Filter element

A technology of filter element and coarse filtration, which is applied in the direction of fixed filter element filter, filtration separation, chemical instrument and method, etc., can solve the problems of increasing filter element cost, time-consuming and expensive, complicated production of star-shaped folded filter element, etc., and achieve the improvement of filtration performance , simple arrangement, and the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

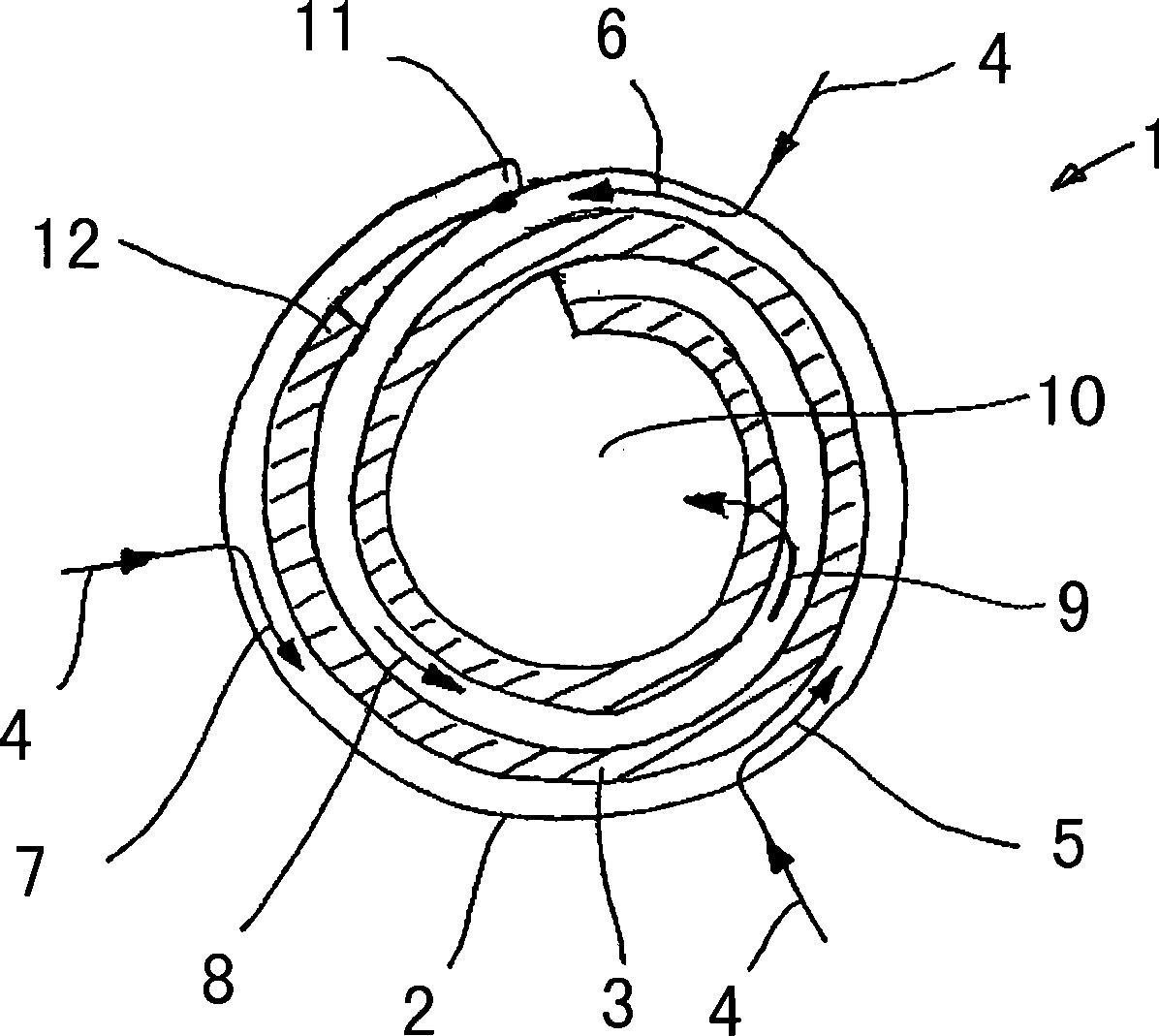

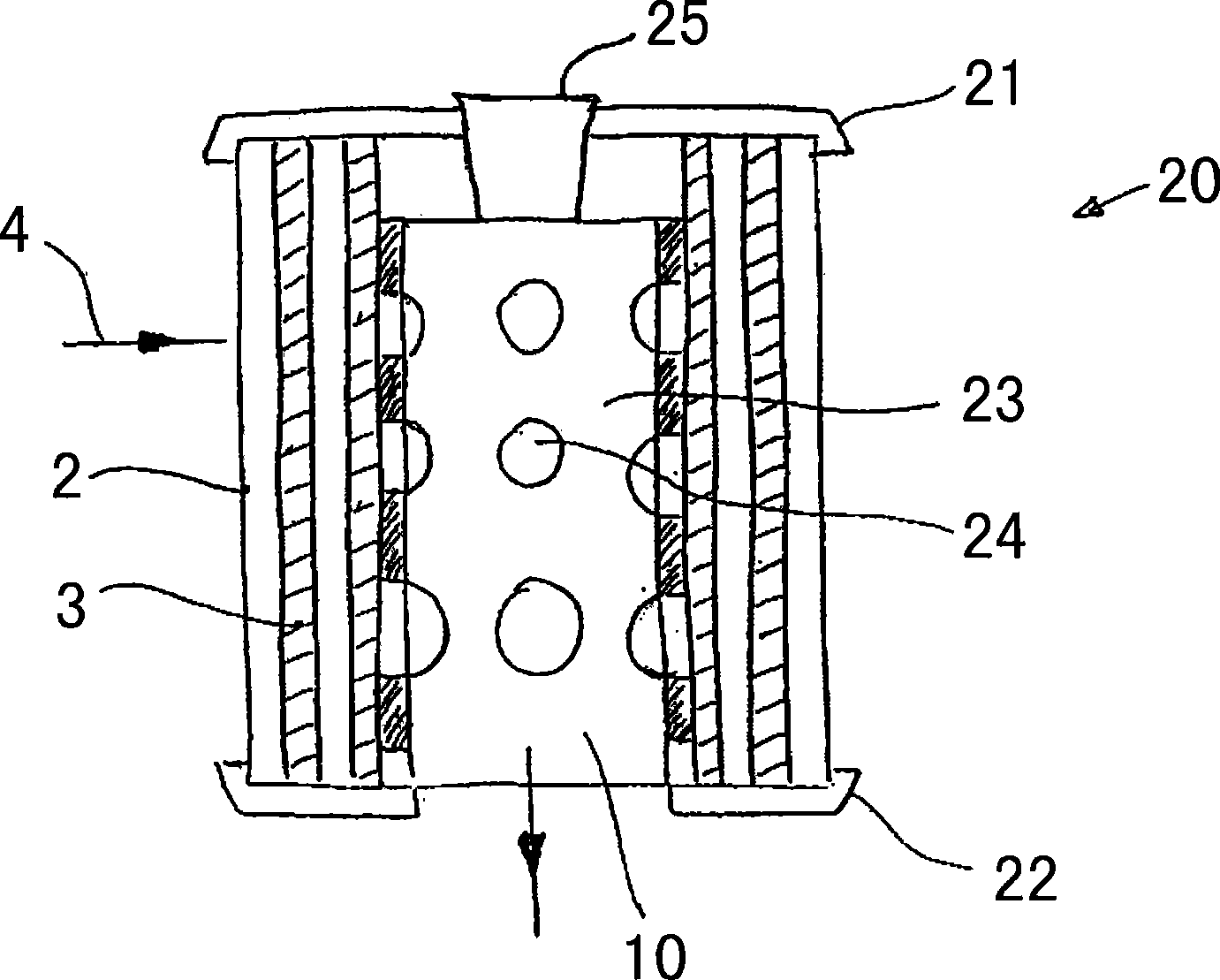

[0021] figure 1 shows a filter insert 1 consisting of a coarse filter medium 2 as an outer layer and a fine filter medium 3 as an inner layer. The two layers are stacked on top of each other and wound together in a helical fashion. in such as figure 1 In the shown embodiment, a space is provided between the two filter media, while the two layers are in contact with each other, so that a compact structure is obtained. The filtered liquid encounters the surrounding surface of the outer layer (see arrow 4) in a vertical manner and penetrates said outer layer. Filtration starts here and the liquid encounters the fine filter medium 3 after penetrating the coarse filter medium 2 . Part of the liquid will permeate into the fine filter medium 3, while the other part advances along the coarse filter medium 2 in a helical manner in the direction of the geometric center of the filter element 1 (see arrows 5 to 8). After passing through the coarse filter medium 2 for a certain path len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com