Patents

Literature

71results about How to "Reduce flow resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

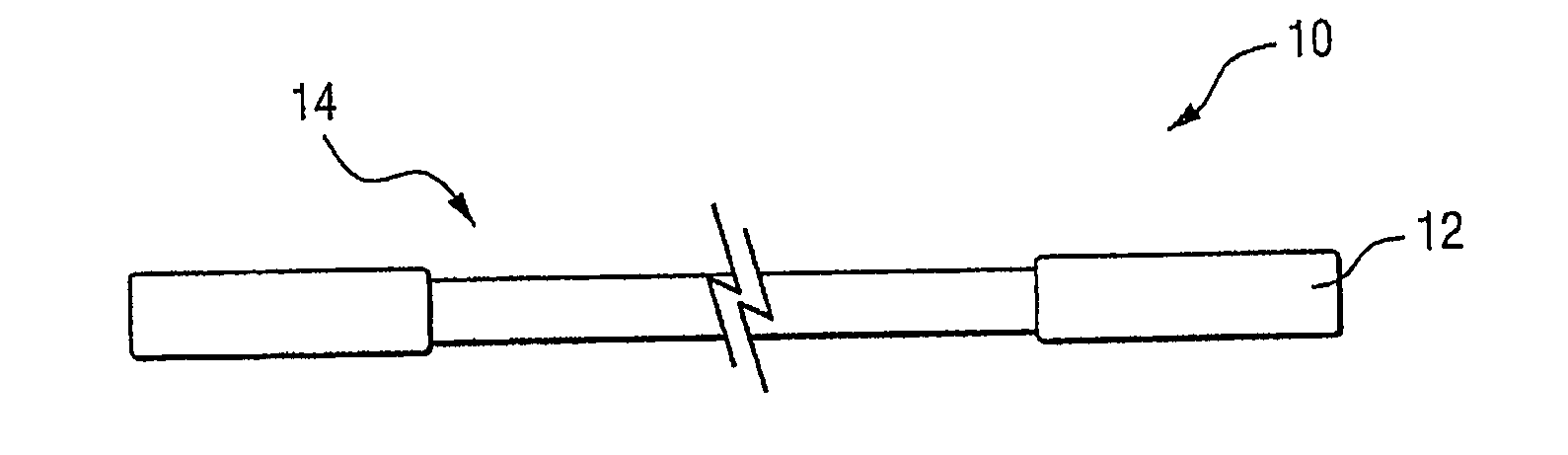

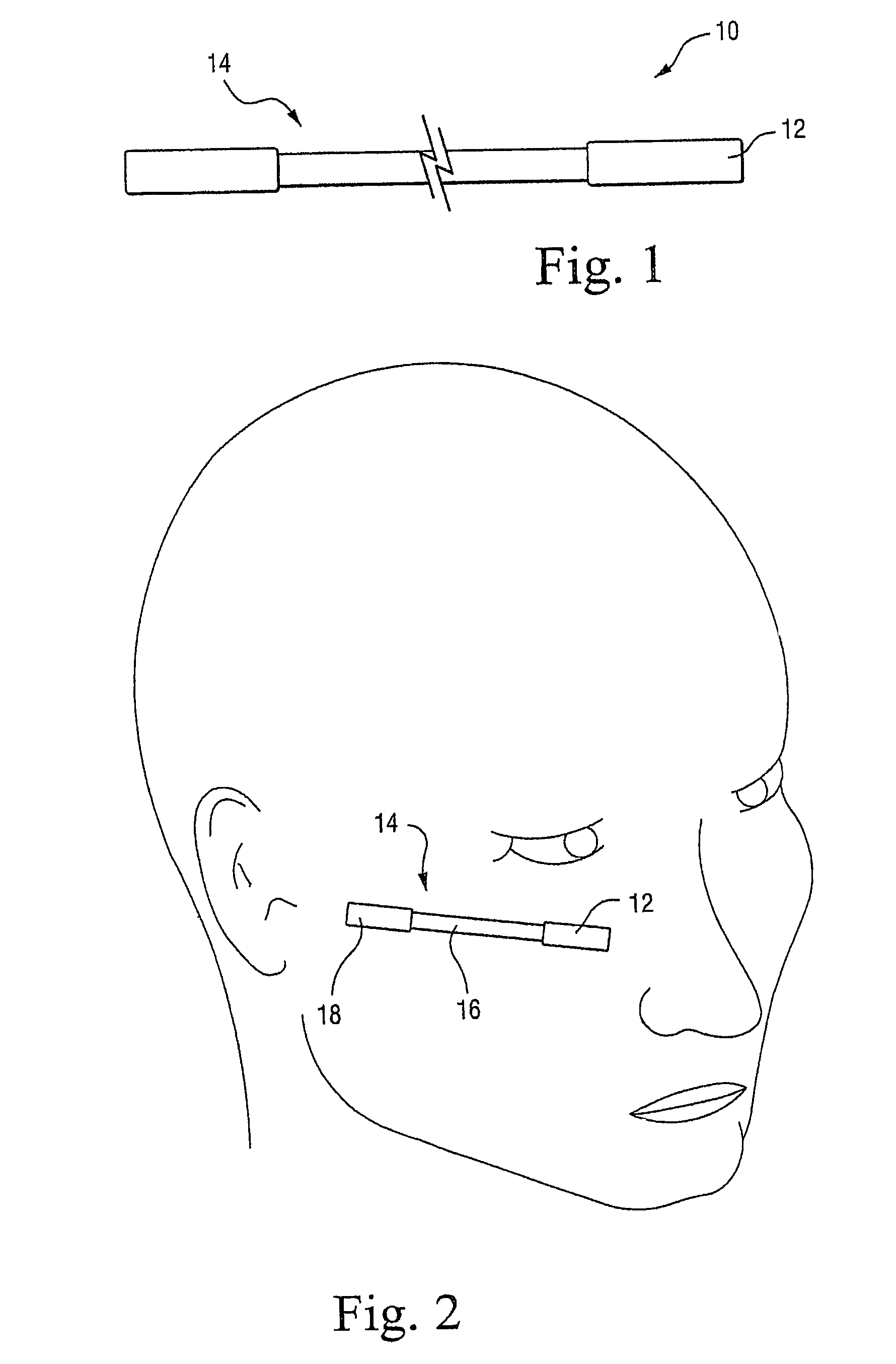

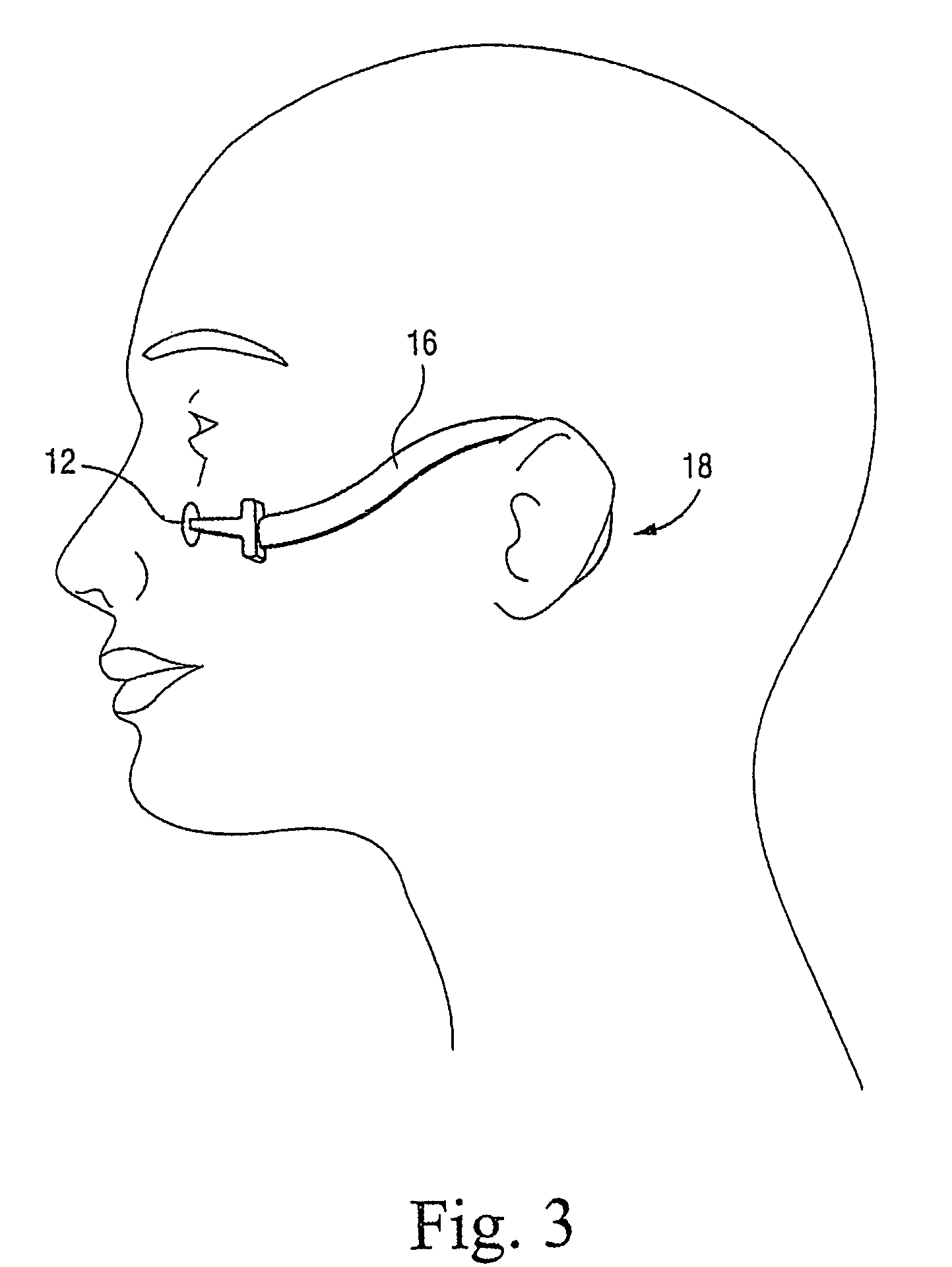

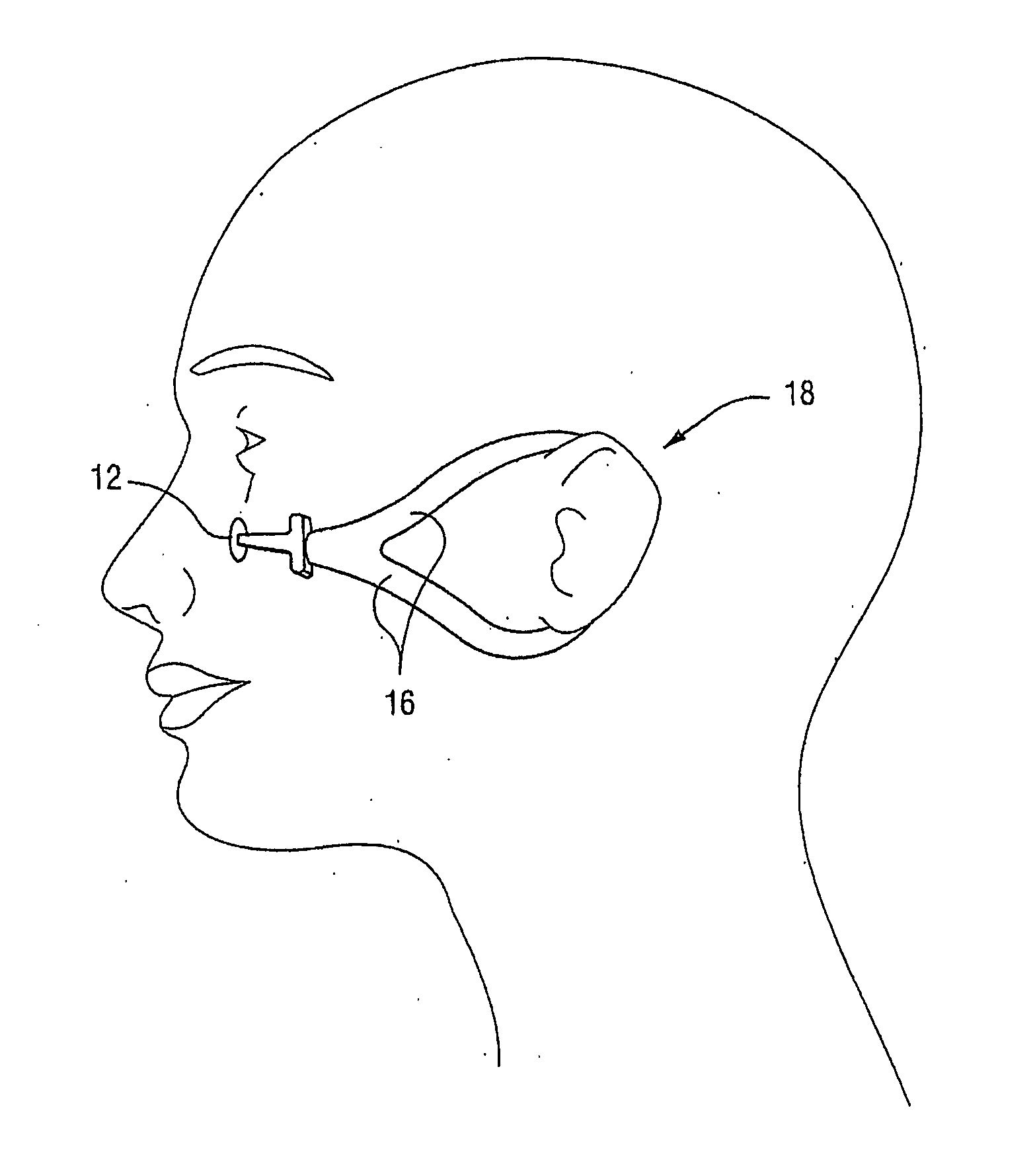

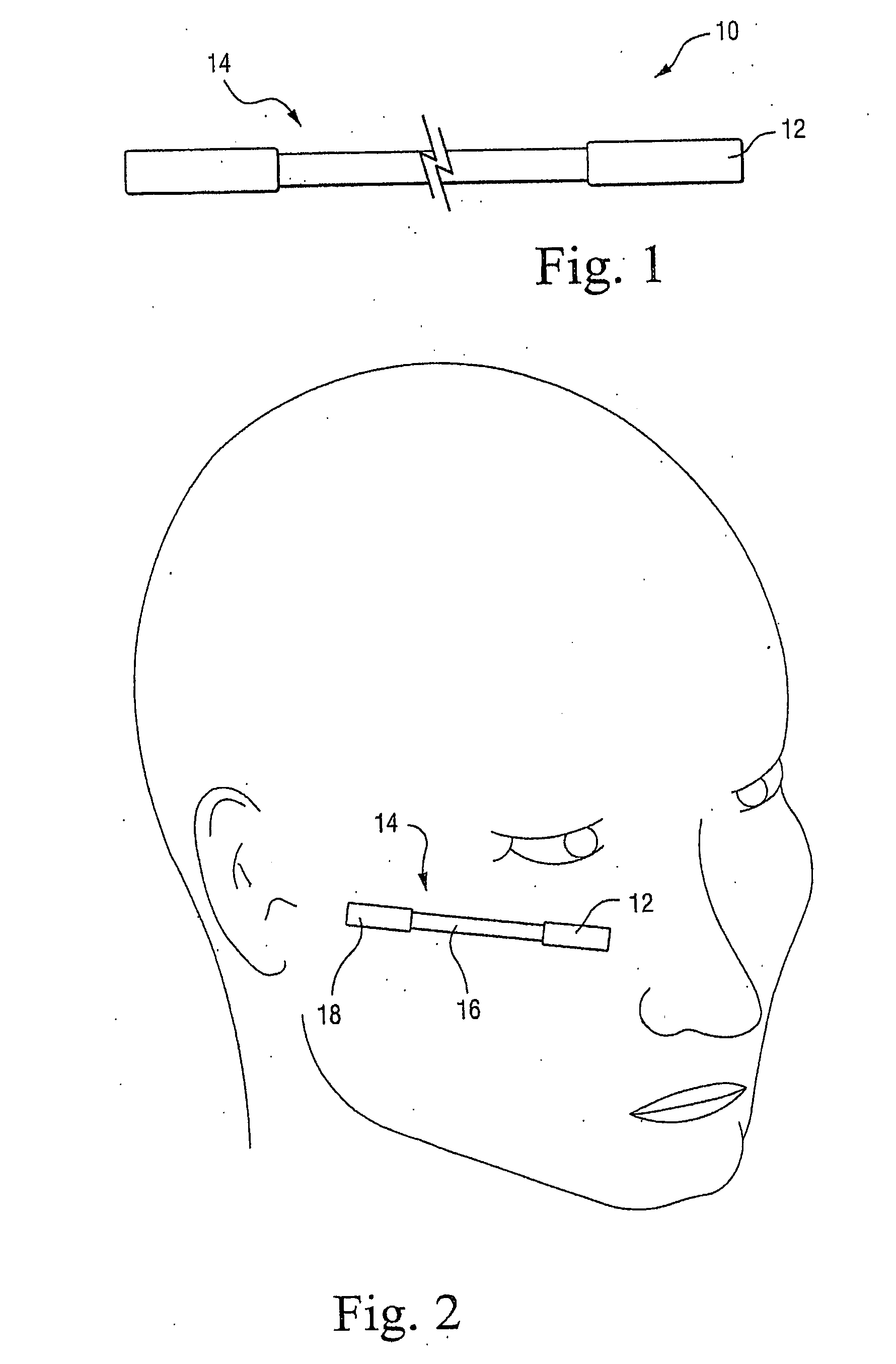

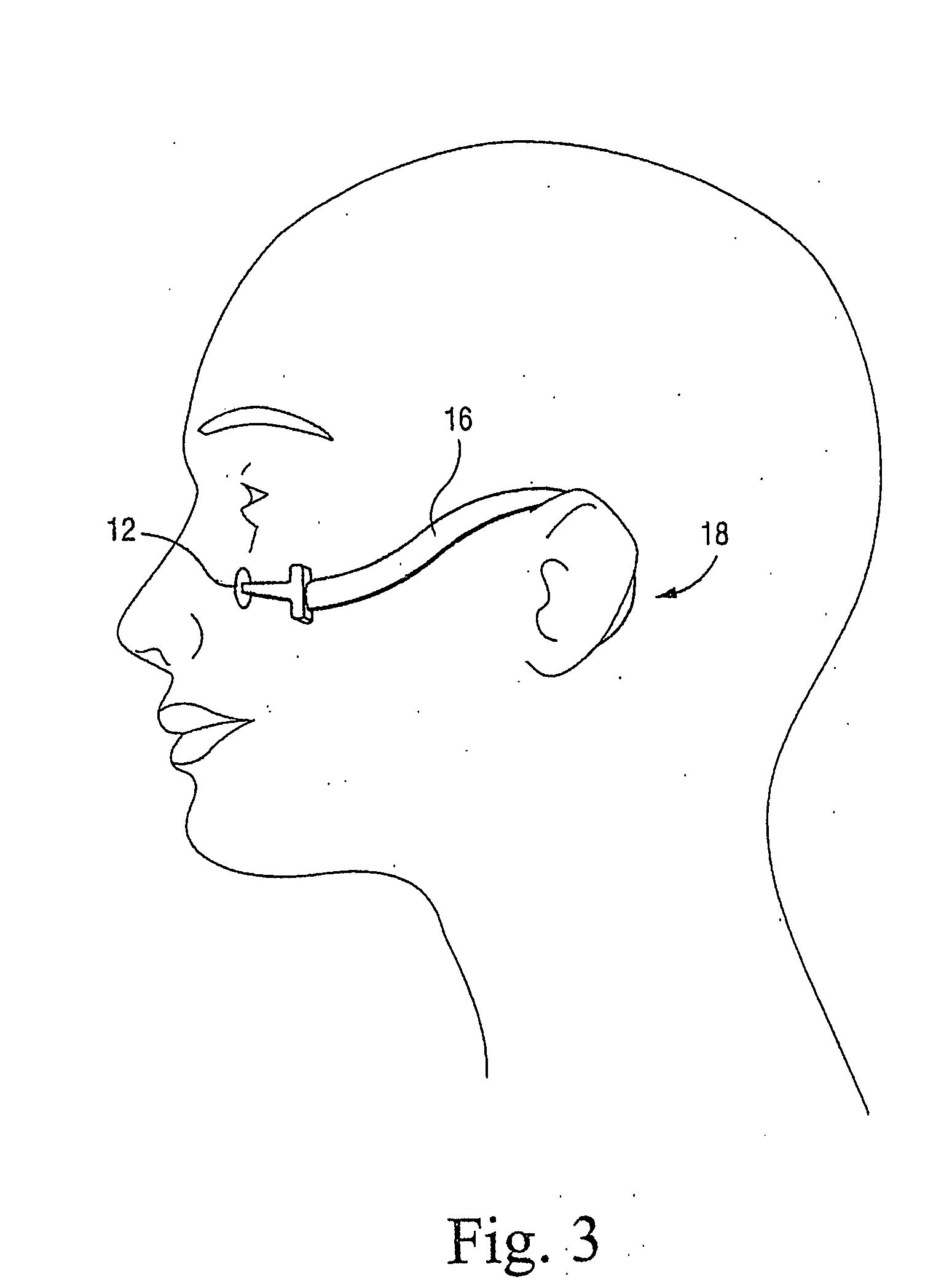

Nasal dilator

InactiveUS8051850B2Reduce flow resistanceLower impedanceRespiratory masksBreathing masksNasal passageNasal passages

A nasal dilator includes a contact pad attachable to a user's facial region below the user's eye and outboard from the user's nose. A tugging device is coupled with the contact pad and urges the contact pad in a direction away from the user's nose. With this structure, effective dilation of the nasal passages can be achieved in a comfortable manner. The dilator may also be incorporated into a CPAP mask and / or form part of an automated control system.

Owner:RESMED LTD

Nasal Dilator

InactiveUS20090183734A1Reduce flow resistanceLower impedanceRespiratory masksBreathing masksNasal cavityNasal passage

A nasal dilator includes a contact pad attachable to a user's facial region below the user's eye and outboard from the user's nose. A tugging device is coupled with the contact pad and urges the contact pad in a direction away from the user's nose. With this structure, effective dilation of the nasal passages can be achieved in a comfortable manner. The dilator may also be incorporated into a CPAP mask and / or form part of an automated control system.

