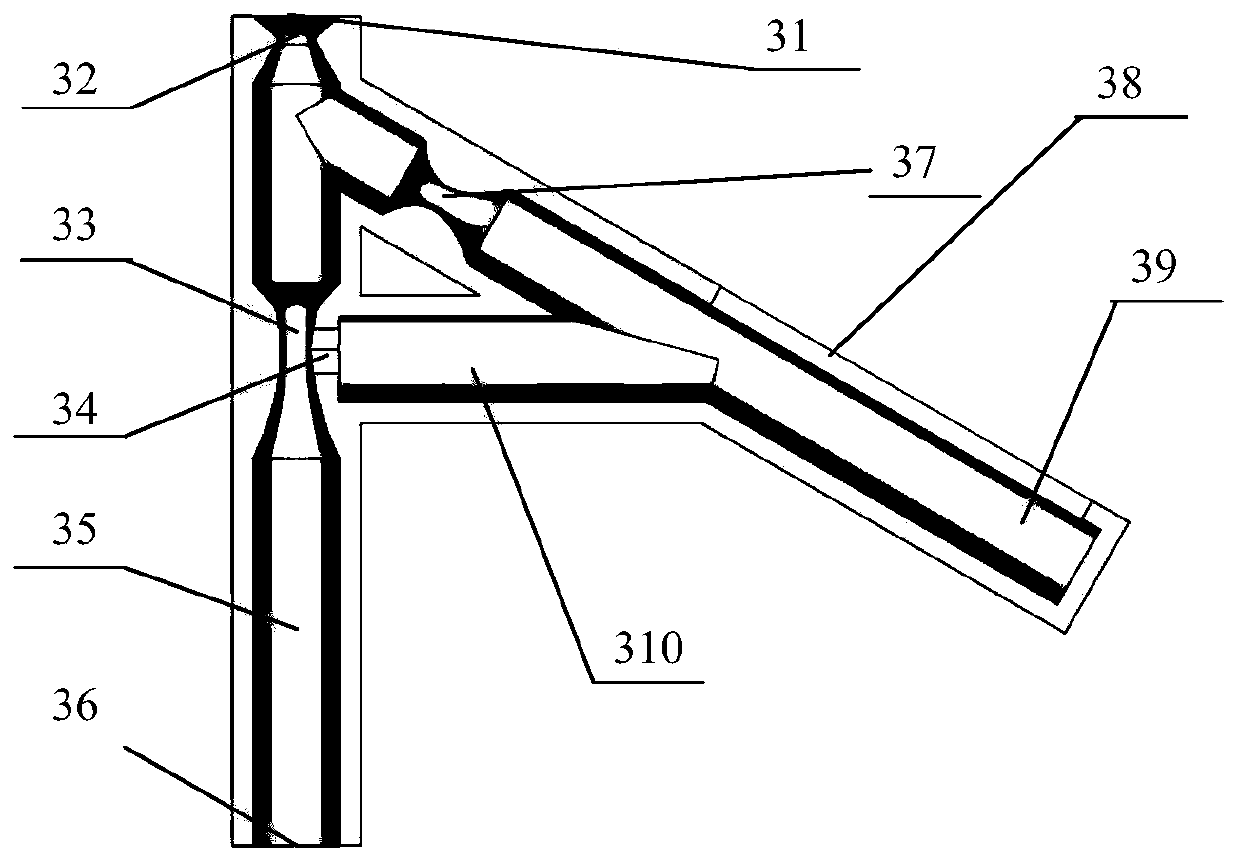

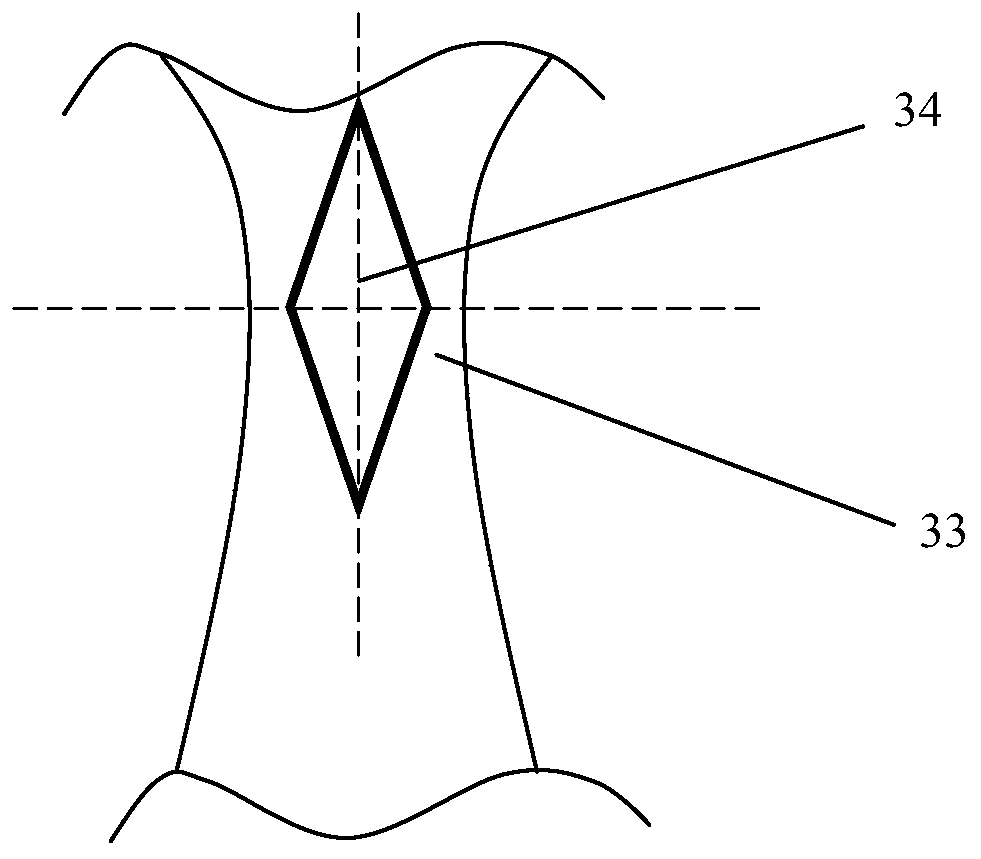

Multi-channel reverse injection type swirl single cone combustor and use method thereof

PendingCN111895400AIncrease mixing rateFire stablePulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a multi-channel reverse injection type swirl single cone combustor and a use method thereof. The combustor comprises a pulverized coal supply mechanism, a transition channel,a multi-stage air distribution assembly, diversion plates, a stable combustion cavity and a rectifying cavity; the multi-stage air distribution assembly comprises N air ducts, the N air duct is connected with the stable combustion cavity and the rectifying cavity in sequence to form a combustor body, the pulverized coal supply mechanism penetrates through the inner part of the combustor body,and the transition channel sleeves the pulverized coal supply mechanism; except for the N air duct, the other air ducts are of double-layer hollow structures, and one end of at least one diversionplate is inserted into the corresponding air duct; at least one direct current channel is formed between each diversion plate and the stable combustion cavity, flaring is formed in the other end of each diversion plate, and the angle of the flaring is the same as the angle of the stable combustion cavity. The combustor adopts the design of the multi-stage air distribution assembly, air is dividedinto N strands to enter the combustor body, and the turbulence intensity at the airflow boundary is strong, so that the air and powder mixing rate is strengthened, pulverized coal ignites stably, andhigh-efficiency and low-nitrogen combustion of the pulverized coal can also be guaranteed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Special-shaped step energy dissipater

