Patents

Literature

128results about How to "Increase side friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

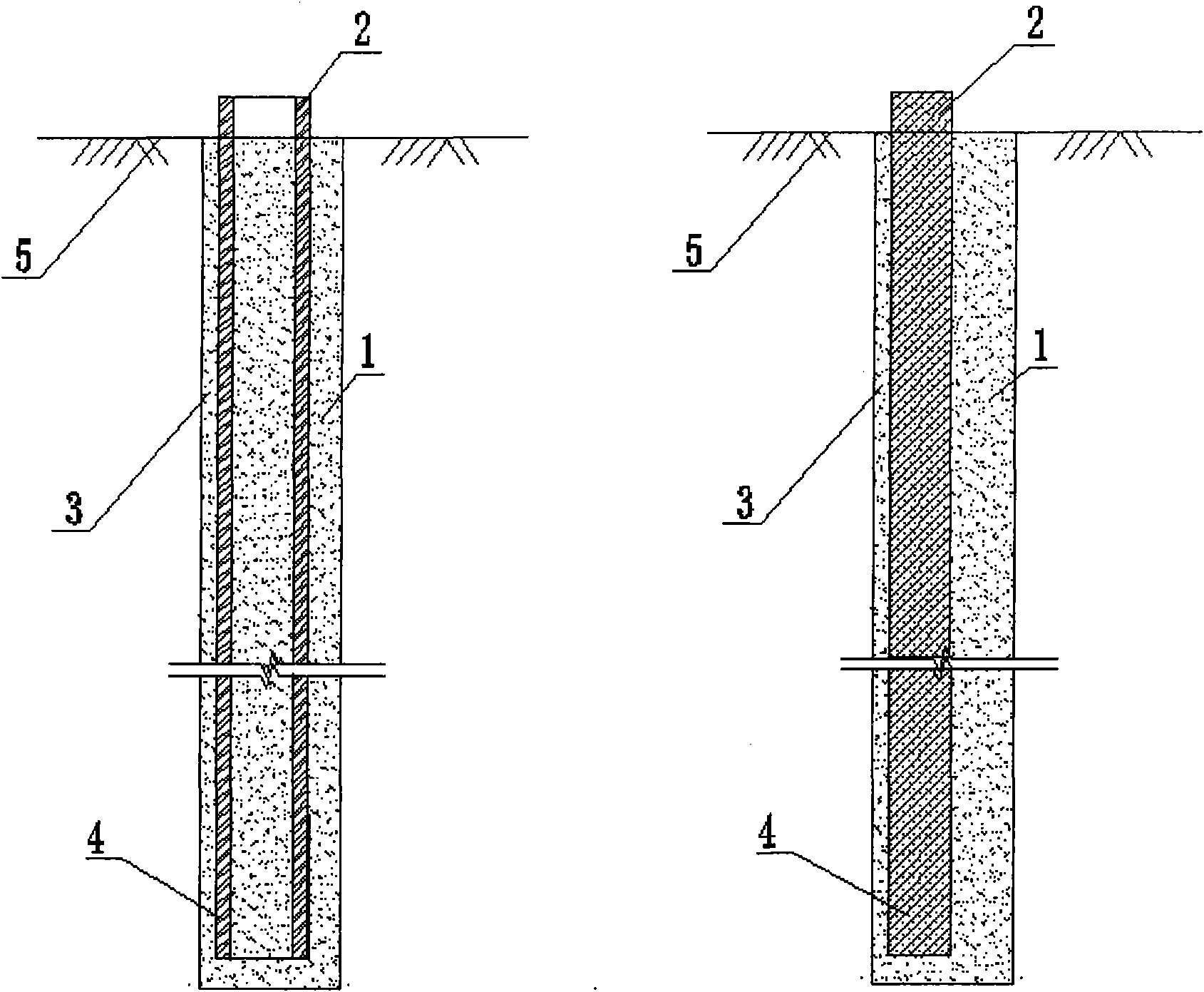

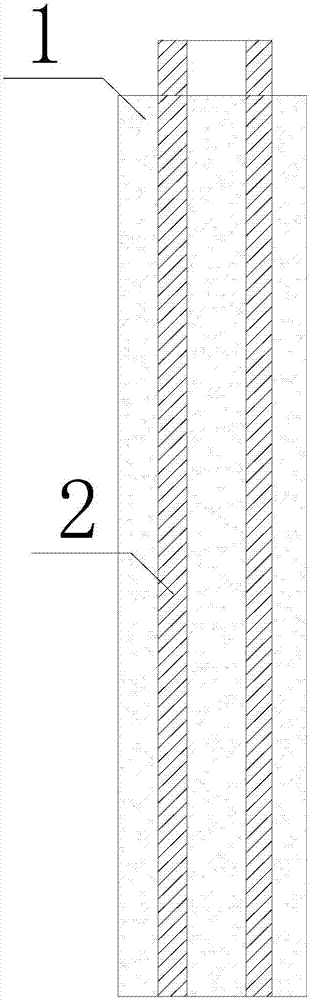

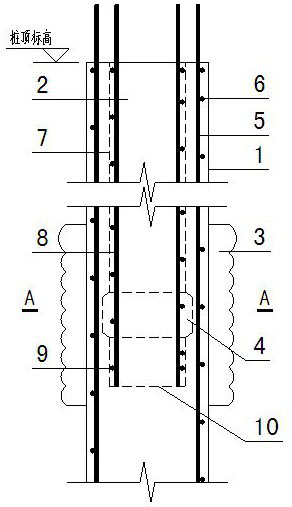

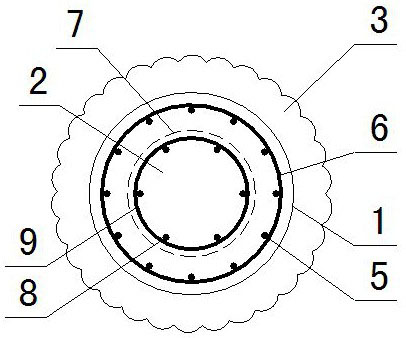

Cement-soil composite pile inserted into reinforced concrete core materials

InactiveCN101798810ATo overcome the problem that deep stirring can only stop water but not supportIncrease side frictionBulkheads/pilesReinforced concreteCement slurry

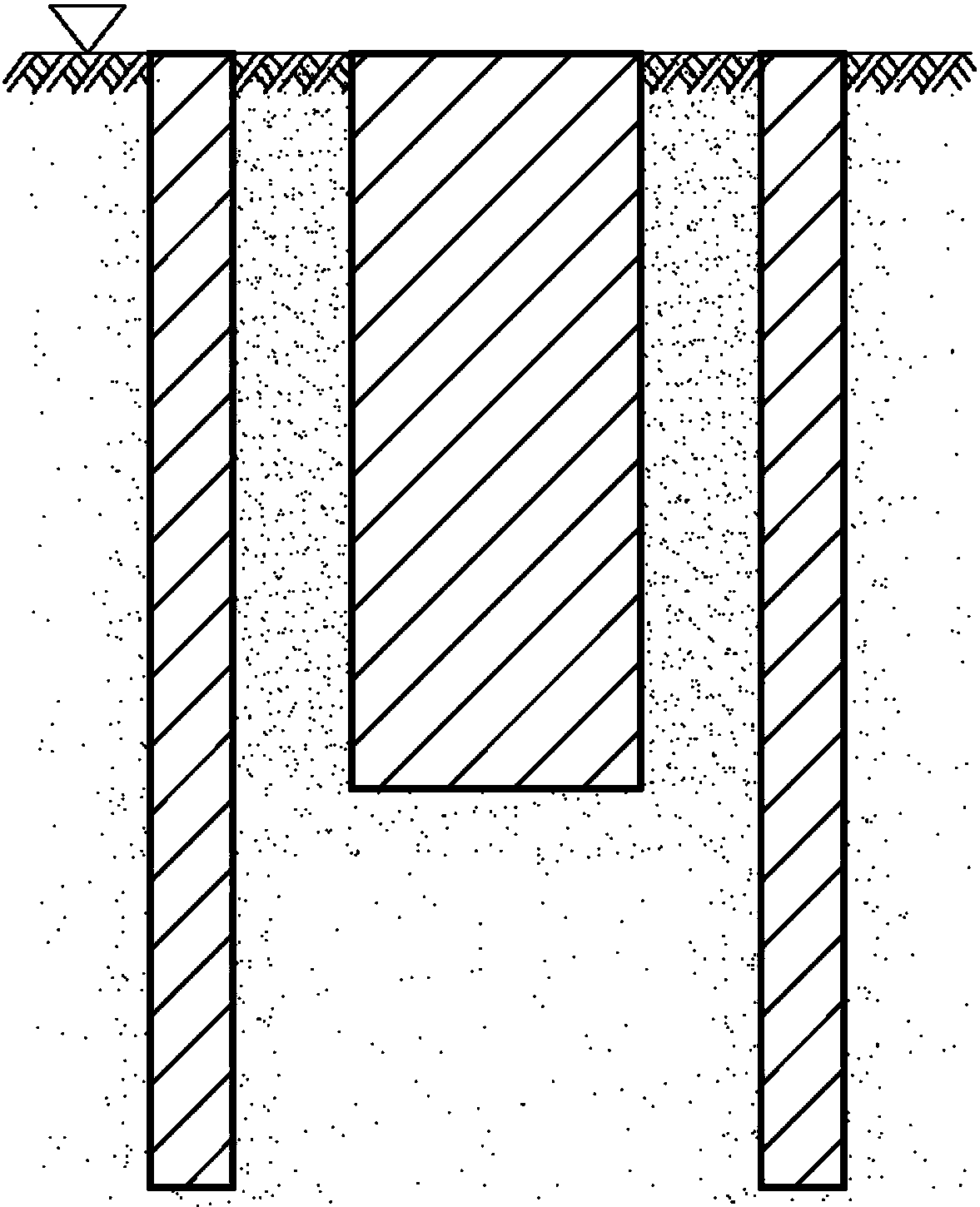

The invention relates to a cement-soil composite pile inserted into reinforced concrete core materials. The cement-soil composite pile is a novel composite pile which is formed by inserting a prestressed concrete tubular pile or a prestressed concrete square pile or a reinforced concrete member, serving as a core material, into a deeply-stirred cement-soil pile (which is formed by deeply stirring through a single-shaft, double-shaft or three-shaft stirring pile machine). The cement-soil composite pile consists of a cement-soil stirring pile and a high-strength core pile. The cement-soil composite pile is formed by the following steps of: stirring soil and cement slurry to form the cement-soil by using the single-shaft, double-shaft or three-shaft stirring pile machine; and then inserting one (or a plurality of) core material (such as the prestressed concrete tubular pile, the prestressed concrete square pile, the precast reinforced concrete member and the like) into the cement-soil by a vibration or self-weight method to obtain the composite pile body. The composite pile has higher bending strength, tensile strength and shear strength so as to meet different bearing requirements, and has the lateral bearing capacity 30 percent higher than that of the core pile and comprehensive cost 40 percent lower than that of a bored pile.

