Patents

Literature

358results about How to "Stir fully and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

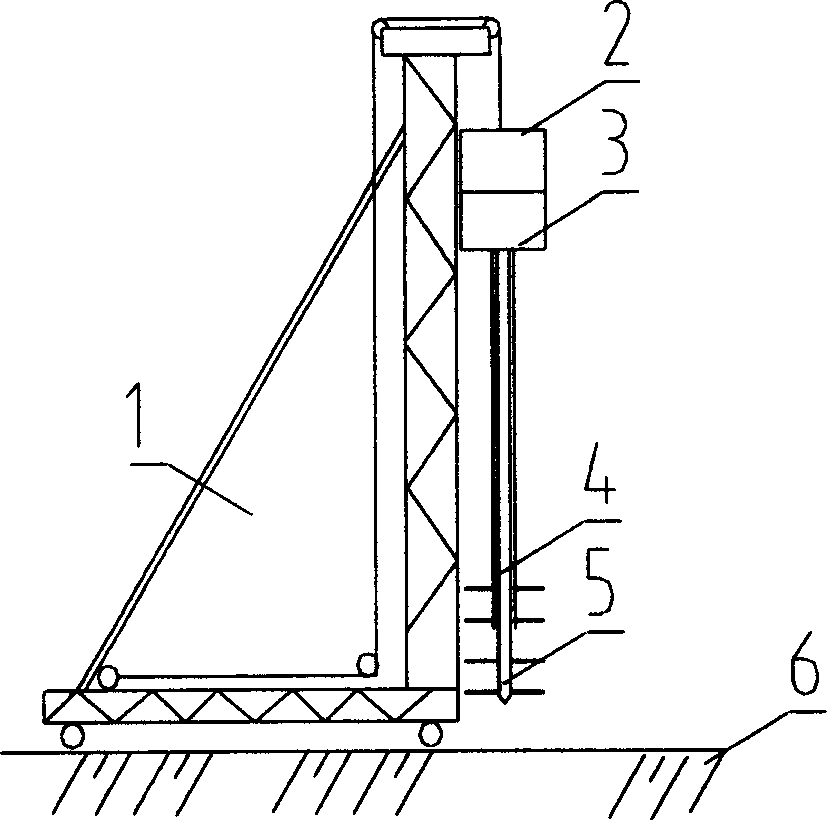

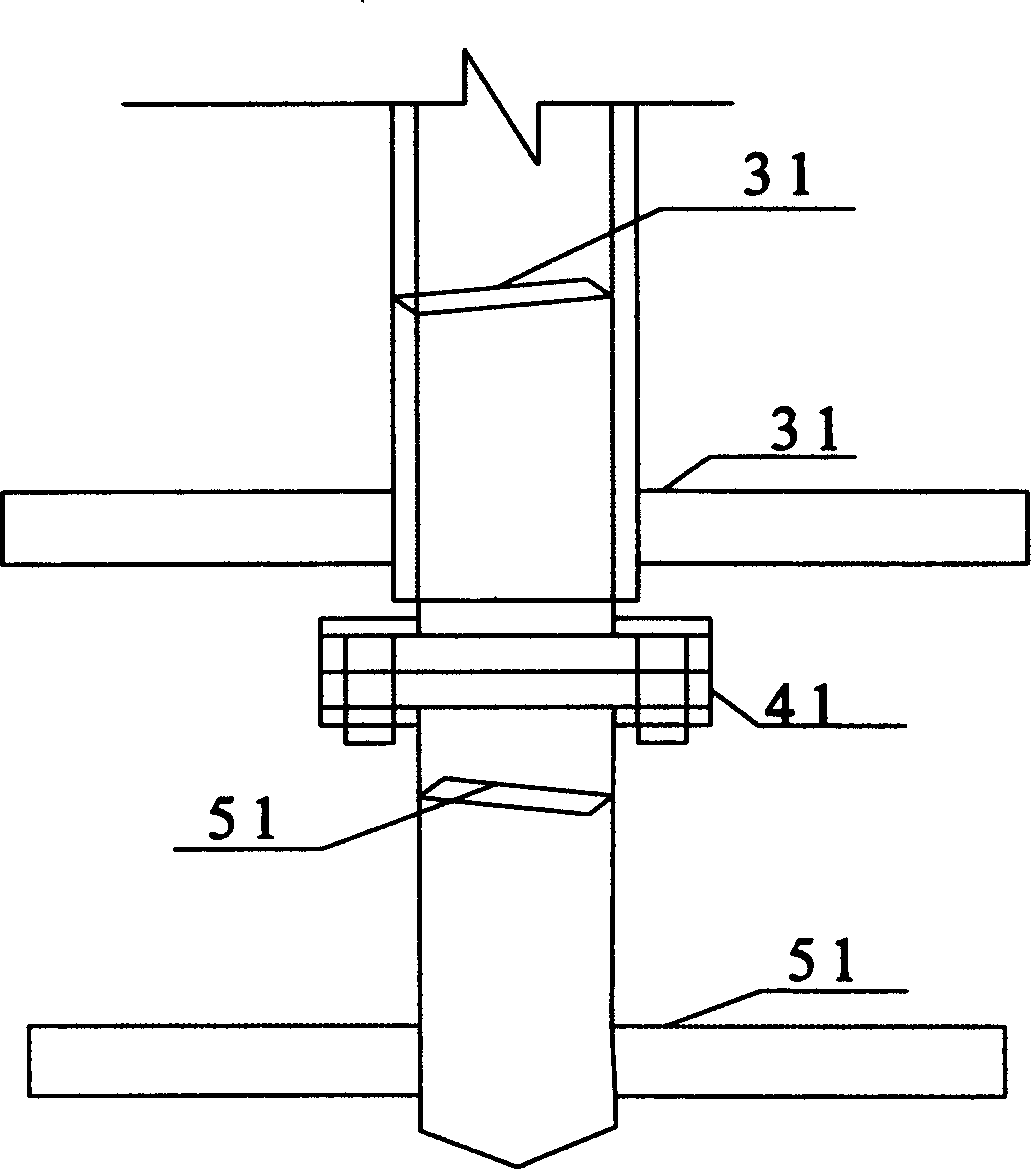

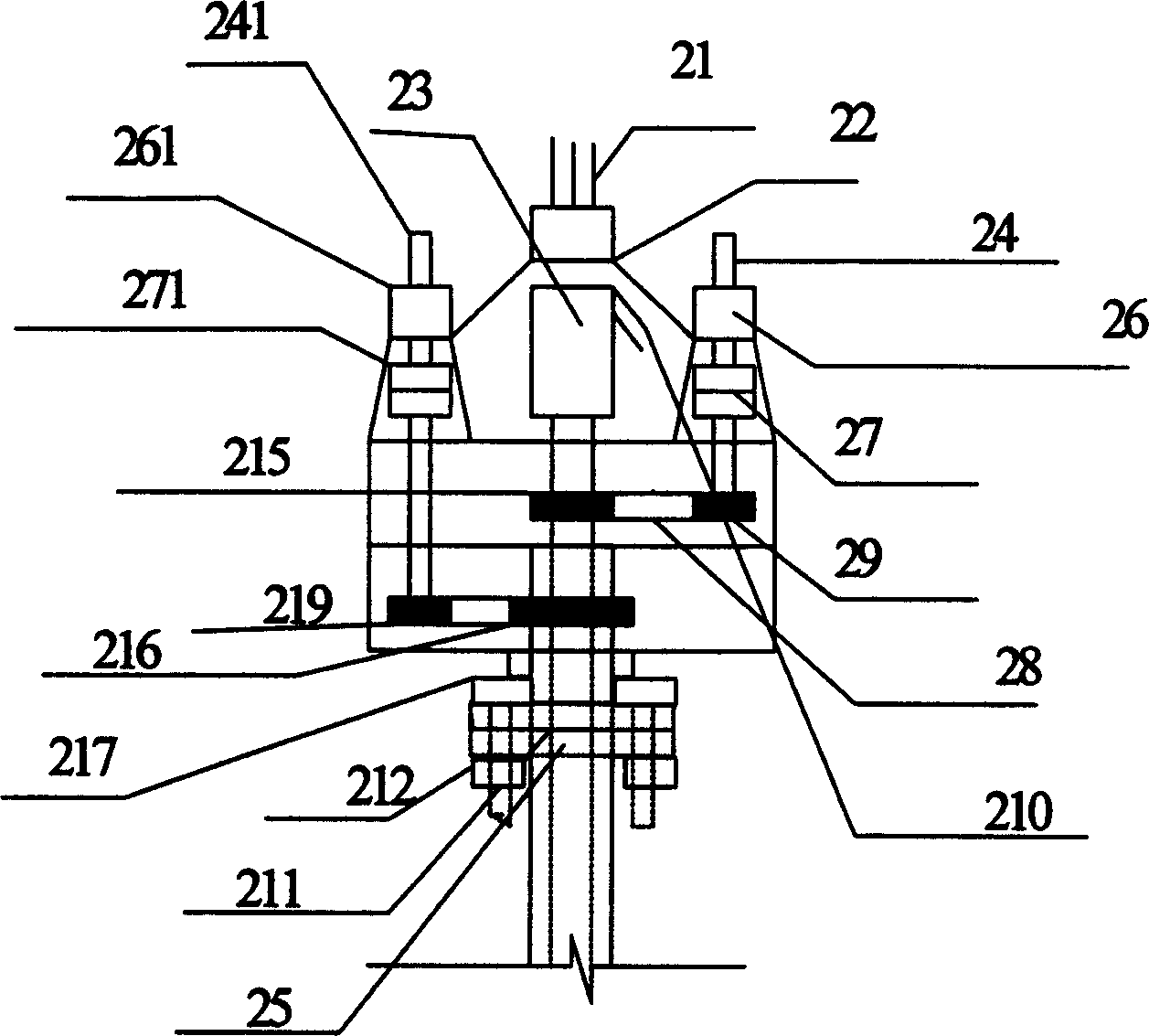

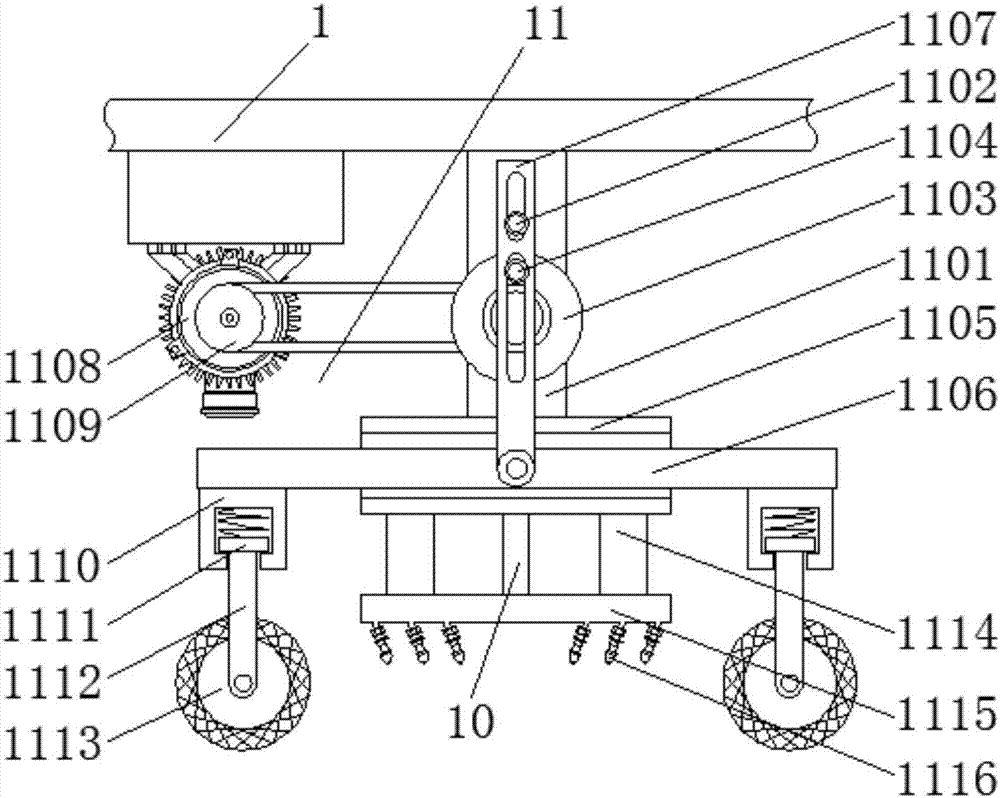

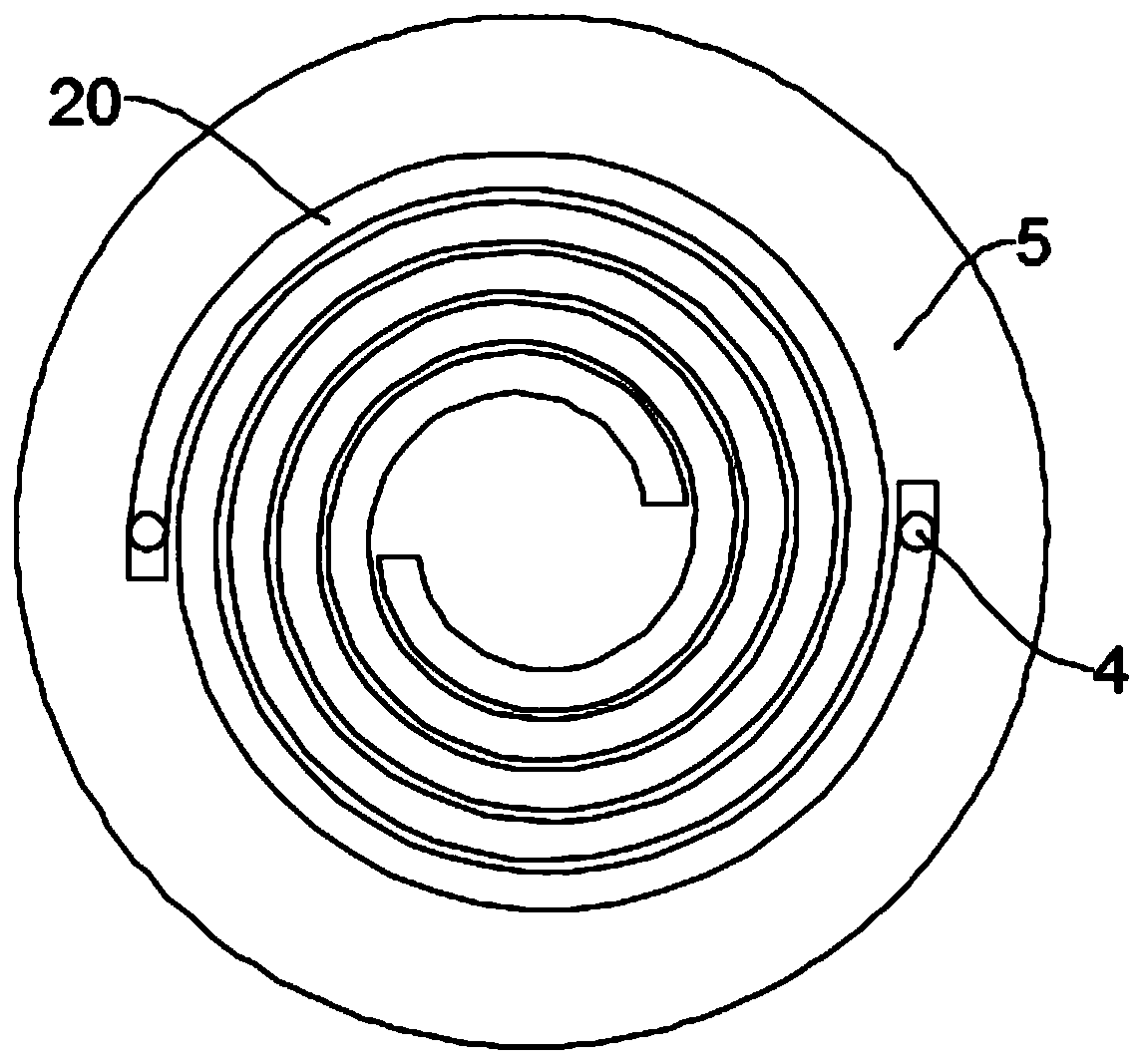

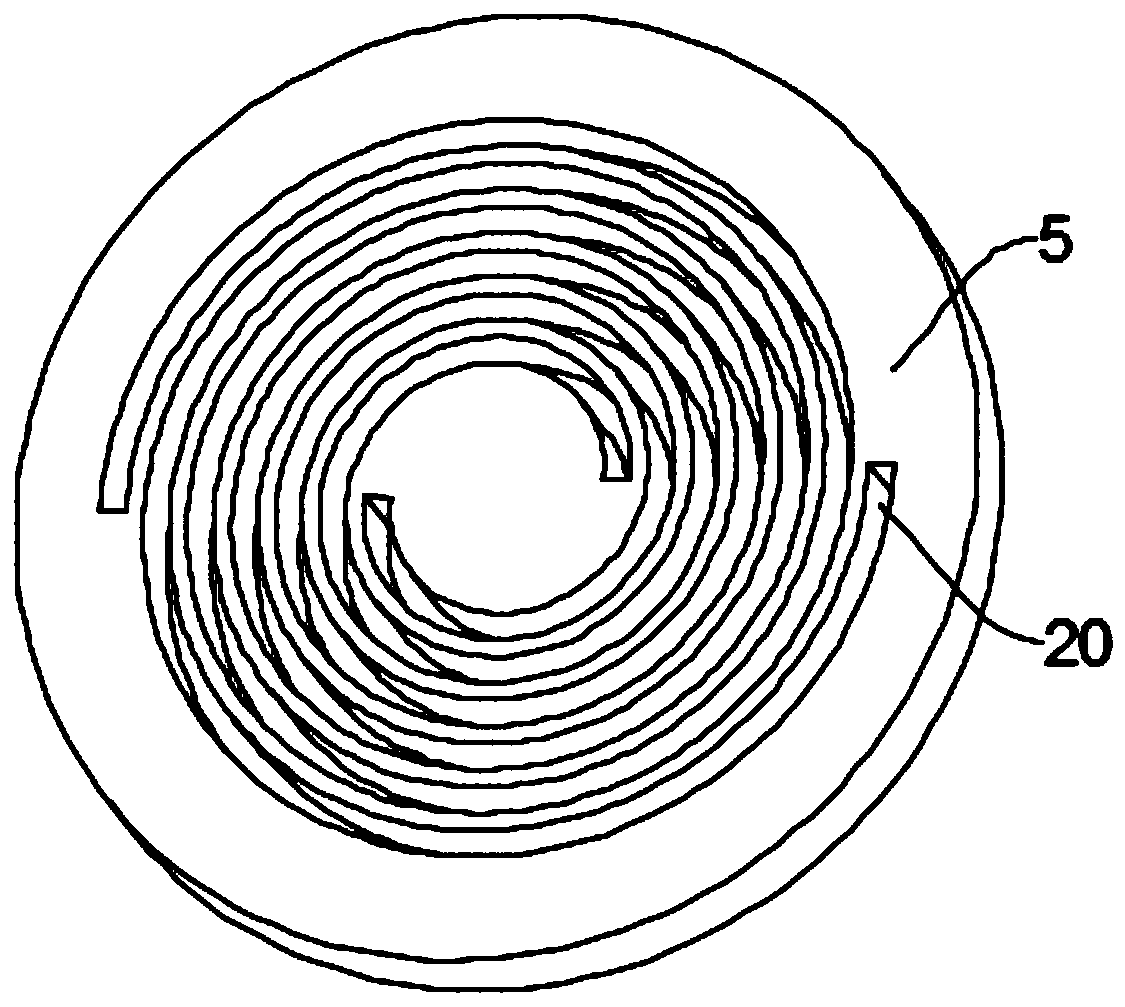

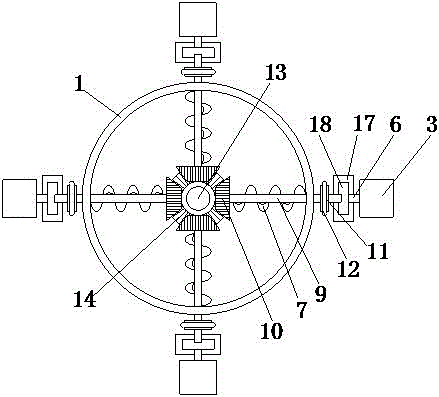

Bi-directional cement soil mixing pile machine

ActiveCN1632232AStir fully and evenlyWon't be lostBulkheads/pilesDrilling machines and methodsDrivetrainSoil mixing