InactiveCN106436659AStrong turbulenceGood energy dissipation effectBarrages/weirsWater flowEngineering

The invention discloses a special-shaped step energy dissipater and belongs to the field of flood discharge and energy dissipation facilities in the water conservancy and hydropower engineering. The special-shaped step energy dissipater comprises steps in different stair shapes, and the steps in different stair shapes are formed by stacking a plurality of trapezoidal steps, triangular steps, dovetail-shaped steps and tongue-shaped steps, wherein the vertical faces of each step are multi-surfaces or curved surfaces. The energy dissipater is applicable to stair energy dissipation of a low-Froude-number and large discharge per unit width spillway or flood discharging tunnel, the energy dissipation rate is effectively increased, and the cavitation and cavitation erosion risk is reduced; and water flow of a traditional rectangular step energy dissipater is two-dimensional flow, water flow of the special-shaped step energy dissipater is three-dimensional flow, the vortex on the special-shaped steps has various dimensions and is a three-dimensional vortex, the water flow turbulence is strong, and therefore the energy dissipation effect is superior to that of a rectangular step spillway or flood discharging tunnel under the same condition. The special-shaped step energy dissipater can serve as a main energy dissipater in flood discharge and energy dissipation of the low-Froude-number and large discharge per unit width spillway or flood discharging tunnel.

Owner:SICHUAN UNIV

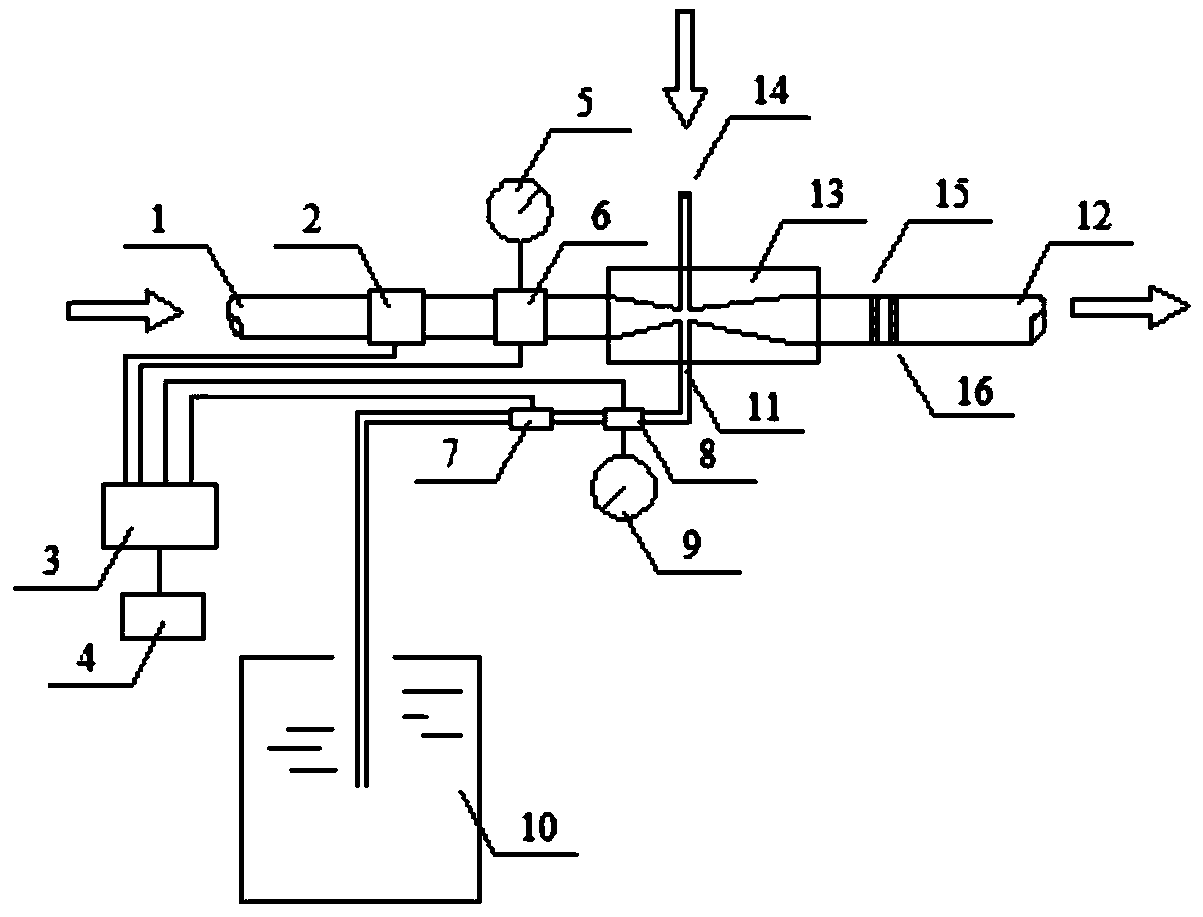

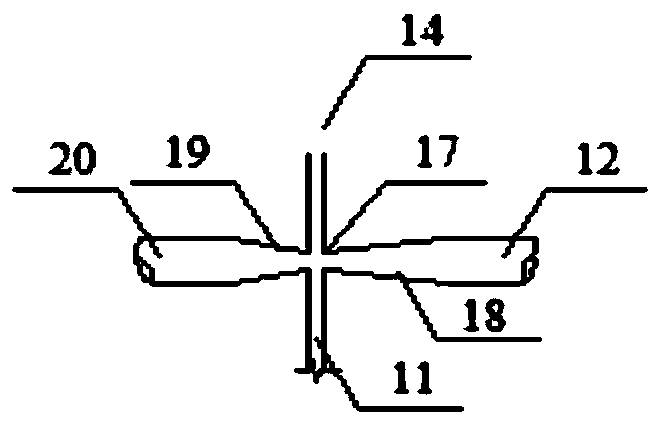

Hydraulic precise proportional fertilizer applicator

InactiveCN110122028ANo external power requiredStrong turbulencePressurised distribution of liquid fertiliserMicrocomputerGas phase

The invention discloses a hydraulic precise proportional fertilizer applicator and belongs to the technical field of agricultural tools. The fertilizer applicator comprises an inlet section, an outletsection, a fertilizer suction pipe, a single-chip microcomputer and a venturi tube, wherein flow regulators and electromagnetic flowmeters are arranged on the inlet section and the fertilizer suctionpipe; the single-chip microcomputer is connected with a first flow regulator, a second flow regulator, a first electromagnetic flow meter and a second electromagnetic flow meter and monitors and controls the flows in the inlet section and the fertilizer suction pipe; the inlet section and the outlet section are connected through the venturi tube; the venturi tube comprises an inlet section, a contraction section, a throat and a diffusion section. When water flow flows through the contraction section of the venturi tube, negative pressure can be produced at the throat part, fertilizer liquidand air are sucked in a pipeline to be mixed with water to form a gas phase flow and a liquid phase flow, and the fertilizer liquid and water are fully mixed while the automatic fertilizer suction process is realized. The fertilizer applicator has the advantages that fertilizer application is precise, the concentration of the fertilizer liquid is adjustable, the structure is simple and the like; meanwhile, the fertilizer applicator is convenient to operate and has considerable economic benefits.