Owner:SHANGHAI STRONG FOUND ENG

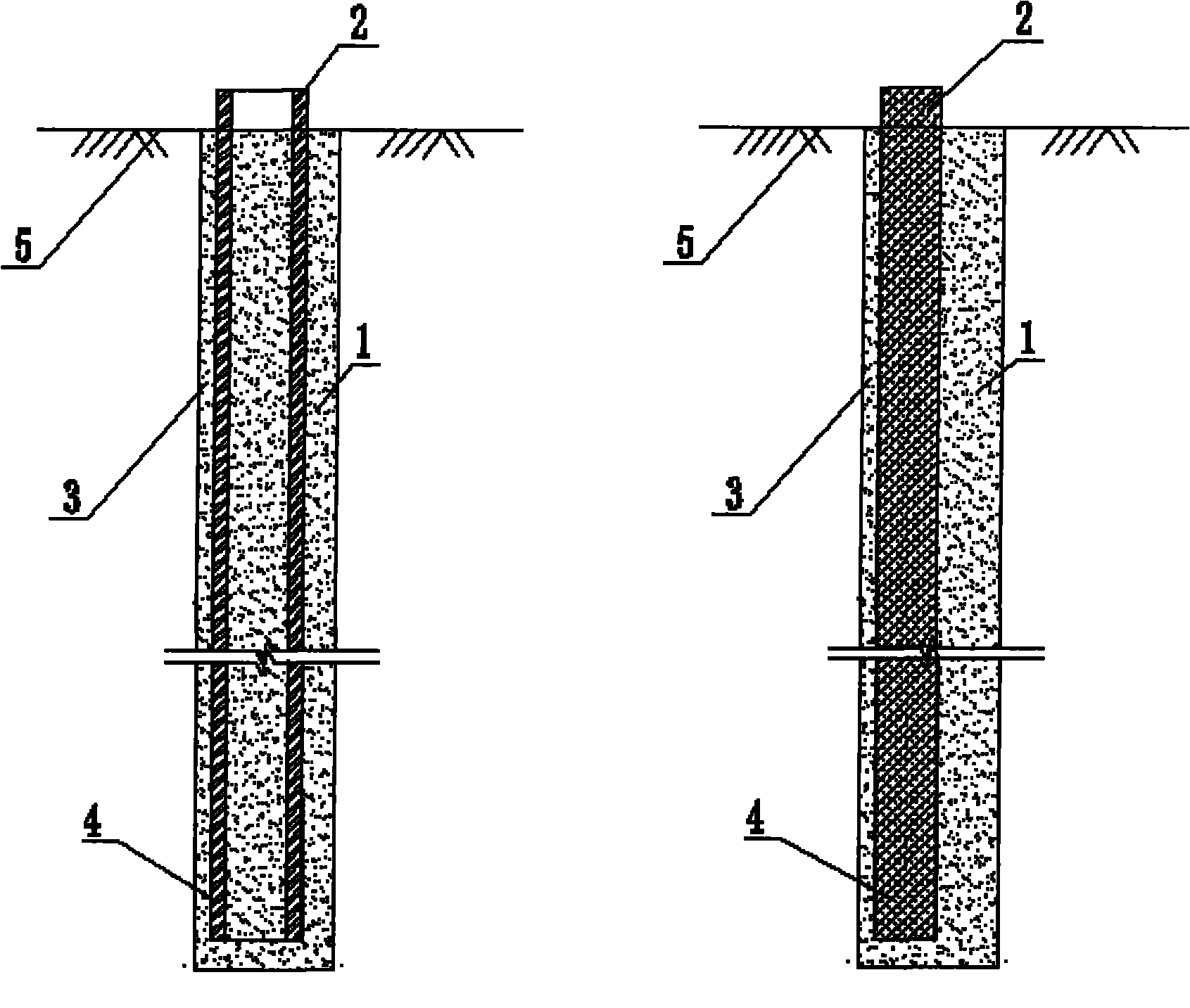

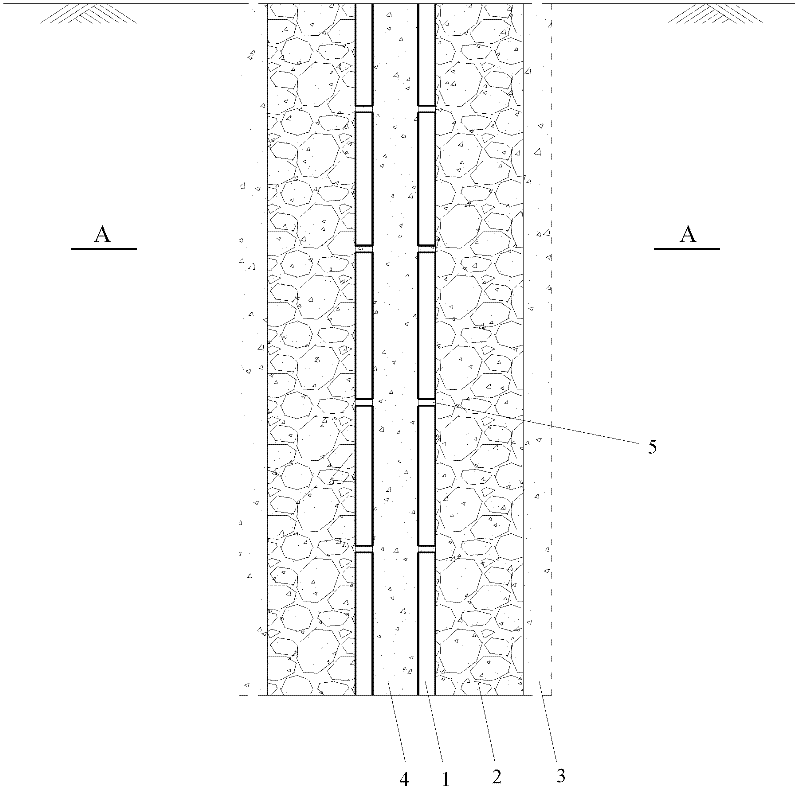

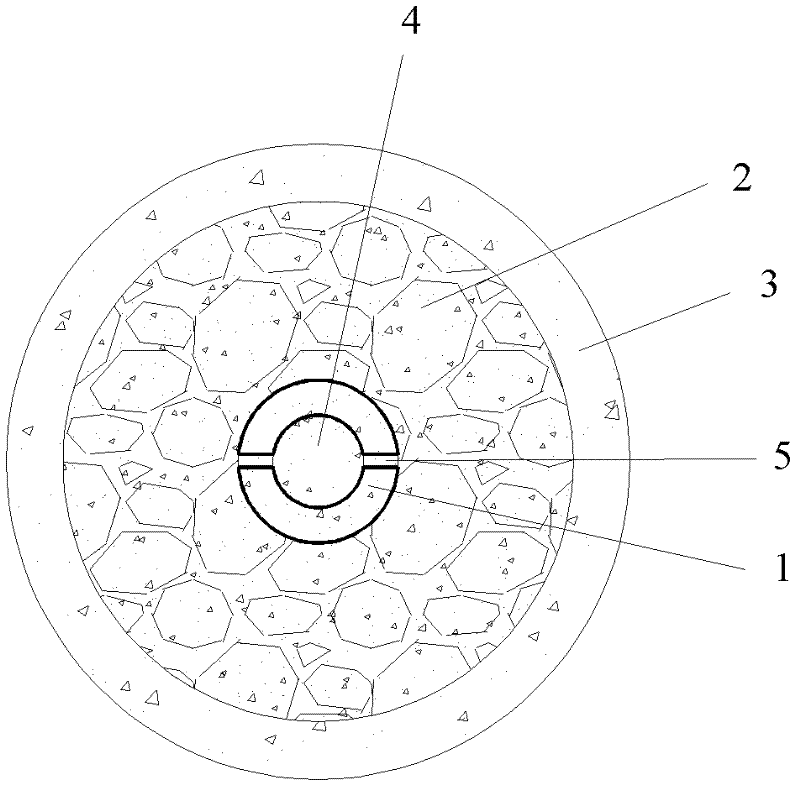

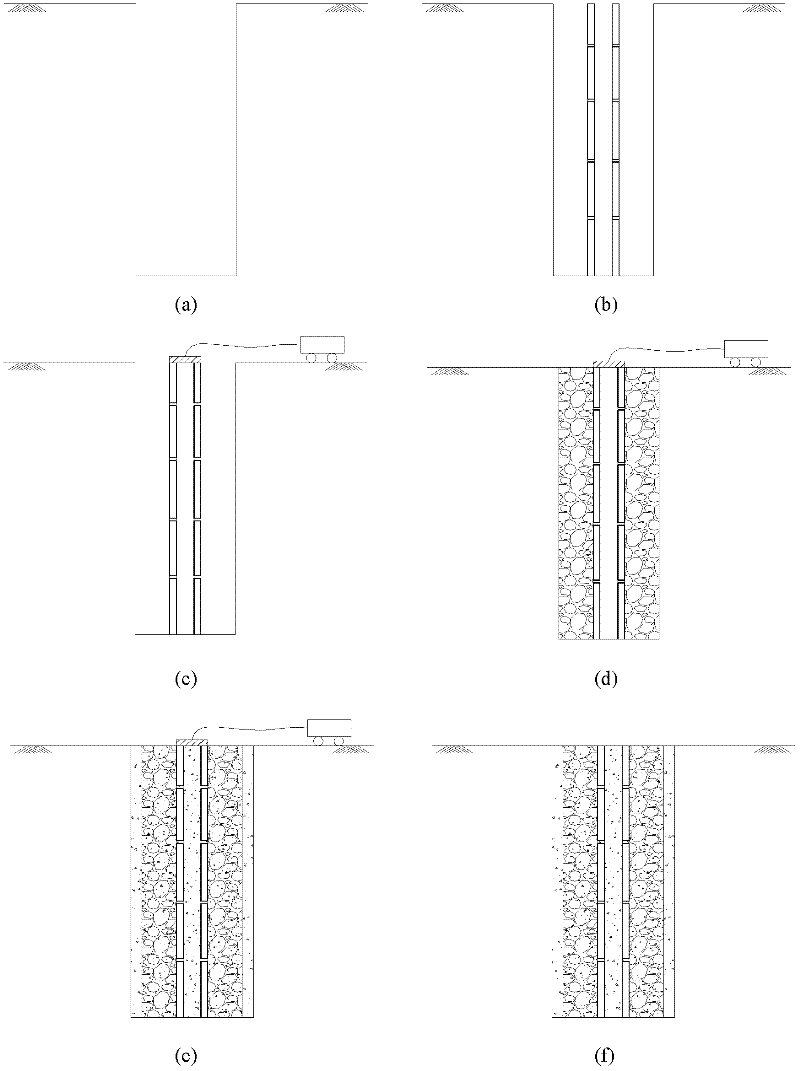

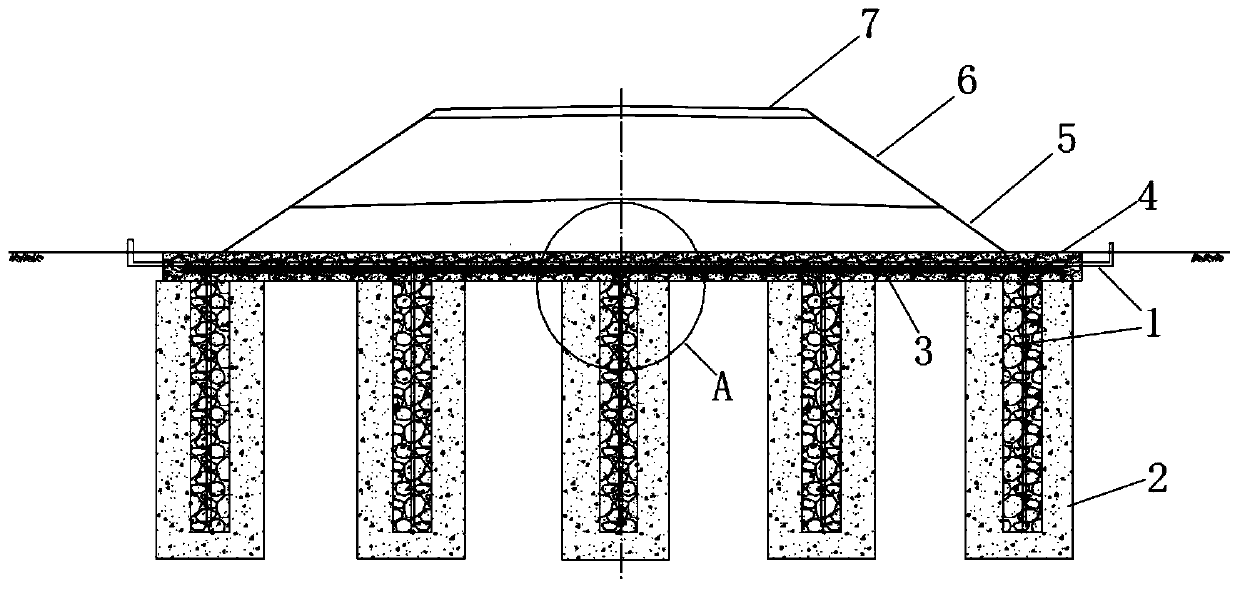

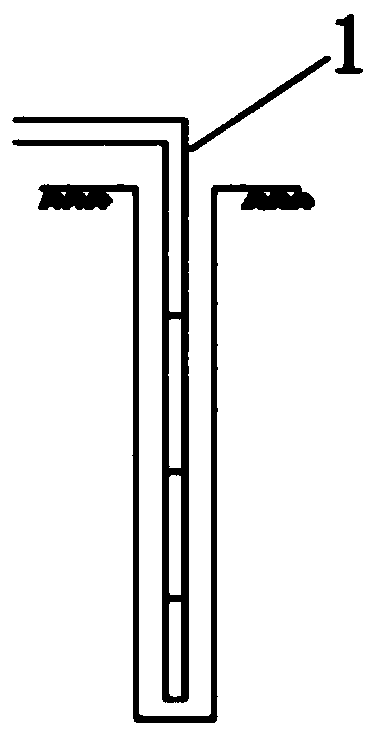

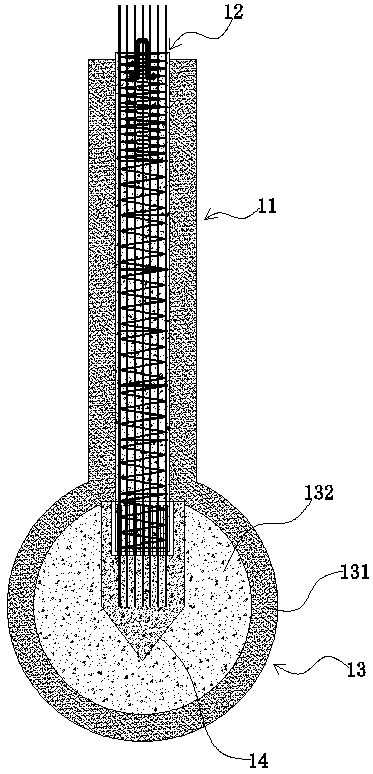

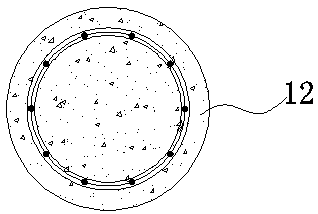

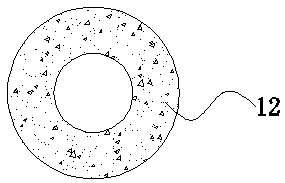

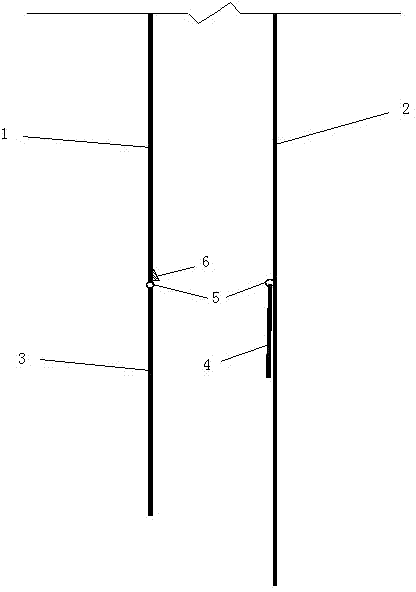

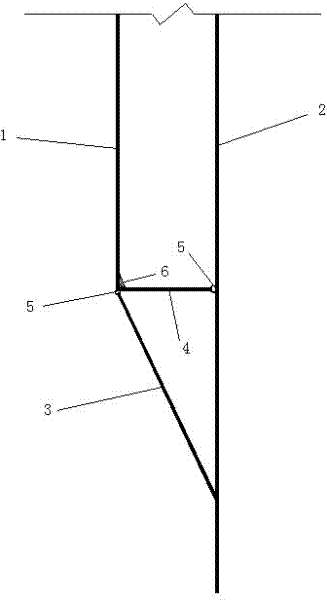

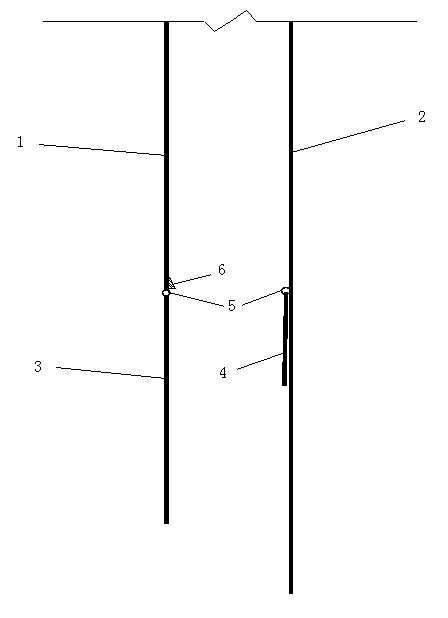

Hollow stiffness-core slurry-solidified discrete material pile and construction method thereof

ActiveCN102505684AImprove carrying capacityIncrease side frictionBulkheads/pilesCement slurryPrecast concrete

The invention discloses a hollow stiffness-core slurry-solidified discrete material pile and a construction method thereof. The periphery of a pile body is a slurry-solidified discrete material pile. The center of the pile body is a small-diameter prefabricated concrete pipe pile. Slurry filling holes are left on the pile wall of the prefabricated concrete pipe pile at intervals. Slurry enters discrete materials through holes in the middle of the concrete pipe pile and the slurry filling holes. Peripheral discrete materials are integrally cemented and solidified through cement slurry. At the same time, under the effect of slurry filling pressure, the slurry seeps into pile periphery soil bodies and the strength of the pile periphery soil is improved; the slurry fills the holes in the middle of the concrete pipe pile; and a prefabricated pipe pile can be formed by multiple sections which can be connected through bolts. The construction method comprises technical steps of: forming holes, placing the pipe pile, installing a sealing cover and a slurry filling pump, washing the holes by using clean wash, putting the discrete materials, filling the slurry, solidifying, forming the pile and the like. The hollow stiffness-core slurry-solidified discrete material pile and the construction method have the advantages that the construction processes are clear, the construction speed is fast, the pile forming effect is good, the bearing capacity is high, the manufacturing cost is low, the resources are fully utilized, the environment is protected and the energy is saved.

Owner:HOHAI UNIV

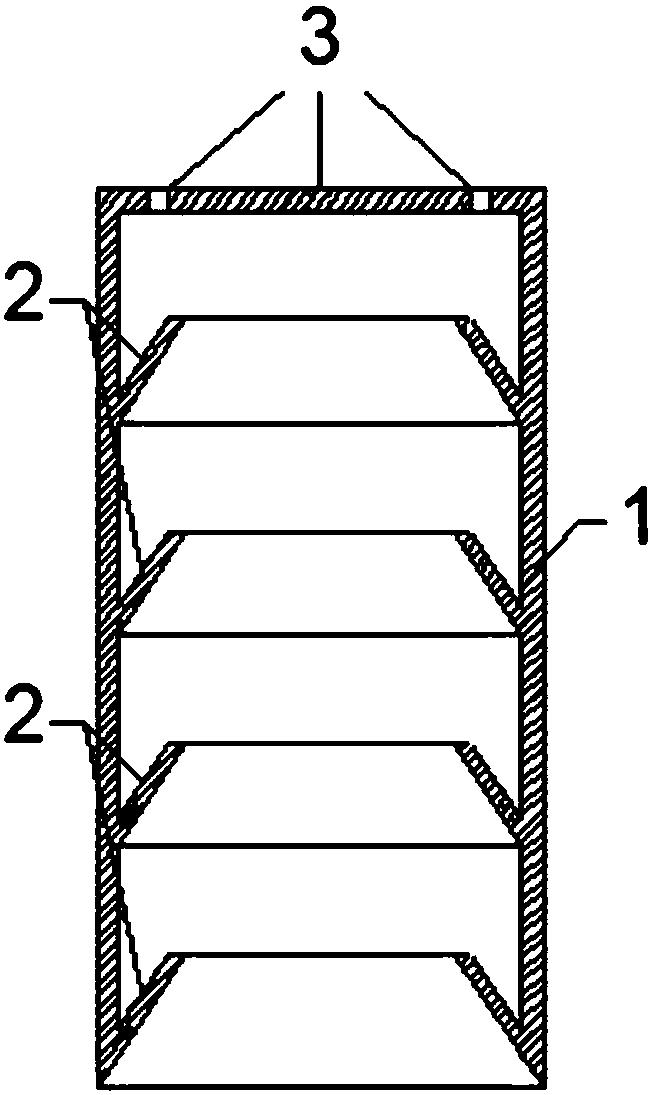

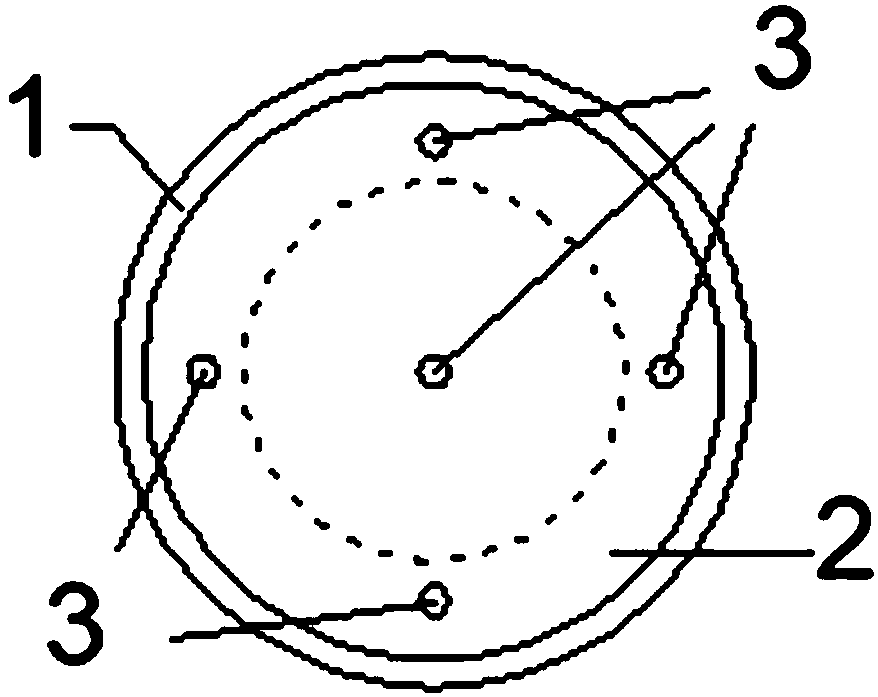

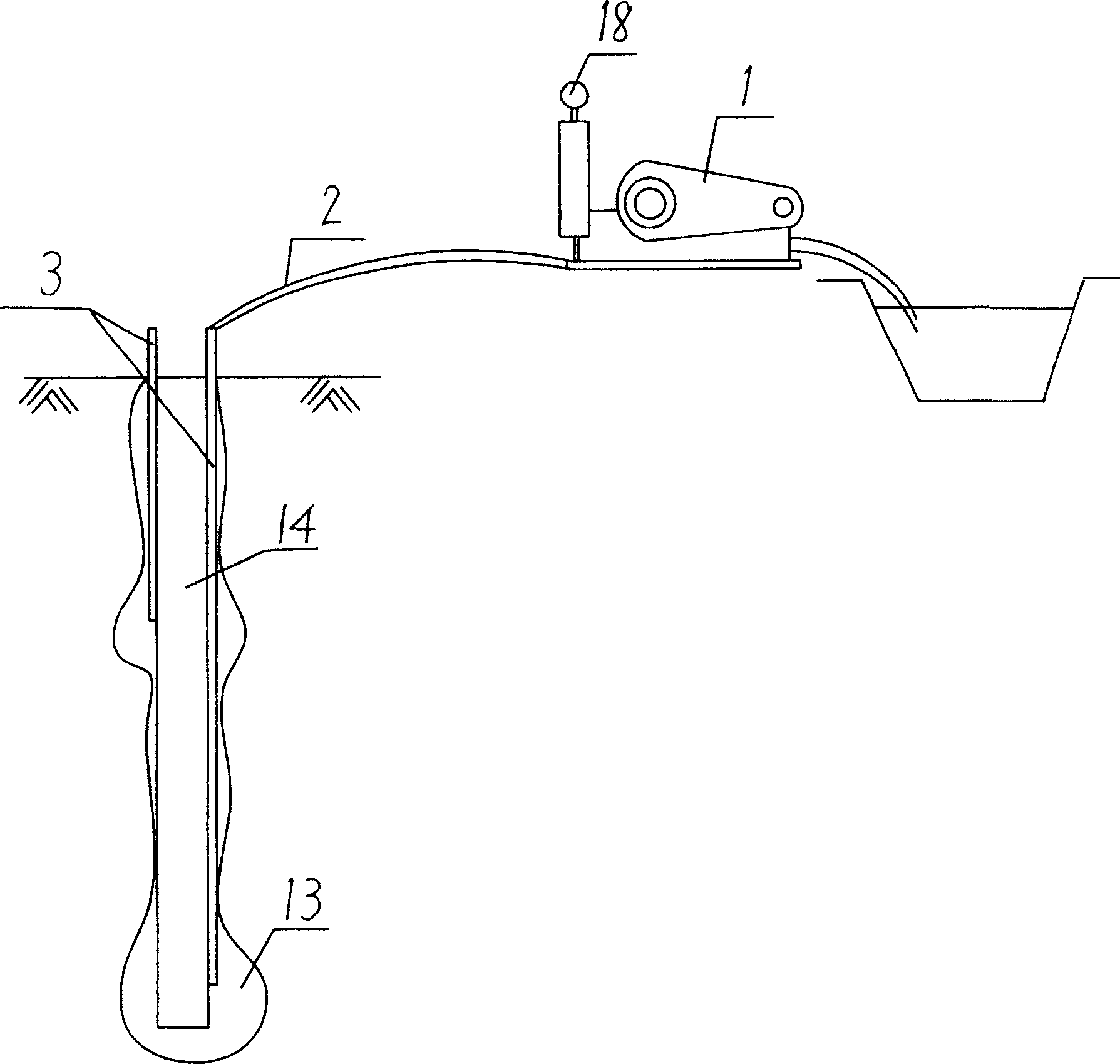

Inner ring type seabed suction anchor for deep sea and installation method thereof

