High-pressure rotational flow mixing device

A technology of mixing device and high-pressure swirling flow, which is applied in the direction of fluid mixer, mixer, dissolution, etc., to achieve the effect of large velocity gradient, sufficient and uniform mixing, and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

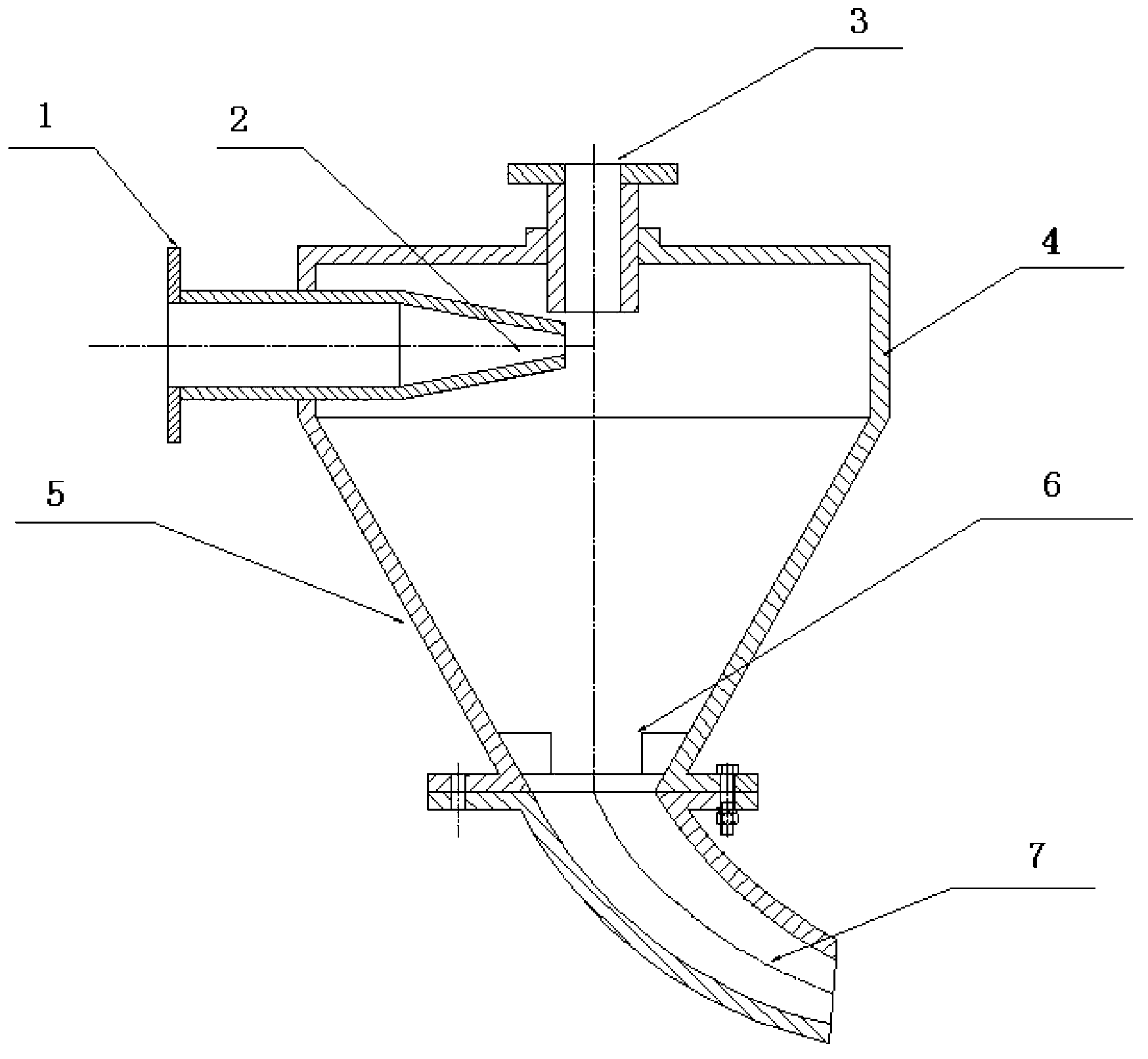

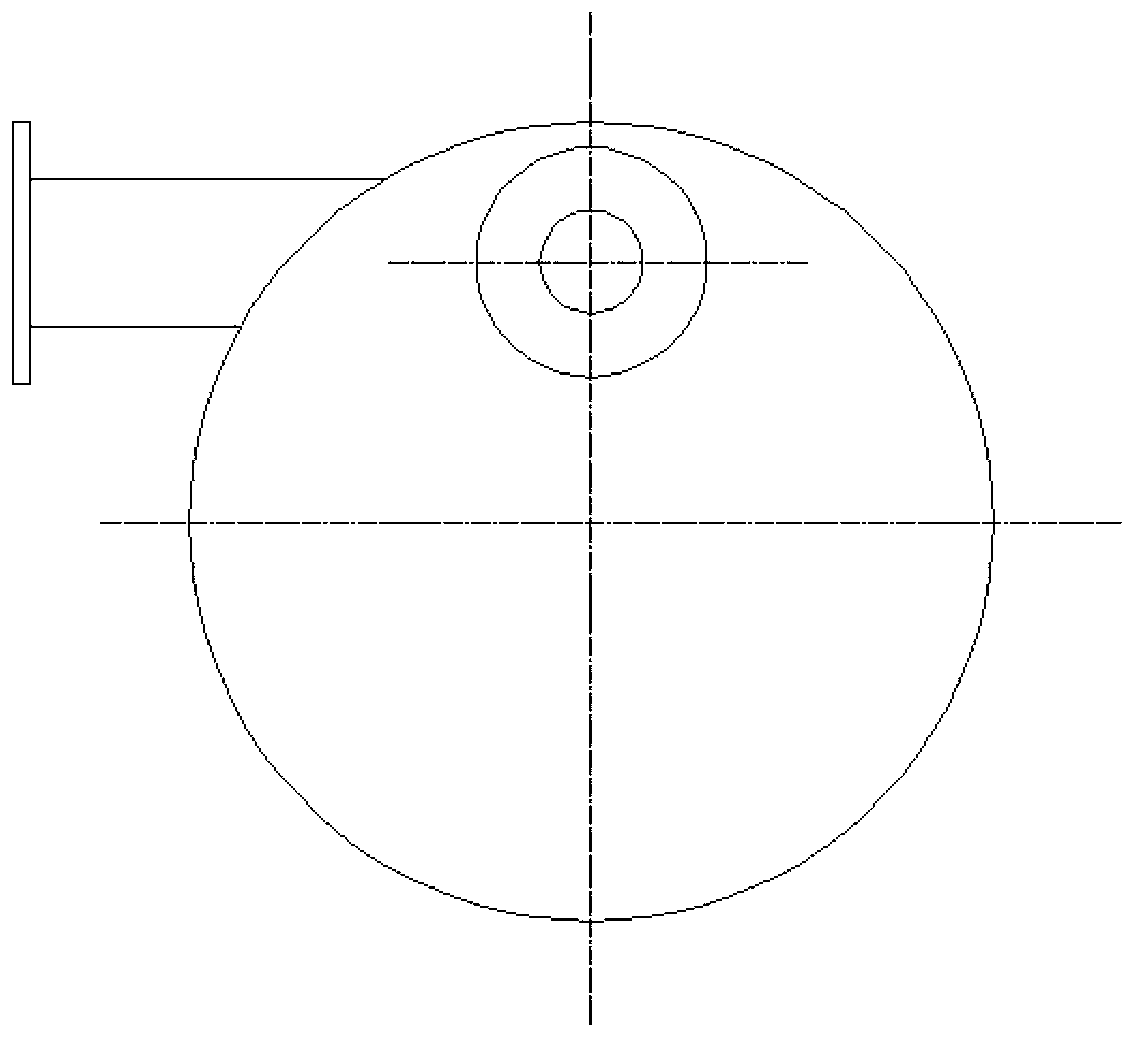

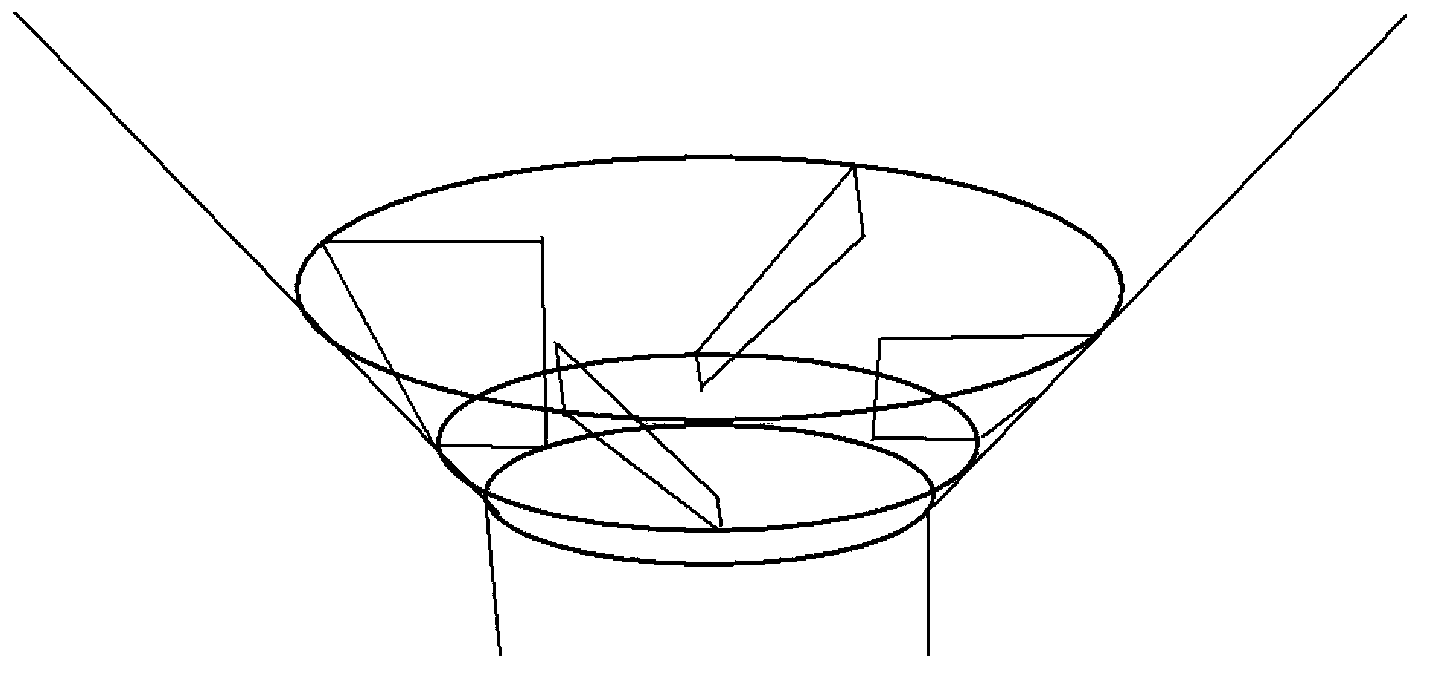

[0013] Embodiment 1: as Figure 1-3 As shown, the main mixing chamber of the high-pressure swirl mixing device is composed of a cylindrical mixing chamber 4 and a conical mixing chamber 5 connected in series. The fluid inlet pipe 1 is connected to the cylindrical mixing chamber 4, and the fluid inlet pipe 1 is provided with a nozzle 2 with a pressure greater than 10 MPa. A solid phase feeding port 3 is installed above the cylindrical mixing chamber 4, and the axis of the solid phase feeding port 3 is perpendicular to the axis of the nozzle 2. A mixing baffle 6 is designed at the outlet of the conical mixing chamber 5, and the mixing baffle 6 is composed of 2 blades distributed at an angle of 20° between the