Owner:JIANGSU UNIV

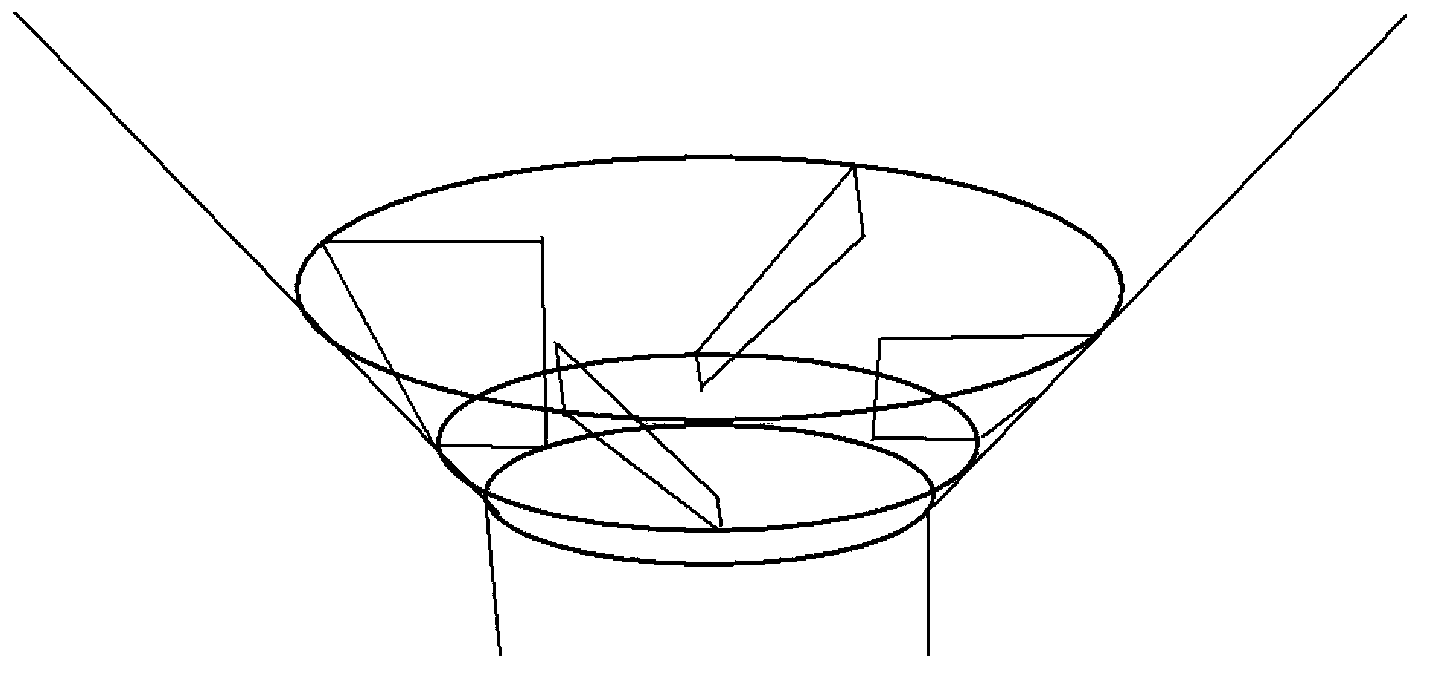

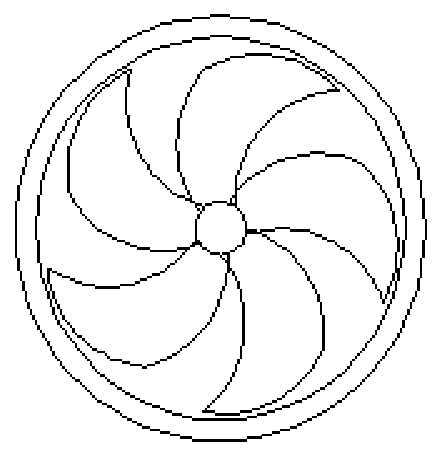

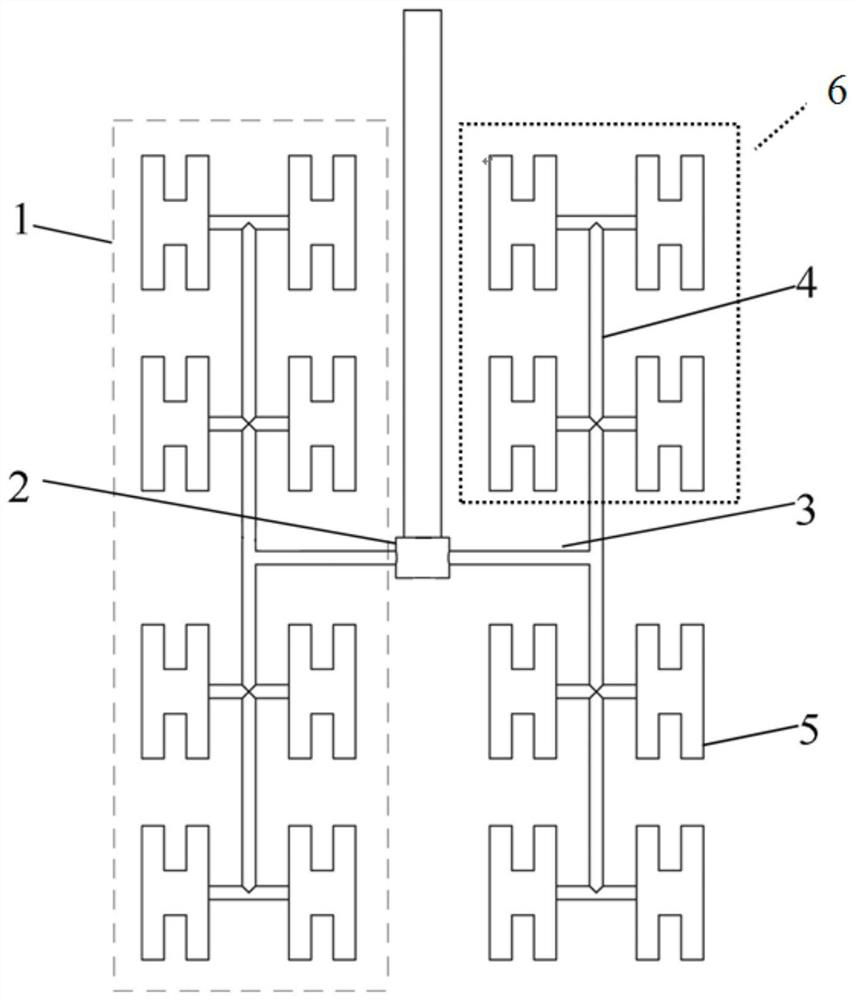

Fractal bubble configuration controllable type slurry bed reactor

PendingCN110270282AScale controllableStrong turbulenceHydrocarbon oil crackingHydrocarbon oils refiningJet flowGas phase

The invention relates to a fractal bubble configuration controllable type slurry bed reactor, and belongs to a gas-liquid reactor device. The bubble controllable strong mixing is conducted at different reactor heights. According to a strong mixing internal part, a plurality of A-type strong mixing components are evenly distributed on a supporting partition plate of the reactor, and an M-type distribution component is arranged on the upper side of each A-type strong mixing component. Each A-type strong mixing component comprises a liquid phase lifting pipe, a gas phase lifting pipe, a short connection transverse pipe and a tail end nozzle, wherein liquid in the liquid phase lifting pipe is mixed with gas from the gas phase lifting pipe and the short connection transverse pipe, the mixture enters the tail end nozzle to release nitrogen bubbles of multiple dimensions, and the local liquid phase jet flow is formed above the partition plate. According to the slurry bed reactor, small bubbles are generated in throat pipes of the liquid phase lifting pipes through liquid phase entrainment, large bubbles are formed in the tail end nozzles through curved surface nozzle shearing, the gas-liquid flowing is even, the gas-liquid level below the partition plate is stable, the bubbles formed above the partition plate are controllable in dimensional, the liquid phase turbulence is strong, and the heat removal and mass transfer of the slurry bed reactor are facilitated.

