Homogeneous three-phase reactor for jet aeration

A jet aeration and reactor technology, applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc., can solve problems such as low reaction efficiency, difficulty in gas, and sufficient and uniform mixing of liquid and solid three-phase , to achieve high reaction efficiency, ensure utilization efficiency, and fully react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

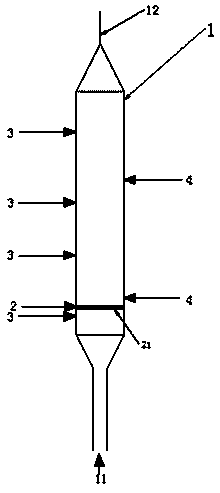

[0038] This embodiment provides a jet aeration three-phase homogeneous reactor, its structure is as follows figure 1 shown, including:

[0039] The reactor shell 1 is connected to the bottom of the reactor shell with a slurry inlet channel 11, and connected to the top of the reactor shell with a discharge channel 12;

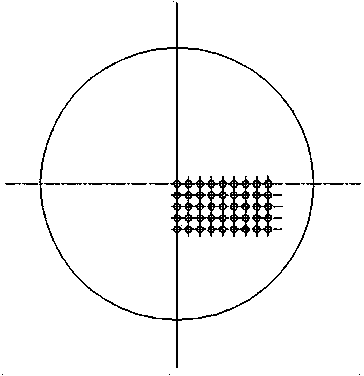

[0040] The jet aeration three-phase homogeneous plate 2, the jet aeration three-phase homogeneous plate is horizontally arranged in the reactor shell and is located at the bottom of the reactor shell, such as image 3 and Figure 4 As shown, micropores 21 are evenly arranged on the jet aeration three-phase homogeneous plate 2, and the micropores are set through the jet aeration three-phase homogeneous plate; as an optional embodiment, the jet The porosity of the micropores on the aerated three-phase homogeneous plate is 0.0001-0.1, and the distance between two adjacent micropores is 100-10000 microns. As a preferred embodiment, the porosity described in this e...

Embodiment 2

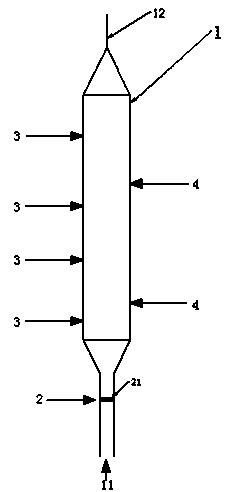

[0047] The jet aeration three-phase homogeneous reactor described in this embodiment has the following structure: figure 2 shown, including:

[0048] The reactor shell 1 is connected to the bottom of the reactor shell with a slurry inlet channel 11, and connected to the top of the reactor shell with a discharge channel 12;

[0049] The jet aeration three-phase homogeneous plate 2, the jet aeration three-phase homogeneous plate is arranged in the described slurry inlet channel, and is parallel to the cross section of the described slurry inlet channel 11; the jet aeration three-phase homogeneous plate Micropores 21 are evenly arranged on the mass plate 2, and the micropores are set through the jet aeration three-phase homogeneous plate; as an optional embodiment, the pores of the micropores on the jet aeration three-phase homogeneous plate The ratio is 0.0001-0.1, and the distance between every two adjacent micropores is 100-10000 microns. Preferably, the porosity described i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com