ActiveCN108425379AReduce resistanceReduce construction costsFoundation engineeringSuction stressSea waves

The invention discloses an inner ring type seabed suction anchor for deep sea and an installation method thereof. The suction anchor comprises a suction main barrel, the suction main barrel is of a barrel type structure of which the bottom is opened and the top end is closed, the inner wall of the suction main barrel is provided with a plurality of hollow annular bulges at equal intervals along anaxial direction, the inner wall of the suction main barrel and the side walls of the hollow annular bulges form a barb-shaped structure, and the center and the edges of the top of the suction main barrel are provided with drainage holes. The suction anchor can more smoothly sink and penetrate into the soil, can sink to the preset design depth, reduces the disturbance to the soil outside the barrel to the maximum extent under the effect of increasing side friction resistance, and reduces the erosion of sea waves on existing foundations; the vertical bearing capacity and the ultimate pull-out resistance bearing capacity of the suction anchor can be greatly improved under various working conditions; and under the condition of realizing the functions, the convenience of recycling the suctionanchor can also be ensured.

Owner:ZHEJIANG UNIV

Concrete long-core cement-soil composite pile building foundation treating method

InactiveCN1851154AIncrease stiffness ratioIncreased combined stiffnessBulkheads/pilesUltimate tensile strengthSediment

The invention is a concrete long-core cement combined pile building groundsill processing method, selecting load bearing value of a single pile according to the minimal value of the four bearable resistances of: 1. cement intensity damage; 2. groundsill soil intensity damage; 3. pile body combination intensity damage; and 4. upper-stage groundsill soil and core pile combination intensity damage, and selecting synthetically pile distance according 2.5 times combined pile diameter and >=4 times core pile diameter, where the combined pile diameter is 400mm-850mm and the combined pile length is 3m-25m and the extended length of the core pile is 2m-45m. And it merges concrete pile, cement blended pile, long- short pile processes into an organic whole, giving full play to their advantages, and having advantages of high bearing value, low sediment, simple and convenient device, reliable quality, etc, and especially applied to thick and soft soil groundsill processing.

Owner:饶之帆

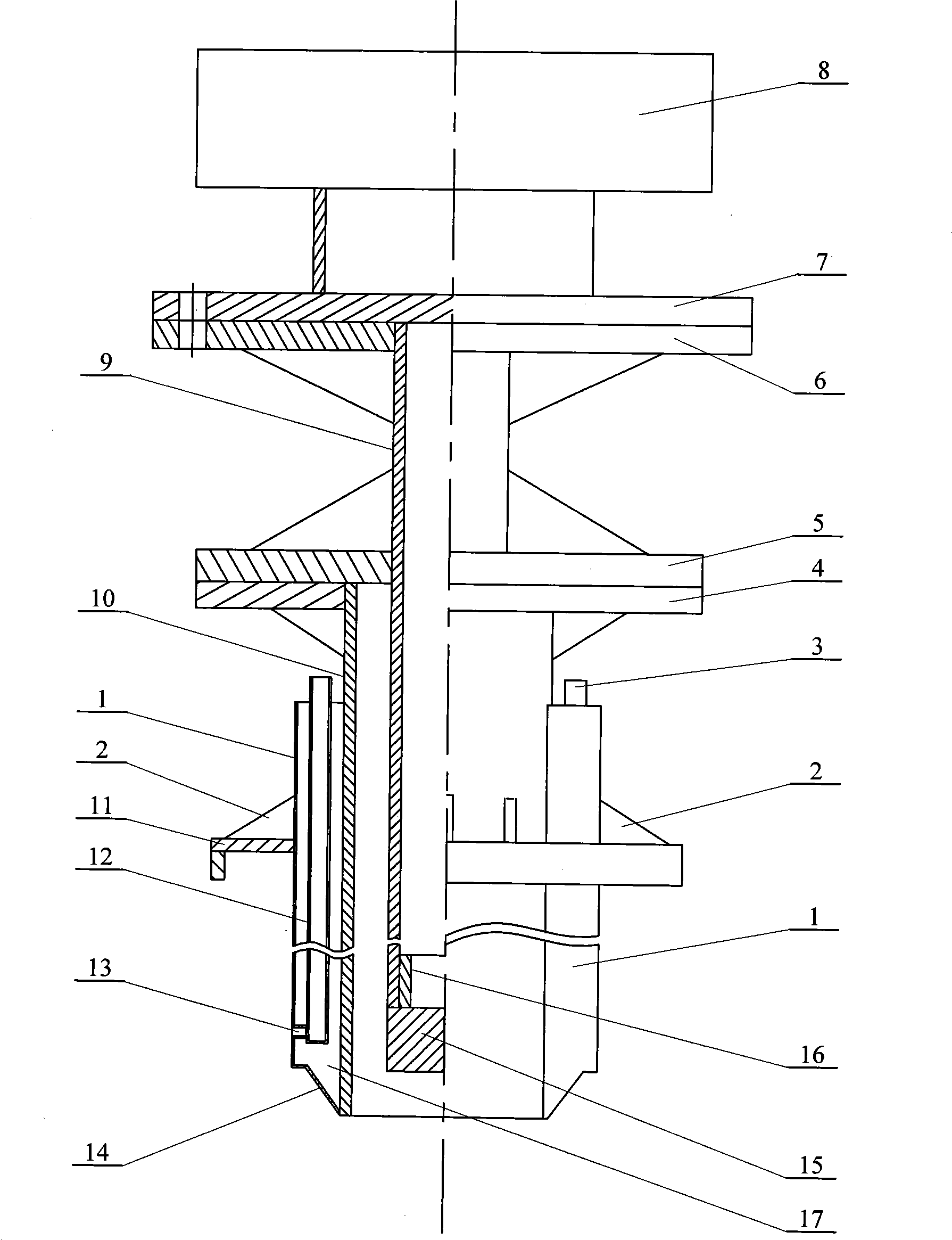

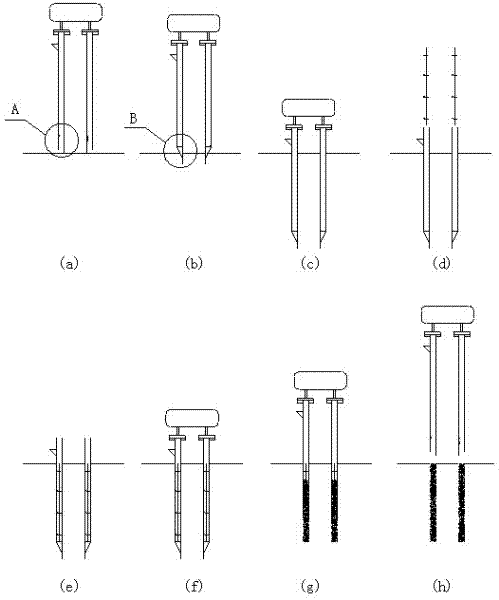

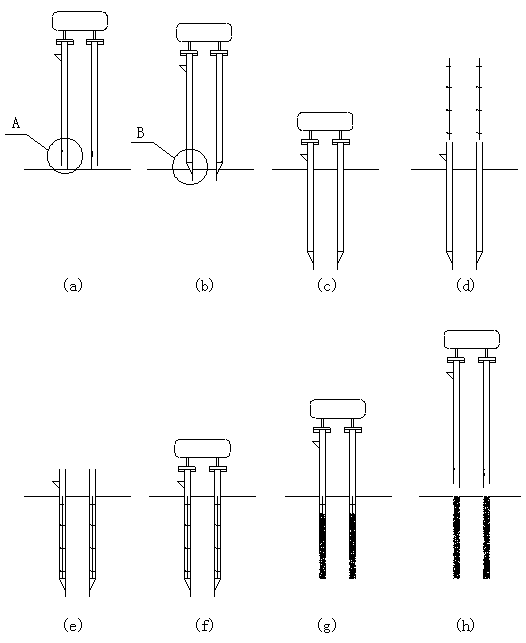

Concrete pile construction equipment and construction method thereof

The invention aims at providing construction equipment for a concrete pile. The construction equipment for the concrete pile comprises a protective cylinder, a heavy hammer, hoists, a chassis and a support and is characterized in that a large hoist and a small hoist are fixed on the chassis; the support is arranged at the front end of the chassis; a pulley is arranged at the upper end of the support; a steel wire rope in the large hoist penetrates pulleys at the tops ends of the support and the heavy hammer to drive the heavy hammer to rise and fall; a steel wire rope in the small-power hoist penetrates the support pulley and a reversing device to drive the protective cylinder to rise and fall; the upper end of the protective cylinder is provided with a perpendicularity control device, a padding opening and a vibration device. The invention also comprises a construction method adopting the concrete pile. The construction method adopting the concrete pile comprises the following steps of (1) enabling equipment to be in position; (2) promoting the heavy hammer to impact and squeeze soil bodies sink into the protective cylinder after the soil bodies form into a pile hole; (3) repeatedly hammering a punching hole and sinking the protective cylinder to the designed depth; (4) performing pile tip processing through one method of a plurality of methods according to the soil layer characteristics and the upper portion loading requirement; (5) constructing a pile body through one method of a plurality of methods.

