Spraying ammonia mixing system device for SCR flue gas denitrification project

A mixing system and flue gas technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high ammonia escape rate, achieve uniform flow, reduce operating costs, and enhance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a further description of the present invention by taking the SCR flue gas denitration engineering device of a 300MW unit of a certain power plant as an example in conjunction with the figure.

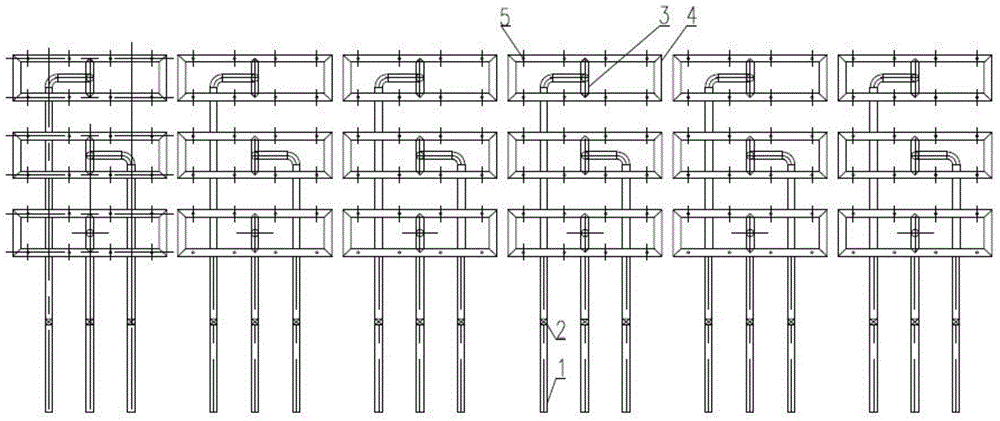

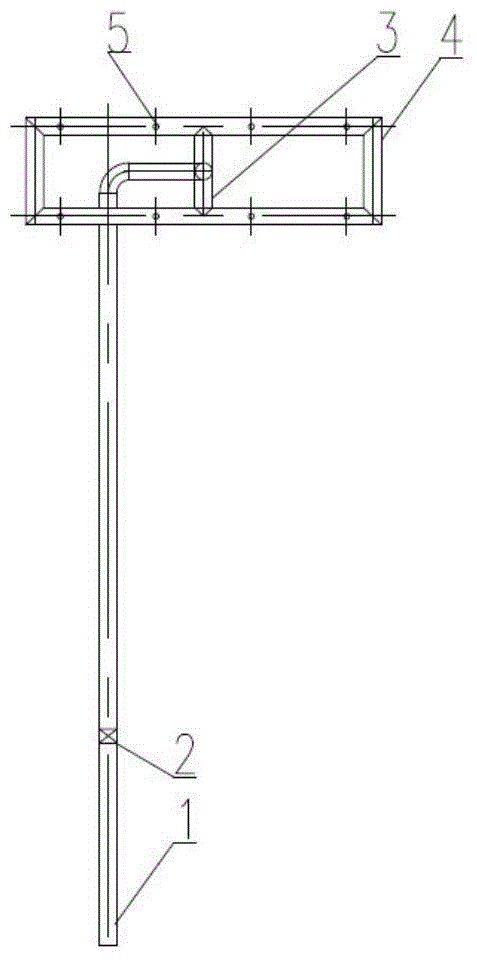

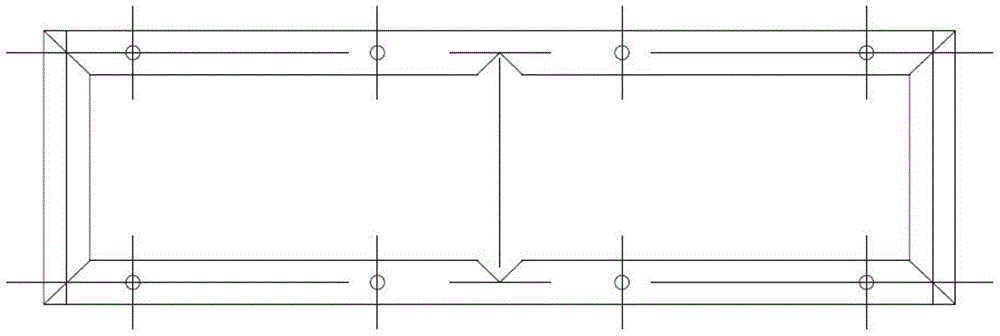

[0017] Such as Figure 5 As shown, the cross section of the flue at the location where the ammonia injection mixing system is installed at the SCR flue gas denitration engineering device of a 350MW unit in a power plant is a rectangle of 2400×10200 (mm). According to the shape and size of the flue cross section, when designing the ammonia injection mixing system , The nozzle spacing is chosen to be 425mm, six groups of ammonia injection mixing units are arranged in the direction of length 10200mm, and three groups of ammonia injection mixing units are arranged in the direction of 2400mm width. There are 18 groups of ammonia injection mixing units, and the total number of nozzles is 144. The size of the connecting nozzle is Φ76×3.5(mm), and each connecting nozzle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com