Owner:EAST CHINA UNIV OF SCI & TECH +2

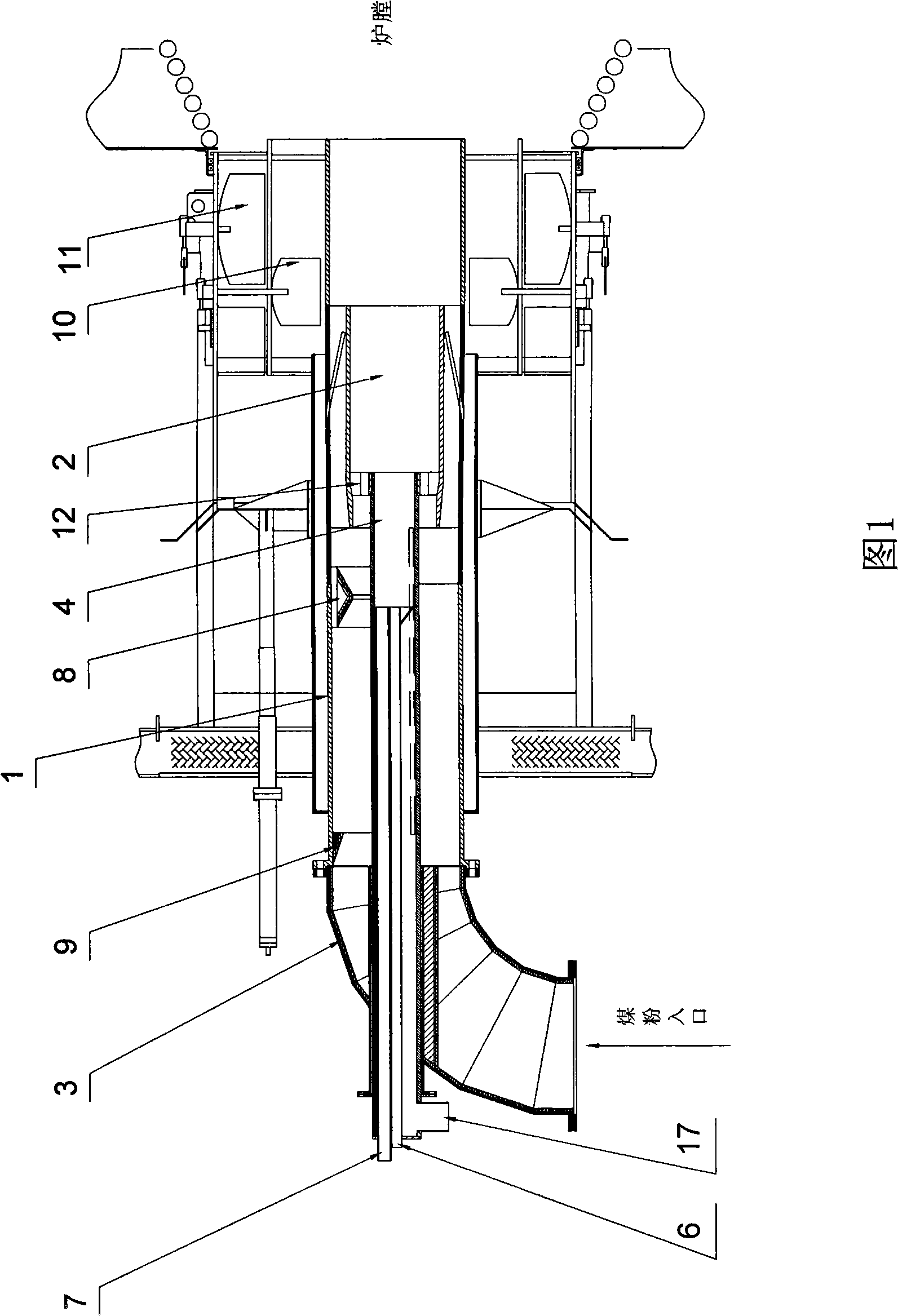

Low NOx cyclone micro-oil coal powder burner

InactiveCN101290119AStrong turbulenceEmission reductionPulverulent fuel combustion burnersCycloneCombustion chamber

Aiming at the disadvantages that the prior cyclone pulverized coal burner can not effectively reduce the emission amount of NOx, the invention provides a low-NOx cyclone micro-oil pulverized coal burner which reduces mass NOx in the igniting and burning process. The low-NOx cyclone micro-oil pulverized coal burner comprises a burner body and a primary pulverized coal burning chamber arranged inside the burner body; an inlet of the burner body is connected with an elbow piece; an inlet of the primary pulverized coal burning chamber is provided with an oil burning chamber which is inserted into the primary pulverized coal burning chamber from the elbow piece; the burner body is provided inside with a pulverized coal concentrated ring; an outlet of the burner body is provided with a secondary wind port inside the cyclone and a secondary wind port outside the cyclone; an outlet of the oil burning chamber and an inlet of the primary pulverized coal burning chamber are provided with a pulverized coal distributor. The burner can use a small quantity of fuel to ignite the pulverized coal in the burning chamber; the pulverized coal in the burning chamber has large concentration in order that the burning is in reducing atmosphere and mass NOx is deacidized, thereby reducing the emission of pollutant.