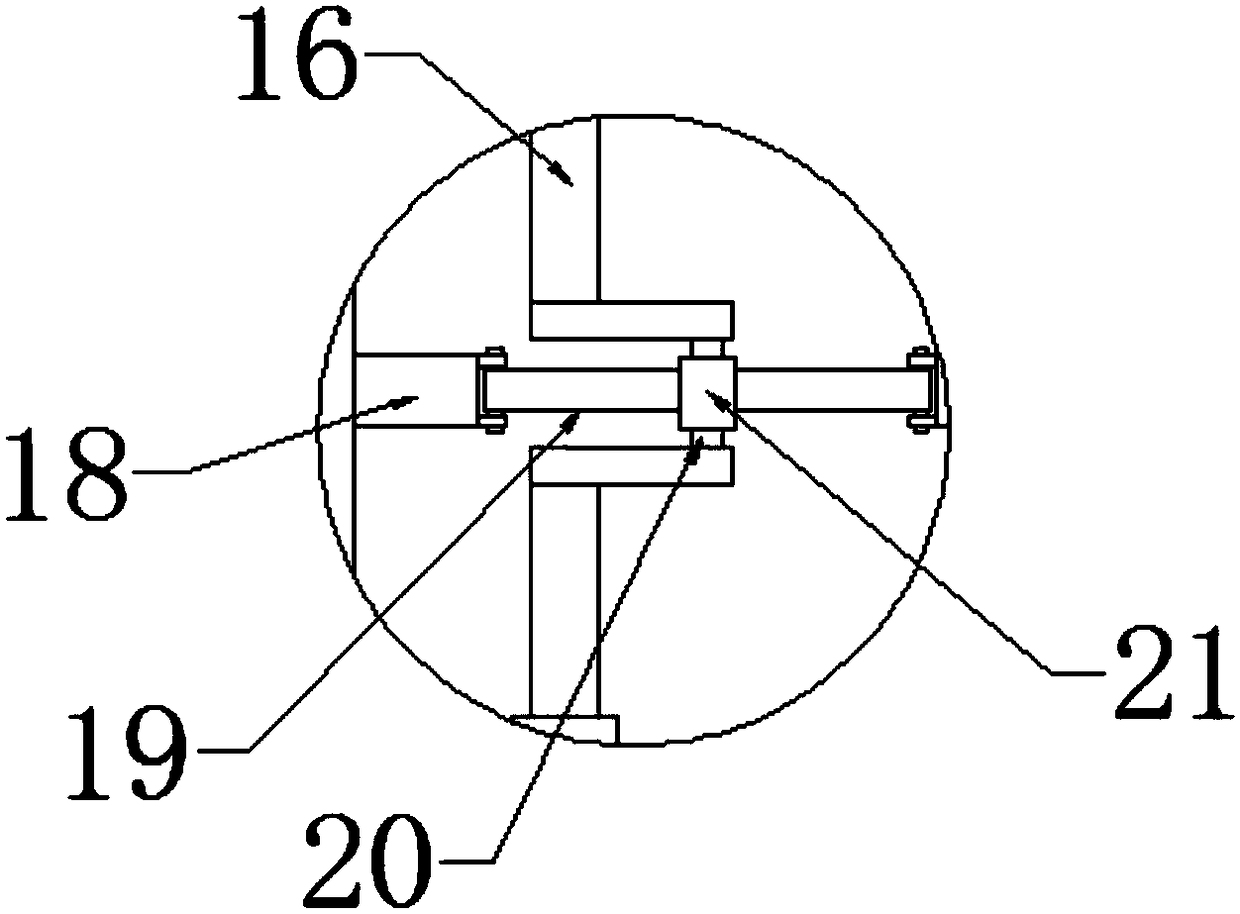

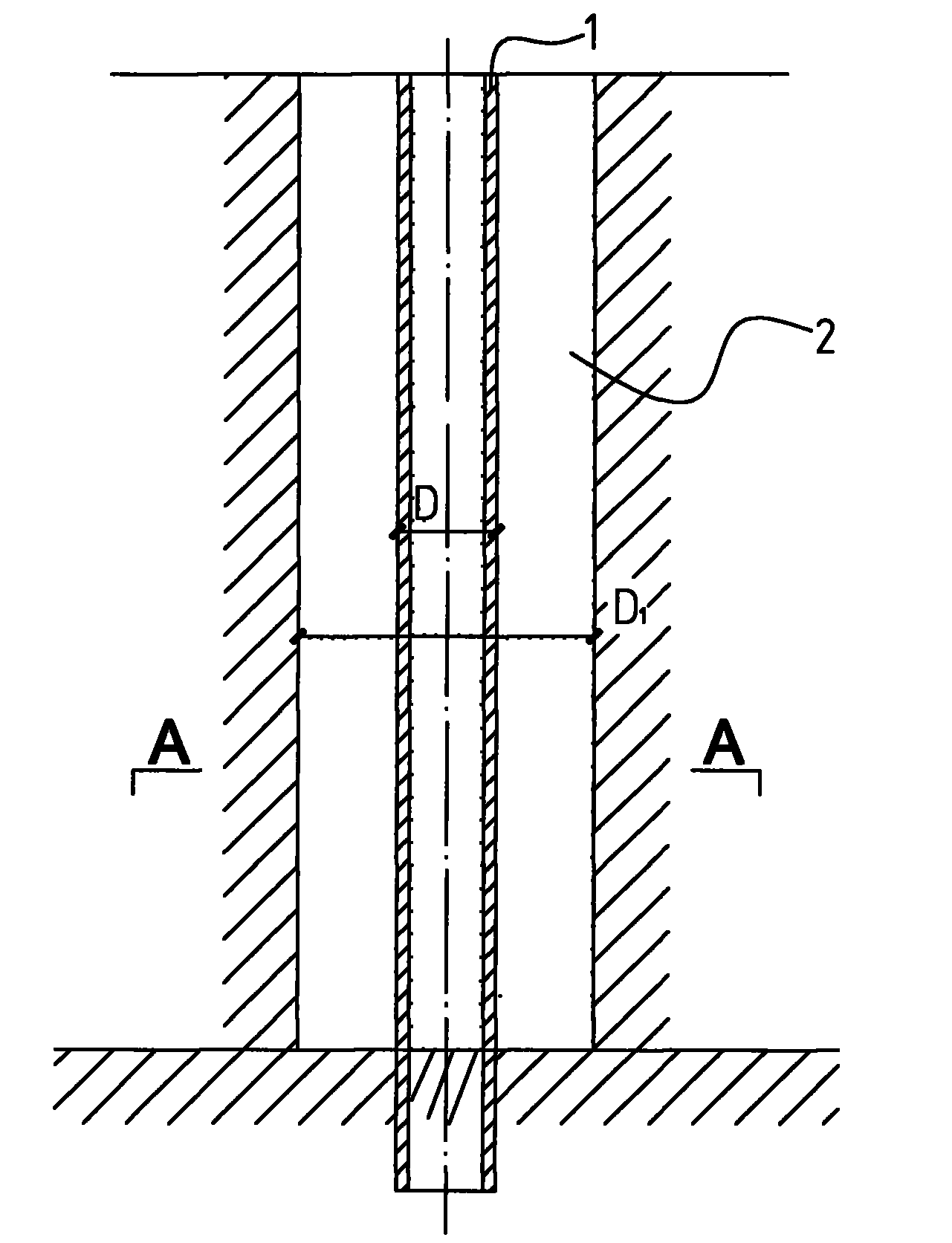

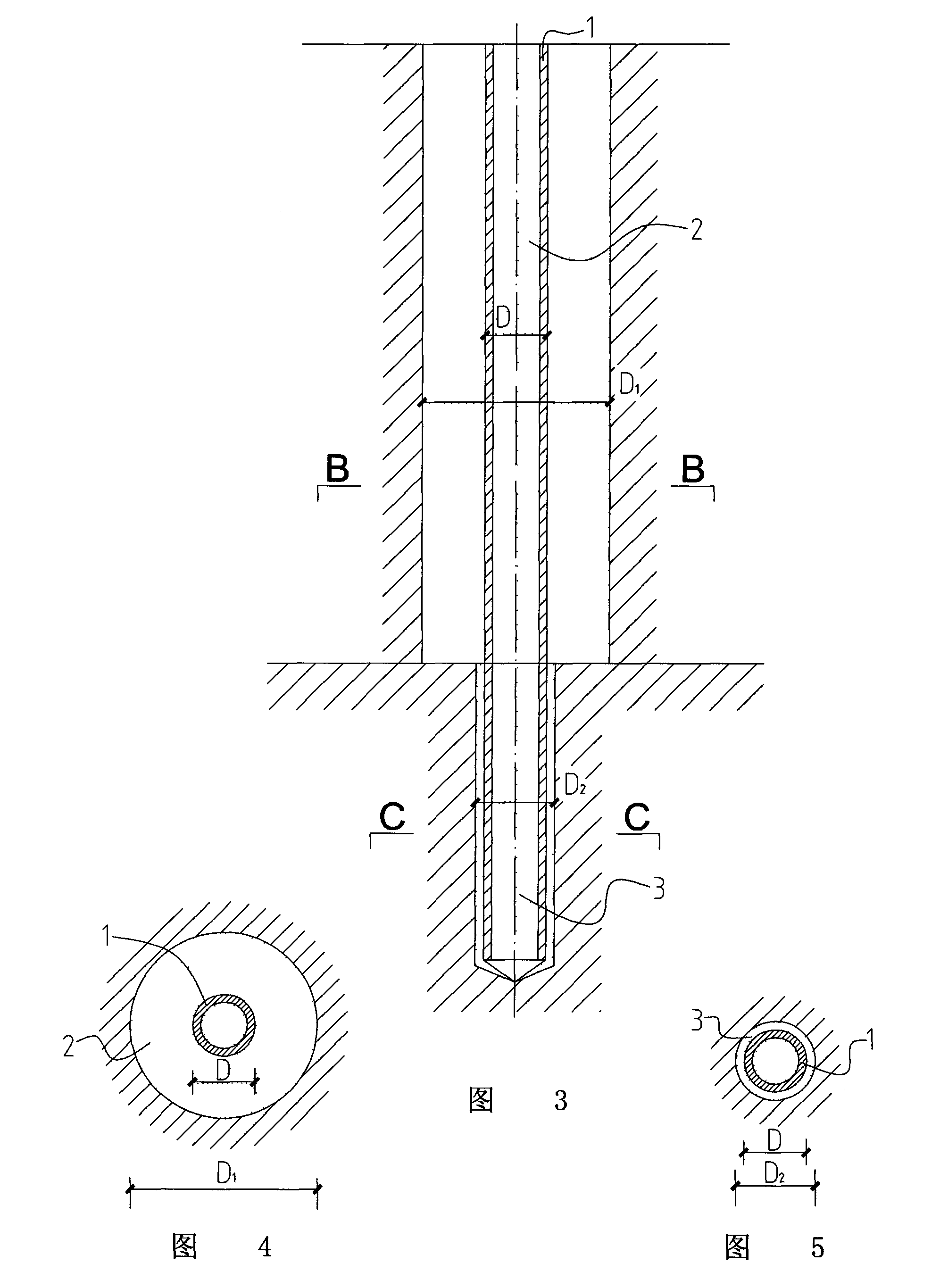

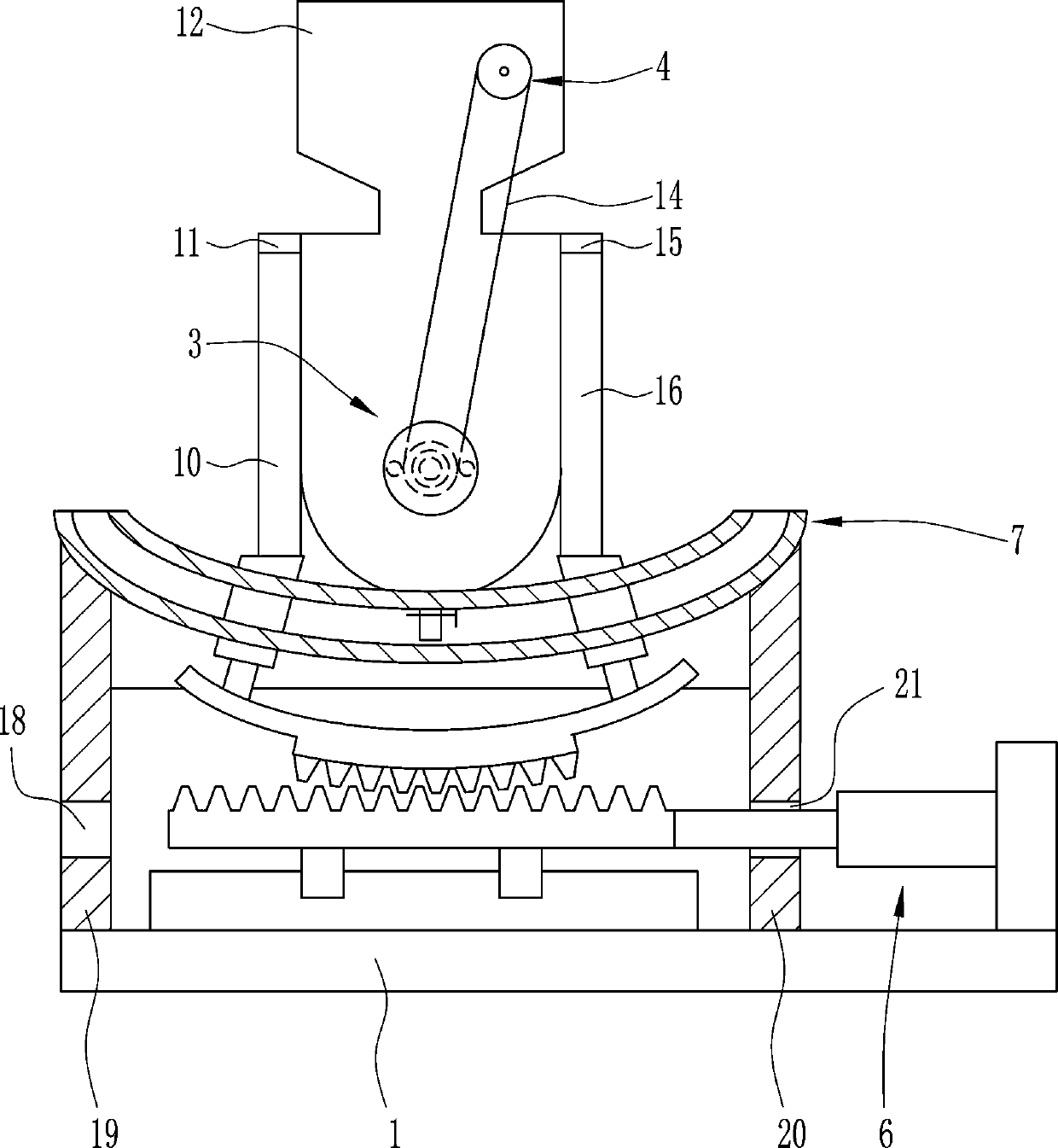

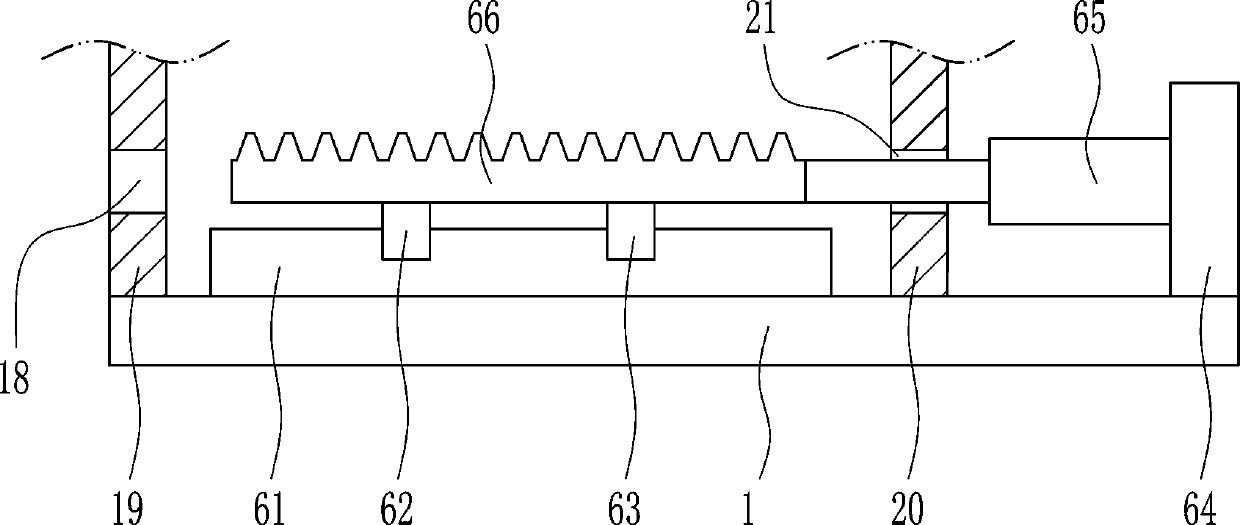

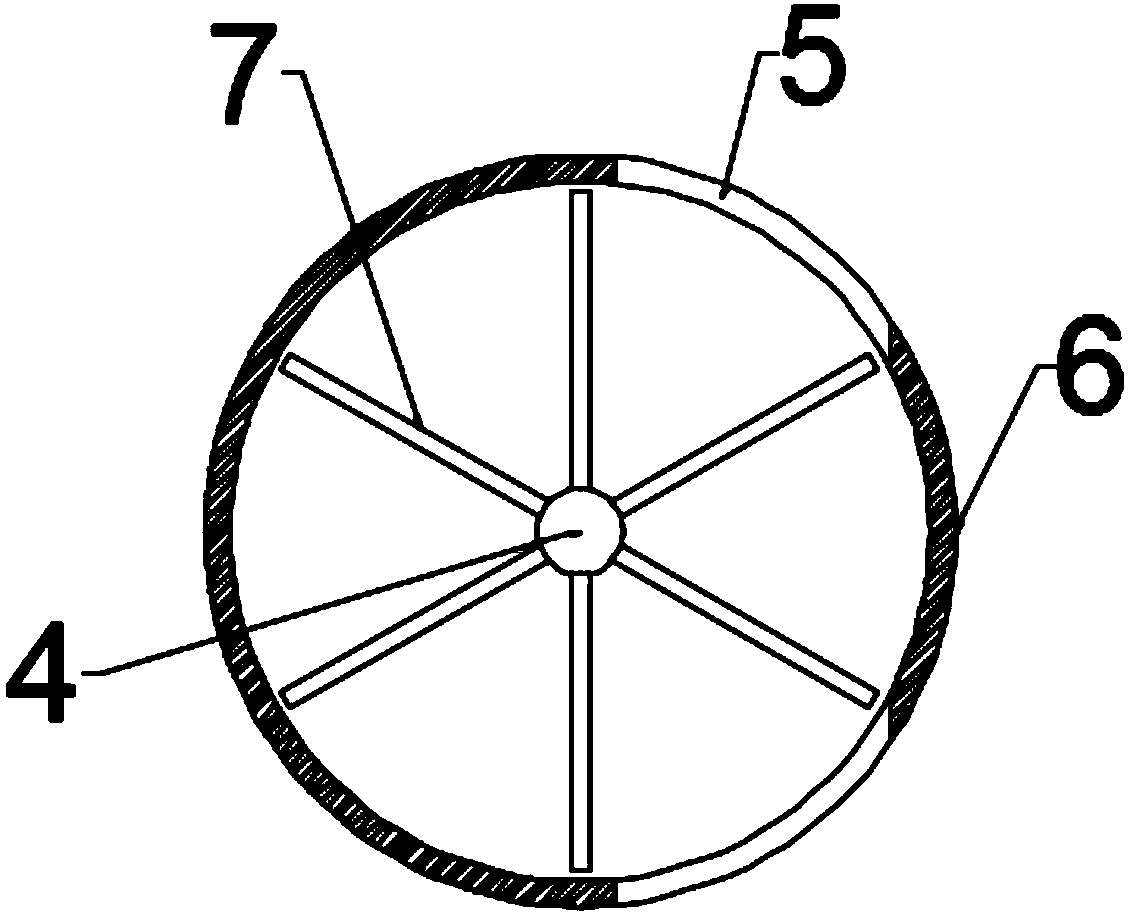

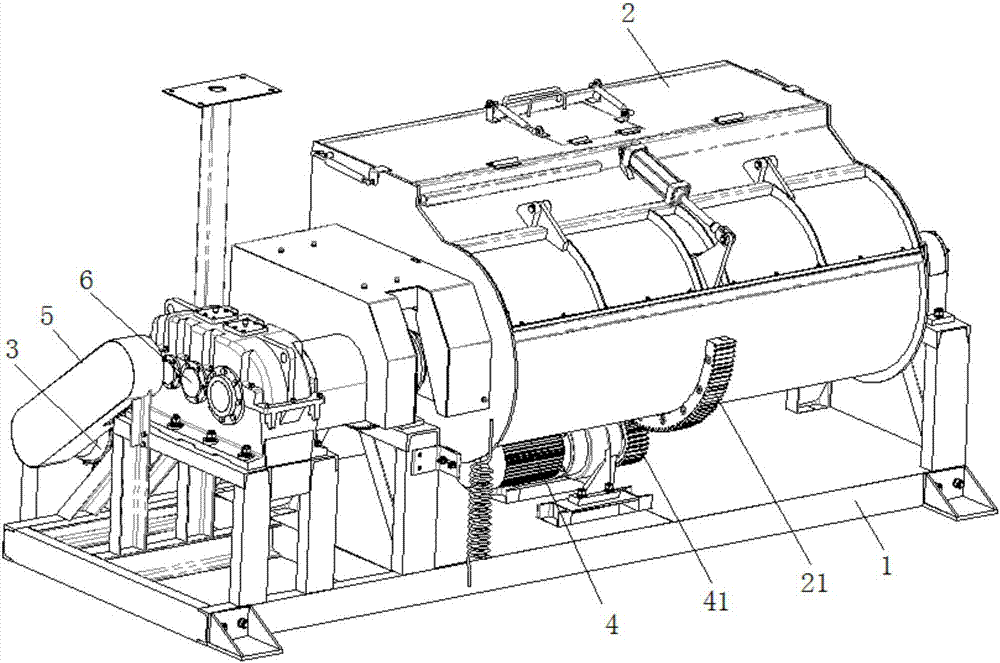

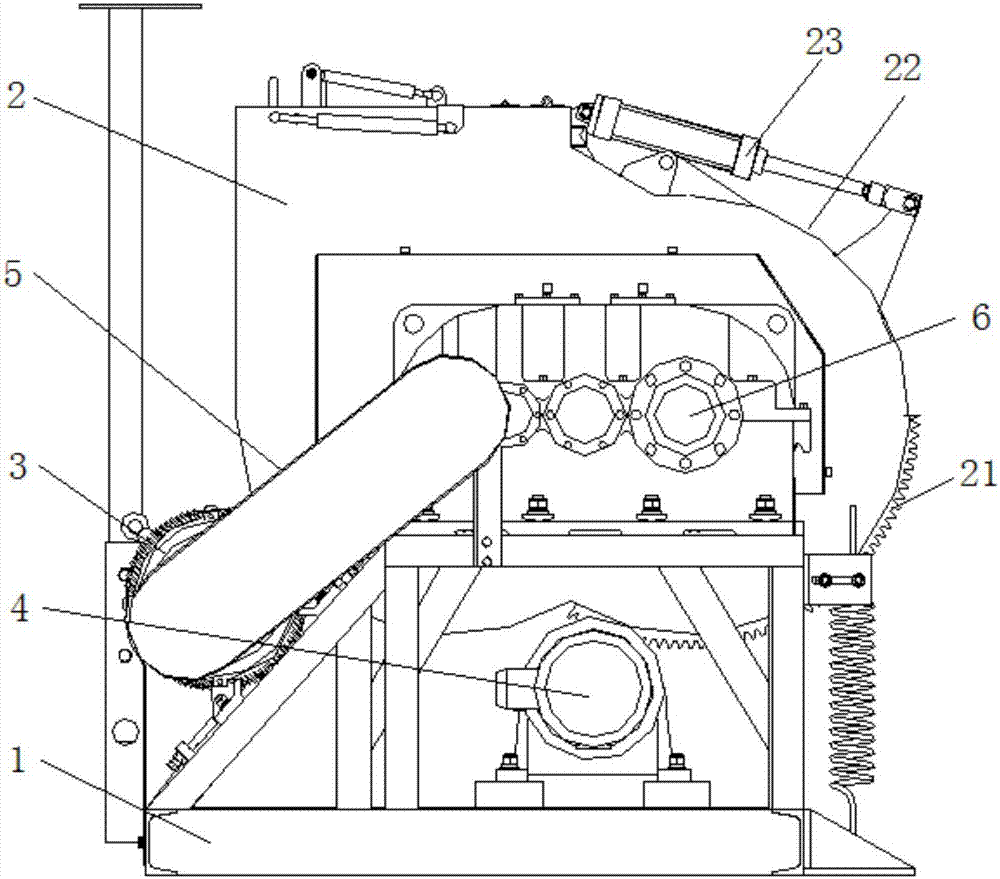

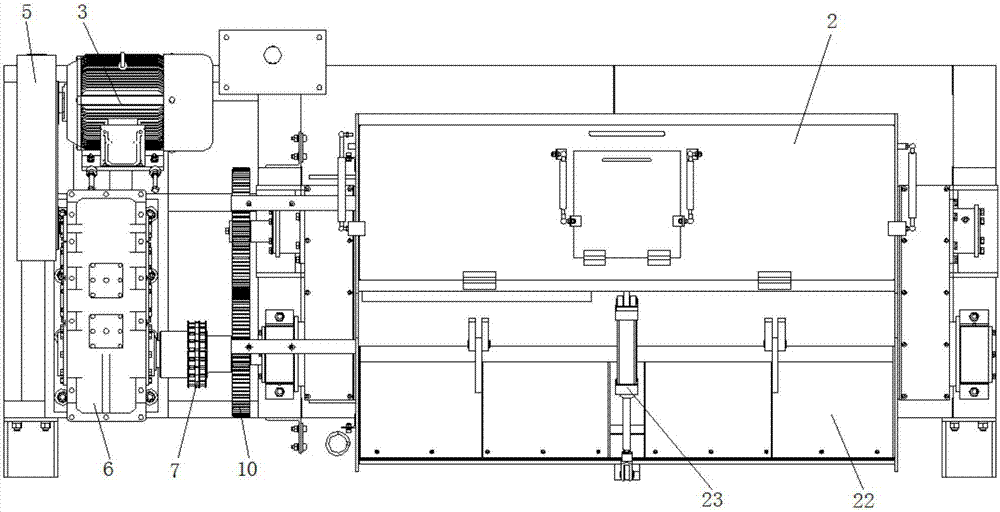

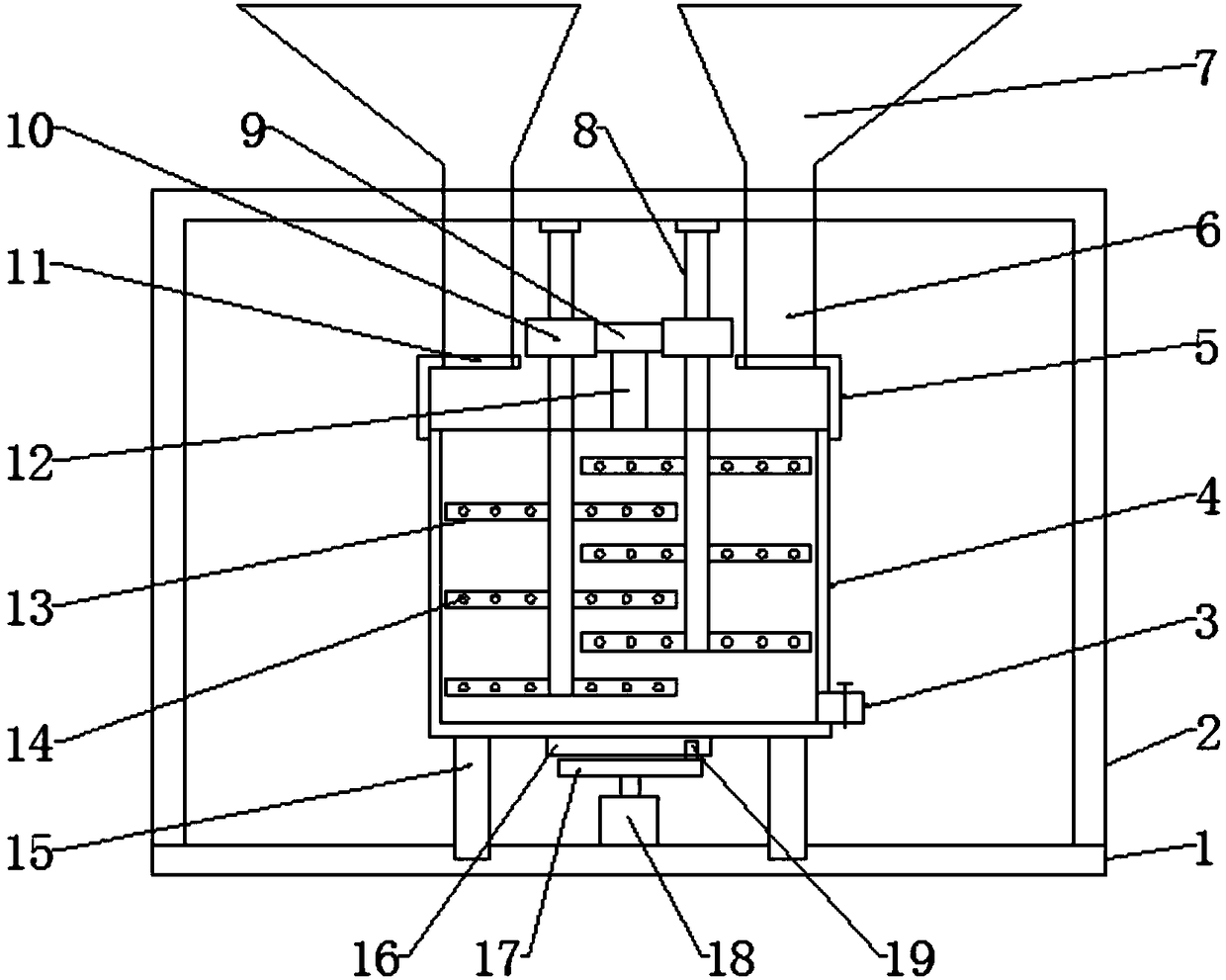

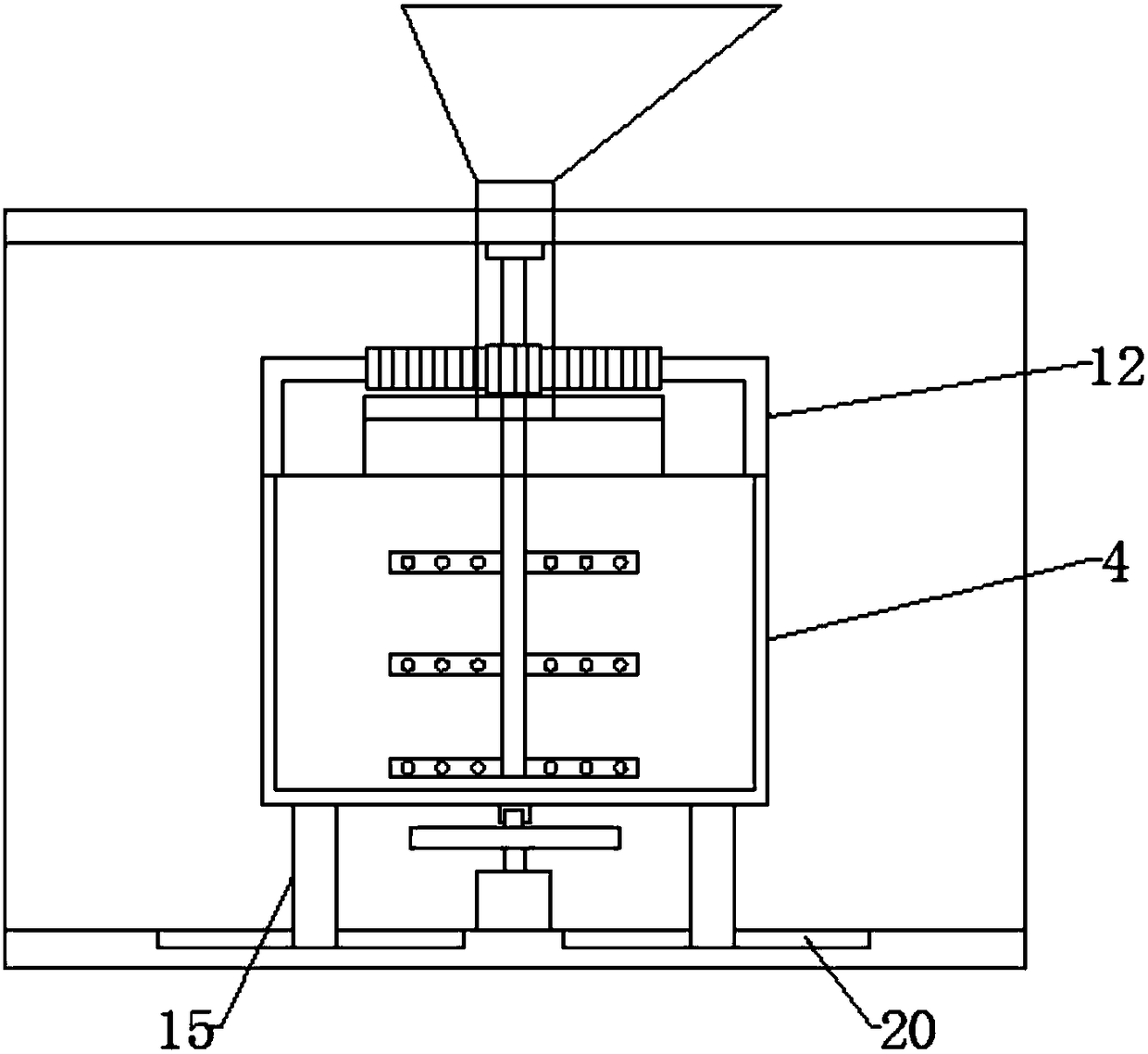

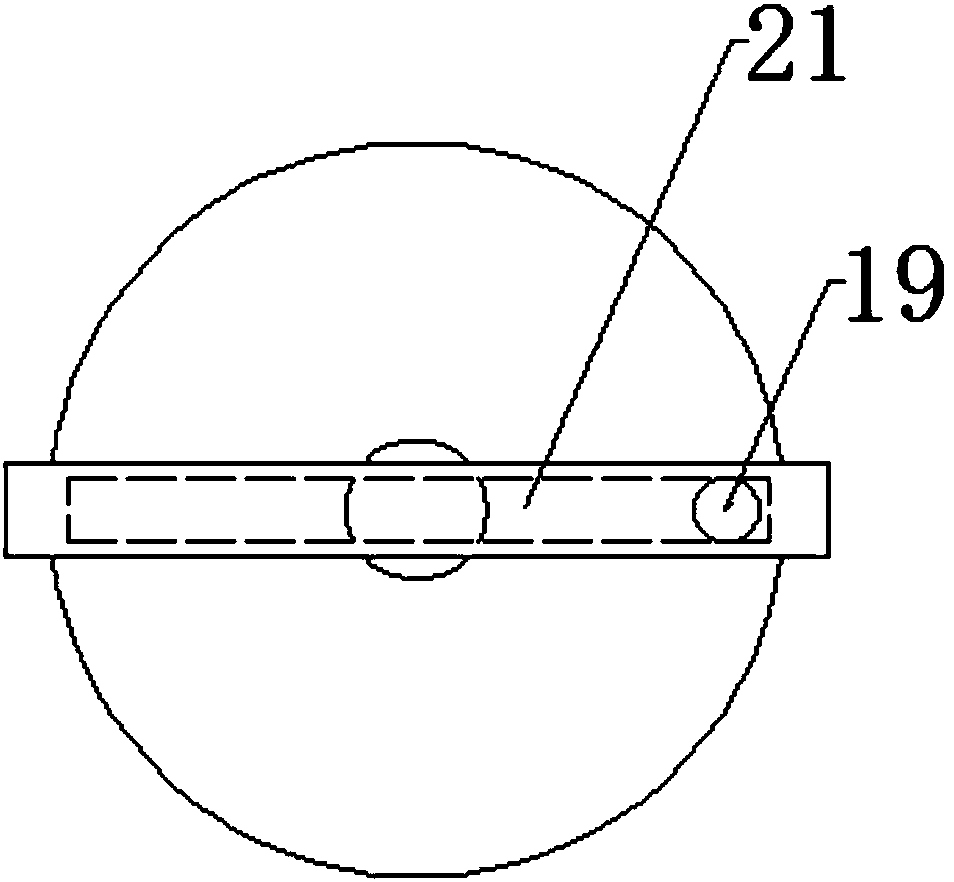

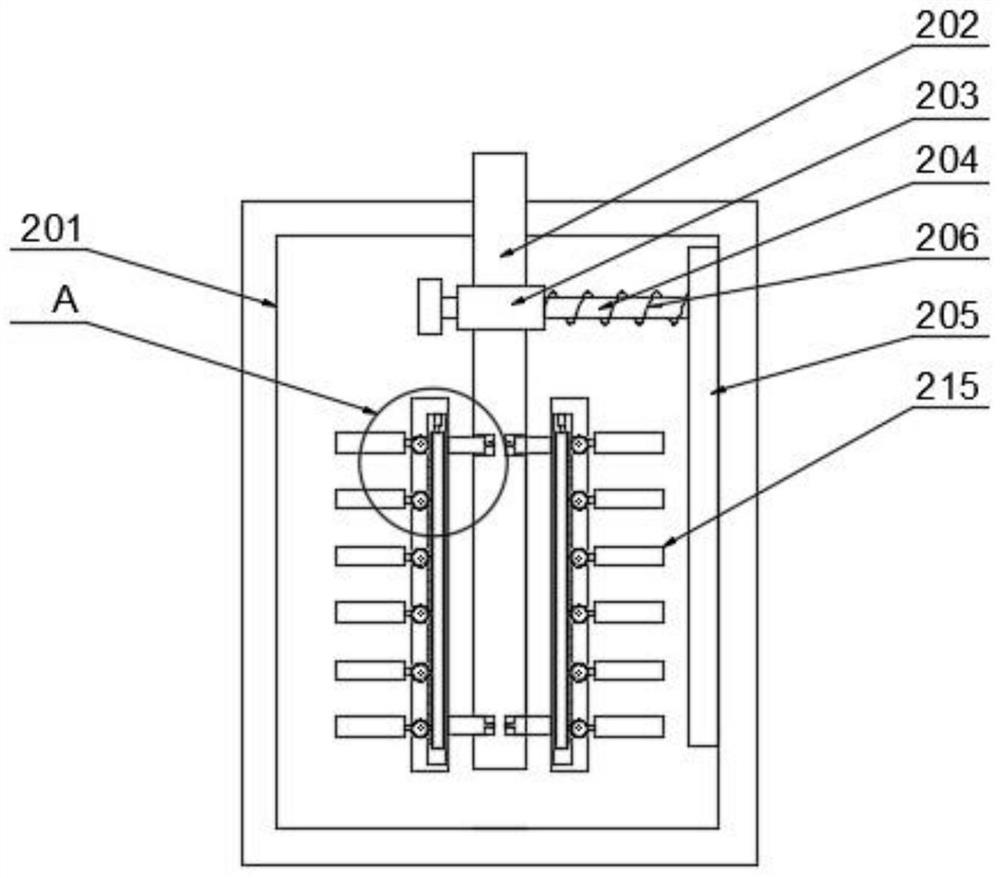

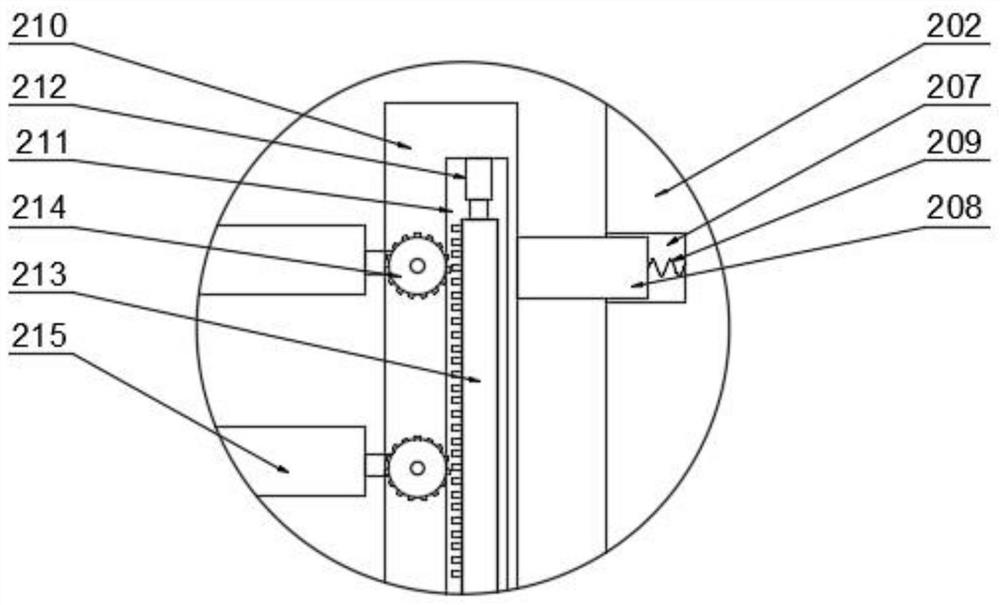

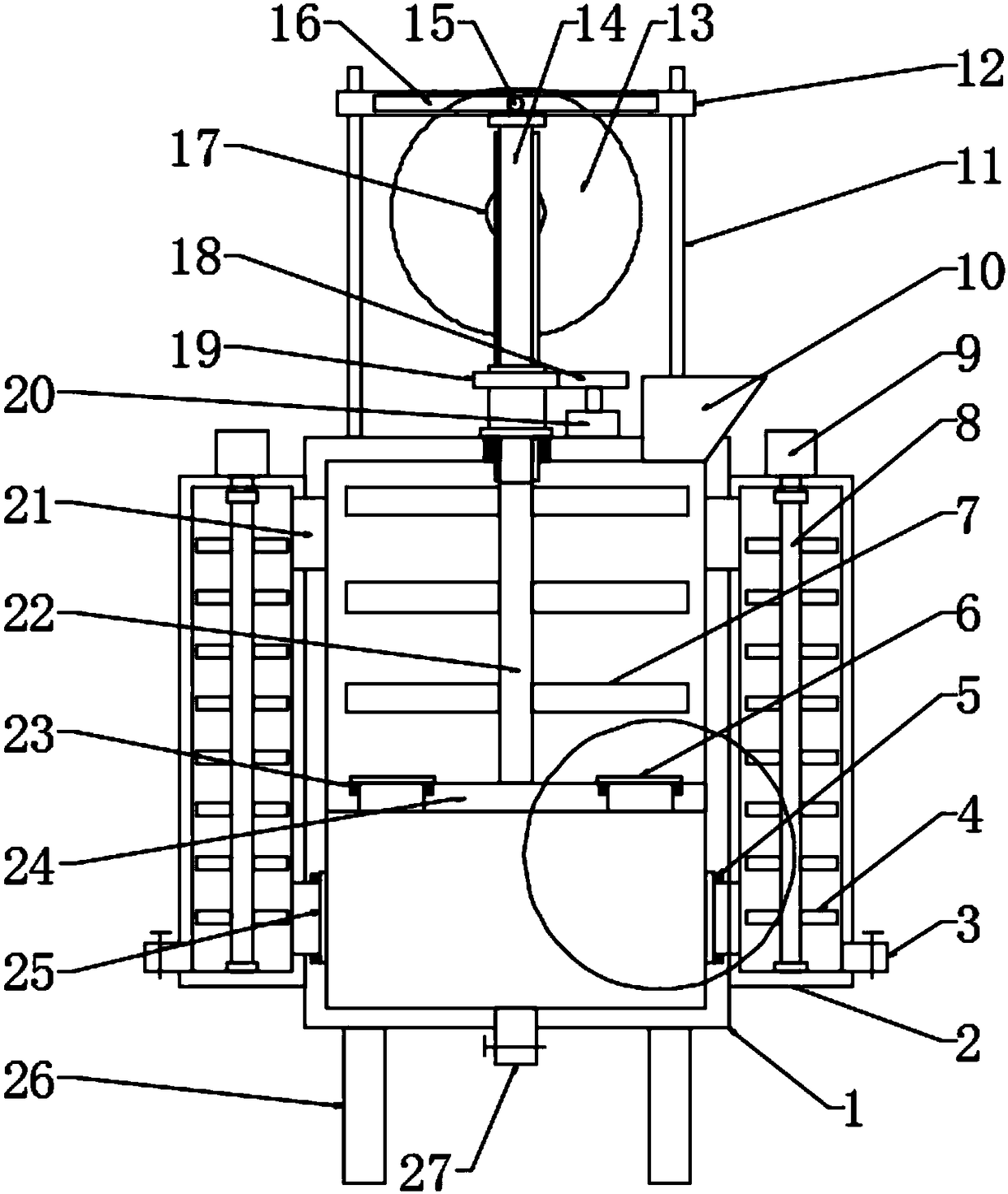

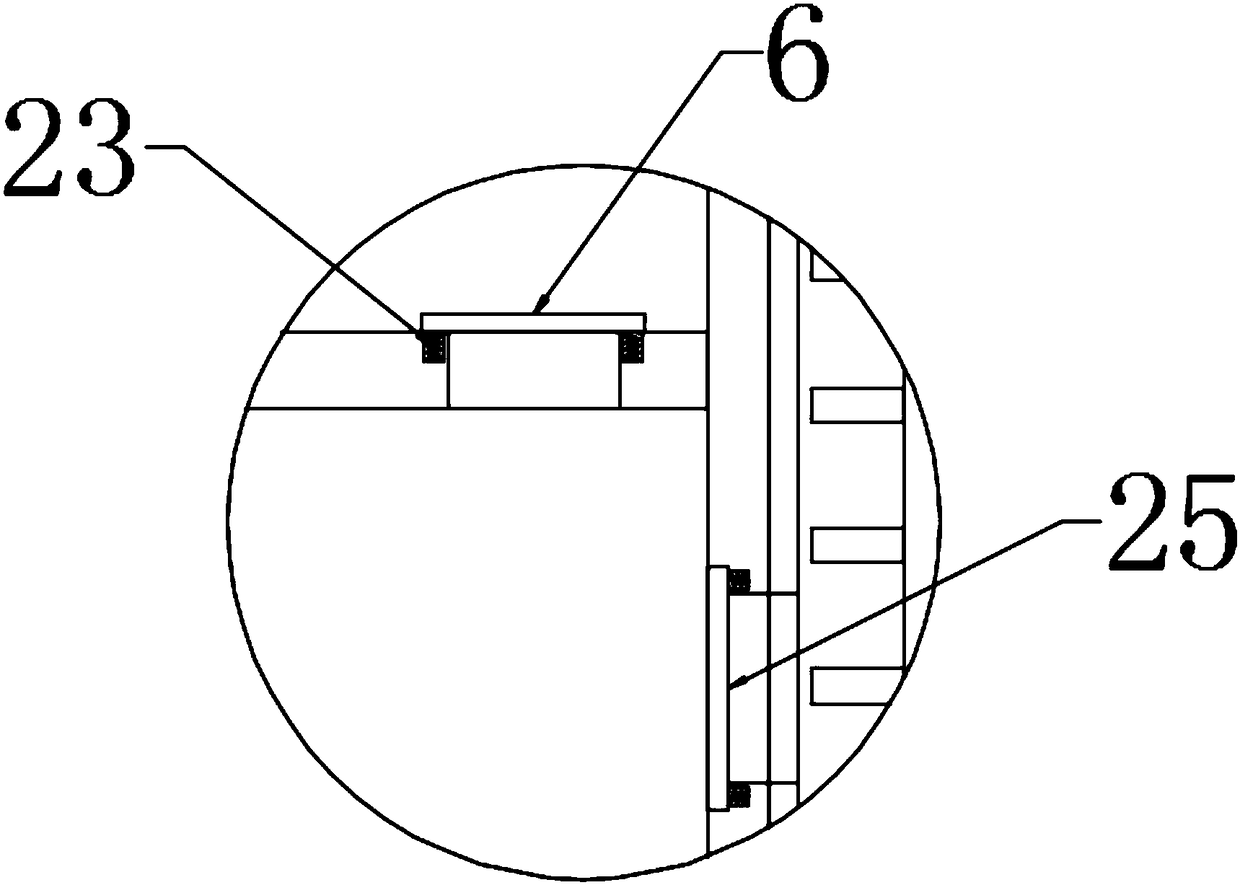

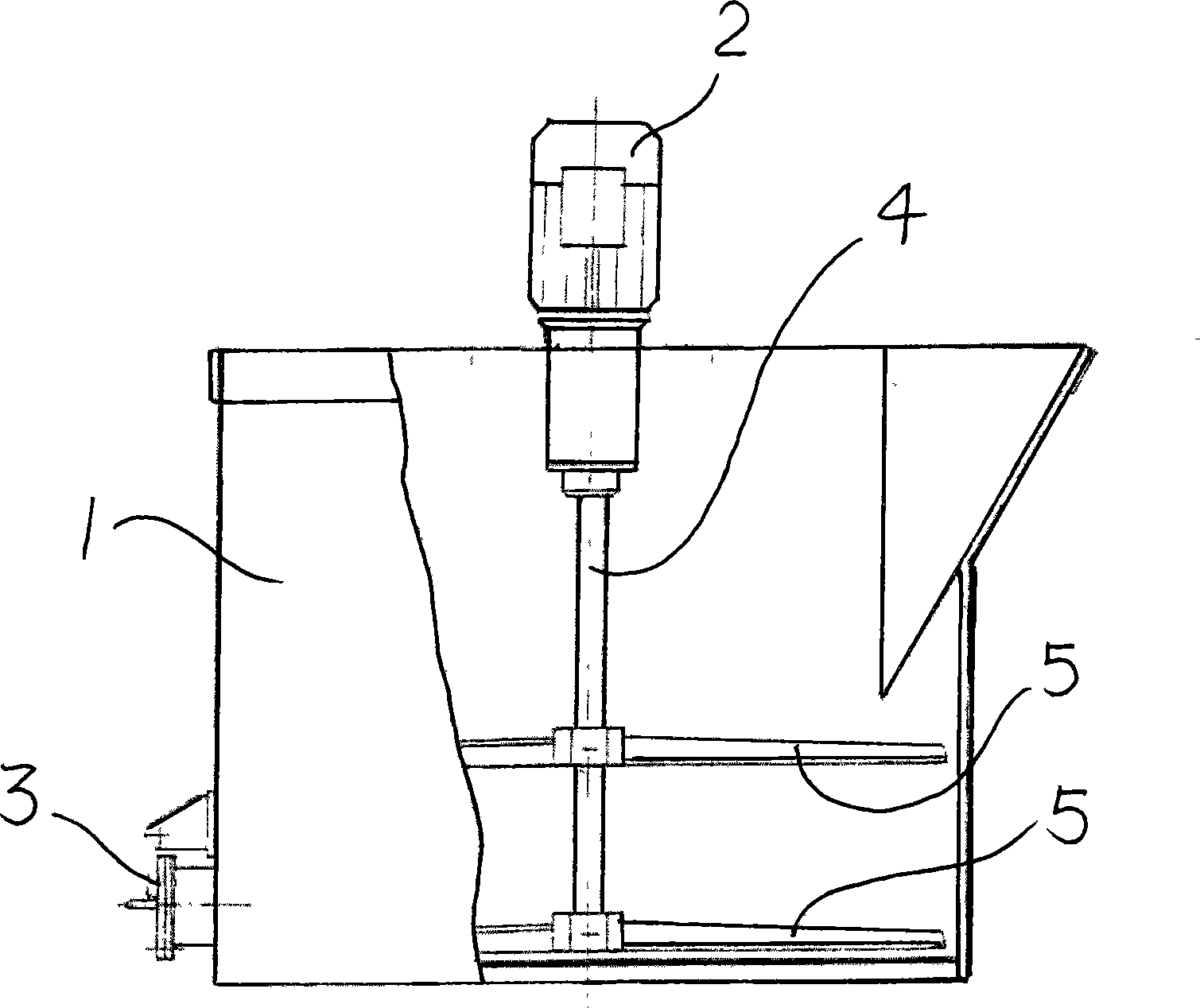

Two-way cement-soil mixer is a kind of construction machinery equipment suitable for soft soil foundation treatment. The mixer consists of body (1), power transmission system (2), outer drill rod (3), inner drill rod (4), drill bit ( 5) Composition, wherein the power transmission system is located on the upper part of the fuselage (1), the inner drill rod (4) is located in the outer drill rod (3), and the inner drill rod (4) and the inner drill rod in the power transmission system (2) The rod power transmission system connection flange (211) is connected, the outer drill rod (3) is connected with the outer drill rod power transmission system connection flange (25), and the drill bit (5) is located at the bottom of the inner drill rod (4). The machine is easy to construct, easy to operate, and easy to master. The two-axis two-way rotation drives two sets of mixing blades to rotate in two directions at the same time, which can ensure the mixing amount of cement slurry in the pile body, and there will be no slurry phenomenon; at the same time, it can ensure that the pile body cement The soil is fully stirred evenly to ensure the quality of the pile and the quality of the pile body; the efficiency is more than doubled.