Owner:RESMED LTD

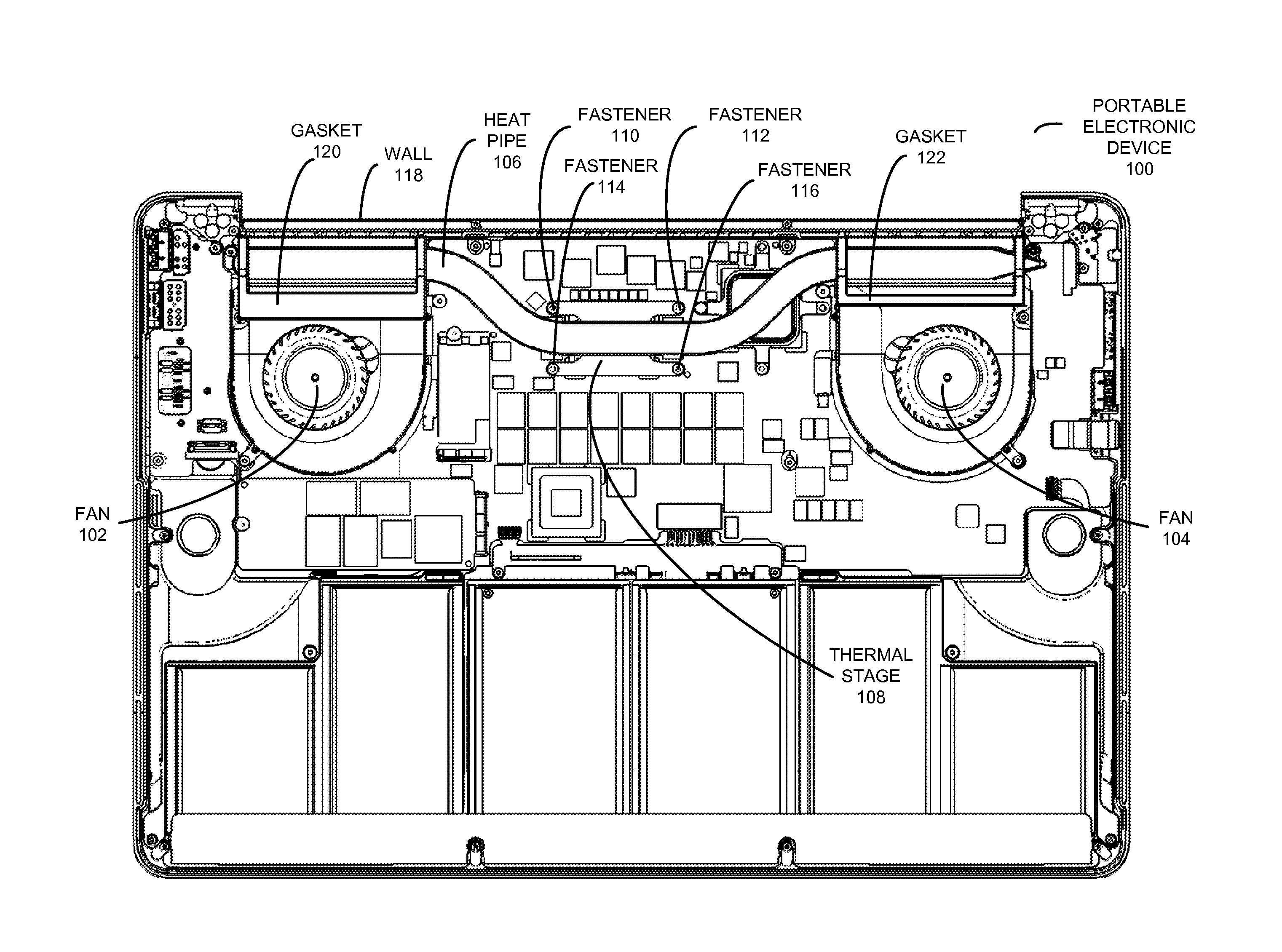

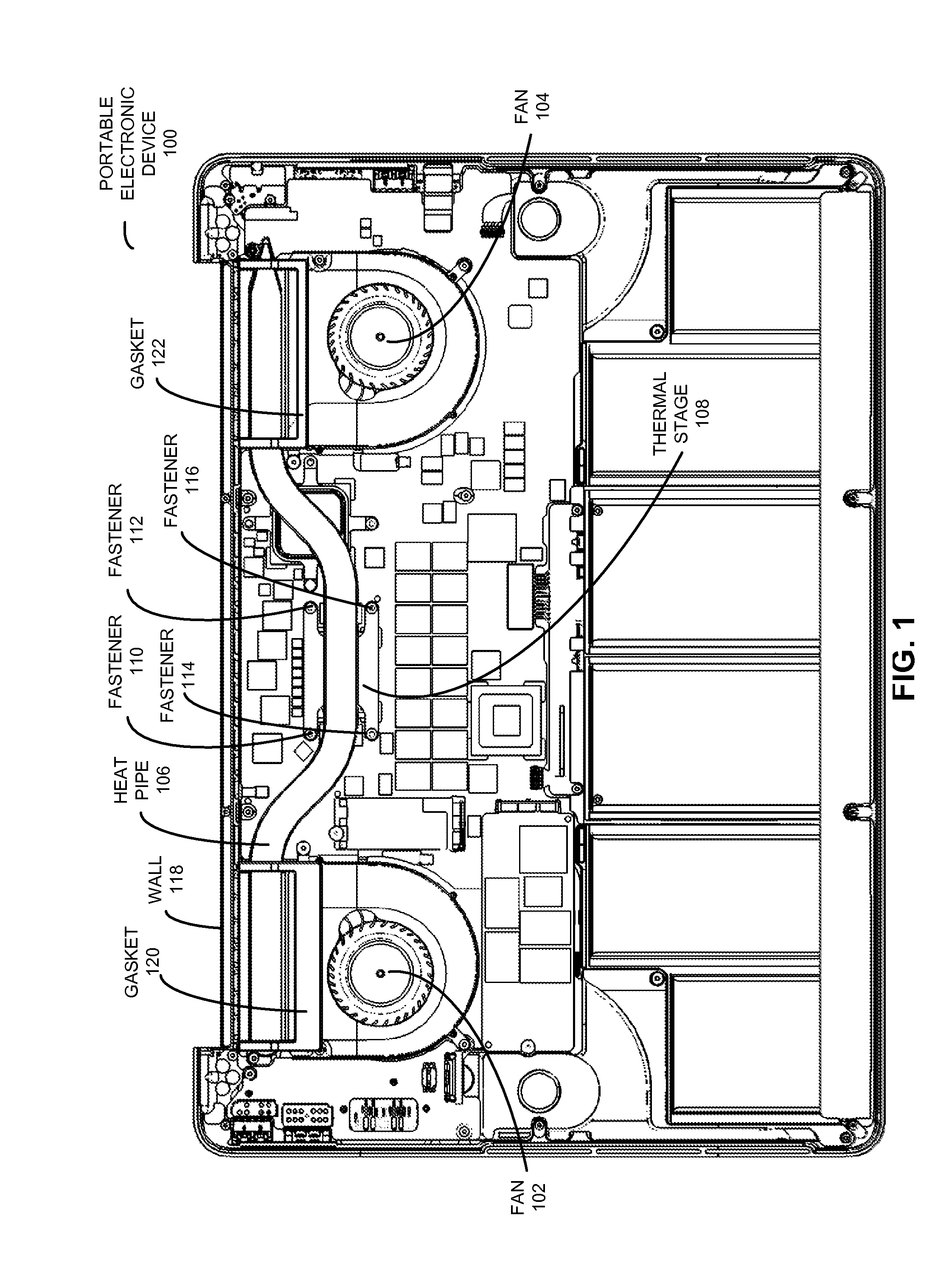

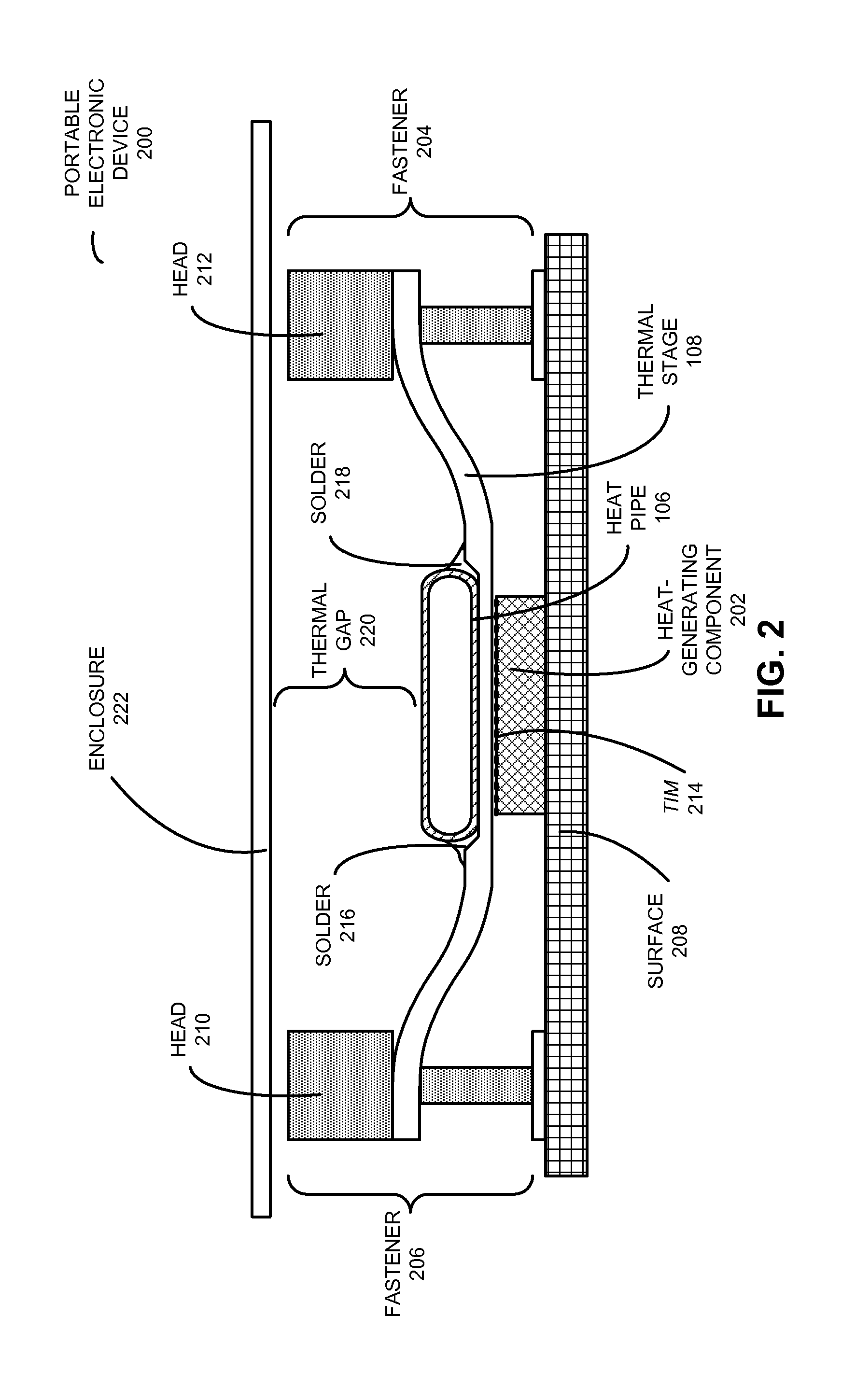

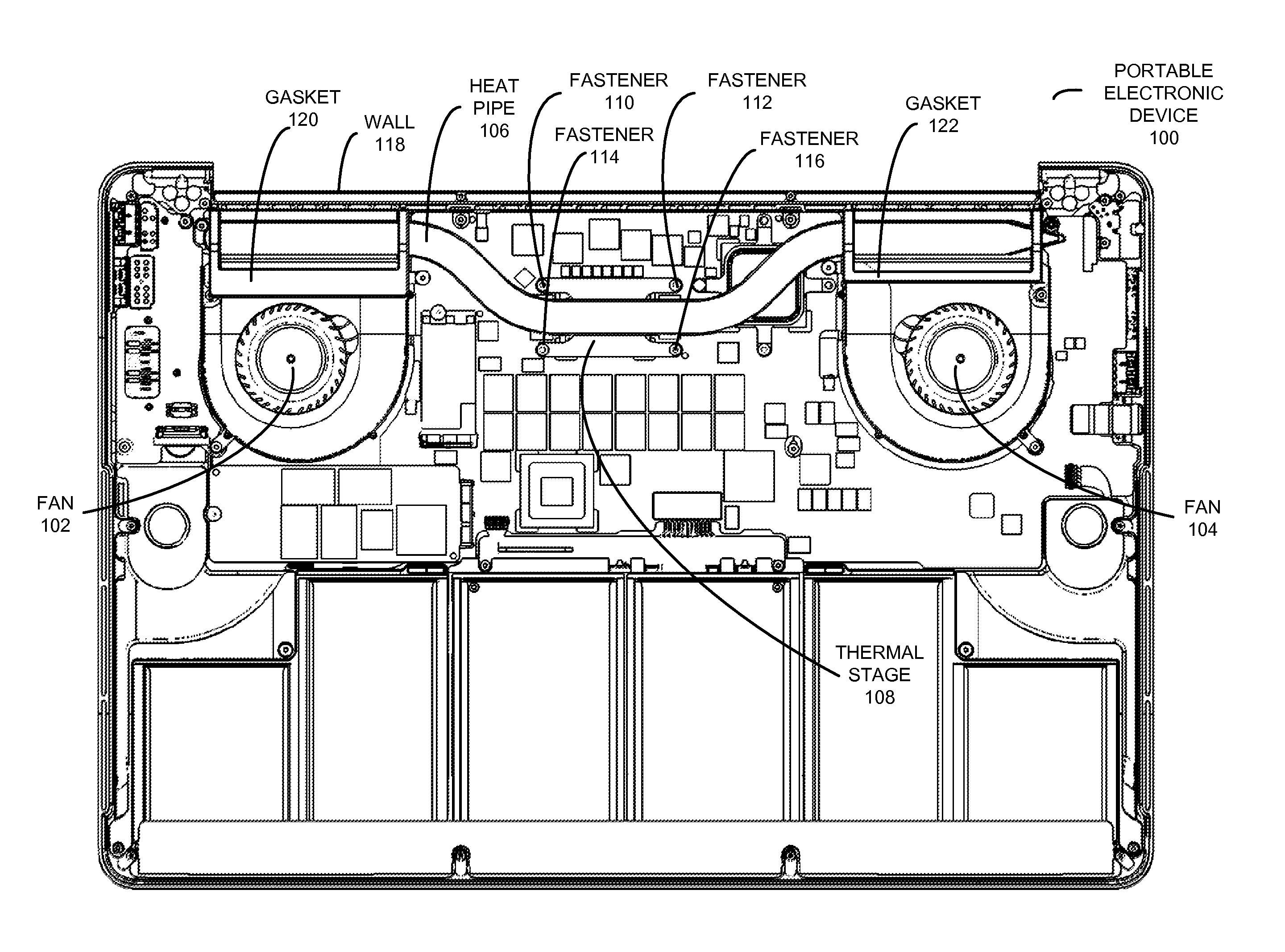

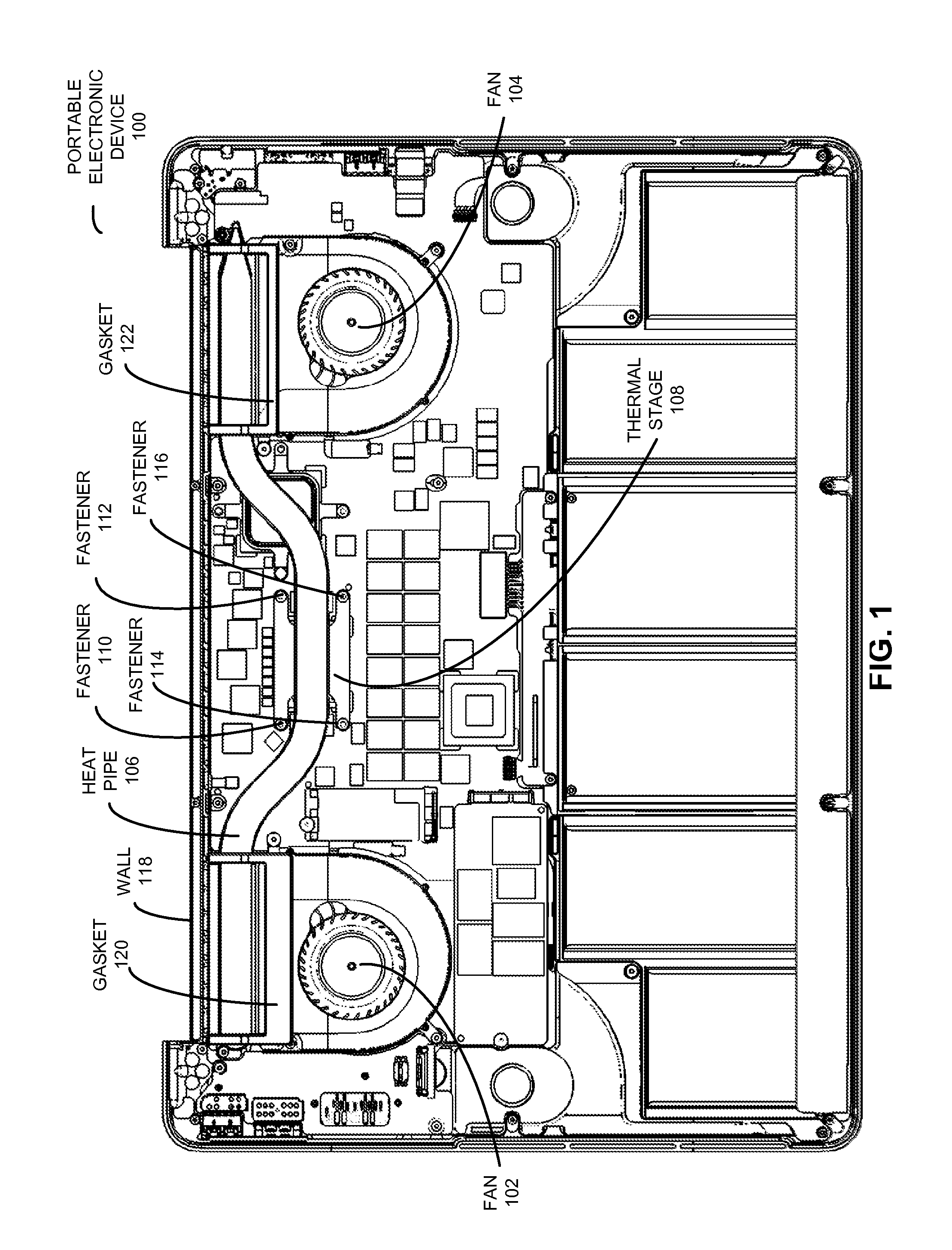

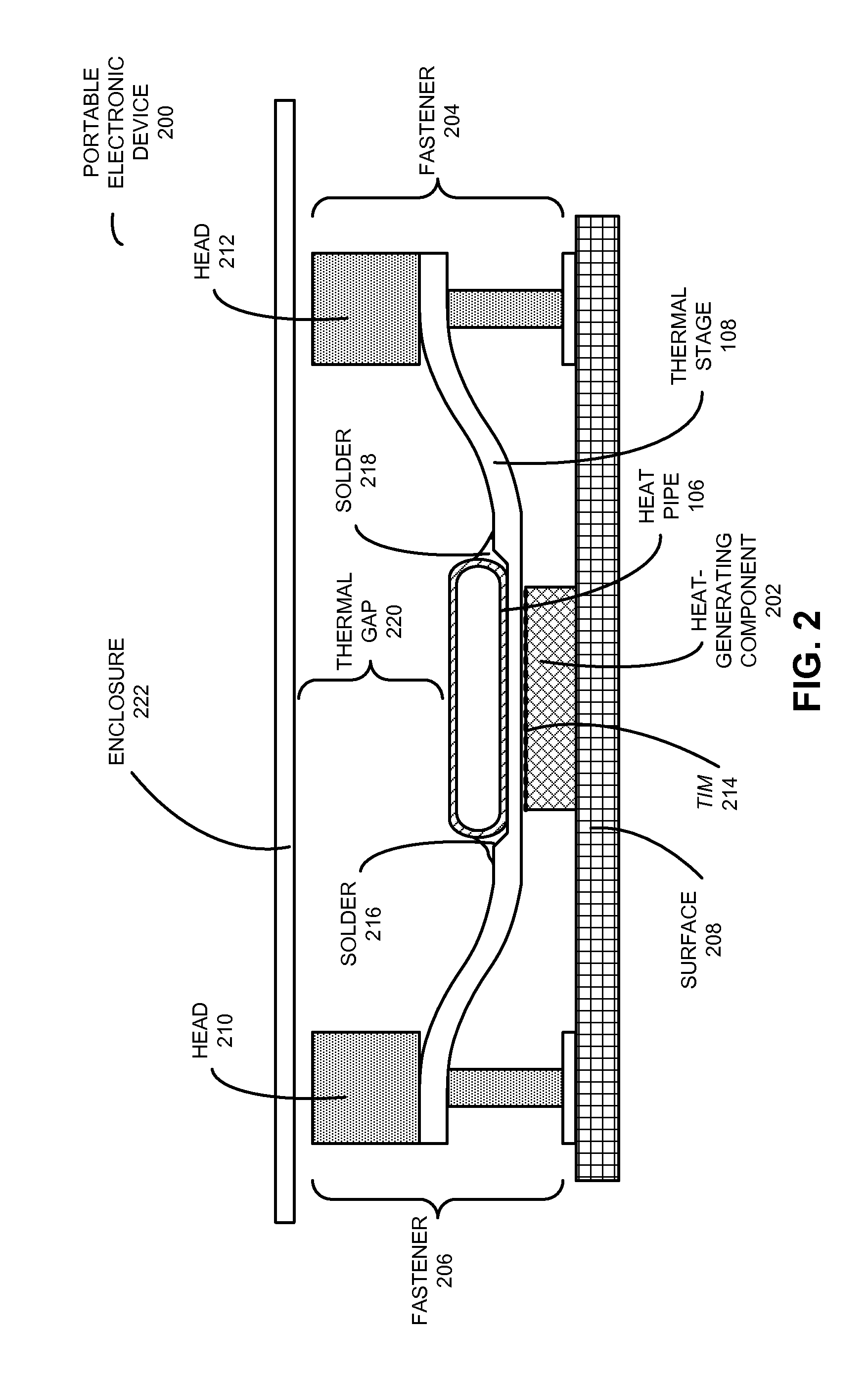

Optimized vent walls in electronic devices

ActiveUS20130327507A1High temperatureReduce flow impedanceWave amplification devicesDigital data processing detailsEngineeringElectronic equipment

Owner:APPLE INC

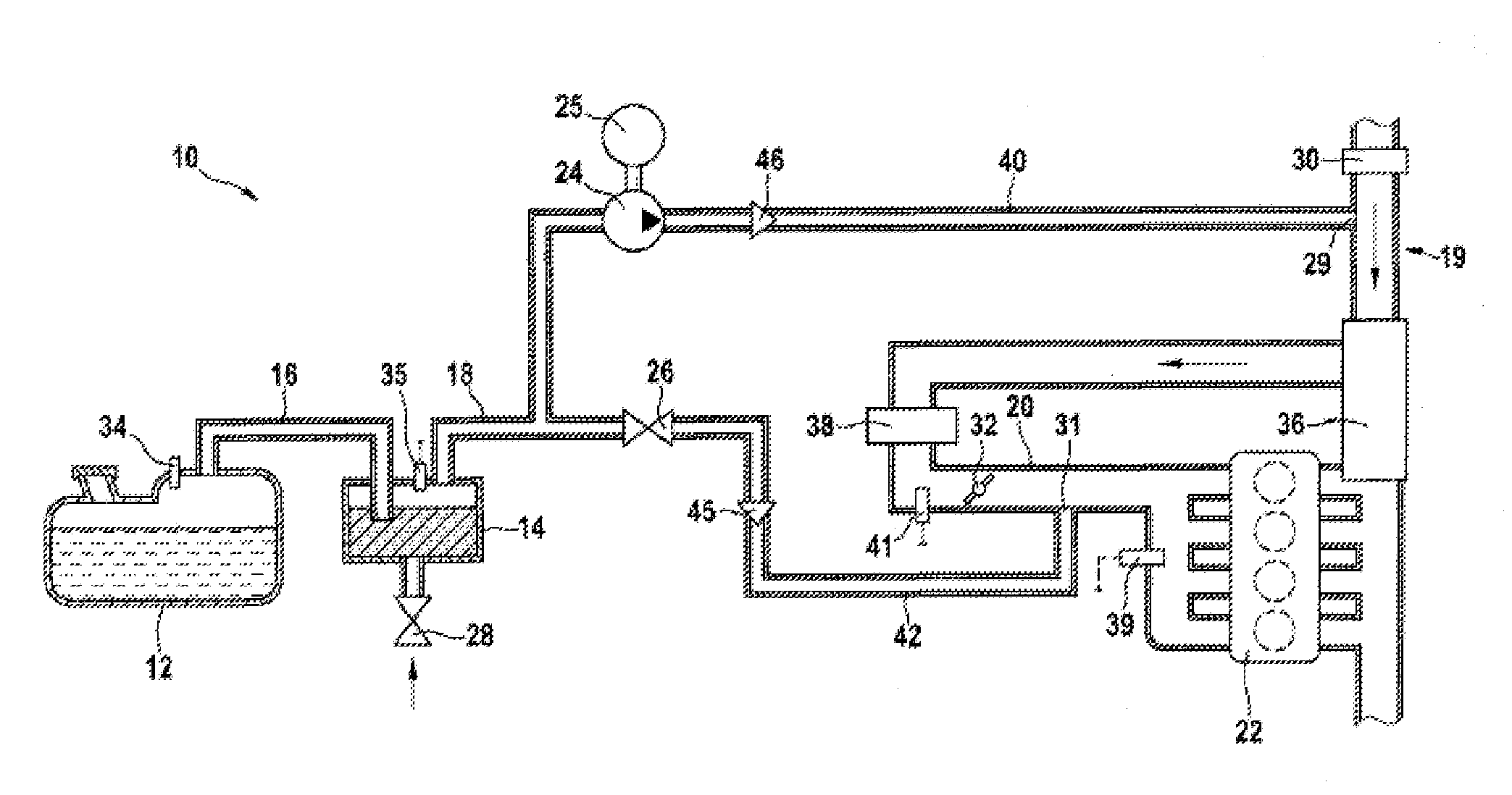

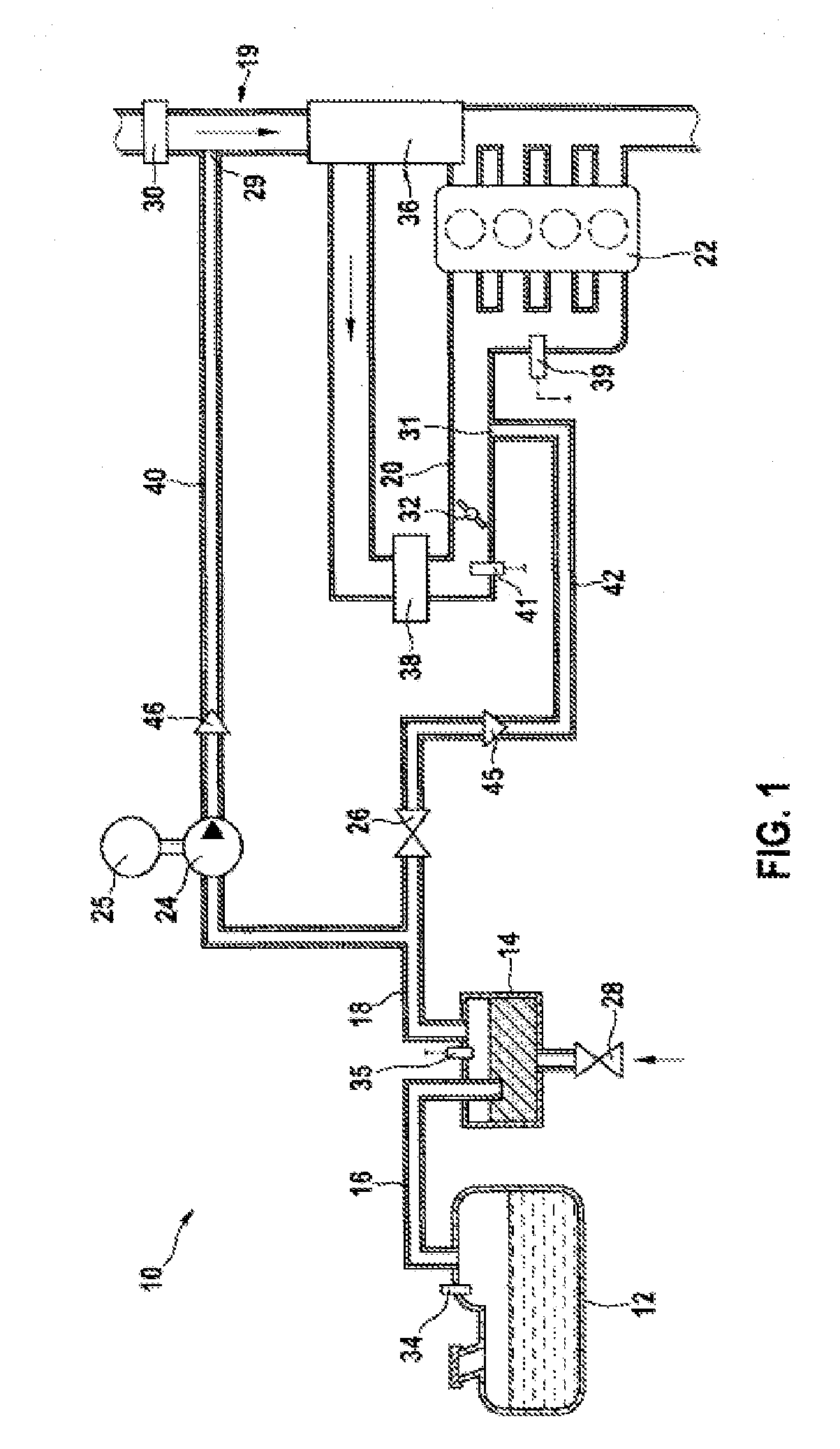

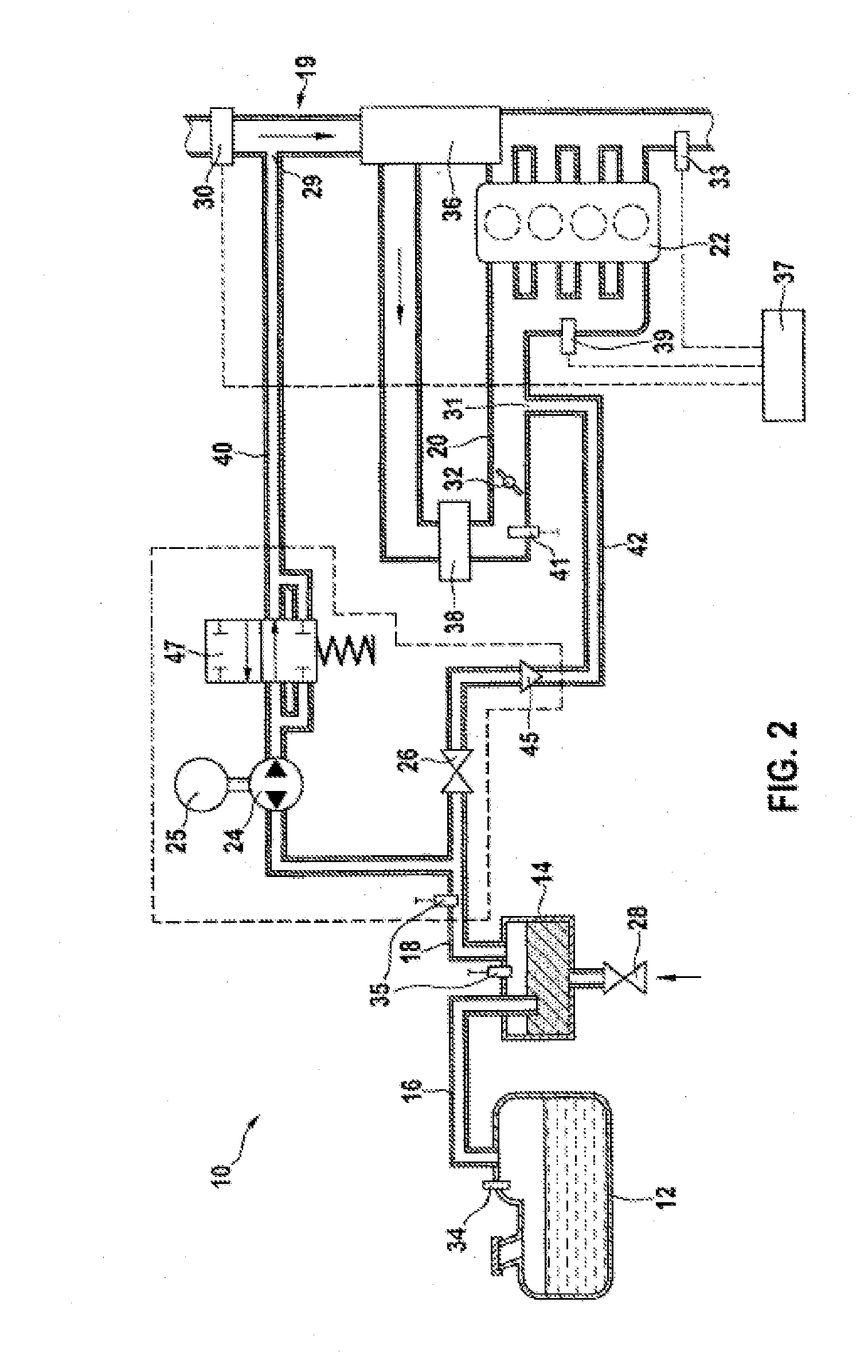

Venting system for a fuel tank

InactiveUS20140299111A1Reduce flow resistanceIncrease regeneration rateElectrical controlNon-fuel substance addition to fuelSorptionFuel tank

A venting system for a fuel tank includes a sorption filter for temporarily storing fuel evaporating from the fuel tank and a delivery device arranged between the sorption filter and an air supply system of an internal combustion engine in a fluid-conducting manner. The internal combustion engine is a turbocharged engine with a turbocharger unit and a throttling device in the air supply system. The sorption filter is connected to the air supply system in a fluid-conducting manner by a first line at a first inlet point arranged upstream of the turbocharger unit and by a second line at a second inlet point arranged downstream of the throttling device. A tank venting valve is arranged in the second line, and the first line branches off from the second line upstream of the tank venting valve in the flow direction towards the second inlet point.

Owner:ROBERT BOSCH GMBH

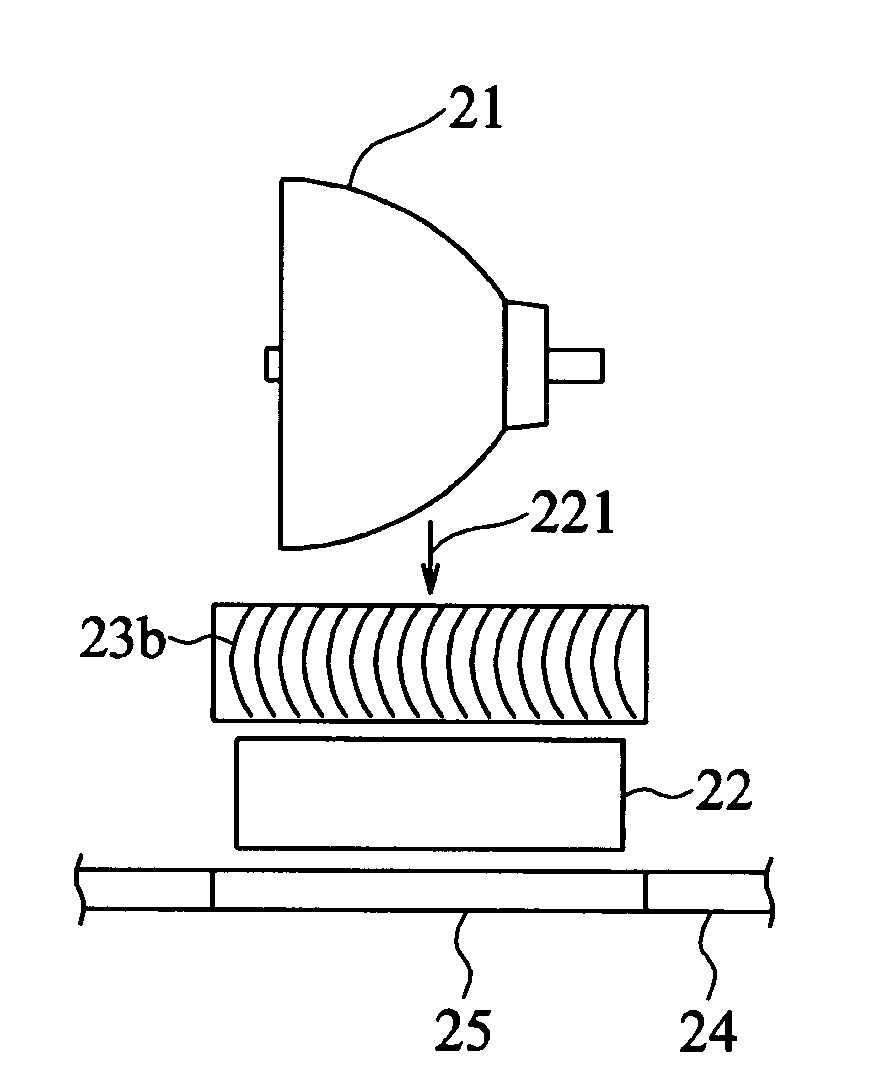

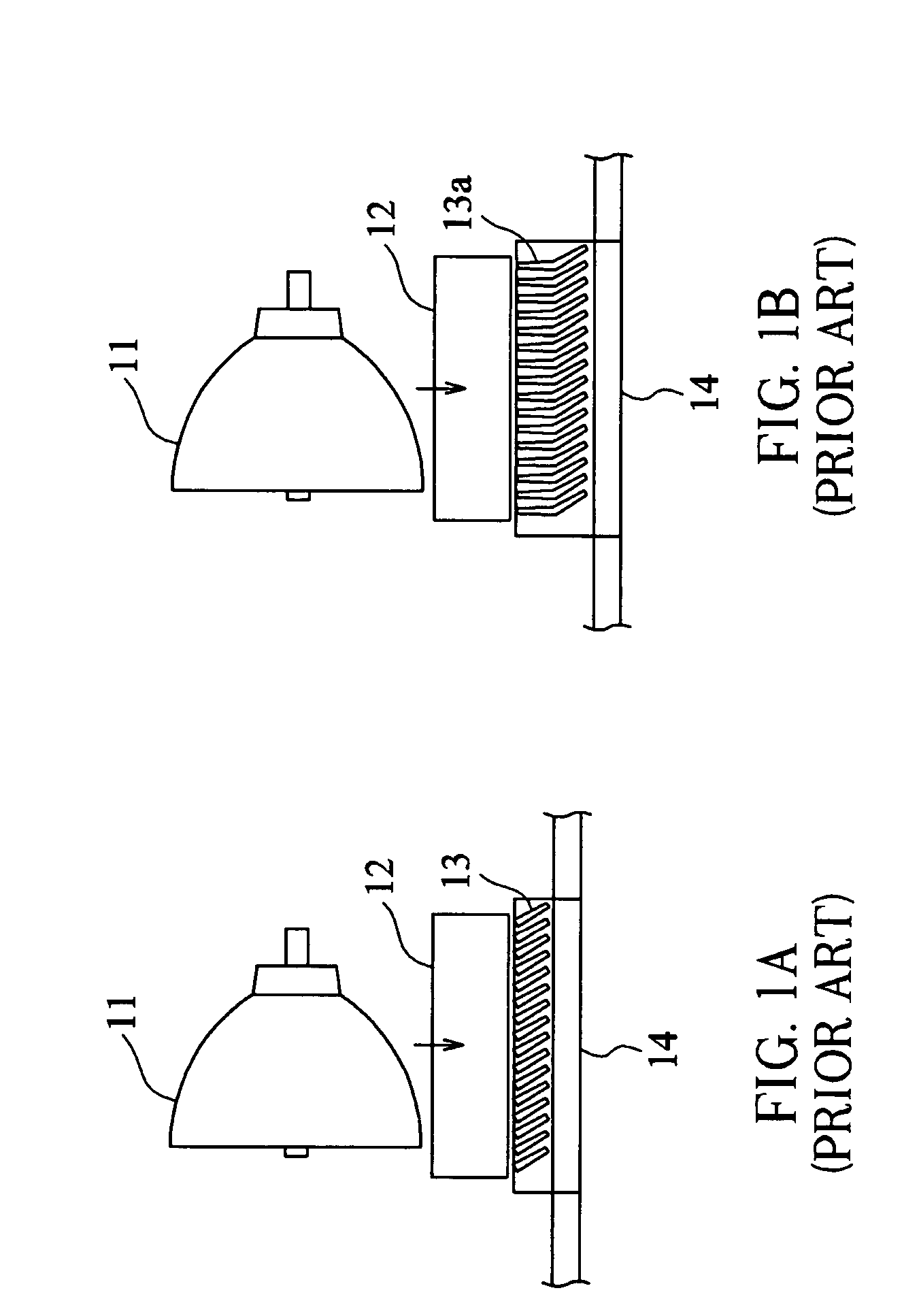

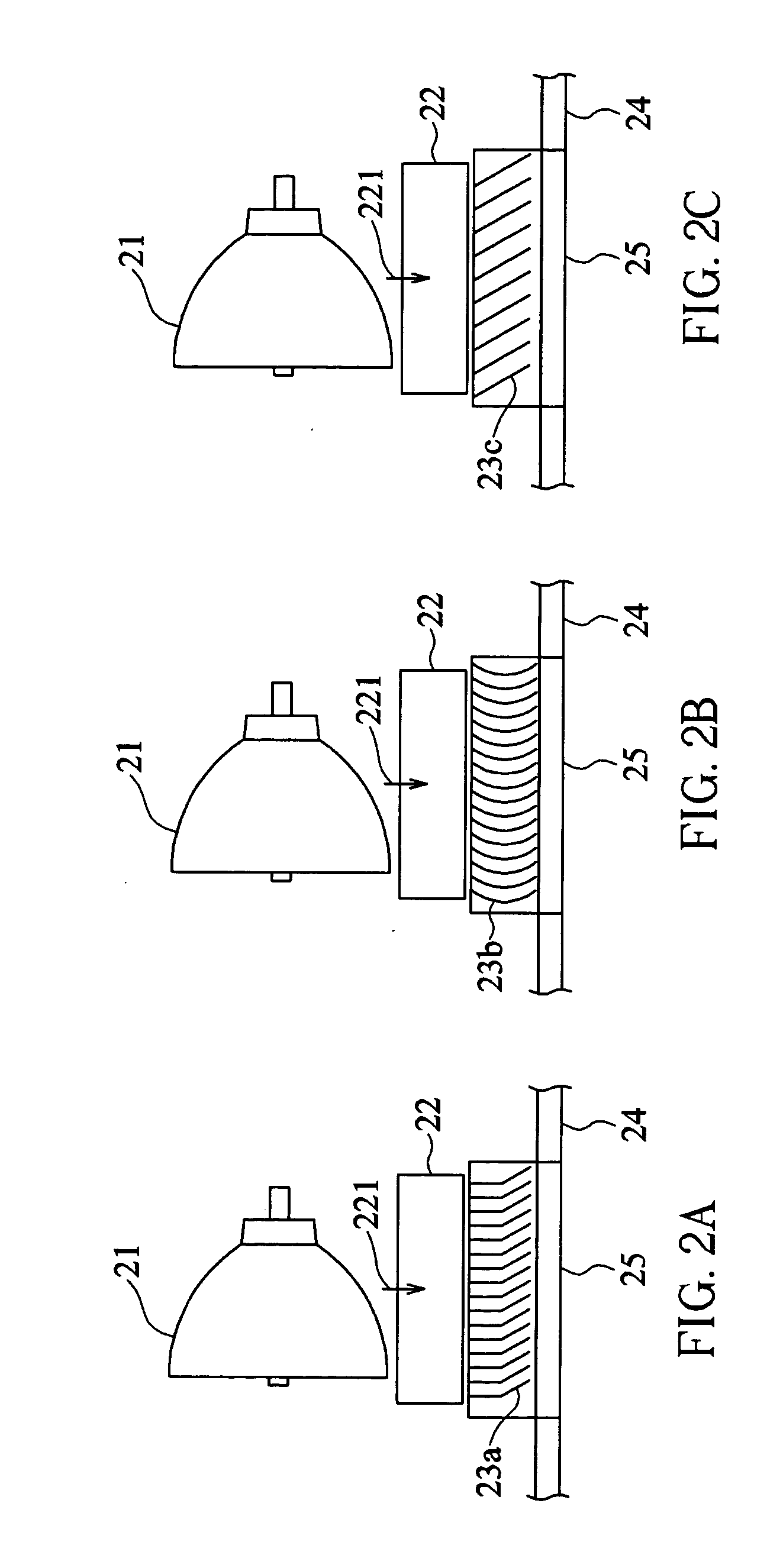

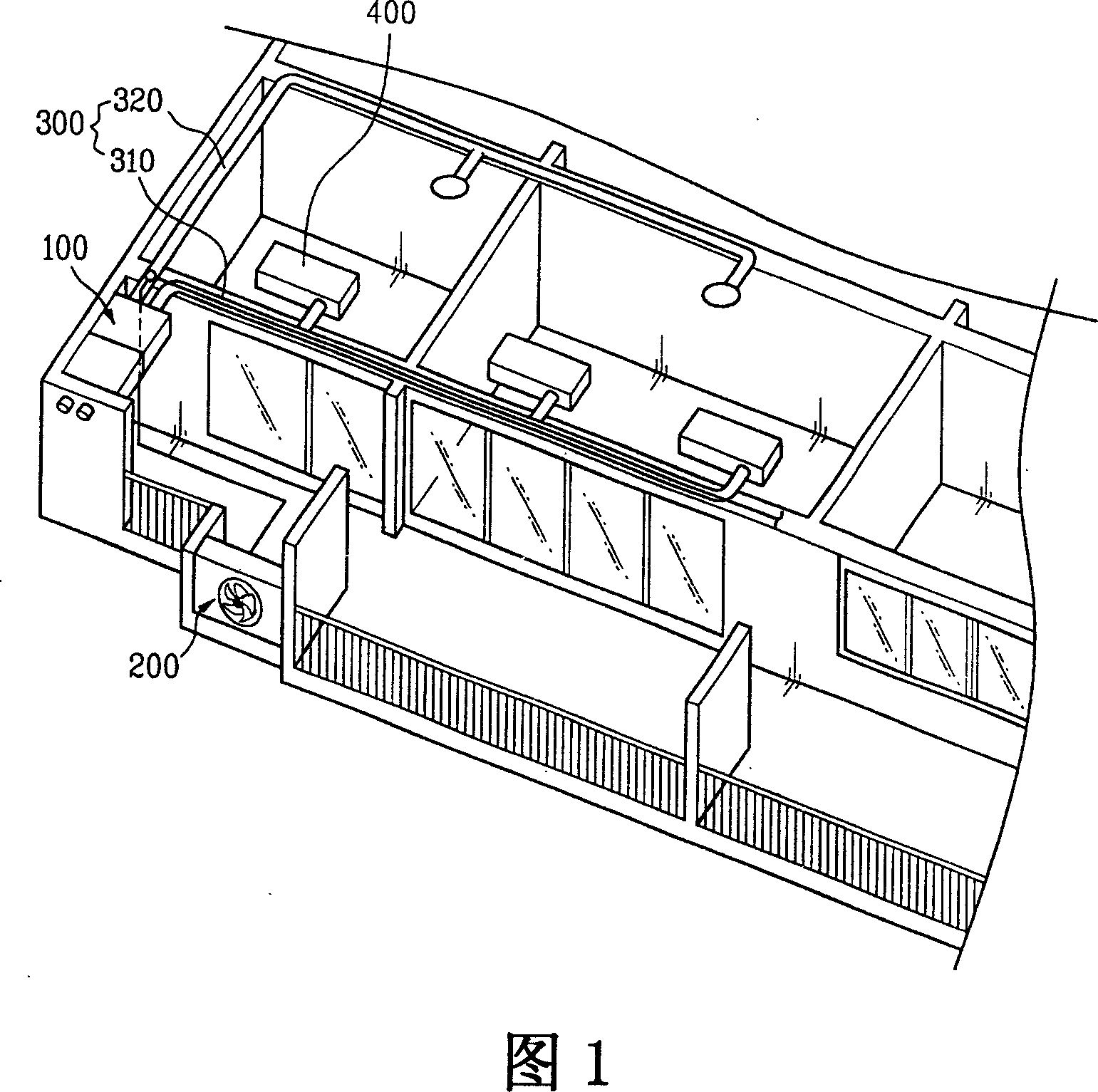

Projector and light-shielding heat-dissipating mask for the same

InactiveUS20050073658A1Improve thermal conductivityReduce the temperatureProjectorsOptoelectronicsMetal sheet

The present invention discloses a light-shielding heat-dissipating mask for a projector. The projector has a light source, a fan, and an air vent. The light-shielding heat-dissipating mask comprises a plurality of metal sheets which are positioned at the air vent for dissipating the heat generated by the light source and decreasing the possibility of the light emitted form the light source escaping out of the air vent.