Owner:杭州意能节能技术有限公司

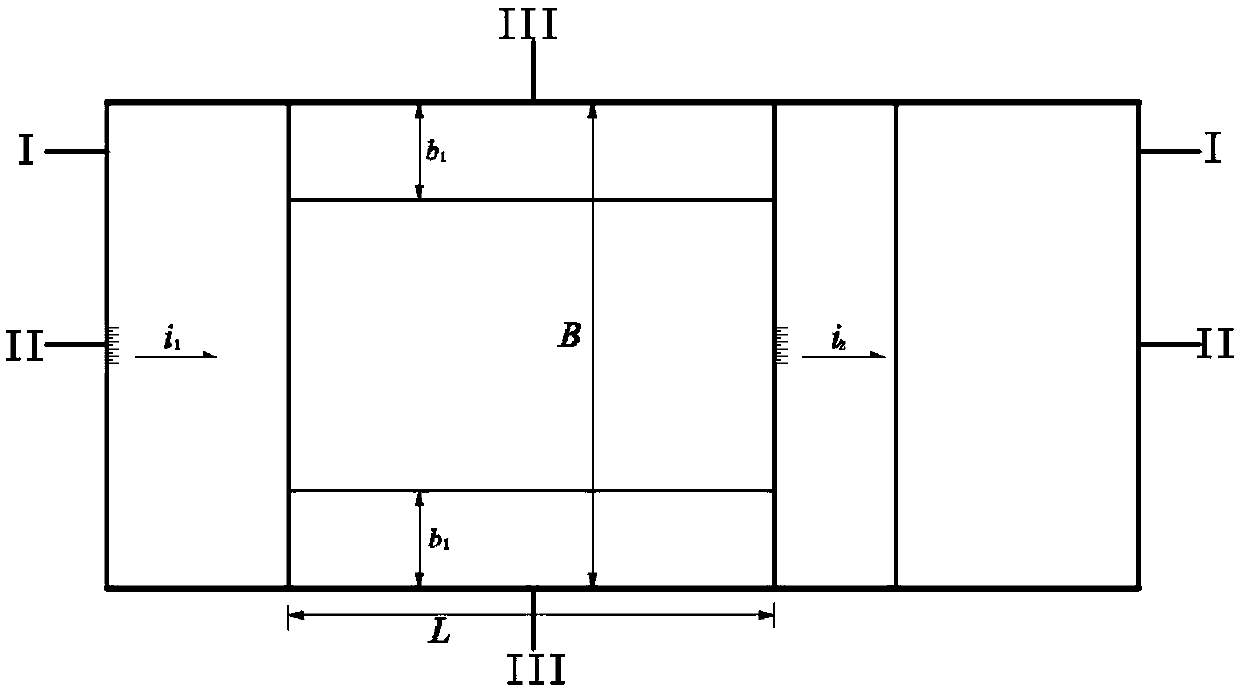

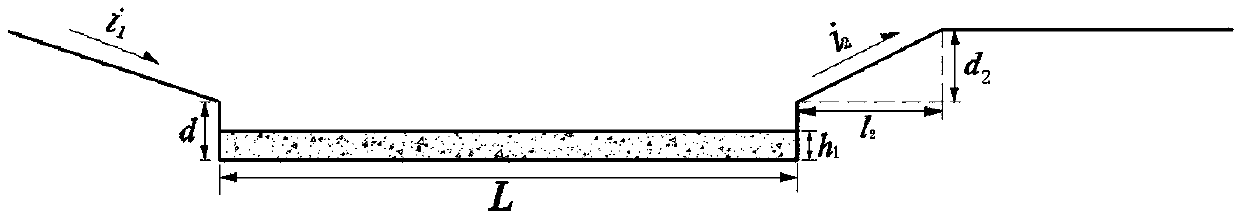

Differential falling-sill type stilling pool

The invention aims to provide a differential falling-sill type stilling pool and relates to a novel stilling pool. The differential drop-sill type stilling pool comprises a diversion connection reverse slope section, a differential falling-sill stilling pool main body section and a stilling pool tail sill reverse slope section which are sequentially connected in the water flow direction, wherein the stilling pool tail sill reverse slope section is connected with a downstream apron, and a plurality of longitudinal sills protruding from a bottom plate are arranged on a bottom plate in the differential falling-sill stilling pool main body section in the water flow direction. The differential drop-sill type stilling pool is particularly suitable for underflow energy dissipation of high-speed water flow during flood discharge of hydropower stations, the energy dissipation rate is effectively increased, the hydraulic index near the bottom is reduced, protection engineering of downstream river slope of the stilling pool is reduced and even removed, and thus, construction funds are saved.