Owner:南京路鼎搅拌桩特种技术有限公司

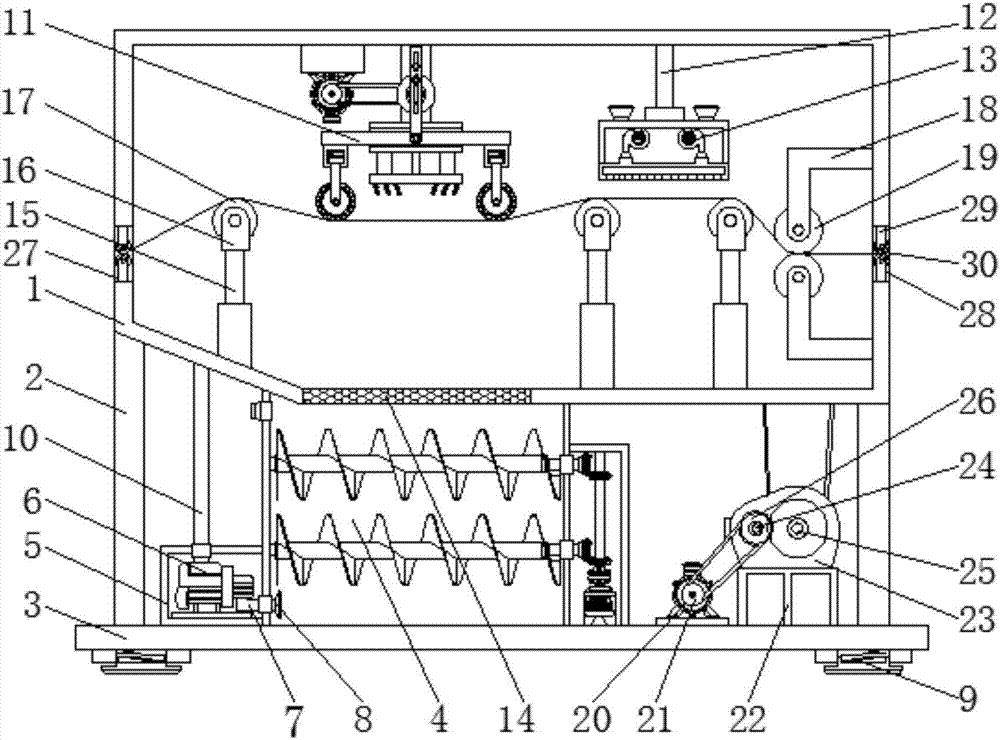

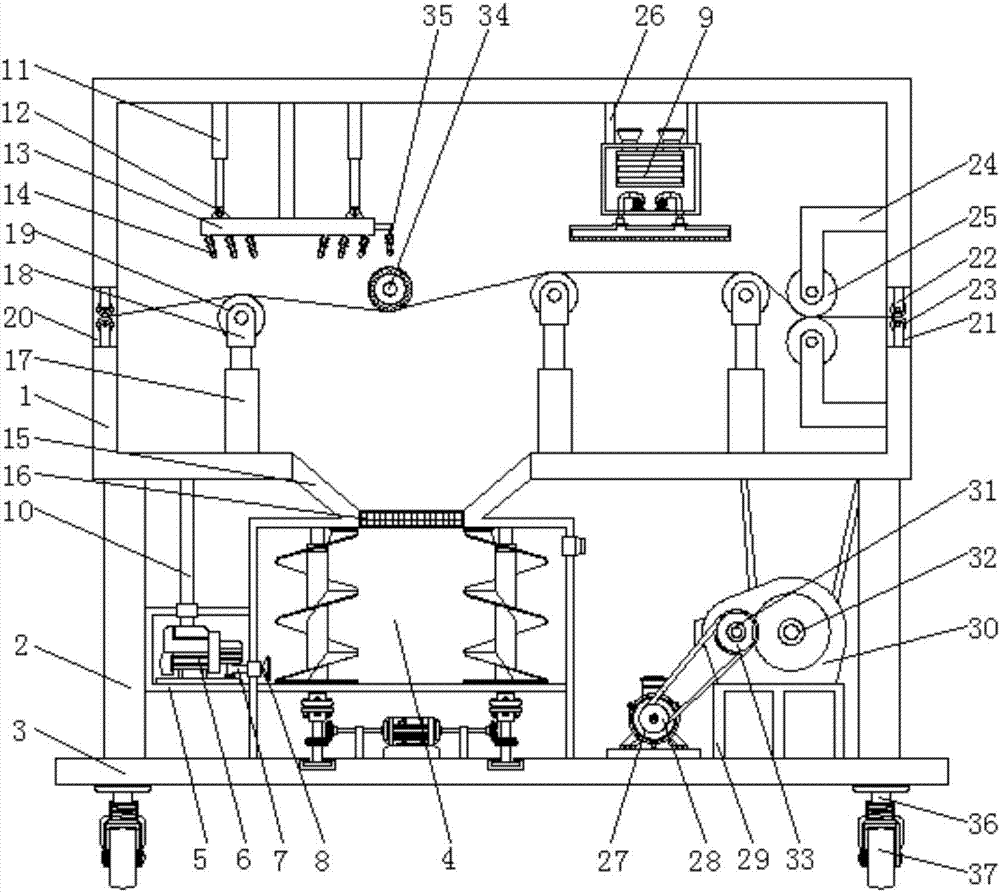

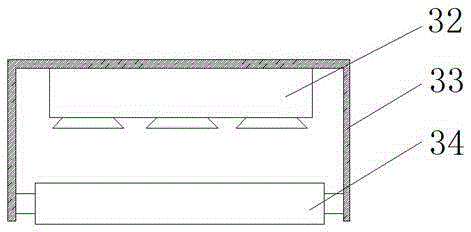

Environment-friendly spray printing and dyeing device for textile fabric

InactiveCN107447389AStir fully and evenlyImprove utilization efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingEngineeringUltimate tensile strength

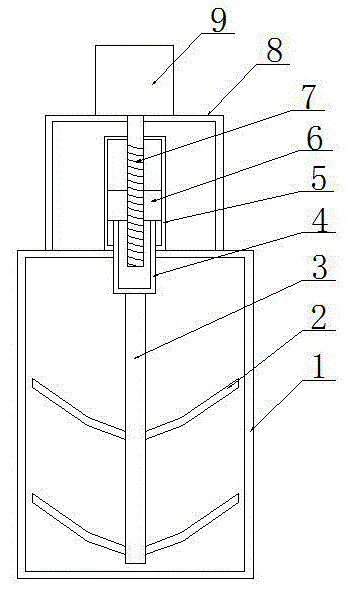

The invention discloses an environment-friendly spray printing and dyeing device for a textile fabric, and relates to the technical field of textile machinery equipment. The environment-friendly spray printing and dyeing device comprises a box, two sides of the bottom of the box are fixedly connected with mutually symmetric supporting vertical plates, the bottoms of the two supporting vertical plates are fixedly connected with bottom supporting plates, two sides of the bottoms of the bottom supporting plates are fixedly connected with mutually symmetric damping anti-slip mats, the centers of the tops of the bottom supporting plates are fixedly connected with dye stirring devices, through holes are formed in the bottom of the inner wall of the box and positioned above the dye stirring devices, and an impurity filter screen is arranged on the inner walls of the through holes. The environment-friendly spray printing and dyeing device for the textile fabric solves the problems of high dyeing cost, environmental pollution, low use ratio and poor fabric dyeing effect of existing textile fabric dyeing equipment. The use efficiency of dyes is effectively improved, the device is safe and environmentally friendly, environmental pollution is reduced, manual operation of workers is omitted, the labor intensity of staff is reduced, and production efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

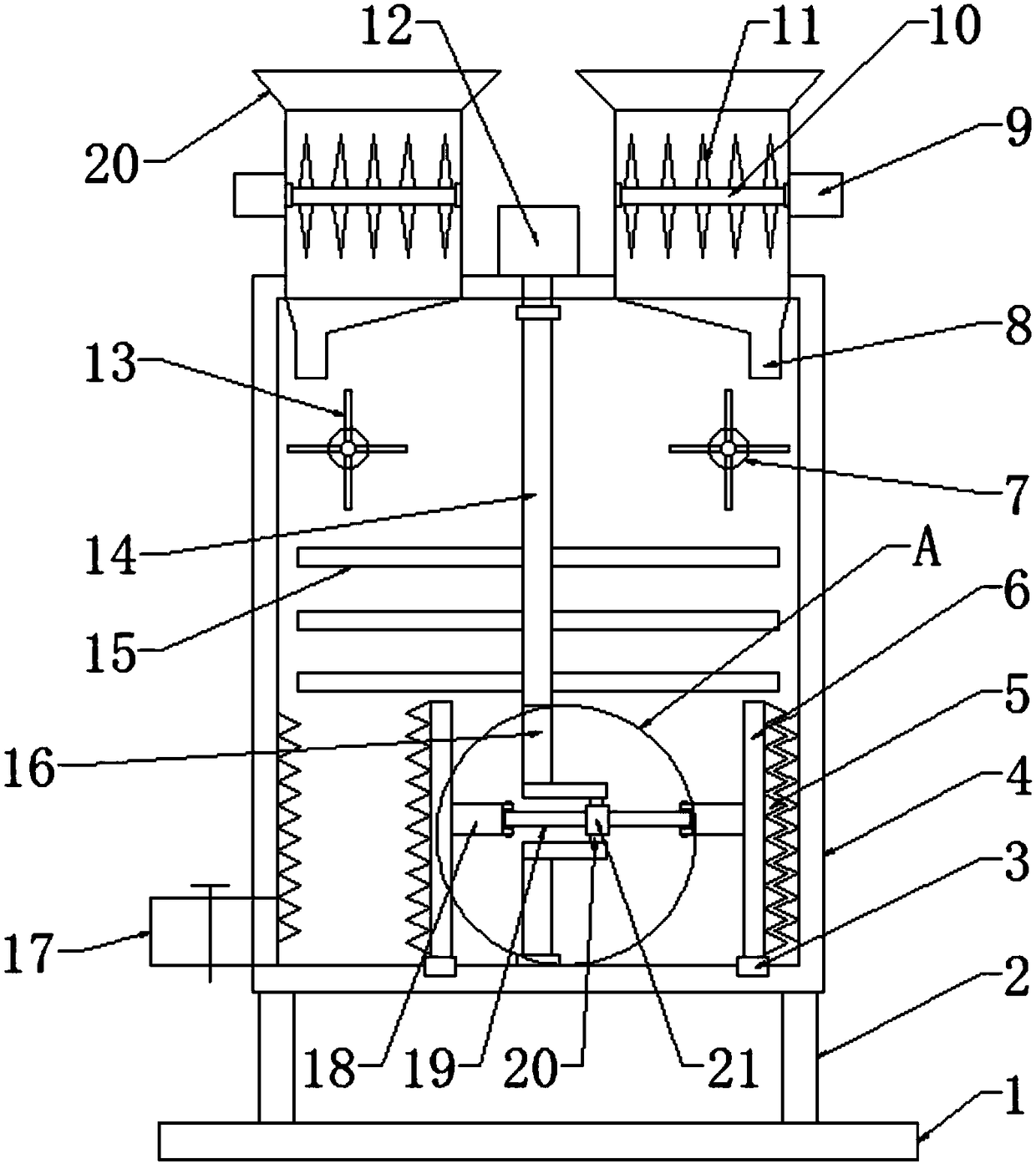

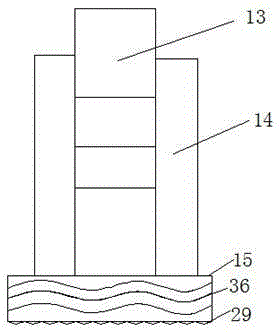

Spraying, dyeing and drying device for textile fabric

InactiveCN107574602AStir fully and evenlyStir wellTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringUltimate tensile strength

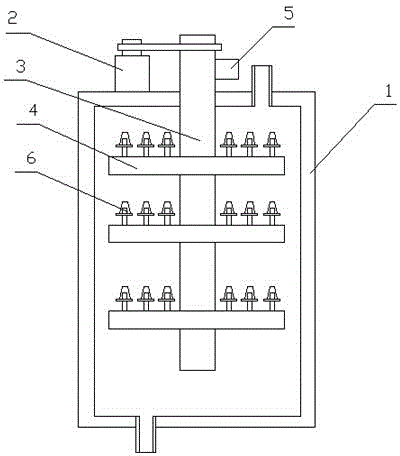

The invention discloses a spraying, dyeing and drying device for textile fabric. The device comprises a tank body, supporting vertical plates which are mutually symmetric are fixedly connected to twosides of the bottom of the tank body, and a bottom supporting plate is fixedly connected to the bottoms of the two supporting vertical plates; a dye stirring device is fixedly connected to the left side of the top of the bottom supporting plate, a liquid pumping pump placement tank is fixedly connected between the surface of the left side of the dye stirring device and the surfaces of the right sides of the supporting vertical plates, and a liquid pumping pump is fixedly connected to the bottom of the inner wall of the liquid pumping pump placement tank; a liquid pumping pipe is communicated with the right side of the liquid pumping pump. The invention relates to the technical field of textile machinery equipment. According to the spraying, dyeing and drying device for the textile fabric,the problems of high dyeing cost, environmental pollution, low use ratio and low cloth dyeing effect of an existing drying device for the textile fabric are solved, the use efficiency of dye is effectively improved, the device is safe and environmentally friendly, the pollution to the environment is lowered, manual operation is not needed, the labor intensity is lowered, and the economic efficiency is improved.