Owner:王继忠 +1

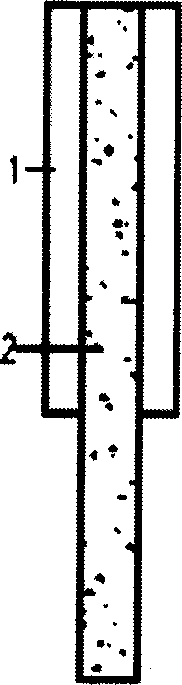

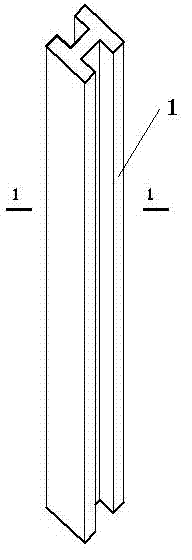

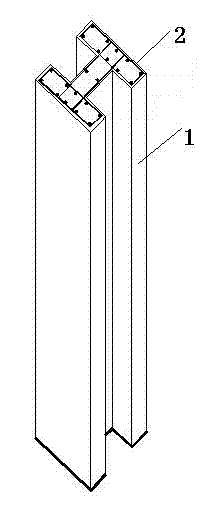

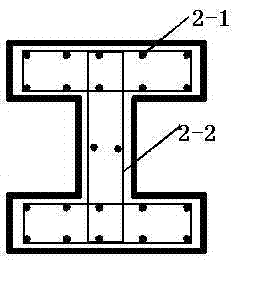

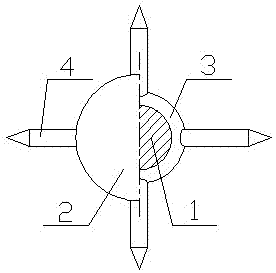

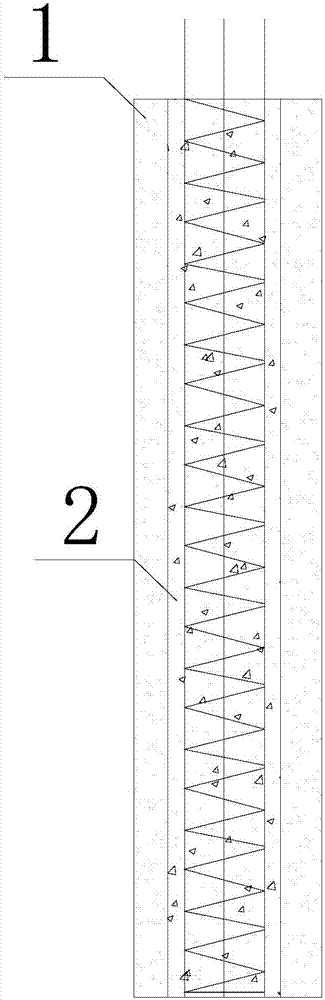

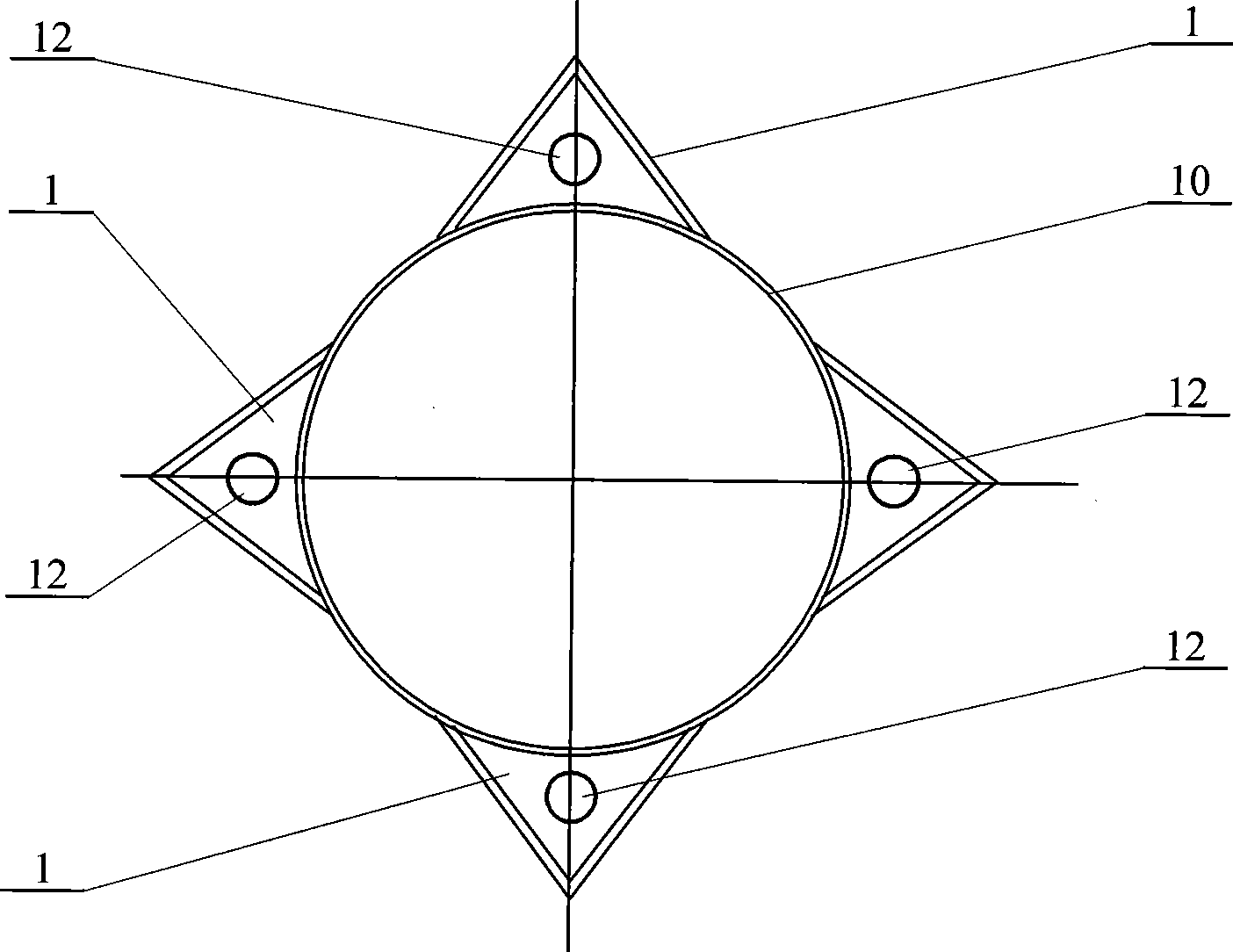

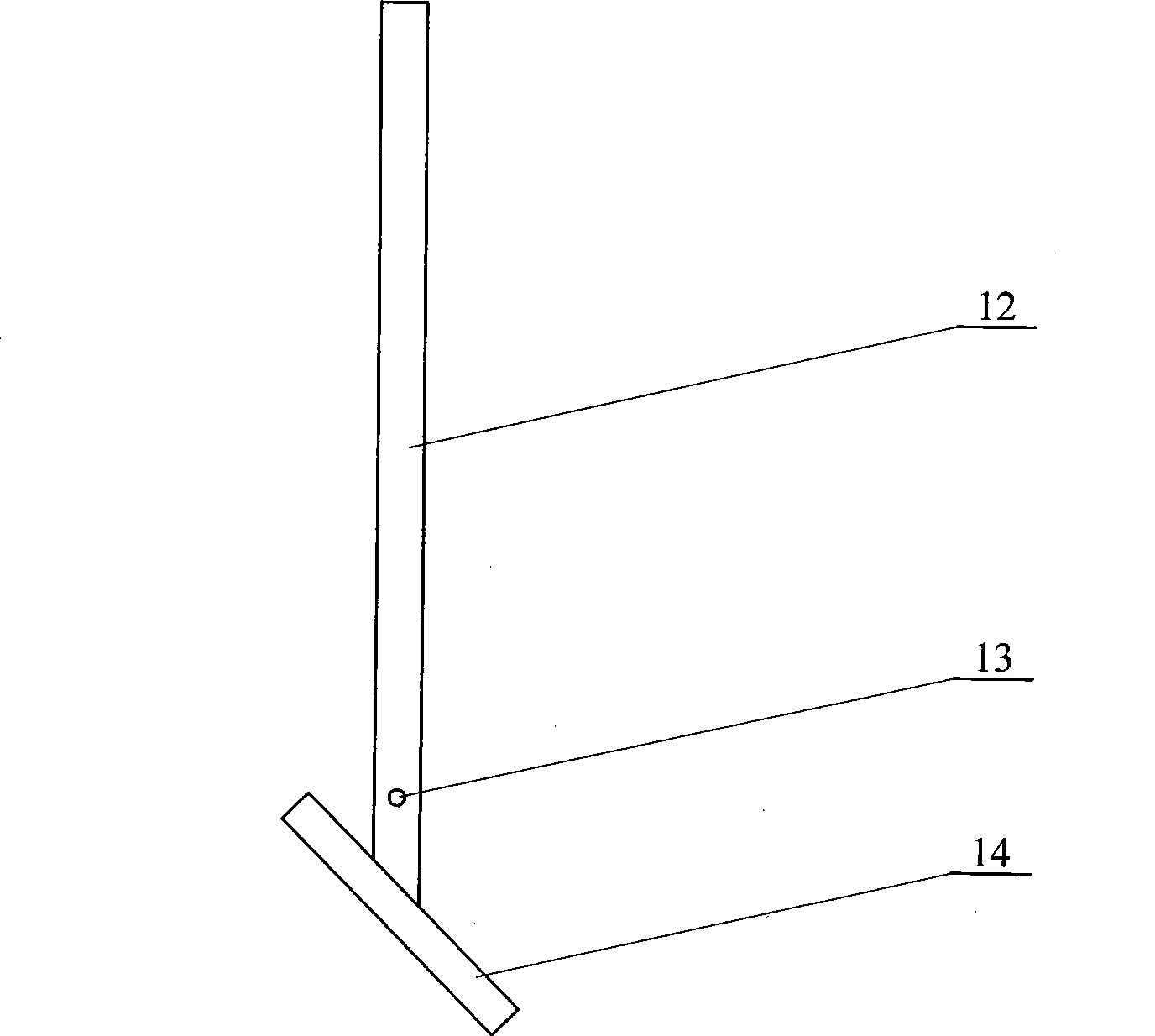

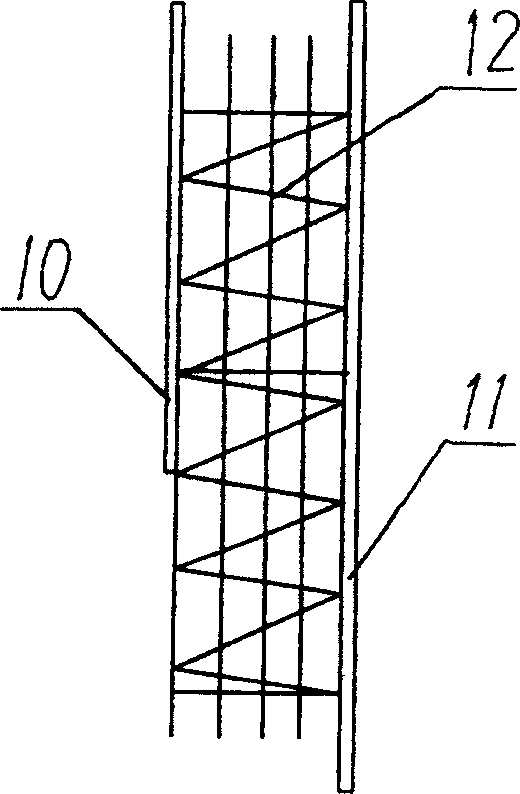

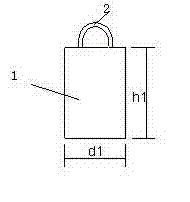

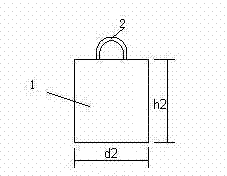

Prefabricated concrete irregular-shaped pile

InactiveCN102776880AImprove bearing capacityImprove shear resistanceBulkheads/pilesManufacturing technologyArchitectural engineering

The invention discloses a prefabricated concrete irregular-shaped pile, which comprises a concrete pile body (1) and is characterized in that the outer outline of the cross section of the concrete pile body (1) is H-shaped or T-shaped, a reinforcement cage (2) is arranged in the concrete pile body (1), the outer outline of the cross section of the reinforcement cage (2) is H-shaped or T-shaped, and the reinforcement cage (2) is composed of a framework main reinforcement (2-1) and a stirrup (2-2). The prefabricated concrete irregular-shaped pile is simple in manufacturing technology, superior in application performance, good in anti-shearing, anti-bending, anti-pulling and anti-pressing performances, simple in manufacturing, material-saving, economical, wide in application range, and good in market prospect.