Owner:DELTA ELECTRONICS INC

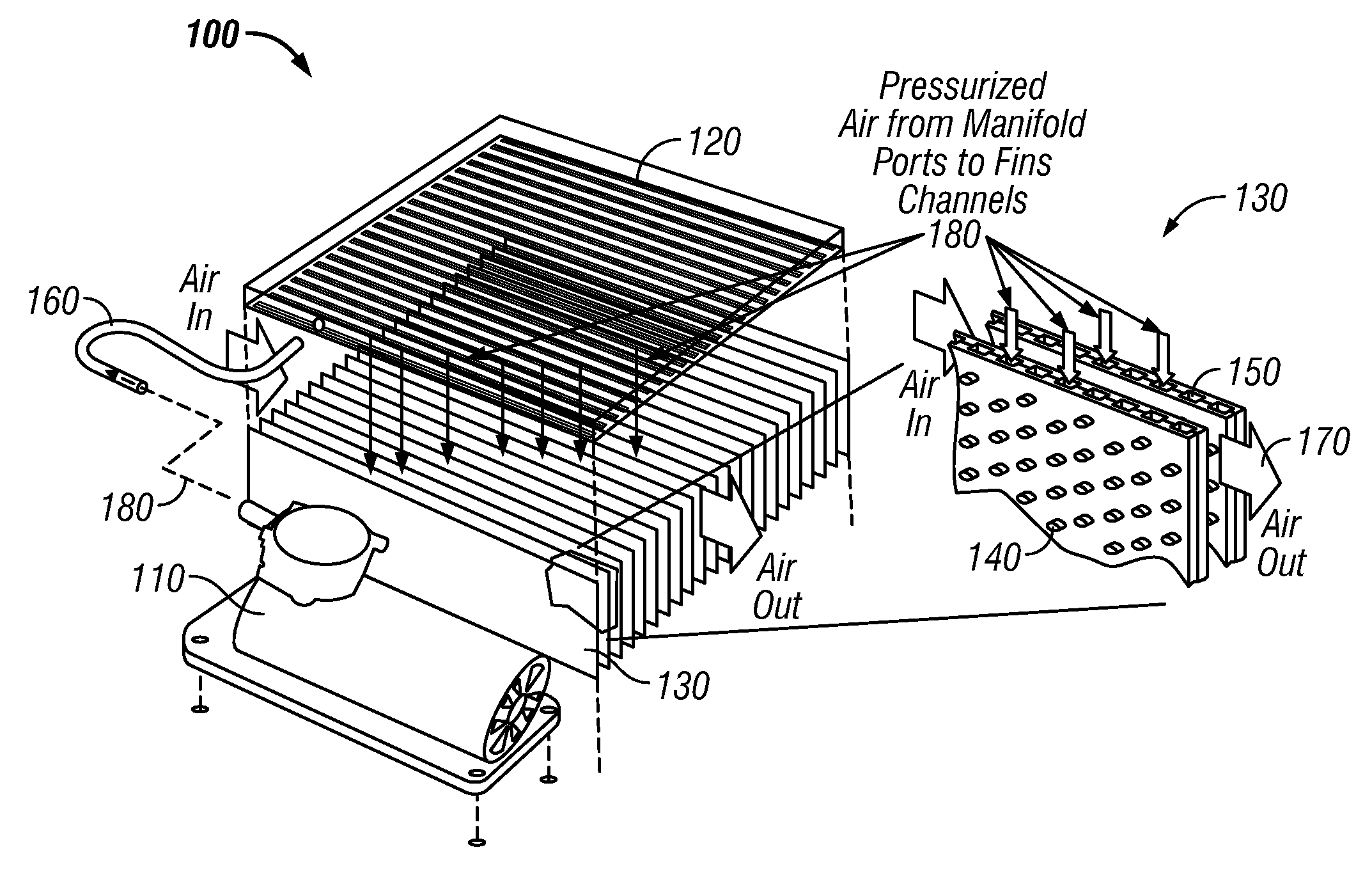

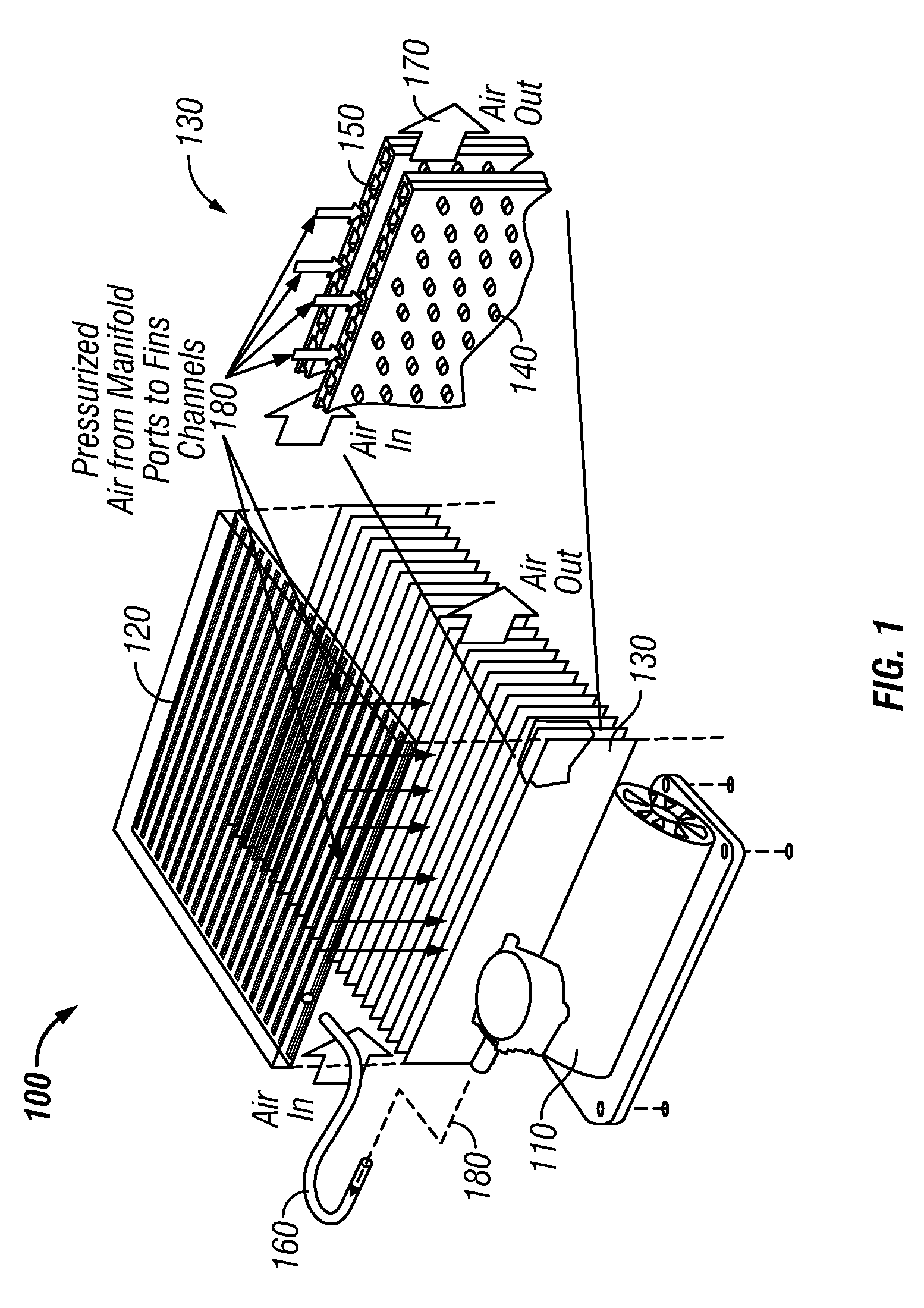

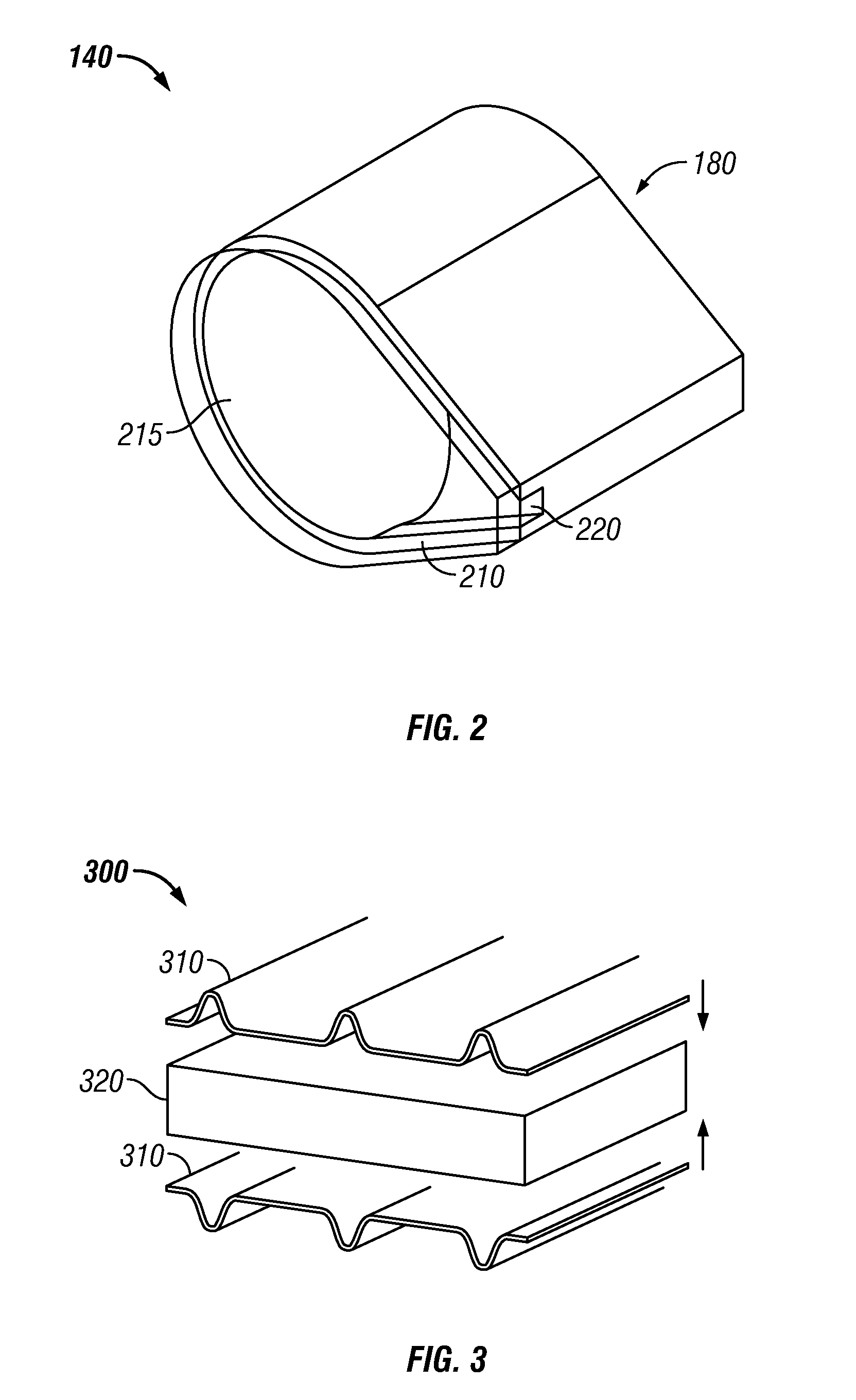

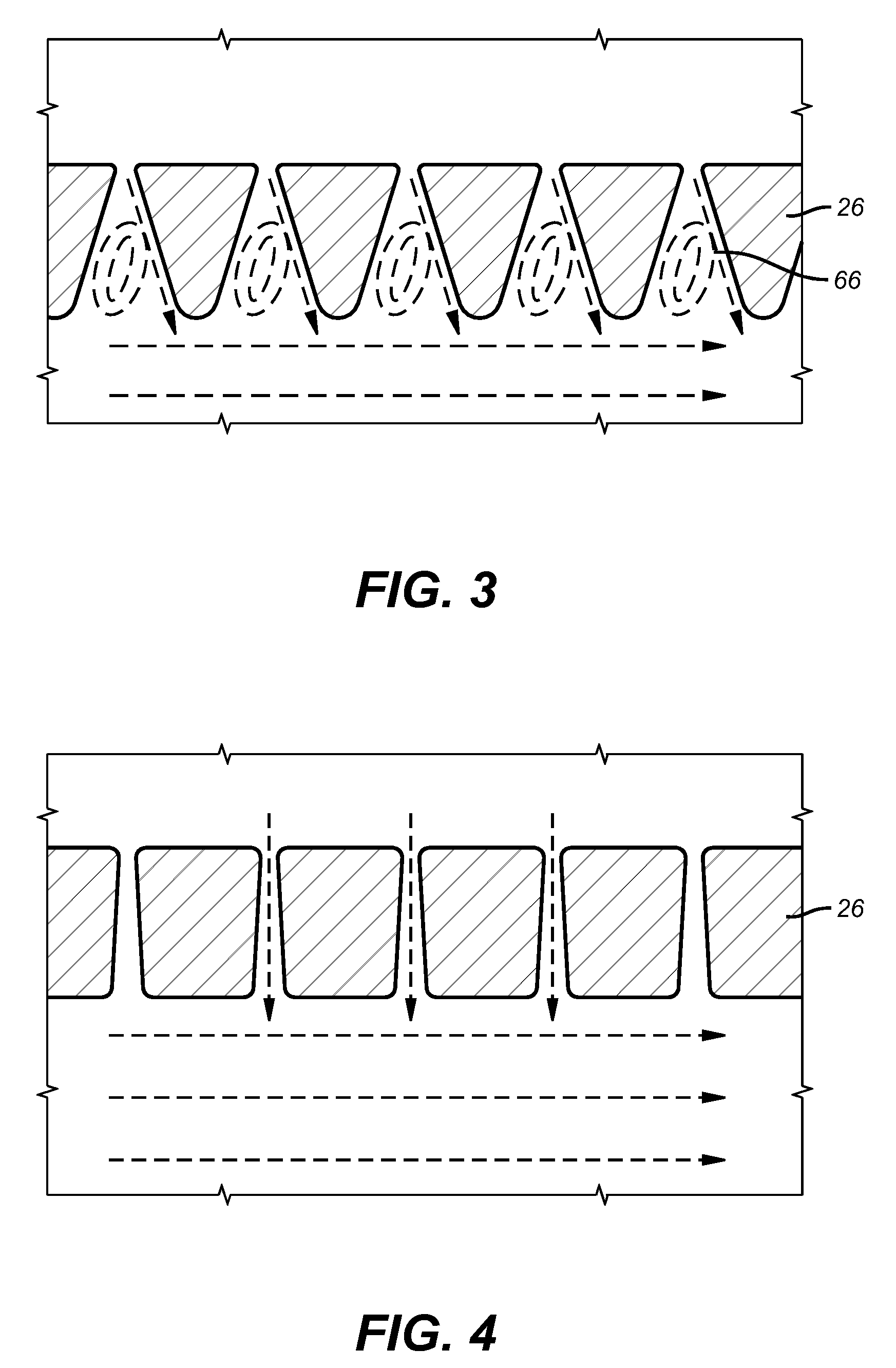

Blowerless heat exchanger based on micro-jet entrainment

ActiveUS20090288807A1Improve heat transfer performanceReduce flow resistanceSemiconductor/solid-state device detailsMetal-working apparatusAir movementEngineering

A blowerless heat exchanger apparatus based on micro-jet entrainment is disclosed. The heat exchanger apparatus incorporates a number of fins regularly spaced apart from each other and parallel to each other, thus letting air currents flow in the space defined between them. A dense array of micro-jet nozzles can be fabricated on the fins surface pointing to the flow direction of the air movement in order to induce increase airflow. The air from an air compressor delivers sufficient airflow on the fins surface utilizing micro-jets entrainment. The micro-jet entrainment confirms strong turbulent around the micro-jets and suggests significant heat transfer enhancement. The turbulence from the micro-jets enhance the heat transfer coefficient, potentially by an order of magnitude, therefore allowing much larger fin spacing and leads to huge reduction of flow resistance and overall power consumption.

Owner:HONEYWELL INT INC

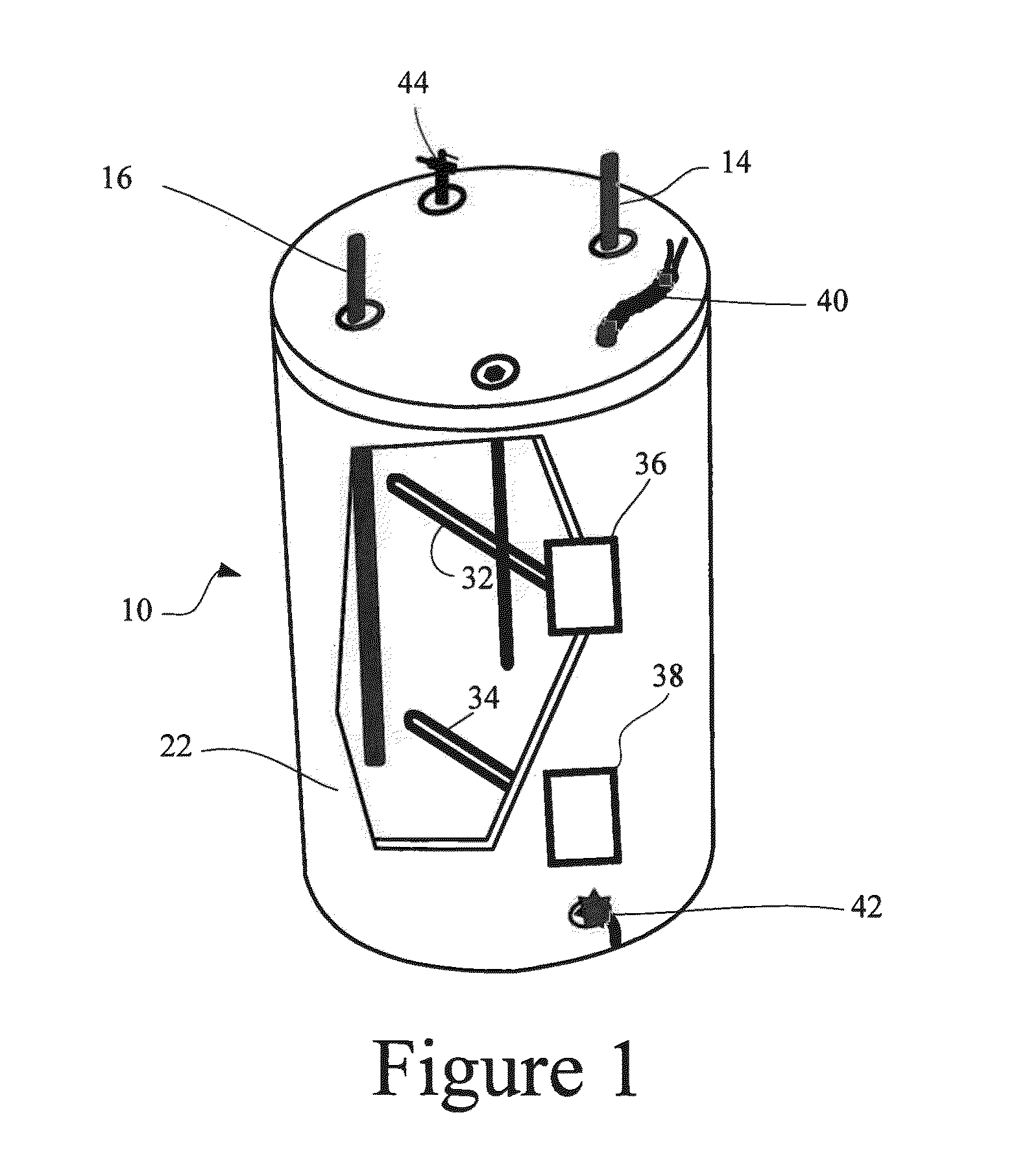

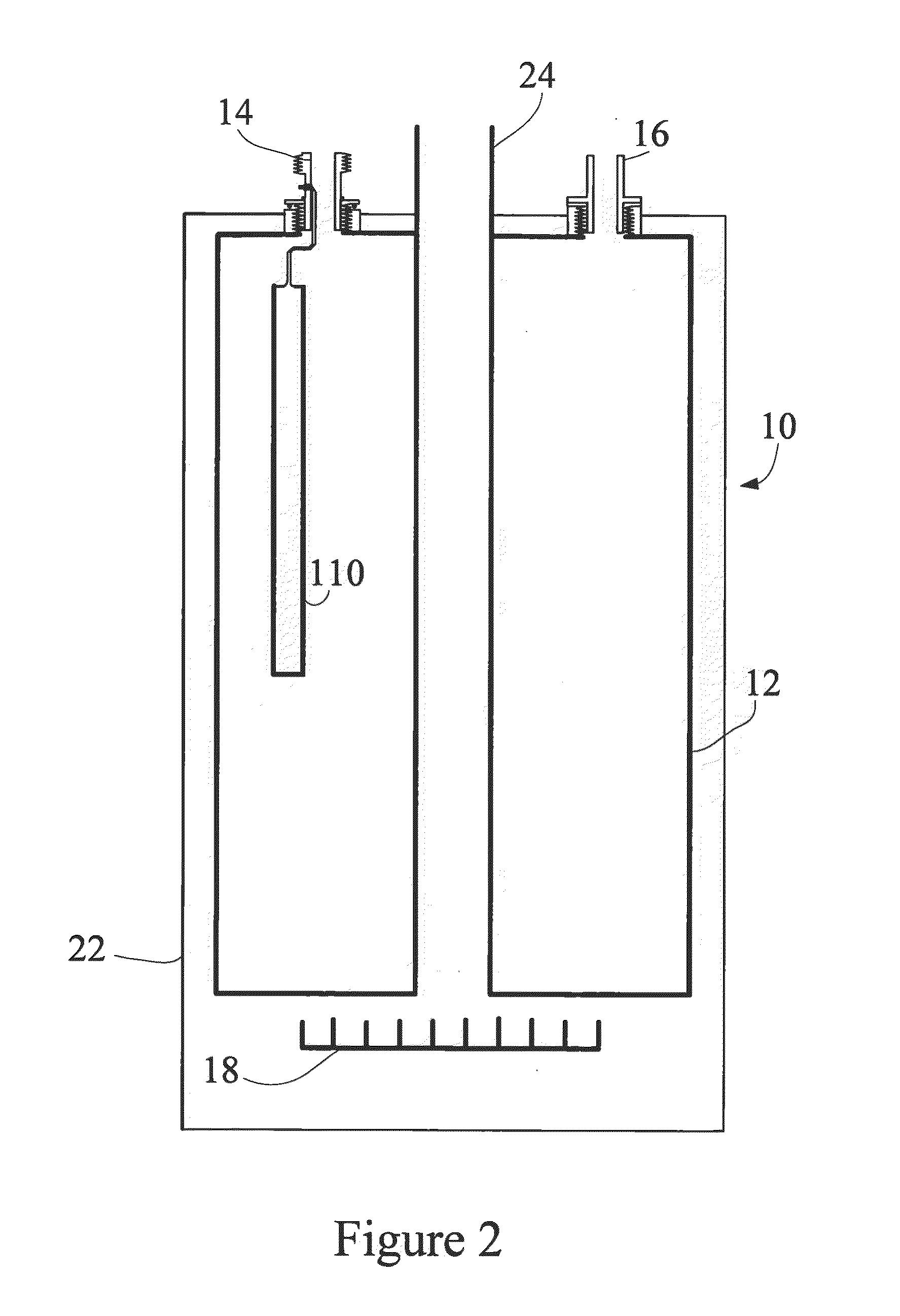

Renewable Energy Hot Water Heating Elements

ActiveUS20130266300A1Improve efficiencyEnhancing of generationMechanical apparatusCentral heating storage tanksEngineeringThermal water

Provided herein are systems and methods directed to using renewable energy sources with hot water heating systems.

Owner:KREUTZMAN DAVID

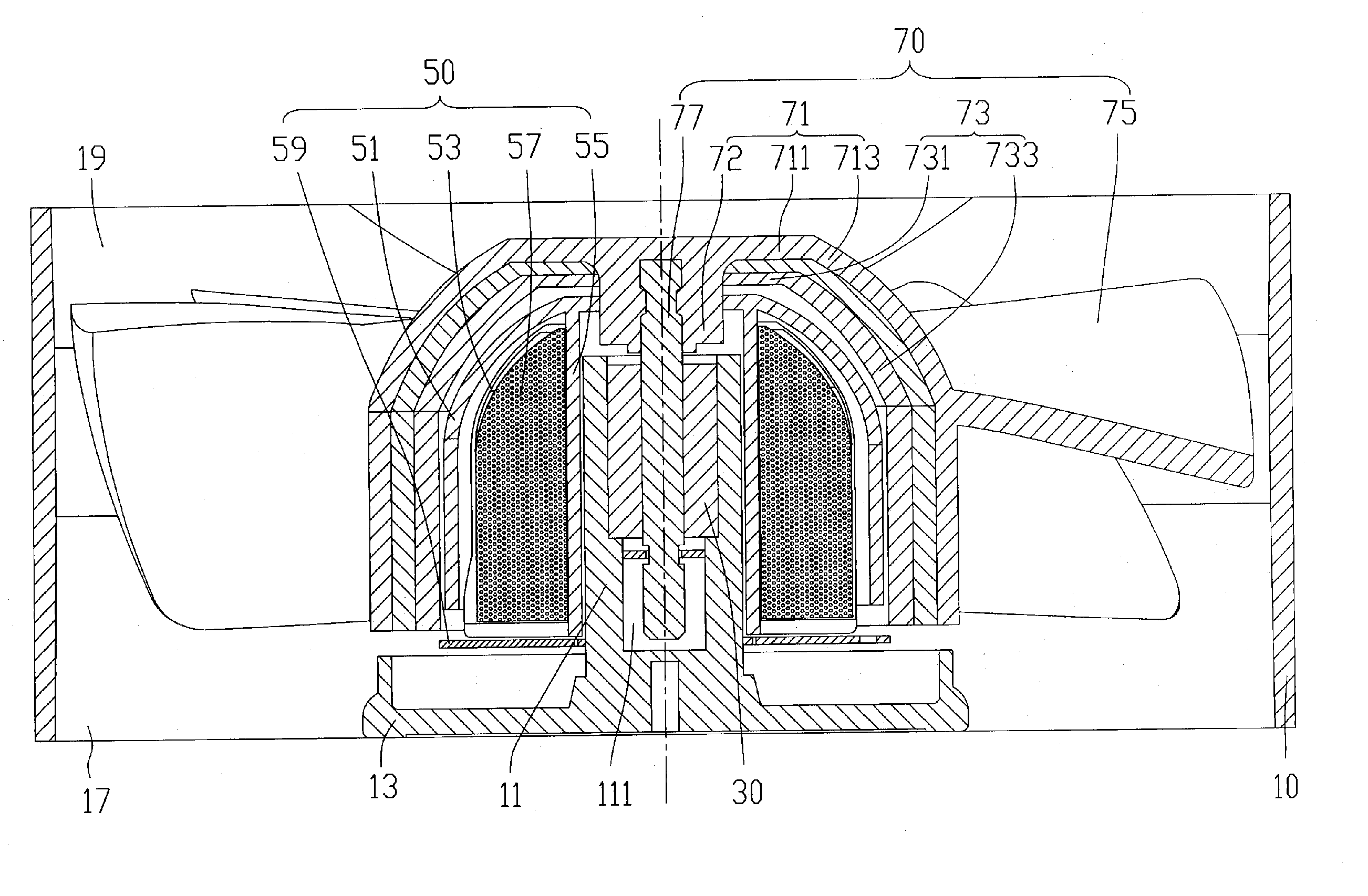

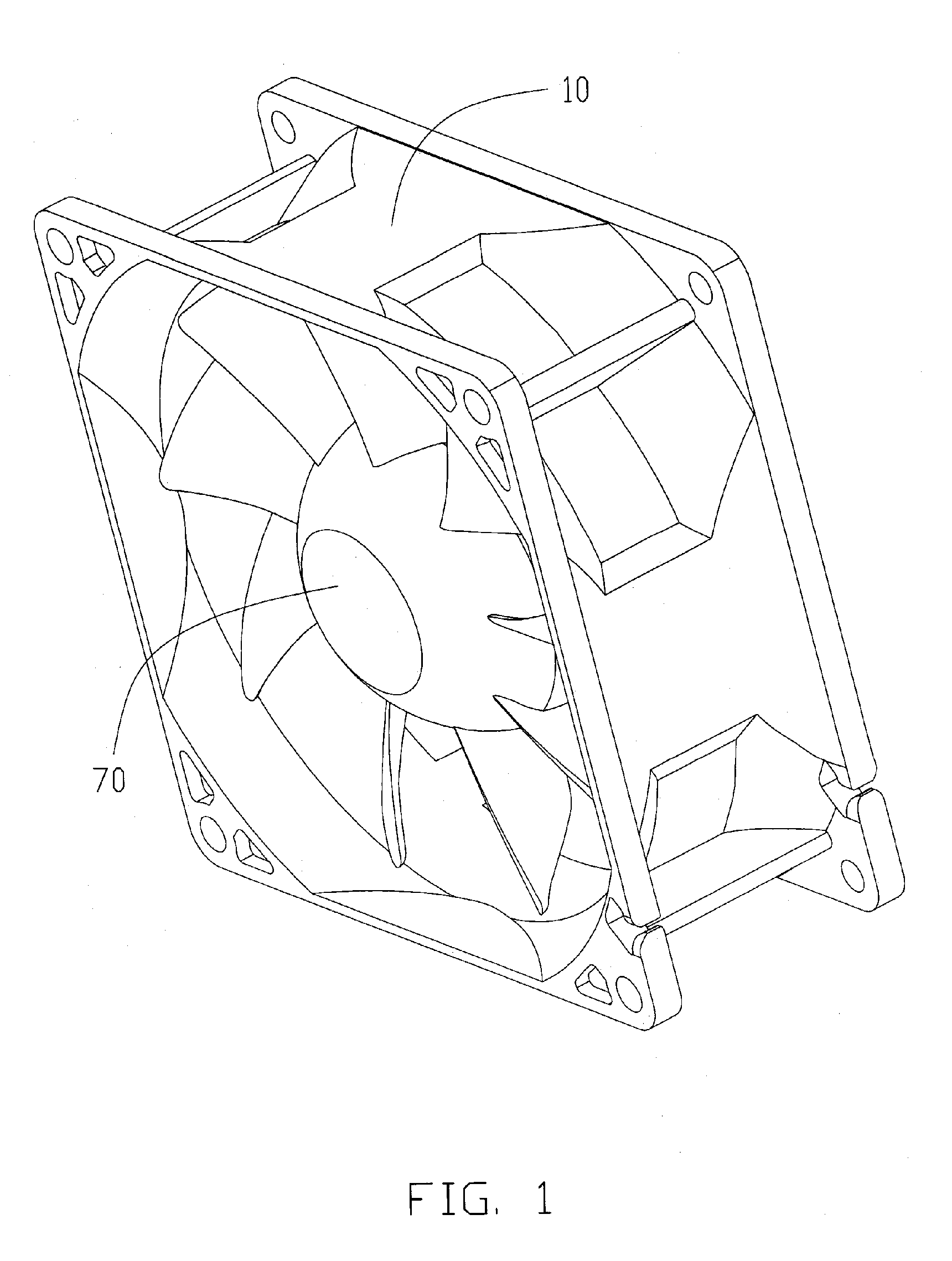

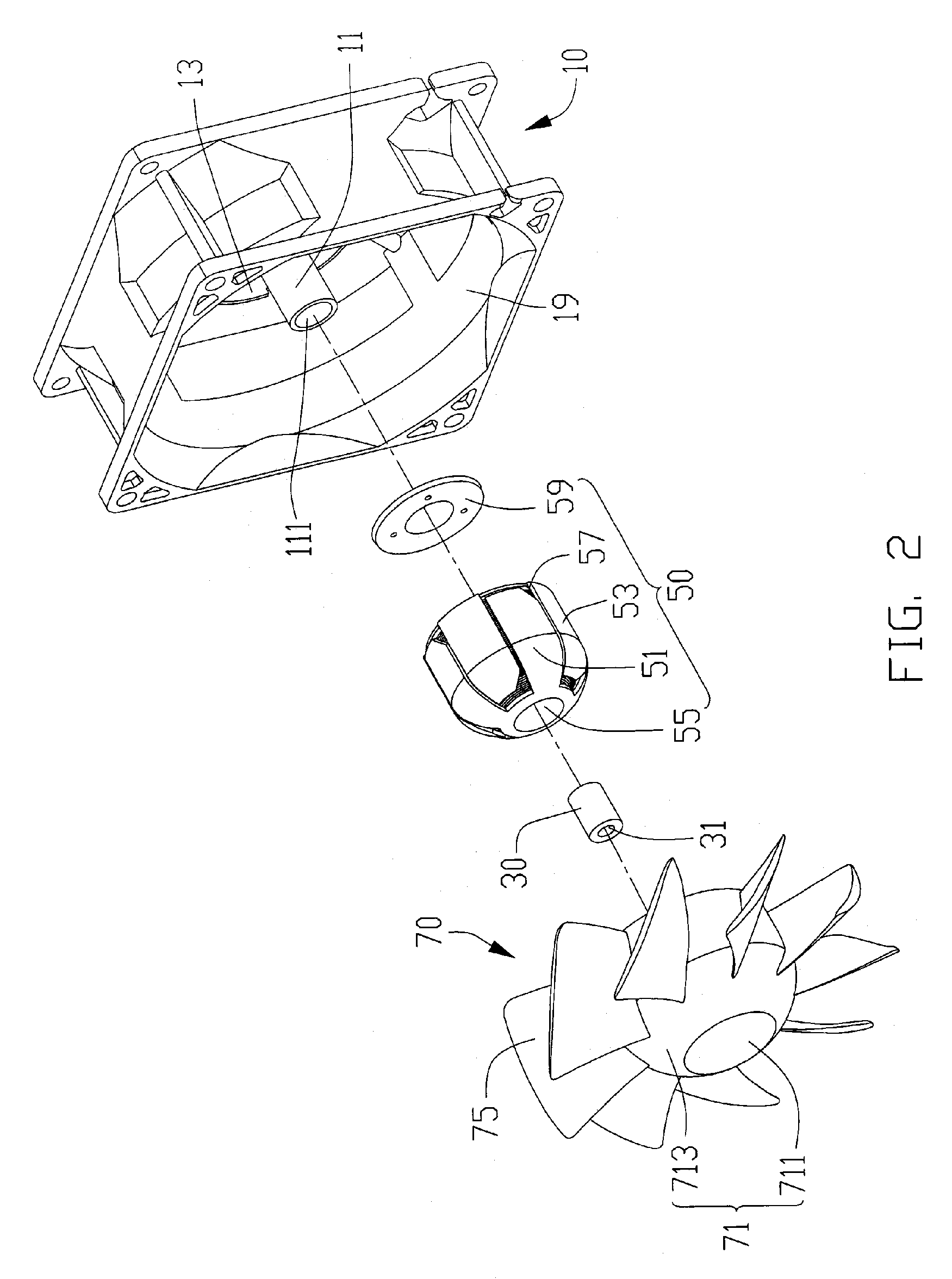

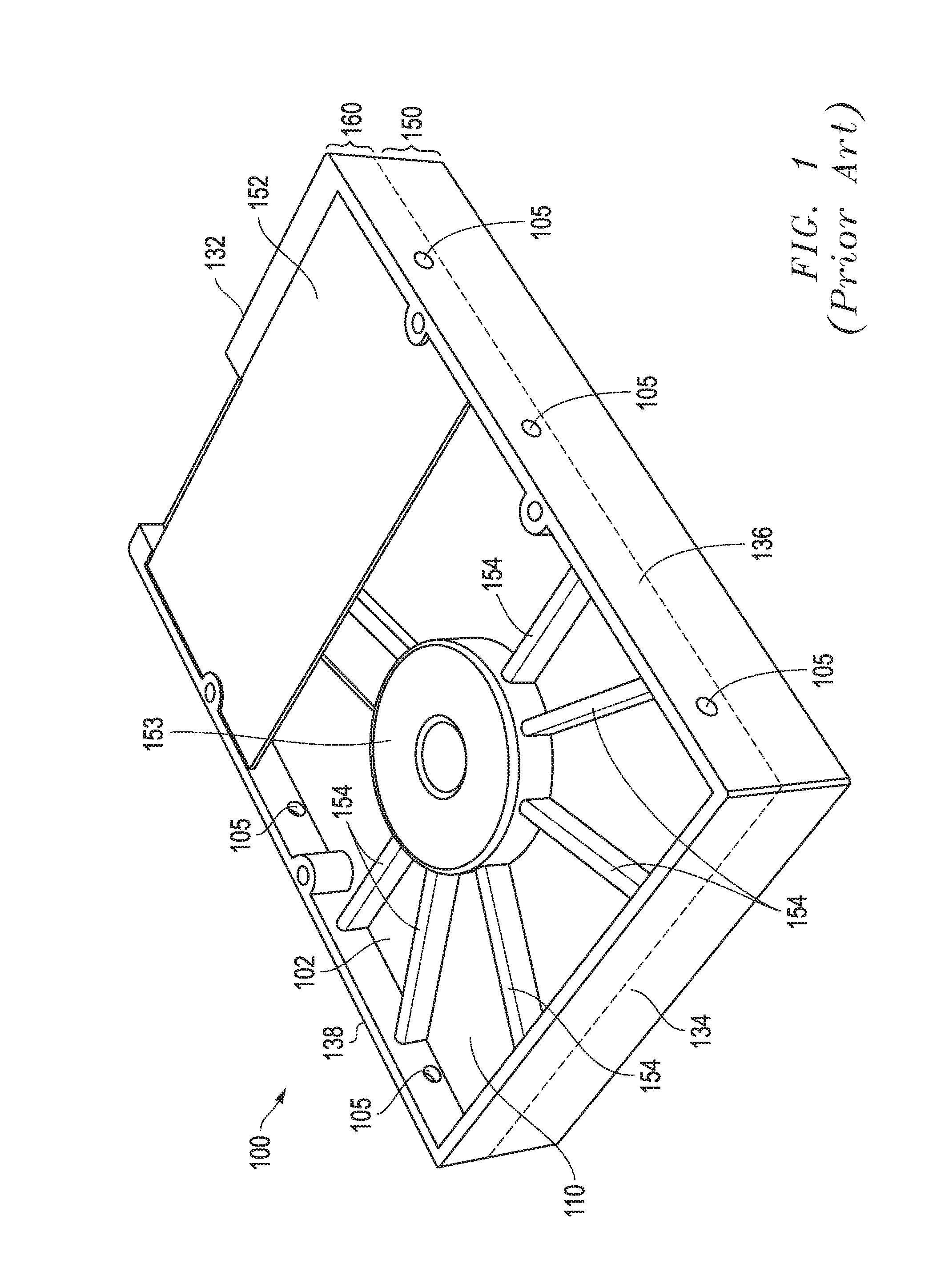

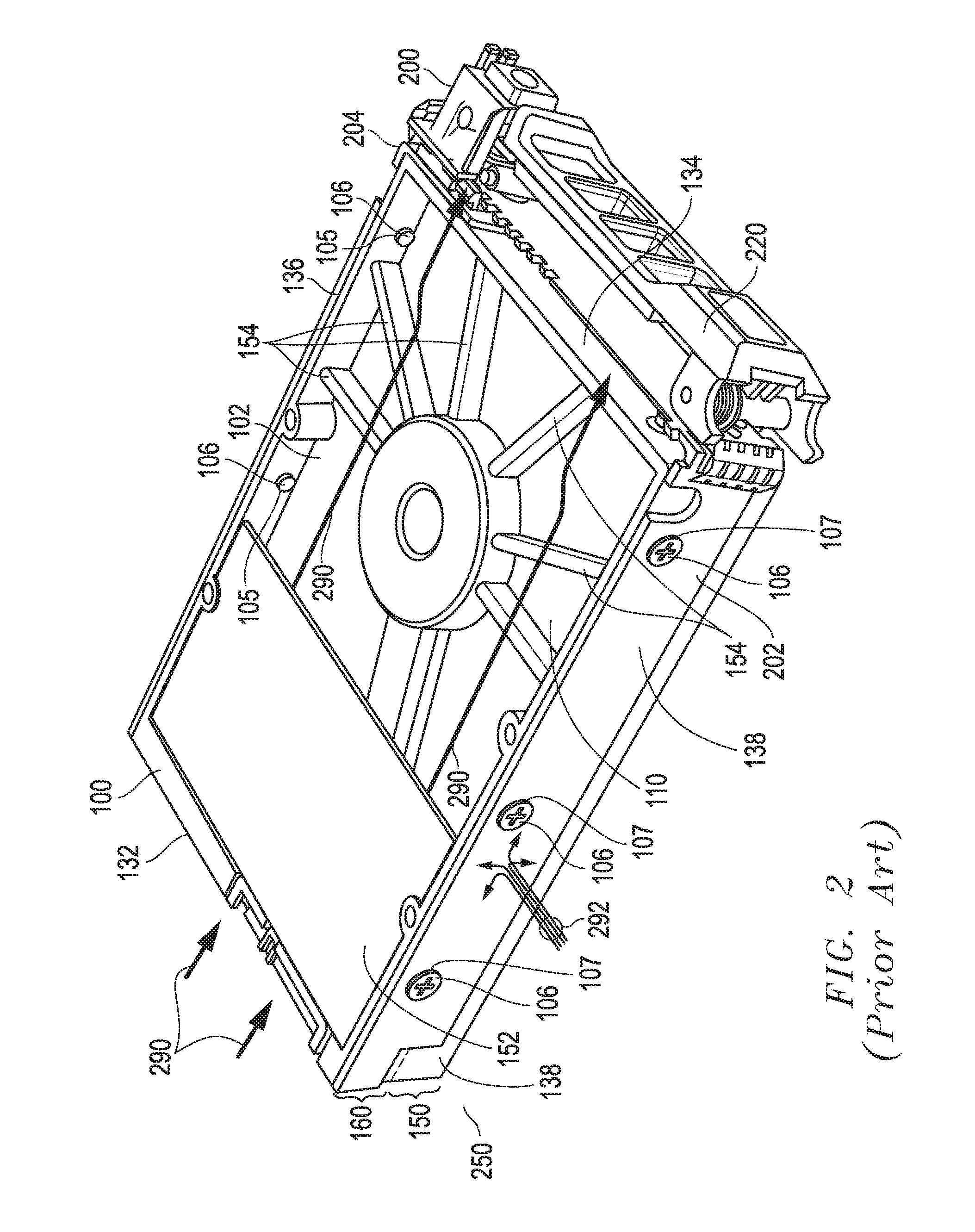

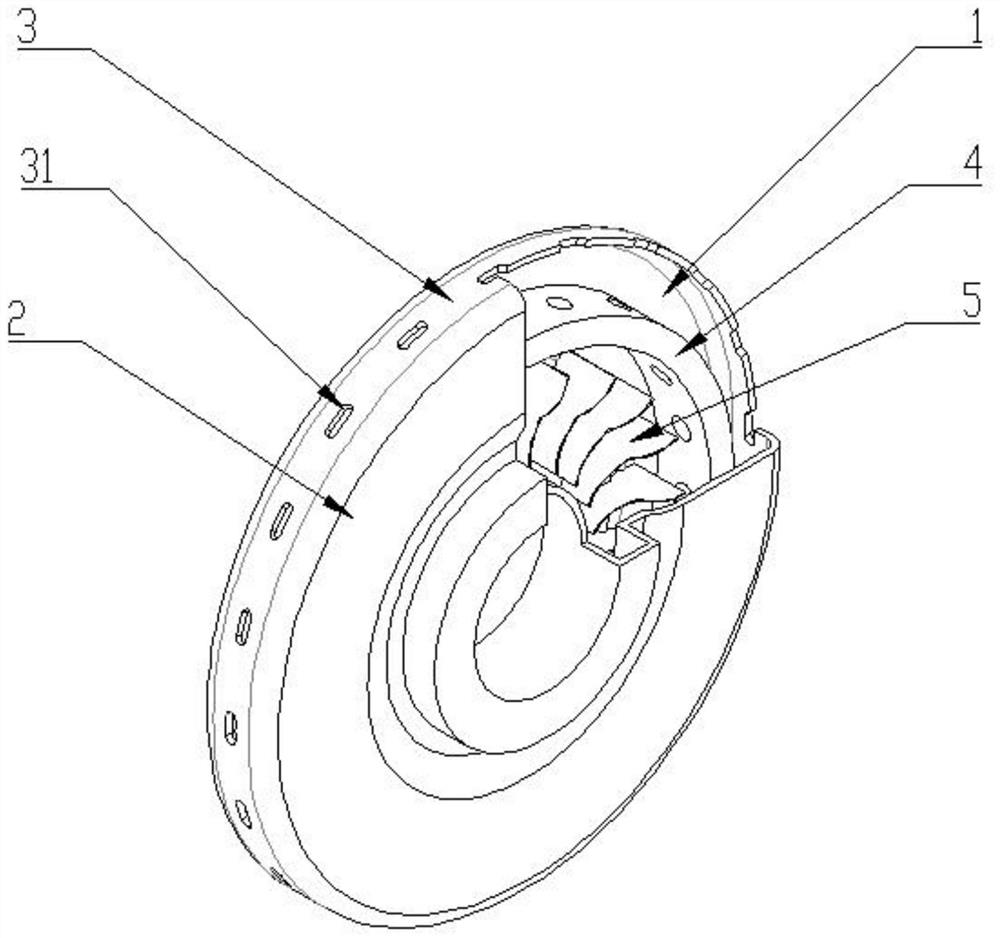

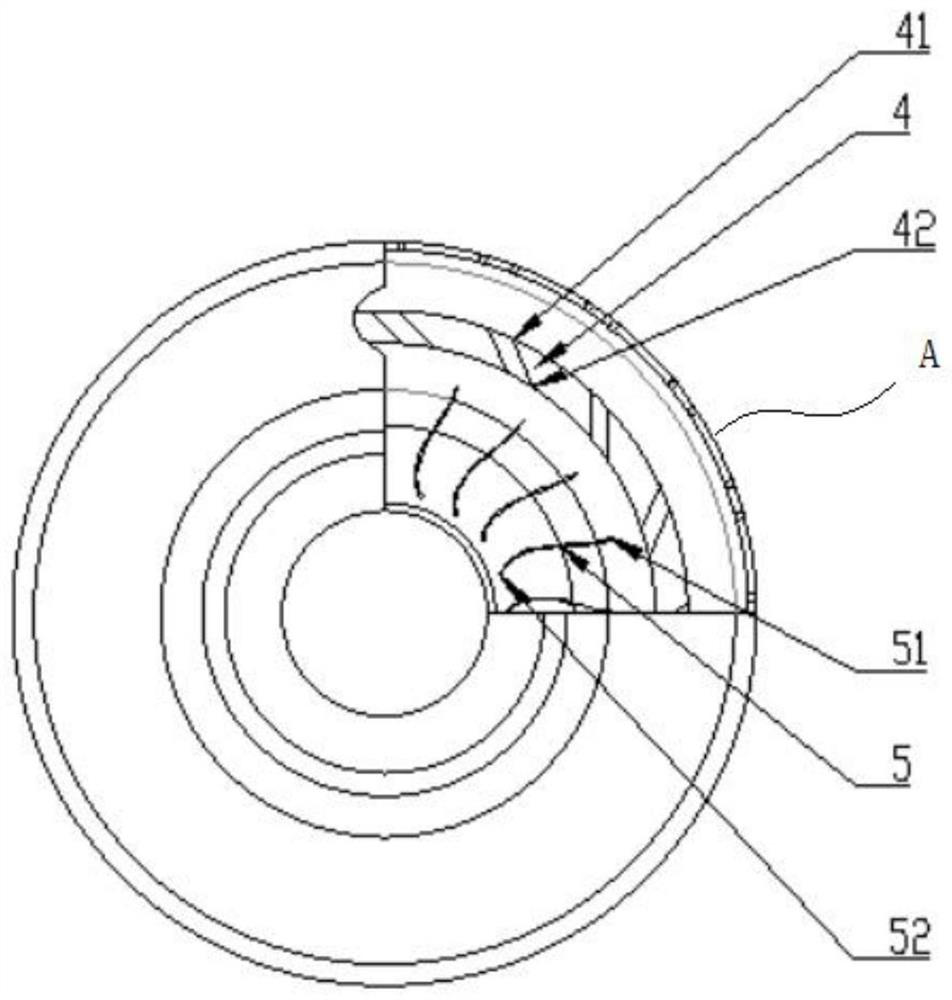

Electric fan

InactiveUS20070080604A1Reduce flow resistanceTurbulent flow and noise be avoidPump componentsMagnetic circuit stationary partsStatorEngineering

An electric fan includes a frame (10) having a central tube (11) extending therefrom, a bearing (30) received in the central tube, a stator (50) mounted around the central tube, and a rotor (70) being rotatably supported by the bearing received in the central tube. The frame defines an air inlet (19) and an air outlet (17) at two different sides thereof. The stator includes two poles (51, 53) and a tube (55) arranged between the poles. Each pole includes a basewall (511, 531) and a sidewall (513, 533) extending from the basewall. Each sidewall includes an upper portion adjacent to the air inlet expanding radially along a direction from the air inlet to the air outlet of the electric fan.

