Construction method of composite pile with implanting-in rigid-body embedded into hard bearing stratum

A construction method and a technology of hard holding force, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of mud transportation, soil extrusion, etc., and achieve the effect of convenient pile formation, increased surface area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] When constructing composite piles, the upper drill pipe for large-diameter stirring and the lower drill pipe for small-diameter stirring in the hard bearing layer are firstly configured according to the distribution of the soil layer. If it is to be embedded in the bedrock, a special drill bit with air impact should be equipped. And align the pile driver to the soil position required by the design.

[0044] Such as Figure 9As shown, the drill pipe of the piling machine is composed of upper and lower parts. The upper drill pipe and the lower drill pipe are connected into one body through the connecting mechanism. The upper drill pipe has spiral stirring blades and drill bits distributed at intervals, and the lower drill pipe has Continuously distributed spiral blades and bedrock drill bit with auxiliary air impact function.

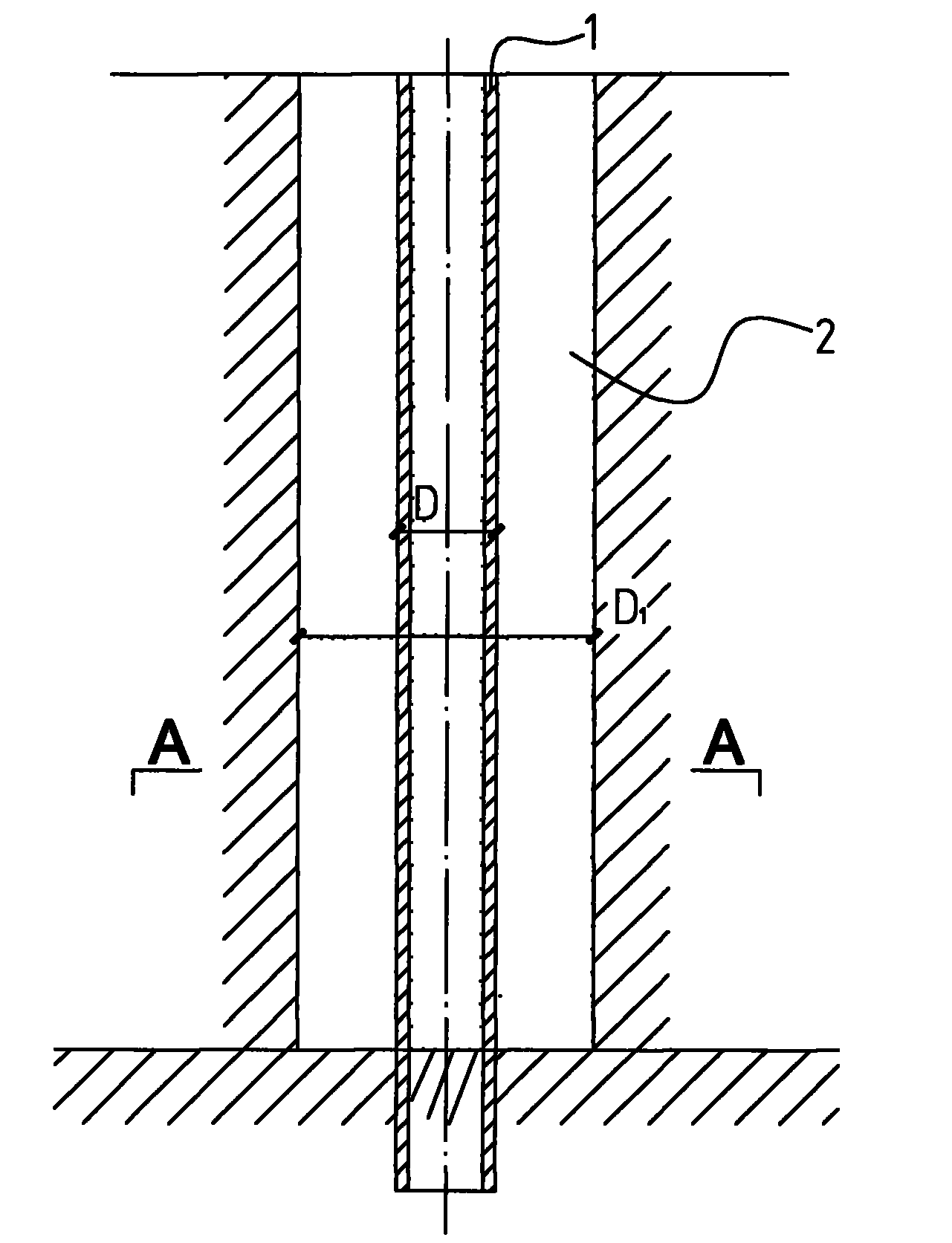

[0045] Such as Figure 1-2 As shown, when the upper part of the soil is a soft soil layer commonly found in coastal areas, and the lower part is...