outlet of the conical mixing chamber and the horizontal plane. The outlet of the conical mixing chamber 5 is connected to the inlet of the steady flow elbow 7, and the steady flow elbow 7 adopts a variable diameter structure, and its inlet diameter is D 1 , the outlet dia...

Embodiment 2

[0014] Embodiment 2: as Figure 1-3 As shown, the main mixing chamber of the high-pressure swirl mixing device is composed of a cylindrical mixing chamber 4 and a conical mixing chamber 5 connected in series. The fluid inlet pipe 1 is connected to a cylindrical mixing chamber 4 . The fluid inlet pipe 1 is provided with a nozzle 2 with a pressure resistance greater than 10 MPa. A solid phase feeding port 3 is installed above the cylindrical mixing chamber 4, and the axis of the solid phase feeding port 3 is perpendicular to the axis of the nozzle 2. A mixing baffle 6 is designed at the outlet of the conical mixing chamber 5, and the mixing baffle 6 is composed of 4 blades distributed at an angle of 45° between the outlet of the conical mixing chamber and the horizontal plane. The outlet of the conical mixing chamber 5 is connected to the inlet of the steady flow elbow 7, and the steady flow elbow 7 adopts a variable diameter structure, and its inlet diameter is D 1 , the out...

Embodiment 3

[0015] Embodiment 3: as Figure 1-3 As shown, the main mixing chamber of the high-pressure swirl mixing device is composed of a cylindrical mixing chamber 4 and a conical mixing chamber 5 connected in series. The fluid inlet pipe 1 is connected to a cylindrical mixing chamber 4 . The fluid inlet pipe 1 is provided with a nozzle 2 with a pressure resistance greater than 10 MPa. A solid phase feeding port 3 is installed above the cylindrical mixing chamber 4, and the axis of the solid phase feeding port 3 is perpendicular to the axis of the nozzle 2. A mixing baffle 6 is designed at the outlet of the conical mixing chamber 5, and the mixing baffle 6 is composed of 6 blades distributed at an angle of 60° between the outlet of the conical mixing chamber and the horizontal plane. The outlet of the conical mixing chamber 5 is connected to the inlet of the steady flow elbow 7, and the steady flow elbow 7 adopts a variable diameter structure, and its inlet diameter is D 1 , the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com