Owner:占昌成

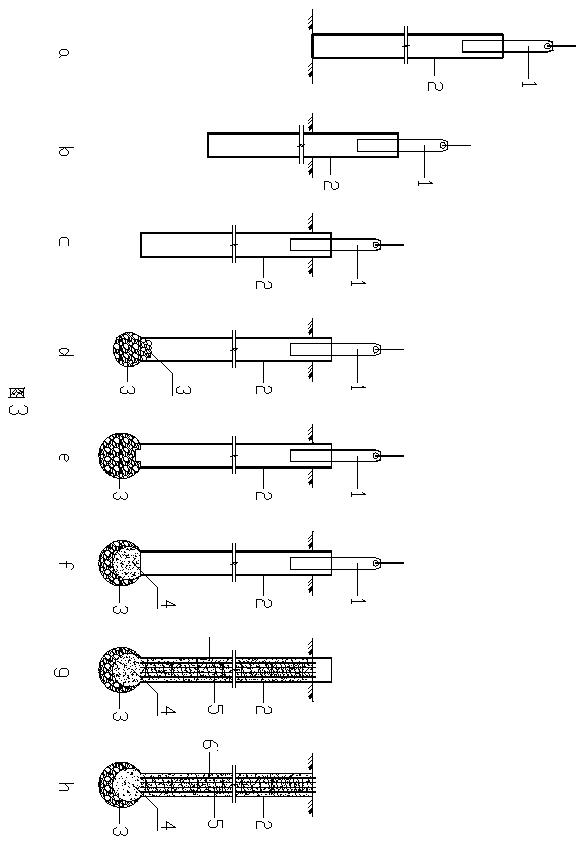

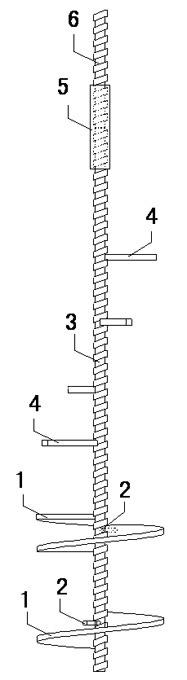

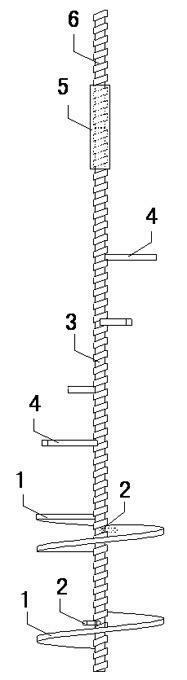

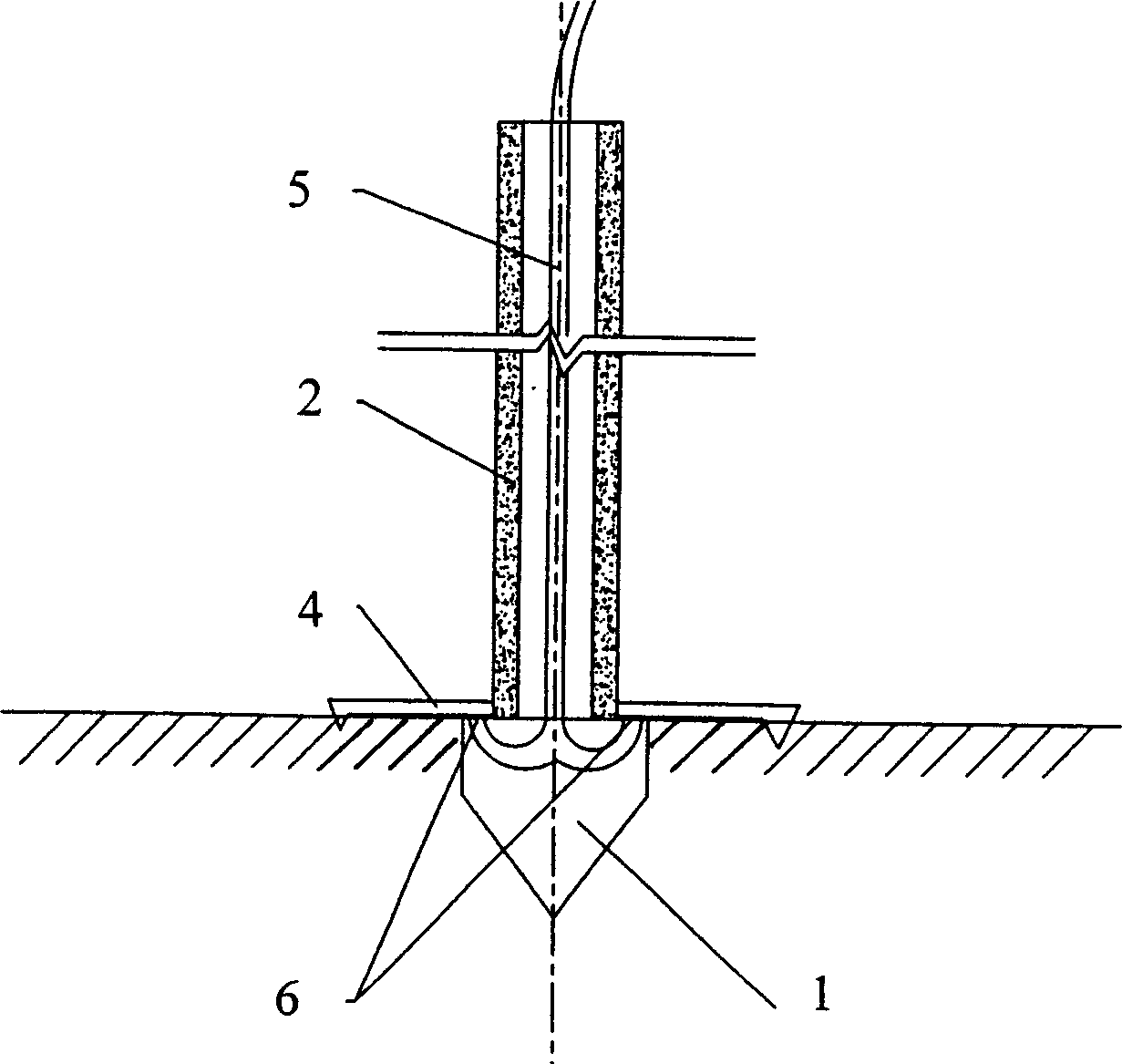

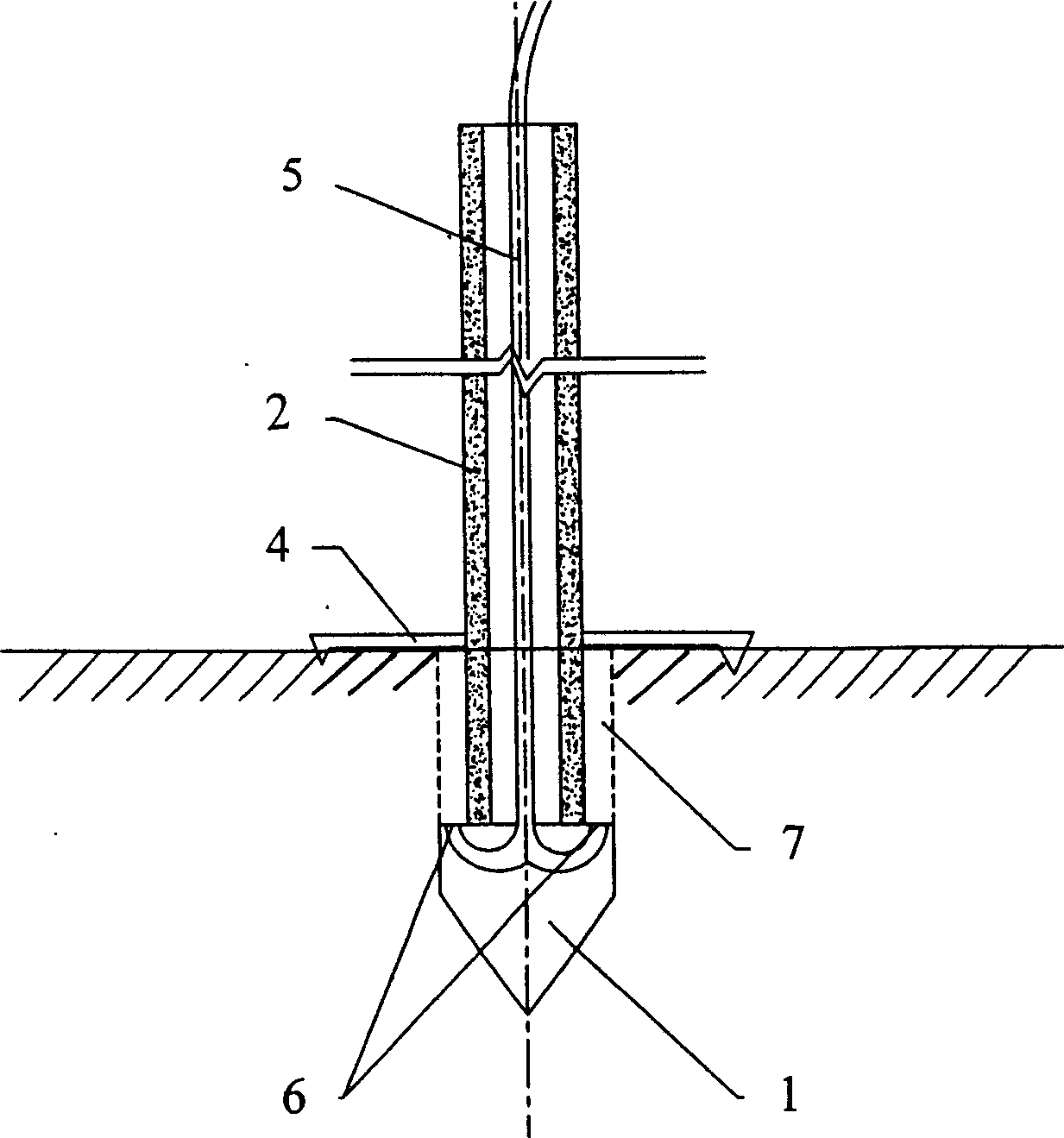

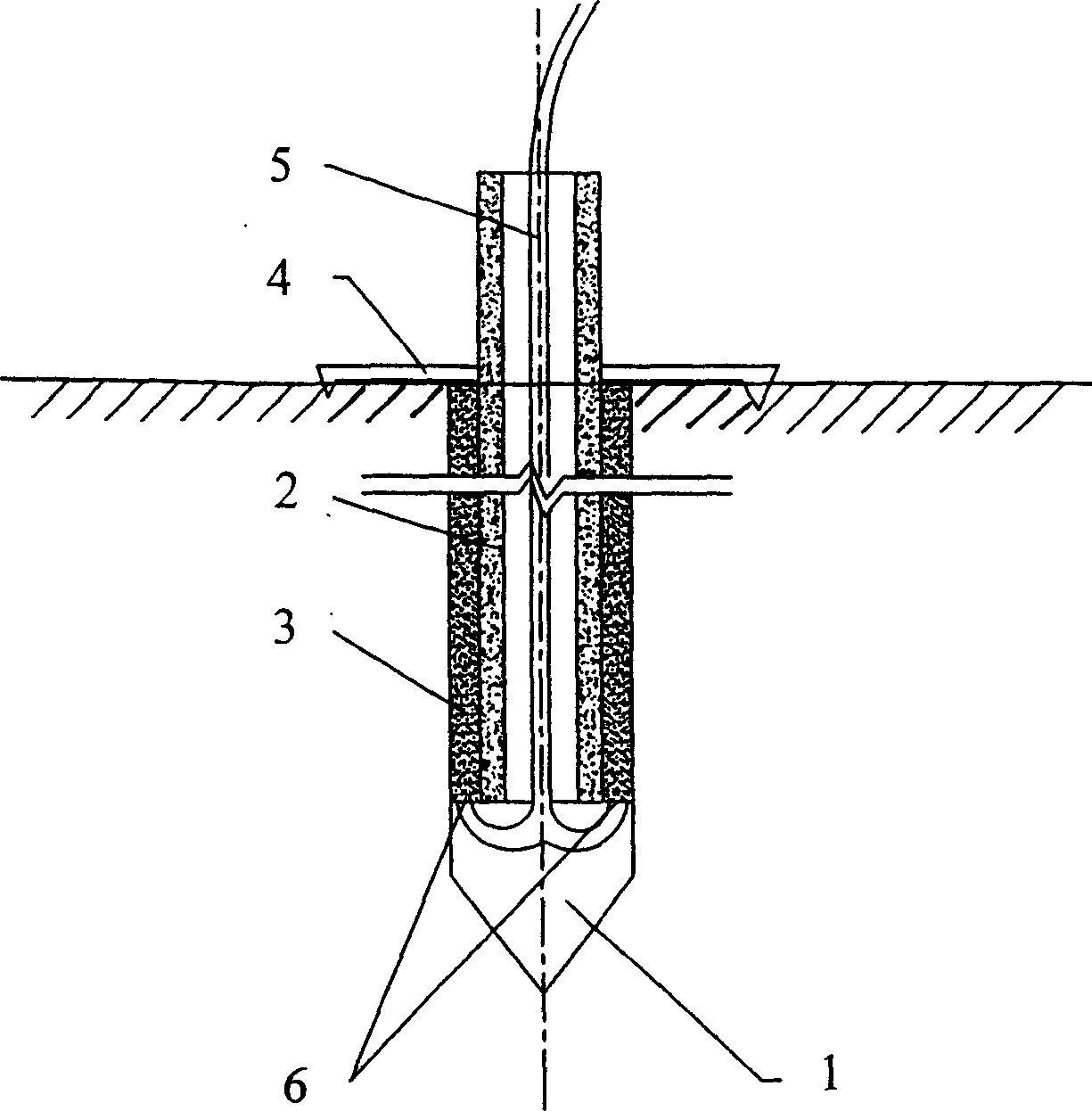

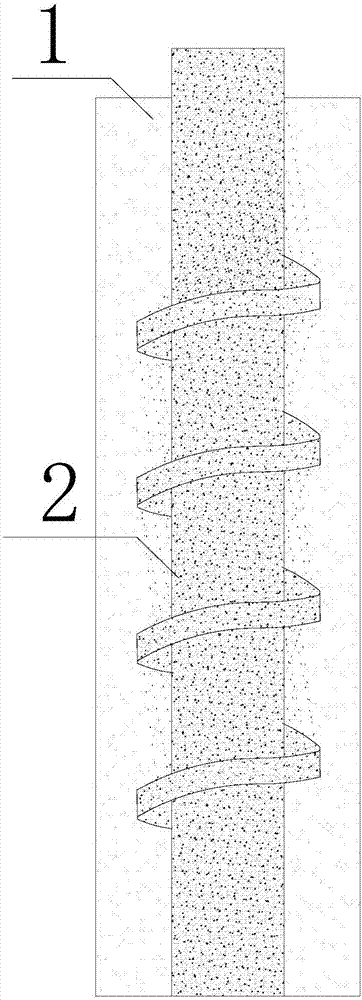

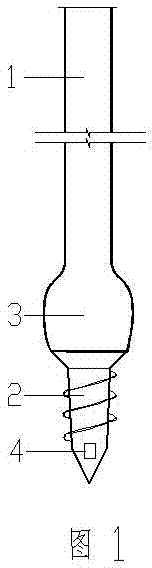

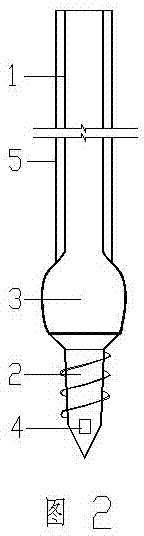

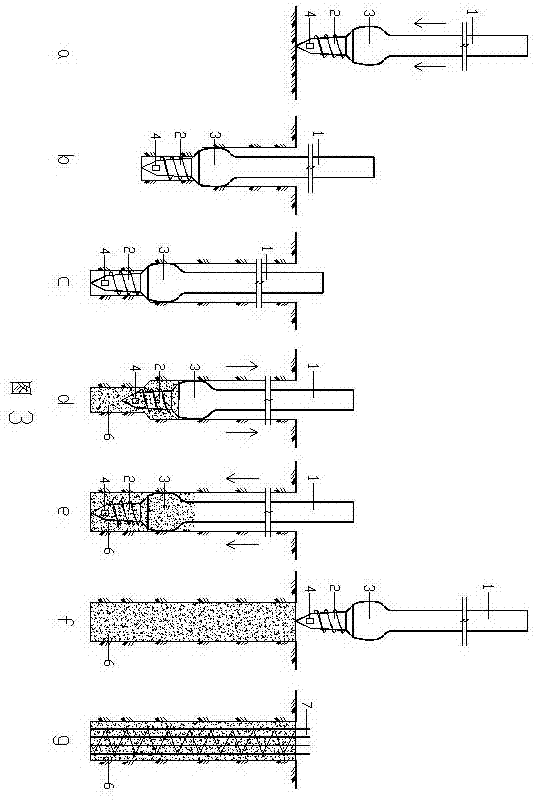

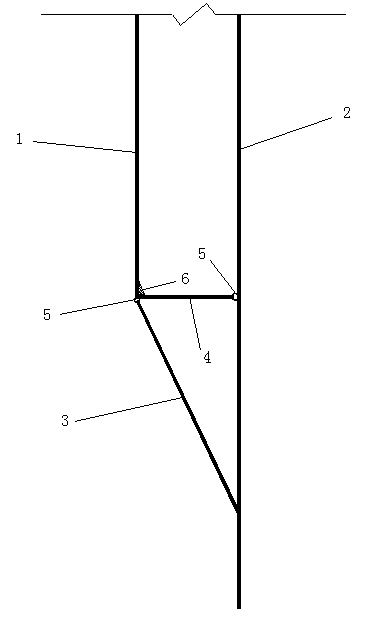

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

Root pressure grouting pile and construction method thereof

InactiveCN103205965AIncrease side frictionIncrease the bearing areaBulkheads/pilesRoot pressureSupporting wall

The invention discloses a root pressure grouting pile comprising a cylindrical pile foundation, wherein the root pressure grouting pile further comprises a bearing platform surface arranged on the top of the cylindrical pile foundation, and a plurality of root keys are arranged on the cylindrical surface of the pile foundation; or concentrically projecting support disks are arranged on the cylindrical surface of the pile foundation, and the plurality of root keys are connected with the support disks. The construction method comprises the following steps of: firstly, digging the earthwork of a first segment of pile hole, and extruding the holes of the support disks after forming the first segment of pile hole; horizontally knocking the root keys out of the holes of the support disks, respectively, and reserving the inner ends of the root keys in the pile hole; building a supporting wall template along the side wall of the pile hole, and pouring supporting wall concrete; repeating the steps, circularly working downwards segment by segment until the depth of the pile hole reaches a required demand; and hanging a preformed pile foundation reinforcement cage in a supporting wall hole, and pouring the pile body of the pile foundation. Therefore, in the pile structure built by the invention, the stress area of the pile foundation is increased, the bearing pressure of the pile foundation is improved, the construction materials are few, the construction is convenient, and the construction cost is lowered.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

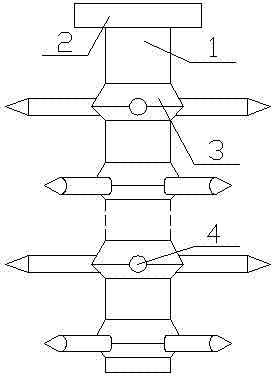

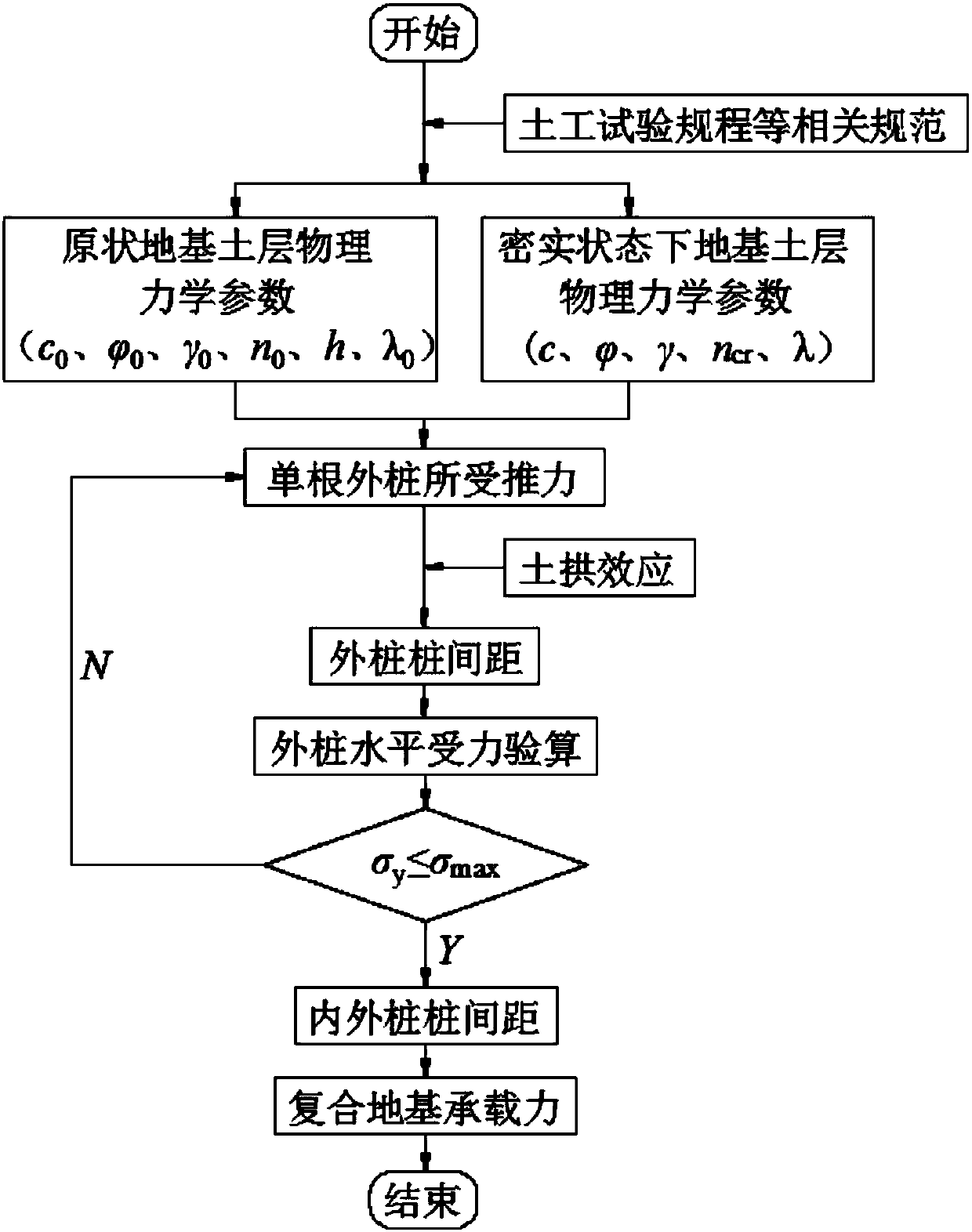

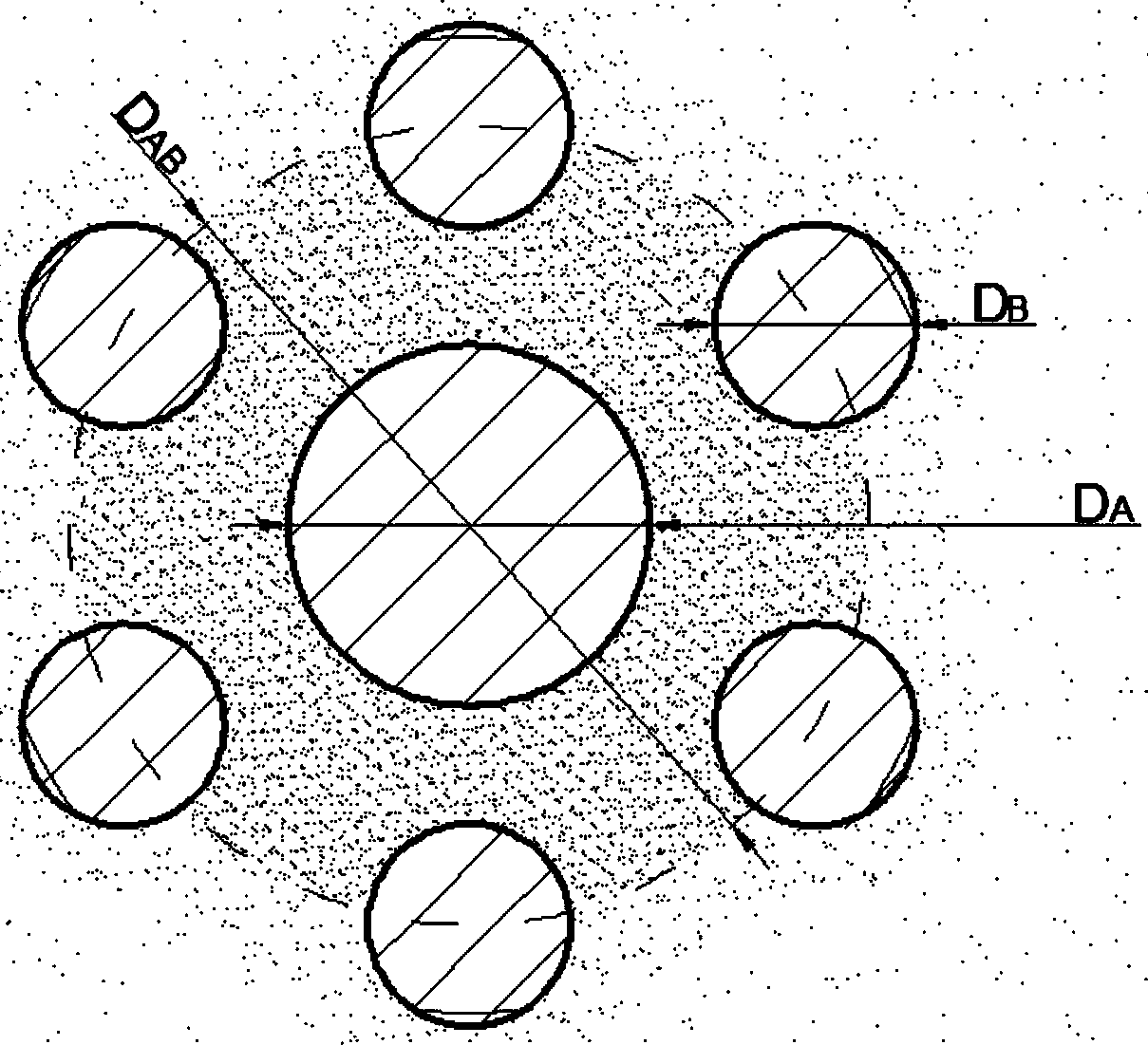

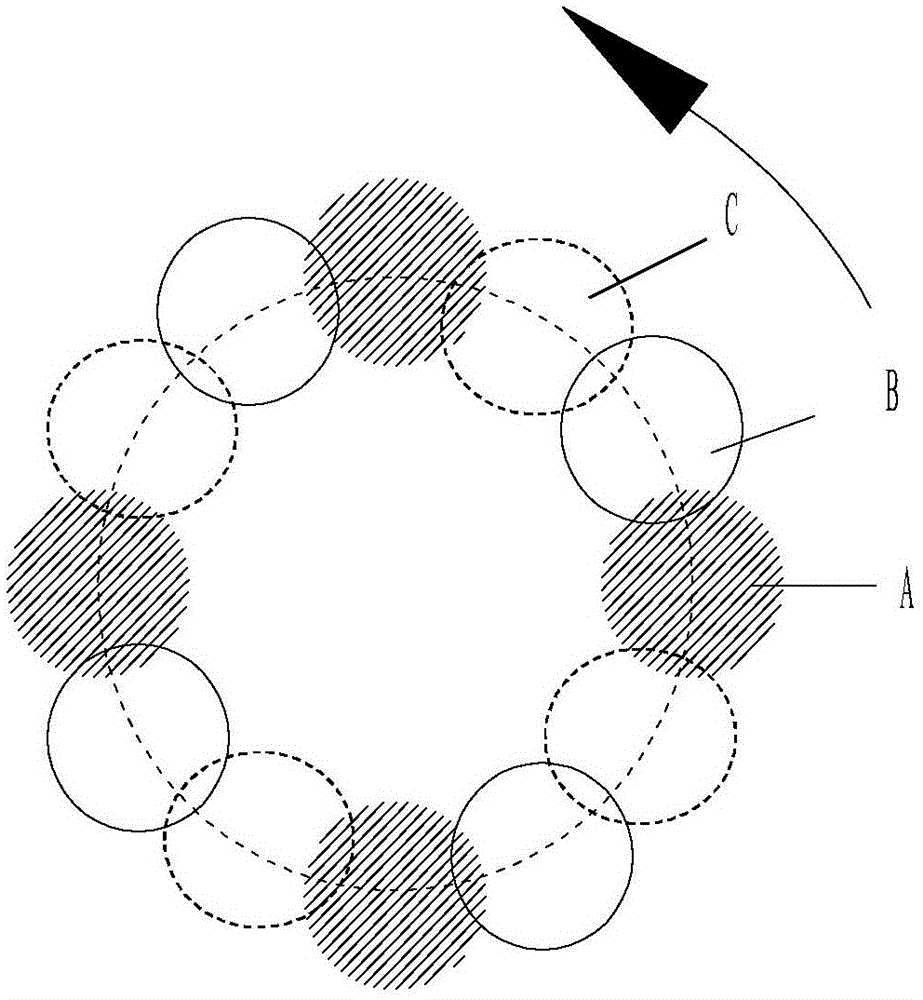

Pile arrangement method for friction pile groups and computing method of composite-foundation bearing capacity thereof

InactiveCN106991239AFully increase the carrying capacityIncrease side frictionGeometric CADDesign optimisation/simulationHoopingStructure of the Earth

The invention relates to a pile arrangement method for friction pile groups and a computing method of composite-foundation bearing capacity thereof, and belongs to the application filed of bearing capacity of construction foundation and foundation reinforcement. Pile groups under one cushion cap are composed of an inner pile positioned at the center of the pile location and a plurality of outer piles around the inner pile, wherein the inner and outer piles are formed in the mode that solid preformed piles, tubular piles with closed lower ends, tube-sinking cast-in-situ piles and other driven piles are disposed with the methods of hammering, vibratory injection, pressfit and the like, and the inner and outer piles confirm the bearing capacity of pile group composite foundations by measuring various kinds of parameters. The pile arrangement method for friction pile groups and the computing method of composite-foundation bearing capacity thereof, have the advantages that as for the foundation with large areas of loose cohesionless soils, the composite foundation bearing capacity outside and inside the pile group structures is enhanced as much as possible within a local range, without a requirement of disposing the whole foundation soils, thereby lowering difficulties of construction, shortening construction periods and improving economical efficiency; by the means of squeezing effect of piles and hooping effects of the outer piles, the soils between piles are compacted tightly and the internal bearing capacity of the soils are fully exerted, thereby making the inner piles, soils between piles and outer piles work together as a whole.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

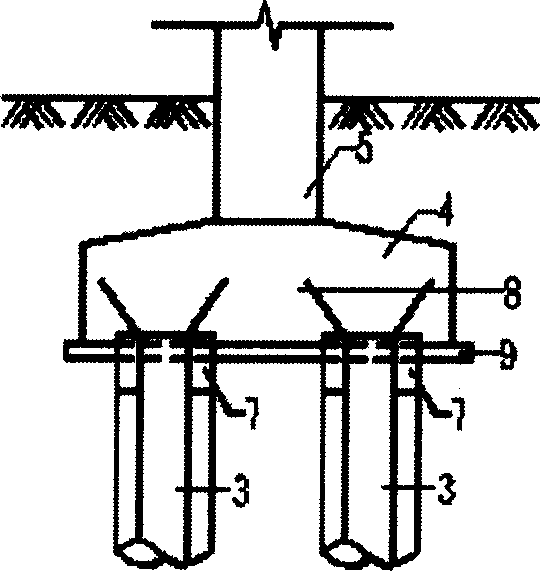

Method for construction of large head expanding combined pile

InactiveCN1793524AIncrease side frictionPlay the role of expanding the holeBulkheads/pilesGuide tubeBearing capacity

The invention discloses a big-end expansion composite pile construction method. The hole enlarging big end pile squeezes earth body to form annular pile hole around the core pile in pile sinking. Before it closes, the filling is topping up by filling guide tube to form loop type outer pack pile. The big end pile is enlarged hole to increase end bearing of core pile. The outer pack pile can increase its lateral friction resistance to increase bearing. The construction is convenient. And the pile forming quality is reliable. The composite pile can greatly increase bearing, and reduce cost. It can be applied to various constructions of drawing resistant, loading pile foundation, composite foundation, deep foundation pit supporting and anti-seep.