Owner:HUZHOU BOREN TEXTILES

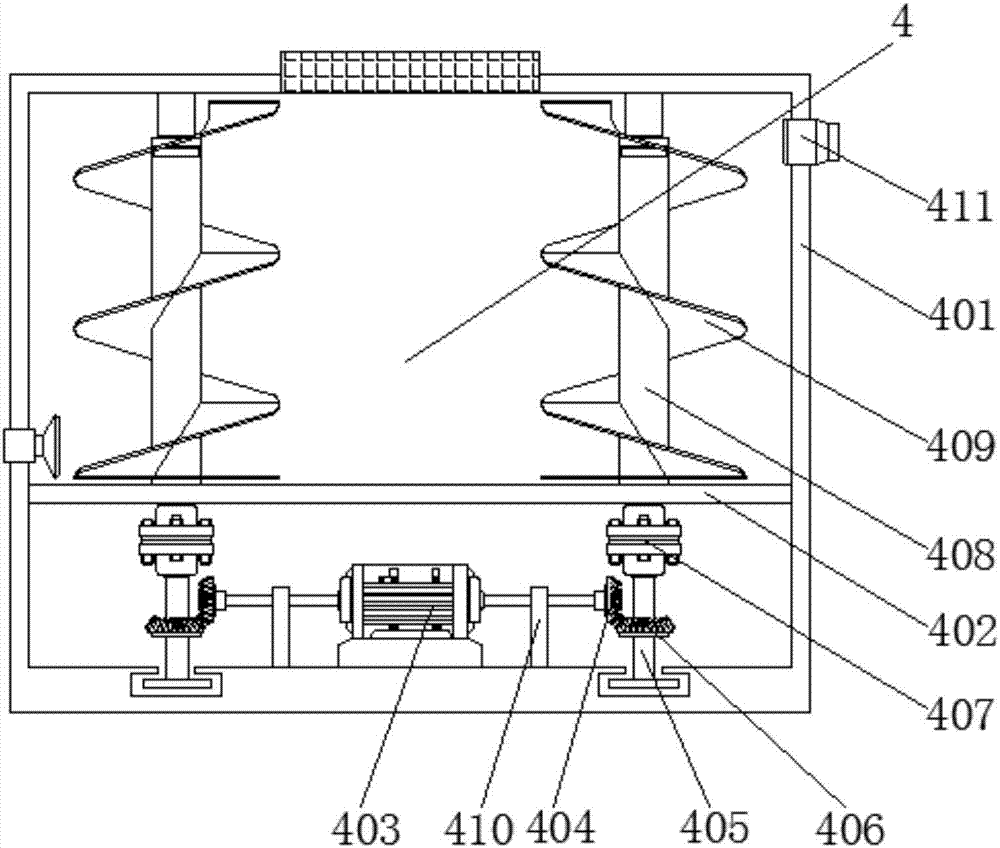

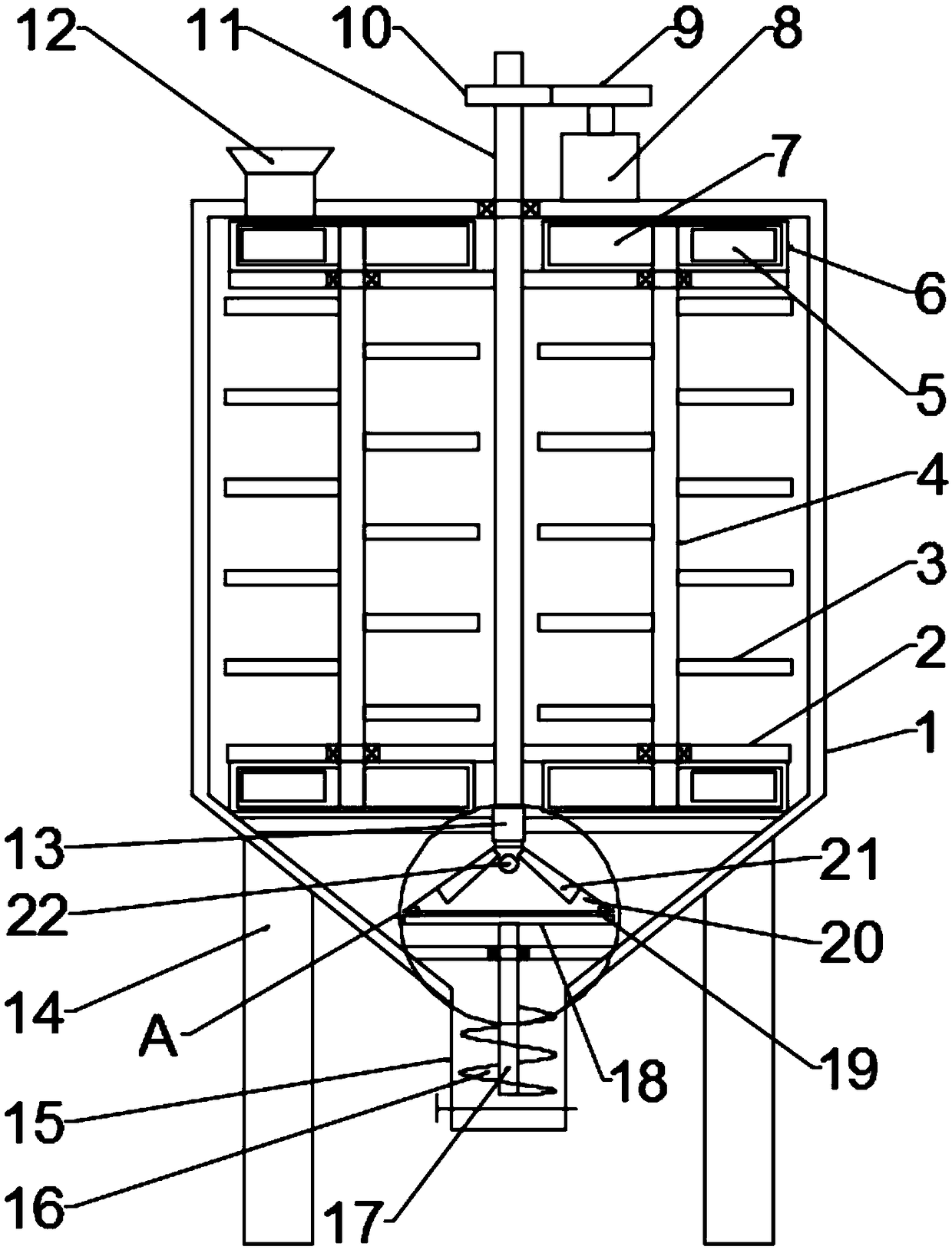

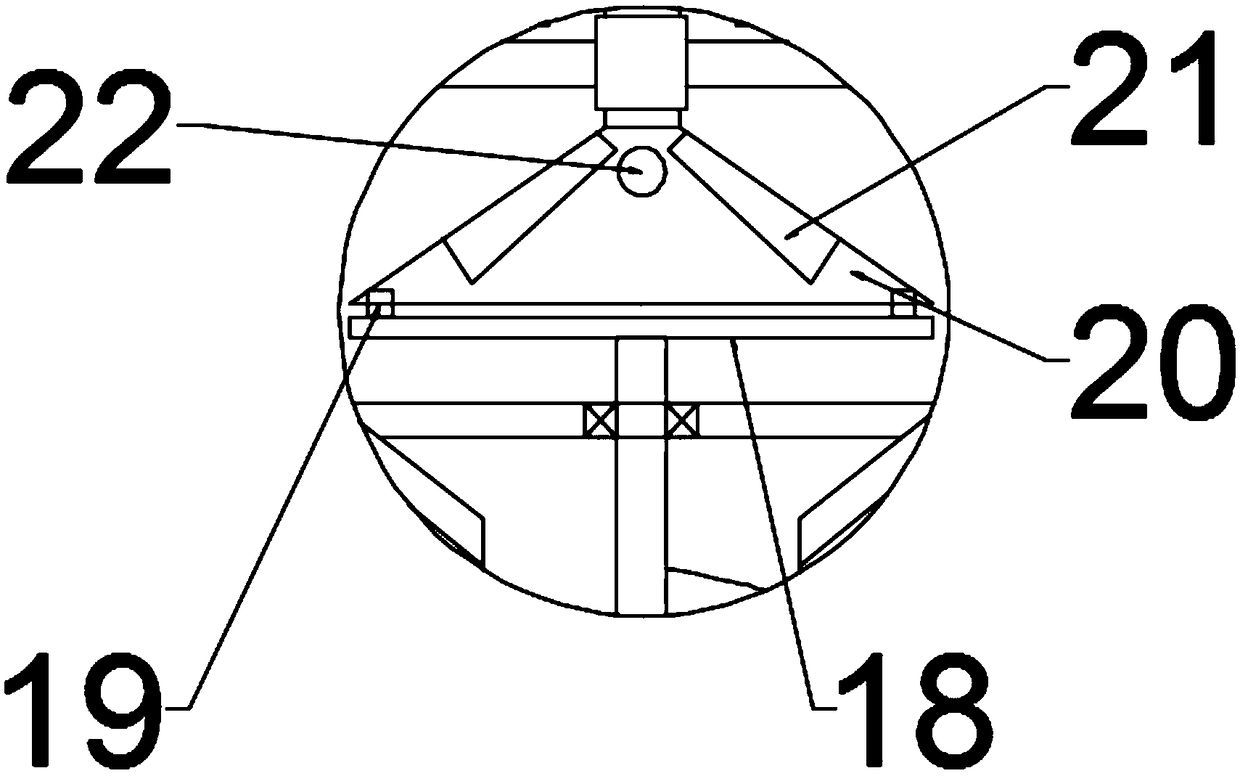

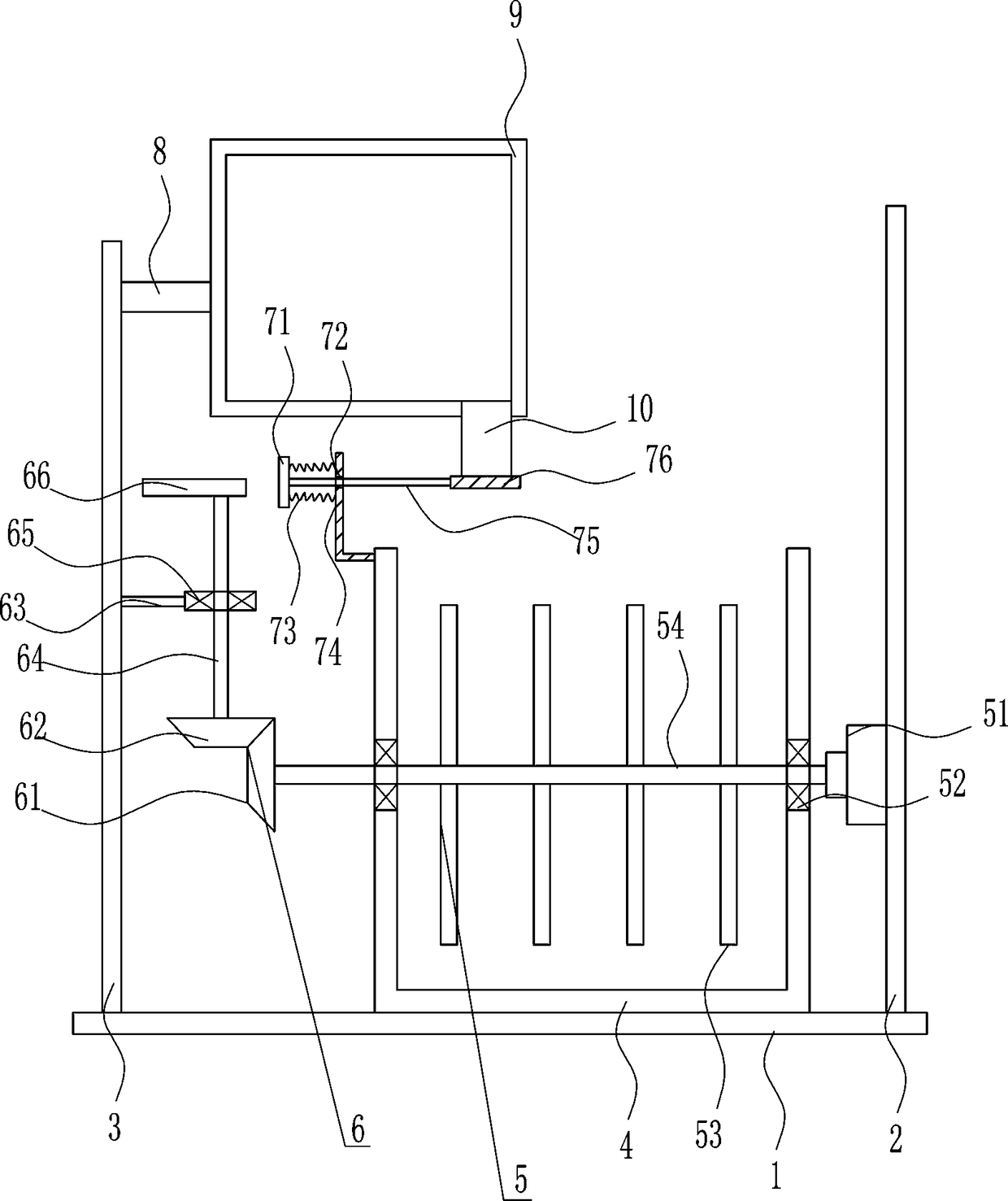

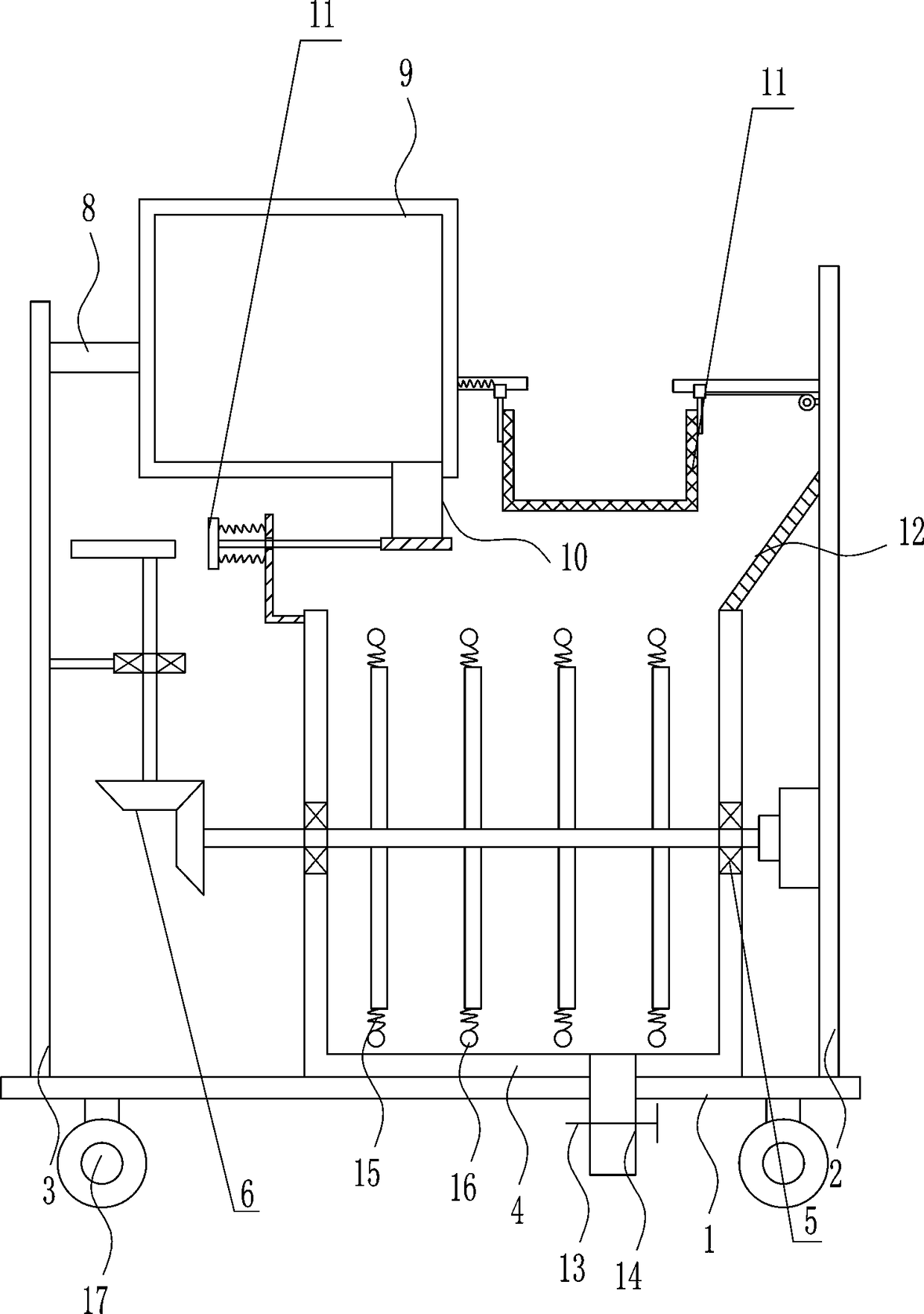

High-efficiency type concrete stirring machine for building construction

InactiveCN107297825AStir fully and evenlySave energyCement mixing apparatusArchitectural engineeringBuilding construction

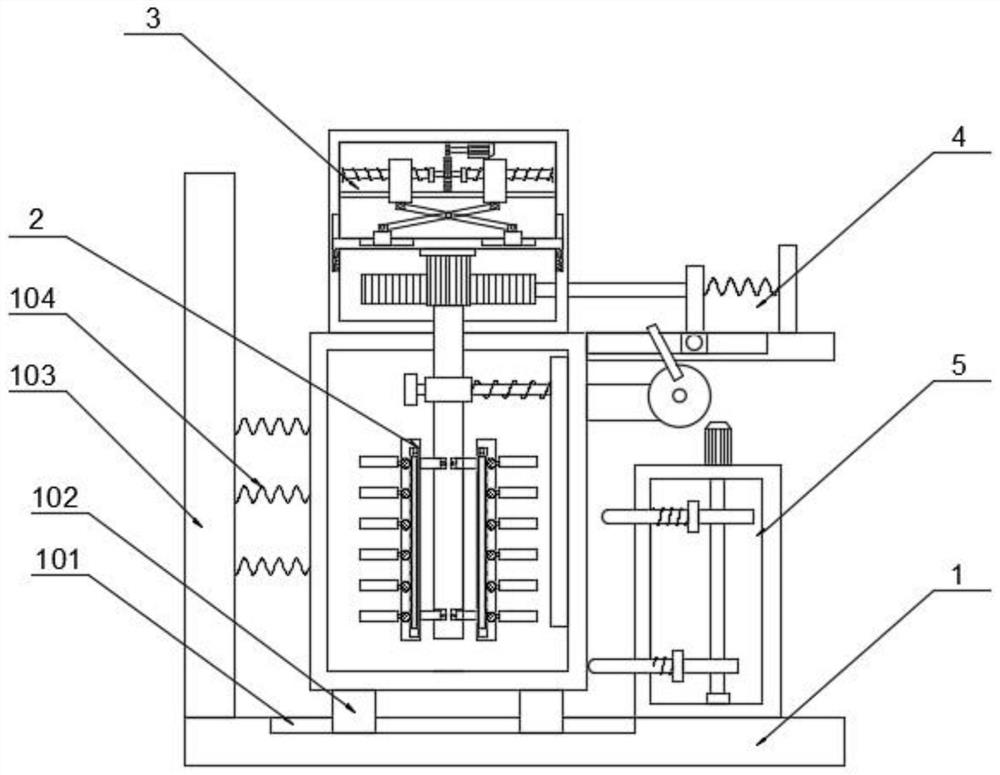

The invention relates to a stirring machine, in particular to a high-efficiency type concrete stirring machine for building construction, which aims at solving the technical problem of difficultly providing a high-efficiency type concrete stirring machine for building construction with the advantage of uniform and sufficient stirring. To solve the technical problem, the high-efficiency type concrete stirring machine for building construction comprises a top plate, a side plate, a driving mechanism, a stirring mechanism, a linkage mechanism, a left and right swinging mechanism, a top and down swinging mechanism, a bottom plate, a third slide block, a third slide rail, a ninth support rod, a material discharging pipe, a valve, a stirring frame, a material feeding hopper, a first flat belt, a second flat belt and a third flat belt, wherein the side plate is fixedly connected with the bottom plate in a vertical direction; the top plate is fixedly connected with the top part of the side plate; the third slide rail is fixedly connected with the bottom plate. The high-efficiency type concrete stirring machine has the advantages that concrete can be sufficiently and uniformly stirred, and the effect of accelerating stirring speed is achieved.

Owner:徐士忠

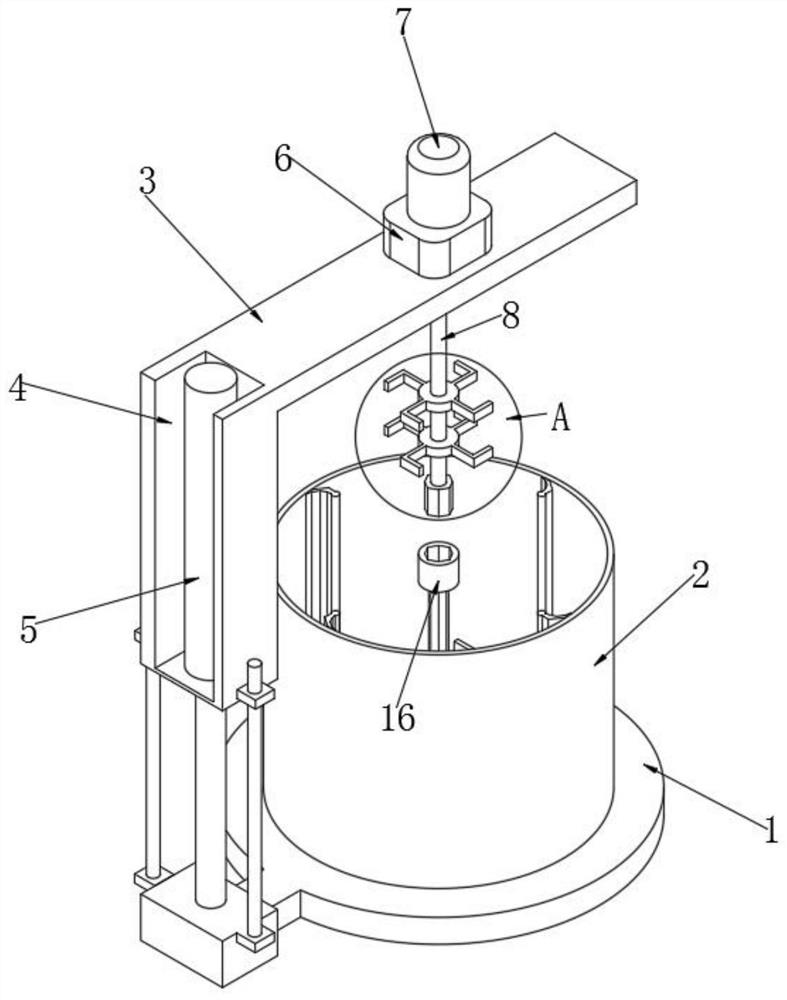

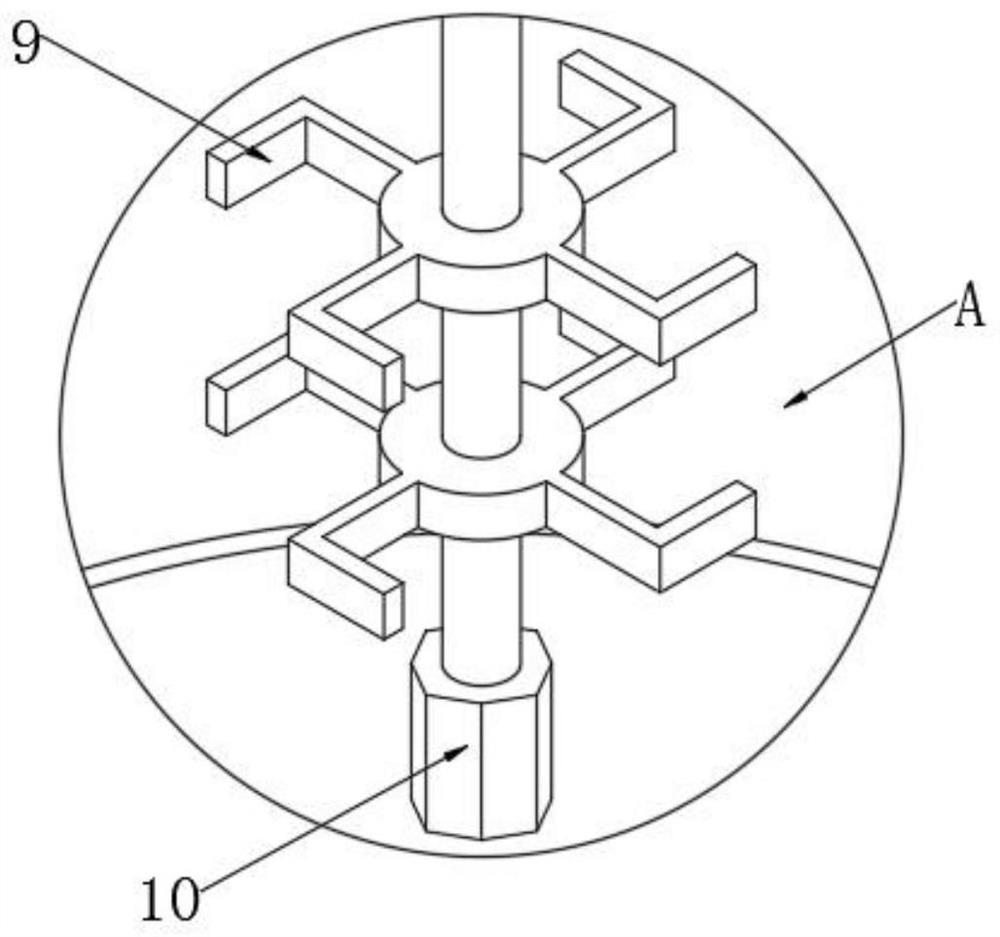

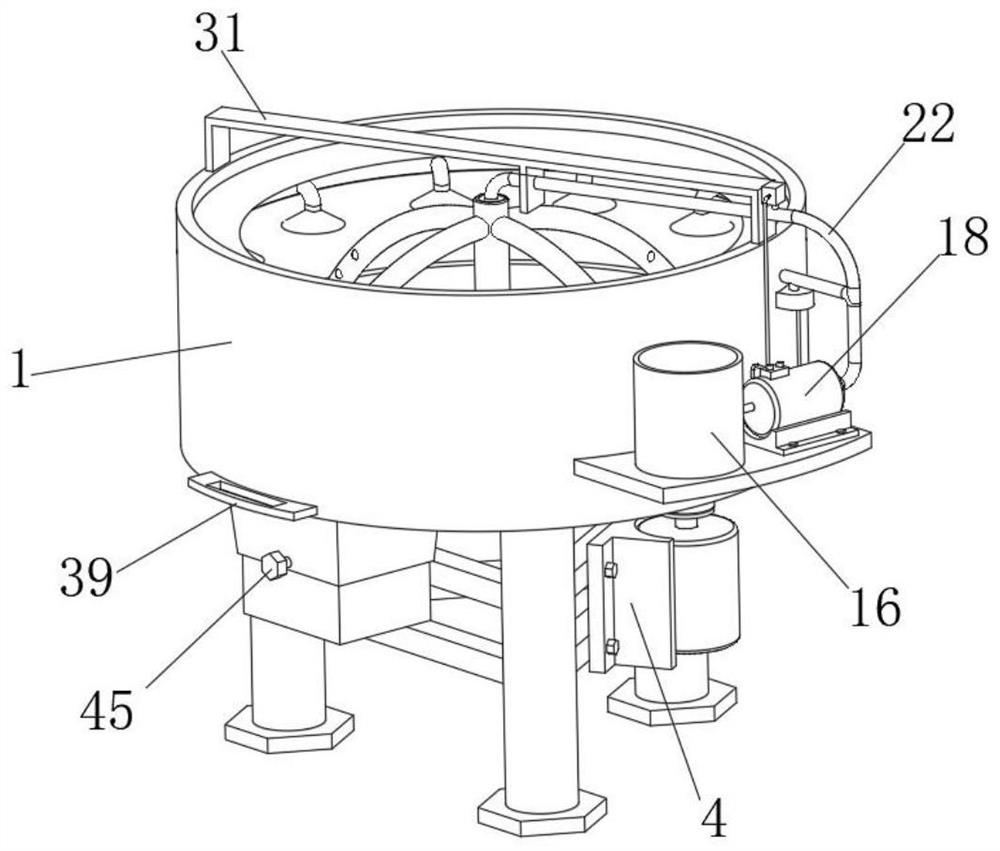

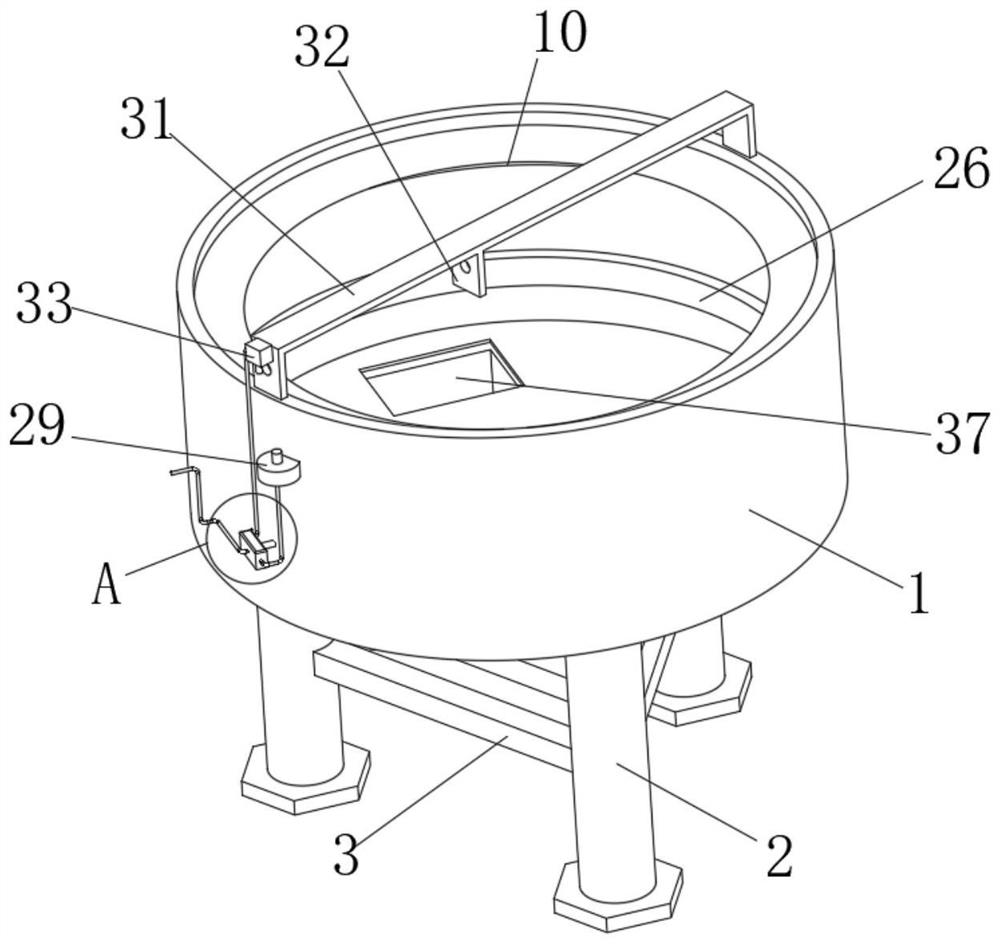

Device for quickly preparing fertilizer water for forestry

InactiveCN110585941AExpand the mixing rangeImprove stirring efficiencyTransportation and packagingRotary stirring mixersReciprocating motionFertilizer

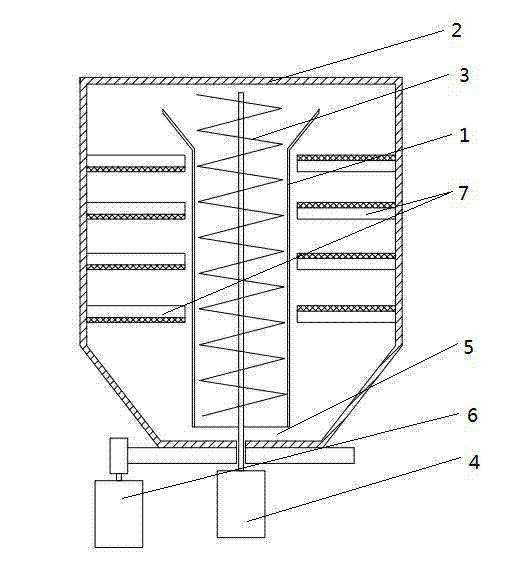

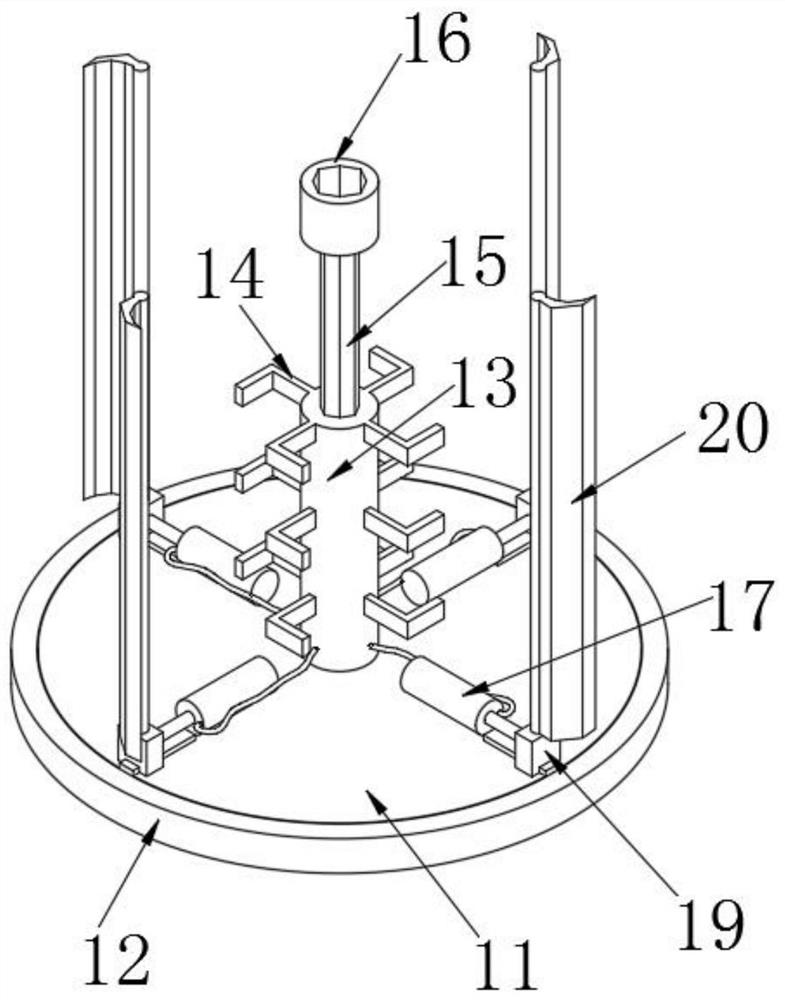

The invention discloses a device for quickly preparing fertilizer water for forestry. The device for quickly preparing the fertilizer water for the forestry comprises a preparation barrel and a stirring mechanism, wherein the stirring mechanism comprises a rotating shaft, a mounting shell, a guiding plate, a stirring shaft, a stirring rod and a driving unit, wherein the stirring rod is mounted onthe stirring shaft; the driving unit is used for driving the rotating shaft to rotate forwards and backwards; and the driving unit comprises a second gear mounted at the top end of the rotating shaft,a second rack engaged with the second gear and a power mechanism for driving the second rack to move left and right in a reciprocating manner. The device is provided with the stirring mechanism, thedriving unit drives the rotating shaft to rotate forwards and backwards, the rotating shaft drives the stirring shaft to rotate forwards and backwards around the rotating shaft through the mounting shell, when the stirring shaft rotates forwards and backwards around the rotating shaft, under the effect of the guiding plate, the stirring shaft and a first sliding block can move in a reciprocating manner along a first chute formed in the mounting shell, when the stirring shaft moves in a reciprocating manner, the first gear and the first rack are engaged with each other to drive the stirring shaft to rotate forwards and backwards, the stirring shaft drives the stirring rod to rotate forwards and backwards, a stirring range is expanded greatly, the stirring efficiency is improved, and full and uniform stirring is implemented.

