Device and method for achieving uniformity of electroless nickel plating layer

A technology of electroless nickel plating and uniformity, applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problems of uneven adhesion, concentration effect, slow progress, etc., to increase the degree of turbulence and achieve uniformity The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

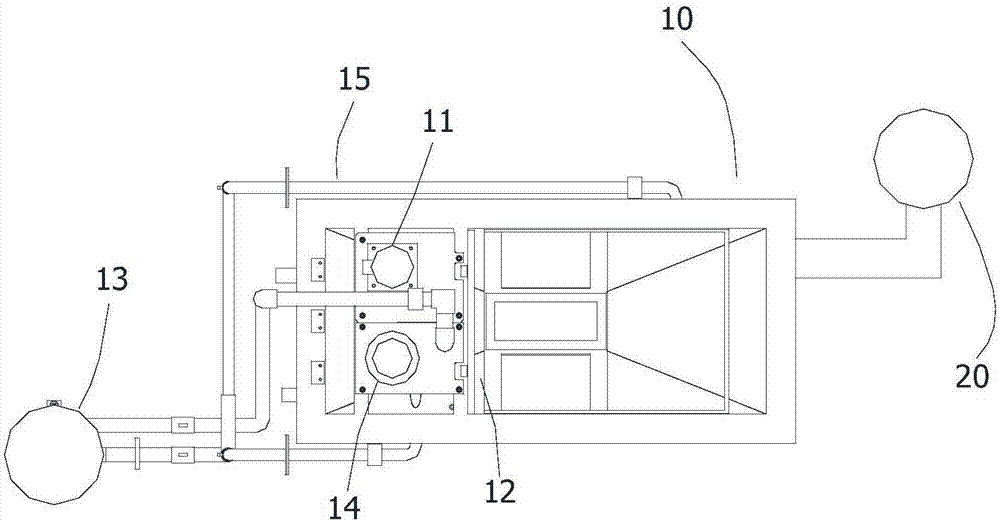

[0017] Combine below figure 1 , the present invention is described in further detail.

[0018] A device for realizing the uniformity of electroless nickel plating layer, comprising an electroless nickel plating tank 10, an automatic dosing device 20 is arranged on the outside of the chemical nickel plating tank 10, and the dosing pipe of the automatic dosing device 20 is arranged on the electroless plating tank 10 The side wall of nickel tank 10, automatic dosing equipment 20 comprises the nickel ion concentration detection system that is arranged on electroless nickel plating tank 10 side walls, and nickel ion concentration detection system collects nickel ion concentration information and transmits by being placed in the sampling tube in plating bath To the PLC control system on the automatic dosing equipment 20, the dosing pump on the automatic dosing equipment 20 is controlled by the PLC control system to add medicine to the chemical nickel plating tank 10, and the describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com