Chemical waste treatment device and treatment process

A technology of waste treatment and treatment process, which is applied in the chemical industry, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problem of simultaneous treatment of waste oil, waste gas, and solid chemical waste, the inability to completely remove organic matter from chemical waste gas, and the complex composition of chemical waste gas and other problems, to achieve the effect of reducing side reaction products, reducing exhaust gas concentration, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

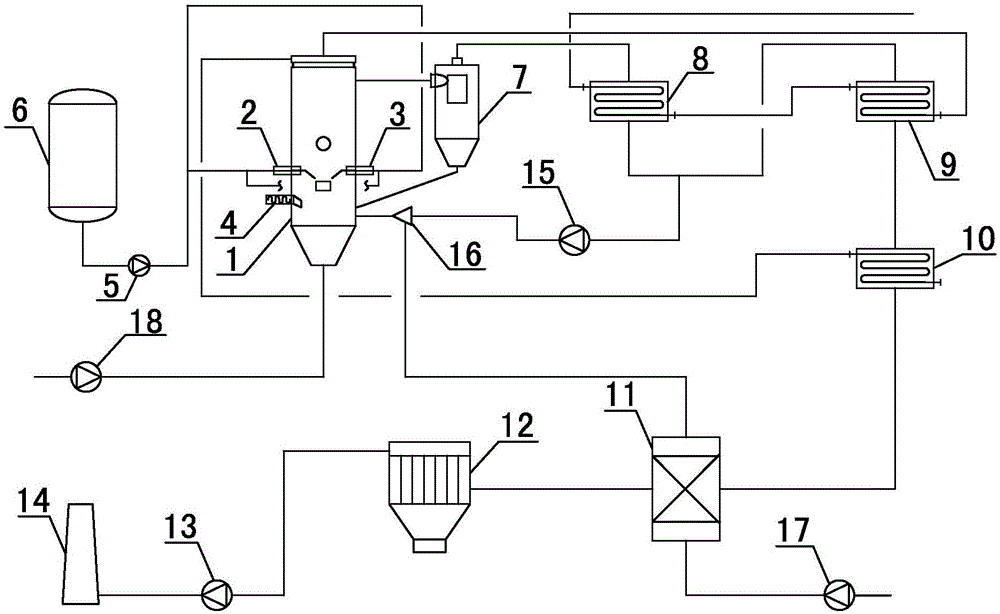

[0067] like figure 1 As shown, the chemical waste treatment device of the present invention includes a reactor 1, and the side of the reactor 1 is provided with a first material gun 2, a second material gun 3 and a solid material conveyor 4, a first material gun 2, a waste oil transfer pump 5 is connected to the waste oil storage tank 6 in turn, the second material gun 3 is connected to the waste oil delivery pump 5, the reactor 1, the cyclone separator 7, the front heat exchanger 8, the rear heat exchanger 9, the energy-saving heat exchanger 10, The air preheater 11, the dust collector 12, and the exhaust fan 13 are connected to the chimney 14 in sequence; Connected in sequence, the flue gas mixer 16 is connected to the air preheater 11 , the energy-saving heat exchanger 10 is connected to the reactor 1 , the secondary fan 17 is connected to the air preheater 11 , and the primary fan 18 is connected to the reactor 1 .

[0068] When the device is running, the waste oil is sen...

Embodiment 2

[0091] The chemical waste treatment device is the same as that in Example 1.

[0092] Adopt the processing technology of the above-mentioned chemical waste treatment device, and the steps are as follows:

[0093] (1) The reactor of the device is Φ1000mm diameter specification; 300kg of catalyst and 60kg of desulfurizer are put into the reactor for the first time;

[0094] (2) The waste gas is fed into the jacket of the first material gun and the second material gun of the reactor, the reaction is started, and the waste gas is adjusted to 350Nm 3 / h;

[0095] (3) Start the primary fan, adjust the frequency conversion, and provide an air volume of 4000m 3 / h;

[0096] (4) the temperature in the reactor is increased, and the temperature reaches 400 °C;

[0097] (5) The waste oil is sent to the waste oil storage tank from the outside, heated to 100 ℃ with steam, pressurized by the waste oil pump to 0.5MPa, and sent into the waste oil into the nozzles of the first and second fe...

Embodiment 3

[0109] The chemical waste treatment device is the same as that in Example 1.

[0110] Adopt the processing technology of the above-mentioned chemical waste treatment device, and the steps are as follows:

[0111] (1) The device reactor is Φ900mm diameter specification; 200kg of catalyst and 40kg of desulfurizer are put into the reactor for the first time;

[0112] (2) The waste gas is fed into the jacket of the first material gun and the second material gun of the reactor, the reaction is started, and the waste gas is adjusted to 200Nm 3 / h;

[0113] (3) Start the primary fan, adjust the frequency conversion, and provide an air volume of 3000m 3 / h;

[0114] (4) the temperature in the reactor is increased, and the temperature reaches 400 °C;

[0115] (5) The waste oil is sent to the waste oil storage tank from the outside, heated to 120 ℃ with steam, pressurized by the waste oil pump to 0.6MPa, and sent into the waste oil into the nozzles of the first and second feed guns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com