Embodiment 2

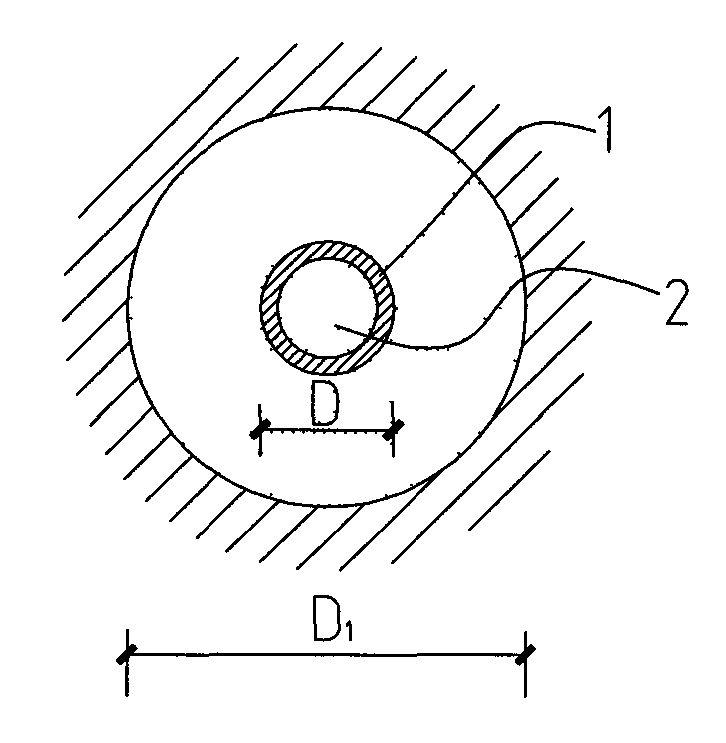

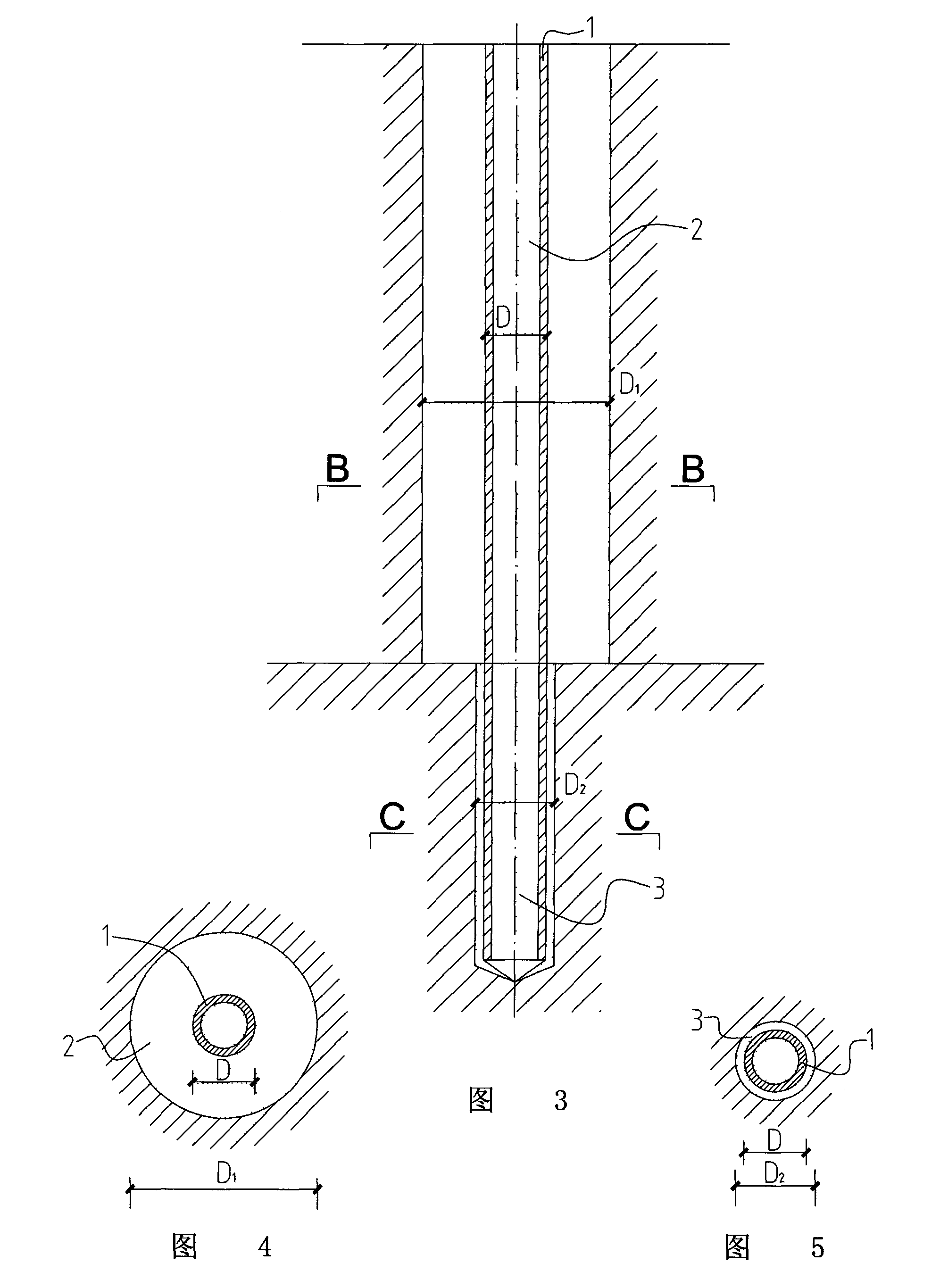

[0051] Such as Figure 3-5 As shown, when the upper part of the soil is a soft soil layer and the lower part is a hard-bearing layer, the design requires that the composite pile enter the hard-bearing layer deeper or even into the bedrock layer. The specific construction method of the composite pile is:

[0052] First of all, the pile machine should be equipped with the upper drill pipe, the lower drill pipe and the mixing blades, helical blades and drill bits matched with the upper and lower drill pipes;

[0053] The construction method of the upper soft soil layer is the same as that of the soft soil layer in Example 1, all of which are to carry out large-diameter stirring and grouting to the soil body through the stirring blades on the drill pipe of the pile planter, and form in the soft soil layer. A cement-soil hole with a diameter of D1, but the drilling speed of the pile driver is 1 m / min, and the rotational stirring rate is 30 rpm.

[0054] When the drill bit and heli...

Embodiment 3

[0057] Such as Figure 6-7 As shown, when the soil properties of the upper and lower layers of the soil body of the construction site are good, but it is difficult to use the traditional driving or pressing prefabricated piles to form piles in place, the method of the present invention is relatively simple, and the specific construction steps are as follows:

[0058] The pile planting machine drills and mixes the soil through the mixing blades and helical blades on the drill pipe, grouting while drilling, and then enters the depth of the hard bearing layer or bedrock layer required by the design, withdraws the rod, and uses pile planting The vibration and press-in functions of the machine implant the rigid body in place, and the cement slurry condenses to form cement soil 2, and the cement soil 2 wraps the rigid body 1 to form a composite pile that meets the bearing capacity requirements.

[0059] The diameter of the circle formed by the stirring blade and the helical blade is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com