Owner:HON HAI PRECISION IND CO LTD

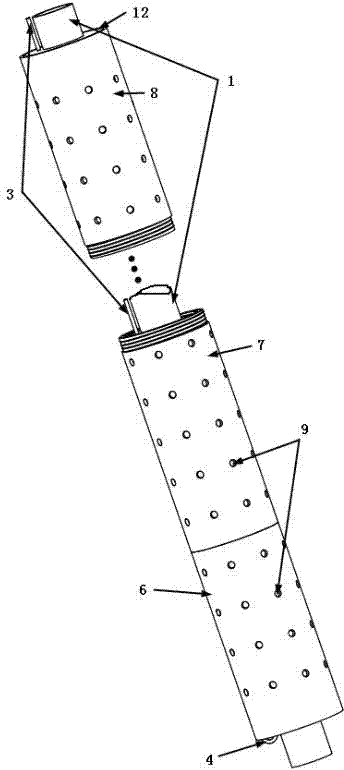

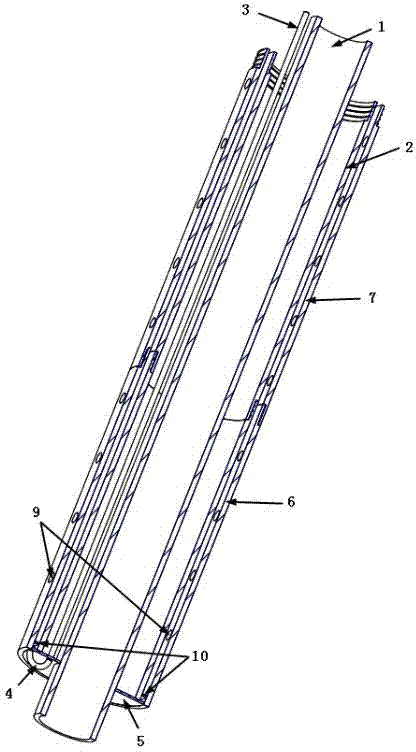

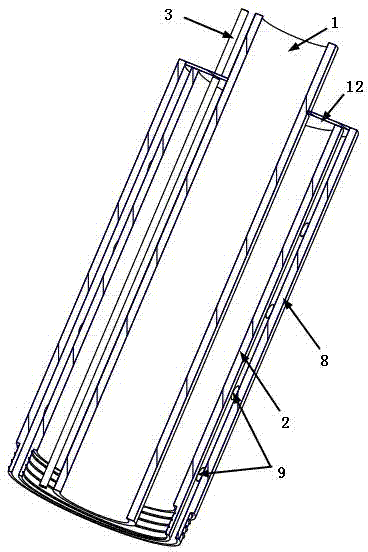

Sieve hole air-jetting vortex-induced vibration suppression device and method

InactiveCN103883268AReduce flow resistanceSuppression of vortex induced vibrationDrilling rodsFluid dynamicsSeawaterWater pipe

The invention relates to a sieve hole air-jetting vortex-induced vibration suppression device and method. The sieve hole air-jetting vortex-induced vibration suppression device is characterized by comprising an air injection pipe, a U-shaped flow guide bent pipe, a bottom air exhaust sieve pipe, an air exhaust sieve pipe, a top air exhaust sieve pipe, an air distribution plate, a base plate and a top plate, wherein the air exhaust sieve pipe is arranged outside a water isolation pipe in a sleeved mode, the air injection pipe leads high-pressure air flow into an annular space between the air exhaust sieve pipe and the water isolation pipe through the U-shaped flow guide bent pipe, the air flow flows out from air exhaust holes in the air exhaust sieve pipe, a seawater streaming boundary layer on the surface of a pipeline is damaged, formation of vortexes of the tail of the pipeline is interfered, and vortex-induced vibration is effectively suppressed. The sieve hole air-jetting vortex-induced vibration suppression device and method can deal with flow in different directions, is not corroded or damaged easily, is put in along with the water isolation pipe in the on-site construction process, does not affect the normal construction process, can be recycled after construction, and saves cost.

Owner:SOUTHWEST PETROLEUM UNIV

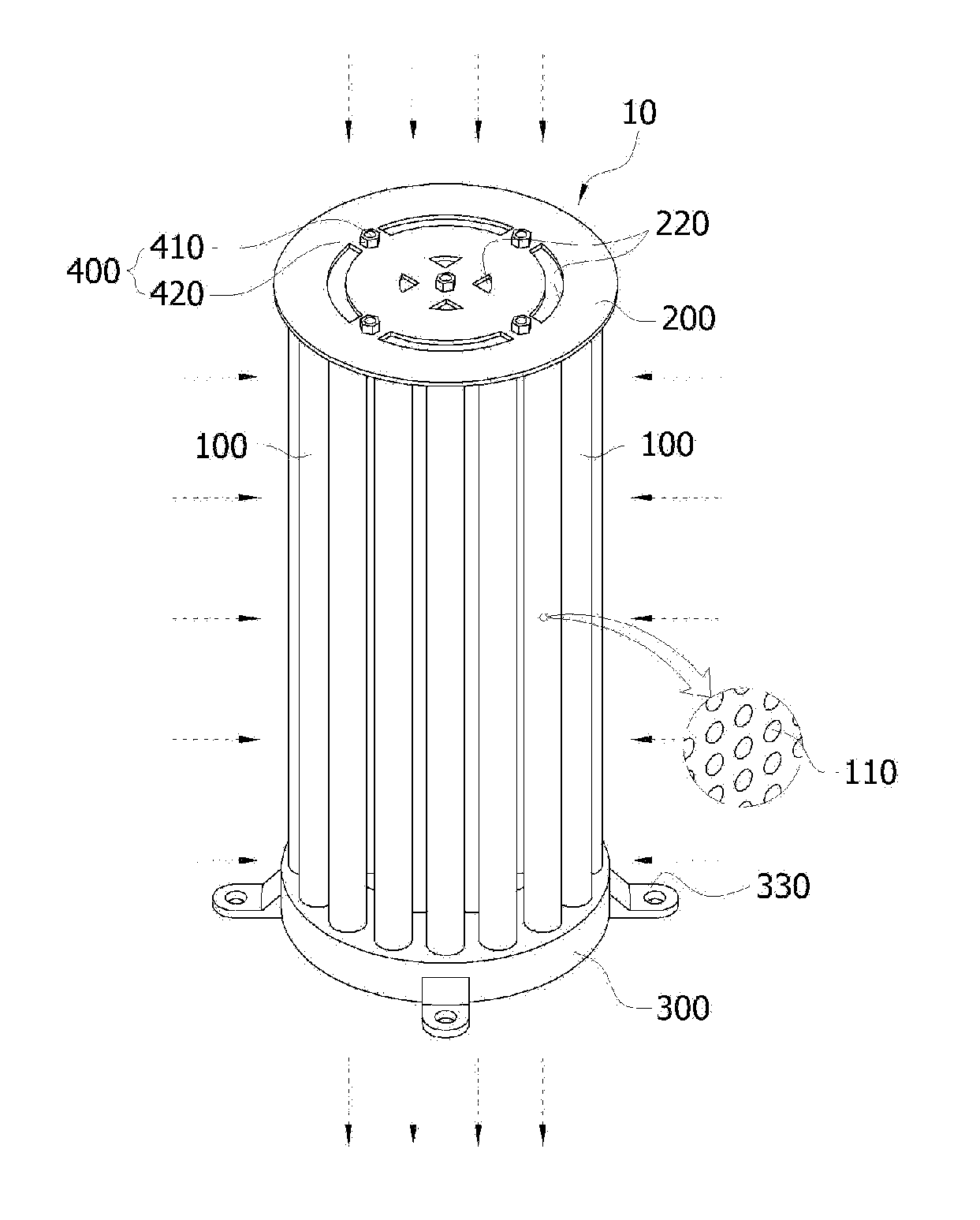

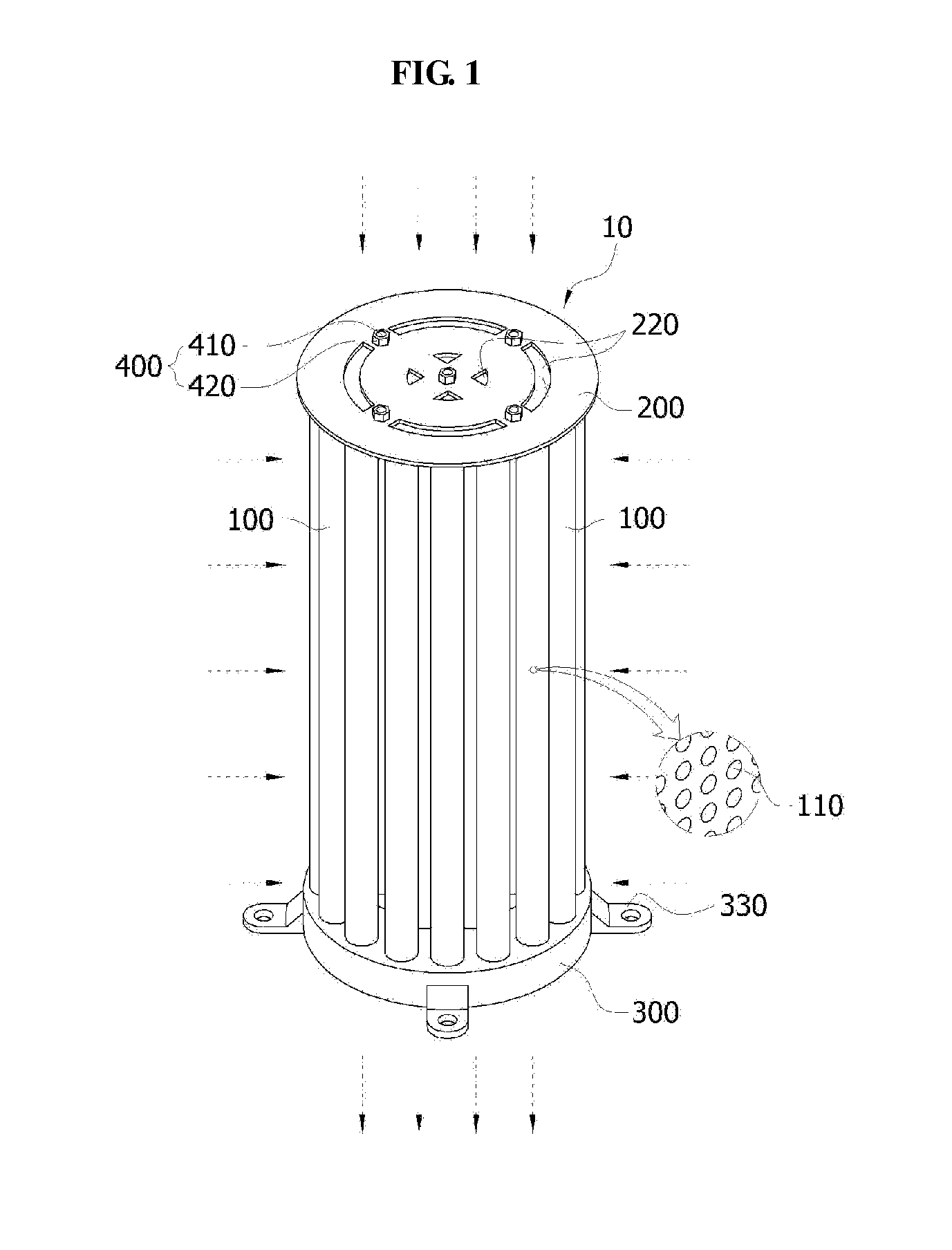

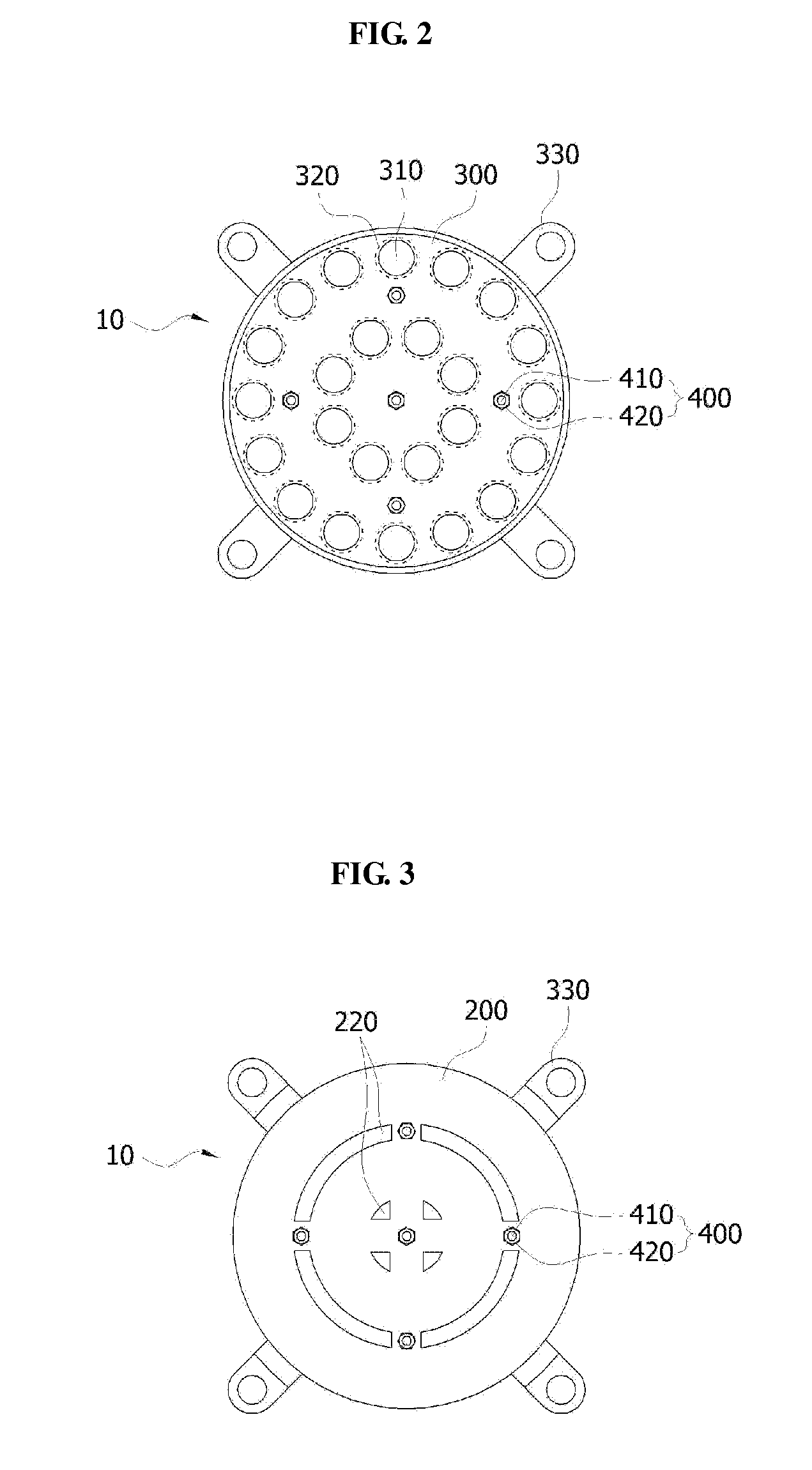

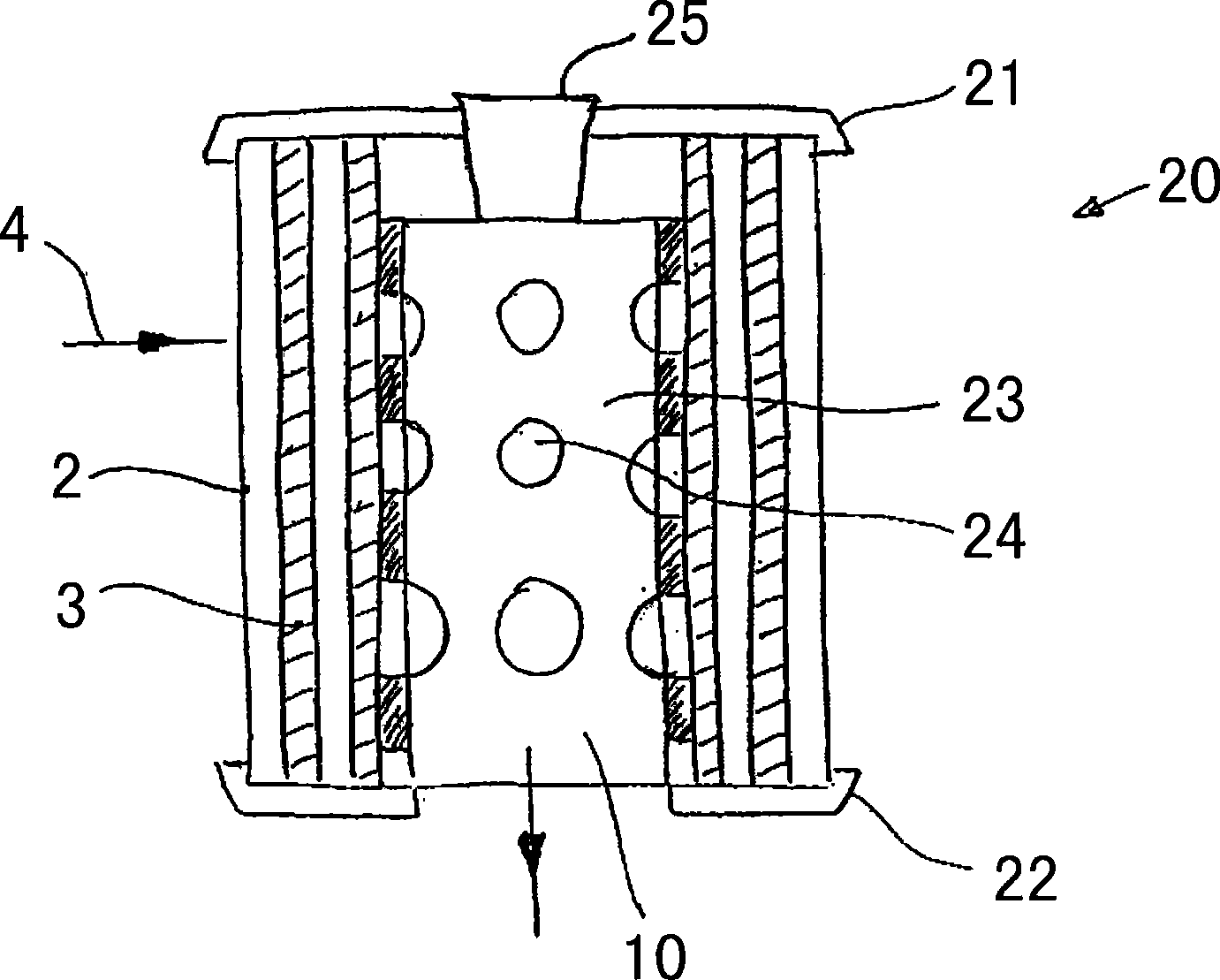

Strainer filtering apparatus including filtering tube

InactiveUS20120037559A1Reduce flow resistanceReduced pressure dropMembrane filtersLoose filtering material filtersForeign matterForeign substance

A strainer filtering apparatus including a filtering tube providing a substantially larger effective filtering area for its length and width, substantially reducing foreign substances covering a suction surface and flow resistance of the foreign substances, and reducing pressure drop at a cooling water passage. The strainer filtering apparatus includes at least one inlet side into which cooling water is introduced and an outlet side through which the cooling water is discharged, hollow filtering tubes with filtering holes along their lengths, an upper plate having first grooves located at a lower surface and coupled to upper ends of the filtering tubes and an inlet part into which the cooling water is introduced, and a lower plate having punched holes to which lower ends of the filtering tubes are coupled. The cooling water in the filtering tubes is introduced through the punched holes and discharged at the outlet side.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

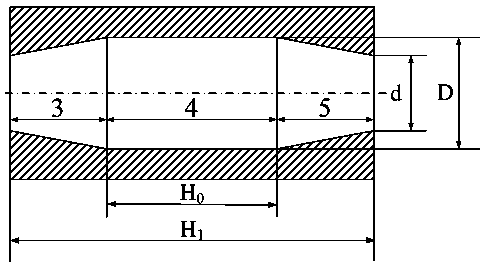

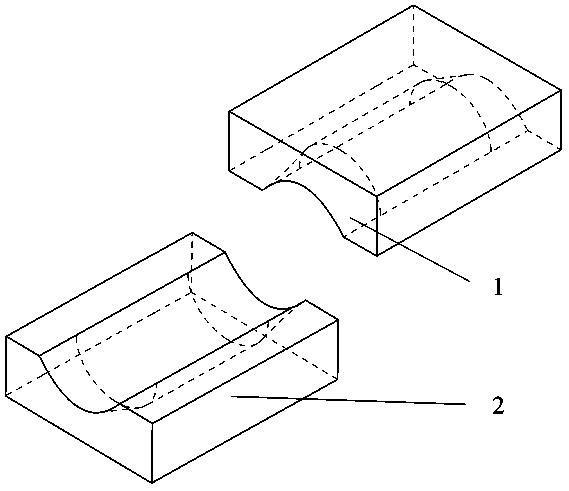

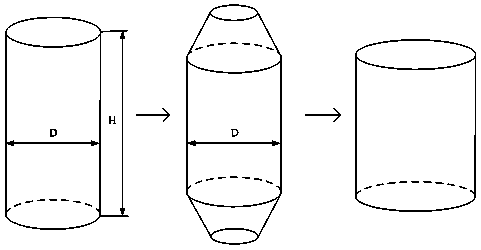

Blank pre-upsetting forming die and method

InactiveCN104384416AReduce contact areaReduce flow resistanceForging/hammering/pressing machinesDiameter ratioMaterials science

The invention discloses a blank pre-upsetting forming die and a blank pre-upsetting forming method, and belongs to the technical field of material forging. The blank pre-upsetting forming die is firstly designed, a cylindrical blank with a high height-diameter ratio is changed into a blank of which the two ends are frustum-shaped and which is low in height-diameter ratio, and a flat anvil upsetting technology is carried out. For an original blank with a high height-diameter ratio, the original blank is pre-upset by adopting the method in the upsetting forming process to form a cylindrical structure of which the two ends are frustum-shaped; as a contact area between the blank and the die is small, the die slightly hinders the flow of metal on the end part of the blank, and a hard deformation area does not exist, the blank difficultly forms a drum type in the later upsetting process, the deformation is uniform, and the upsetting effect is good. The invention provides a good preprocessing method for upsetting and forming the cylindrical blank with the high height-diameter ratio.