Owner:孙海馥

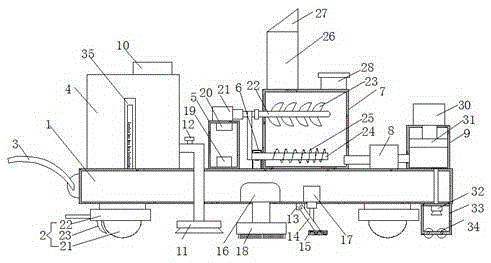

Multistage crushing stirring device used for forage production

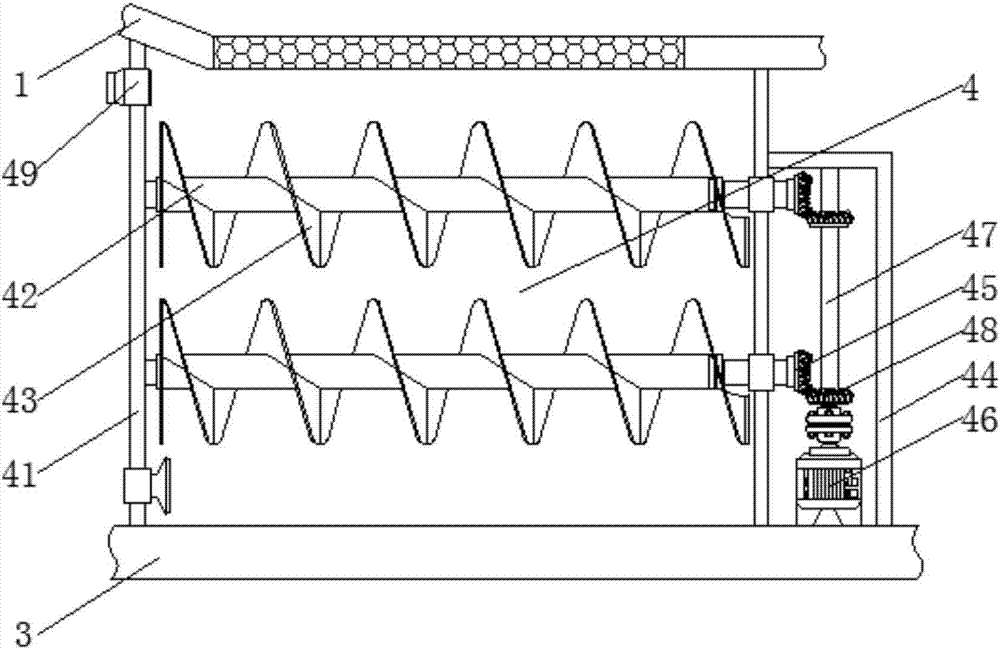

InactiveCN108126571AStir fully and evenlyImprove mixing efficiencyFlow mixersFeeding-stuffAnimal ForagingAgricultural engineering

The invention discloses a multistage crushing stirring device used for forage production. The multistage crushing stirring device used for forage production comprises a bottom plate, a pre-crushing device, a material throwing device, a third motor, a second rotating shaft, a stirring rod, a crankshaft, a pitman shaft neck, a sleeve, a first connecting rod, a second connecting rod, and a crushing plate; the pre-crushing device comprises a feed hopper, a first motor, a first rotating shaft, and a crushing blade; the material throwing device comprises a second motor, an installation shaft, and afan plate. The multistage crushing stirring device is provided with the pre-crushing device, so that pre-crushing of forage raw materials is realized, and it is convenient for subsequent processing; the multistage crushing stirring device is provided with the material throwing device, so that forage can be thrown into an internal cavity of a stirring tank at the same time, collisional mixing of the forage is realized, and mixing efficiency is increased; the multistage crushing stirring device is provided with the third motor, the second rotating shaft, the crankshaft, the sleeve, the pitman shaft neck, and the crushing plate, the crushing plate is driven to move to the left and the right, forage secondary crushing smashing is realized, crushing stirring efficiency is improved, and forage mixing is more uniform.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

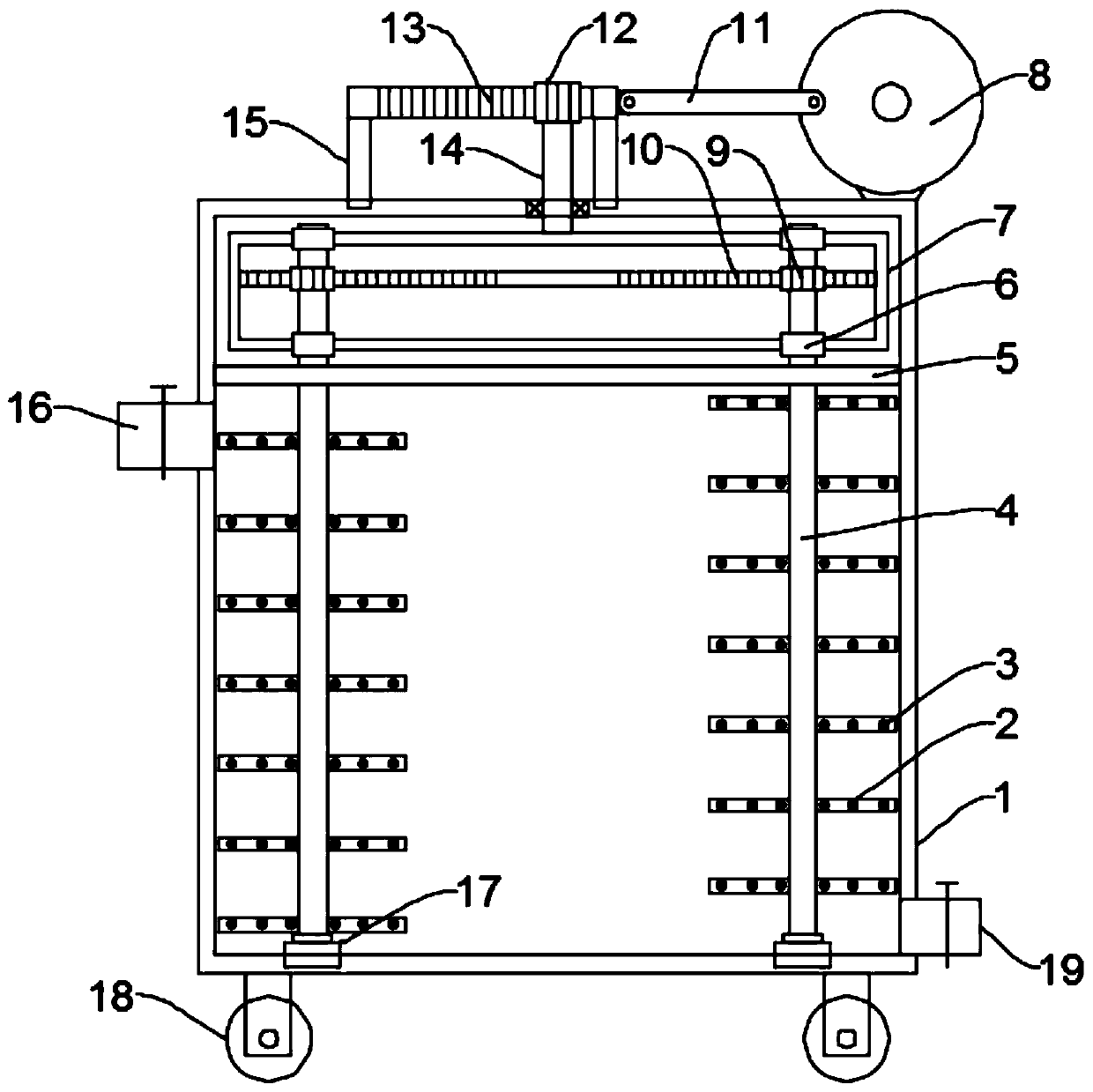

Vertical lifting stirring machine

InactiveCN105058584AStir fully and evenlyExtended working hoursCement mixing apparatusPulp and paper industryThreaded rod

The invention discloses a vertical lifting stirring machine. The vertical lifting stirring machine comprises a motor, a rotating shaft, a stirring barrel and blades, wherein a bracket is arranged between the motor and the stirring barrel; the bracket is fixedly connected with the stirring barrel; the motor is arranged on the bracket; a guide cylinder is arranged in the bracket; the guide cylinder is fixedly connected with the stirring barrel; a ball nut is arranged in the guide cylinder; an annular cylinder is arranged between the ball nut and the rotating shaft; one end of the annular cylinder is connected with the ball nut; the other end of the annular cylinder is fixedly connected with the rotating shaft; a ball threaded rod which is matched with the ball nut is arranged at the output end of the motor. According to the vertical lifting stirring machine, the work efficiency of concrete stirring is improved.

Owner:CHENGDU BAOMIHUA INFORMATION TECH

Stirrer for feed production

InactiveCN104689748ANo additional consumptionReduce wasteFeeding-stuffMixersElectric energyEngineering

The invention discloses a stirrer for feed production. The stirrer comprises a shell, a stirring device and a motor, wherein the motor is mounted on the shell; a material inlet is formed in the top of the shell; a material outlet is formed in the bottom of the shell; the stirring device comprises a stirring shaft, a stirring stick and an air pump; the stirring stick is perpendicularly fixed on the stirring shaft; the air pump is fixed on the stirring shaft; the stirring shaft and the stirring stick adopt hollow structures; the hollow structures of the air pump and the stirring shaft are communicated; the hollow structure of the stirring stick is communicated with the hollow structure of the stirring shaft; an air outlet is formed in the stirring stick and is communicated with the hollow structure of the stirring stick; the stirring shaft is connected with an output shaft of the motor and is positioned in the shell. During stirring, stirred substances cannot be stuck to the stirring stick, so that extra work load of the motor cannot be increased, loss of electric energy is reduced, the stirring stick is not needed to be cleaned, and the labor is saved.

Owner:浙江东立绿源科技股份有限公司

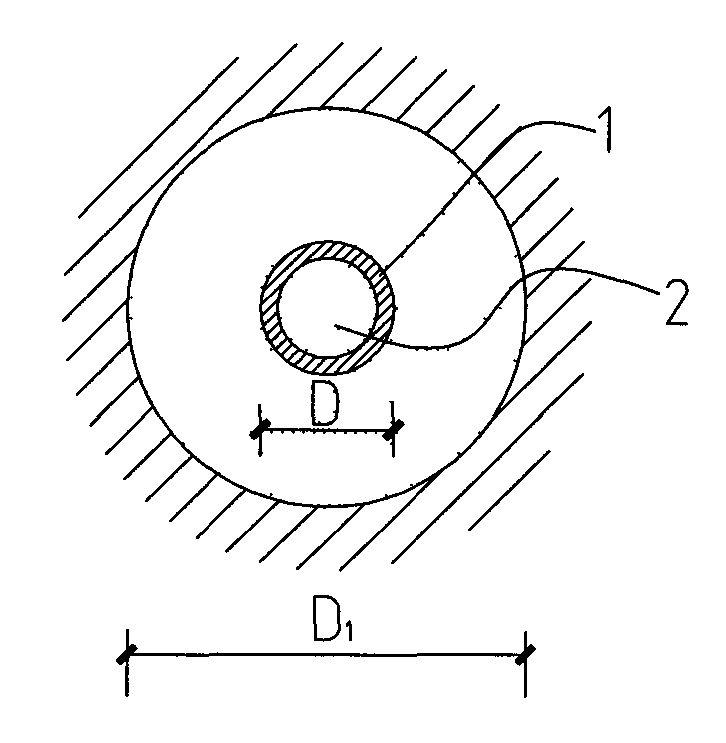

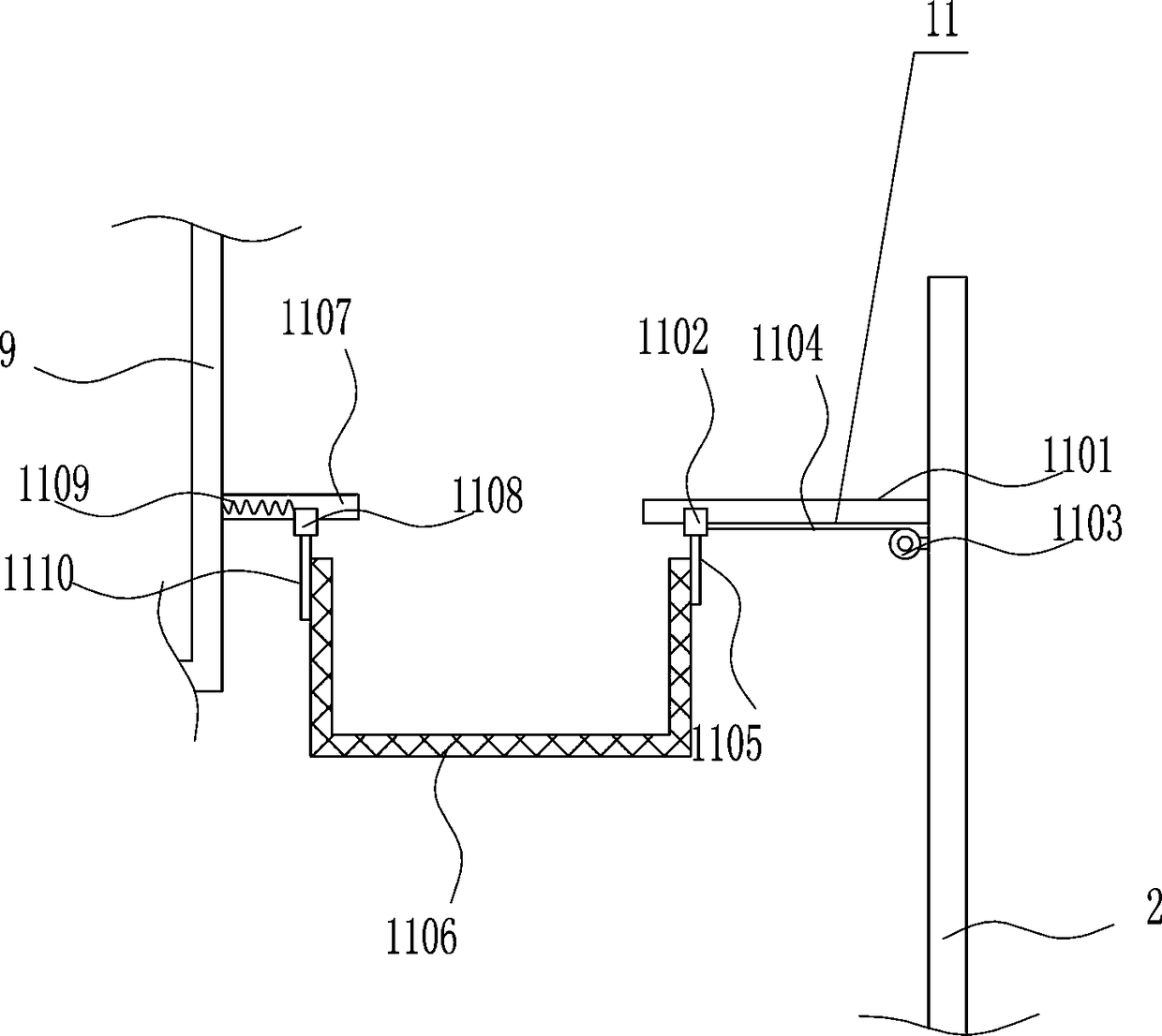

Construction method of composite pile with implanting-in rigid-body embedded into hard bearing stratum

The invention discloses a construction method of a composite pile with an implanting-in rigid-body embedded into a hard bearing stratum. The method comprises the following steps: configurating drill rods and drill bits: configurating an upper drill rod used for large-diameter stirring and a lower drill rod used for small-diameter stirring in the hard bearing stratum according to soil layer distribution, and aligning a pile implanting machine to the soil position required by a design; grouting and drilling: using the pile implanting machine to drill and stir the soil through stirring blades of the upper drill rod and helical blades of the lower drill rod, meanwhile, pouring cement paste to the stirring soil, and drilling and stirring to the predetermined depth in place; withdrawing the rods: lifting the drilling rods to quit the stirring soil; implanting the pile: utilizing the pressure and vibration function of the pile implanting machine to embed the rigid body into the hard bearing stratum, so that the composite pile is formed. The method has the benefits that no slurry is transported outwards, the adjacent soil cannot be extruded, the bearing capacity of the pile body can be greatly improved, and the range of application is wide; and the method has the advantages of convenience for pile forming, fast construction speed, low construction cost, high bearing capacity and the like.

Owner:HANGZHOU NANLIAN BASE FOUND ENG

Efficient fertilizer mixing machine for gardens

InactiveCN107551914AEnergy savingStir wellShaking/oscillating/vibrating mixersMixer accessoriesFertilizerAgricultural engineering

The invention relates to a mixing machine and especially relates to an efficient fertilizer mixing machine for gardens. The technical problem to be solved by the invention is to provide the efficientfertilizer mixing machine for gardens, that is capable of uniformly and fully mixing. In order to solve the technical problem, the efficient fertilizer mixing machine for gardens, provided by the invention, comprises a first mounting plate, a collecting box, a stirring mechanism, a linking mechanism, a crushing mechanism, a driving mechanism, a swinging mechanism, a valve, a discharging pipe, a first fixing rod, a second fixing rod, a feeding hopper, a sieving plate, a flat belt, a third fixing rod, a fourth fixing rod, a mixing tank, a first support plate and a second support plate; the collecting box is arranged at the top of the first mounting plate; the driving mechanism is fixedly arranged at the top of the first mounting plate. The efficient fertilizer mixing machine for gardens canachieve the effect of uniformly and fully mixing.

