Sieve hole air-jetting vortex-induced vibration suppression device and method

A technology of vortex-induced vibration and suppression device, which is applied in earthwork drilling, fluid flow, drilling equipment and other directions, can solve the problems of limited effect of passive suppression and control of flow field, difficulty in adapting to deep-sea marine environment, slow development of active suppression technology, etc. The effect of suppressing vortex-induced vibration, prolonging life, and being less prone to corrosion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

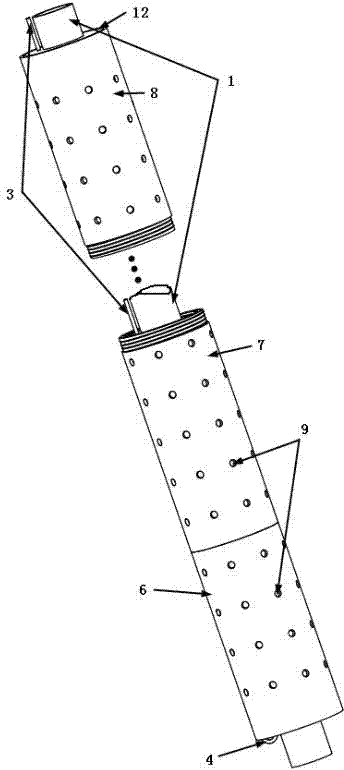

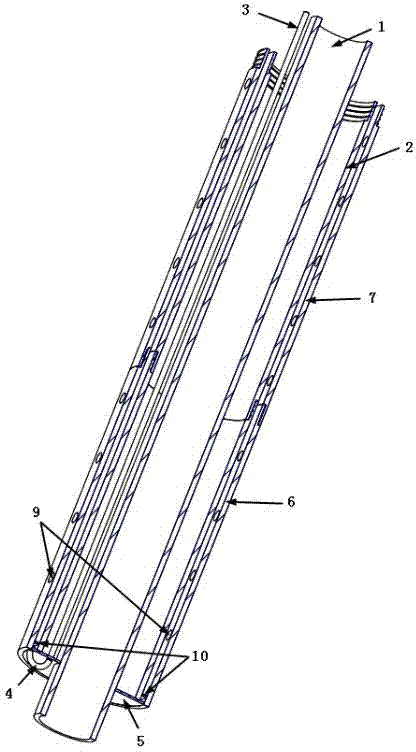

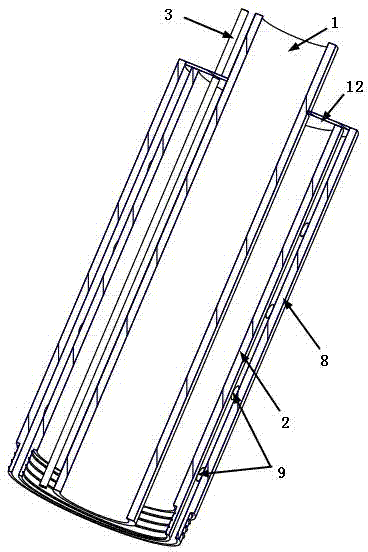

[0025] According to the perennial statistical information of local ocean waves and currents and the water depth of the riser 2, calculate the water pressure to be borne by the bottom exhaust screen 6, and determine the bottom exhaust screen 6, exhaust screen 7, and top exhaust screen The wall thickness of pipe 8 and the gas injection pressure of gas injection pipe 3.

[0026] When the device is installed, first, the bottom exhaust screen 6 is set outside the riser 2; under the bottom exhaust hole 9 of the bottom exhaust screen 6, it is embedded between the bottom exhaust screen 6 and the riser 2 Air distribution plate 10; then, install the bottom plate 5 at the bottom of the riser 2; pass the gas injection pipe 3 through the bottom plate 5, and connect with the U-shaped diversion elbow 4; the other end of the U-shaped diversion elbow 4 passes through the bottom plate 5 to extend into the annular space between the riser 2 and the bottom exhaust screen 6, and there is a gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com