Owner:TAIYUAN UNIV OF TECH

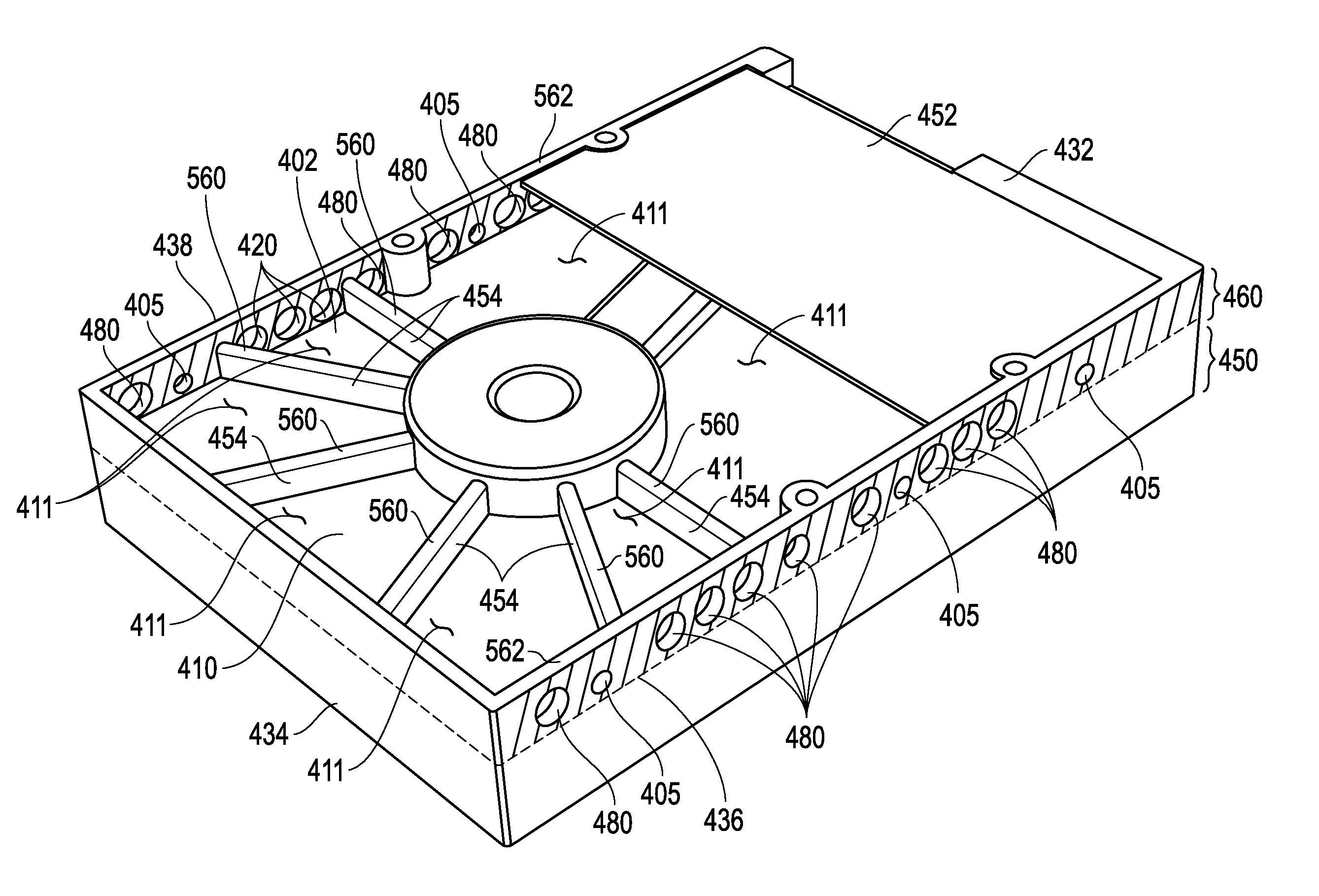

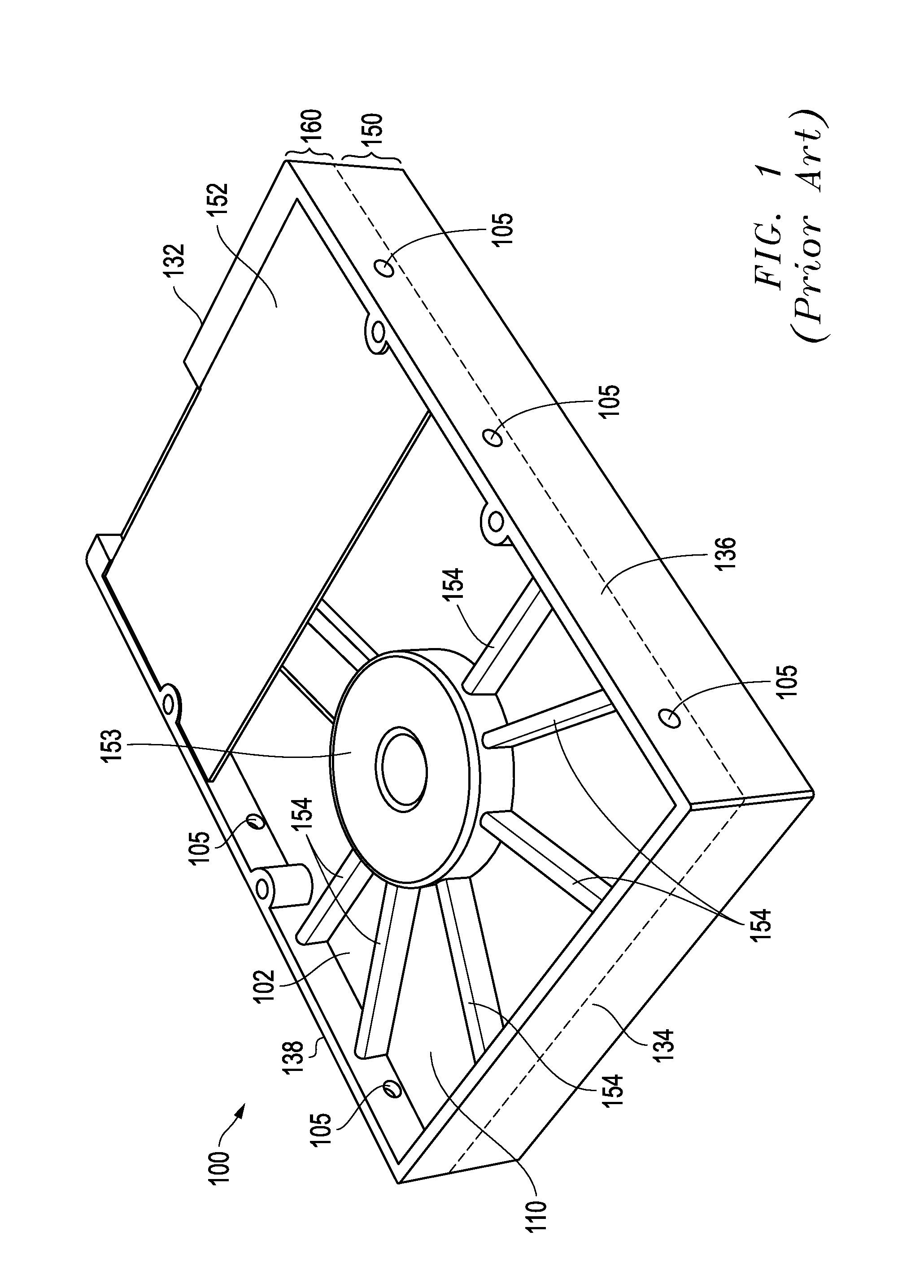

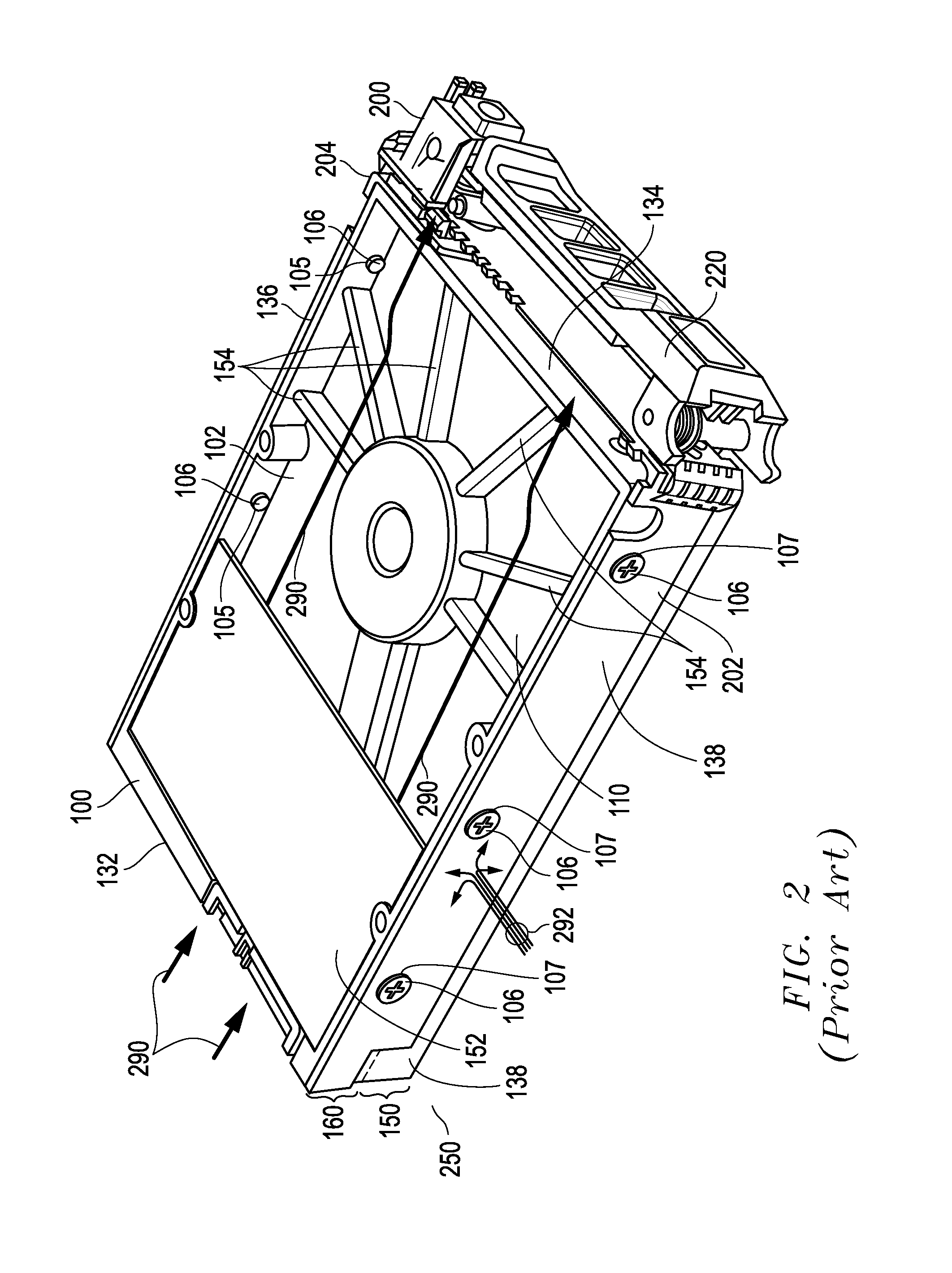

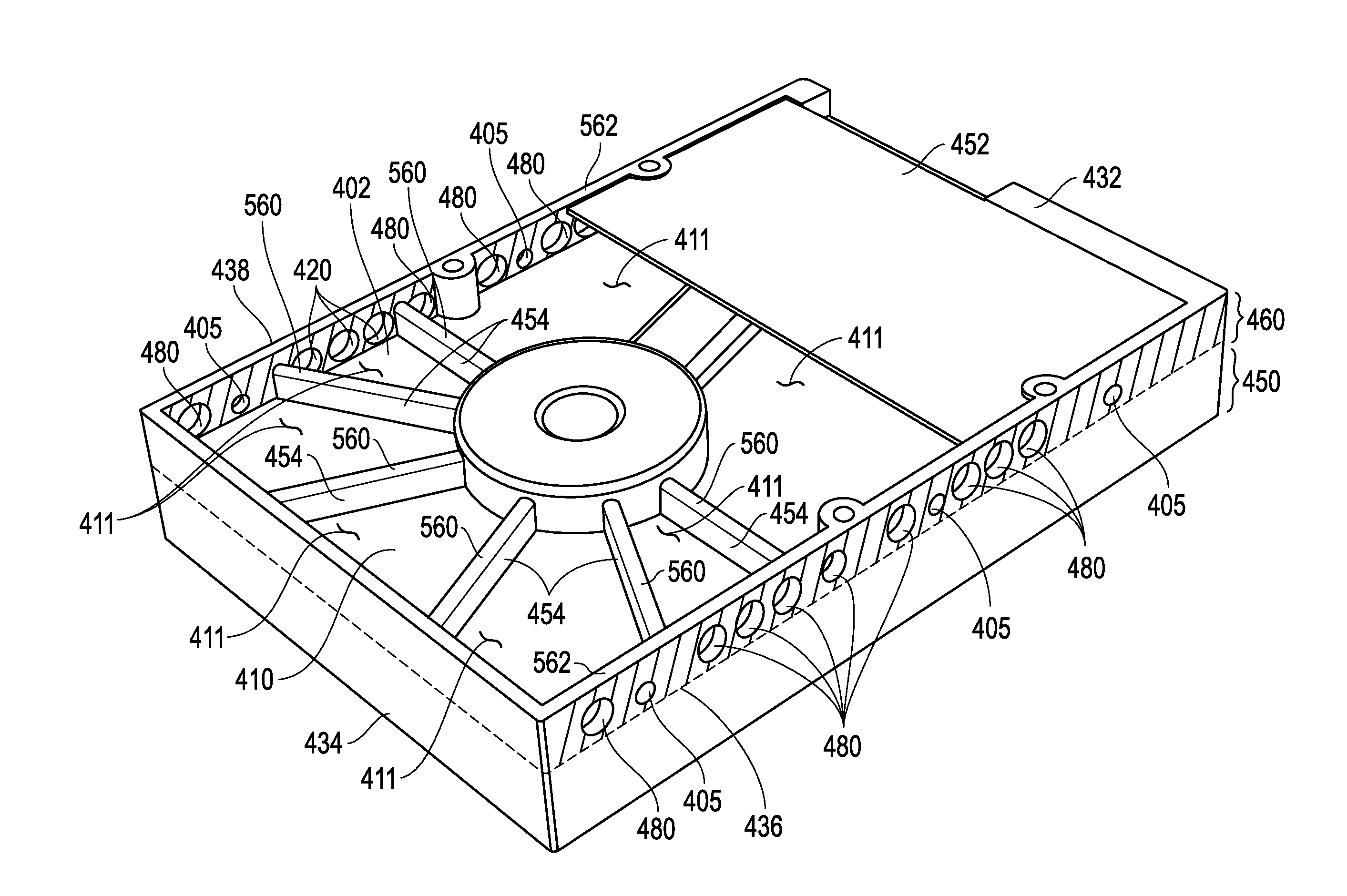

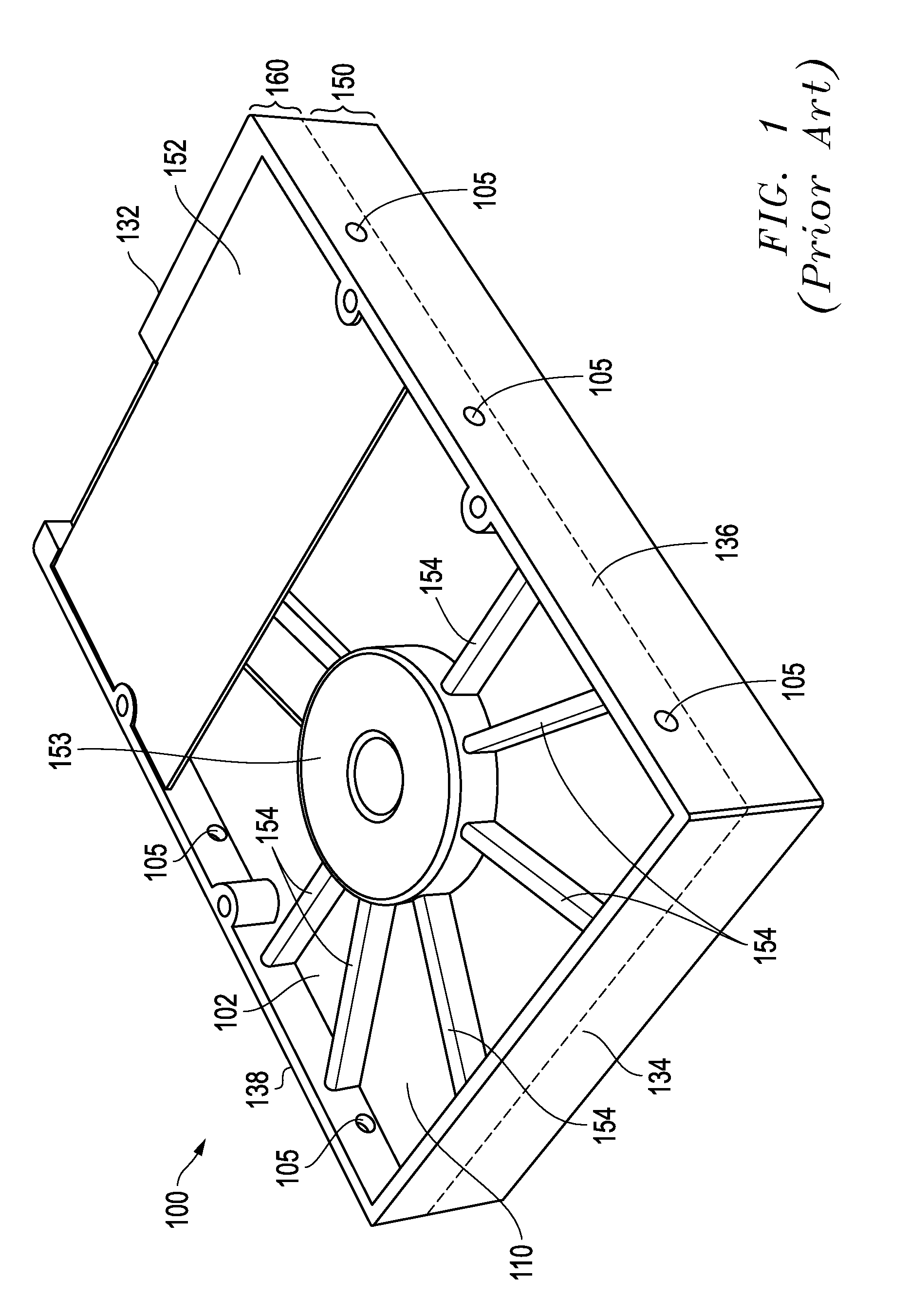

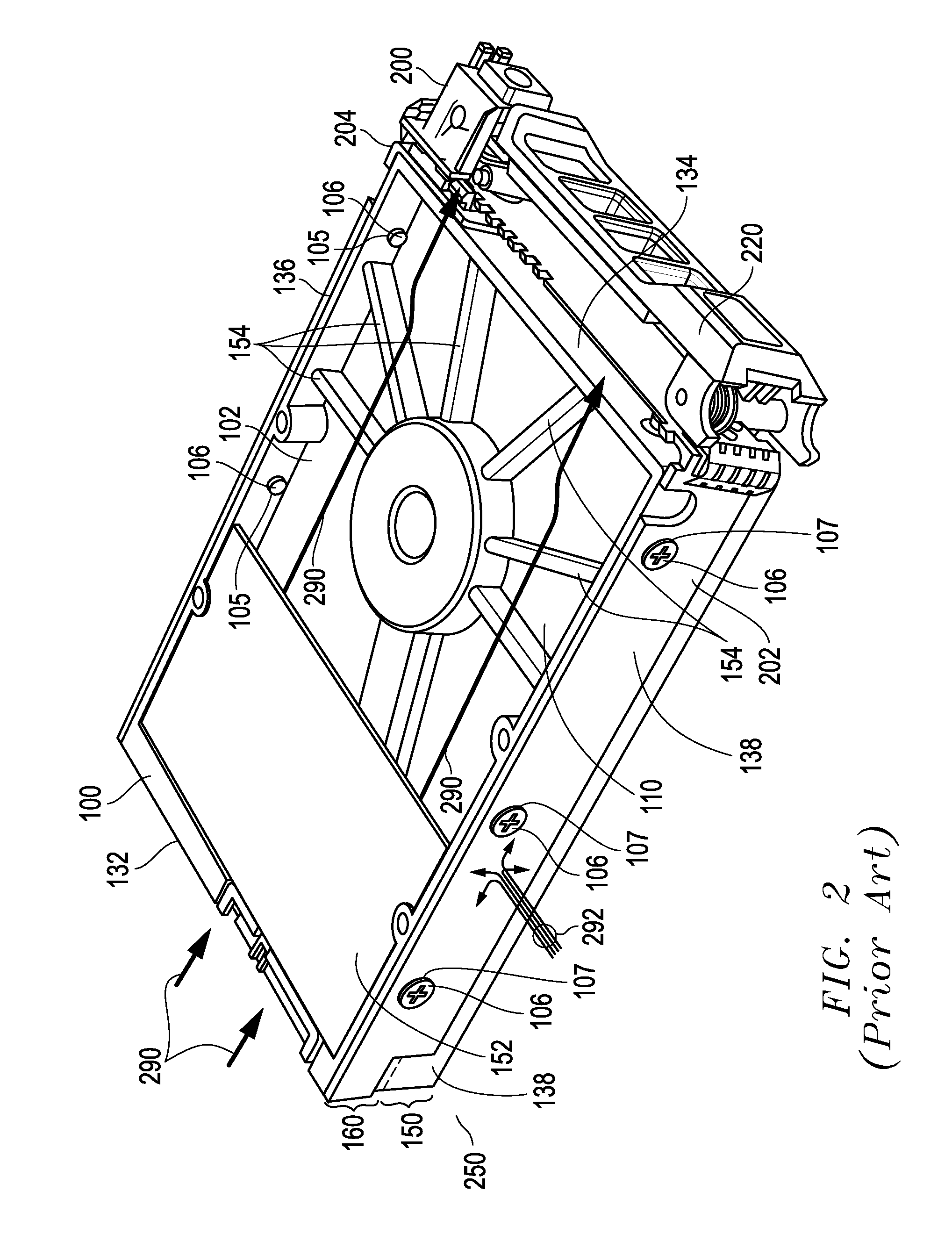

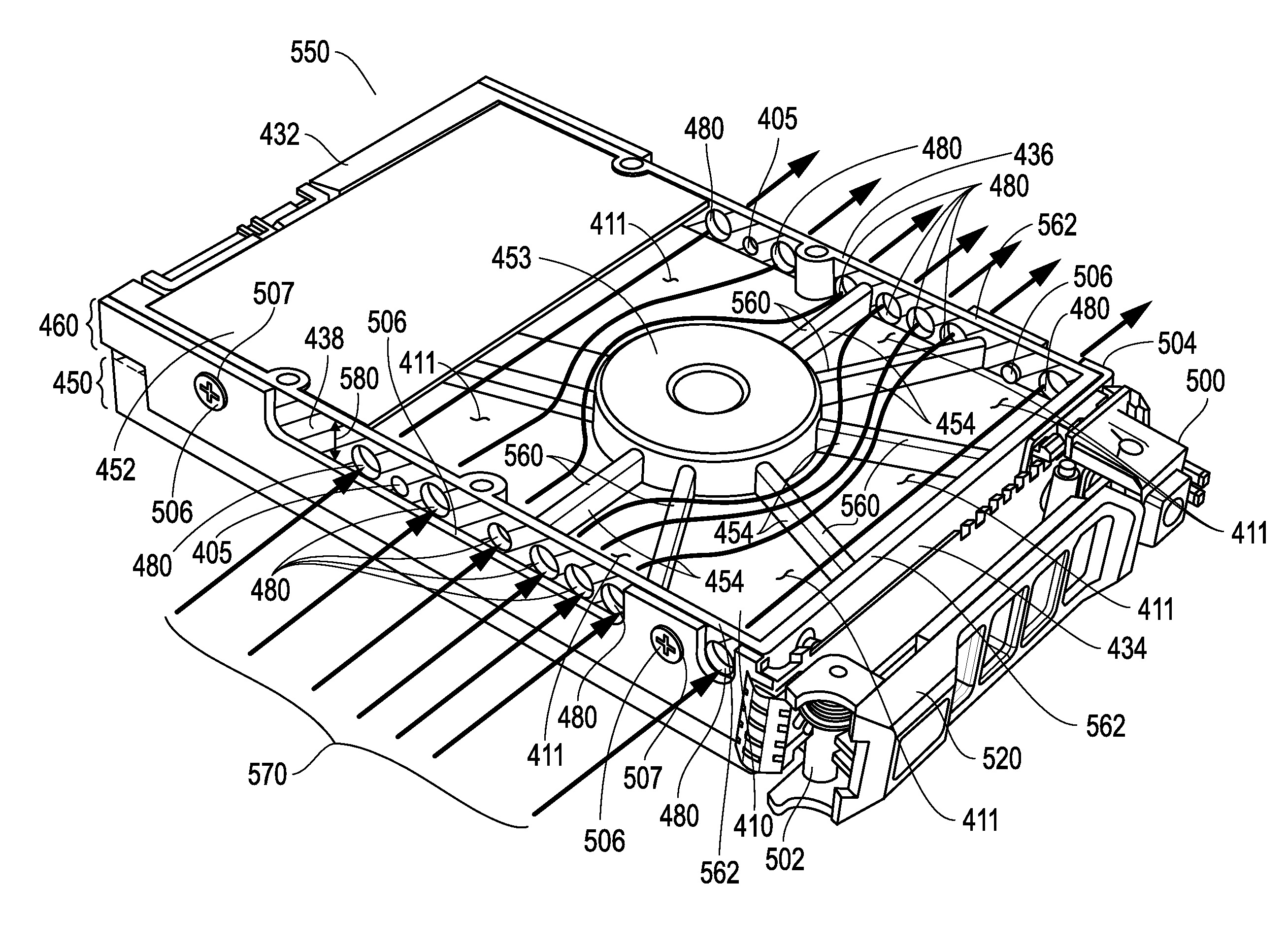

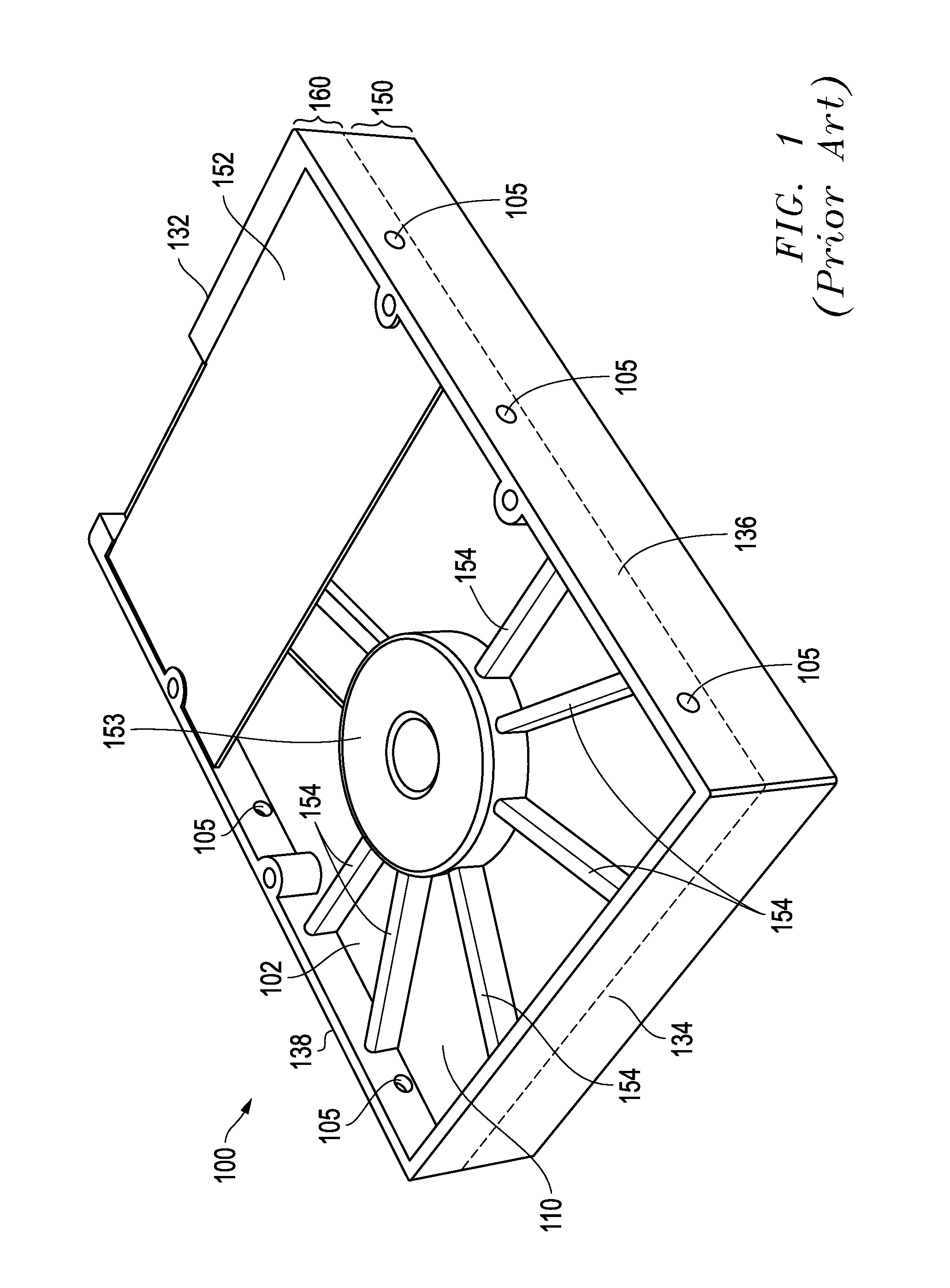

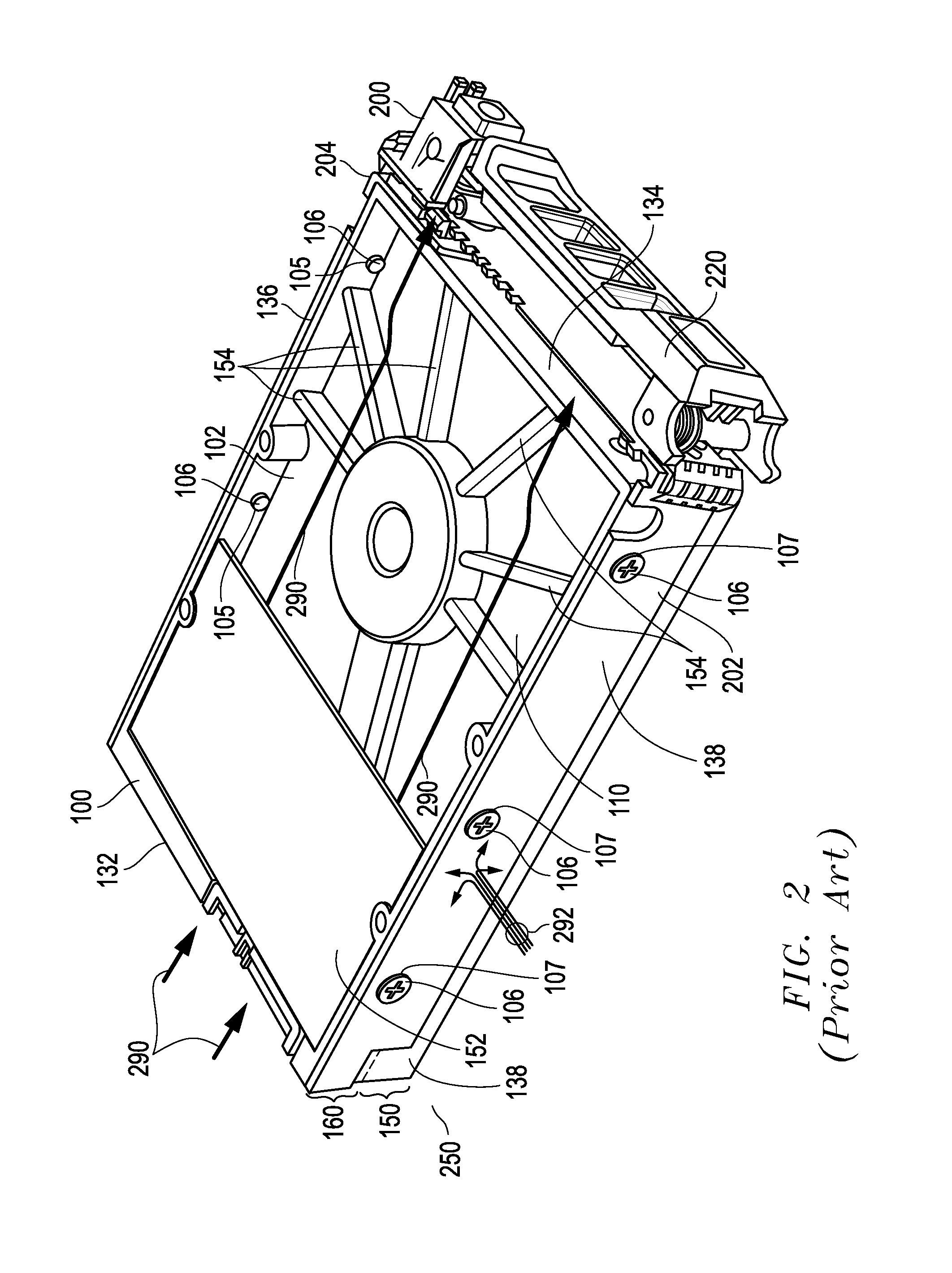

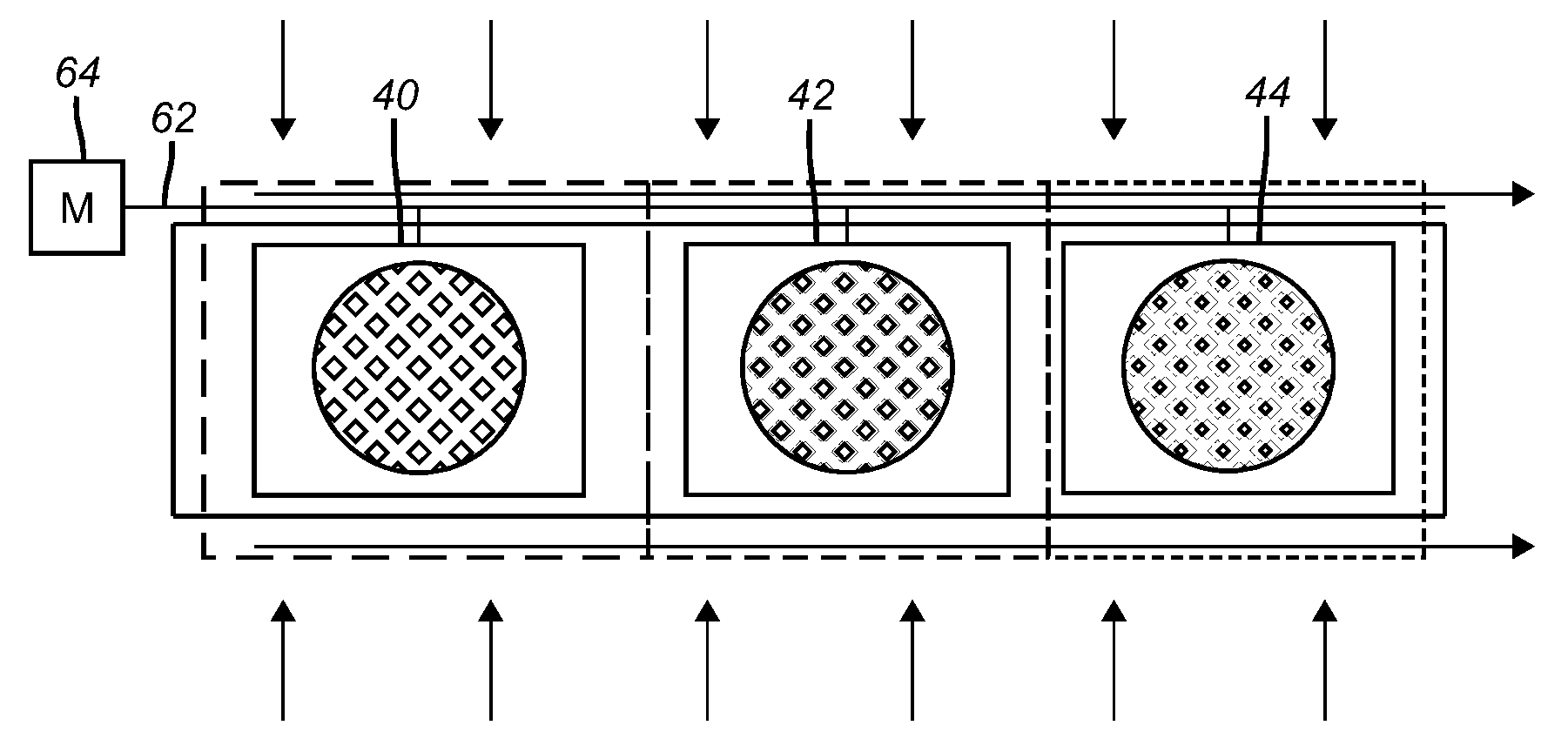

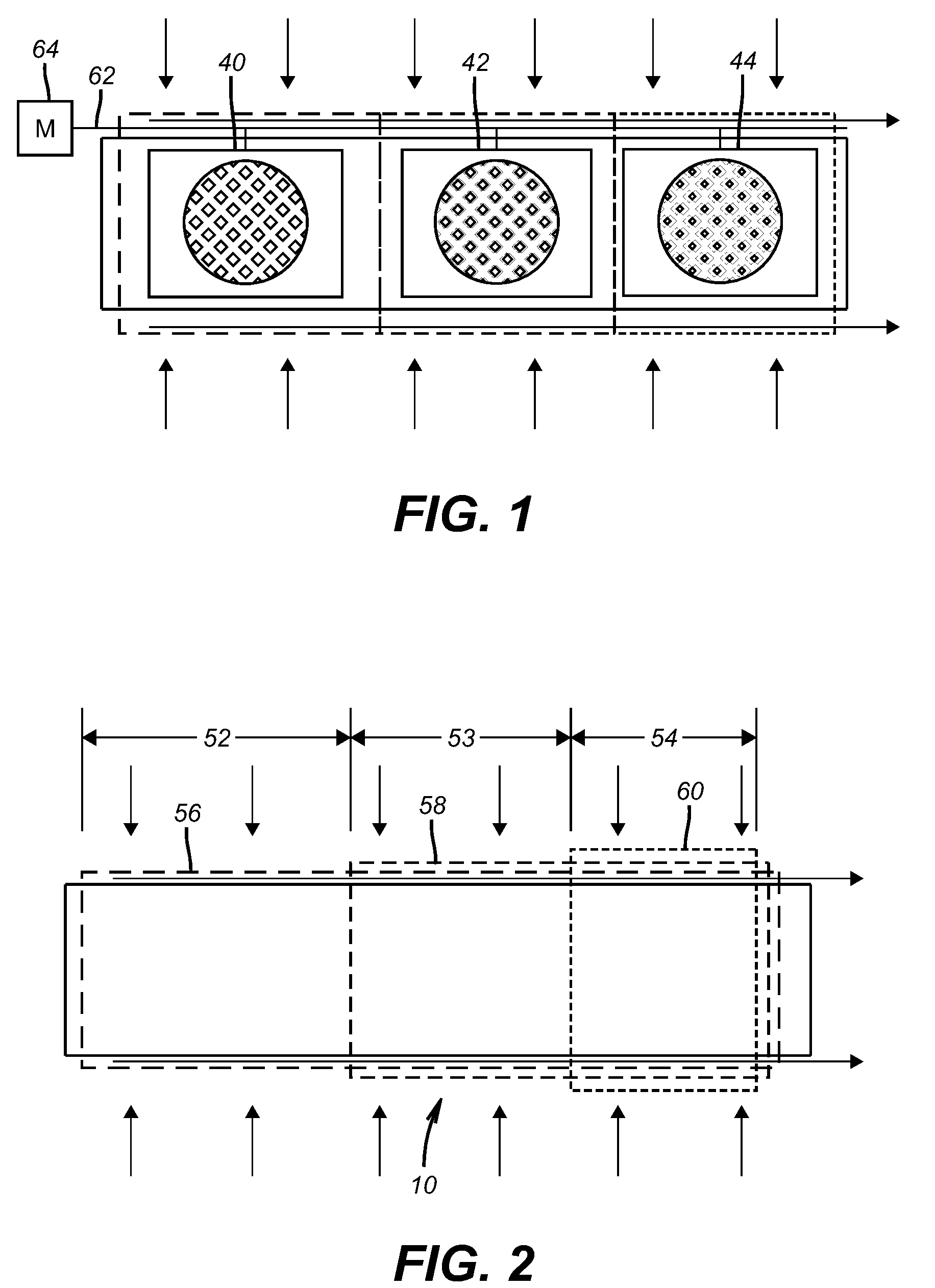

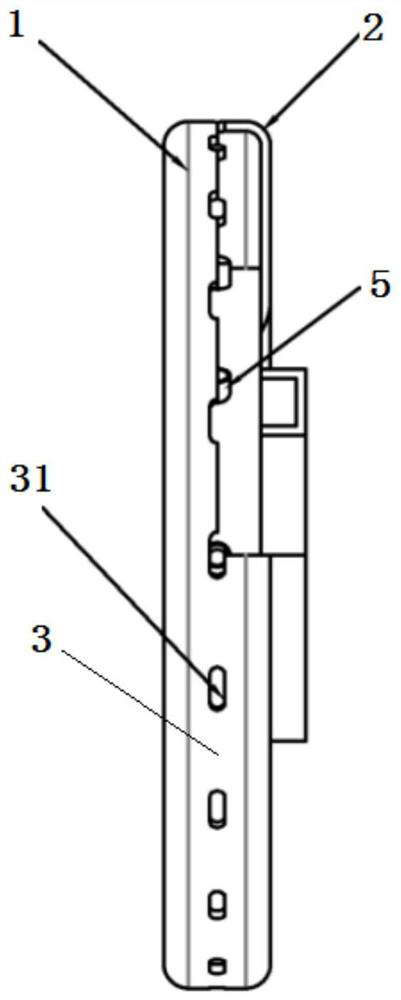

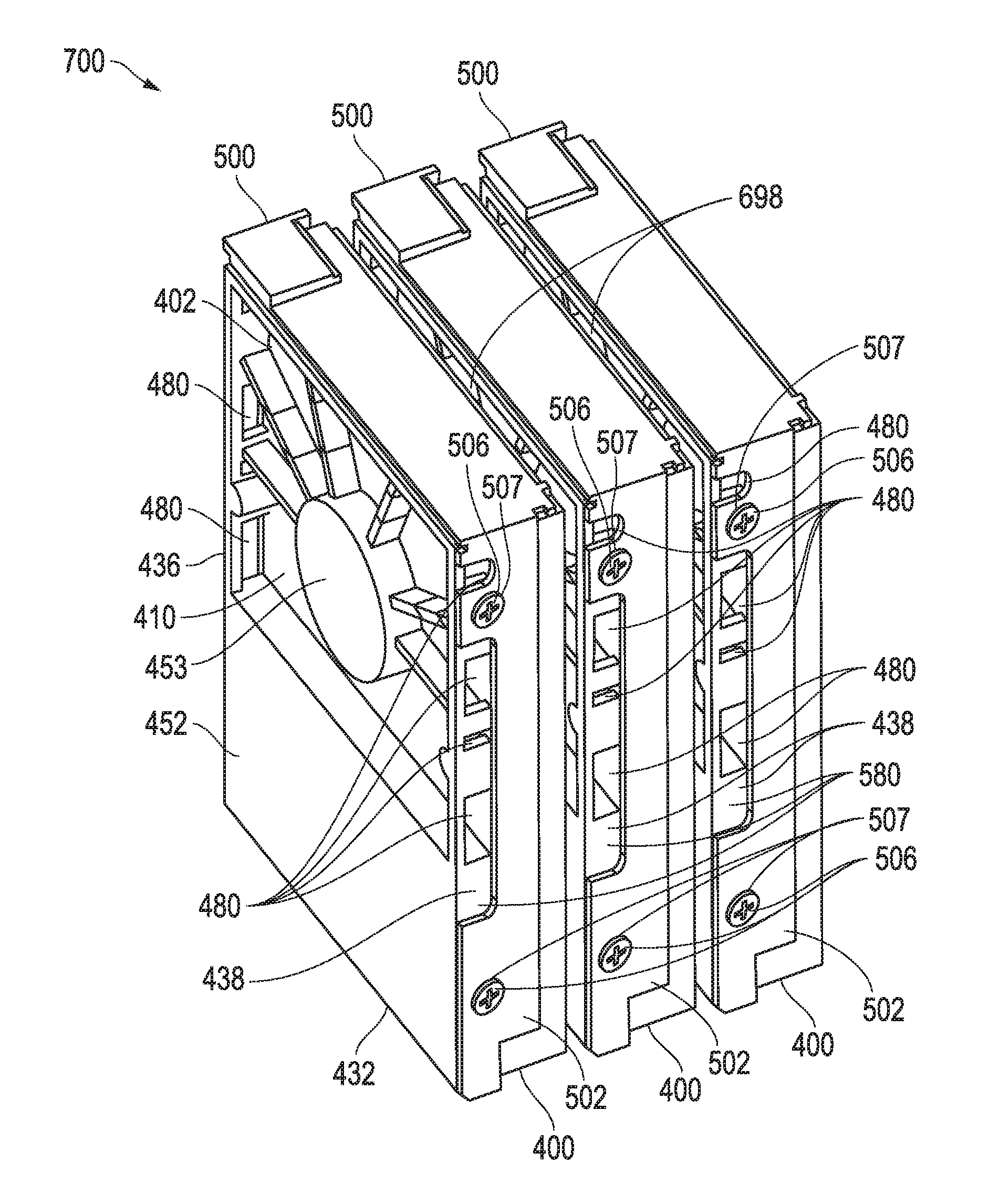

Disk Drive Carriers And Mountable Hard Drive Systems With Improved Air Flow

ActiveUS20150072606A1Lower impedanceReduce flow resistanceShow cabinetsReducing temperature influence on carrierHard disc driveFlow impedance

The side profile of a hard drive assembly may be configured with one or more open areas to allow cooling air to pass side-to-side through a lateral flow channel provided by a cavity defined in the base portion of the hard drive assembly. Corresponding and complementary open areas may be also be defined in mating drive carrier assembly side components to allow passage of lateral side-to-side cooling air through the base portion flow channel of a hard drive assembled to the drive carrier assembly to form a mountable hard drive system that is installed into a storage enclosure. The at least partially aligned open flow areas of the assembled hard dive assembly and drive carrier assembly may cooperate to reduce air flow impedance across multiple rows of hard drive systems through a storage enclosure.