Owner:雷玉华

Pile forming method for submerged orifice impact jet grouting composite pile

InactiveCN107023002AIncrease side frictionIncrease end resistanceBulkheads/pilesStructural engineeringHigh pressure

The invention provides a pile forming method for a submerged orifice impact jet grouting composite pile. The pile forming method for the submerged orifice impact jet grouting composite pile comprises the following steps that A, a cement soil outer pile is formed by the adoption of a submerged orifice impact high-pressure jet grouting pile construction process; and B, then a core pile is arranged in the cement soil outer pile, and the submerged orifice impact jet grounding composite pile is formed, wherein the core pile is a grouting pile or a cement soil prefabricated pile or a steel pile. The pile forming method is suitable for general stratums such as cohesive soil, floury soil and sandy soil and also suitable for complex stratums such as muddy soil, grait, gravel, boulder, ripraps and artificial land reclamation regions. The submerged orifice impact jet grouting composite pile can be used as a compressive pile or an uplift pile in a pile foundation and also can be used as a strengthened body of a composite ground foundation or a support pile in foundation pit engineering.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

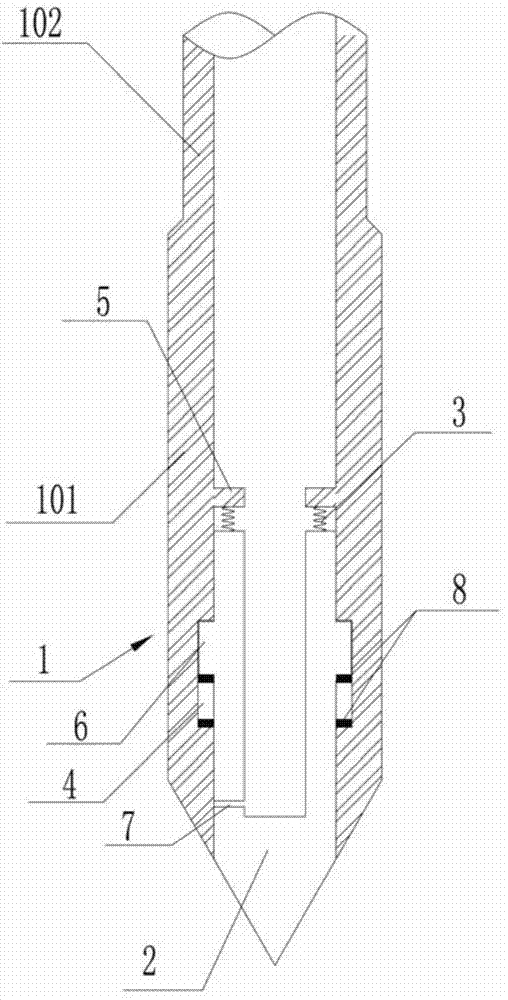

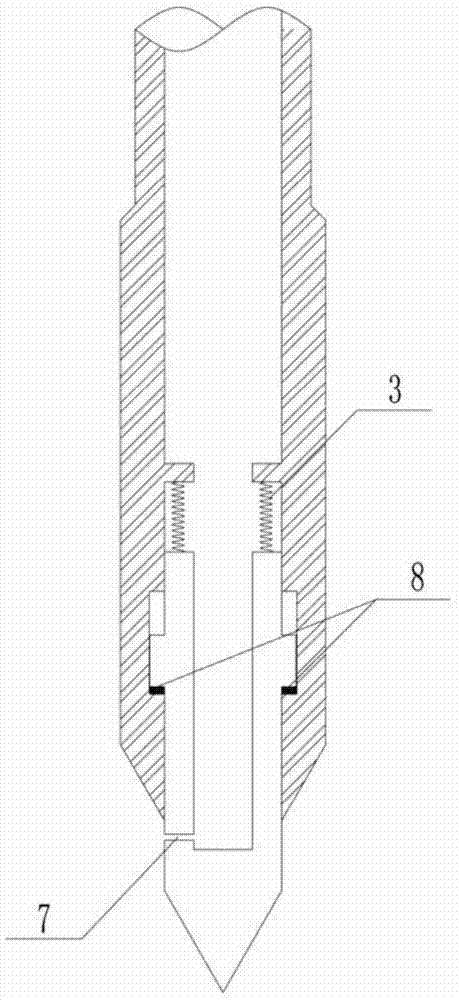

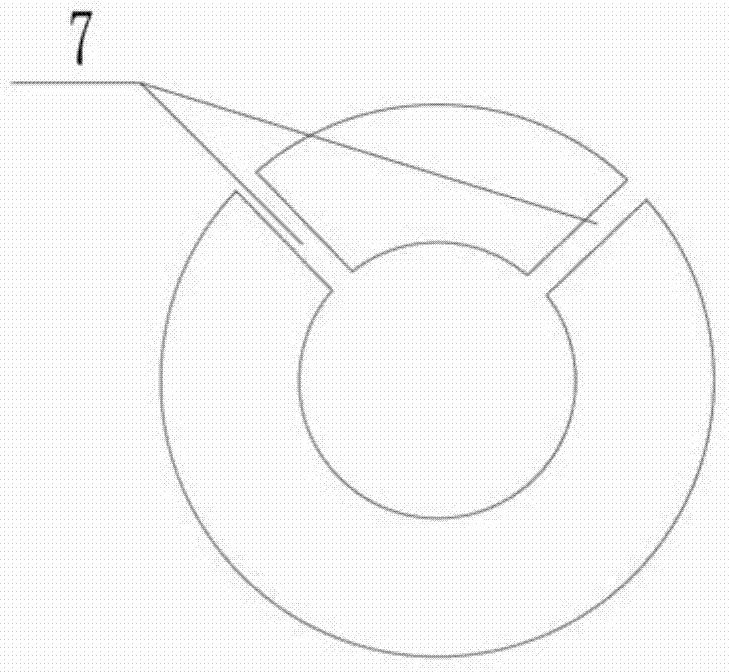

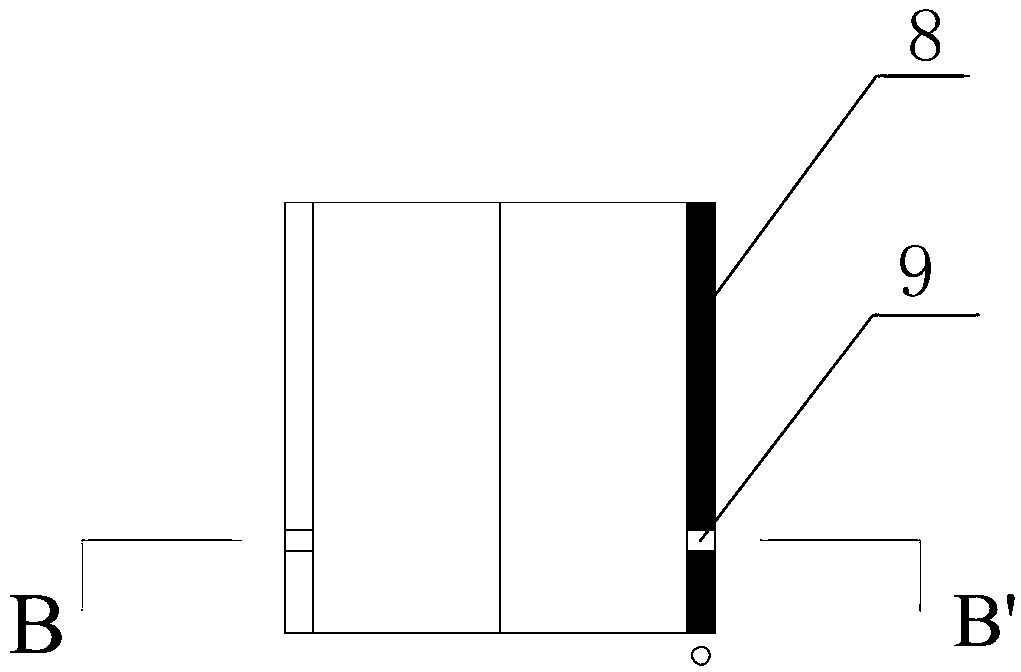

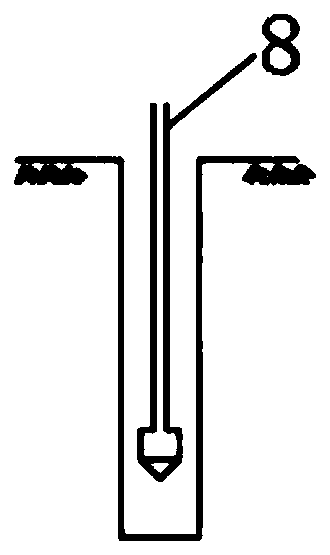

Rear side grouting device for pile

ActiveCN104514221AIncrease contact areaIncrease resistanceFoundation engineeringEngineeringHigh pressure

The invention discloses a rear side grouting device for a pile, which comprises a grouting pipe, a grouting head and a spring, the outlet end of the grouting pipe is a truncated cone, the side wall of an inner cavity of the grouting pipe is provided with an annular clamping slot and a baffle ring, the head portion of the grouting head is a cone, the tail portion of the grouting head stretches into the grouting pipe from the outlet of the grouting pipe, the outer side wall of the grouting pipe is provided with a grouting hole and an edge clamping ring, the clamping ring is embedded into the annular clamping slot, one end of the spring abuts against the baffle ring, the other end of the spring abuts against the tail portion of the grouting head, the head portion of the grouting head is sealed, a hollow cavity is formed inside the grouting head, the hollow cavity is communicated with the grouting hole, and penetrates the tail portion of the grouting head; during grouting, a high polymer grouting material enters the cavity of the grouting head via the inner cavity of the grouting pipe under the action of high pressure, and is erupted via the grouting hole to form high-pressure jet flow. The rear side grouting device has stronger operability, wider applicability, more remarkable grouting effect, and higher reliability, does not need be pre-buried in a pile body, and does not generate any damage and influence on the original pile body.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

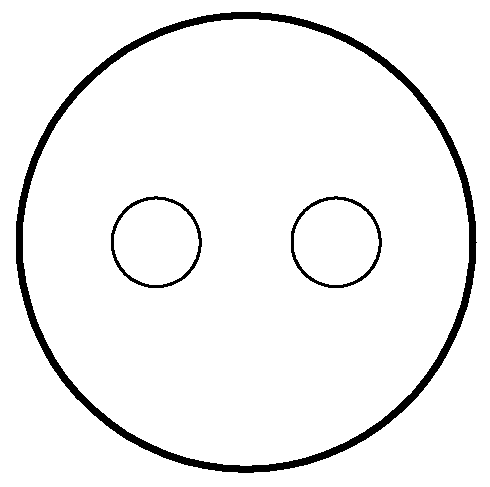

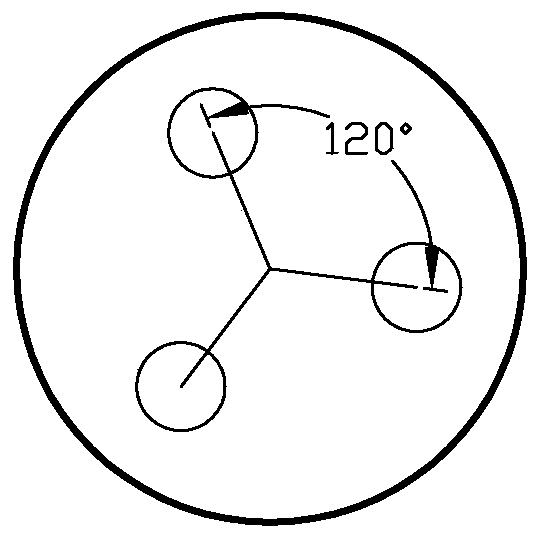

Manual hole digging pile and construction method thereof

ActiveCN103233464AImprove bearing capacityReduce load capacityBulkheads/pilesEngineeringUltimate tensile strength

The invention discloses a manual hole digging pile and a construction method thereof. The manual hole digging pile is characterized by comprising a cylinder-shaped trunk pile body and a plurality of cylinder-shaped branch pile bodies. The branch pile bodies are fixedly distributed on the external wall of the trunk pile body and are distributed on a circumferencial section of the trunk pile body in a regular triangle way; a trunk spiral stirrup and a plurality of trunk force bearing ribs are arranged inside the trunk pile body; the trunk spiral stirrup is arranged on the inner wall of the trunk pile body along pile long spirals; the trunk force bearing ribs are uniformly distributed along the circumference of the inner surface of the trunk spiral stirrup; every branch pile body is provided with a branch spiral stirrup and a plurality of branch force bearing ribs; the branch force bearing ribs are arranged on the inner wall of every branch pile body along pile long spirals; a soil body which is corresponding to the trunk pile body is manually dug mainly in a cylinder-shaped trunk steel pile casing; and soil bodies which are corresponding to the branch pile bodies are manually dug mainly in cylinder-shaped branch steel pile casings. The manual hole digging pile and the construction method of the manual hole digging pile have the advantages of improving the side friction resistance, ultimate bearing capacity of the pile bodies and strength and stiffness of soil bodies around the pile and being capable of being widely applied to coastal soft soil areas.

Owner:宁波市产城生态建设集团有限公司

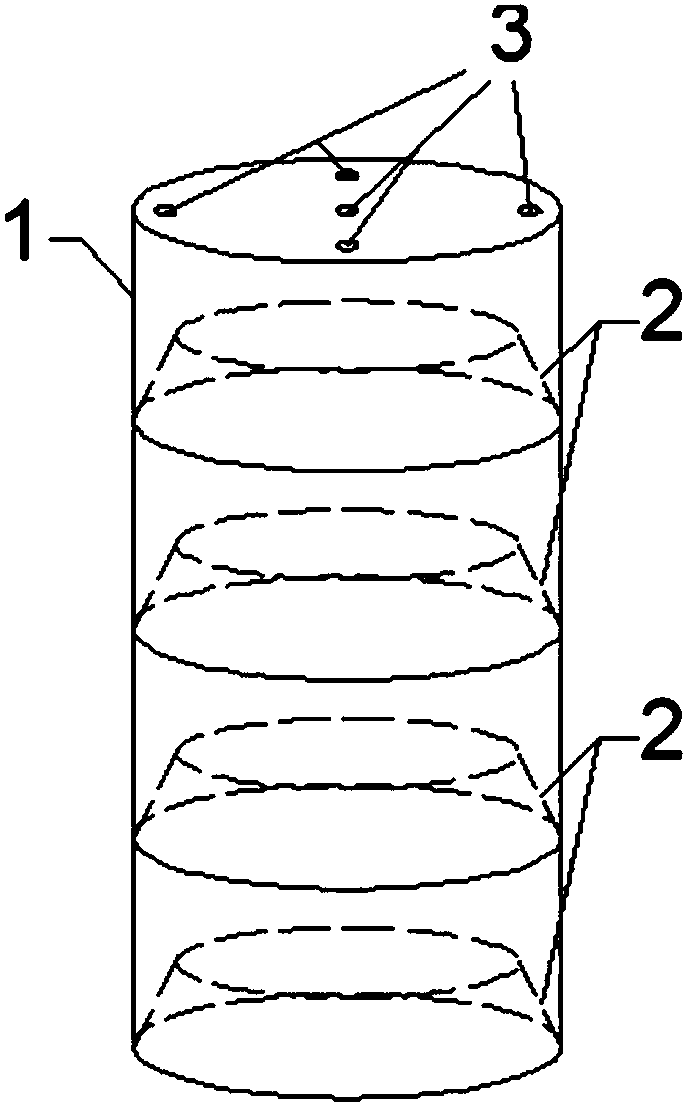

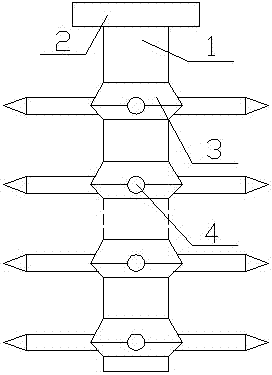

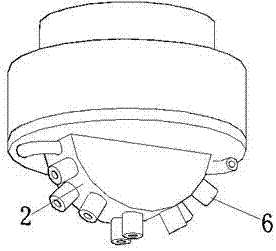

Deep-sea bamboo joint type suction anchor

ActiveCN107299645ALarge amount of waterBig impactArtificial islandsBulkheads/pilesJoints typesResistance force

The invention discloses a deep-sea bamboo joint type suction anchor. The deep-sea bamboo joint type suction anchor comprises a bamboo joint type anchor cylinder, a bearing and a rotatable nozzle. The bamboo joint type anchor cylinder is a cylinder body with an open bottom and a closed top. A plurality of convex bamboo-joint-shaped structures around the cylinder body are arranged at the middle upper portion of the cylinder body of the anchor cylinder at fixed intervals. The middle lower portion of the cylinder body of the anchor cylinder is in an expanded cylinder shape, and the external diameter of the expanded portion of the cylinder is larger than that of each bamboo-joint-shaped structure. A drainage hole communicated with the internal portion of the cylinder body is formed in a top cover of the anchor cylinder. The rotatable nozzle is located in the cylinder body, is connected with the inner wall of the top cover of the anchor cylinder through the bearing and is fixed to the circle center of the top cover of the bamboo joint type anchor cylinder, and therefore the needed suction anchor is formed. According to the suction anchor, side friction resistance force can be increased, it is ensured that the suction anchor can sink to a preset designed depth, and the vertical bearing capacity and ultimate anti-uplifting bearing capacity of the suction anchor are significantly improved.