Owner:刘治国

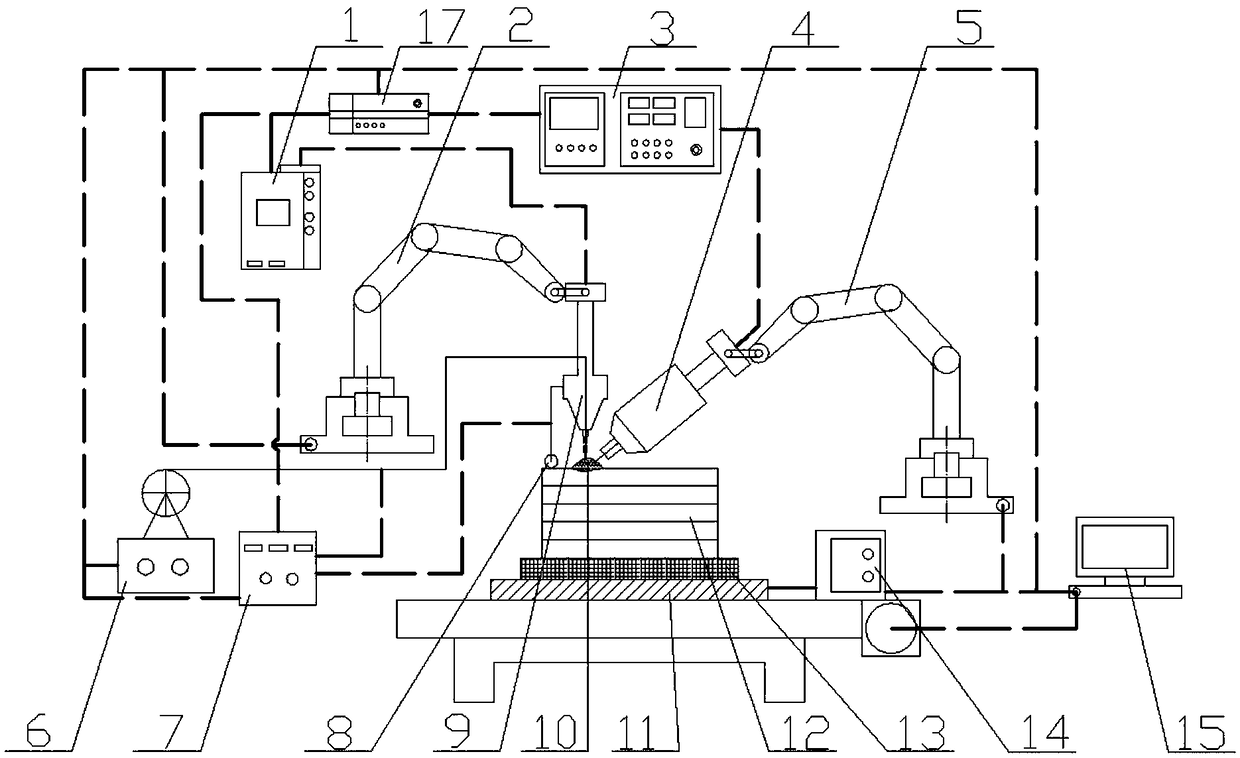

Laser additive device and additive manufacturing method thereof

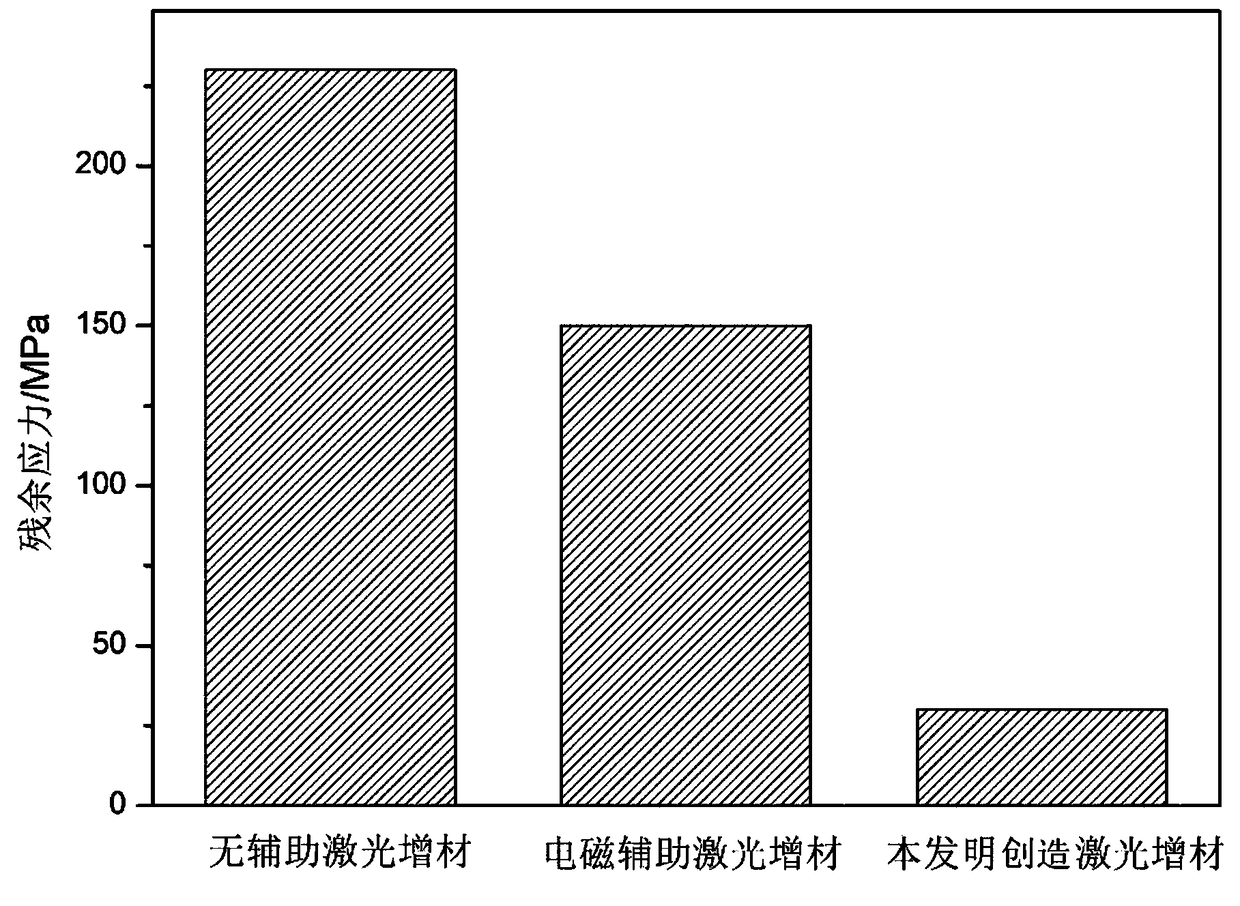

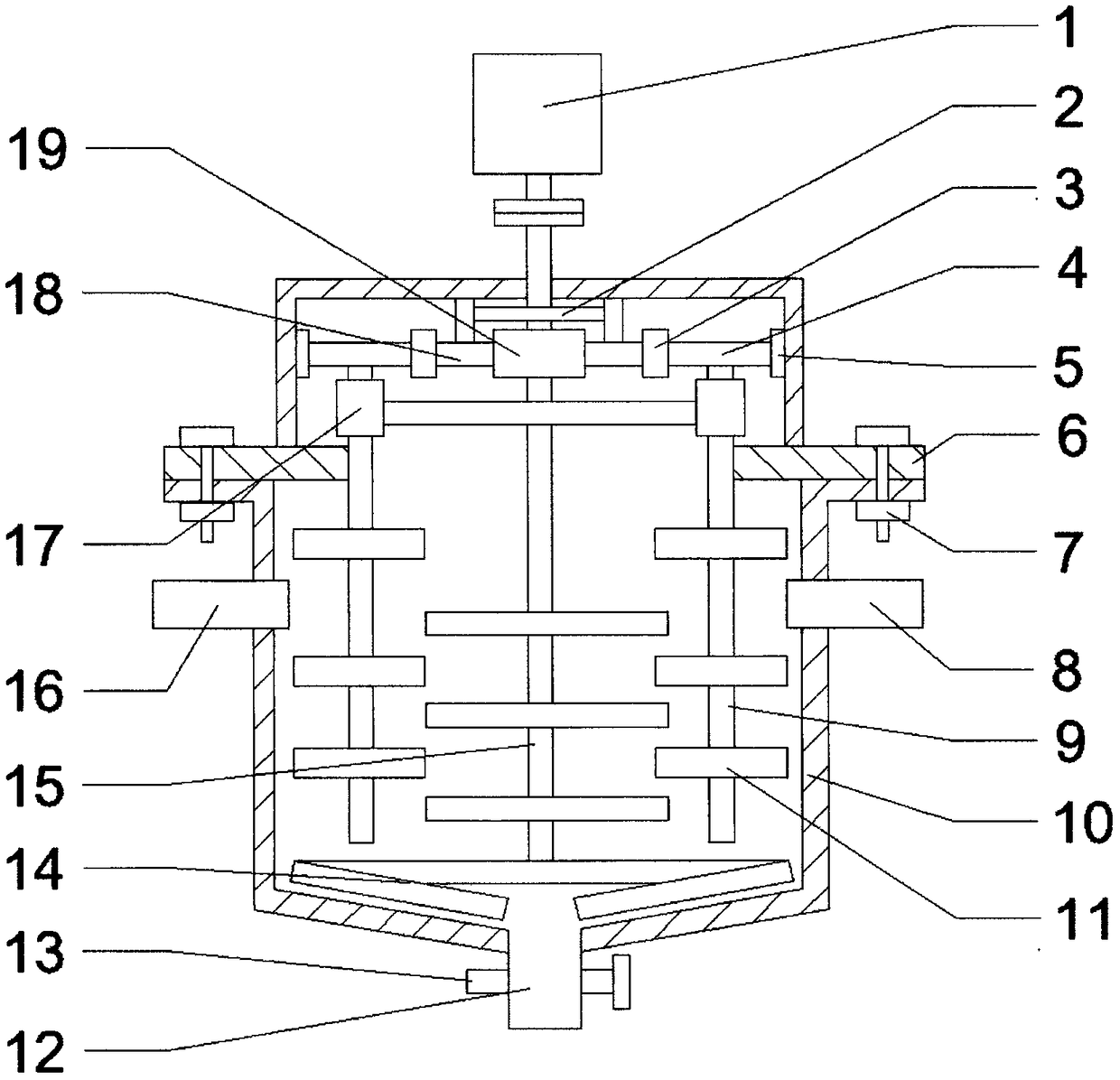

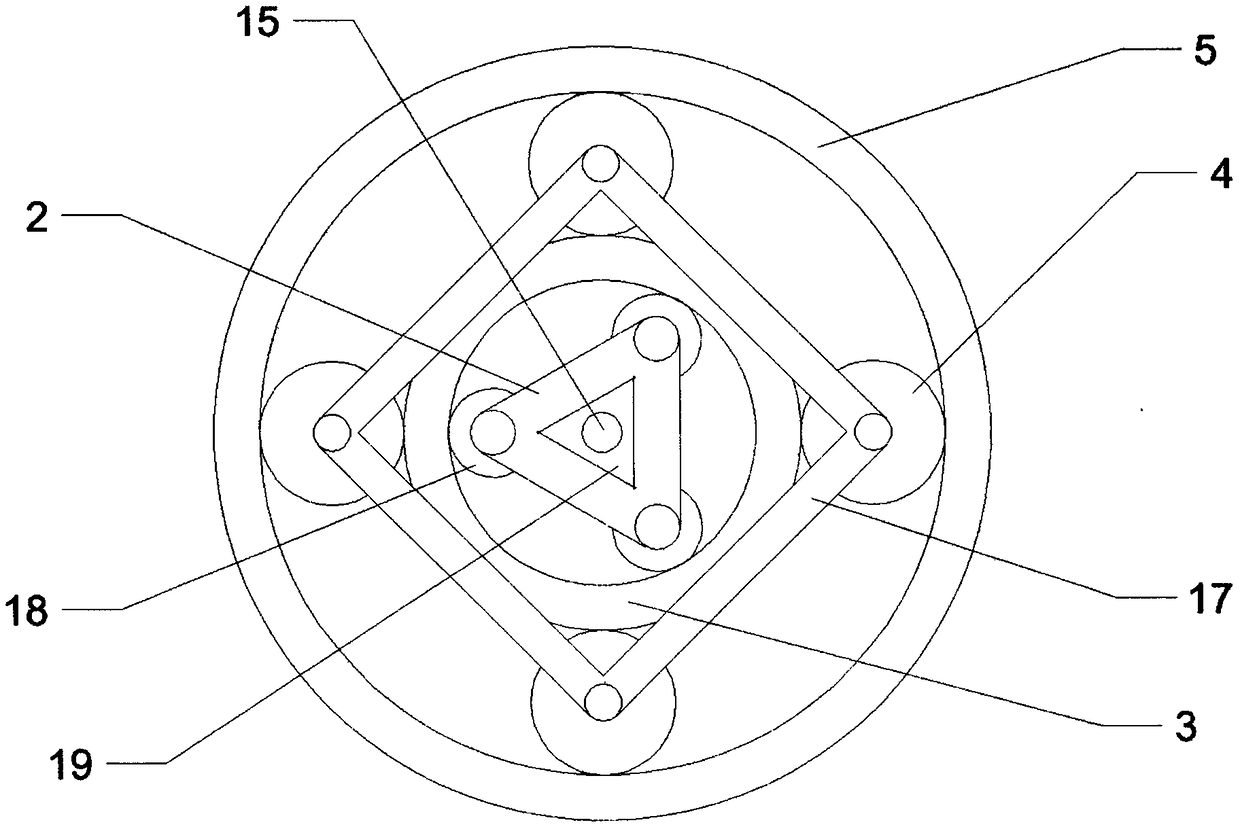

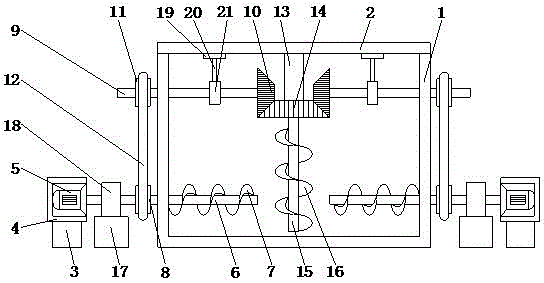

InactiveCN109175364AUniform distribution of energy and temperature fieldsStir wellAdditive manufacturing apparatusIncreasing energy efficiencyPower flowHigh frequency

The invention provides a laser additive device which comprises a rotary light beam laser system, a high-frequency short pulse laser system and an auxiliary current system. The rotary light beam lasersystem outputs rotary continuous laser light, and the continuous laser light is used for melting and depositing wires to the surface of a base material; the high-frequency short pulse laser system outputs high-frequency short pulse laser light, and the high-frequency short pulse laser light is used for inputting a pulse laser beam into a molten bath. The auxiliary current system is used for enabling the wires and the molten bath to form a current loop, and therefore strong electromagnetic force is directly produced in the molten bath. The rotary light beam laser system comprises a continuous laser generator, a first high precision mechanical arm and a continuous laser device laser head. The high-frequency short pulse laser system comprises a high-frequency short pulse laser generator, a high-frequency short pulse laser head and a second high precision mechanical arm. The defects that element segregation is likely to be caused in the molten bath, gas cannot be exhausted, the structure is uneven, and heat stress is concentrated can be overcome.

Owner:JIANGSU UNIV

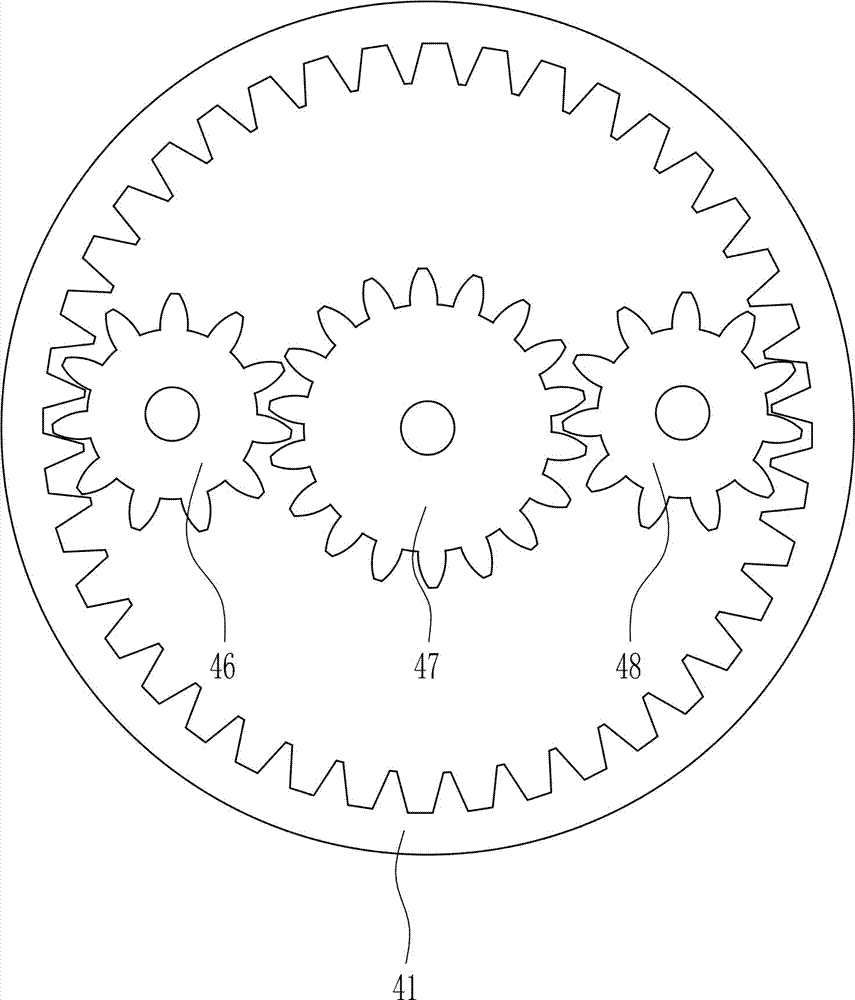

High-low-speed shear emulsifying mixer

InactiveCN108211875APrevent precipitationSimple structureTransportation and packagingMixing methodsLow speedDrive shaft

The invention discloses a high-low-speed shear emulsifying mixer. The high-low-speed shear emulsifying mixer comprises a tank body and a cover body, wherein a discharge opening is formed in the bottomcentral position of the tank body; a first feed opening and a second feed opening are formed in the upper part of the side face of the tank body; a big gear ring is fixed on the inner wall of the cover body and is meshed with a second planet gear inside the big gear ring; a driven shaft is arranged on the second planet gear; the second planet gear is meshed with a small gear ring at the central position of the big gear ring; the small gear ring is meshed with a first planet gear inside the small gear ring; the first planet gear is meshed with a sun gear at the central position of the small gear ring; a driving shaft is arranged on the sun gear; a scraper is arranged at the bottom of the driving shaft. By gear train transmission, the driven shaft rotates and revolves around the driving shaft, so that uniformity and sufficiency in mixing are realized; by transmission of two gear trains, opposite rotating directions of the driving shaft and the driven shaft are realized; meanwhile, the speed difference between the driving shaft and the driven shaft is increased, and uniformity and sufficiency in emulsifying are realized; the scraper arranged at the bottom of the driving shaft can effectively prevent the settlement of materials.

Owner:余姚市滨腾电器有限公司

Stirring-uniform plastic particle production stirrer

Owner:无锡优萌模塑制造有限公司

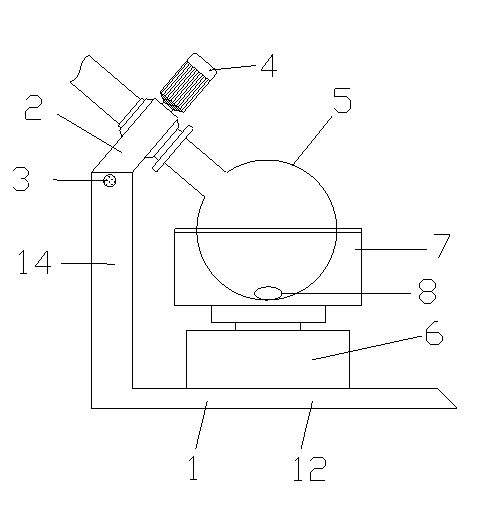

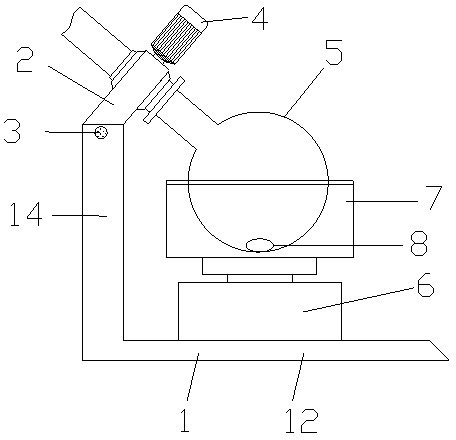

Rotating and revolving magnetic stirrer for production of conductive gold balls

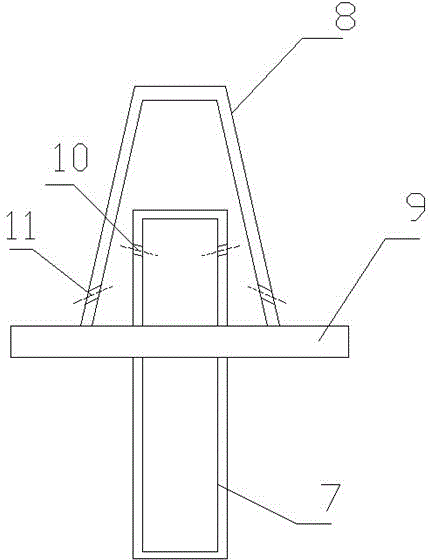

ActiveCN102641686AStir fully and evenlyGood surface treatmentRotating receptacle mixersTransportation and packagingGold ballElectric machine

A rotating and revolving magnetic stirrer for the production of conductive gold balls comprises a mounting rod, a rotary motor, a flask, a magnetic stirrer and a magnetic rotor; the rotary motor is mounted on the mounting rod; the flask is rotatably mounted on the mounting rod; the rotary motor provides rotating power, so that the flask can rotate; the magnetic rotor is placed in the flask; and the magnetic rotor is rotated under the effect of the magnetic force of the magnetic stirrer. According to the rotating and revolving magnetic stirrer, the solvent in the flask not only can revolve as the flask rotates, but also can rotate as the magnetic rotor rotates, carrying out revolution and rotation at the same time, consequently, mixing is more uniform and sufficient, and an excellent mixing effect can be achieved.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Normal temperature manufacturing process for MMA high-intensity artificial stone special-shaped pot/trough

InactiveCN101474827AWell mixedEfficient mixingStone-like material working toolsMechanical propertyMaterials science

The present invention discloses a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The methyl methacrylate resin, arenaceous quartz, accelerating agent and solidifying agent are executed with mixing, injection molding and solidifying forming. The mixing is vacuum mixing which is executed in a mixer with a vacuum degree of 8MPa. The vibration is executed while the squeezing is executed for pouring into the mold for completing injection molding. The mould is closed to a static solidifying exothermic peak, and mould removing and baking are executed. The invention aims at the disadvantages of high cost and hard mould removing of prior art. The invention provides a technique for manufacturing MMA high-strength artificial stone special-shaped basin / groove at normal temperature. The cost is reduced on one hand. On the other hand the mechanical property of product is increased. The technique of the invention has the following remarkable effects: adoption of normal temperature pouring for replacing the previous high temperature pouring, low energy consumption and convenient construction; and 2. adoption of vacuum mixing, excellent texture of finished product, and beautiful external appearance.

Owner:SHANGHAI MOERSHU CORP DEVING

Ship deck painting device with flushing device

ActiveCN105396747ATo achieve a uniform effect of spray paintQuality improvementLiquid surface applicatorsCoatingsMarine engineeringControl valves

The invention discloses a ship deck painting device with a flushing device. The ship deck painting device comprises a base. Sliding devices are arranged at four corners of the bottom of the base. A handle is arranged on the left side of the base. A water tank, a control box, a bearing seat, a storage box, a high-pressure pump and a feeding box are sequentially arranged on the upper surface of the base from left to right. A water inlet is formed in the top of the water tank, the bottom of the right side of the water tank is connected with a spraying head below the base through a water spraying pipe, and the water spraying pipe is provided with a control valve. A connecting block is arranged on the lower surface of the middle of the base, and the surface of the connecting block is connected with a supporting frame through bolts. The ship deck painting device with the flushing device achieves the effect of evenly painting a ship deck, protects a ship body against damage, and improves the quality and durability of the deck. A paint spraying head and a coating roller are improved, the effect of uniform spraying is achieved, and the phenomenon of unevenness is avoided.

Owner:JIANGSU NEW HANTONG SHIP HEAVY IND

Self-inhalation paint stirring device for building

InactiveCN109012357AAvoid depositionAvoid cloggingTransportation and packagingRotary stirring mixersInhalationFunnel shape

The invention discloses a self-inhalation paint stirring device for building. The device comprises a mixing barrel, a hollow stirring shaft, a motor, a first gear, a second gear, a funnel-shaped cover, a liquid inlet hole, a flow deflector, a mounting shaft, a stirring rod, a sector plate and a circular box body. With the arrangement of the hollow stirring shaft, the funnel-shaped cover, a disc and screw blades, the air can automatically inhaled, thus realizing high-efficiency gas-liquid mixing; by continuously blowing air into the mixing barrel and continuously turning over a paint, the stirring and mixing efficiency is improved, deposition and clogging of the paint in a discharge pipe can be effectively prevented, and discharging is also convenient; and with the arrangement of the mounting shaft, the sector plate and the circular box body, the paint will enter through a through hole at one side of the circular box body and then is discharged through a through hole at the other side during the rotating process, and then the paint continuously pushes the sector plate during the motion process, the sector plate drives the mounting shaft to rotate around its own axis, and finally thestirring rod is driven to rotate. Through the revolution and rotation, mixing is more uniform, and the stirring efficiency is further improved.

Owner:杜鑫

Stirring machine for intermediate materials

PendingCN107413225AExtended service lifeNo dead endsRotary stirring mixersTransportation and packagingMotor driveCoupling

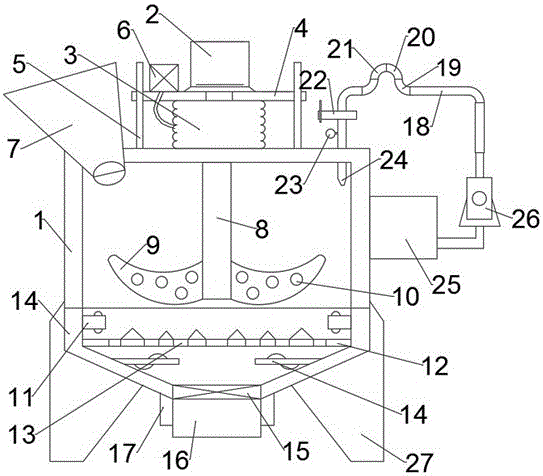

The invention discloses a stirring machine for intermediate materials. The stirring machine comprises a rack, a stirring barrel, a stirring mechanism, a stirring motor and an overturning motor, wherein the stirring barrel is supported on the rack; the stirring mechanism is arranged in the stirring barrel; the stirring motor drives the stirring mechanism; the overturning motor is used for overturning the stirring barrel; the stirring mechanism comprises a driving stirring shaft and a driven stirring shaft; the driving stirring shaft and the driven stirring shaft are connected by a synchronous gear group in a transmission manner; the stirring motor is connected with the driving stirring shaft in the stirring mechanism by a triangular belt, a speed reducing box and a coupling in sequence in a transmission manner; the driving stirring shaft and the driven stirring shaft are respectively provided with stirring blades which are mutually distributed at intervals; the bottom part of the stirring barrel is a curved surface formed by intersection of two semicircular barrel parts, and the radial middle position of the curved surface positioned at the front part is provided with an arc-shaped overturning gear ring; and an overturning gear is arranged at an output shaft of the overturning motor and is meshed with the overturning gear ring. The stirring machine disclosed by the invention has the advantages that no dead corners in the stirring process can be guaranteed, full and uniform stirring is guaranteed, and the stressing in overturning and discharging is uniform, smooth and convenient.

Owner:青岛美中建材机械有限公司

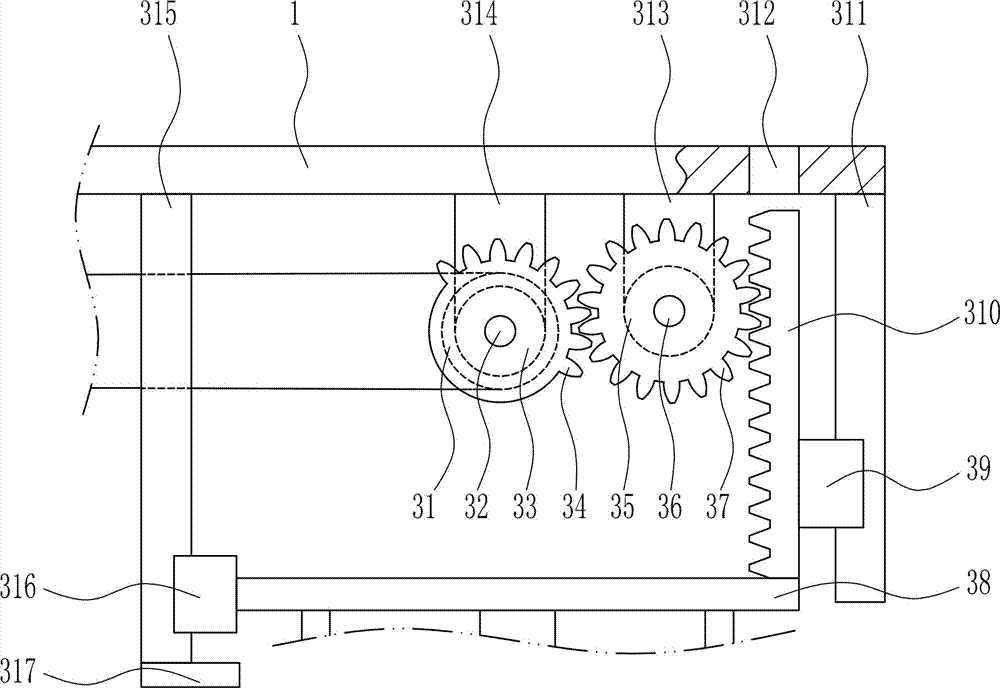

Double-side-rack type concrete mixing equipment

InactiveCN108214910AReduce stirring efficiencyStir wellCement mixing apparatusArchitectural engineering

Owner:南宁腾宁商品混凝土有限公司

Self-rolling type low-temperature protective sleeve for aviation

ActiveCN112117059AExpand the mixing rangeImprove stirring efficiencyCable/conductor manufactureAviationKneader reactor

The invention discloses a self-rolling type low-temperature protective sleeve for aviation, which is prepared by the following steps: S1, mixing protective sleeve materials to obtain a mixture, putting the mixture into a kneading machine, controlling the air pressure to be 0.23 MPa, and kneading and banburying for 10-15 minutes; S2, heating the mixture subjected to internal mixing to 110120 DEG C,and carrying out plastication for 22 hours; S3, adding the plastified mixture into an open mill, mixing for 10-15 minutes at the temperature of 110-120 DEG C, and then carrying out roller wrapping atthe temperature of 40-50 DEG C; S4, adding the mixed mixture into mixing and stirring equipment, uniformly mixing and stirring the mixture, granulating the same, extruding the same and granulating the same to obtain the self-rolling type low-temperature protective sleeve for aviation. The protective sleeve is made of one or a mixture of more of polyethylene, polyvinyl chloride, polypropylene andnylon in any proportion.