Owner:DELL PROD LP

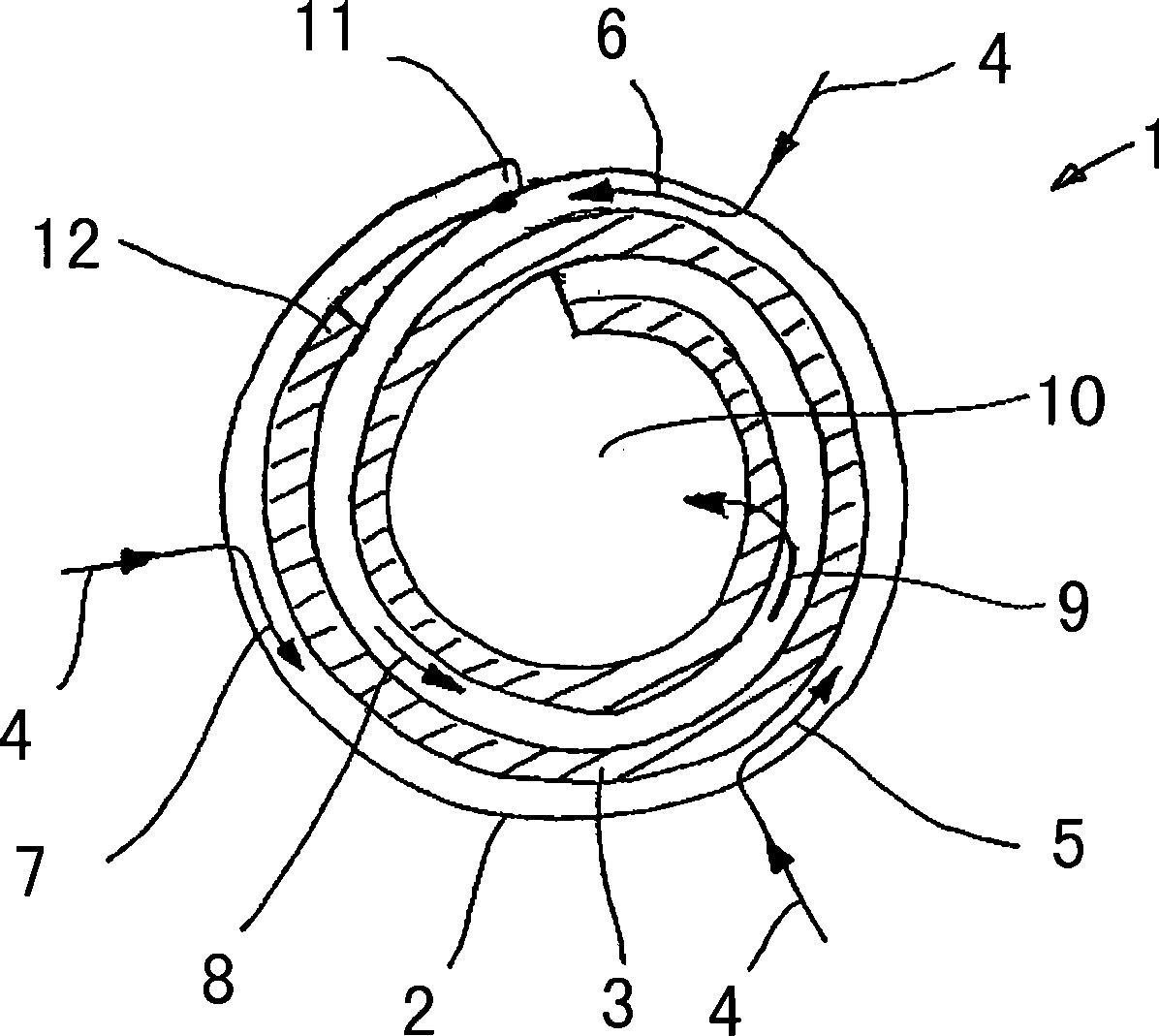

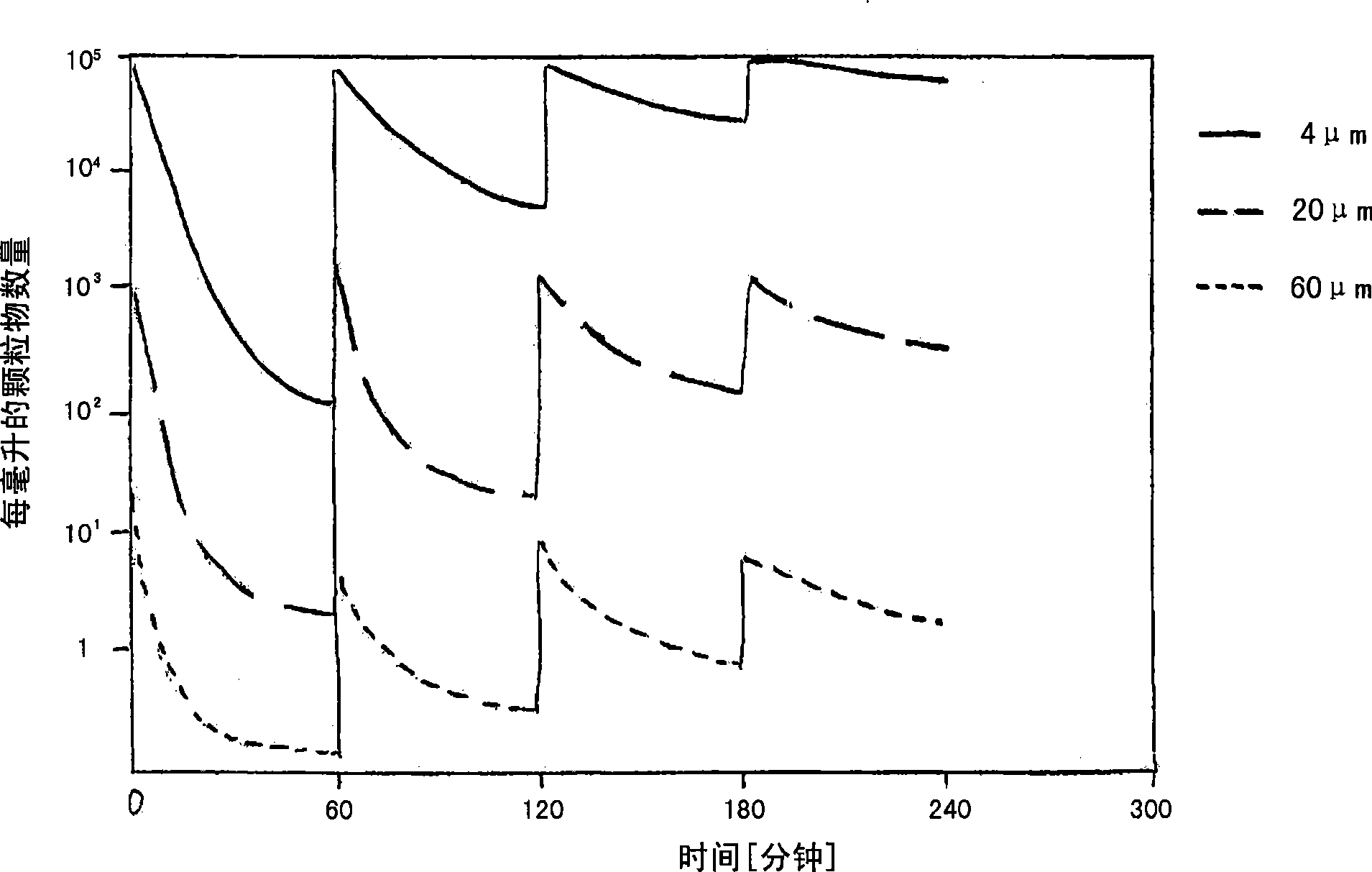

Filter element

InactiveCN101439242AUniform loadLow differential pressure riseStationary filtering element filtersAbsorption capacityFilter media

The invention relates to a filter element for filtering fluid for a motor or gearing, comprising a first filter medium which is arranged in a cylindrical way, with the fluid impinging in a perpendicular way on the circumferential surface of the first medium for filtering in an associated filter apparatus, then penetrating and passing through the same. The filter element comprises a second filter medium with a filter density differing from the first filter medium, the first filter medium and the second filter medium being stacked upon each other as filter layers and being jointly wound in a spiral manner. A desired purity of the fluid can thus be achieved more quickly than in filter elements which exclusively allow a radial passage of the fluid through the filter elements. The spiral configuration also achieves a higher dirt absorption capacity.

Owner:IBS菲尔特兰塑料金属产品有限责任公司

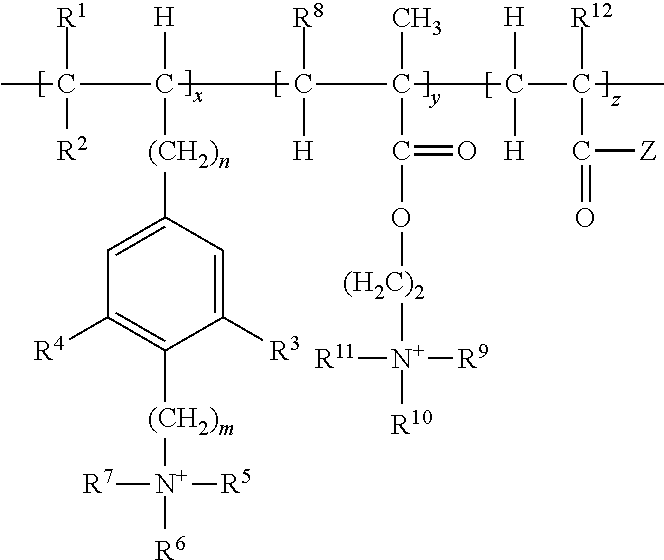

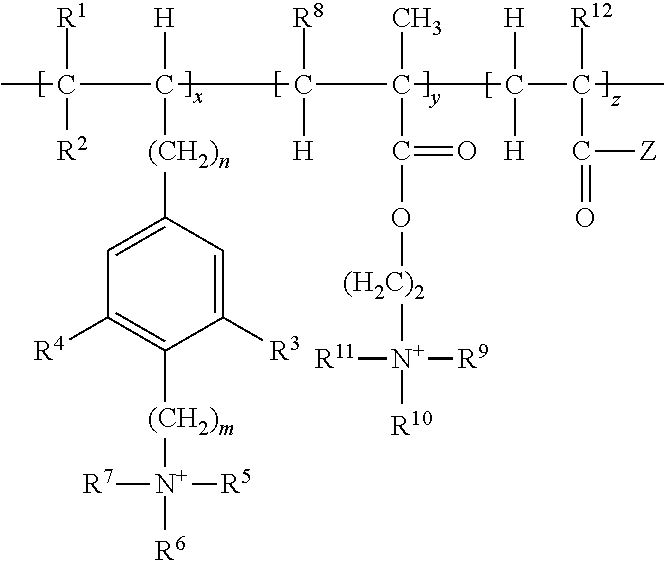

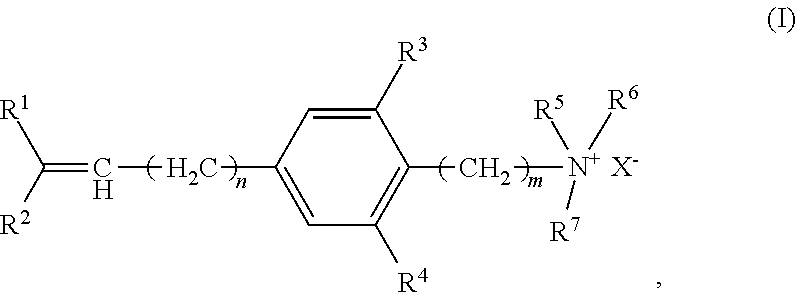

Cationic copolymer and use thereof in lost circulation additive

ActiveUS20160200848A1Reduce flow resistanceReduces viscosity resistanceDrilling compositionPolymer scienceLost circulation

A cationic copolymer represented by the following formula (I) has a viscosity average molecular weight in a range from 2 million to 10 million. In the cationic copolymer, the mole fractions of three structural units corresponding to three monomers are as follows: x being in a range from 0.01 to 20%, y being in a range from 0 to 15%, and z=1−x−y. When used in the construction of leaking stoppage in an oil well, a cationic chemical lost circulation additive prepared with the cationic copolymer is mixed with an anionic drilling fluid in a section of the wellbore where lost circulation occurs. Then neutral reaction and cross linking reaction occur, so that the viscosity of the resulting mixture rapidly increases to form a space grid structure. This blocks off the leakage path, and thus effects on efficient leaking stoppage in a short time period.

Owner:CHINA PETROCHEMICAL CORP +1

Hard Disk Drive Assemblies With Open Side Wall Areas

ActiveUS20150070828A1Reduced cooling fan power costImprove cooling efficiencyReducing temperature influence on carrierRecord information storageHard disc driveMechanical engineering

Owner:DELL PROD LP

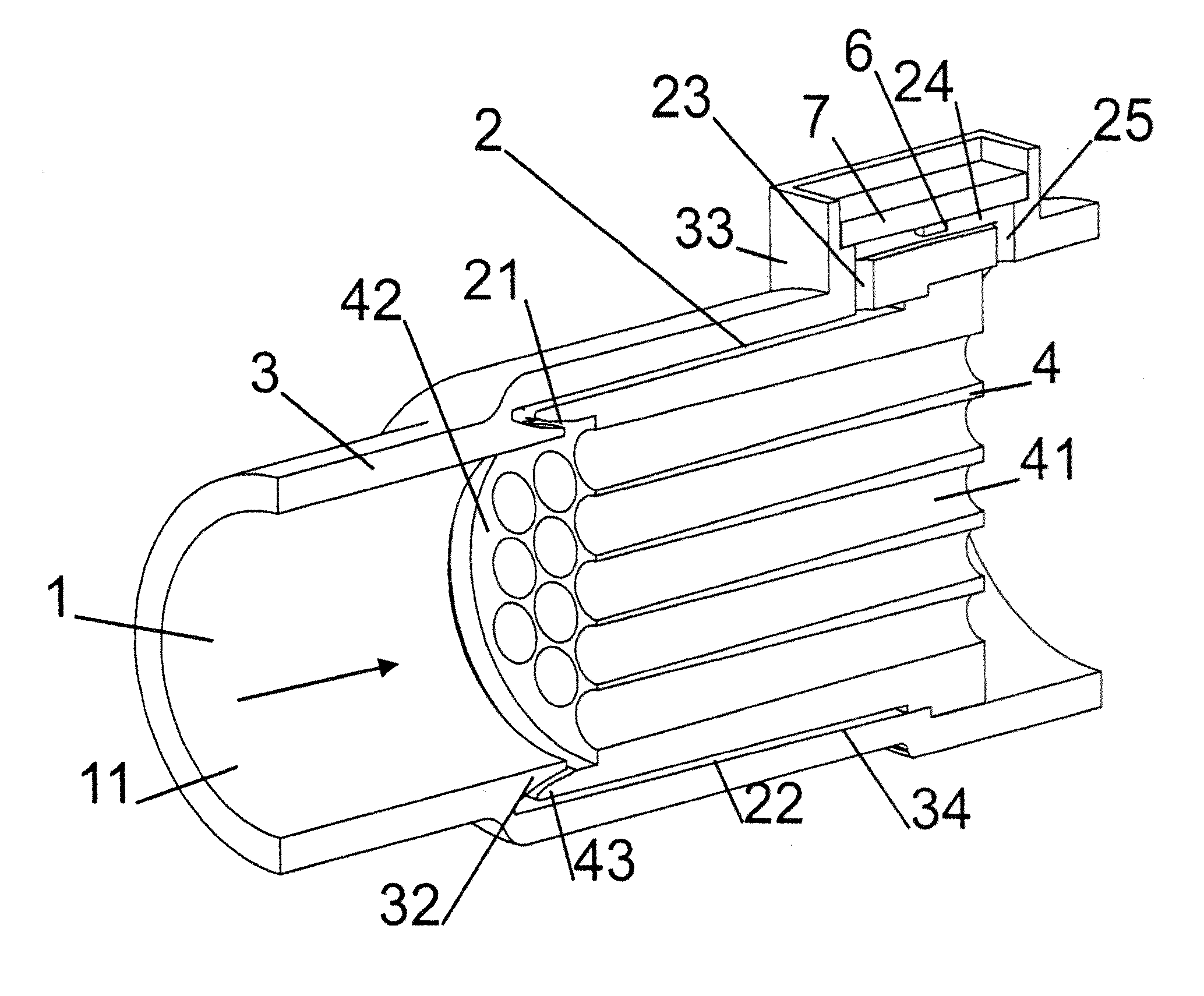

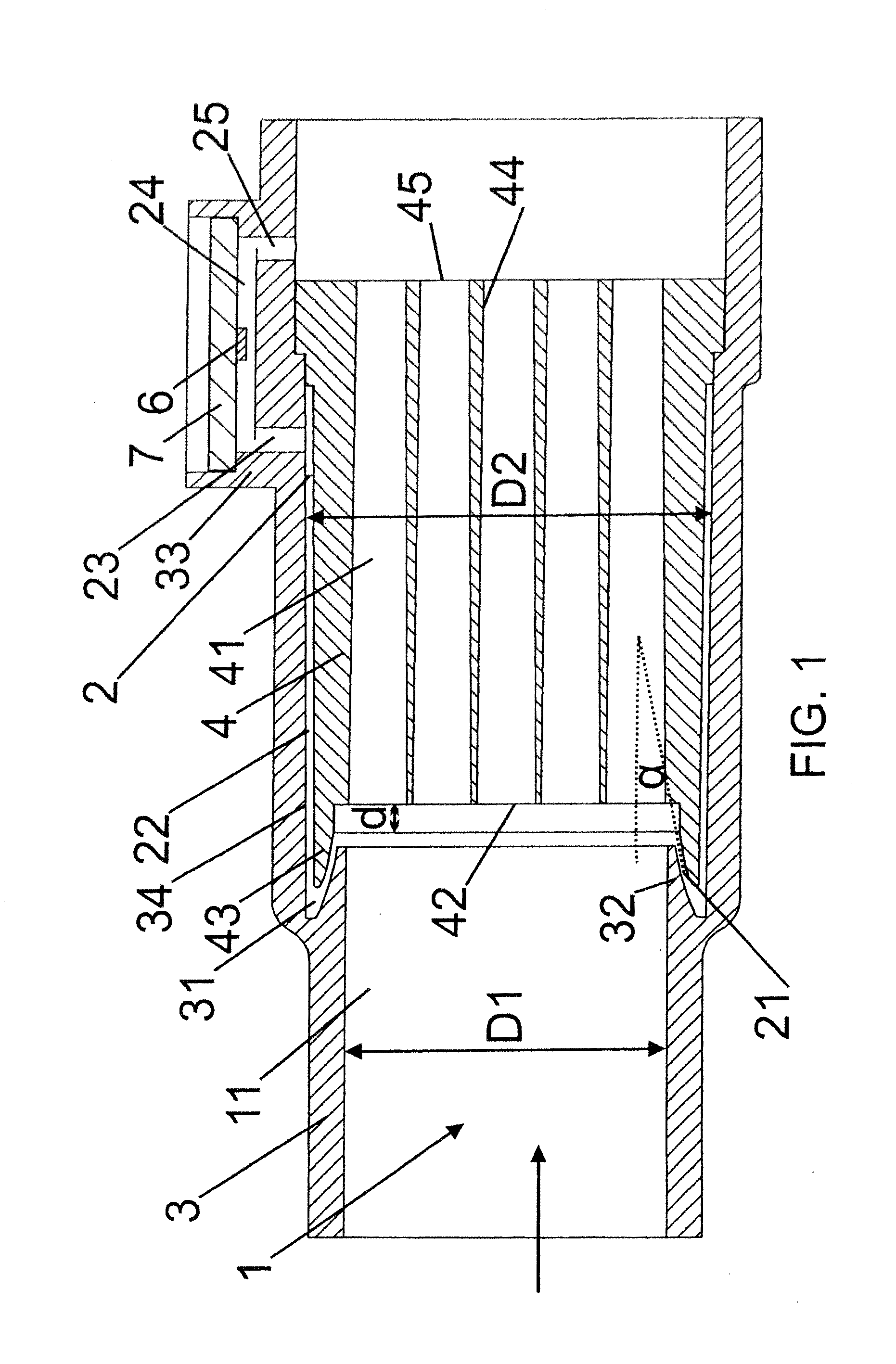

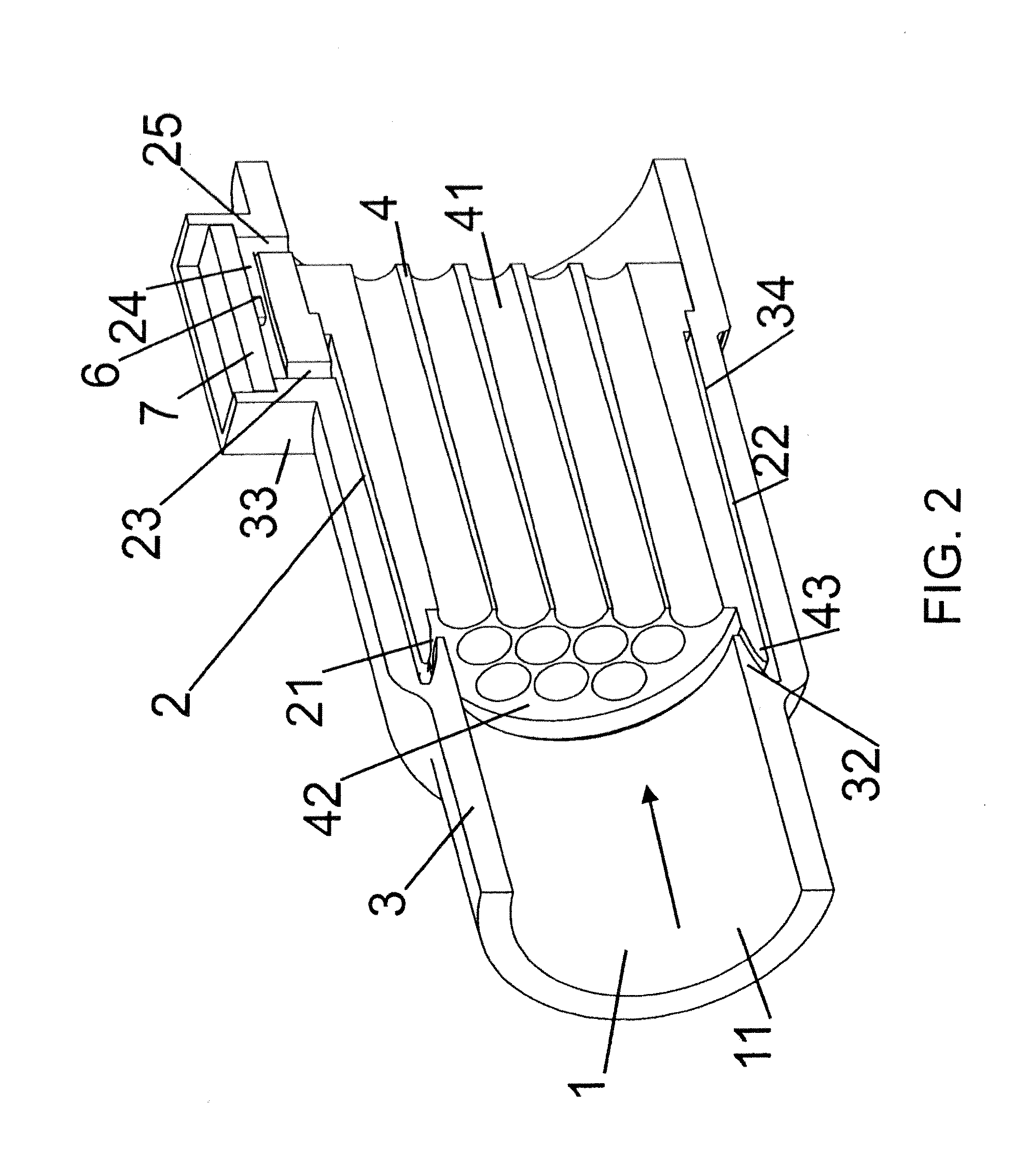

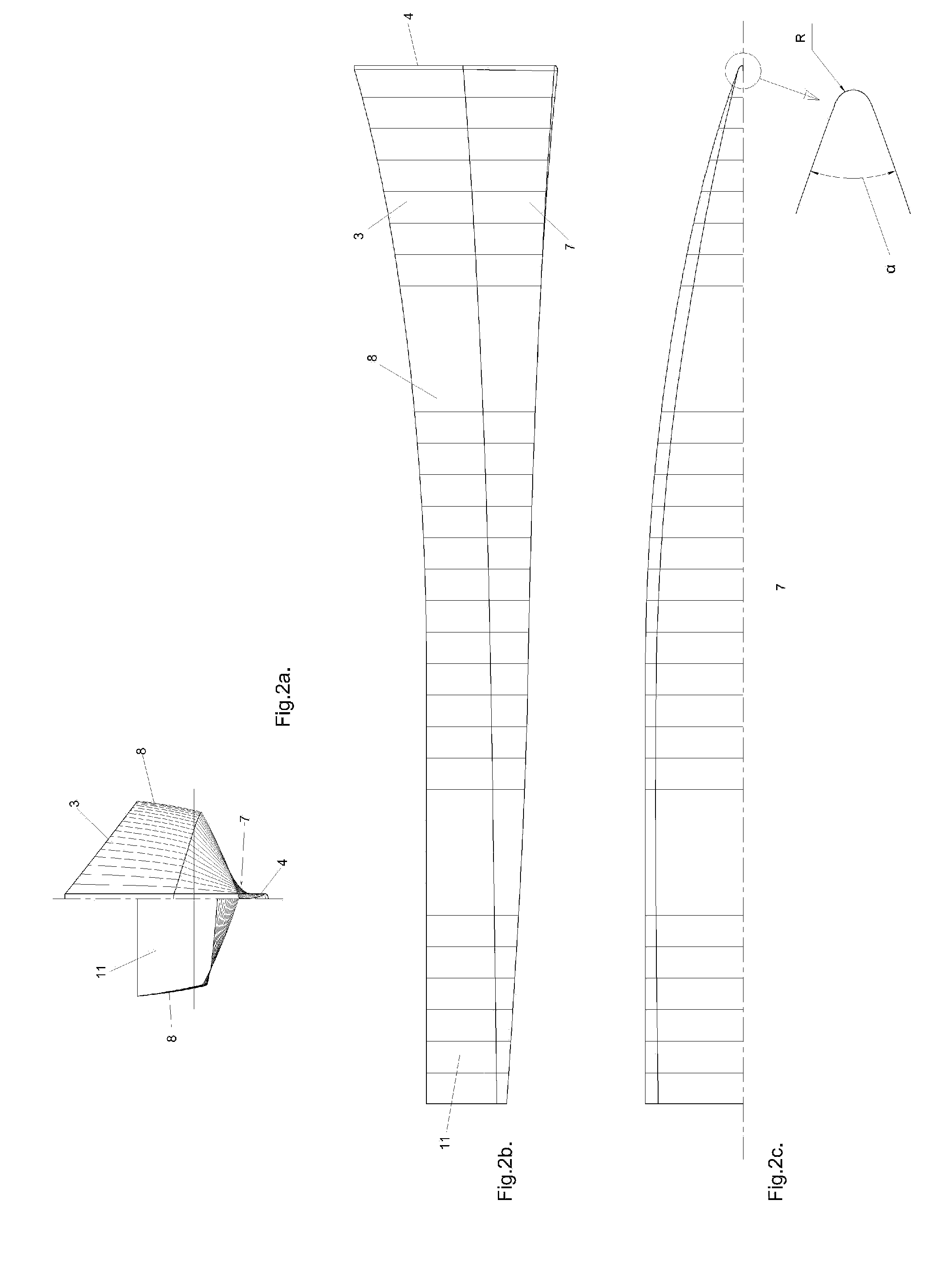

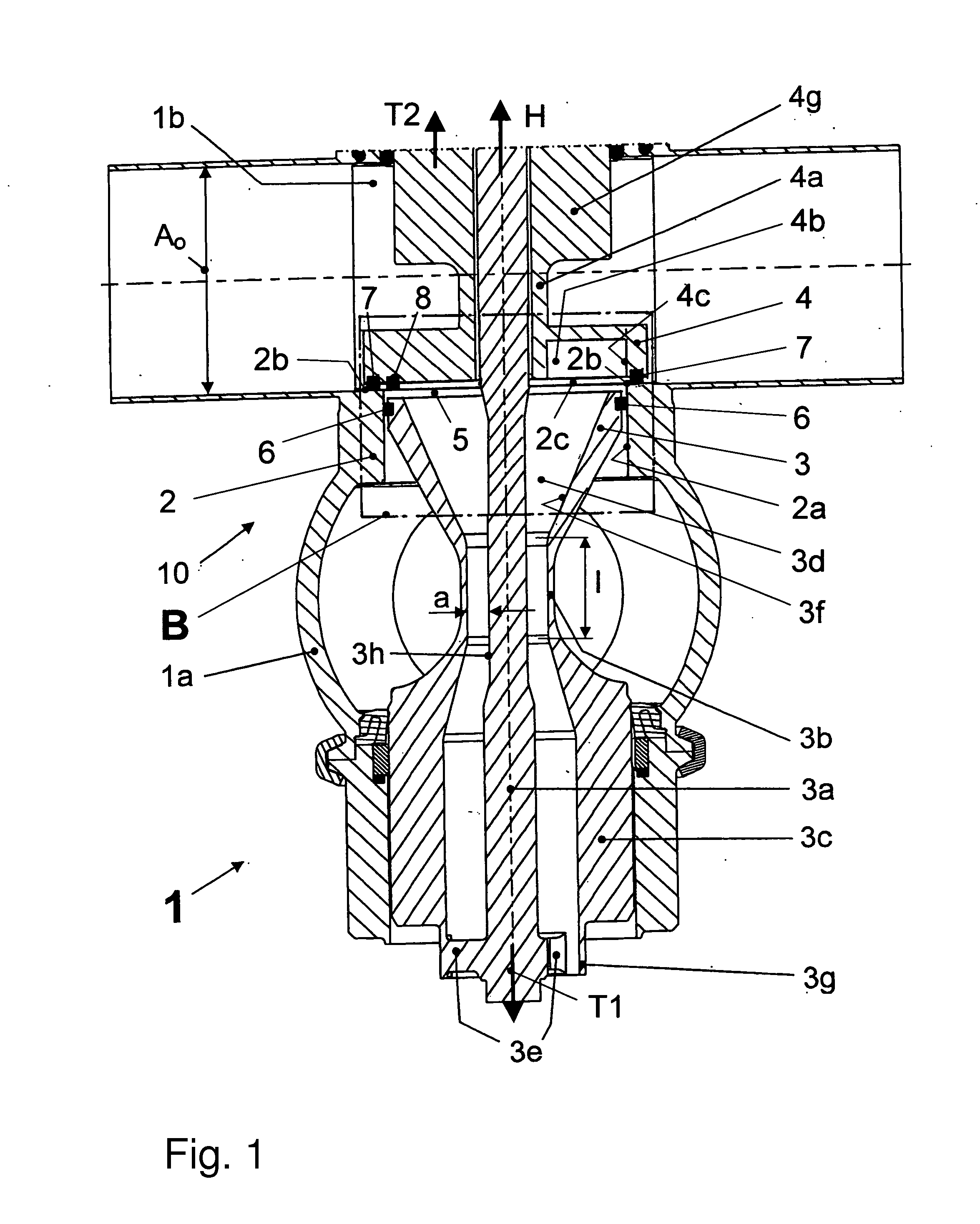

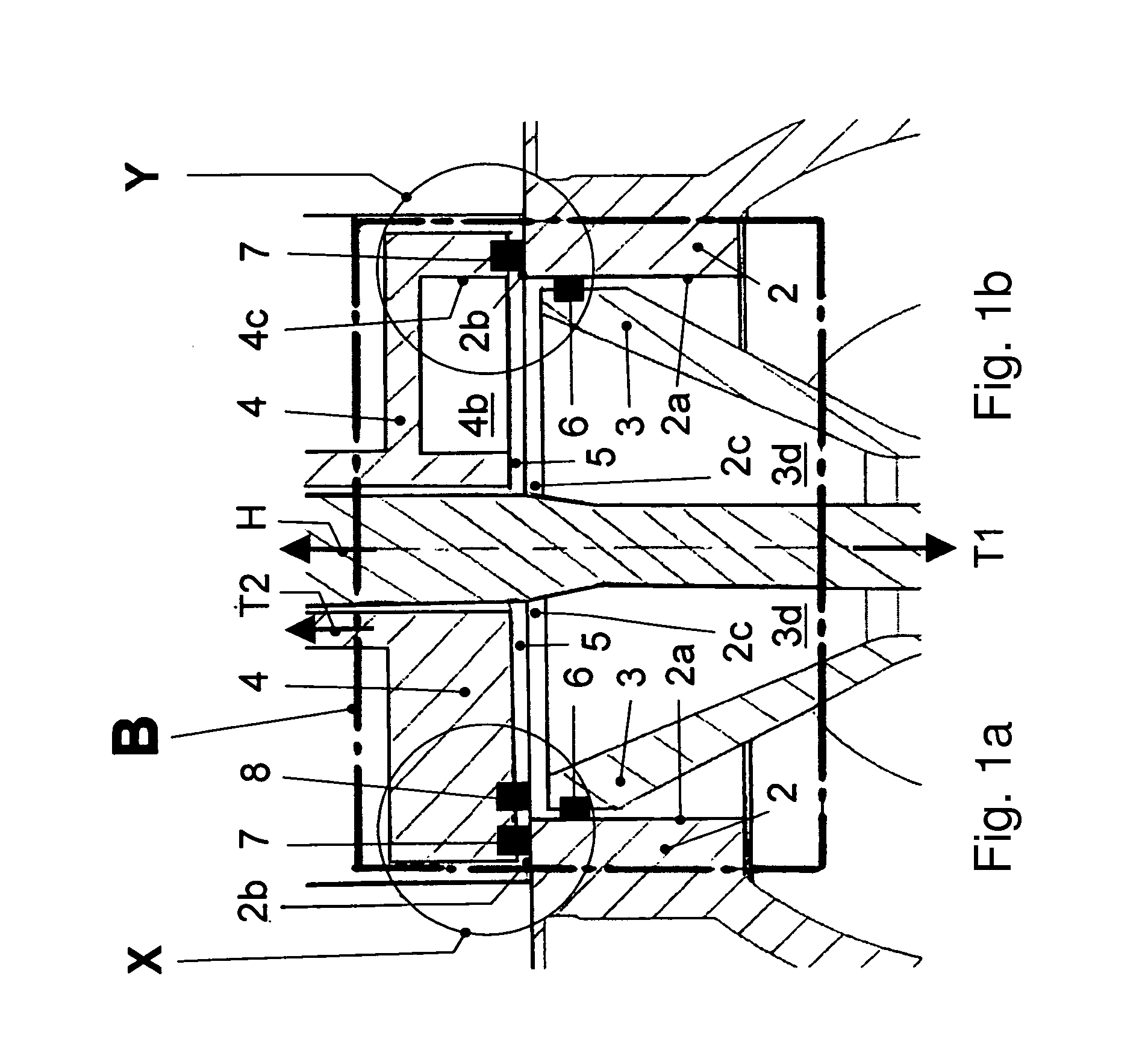

Flow sensor arrangement

ActiveUS20130199289A1Accurate representationReduce flow resistanceVolume/mass flow measurementVolume flow proportion measurementFlow transducerMain channel

There is disclosed a flow sensor arrangement, comprising a main channel (1) for conveying a fluid, a bypass (2) connected to the main channel (1) for conveying a portion of the fluid supplied in the main channel (1), and a flow sensor (6) for measuring a flow of the fluid portion in the bypass (2). The bypass (2) branches off from the main channel (1) at an angle (α) of less than 90 degrees between an inlet section (21) of the bypass (2) and a supply section (11) of the main channel (1). By such design means, particles can be prevented from entering the bypass (2) by this adversely affecting the measurements.

Owner:SENSIRION AG

Disk drive carriers and mountable hard drive systems with improved air flow

ActiveUS9317081B2Lower impedanceReduce flow resistanceReducing temperature influence on carrierUndesired vibrations/sounds insulation/absorptionHard disc drivePartial alignment

The side profile of a hard drive assembly may be configured with one or more open areas to allow cooling air to pass side-to-side through a lateral flow channel provided by a cavity defined in the base portion of the hard drive assembly. Corresponding and complementary open areas may be also be defined in mating drive carrier assembly side components to allow passage of lateral side-to-side cooling air through the base portion flow channel of a hard drive assembled to the drive carrier assembly to form a mountable hard drive system that is installed into a storage enclosure. The at least partially aligned open flow areas of the assembled hard dive assembly and drive carrier assembly may cooperate to reduce air flow impedance across multiple rows of hard drive systems through a storage enclosure.