Owner:SICHUAN UNIV

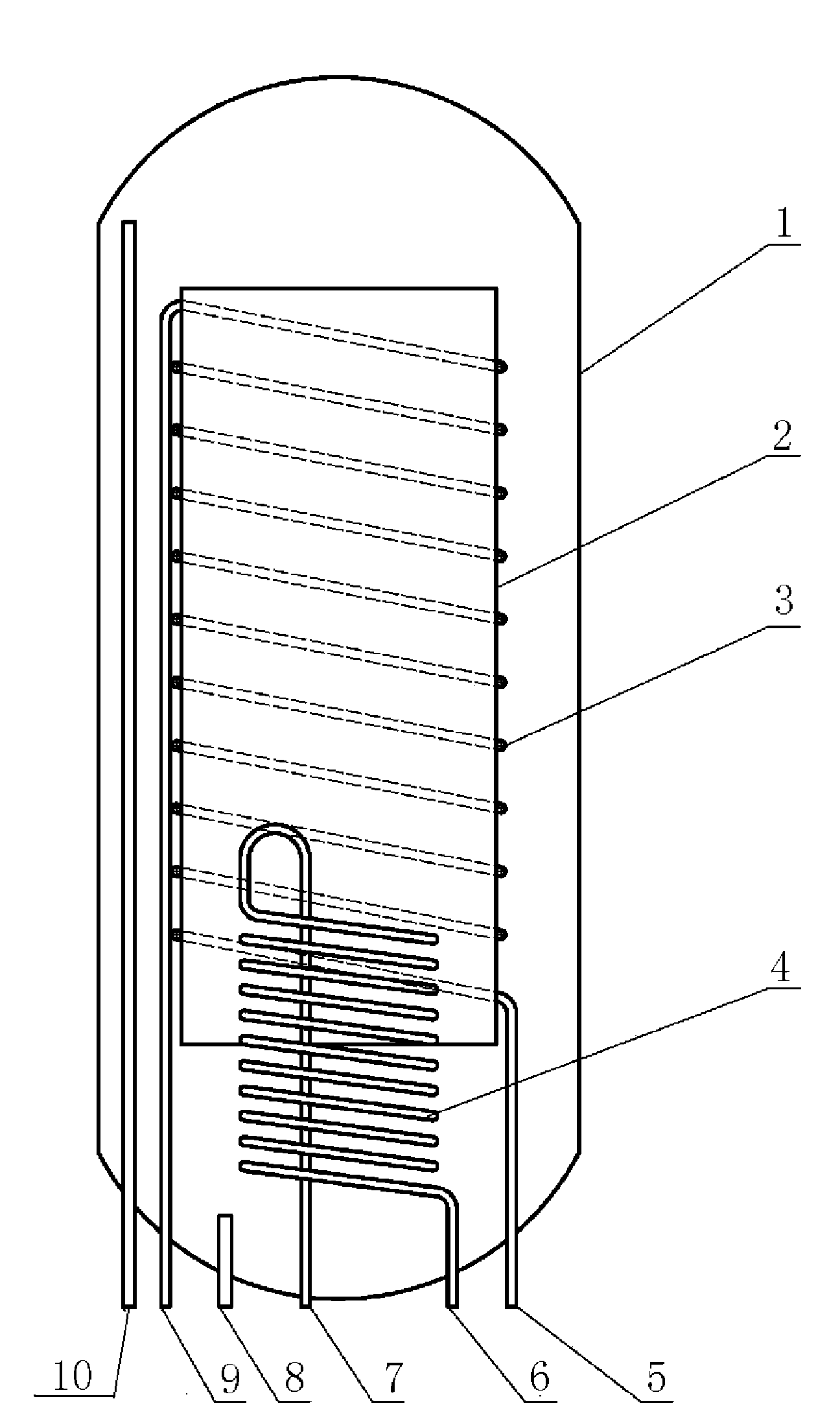

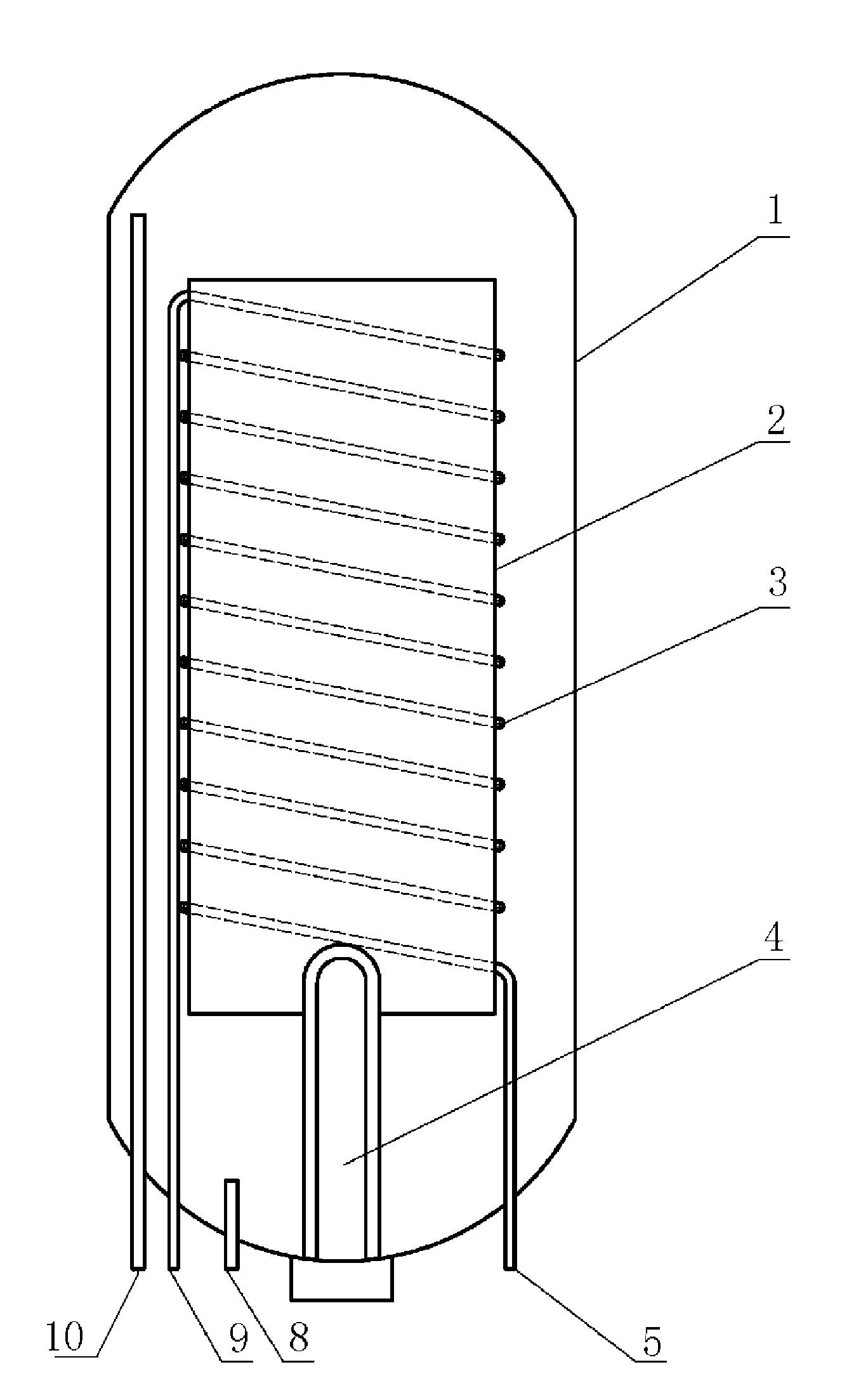

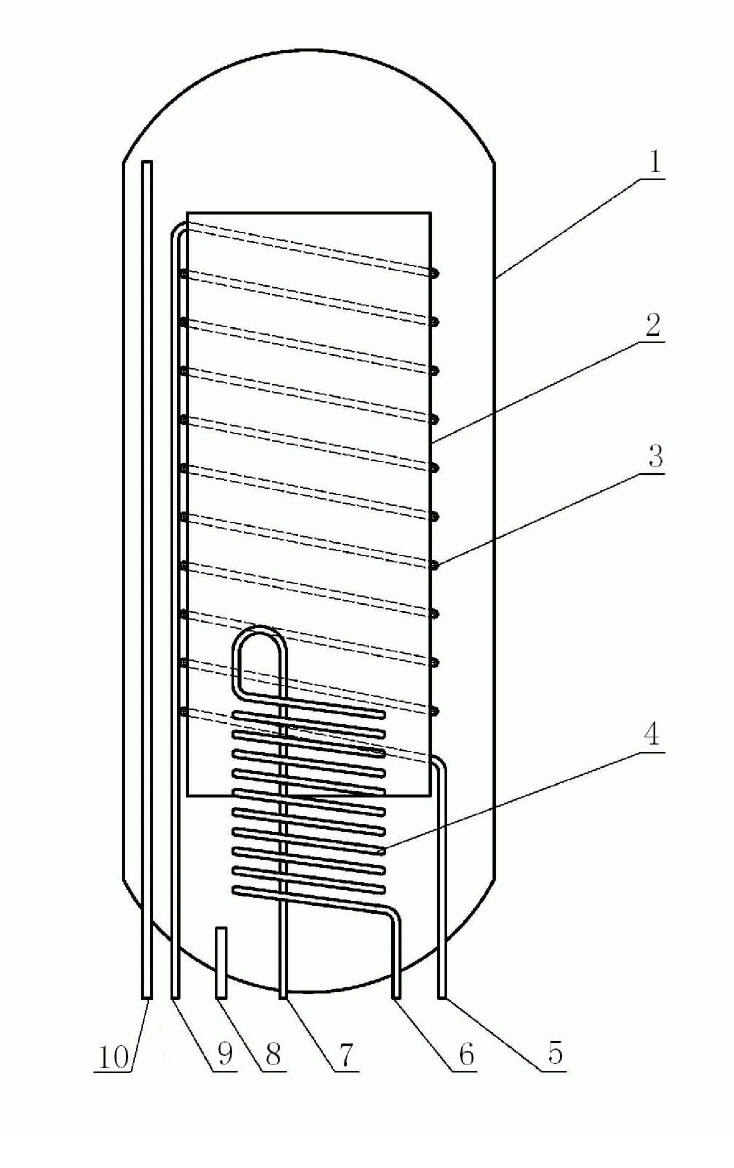

Heat exchange and flow guide structure of hot water storage tank

InactiveCN101825411AImprove anti-corrosion performanceImprove fouling problemHeat storage plantsHeat exchanger casingsEngineeringProduced water

The invention relates to a heat exchange and flow guide structure of a hot water storage tank, which realizes temperature layering of thermal mediums in a hot water storage tank in the using process and avoids mixing of cold water and hot water in the hot water storage tank, so that the water outlet temperature of a heat exchanger is stably maintained above the required temperature for a long time, the produced water which can meet using requirement is increased and the heat utilization efficiency in the hot water storage tank is sufficiently improved.