Owner:OCEAN UNIV OF CHINA

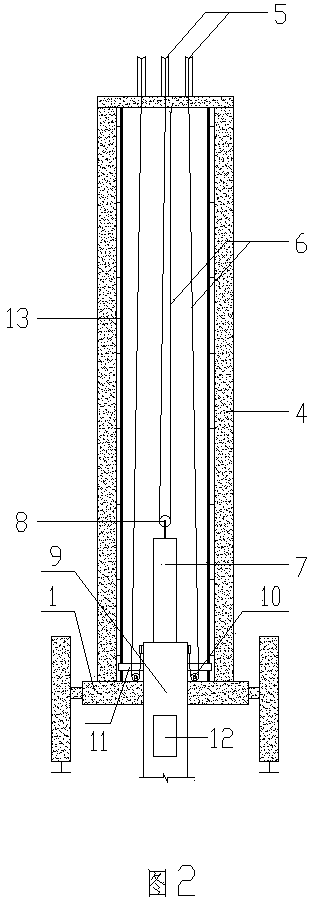

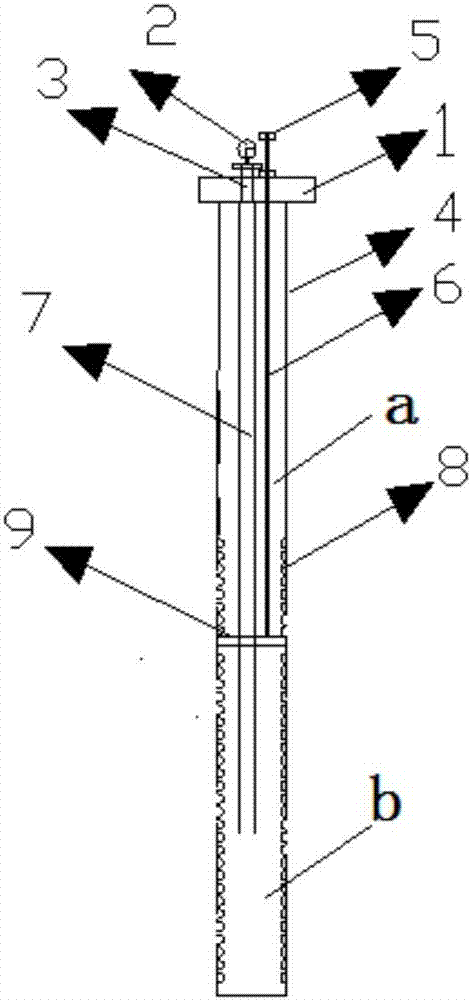

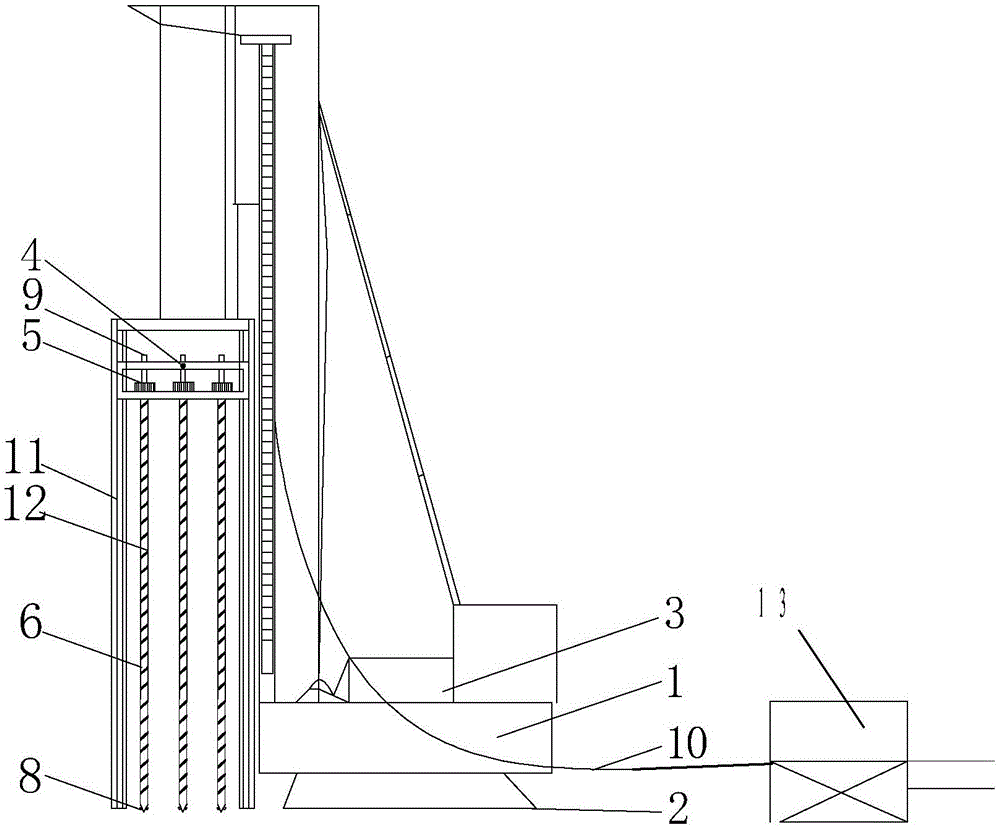

Pile forming apparatus and method for mud-jacking inner-ramming pedestal pile

The invention provides a pile-forming device for a grouting internal-ramming pedestal pile and a pile-forming method thereof, relating to a pile-forming device and a method. The device and the method aim at solving the problems that the existing internal-ramming pile has bad side friction and anti-pulling capability, is easy to generate the necking and breaking problem and has low construction efficiency. The injection pipe of the device is fixed in an external steel plate with a sealed cavity; the bottom end of the external steel plate with the sealed cavity is fixedly provided with a lower sealing plate with a sealed cavity; the invention is provided with four methods as follows: method one: an external pipe is impacted by a hammer, meanwhile, the grout is injected into the injection pipe by a pump, with the injection pressure of 0.3-10MPa; method two: an internal pipe is impacted by a diesel hammer, a hydraulic hammer or a vibration hammer and the filling material is impacted; method three: the external pipe and a pre-fabricated pile are impacted to a design depth by the diesel hammer, the hydraulic hammer or the vibration hammer; method four: the pre-fabricated pile is impacted into the pile hole, wherein, the diameter of the external pipe is less than or equal to the maximum internal tangent round of the pre-fabricating pile. The device has high construction efficiency and is suitable for various soil qualities. The method reduces the generation of necking and breaking, and improves the bearing capability by more than 30%.

Owner:李永刚

Bored pile foundation bearing stratum reinforcing and strengthening construction method

The invention relates to a bored pile foundation bearing stratum reinforcing and strengthening construction method. The bored pile foundation bearing stratum reinforcing and strengthening constructionmethod comprises the following steps that step one, grouting holes are drilled; step two, the grouting holes are cleaned; step three, grouts are prepared; step four, grouting is carried out; and stepfive, grouting hole openings are closed. Hole flushing carried out by adopting double-pipe high-pressure jet grouting is a key strengthening process, through high-pressure water flushing and cutting,soil in sediments, argillaceous contents in pile body separation segments and argillaceous contents in pile bottom fragmental intense weathering and weak intercalated layers can be flushed clean, andthe groutability of the grouts and the quality of induration are further improved, so that the bearing capacity of a sediment segment, pile bottom rock stratum fragments and weak intercalated layersis further improved; and in the grouting process, floral tubes are inserted into the grouting holes in a mode of floral tube grouting after rotary jet grouting is completed, and the problem that in the grouting hole forming, the pile tip soil body strength is reduced due to disturbance of soil around piles and the problem that water softening by soaking exacerbates the pile tip soil body strengthto be reduced during grouting hole cleaning are solved.

Owner:湖南化工地质工程勘察院有限责任公司

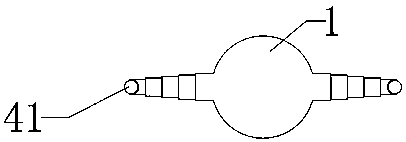

Large-diameter extension arm type steel pipe pile and construction method thereof

ActiveCN108797574AIncrease side frictionImprove bearing capacityBulkheads/pilesEngineeringFriction force

The invention relates to a large-diameter extension arm type steel pipe pile and a construction method thereof. The large-diameter extension arm type steel pipe pile comprises a pile body and a pile tip; the pile body is of a steel pipe structure; the pile tip is of a circular table structure; the bottom of the circular table structure is opened; the pile body and the pile tip are integrally formed; a partition plate is arranged in the pile body and divides an inner cavity of a pile body steel pipe into an upper cavity body and a lower cavity body; the upper cavity body and the lower cavity body are mutually independent; the pile body of the upper cavity body is connected with extension arms; the extension arms can stretch towards the outer side of the pile body and are inserted into a soil body; the extension arms are of hollow structures; one ends of the hollow structures are closed; the other ends of the extension arms are opened; the upper cavity body communicates with the hollow structures through openings; and the extension arms are perpendicular to the pile body. Side friction force and bearing force of the steel pipe pile are increased substantially, and the steel pipe pileis suitable for strengthening of a building foundation.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

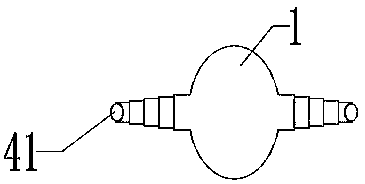

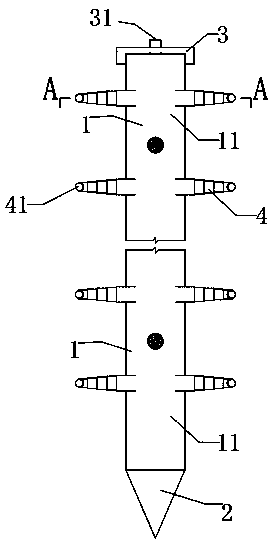

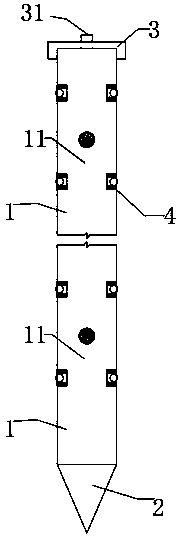

Steel pipe pile with telescopic arm and construction method thereof

ActiveCN108797573AIncrease side frictionImprove bearing capacityBulkheads/pilesSteel tubeBearing capacity

The invention relates to a steel pipe pile with a telescopic arm and a construction method thereof. The steel pipe pile comprises a pile body and a pile toe, wherein the pile body is of a steel pipe structure, the pile toe is of a bottom sealed cone structure, the pile body and the pile toe are integrally formed, the pile body is of a cavity structure inside, the telescopic arm which can stretch toward the outer side of the pile body and is inserted into a soil body is connected to the pile body, one end of the telescopic arm is closed while the other end of the telescopic arm is of an openedhollow structure, the cavity communicates to the hollow structure through the opening, and the telescopic arm is perpendicular to the pile body. The side friction and the bearing force of the steel pipe pile are improved greatly, so that the steel pipe pile is suitable for reinforcing a building foundation.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

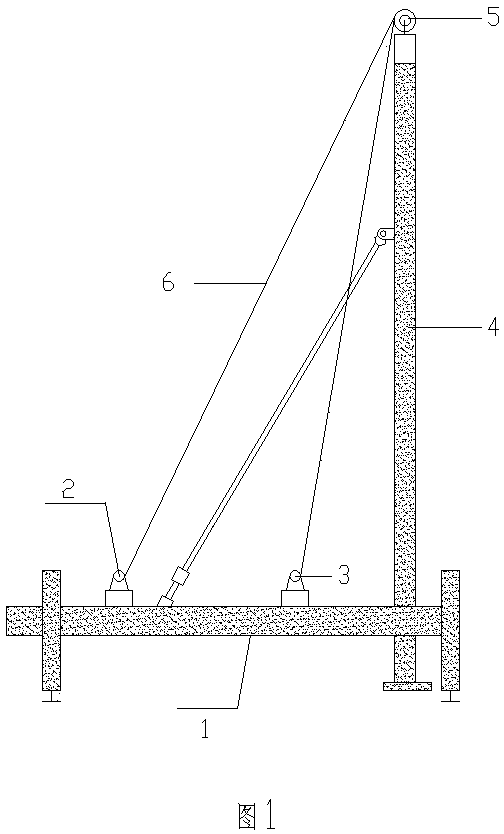

Construction device and method for building foundation

InactiveCN104763345ASpeed and Ergonomics ImprovementsIncrease side frictionDrill bitsDrilling rodsRebarSoil horizon

The invention provides a filing device for a building foundation, and provides a construction method through the device. The construction method has the advantages that the construction of hole forming, diameter expanding and concrete pressing and filling can be performed at a time; the diameter of a pile body can be increased while the original soil is utilized, so that the working efficiency is increased, and the cost is saved. The construction device comprises a drilling rod and a drill bit. The construction device is characterized in that the lower end of the drilling rod is connected with a diameter expanding body; the drill bit provided with spiral blades is connected to the lower end of the diameter expanding body; a hollow pipeline is arranged in the drilling rod and communicated with a discharging opening. The construction method comprises the steps of 1) aligning the drilling rod to a pile position; 2) rotating the drilling rod to synchronously rotate and drill the drill bit and the diameter expanding body, wherein the diameter of a pile hole can be expanded while the soil is extruded into the pile hole, and a backpressure is applied to in case of a hard soil layer; 3) continuing the operation of step 2) until reaching the design depth; 4) selecting one of the two modes to fill the concrete to the pile bottom; 5) continuing the operation of step 4) to form a concrete pile body; 6) reversely inserting a reinforcement cage in the concrete pile body, or paving a cushion layer on the surface of the pile top.

Owner:王继忠

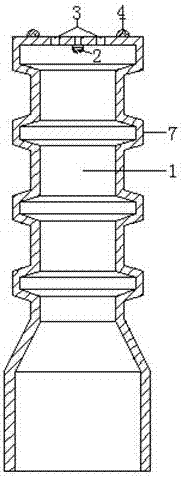

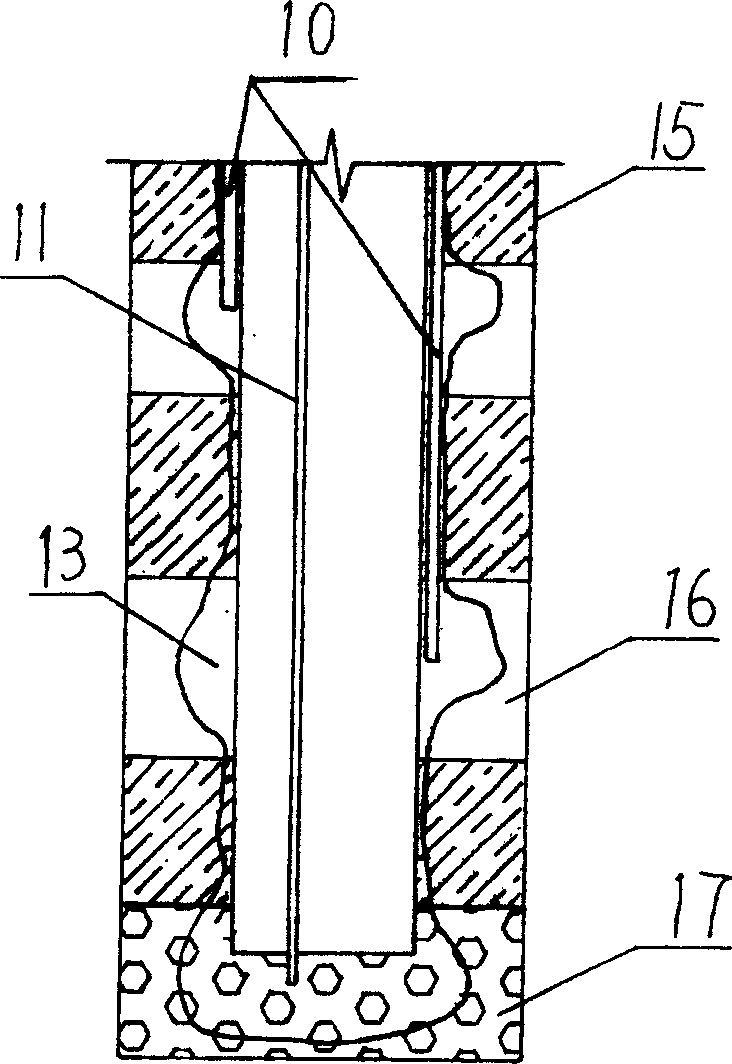

Suction anchor rod device

ActiveCN106939599AIncrease side frictionEffective stress increaseExcavationsBulkheads/pilesEngineeringAtmospheric pressure

A suction anchor rod device comprises a hollow columnar anchor rod. A bottom opening of the anchor rod is sealed, a top opening of the anchor rod is provided with a sealing cover plate, and the sealing cover plate and the anchor rod are detachably connected. The section, close to the bottom opening, of the anchor rod is defined as a bottom section, the section, close to the top opening, of the anchor rod is defined as a top section, a plurality of sieve holes are distributed in the side wall of the bottom section of the anchor rod, and the sieve holes communicate with an inner cavity of the anchor rod. A lifting disk is arranged in the anchor rod, the lifting disk is arranged in the anchor rod in the manner that the lifting disk can move up and down in the axial direction of the anchor rod through a lifting device, the lifting disk divides the inner cavity of the anchor rod into an upper cavity and a lower cavity, the cavity containing the top opening is defined as the upper cavity, and the cavity containing the bottom opening is defined as the lower cavity. The suction anchor rod device further comprises a pressure testing device used for testing the air pressure in the lower cavity and a pressure adjusting device used for adjusting the air pressure in the lower cavity. The suction anchor rod device utilizes the principle of effective stress, under the situation that the total stress is certain, the effective stress is improved by reducing the excess pore pressure, the anchor rod side friction is increased, and the overall stability and safety are improved.

