Differential falling-sill type stilling pool

A differential sill type, stilling pool technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problem of the stilling pool energy dissipation rate is not very high, increasing the river bank slope protection project downstream of the stilling pool and so on. , to achieve the effect of shortening the protection range, easy body shape optimization, and strong turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

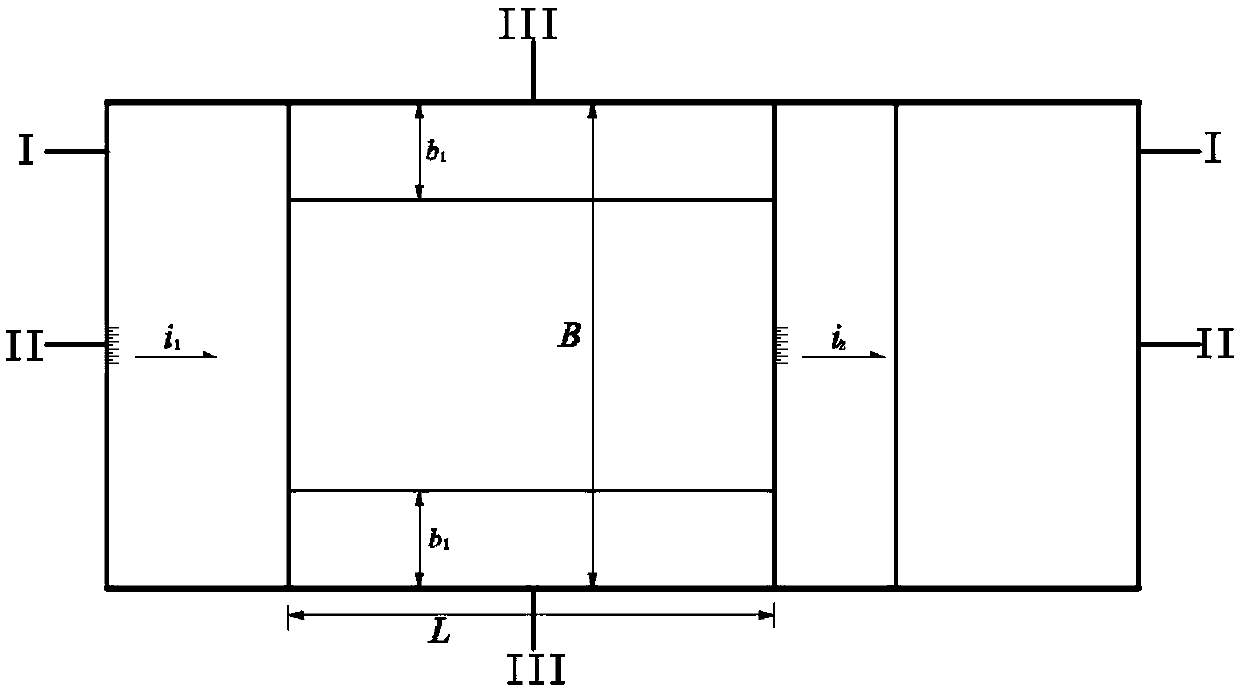

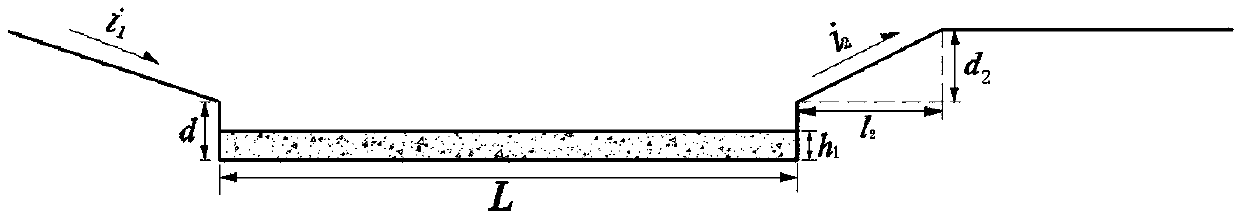

[0035] The A-type differential sill-type stilling pool in this implementation case is used in a middle-head sluice-dam type hydropower station. The stilling pool is composed of a diversion connecting anti-slope section 1, a differential sill stilling pool main section 2, a stilling pool sill anti-slope section 4, which are successively connected in the direction of water flow. The downstream sea is connected, and the inner bottom of the main section 2 of the differential slumping stilling pool is provided with two longitudinal sills 3 along the water flow direction. The two sills are symmetrically attached to the left and right side walls of the stilling pool and are set on the bottom plate of the main section of the stilling pool, and the structural dimensions of the two longitudinal strips are exactly the same.

[0036] The water head in front of the gate is 50m, and the maximum single-width flow is q=200m 3 / s.m; the slope of the reverse slope section connected by diversion i ...

Embodiment 2

[0039] In this case, the B-type differential step-down stilling pool is used in a middle-head sluice-dam type hydropower station. It is composed of the reverse slope section 1, the main section of the differential sill stilling pool, and the reverse slope section 4 of the stilling pool tail sill, which are connected in sequence along the flow direction. In connection, the inner bottom of the main section 2 of the differential slumping stilling pool is provided with three longitudinal sills 3 along the water flow direction.

[0040] The water head in front of the gate is 60m and the maximum single-width flow is q=180m 3 / s.m; the slope of the reverse slope section connected by diversion i 1 =d 1 / l 1 =1:8, the horizontal length of the diversion connecting the reverse slope section l 1 =24m, the vertical height d of the anti-slope section connected by the diversion 1 = 3m; the width of the main section of the stilling pool is B=48m, the length is L=55m, and the height of the falling...

Embodiment 3

[0043] The C-type differential falling sill stilling pool in this implementation case is used for the underflow energy dissipation at the spillway exit of the middle water head hydropower station, and the reverse slope section is connected by the diversion in sequence along the flow direction. 1. The differential falling sill stilling pool The main body section 2, the stilling pool sill reverse slope section 4, the stilling pool sill back slope section is connected with the downstream ocean, and the inner bottom of the differential sill stilling pool body section 2 is provided with two longitudinal sections along the water flow direction Article threshold 3.

[0044] Among them, the maximum operating head is 80m, the spillway width B=30m, and the maximum single-width flow rate is q=100m 3 / s.m; the slope of the reverse slope section connected by diversion i 1 =d 1 / l 1 =1:6, the horizontal length of the diversion connecting the reverse slope section l 1 =18m, the vertical height d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com