Owner:李博峰

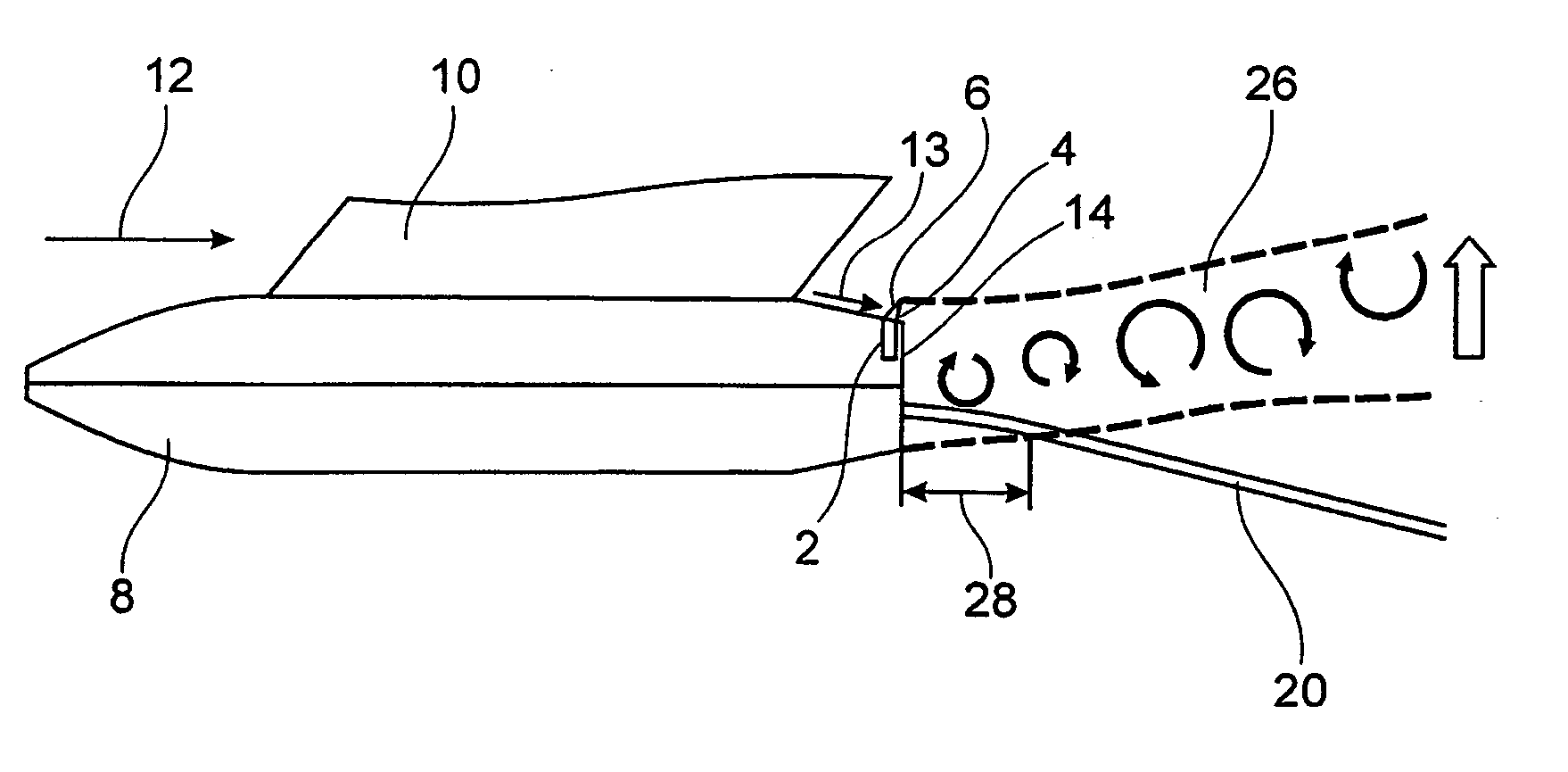

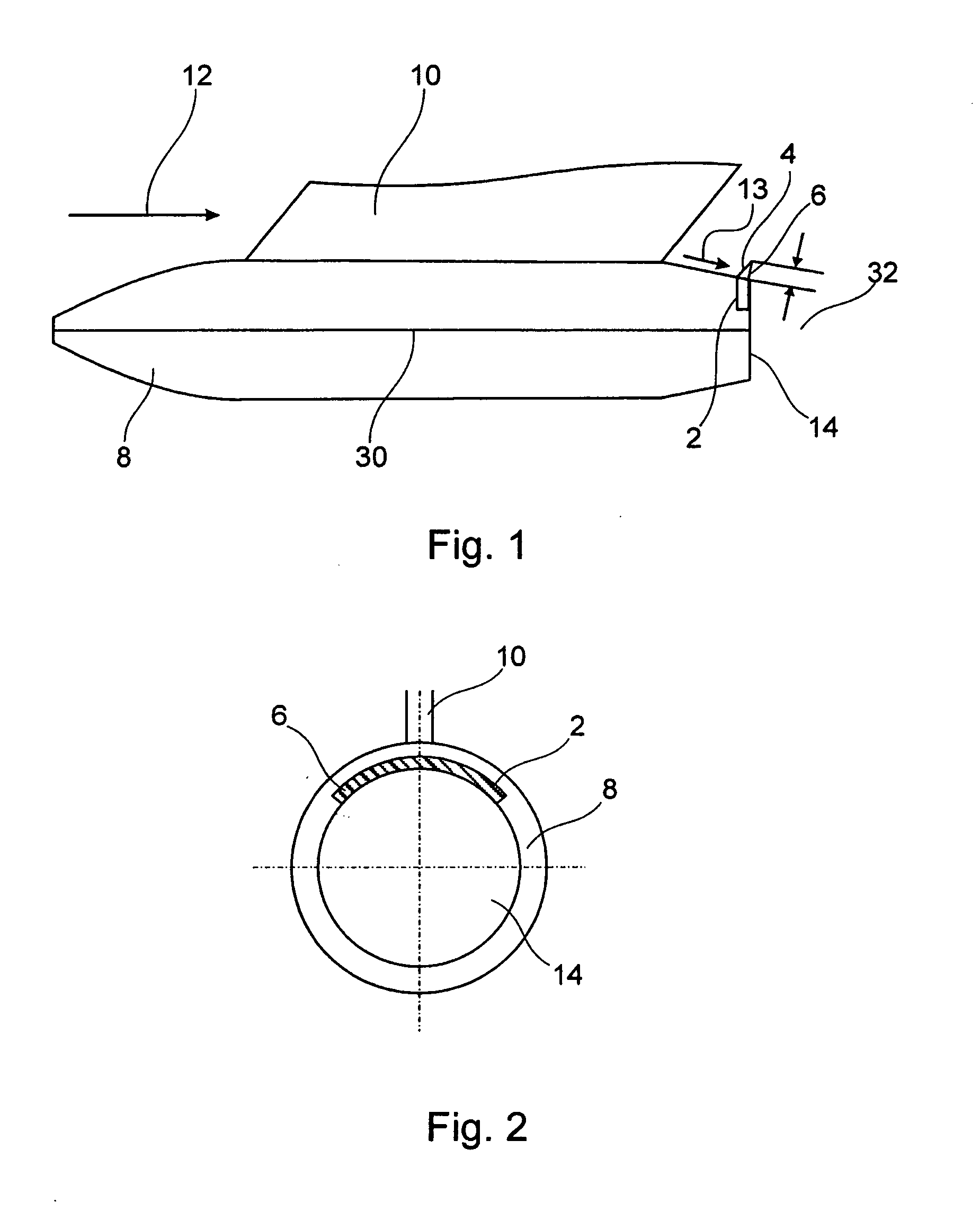

Deflection device for a stream body

ActiveUS20080142640A9Good effectRemarkable effectAircraft stabilisationAir braking surfacesInstabilityEngineering

The present application describes to a deflection device, for example, for a blunt stream body. The deflection device has an edge, which, for example, can be mounted to the stream body. In an advantageous manner, the deflection device allows an influencing of the slipstream in such a way that turbulences, which are connected with the slipstream and form downstream of blunt stream bodies, have as little influence as possible on the dragged object in order to avoid the formation of building-up motions of the dragged object, which lead to instabilities.

