Heat-resistant steel structure hard alloy and preparation method thereof

A steel-bonded hard alloy and heat-resistant technology, which is applied in the field of heat-resistant steel-bonded hard alloy and its preparation, can solve problems affecting the performance of the alloy, and achieve the effects of low manufacturing cost, high density, and avoiding segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

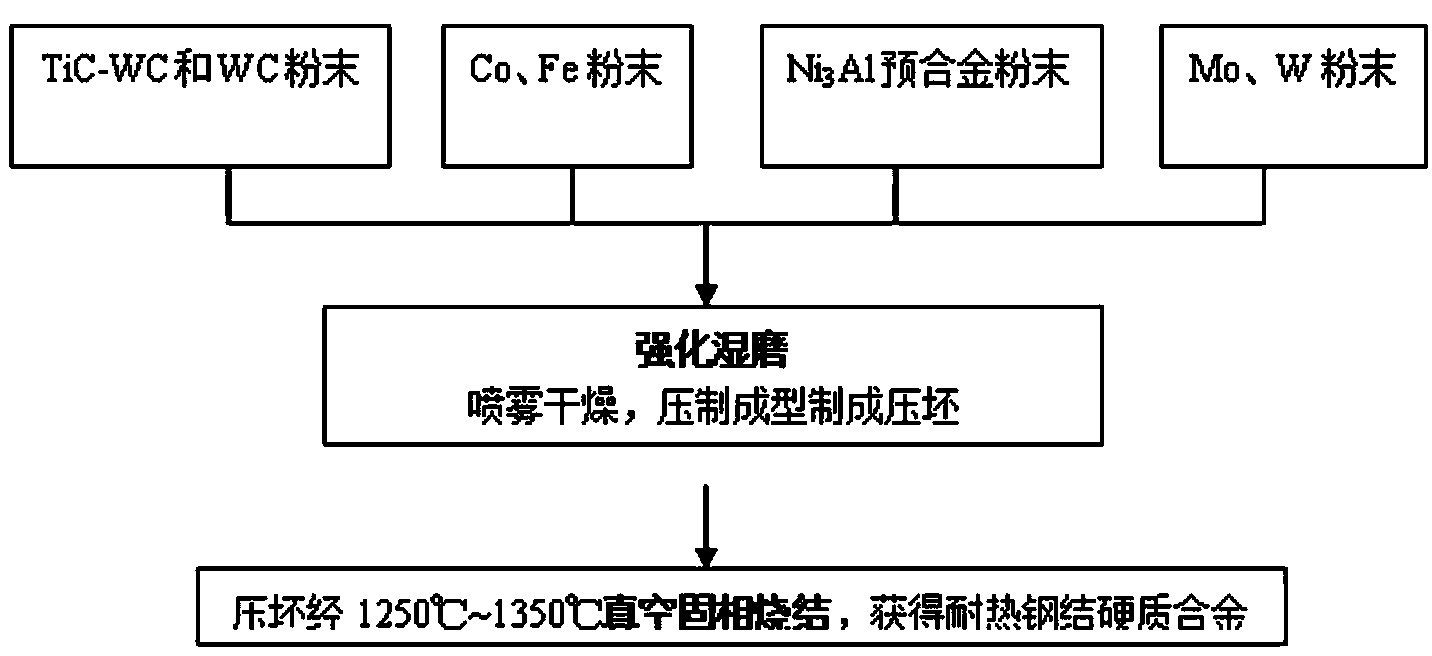

[0024] Embodiment 1: According to figure 1 The process shown is based on 34.8%WC, 15.2% saturated solid solution WC-TiC(3:7), 9%Co, 11.5%Ni 3 Al, 0.5% W powder and the rest of Fe powder are mixed evenly to form a mixture. The mixture is mixed according to the ball-to-material ratio of 6 and the liquid-solid ratio of 600ml / Kg. In the ball mill, alcohol is used as the wet grinding medium to carry out intensive wet grinding. After 48 hours, the wet-milled mixture was obtained; the wet-milled mixture was spray-dried and pressed into shape, and then the compact was subjected to vacuum solid-phase sintering at 1350°C to obtain a heat-resistant steel-bonded hard alloy, wherein the weight percentage of the binder phase was 50%.

Embodiment 2

[0025] Embodiment 2: According to figure 1 The flow shown is based on 21.1%WC, 28.9% saturated solid solution WC-TiC(3:7), 14%Co, 14%Ni 3Al, 0.5% Mo, 1% W powder and the rest of Fe powder are mixed evenly to form a mixture. The mixture is mixed according to the ball-to-material ratio of 6 and the liquid-solid ratio of 600ml / Kg. The wet grinding time is 48 hours to obtain the wet grinding mixture; the wet grinding mixture is spray-dried, pressed and formed, and then the compact is vacuum solid-phase sintered at 1350°C to obtain a heat-resistant steel-bonded cemented carbide, in which Phase weight percentage is 50%.

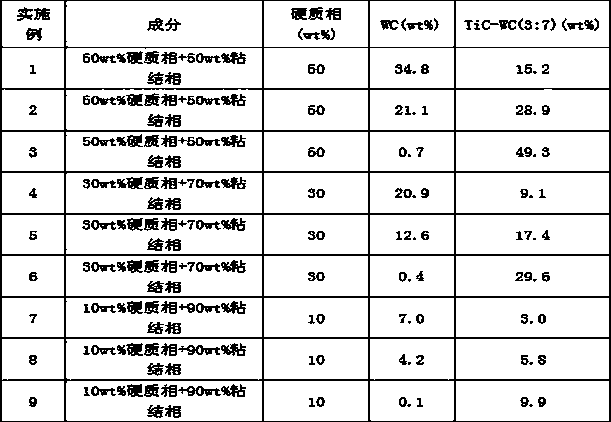

[0026] The preparation technological process of embodiment 3~9 of the present invention is as figure 1 As shown, its specific process parameters are shown in Table 2

[0027] Table 2 Preparation parameter table of the present invention

[0028]

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com