Anti-separation dry sand silo and method

An anti-segregation and dry sand technology, applied in the field of dry sand silo, can solve the problems affecting the quality of the finished dry-mixed mortar, unclean discharge of the dry sand silo outlet, and speeding up the aging speed of the equipment, so as to improve the quality of the finished mortar, The effect of high reliability and avoiding unsmooth falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

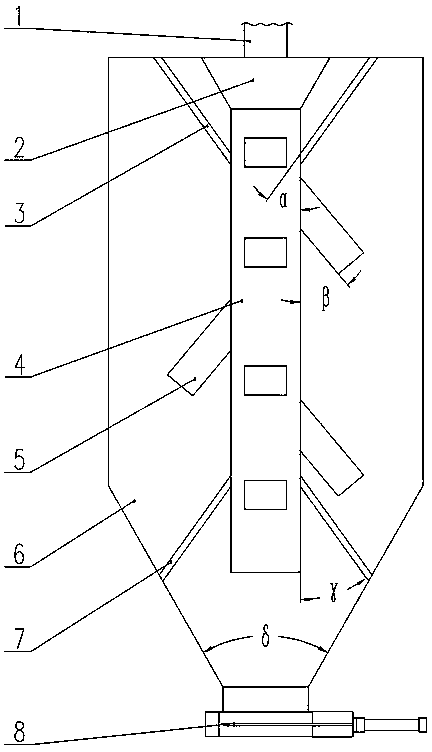

[0014] refer to figure 1 Among them, the present invention includes a silo and an anti-segregation device. The silo includes a feed chute (1), a feed hopper (2), a silo body (6) and a discharge valve (8), and the feed chute (1) is fixed on the upper cover of the silo body (6) , the outlet of the feed chute (1) is docked with the feed hopper (2); the bin body (6) mainly includes the upper cylinder and the lower cone, and in order to ensure smooth discharge, the cone The cone angle δ of the body is set to 60°~65°; the discharge valve (8) is installed on the discharge pipe at the lower end of the bin body (6).

[0015] The anti-segregation device includes a main pipe (4) and multiple side pipes (5); the main pipe (4) is a square pipe with a quadrilateral cross-section, and is fixed on the bin body (6) by the upper bracket (3) and the lower bracket (7). inside, and make the upper end of the main pipe connect with the feed hopper (2), and the lower end is suspended in the air, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com