Owner:AIRBUS OPERATIONS GMBH

Device for purifying oily wastewater

InactiveUS8828224B2Simple but reliable treatment processReduce investmentWaste water treatment from quariesTreatment involving filtrationFlocculationFiltration

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Acid-resistant reaction device

InactiveCN105771838AStrong acid resistanceImprove sealingChemical/physical/physico-chemical stationary reactorsFeed devicesGlass fiberExhaust valve

The invention discloses an acid-resistant reaction device, comprising a tank body and a tank cover. Each of the tank body and the tank cover comprises a steel reinforced concrete layer, a glass fiber reinforced plastic layer, a temperature and acid resistant ceramic tile layer and an acid resistant porcelain plate layer from outside to inside; a feeding hole, an exhaust valve and a steam connector are arranged on the tank cover; a stirring device for stirring a reaction solution is further arranged in the tank body; the exhaust valve comprises a valve body, an air inlet and a connecting structure connected with the tank cover in a sealing manner are arranged at the bottom of the valve body; an exhaust hole is formed at the top of the valve body; a lower cavity communicated with the air inlet and an upper cavity communicated with the exhaust hole are formed in the valve body; an exhaust passage is formed between the lower cavity and the upper cavity; a floating plug, which is used for plugging the exhaust passage and has density greater than that of air but smaller than that of water, is arranged in the lower cavity; a sealing plug plugging the exhaust passage is arranged in the upper cavity; a spring for pressing the sealing plug on the exhaust passage is arranged in the upper cavity; and an exhaust pipe is arranged on the exhaust hole, and a control valve is arranged on the exhaust pipe.

Owner:CHONGQING HUAXU ENERGY TECH

Algae cultivation systems and methods with bore waves

ActiveUS20170318771A1Enhanced mixing processIncrease gas exchangeBioreactor/fermenter combinationsBiological substance pretreatmentsFisheryEnvironmental engineering

Owner:GLOBAL ALGAE TECH LLC

Process for producing cement clinkers by straws instead of partial fuel coals

The invention discloses a cement production process, and in particular relates to a process for producing cement clinkers by straws instead of partial fuel coals, belonging to the technical field of cement production. The straws are input through a predecomposition kiln after mechanically crushed and processed, and the cement clinkers are produced by the straws instead of partial fuel coals; and smoke gas generated by burning the fuel coals and the straws in a mixing mode, a part of which is processed and exhausted through a novel wet-process cement kiln clinker production process route, and the other part of which is exhausted by virtue of cooling and dust removal through air exhaustion of a bypass air exhaustion pipeline arranged on a smoke chamber between the predecomposition kiln and a rotary kiln. By using the process, rich straw resources are fully utilized, so that the straw utilization rate is improved, precious coal resources are reduced, and an adverse effect that a poor cement production system is caused by substances such as potassium sulphate, sodium sulfate and potassium chloride generated by virtue of reaction of chlor-alkali compounds of the straws serving as a part of fuels is overcome.

Owner:四川利森建材集团有限公司

Fractal blade stirrer

ActiveCN113332937ASimple structureEasy to processChemical/physical/physico-chemical processesEngineeringAnnular array

The invention discloses a fractal blade stirrer, which comprises a fixing sleeve, wherein a plurality of groups of fractalblades are connected to the fixing sleeve and distributed in an annular array with the fixing sleeve as the center, each group of fractal blades comprises at least one small blade, when each group of forming blades comprises a plurality of small blades, the small blades are arranged in a rectangular array, the arrayed small blade groups are symmetrically distributed along a connecting shaft between the fractal blade and the fixing sleeve to form the fractal blade, and the areas of all the small blades are equal. According to the invention, the fractal blade stirrer greatly strengthens uniform mixing of fluids or uniform dispersion among multi-phase fluids, interaction of fractal blades and the fluid leads to consistency in macroscopic scale and shear force and turbulent energy which are uniformly distributed in microscopic scale, the flowing state in a kettle is improved, the fluid mixing efficiency is improved, and the power consumption of the stirrer is reduced; and the fractal blade stirrer is simple in structure and easy to process, and the manufacturing cost is reduced.

Owner:SOUTHEAST UNIV

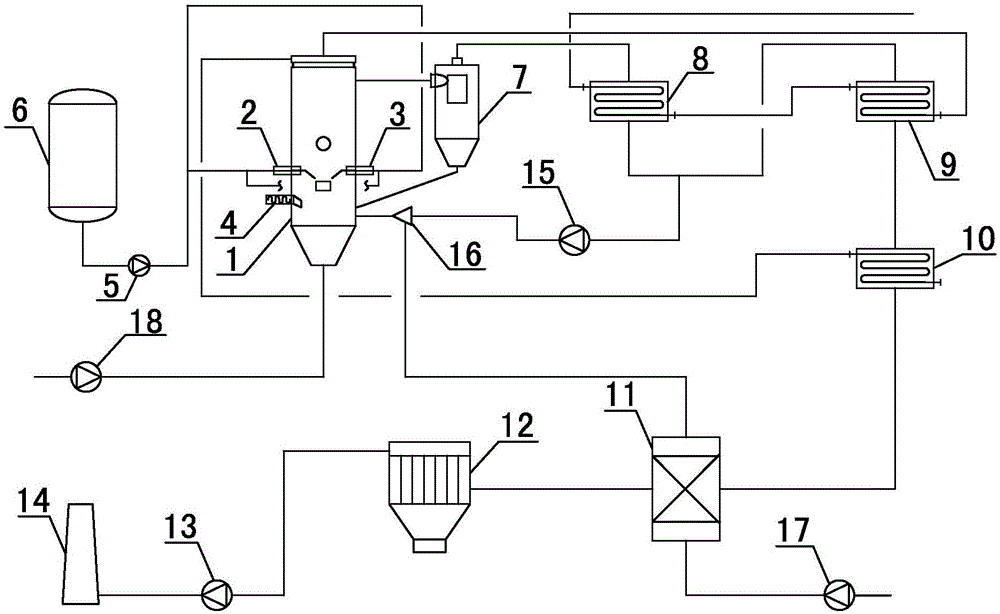

Chemical waste treatment device and treatment process

ActiveCN106215691AImprove adsorption capacityKeep the bed warmSolid waste disposalChemical industryAir preheaterEnergy source

The invention belongs to the technical field of chemical waste treatment, and particularly relates to a chemical waste treatment device and treatment process. The chemical waste treatment device comprises a reactor, wherein a first material gun, a second material gun and a solid material conveyor are arranged at the side part of the reactor; the reactor, a cyclone separator, a front heat exchanger, a rear heat exchanger, an energy-saving heat exchanger, an air preheater, a dust collector, an exhaust fan and a chimney are connected in sequence; a high-temperature fan is connected with the front heat exchanger and the rear heat exchanger; the high-temperature fan, a flue gas mixer and the reactor are connected in sequence; the flue gas mixer is connected with the air preheater; the energy-saving heat exchanger is connected with the reactor; a secondary fan is connected with the air preheater; and a primary fan is connected with the reactor. According to the chemical waste treatment device and treatment process, waste oil, waste gas and solid chemical waste enter into the reactor at the same time for treatment. The waste gas can serve as a preheating energy source, but heavy oil and natural gas do not need to serve as preheating energy sources, so that the cost is relatively low.

Owner:山东天景工程设计有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com