Blank pre-upsetting forming die and method

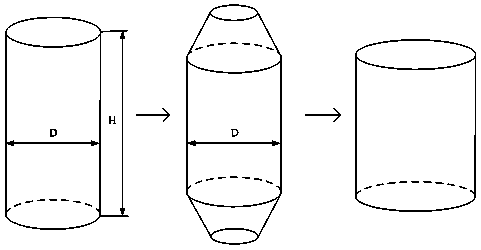

A technology for forming molds and blanks, which is applied in the field of blank pre-upsetting forming molds and forming, can solve the problems of uneven deformation of cylindrical blanks, easy to appear bulging, etc., and achieve uniform deformation, small flow obstruction, and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment: billet pre-upsetting forming die and method

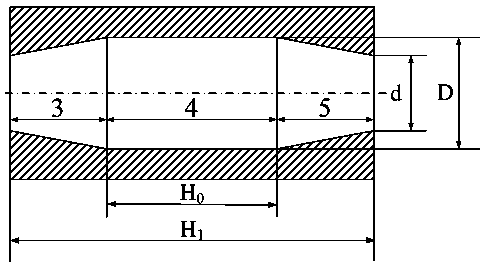

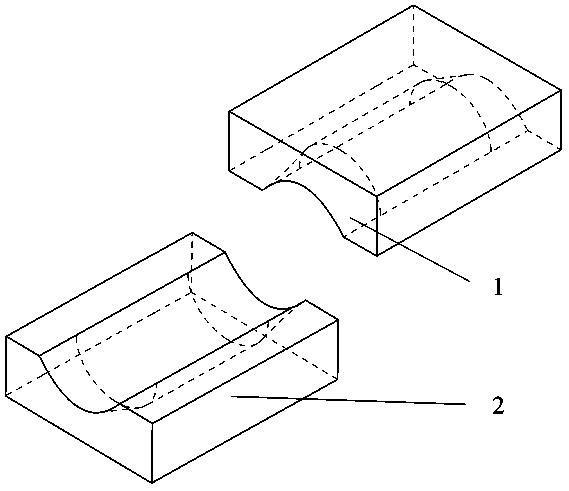

[0045] Figure 1~3 Shows the structure of the billet pre-upsetting forming die. The forming die includes an upper template 1 and a lower template 2. The upper template 1 and the lower template 2 can be buckled together. When the parting contact surfaces of the upper template 1 and the lower template 2 are completely attached The cavity is formed inside, and the length of the upper template 1 and the lower template 2 along the central axis direction is 160mm; the inner cavity includes three chambers: elliptical frustum cavity I3, fixed cavity 4, elliptical truncated cone cavity Cavity II5; the length of the central axis of the fixed cavity is 115 mm, the fixed cavity 4 is located between the elliptical frustum cavity I3 and the elliptical frustum cavity II5, and the elliptical frustum cavity I3 and the elliptical frustum cavity II5 are distributed On both sides, it is symmetrically distributed; the cross-sectiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com