Owner:DELL PROD LP

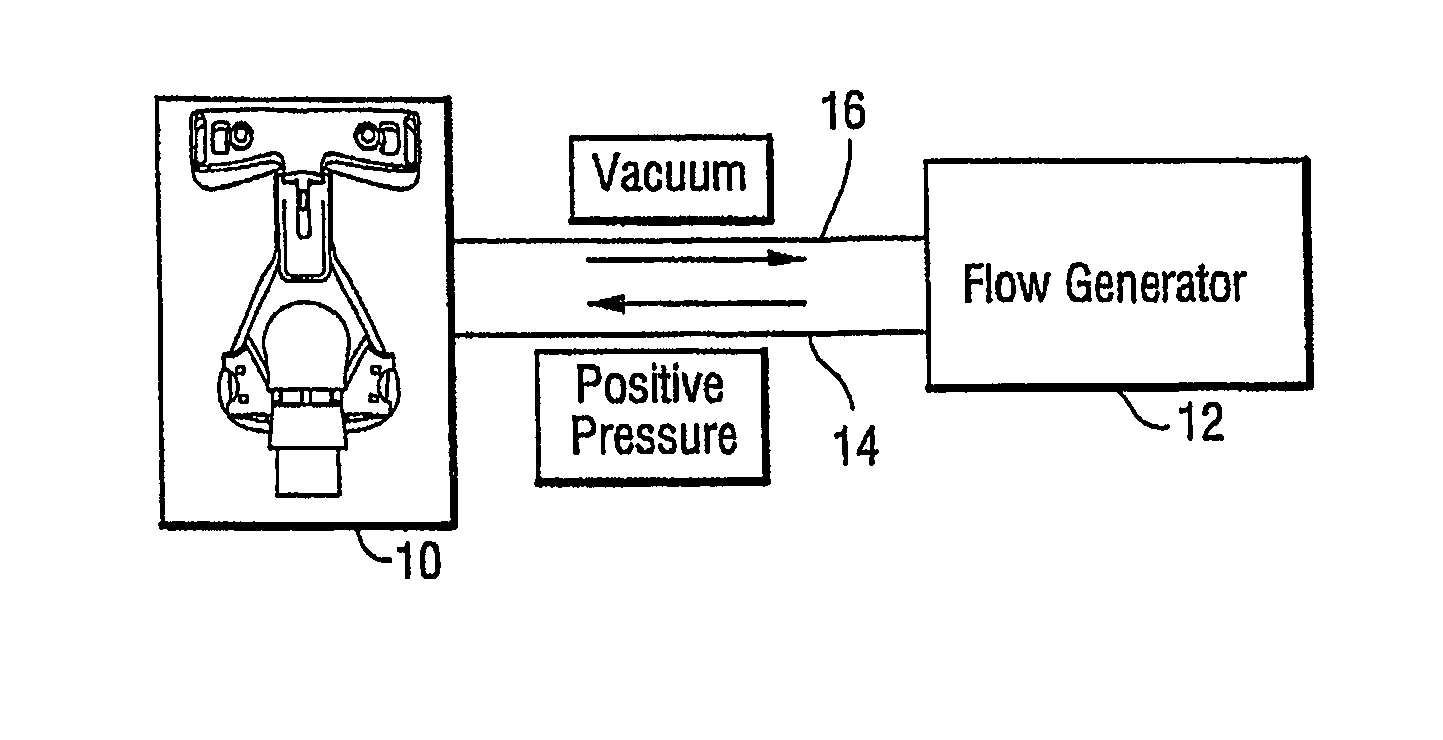

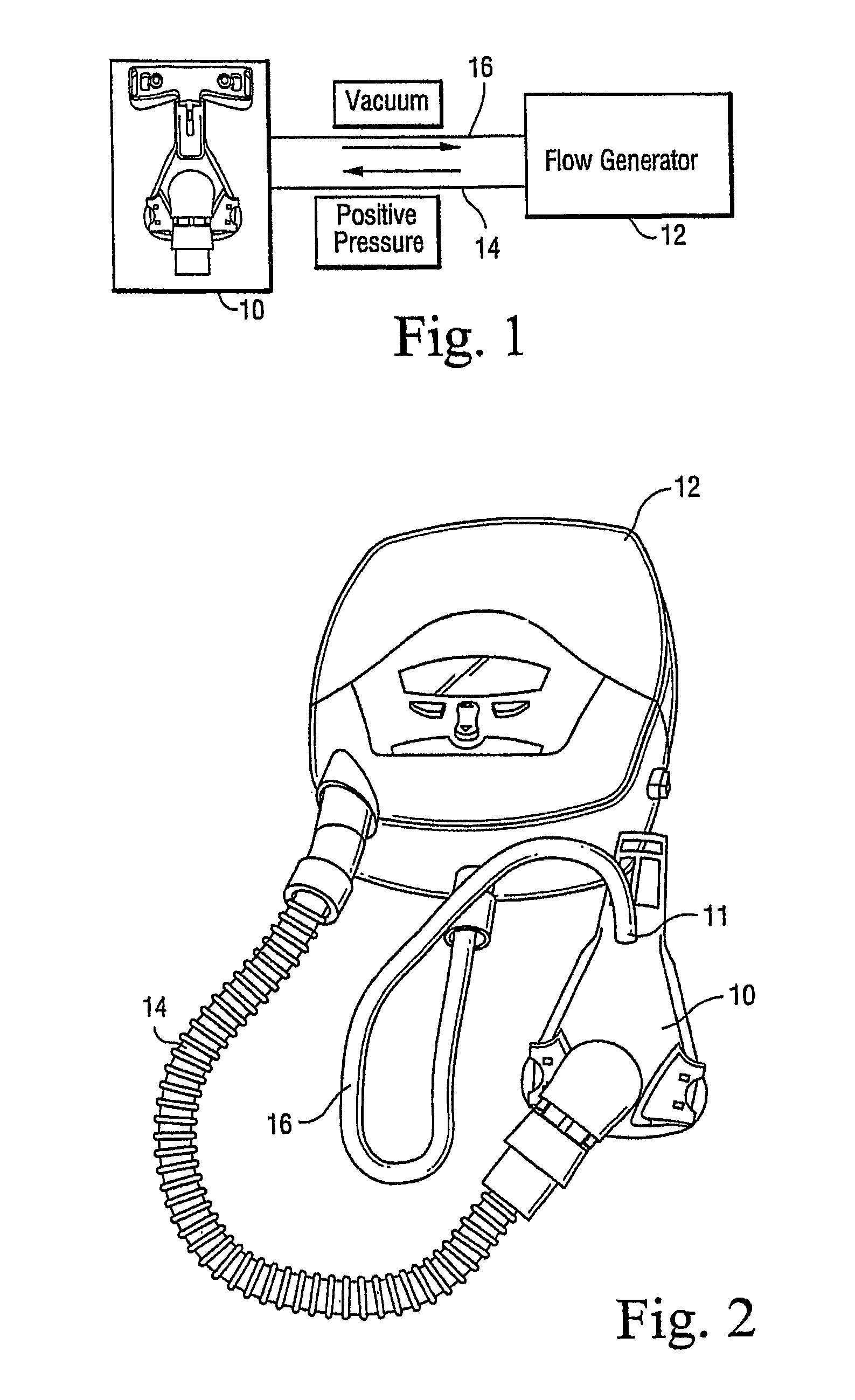

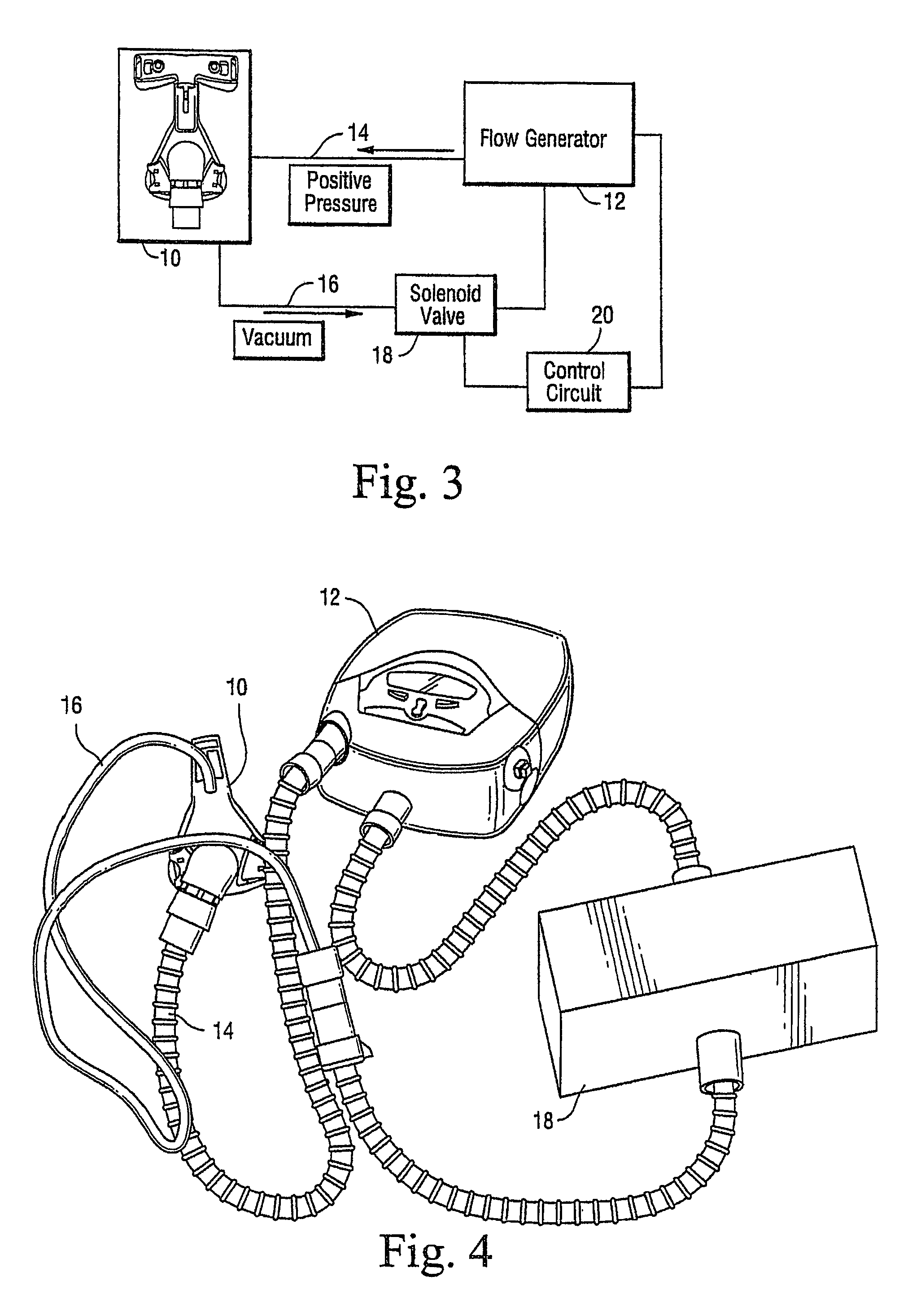

Ventless mask CPAP system

ActiveUS8844529B2Improve functionalityImprove performanceOperating means/releasing devices for valvesRespiratory masksCatheterEngineering

A CPAP or other ventilation system includes a mask, a flow generator, a positive or high pressure line to provide positive or high pressure air from the flow generator to the mask and a vacuum or return line provided to actively extract exhaled gas from the breathing chamber and / or the air delivery conduit of the mask. The vacuum or return line includes a vent outlet preferably positioned remote from the mask.

Owner:RESMED LTD

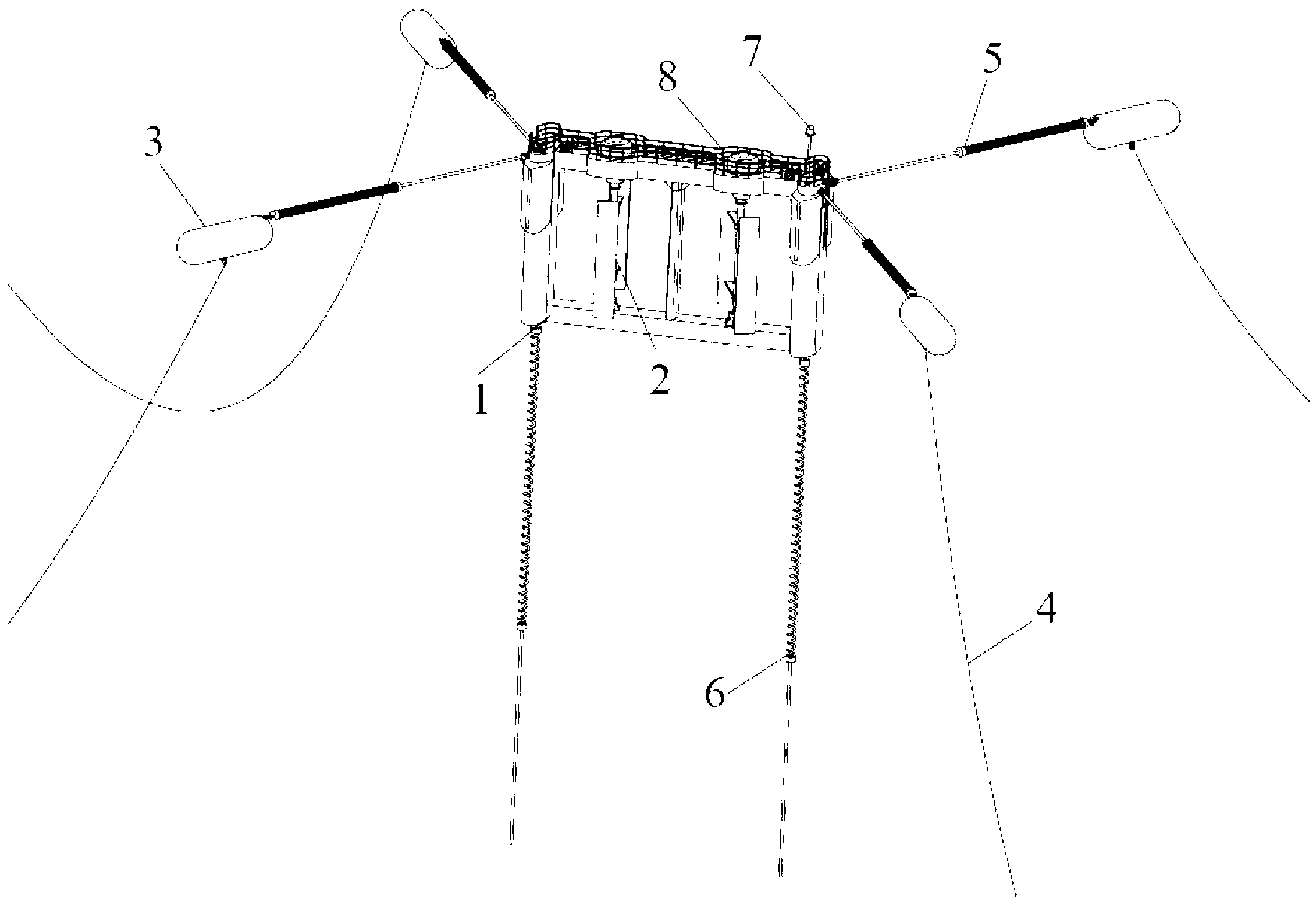

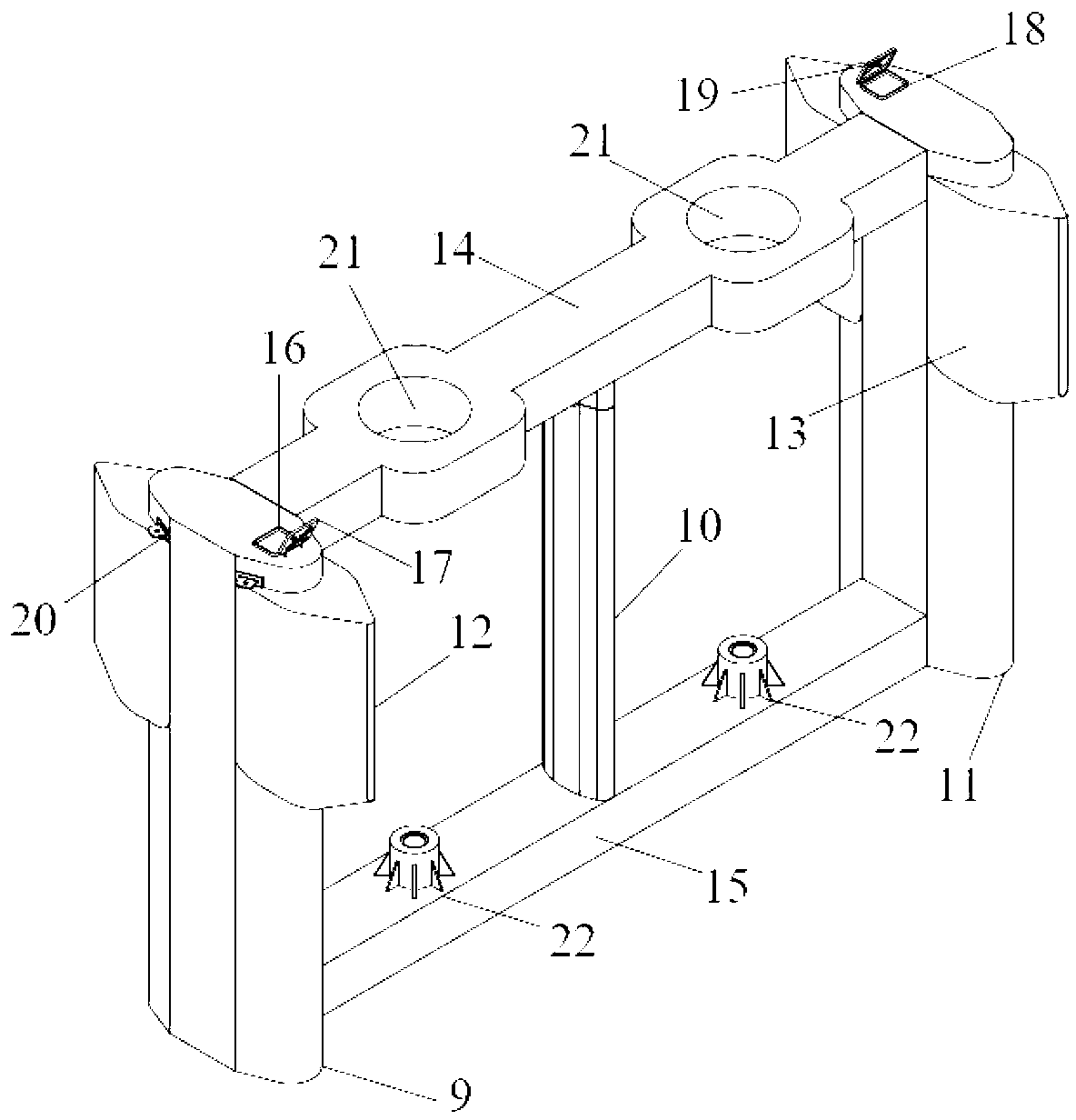

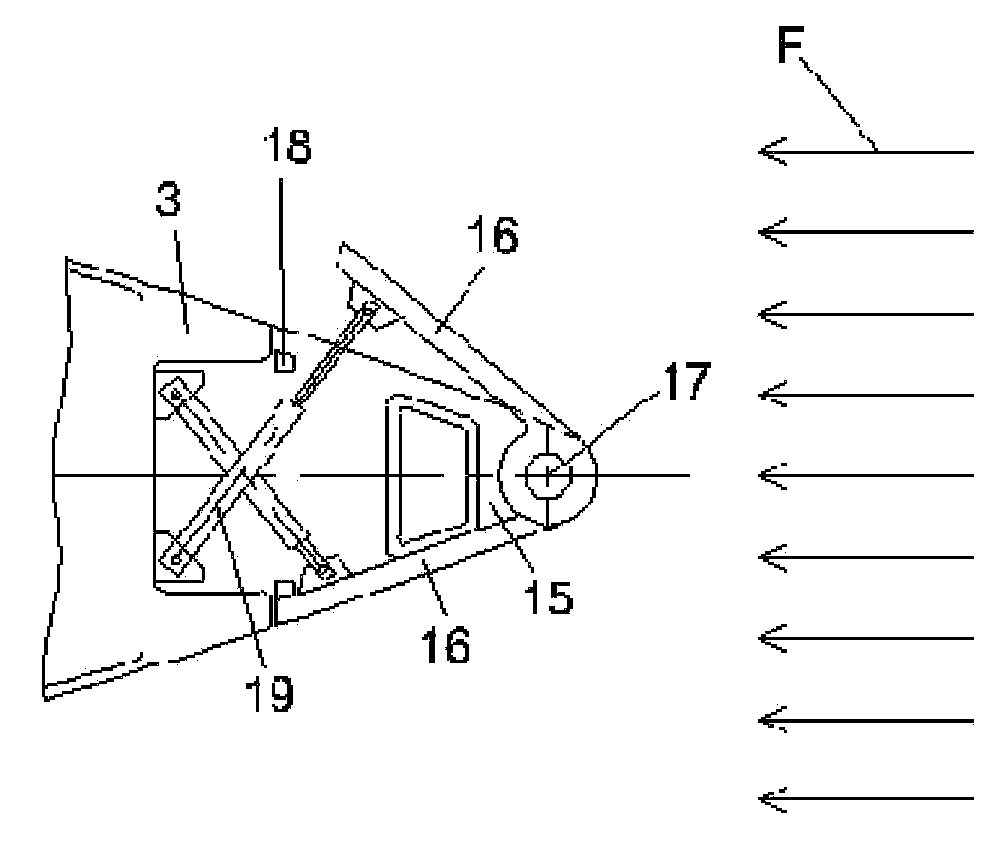

Floating-barrel type tidal current energy generating device

InactiveCN103256170AGuaranteed stabilityReduced motor responseFinal product manufactureHydro energy generationChinese charactersMooring system

The invention provides a floating-barrel type tidal current energy generating device which comprises a mooring system, a carrier and a water turbine / generator set. The floating-barrel type mooring system is used for mooring the carrier provided with the water turbine / generator set. The carrier is of a transversely-arranged door structure, wherein the door is shaped like a Chinese character 'ri'. The carrier comprises a streamline body, a personnel operating platform and a two-line water turbine / generator set support. The water turbine / generator set is used for converting motion energy of tidal currents into electrical energy and formed by connecting a water turbine, a generator and an accessory coaxial line in series. The water turbine / generator set is of a two-line contra-rotating type and is installed inside space of the carrier. The floating-barrel type tidal current energy generating device has the advantages that the floating-barrel type tidal current energy generating device does not need to be carried under a floating-type platform and on a pipe foundation or a tension leg, and therefore yawing force generated when the single-rotor water turbine operates is eliminated. Meanwhile, the generating device is simple in structure, low in production and manufacturing cost, convenient to install and maintain, economical, stable in generating performance, and suitable for being applied to a high sea state environment with rich tidal current energy.

Owner:HARBIN ENG UNIV

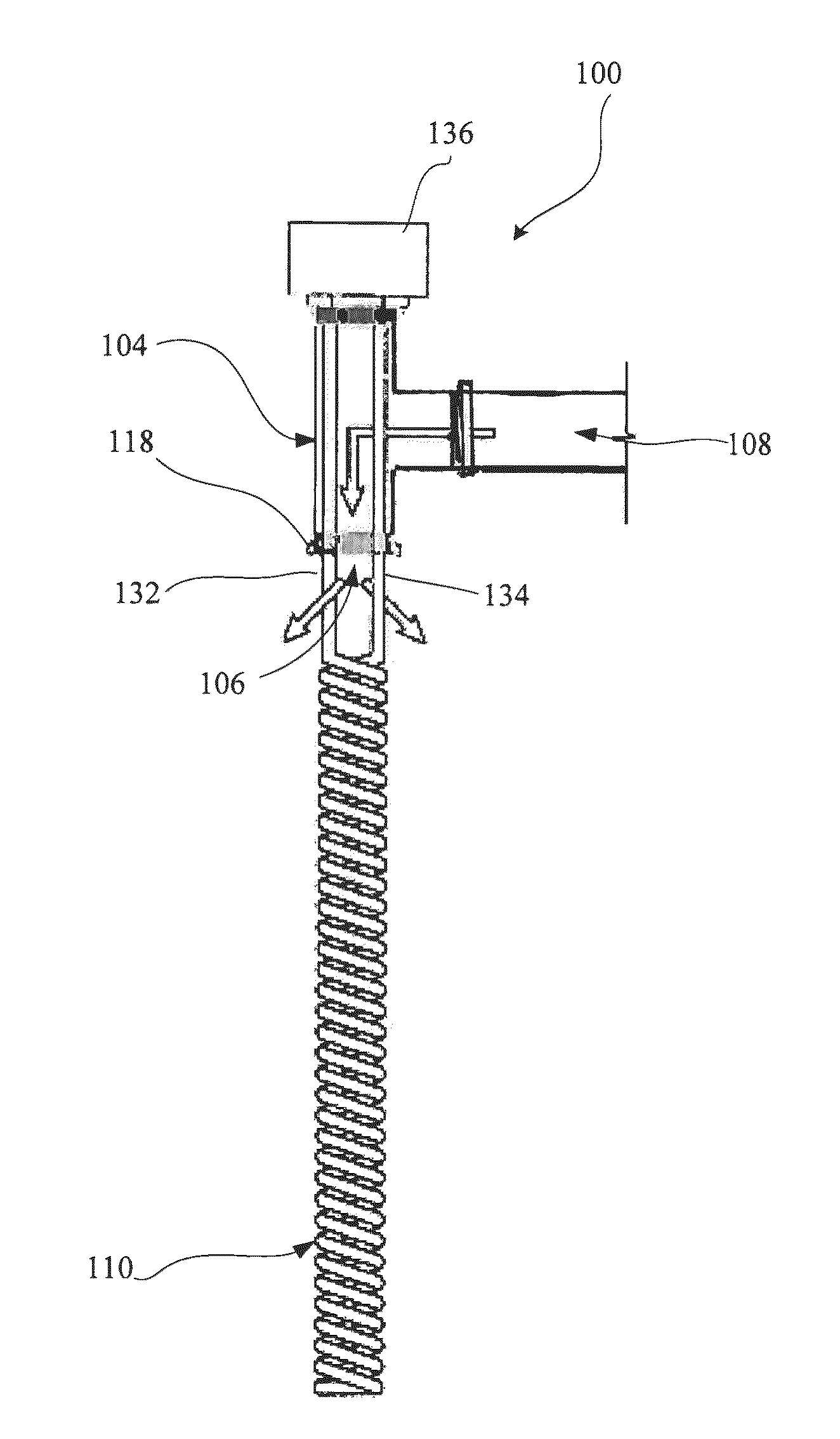

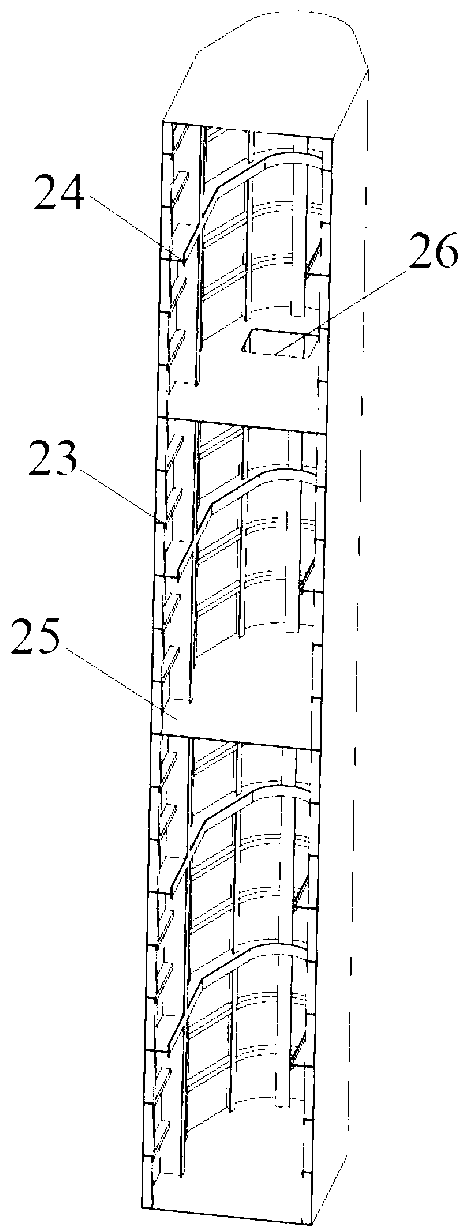

Subterranean Screen with Varying Resistance to Flow

ActiveUS20100224359A1Increase flowReduce flow resistanceFluid removalWell/borehole valve arrangementsEngineeringWire wrap

A screen section is made with variable resistance to flow in the screen material to balance the flow along the screen length. In one variation different discrete zones have screens configured for different percentages of open area while all have the same particle filtration capability. In another variation discrete portions have differing amounts of overlapping screen portions so as to balance flow without affecting the particle size screened. The cross-sectional shape of a wire wrap underlayment for the screen is made closer to trapezoidal to decrease the angle of opening for the incoming flow paths toward the base pipe. In this manner flow resistance is reduced and flow is increased due to reduced turbulence.

Owner:BAKER HUGHES INC

Optimized vent walls in electronic devices

ActiveUS8964383B2Reduce the temperatureReduce flow resistanceWave amplification devicesDigital data processing detailsEngineeringElectric devices

Owner:APPLE INC

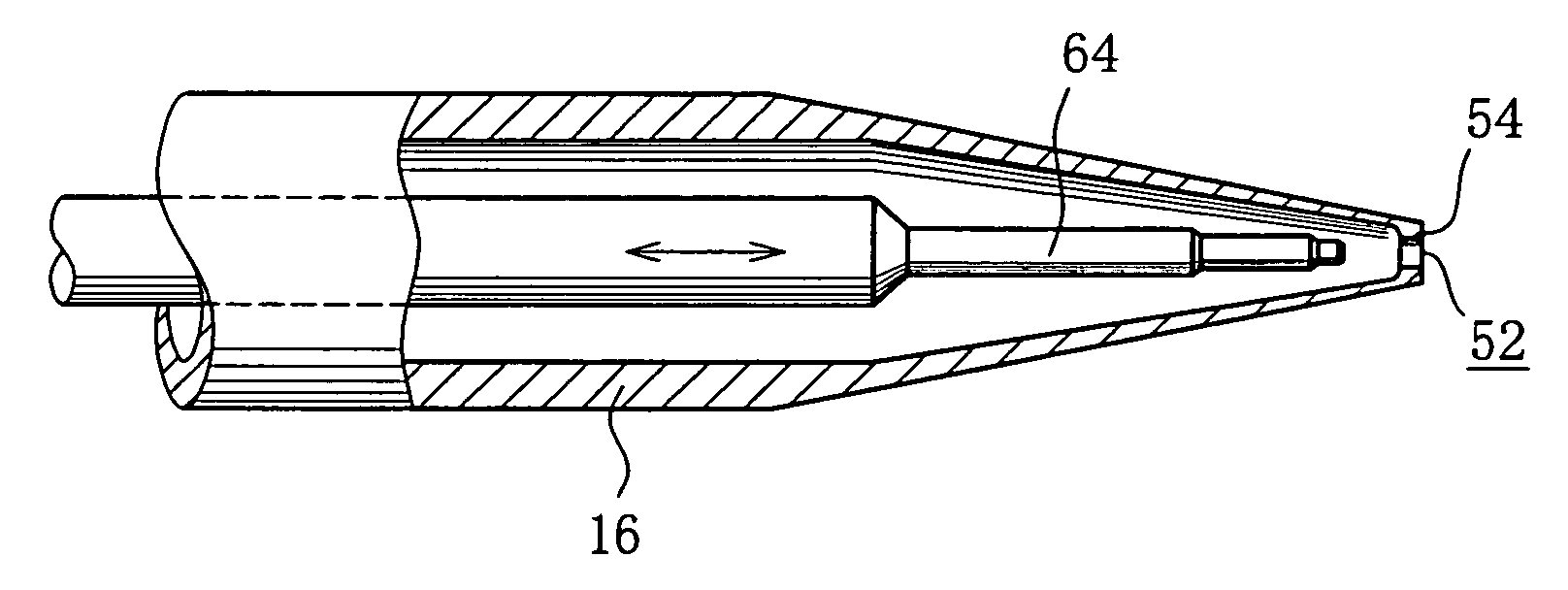

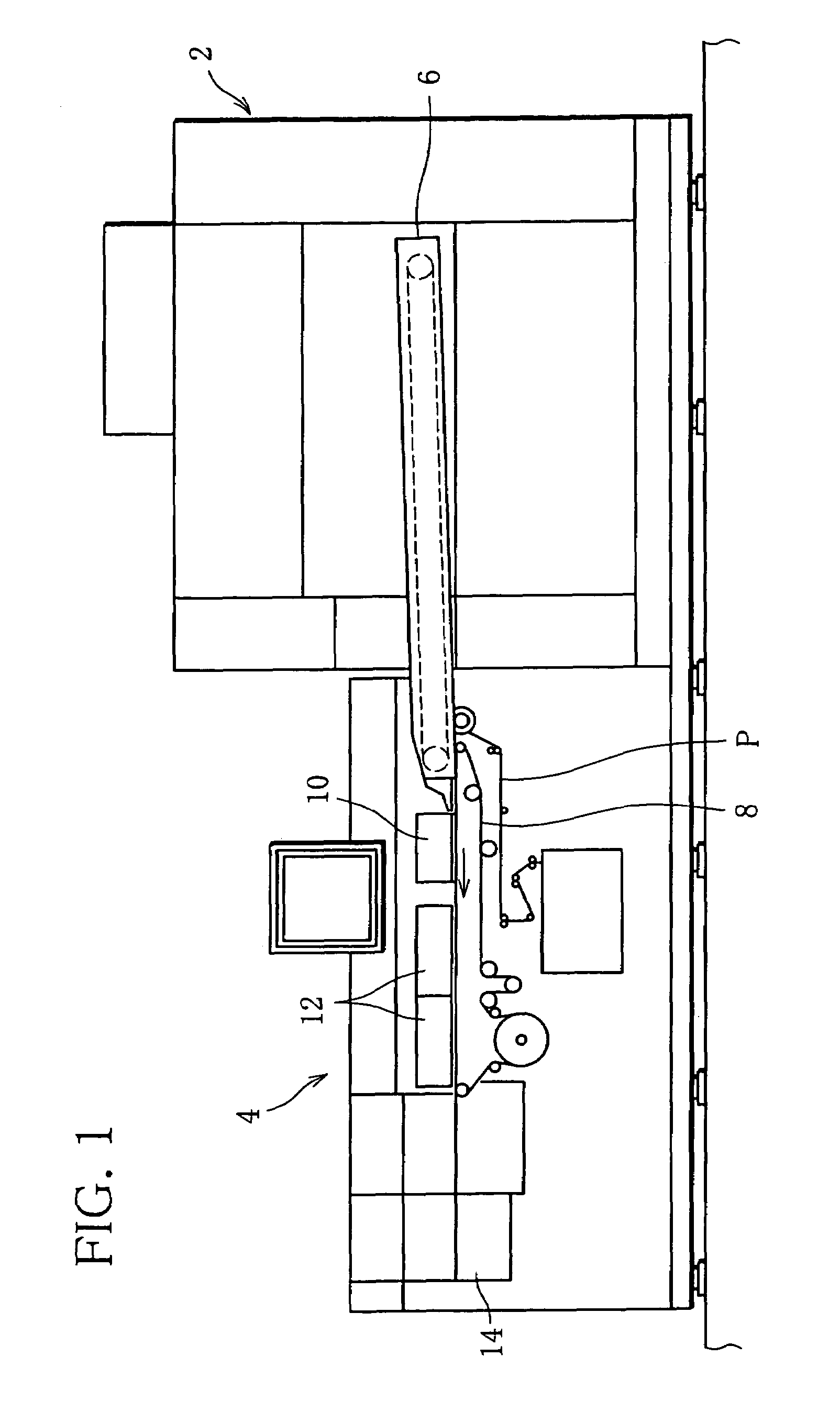

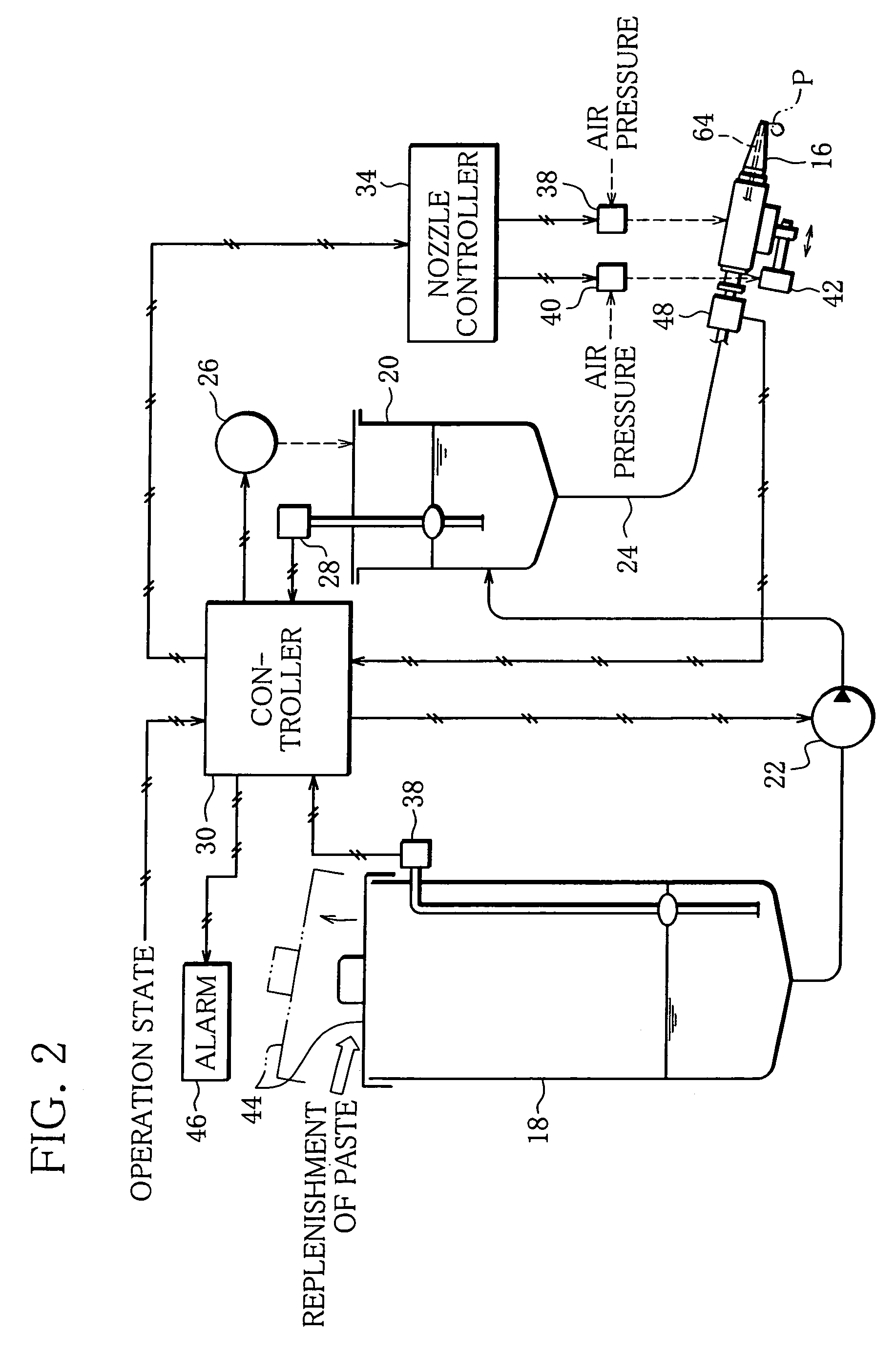

Fluid application device

InactiveUS7101439B2Reduce flow resistanceImprove durabilityCigarette manufactureSpray nozzlesFluid levelEngineering

A fluid application device stores seam paste in a reservoir tank 18 and feeds the seam paste to a pressure tank 20 through a feed pump 22. Inside of the pressure tank 20 is maintained under a given air pressure by a pneumatic unit 26, and the seam paste is supplied from the pressure tank 20 to an application nozzle 16 through a supply pipe 24. A level sensor 28 detects fluid level of stored seam paste in the pressure tank 20, and a detection signal is input to a controller 30. The controller 30 controls operation of the feed pump 22 based on the detection signal that is transmitted from the level sensor 28 and also controls a supply amount of the seam paste to the pressure tank 20 to maintain the fluid level in the pressure tank 20 at a fixed level.