Owner:安徽新特华宇新材料科技有限公司

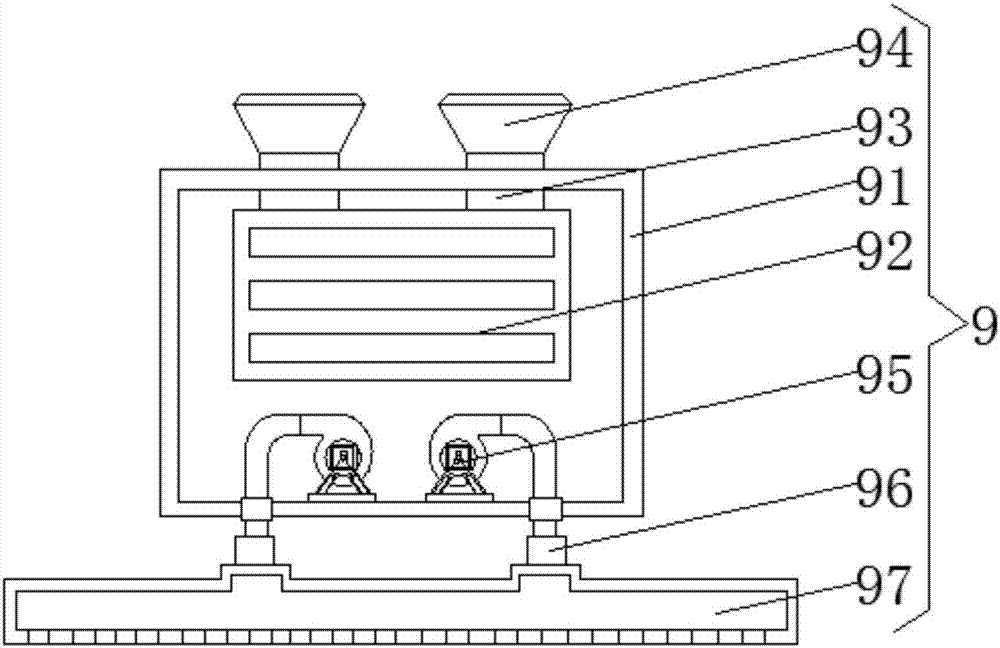

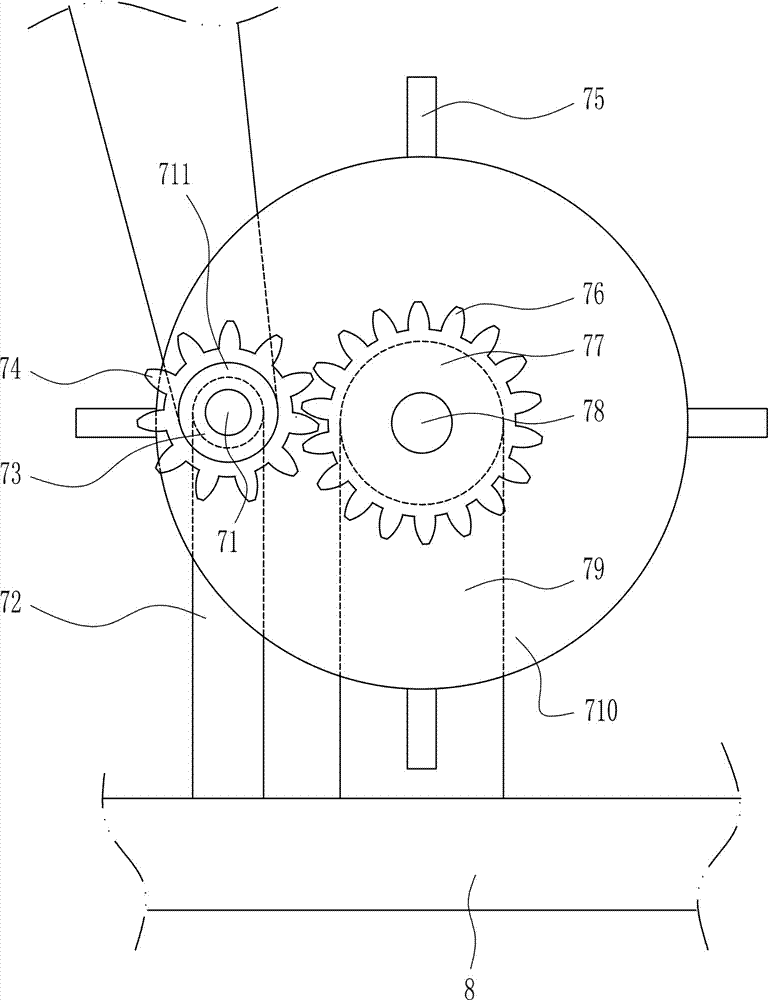

Uniform mixing and agitating device

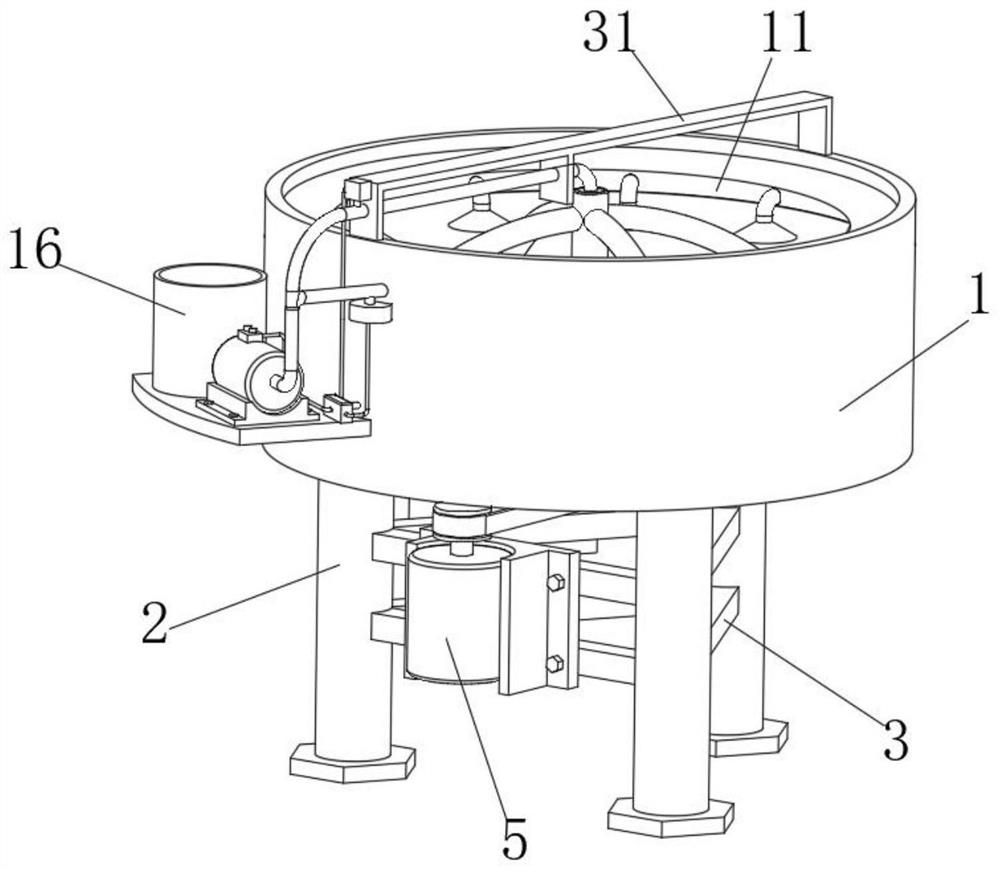

InactiveCN103203197AImprove mixing efficiencyStir fully and evenlyFlow mixersTransportation and packagingEngineering

The invention discloses a uniform mixing and agitating device. The device comprises an inner barrel and an outer barrel, wherein the inner barrel is a cylinder; the top end of the inner barrel is in an opened structure; the inner barrel is internally provided with a lifting screw rod; the screw rod is driven by a screw rod motor; the upper part of the outer barrel is a cylinder and the lower part of the outer barrel is a gradually-reduced cone; the inner barrel and the outer barrel are coaxially arranged; a material lifting gap is reserved between the bottom of the inner barrel and the bottom of the cone; the outer barrel is driven by an outer barrel motor and can rotate along a vertical shaft; and the inner wall of the outer barrel is provided with a radical scraper plate. The uniform mixing and agitating device disclosed by the invention is high in mixing and agitating efficiency and can sufficiently and uniformly agitate.

Owner:CHANGSHU JULI GRINDING WHEEL

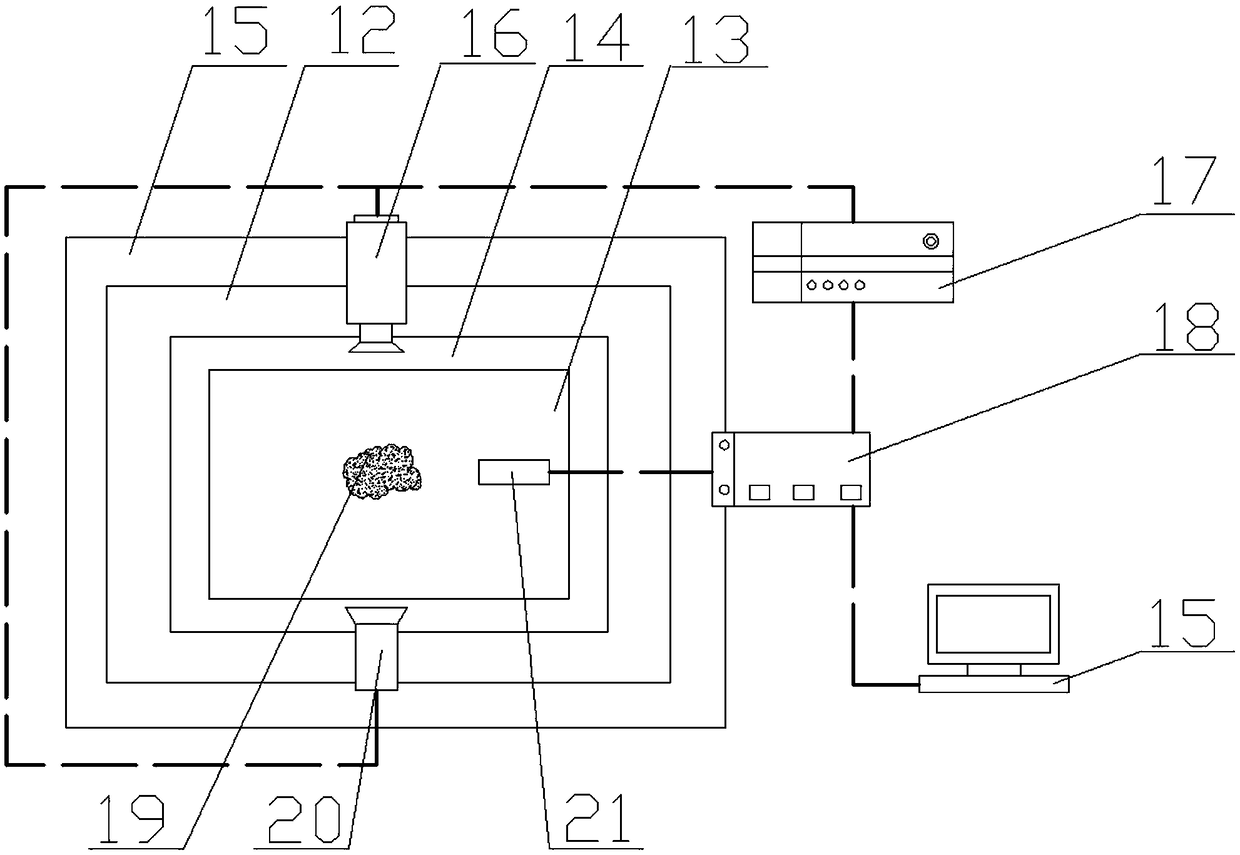

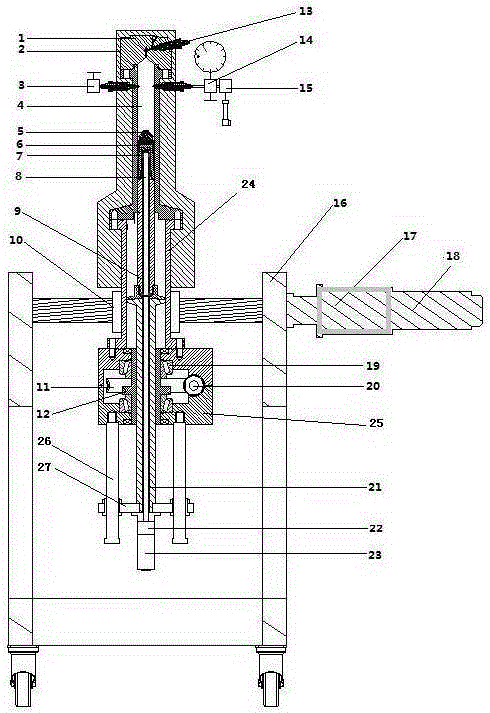

High-temperature high-pressure stratum crude oil physical property analysis system

ActiveCN105223101AStir wellStir fully and evenlyFlow propertiesMaterial testing goodsMagnetic tension forceReduction drive

The invention relates to a high-temperature high-pressure stratum crude oil physical property analysis system. The innovation points of the invention reside in that, the system comprises an analysis cylinder, and a pull rod type piston is arranged in a cylindrical shell; the analysis cylinder comprises a swing stirring system which drives reciprocate swing of the analysis cylinder, a main pump pressure adjusting and driving mechanism, which drives the pull rod type piston in the analysis cylinder to move at an axial direction in order to adjust volume, and a main pump magnetic stirring mechanism, whose magnetic stirring impeller is rotated, wherein the rotation is driven by torque transmitted from a main pump agitator motor, a main pump decelerator, a rotary long rod and a main stirring magnet in order. The invention has the advantages that: the analysis cylinder has a two in one structure, and the analysis cylinder can be used for accommodating, testing and analyzing crude oil, simultaneously is used for driving the pull rod type piston to move by the main pump pressure adjusting and driving mechanism, in order to control the pressure and the volume change, and thereby realizing direct and precise measurement and recording of samples in the analysis cylinder by cooperation of a double-stirring system composed of the swing stirring system and the main pump magnetic stirring mechanism.

Owner:海安华达石油仪器有限公司

Circulating type paint mixing device for producing petroleum pipeline

InactiveCN108246137AStir fully and evenlyImprove stirring efficiencyFlow mixersTransportation and packagingArchitectural engineeringPetroleum

The invention discloses a circulating type paint mixing device for producing a petroleum pipeline. The circulating type paint mixing device comprises a barrel body, a first motor, a disc, a movable rod, a spline shaft, an agitating shaft, a sleeve, a first gear, a second gear, a second motor, agitating rods, a through hole, a round plate, a through hole, a first baffle plate, a first spring, a second through body, a third motor, a second agitating shaft, second agitating rods, a second baffle plate and a second spring. The circulating type paint mixing device is provided with the first motor,the disc, the movable rod, the spline shaft, the second motor, the first gear, the second gear, the agitating shaft and the agitating rods; the agitating rods are enabled to move up and down while being enabled to rotate through cooperation; the agitation is enabled to be more sufficient and uniform; the agitation efficiency is improved; the circulating type paint mixing device is provided with the round plate, the through hole, the first baffle plate, the first spring, the second through body, the third motor, the second agitating shaft, the second agitating rods, the second baffle plate andthe second spring; paint in the barrel body is enabled to continuously circularly move; the paint is sufficiently uniformly agitated, and the agitation efficiency is further improved.

Owner:陈青松

Oat noodle and production process thereof

The invention discloses an oat noodle and a production process thereof. The oat noodle is prepared from the following raw materials in percentage by weight: 8-15% of oats, 0.03-0.08% of iodised salts and 85-92% of flour. The production process of the oat noodle is implemented through the following steps of: cleaning hulled oats, drying the hulled oats by using a drying furnace, and crushing the dried oats into oat flour (120 meshes) by using a crusher; according to the weight percentages of the materials, putting the oat flour, the iodised salts, the flour and drinking water into a vacuum dough kneading machine to carry out dough kneading, then obtaining an oat dough, wherein the ratio of a mixture of the oat flour, the iodised salts and the flour to the drinking water is (4:1)-(6:1); conveying the prepared oat dough into a noodle forming machine to carry out wiredrawing and cutting, then conveying the obtained product into a heat-flow drying machine to dry at a temperature of 50-70 DEG C; and carrying out packaging on the dried product so as to obtain the oat noodle product. The noodle disclosed by the invention has the advantages that the noodle is high in nutritional value, high in medical care value, pliable, chewy, soft, and goluptious.

Owner:SHUICHENG TIANRUI FOOD

High-efficiency hull breaking integrated system for performing anaerobic fermentation on livestock and poultry excrement and straw mixture

PendingCN107760585AAvoid cloggingSolve the problem that the effect of plugging and mixing will be reducedBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryBiology

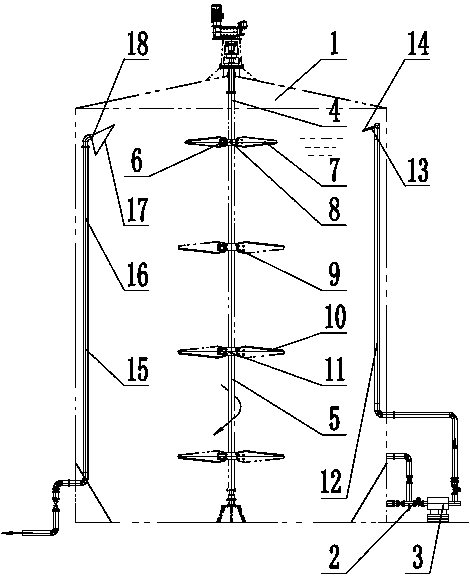

The invention discloses a high-efficiency hull breaking integrated system for performing anaerobic fermentation on a livestock and poultry excrement and straw mixture. The high-efficiency hull breaking integrated system comprises a central stirring unit, a cyclic spraying unit and an upper dross cutting unit, wherein the central stirring unit is arranged on a stirring shaft, the cyclic spraying unit is arranged on the inner wall of a fermentation tank; a first-layer stirrer of the central stirring unit is positioned below the liquid level, a propeller type stirring blade is used for upward turning and pushing materials to flow upward, scatter materials and break hulls, and propeller type stirring blades of the multi-layer stirrers below are used for downward pressing and pushing materialsto flow from bottom to top to form a convection circulation flow field; a nozzle of the cyclic spraying unit is obliquely arranged above the liquid level and performs jet impact to materials on the liquid level for breaking hulls; a bell mouth of a cutting head of the upper-part dross cutting unit is arranged at the liquid level, the cutting head is used for cutting hulled materials on the liquidlevel, and the bell mouth is used for sucking dross and discharging dross out of the tank body. The high-efficiency hull breaking integrated system integrates the anaerobic fermentation stirring, cutting and spraying hull breaking functions, is suitable for efficiently treating livestock and poultry excrement and straw mixtures in large anaerobic fermentation tanks, is high in gas production rateand has energy-saving and emission-reduction effects.

Owner:湖北中涢环保能源科技有限公司

Gypsum raw material mixing apparatus used for medical orthopaedics

InactiveCN108176272AStirring speed is fastStir fully and evenlyTransportation and packagingRotary stirring mixersGypsumMedical treatment

The invention relates to a gypsum raw material mixing apparatus, and especially relates to a gypsum raw material mixing apparatus used for medical orthopaedics. The gypsum raw material mixing apparatus solves the technical problems of fast stirring speed as well as uniform and full stirring, and the gypsum raw material mixing apparatus is capable of screening the size of a gypsum raw material. Forsolving the above technical problem, the gypsum raw material mixing apparatus comprises a base plate, a right support plate, a left support plate, a stirring case, a stirring mechanism, and a transmission mechanism and the like; the left support plate is arranged at a left side at the top of the base plate, the right support plate is arranged at a right side at the top of the base plate, the stirring case is arranged at the central section of the top of the base plate, and the stirring mechanism is arranged at the left side surface of the right support plate. The gypsum raw material mixing apparatus has the advantages of fast stirring speed as well as uniform and full stirring, is capable of screening the size of the gypsum raw material, and is capable of stirring the gypsum raw materialin the stirring case through the stirring mechanism.

Owner:姚宜迁

Environment-friendly coating mixing device

PendingCN112473463ARealize moving back and forthQuality improvementRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to an environment-friendly coating mixing device. The device comprises a base, a mixing cylinder and a lifting frame; the mixing cylinder is placed at the top of the base, and amounting groove is formed in the side wall of the L-shaped lifting frame; the hydraulic rod contracts to drive the lifting frame to move downwards, at the moment, the stirring shaft acts on the connecting base to drive the first movable rod to move downwards, the first movable rod drives the first piston to compress the first spring when the first cylinder moves downwards, meanwhile, air is pressed into the second cylinder through the connecting pipe, and the second piston in the second cylinder is driven to compress the second spring; at the moment, the second movable rod retracts into the second barrel, the sliding block gets close to the first barrel, the position of the stirring scraping blade is adjusted, in the mixing process, the stirring scraping blade moves back and forth throughwork stretching and retracting of the hydraulic rod, paint in the mixing barrel is mixed in all directions, and the paint is stirred and mixed from multiple angles and multiple directions; therefore,the sufficient and uniform stirring is guaranteed, and high coating quality is guaranteed.

Owner:哈尔滨大东方新材料科技股份有限公司

Cement mixer

InactiveCN101417476AStir fully and evenlySatisfy the requirement that the water-cement ratio is about 0.4Cement mixing apparatusReinforced concreteCement grout

The invention relates to a building construction device, in particular to a cement mixer which carries out cement grouting operation to a reserved bellow pore channel after stretching the reinforcing steel bar in a reinforced concrete structure. The cement mixer mainly comprises a mixing drum which is provided with a motor and a stock outlet, the motor is connected with a vertical axis in the mixing drum, and the vertical axis is provided with a group of mixing blades and two groups of mixing blades. As a group of mixing blades are added on the basis of one group of mixing blades in the prior art, the cement can be mixed fully and evenly in the mixing drum, thus meeting the demand that the water cement ratio of the cement used for grouting is about 0.4 in the national construction specifications.

Owner:上海建科建设发展有限公司

Anti-plugging cement slurry stirring device capable of adding admixture conveniently

InactiveCN106738332AStir fully and evenlyImprove finished product qualityDischarging apparatusCement mixing apparatusEngineeringCement slurry

The invention discloses an anti-plugging cement slurry stirring device capable of adding an admixture conveniently. The stirring device comprises an upper stirring shell. A positioning frame is arranged on the top of the upper stirring shell. A lifting base is mounted above a frame body of the positioning frame. An inflator pump is arranged on the lifting base and the lifting base is connected to an air cushion through an air pipe. An admixture storage cylinder is fixedly arranged on the right side wall of the upper stirring shell. A second bend pipeline and a third bend pipeline are connected to form a semicircular pipe structure. Multiple groove bodies evenly distributed are formed in a material baffle. A lower cavity is set to be in a circular truncated cone shape, and multiple uniform material distribution rods are arranged on the inner side wall of the lower cavity. By the adoption of the anti-plugging cement slurry stirring device capable of adding the admixture conveniently, the situation that a drive rotary shaft only conducts stirring in a fixed region is avoided, the retention phenomenon is avoided when the admixture is added, the quantity demand of the admixture is well controlled, the material dispersion efficiency is improved, and the discharging fluency is enhanced.

Owner:顾广才

Concrete mixer not prone to caking

InactiveCN112428431ANot easy to knotAvoid affecting useCement mixing apparatusControl apparatusRotational axisDrive motor

The invention relates to the technical field of concrete mixer devices, and discloses a concrete mixer not prone to caking. The output end of a driving motor drives an input shaft to rotate through acoupling, the input shaft enables a driving pulley to rotate, a rotating shaft is made to rotate through a transmission belt, and the rotating shaft drives a stirring through pipe to mix cement. Whenwater is too little in the stirring process, a sensor transmits a signal into an electromagnetic valve controller through a data transmission line, the electromagnetic valve controller transmits the signal into a cleaning pump through a water pump control line, then the cleaning pump is started, the cleaning pump starts a second electromagnetic valve through a second control line, and meanwhile afirst electromagnetic valve is closed. A water inlet pipe discharges water in a water tank into the cleaning pump, the water is discharged into a water outlet pipe through the pressurization effect ofthe cleaning pump and flows out through a multifunctional pipe, the stirring through pipe and a water injection hole, and therefore water adding stirring can be achieved in the stirring process, andthe situation that the use standard is affected due to over-dry concrete is prevented.

Owner:合肥市日月新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com