Owner:JAPAN TOBACCO INC

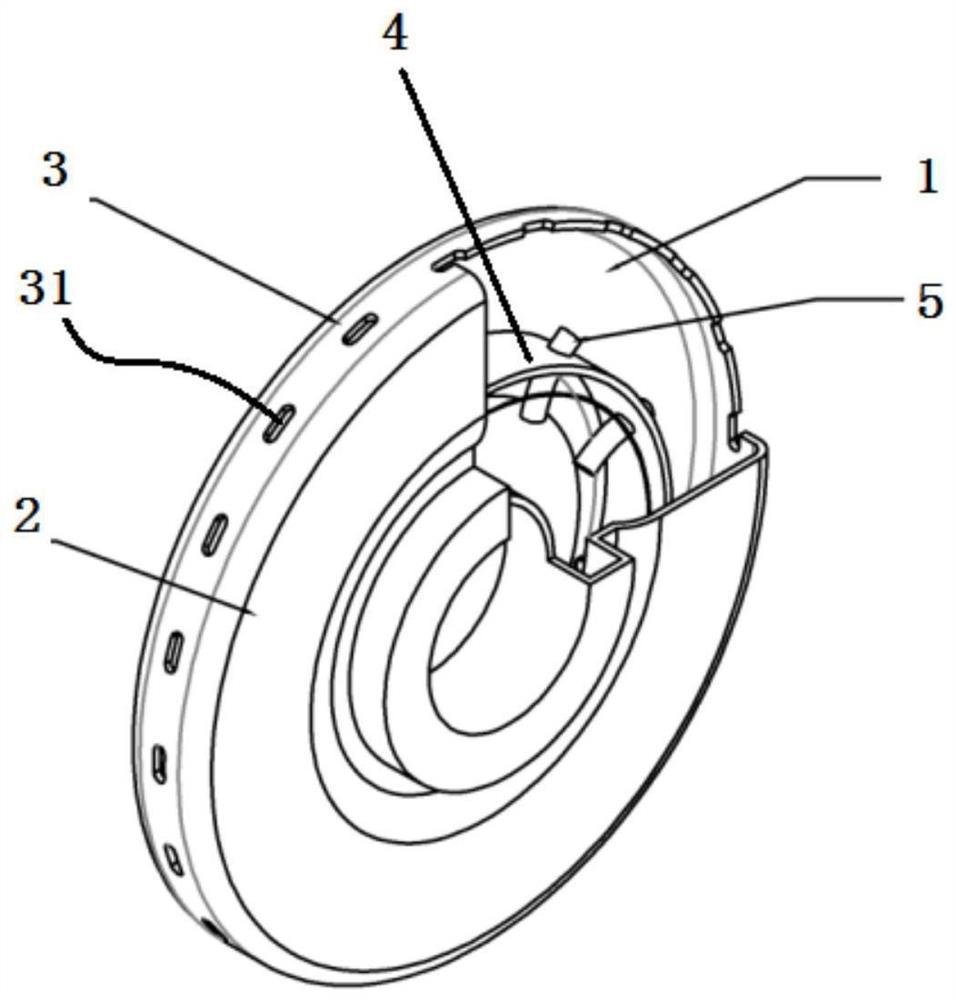

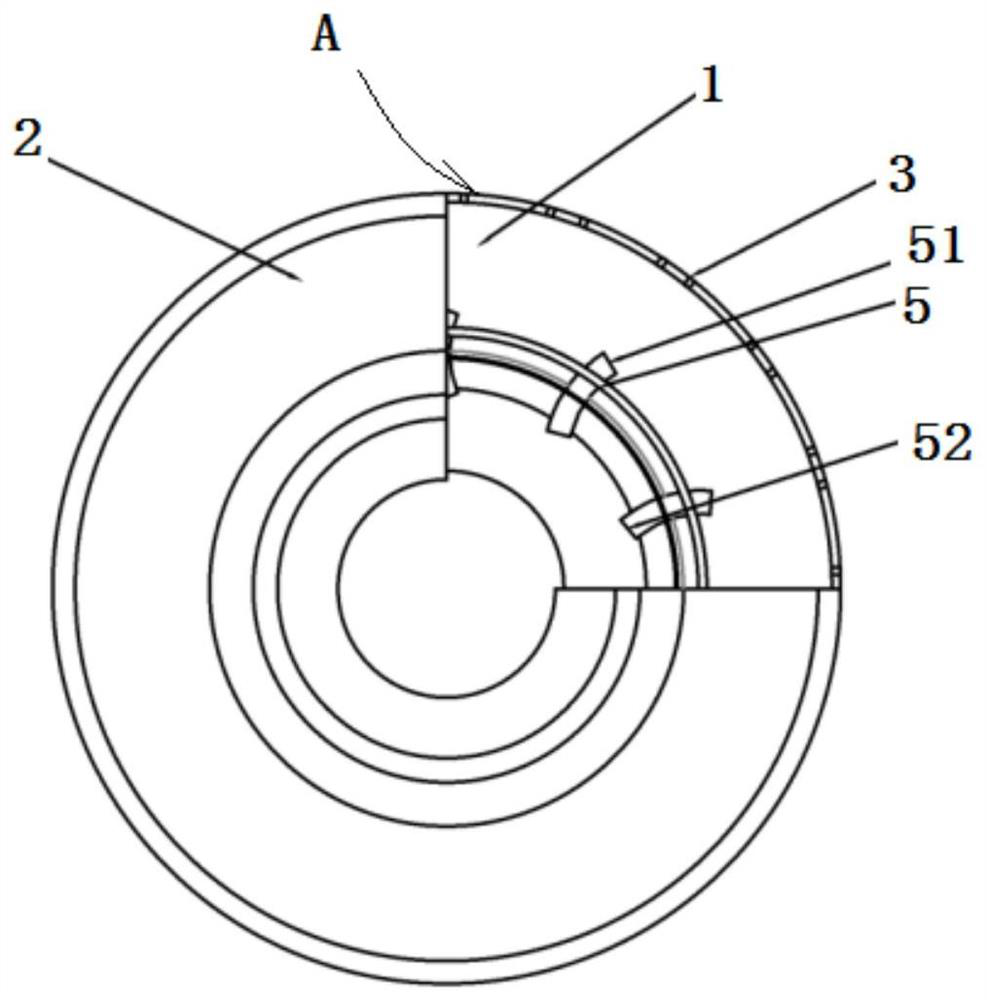

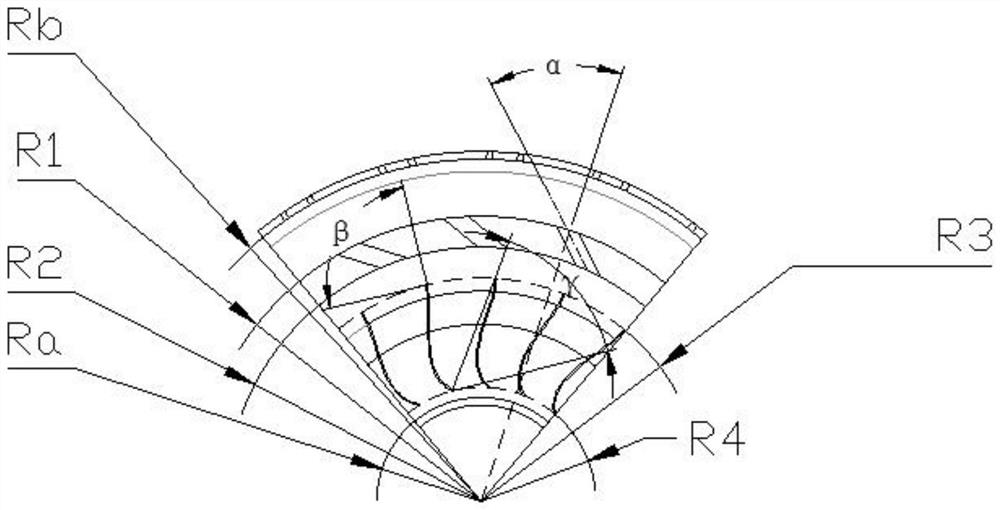

Curved pipe type vortex reduction system with high-radius outlet

PendingCN112377307ASmall pressure lossLimited peripheral speedPump componentsGas turbine plantsAviationEngineering

The invention discloses a curved pipe type vortex reduction system with a high-radius outlet, and relates to aero-engines. The curved pipe type vortex reduction system comprises a chuck and a plurality of curved vortex reducing pipes. A plurality of curved vortex reducing pipes are uniformly arranged in the circumferential direction of the chuck and are coaxial with compressor discs on the two sides, the curved vortex reducing pipes are the same in structure and mounting radius, each curved vortex reducing pipe is provided with a curved vortex reducing pipe inlet and a curved vortex reducing pipe outlet, and the inlet of each curved vortex reducing pipe faces the airflow direction, so that pressure loss caused when the airflow is separated at the inlet of the vortex reducing pipe to form avortex is reduced, and the outlet position of each curved vortex reducing pipe rotates reversely, so that the circumferential speed of the airflow is limited, the development of free vortexes is inhibited, and the flow obstruction is reduced. Therefore, according to the curved pipe type vortex reduction system with the high-radius outlet, aerodynamic characteristics are fully considered, free vortex development in the radial inflow disc cavity is restrained, meanwhile, dissipation, caused by turning, of airflow is reduced, and pressure loss in the system is reduced.

Owner:BEIHANG UNIV

Disk Drive Carriers And Mountable Hard Drive Systems With Improved Air Flow

ActiveUS20160202739A1Lower impedanceReduce flow resistanceReducing temperature influence on carrierRecord information storageHard disc driveEngineering

The side profile of a hard drive assembly may be configured with one or more open areas to allow cooling air to pass side-to-side through a lateral flow channel provided by a cavity defined in the base portion of the hard drive assembly. Corresponding and complementary open areas may be also be defined in mating drive carrier assembly side components to allow passage of lateral side-to-side cooling air through the base portion flow channel of a hard drive assembled to the drive carrier assembly to form a mountable hard drive system that is installed into a storage enclosure. The at least partially aligned open flow areas of the assembled hard dive assembly and drive carrier assembly may cooperate to reduce air flow impedance across multiple rows of hard drive systems through a storage enclosure.

Owner:DELL PROD LP

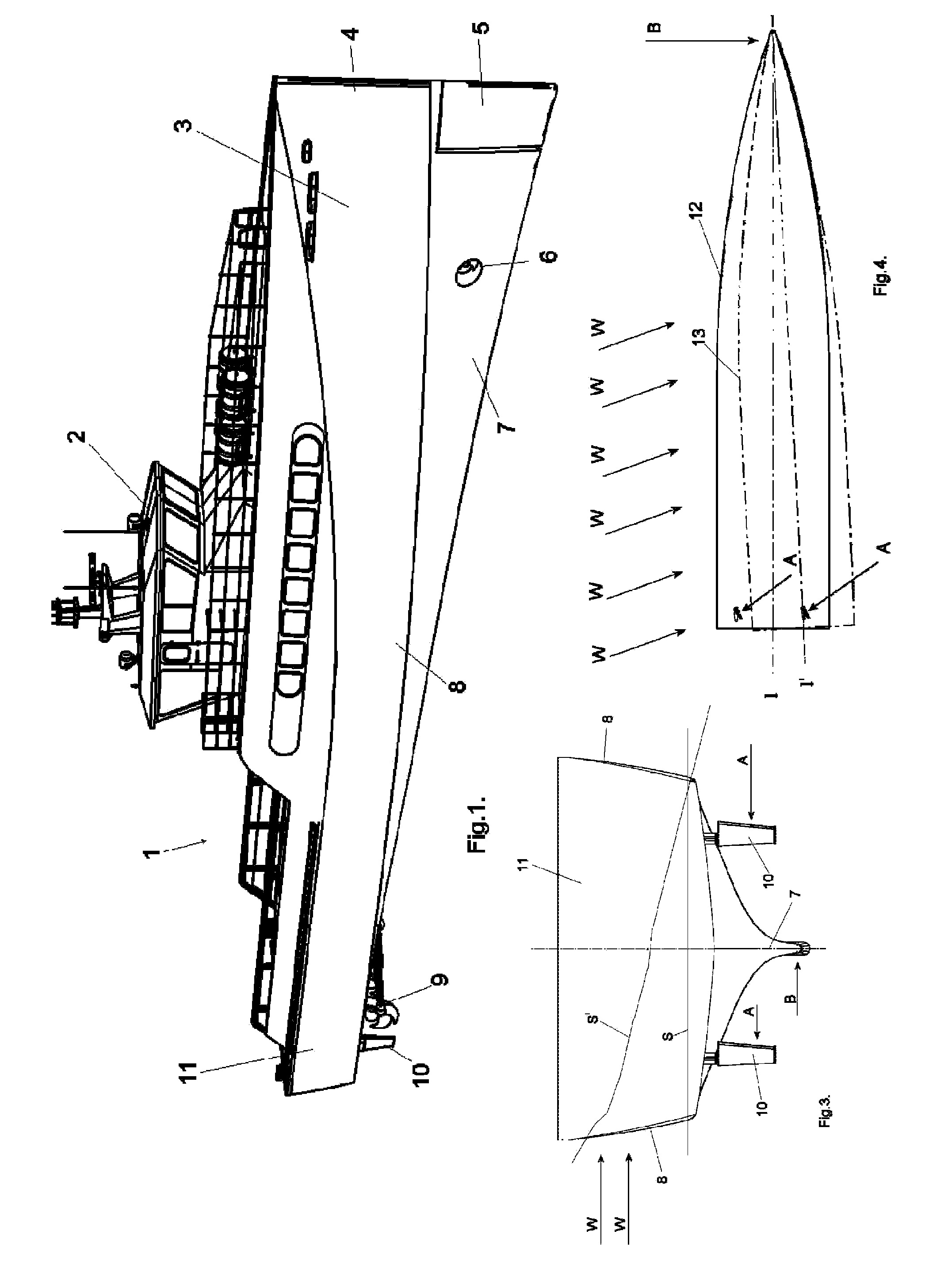

Ship

InactiveUS20090114137A1Shorten the lengthReduce flow resistanceSteering ruddersWatercraft hull designWater flowPropeller

A ship for use at high speed and / or heavy seas having a single long and slender hull, a sharp bow and the aft end of the hull has a flat or slightly V-shaped bottom with at least one aft rudder, and at least one propeller or water jet for propulsion whereby the foreship has a draught that is equal or more than the draught of the aft end. The bow has a control surface that converts the water flow along the forward moving ship into an adjustable lateral force.

Owner:TECH UNIV DELFT

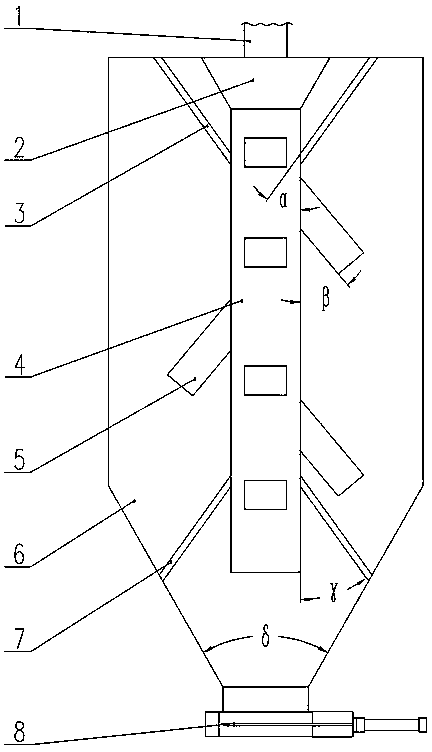

Anti-separation dry sand silo and method

InactiveCN103523408AInhibition of segregationReduced lateral extrusionLarge containersDry sandStructural engineering

The invention discloses an anti-separation dry sand silo and method. The anti-separation dry sand silo comprises a stock silo and an anti-separation device. The anti-separation dry sand silo is characterized in that the stock silo comprises a feed articulated chute, a feed hopper, a silo body and a discharge valve, the feed articulated chute is fixed on the upper cover plate of the silo body, the silo body mainly comprises an upper cylinder body and a lower cone cylinder body, and the discharge valve is mounted on a discharge pipe at the lower end of the silo body. The anti-separation device comprises a main pipe and a plurality of side pipes, the main pipe is fixed inside the silo body through an upper support and a lower support, the upper end of the main pipe is made to be in butt joint with the feed hopper, and the lower end of the main pipe is hung in the air. The anti-separation dry sand silo and method have the advantages that separation is effectively prevented from being generated on dry sand in the process that the dry sand flows into the silo, the integrated falling down of sand materials in the discharge process of the dry sand silo is achieved, the falling down process is clean and smooth, production cost is saved, and quality of finished mortar products is guaranteed. The anti-separation dry sand silo is simple in structure, good in anti-separation effect, high in operational reliability, and capable of effectively improving quality of finished mortar products, and has wide practicability.

Owner:徐州沃土资产管理有限公司

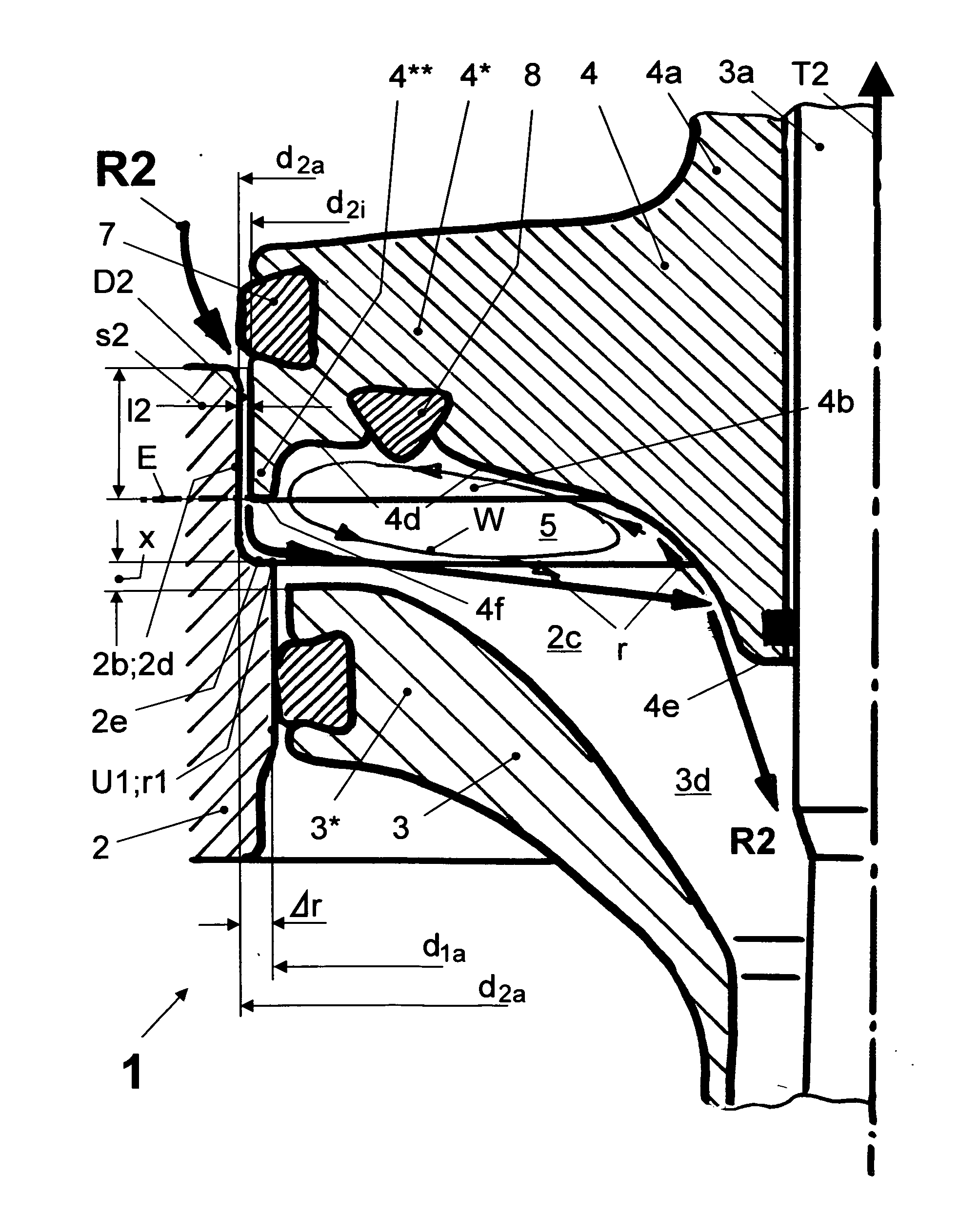

Double-seat valve with a seat-cleaning function

ActiveUS20150211642A1Avoid turbulence and stagnation pressure formationReduce flow resistanceCheck valvesLift valvePressure increaseMechanical engineering

Owner:GEA TUCHENHAGEN GMBH

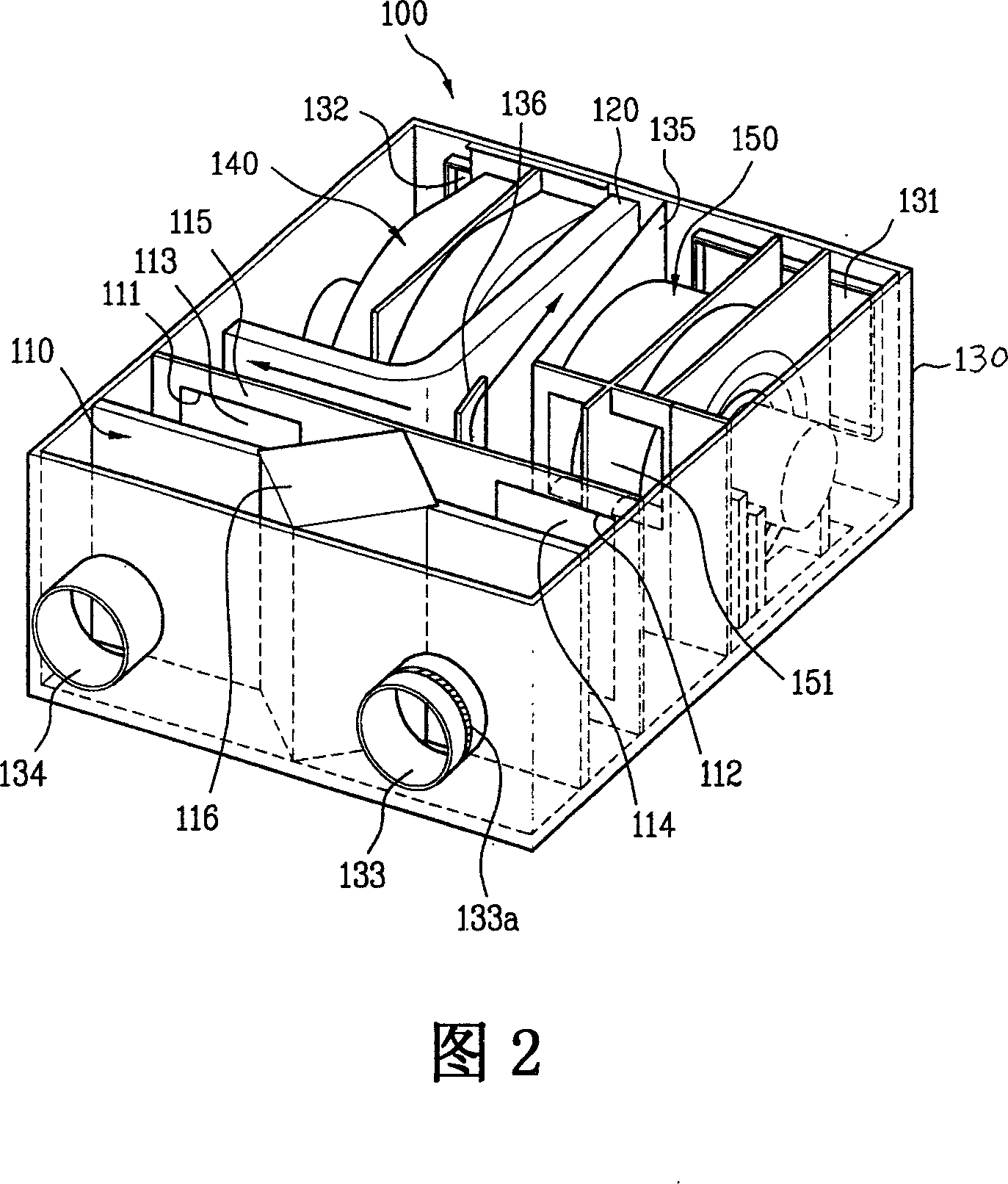

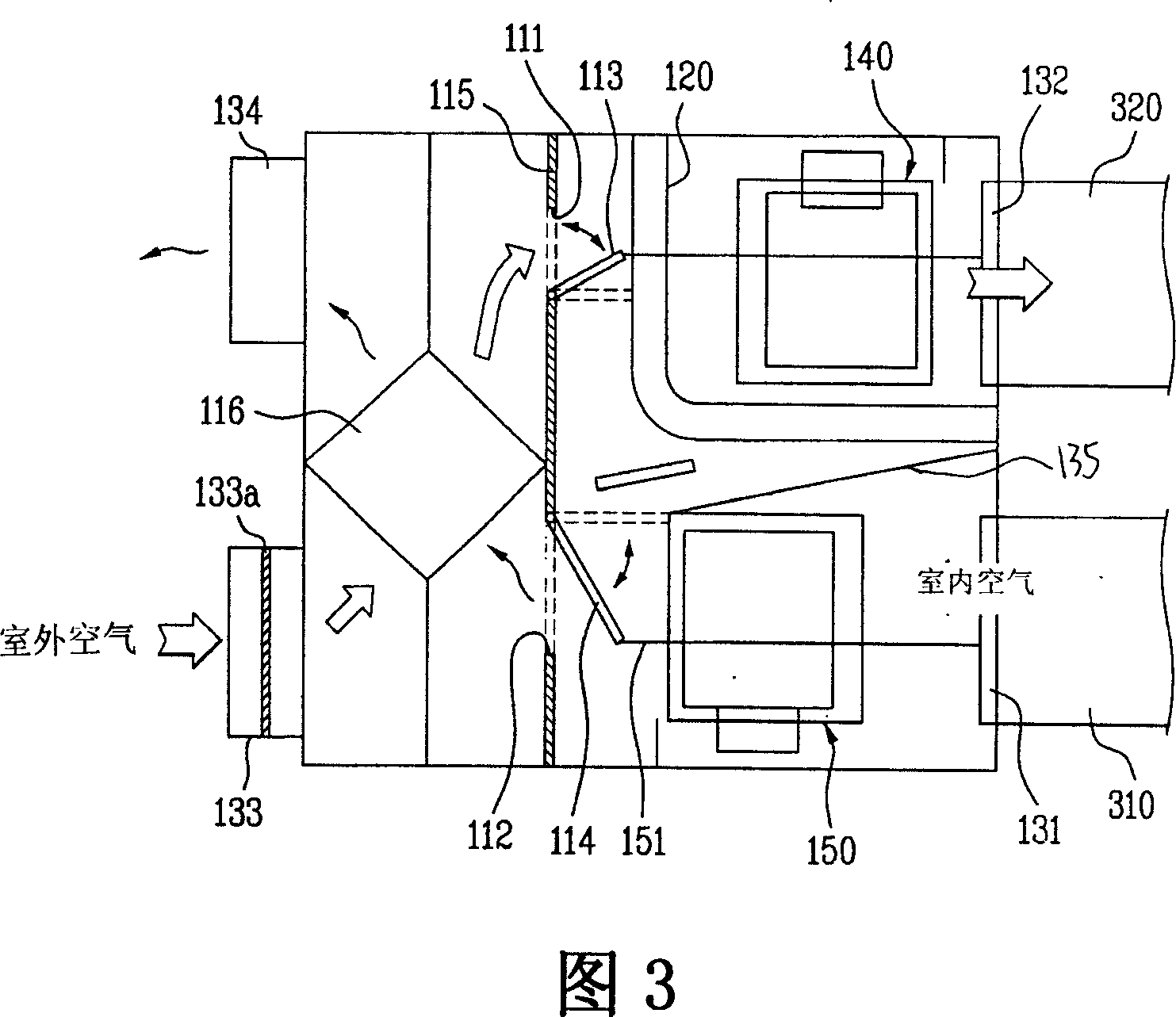

Indoor unit of air conditioner

InactiveCN101086351AImprove efficiencyImprove aestheticsLighting and heating apparatusAir conditioning systemsEngineeringForced-air

An indoor machine of air-conditioner consists of the following components: the shell which is equipped with outer air sucking mouth used for sucking the air heat exchanged outside, and one side of the outer air sucking mouth is open; the baffle which opens and closed the outer air sucking mouth alternatively; the air blast unit which is installed in the shell and force air flow; the flowing separating plate which divides the inner of shell into the part used for installing air blast unit and the outer part, and separates the flowing of the sucked air from the outer air sucking mouth; the zoning plate which is installed on the open surface of shell and divides the inner of shell into the part used for installing air blast unit and the outer part together with the flowing separating plate; the fore grillage which is installed out the zoning plate and is fixed on the open plate of shell, and is formed with the inclined indoor sucking mouth sucking air from indoor and the indoor discharging mouth discharging air out, The invention improves the appearance of the indoor unit, and improve the efficiency of air conditioner through reducing the air-flow impedance when indoor machine discharges and sucks air.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Novel nozzle and fin combined type vortex reduction system

PendingCN112648077AInhibition of developmentReduce flow resistancePump componentsTurbine/propulsion engine coolingViscous dissipationEngineering

The invention discloses a novel nozzle and fin combined type vortex reduction system, and relates to aero-engines. The novel nozzle and fin combined type vortex reduction system comprises a plurality of reverse rotation nozzles and a plurality of reverse rotation fins, each reverse rotation nozzle is installed at the position of a two-stage gas compressor disc, and each reverse rotation fin is installed at the position of a front-stage gas compressor disc and located at the downstream position of the multiple reverse rotation nozzles; the reverse-rotation nozzles and the reverse-rotation fins are evenly arranged in the circumferential direction of the gas compressor discs and are coaxial with the gas compressor discs on the two sides, the structures of the reverse-rotation nozzles and the reverse-rotation fins are the same, the corresponding installation radiuses are the same, the circumferential speed of airflow is limited, development of free vortexes is restrained, and flow hindrance is reduced. Compared with a vortex reducing pipe, the flow area of the reverse rotation fins is large, sudden expansion and sudden shrinkage of a flow channel in the air entraining process are avoided, therefore viscous dissipation caused by airflow mixing is reduced, and airflow total pressure losses are reduced.

Owner:BEIHANG UNIV

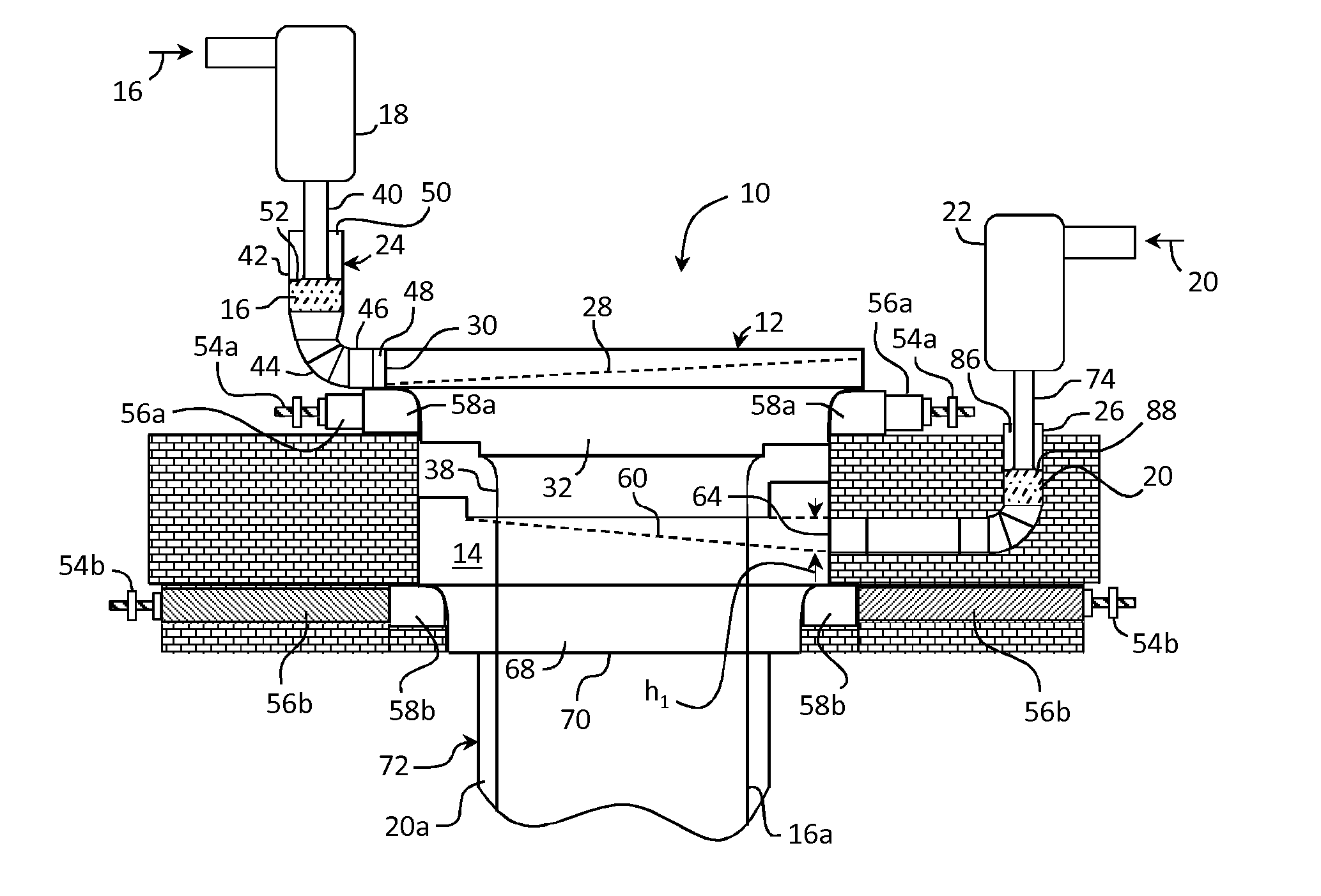

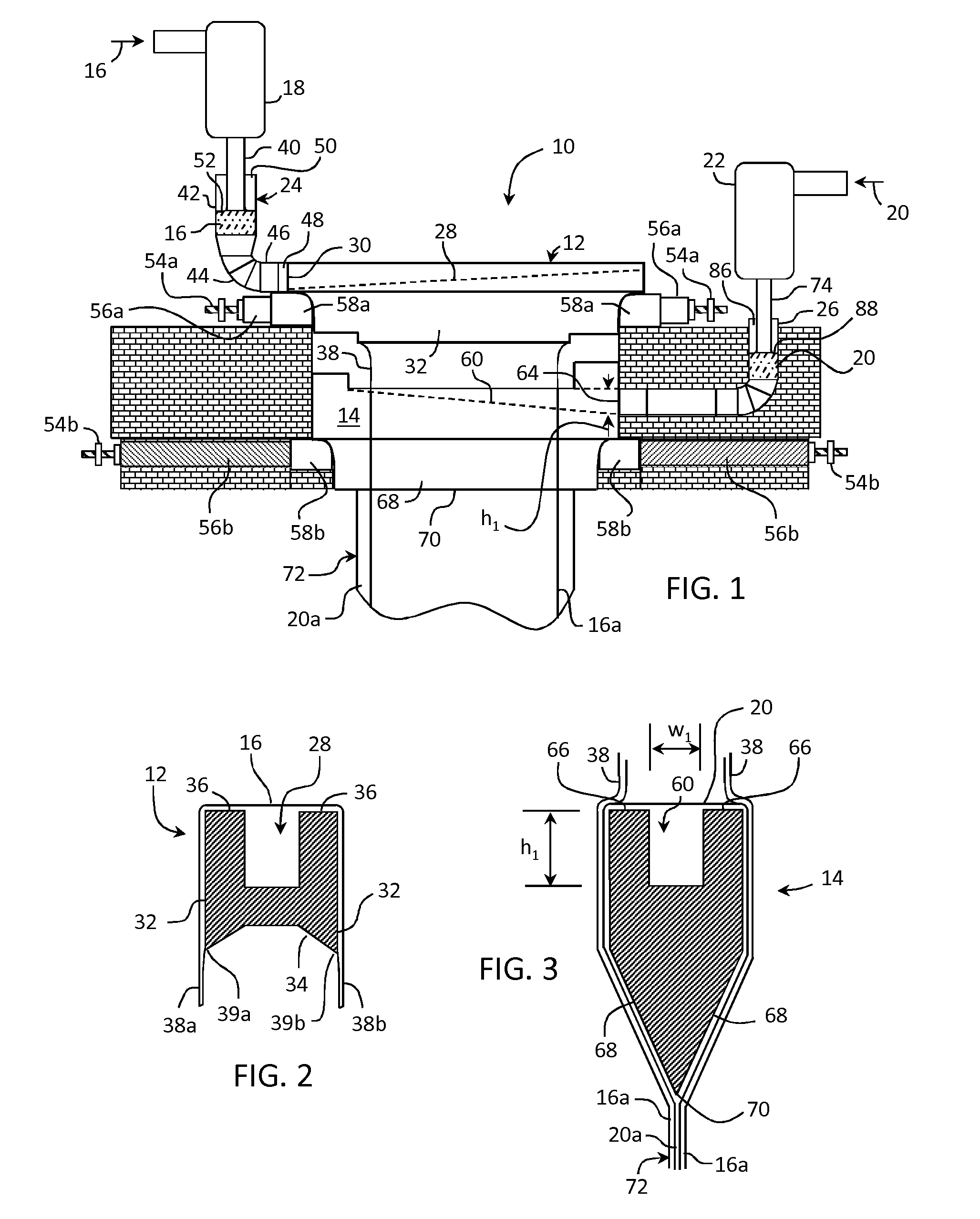

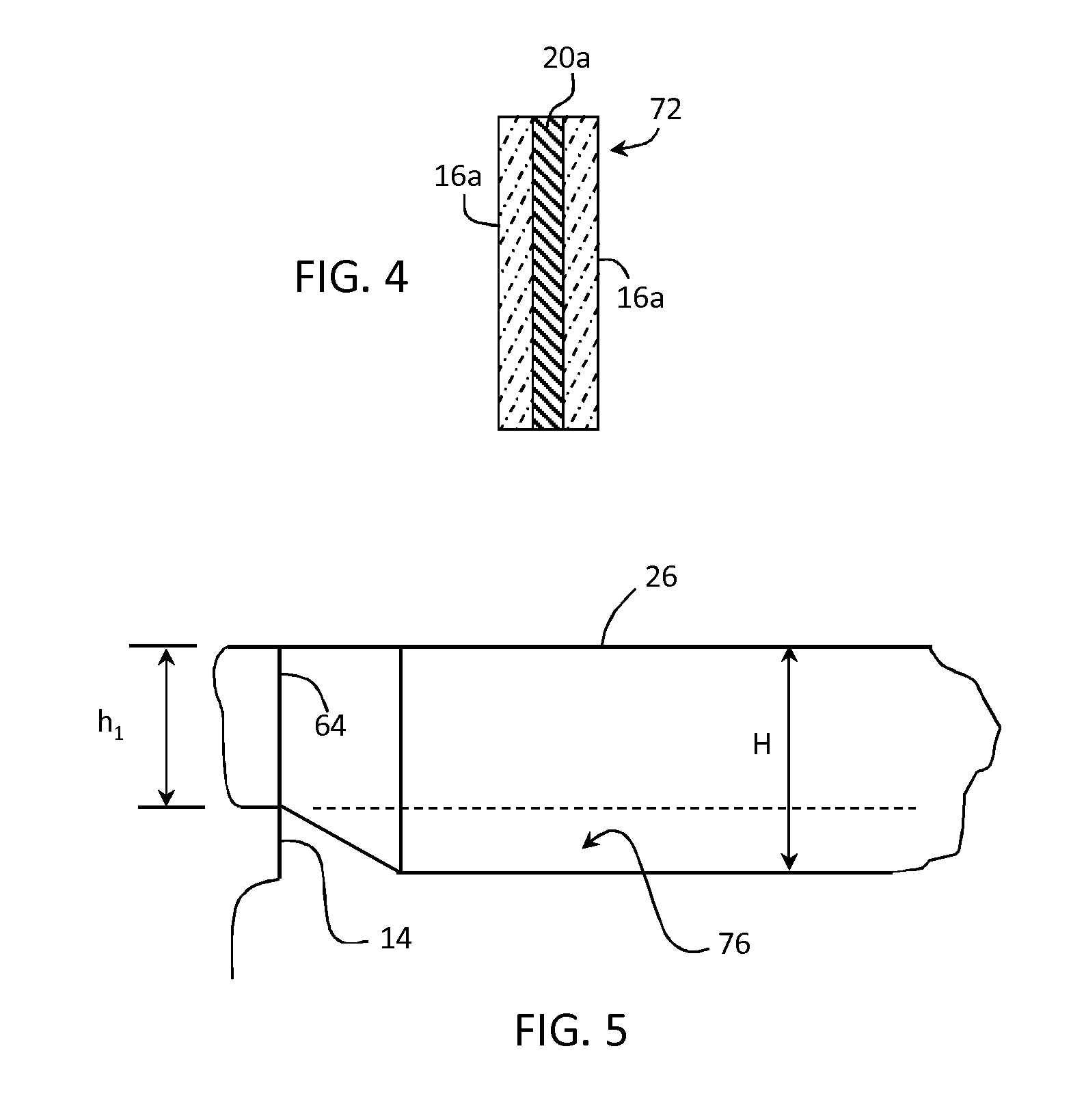

Apparatus and method for processing molten glass

ActiveUS20160185643A1Increase the diameterReduce flow resistanceForehearthsGlass drawing apparatusGuide tubeMolten glass

A glass forming apparatus for processing molten glass is disclosed comprising a delivery vessel for delivery molten glass to a forming body through a delivery conduit, the delivery conduit comprising a first portion have a circular cross-sectional shape, a second portion comprising a circular cross-sectional shape and a third portion comprising a non-circular cross-sectional shape. The delivery conduit further comprises a first transition portion coupling the second portion to the third portion, and a second transition portion coupling the third portion to an inlet of a trough in a forming body. Neither an inside bottom surface of the third portion, nor an inside bottom surface of the second transition portion, is lower than a bottom surface of the forming body trough. A method of processing molten glass is also described.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com