Owner:ZHEJIANG UNIV OF TECH

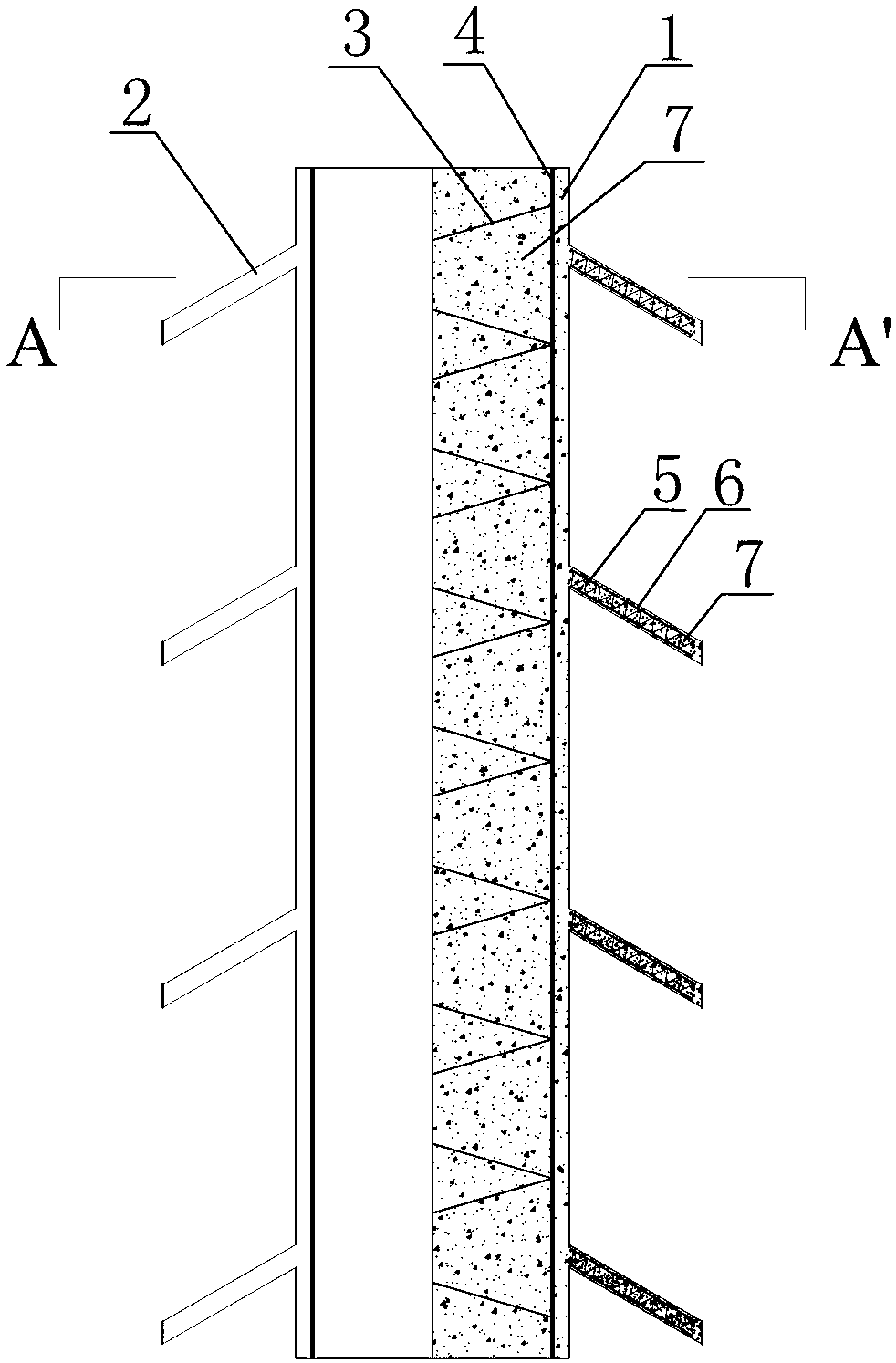

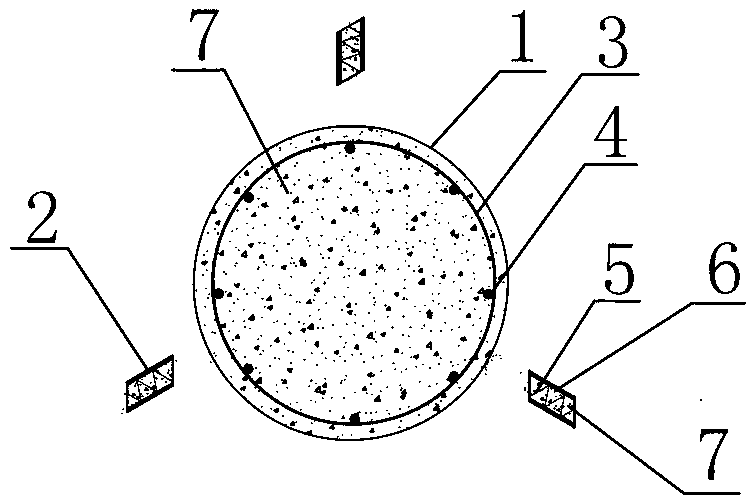

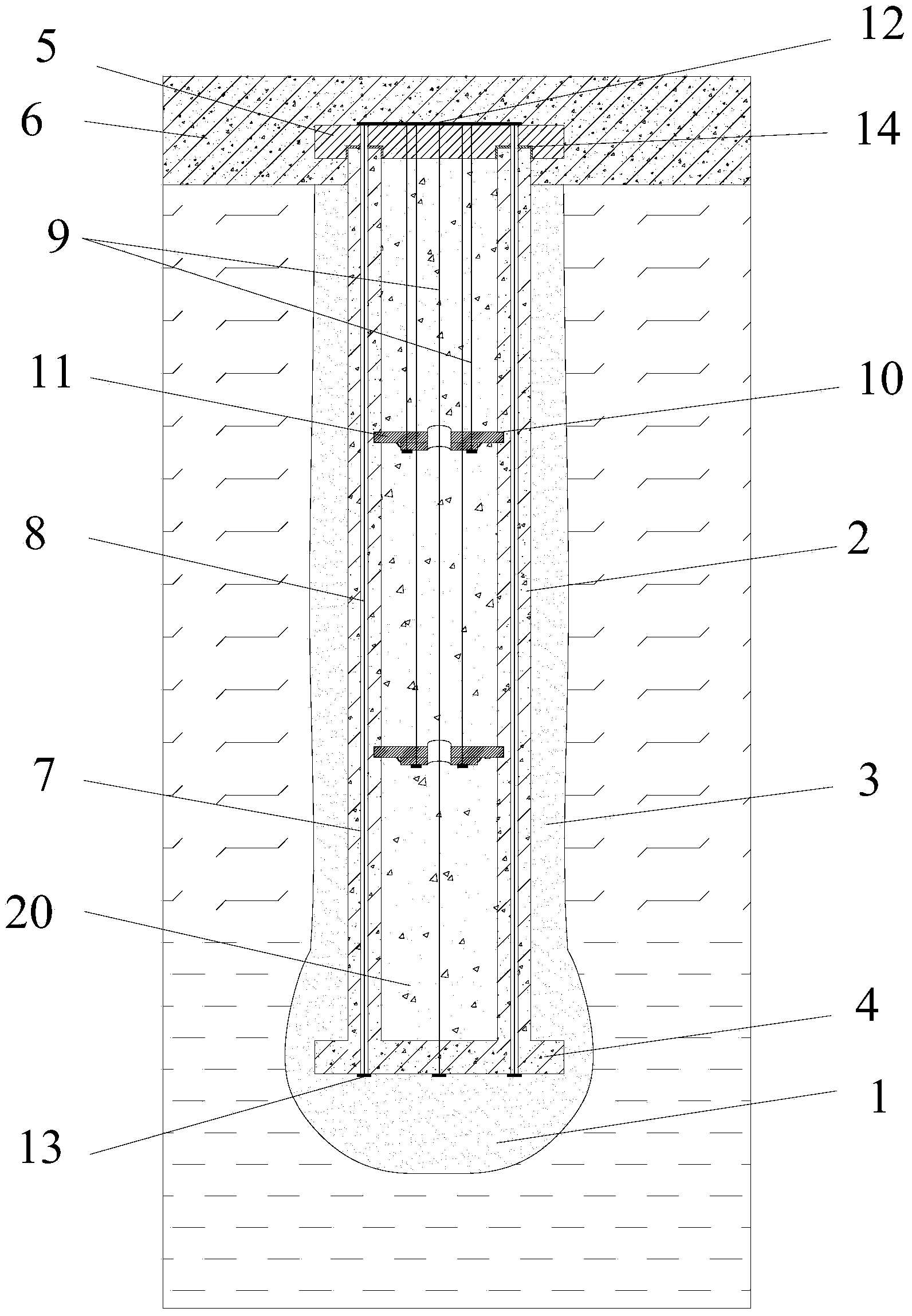

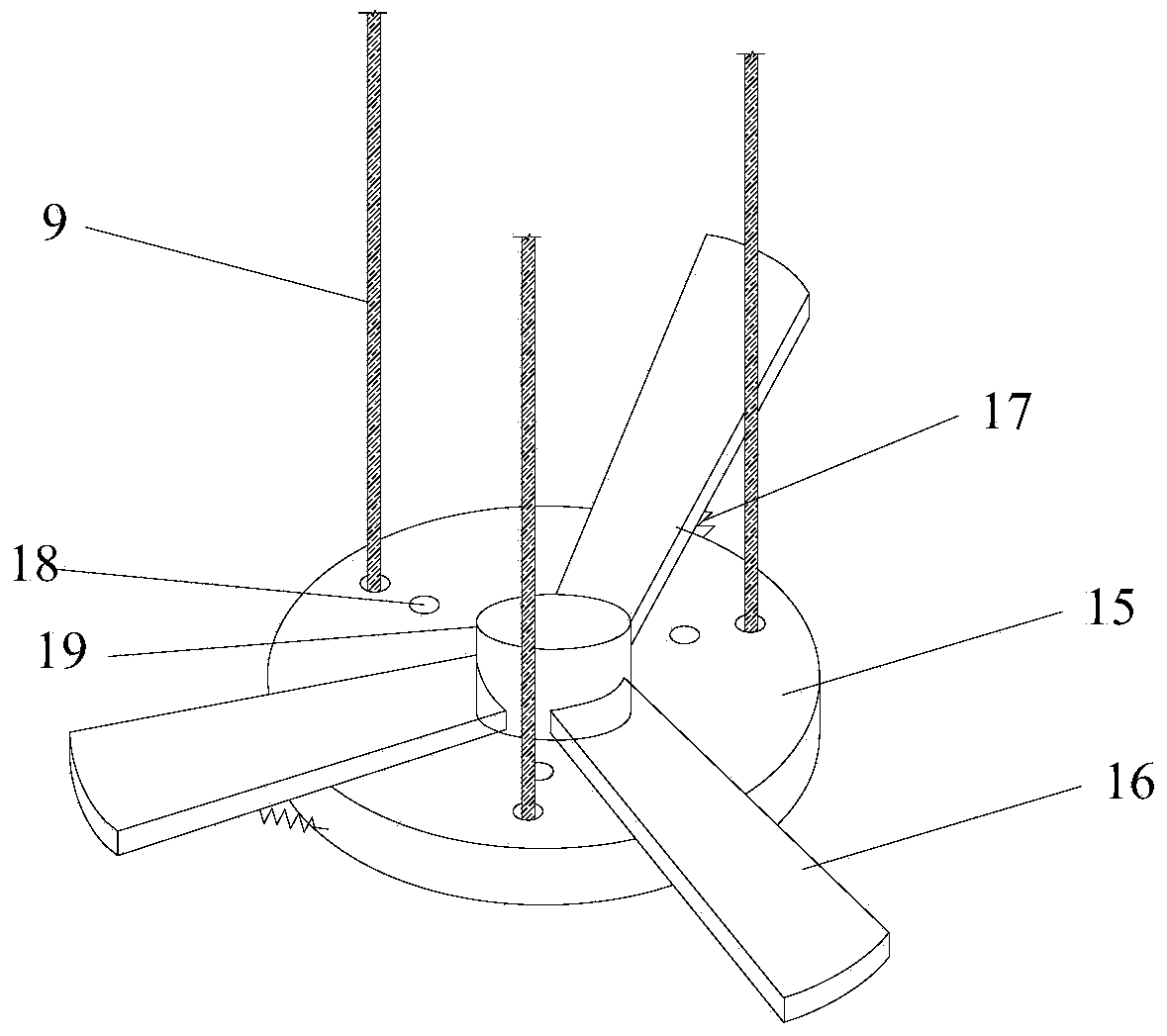

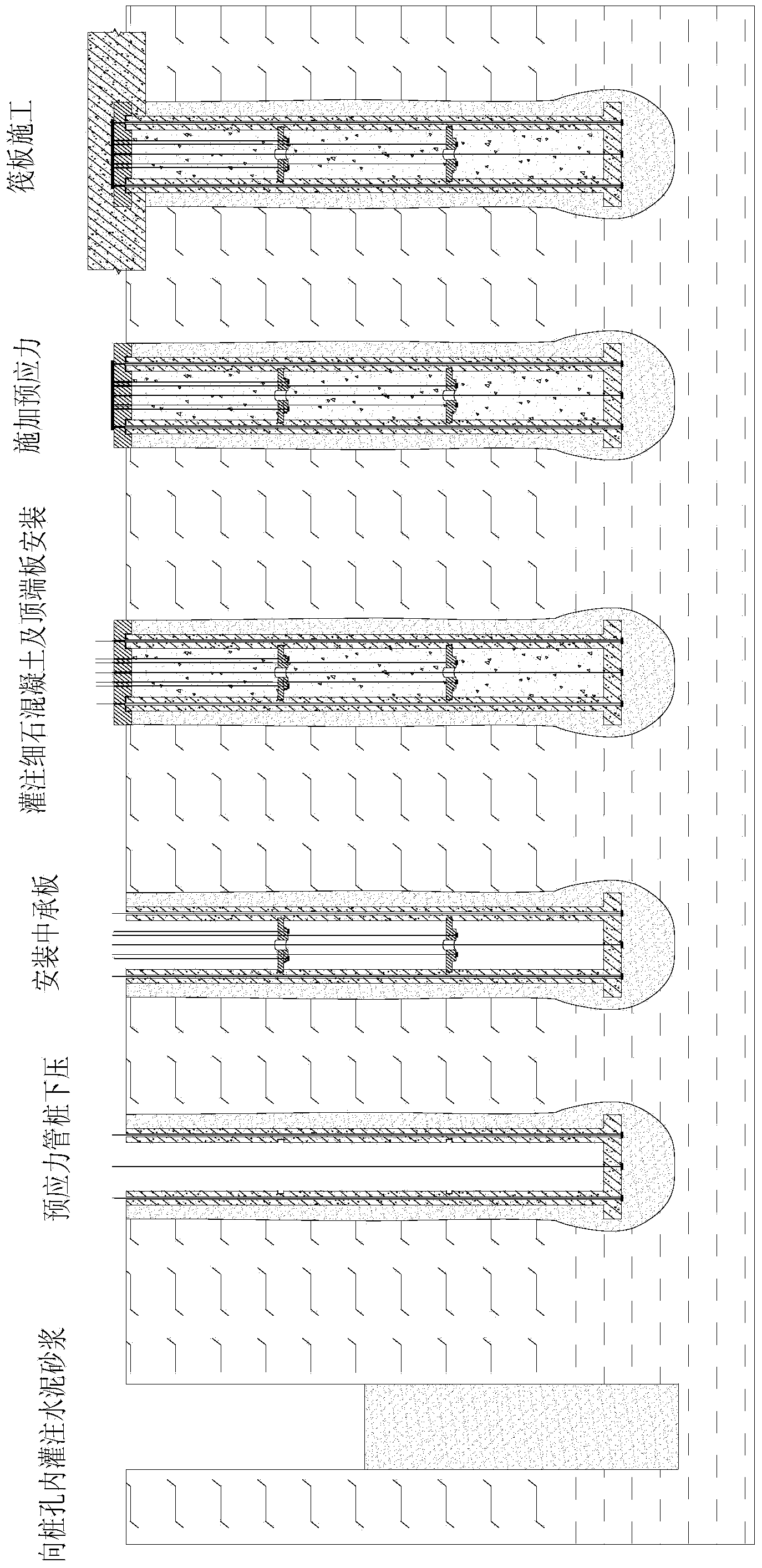

Anti-floating pile structure of pre-stressed pipe pile and construction method

ActiveCN104294823AIncrease buoyancyAchieving total body resistanceProtective foundationBulkheads/pilesPre stressingPre stress

The invention relates to an anti-floating pile structure of a pre-stressed pipe pile. The anti-floating pile structure mainly comprises an expanded file tip, the pre-stressed pipe pile, pile peripheral slurry solids, PVC (polyvinyl chloride) anchor cable holes, a bottom end plate, a top end plate, a middle bearing plate and a foundation raft. The expanded file tip is located at the bottom of the pre-stressed pipe pile. The PVC anchor cable holes and an unbonded pre-stressed anchor cables are evenly arranged on the pile wall of the pre-stressed pipe pile. The pile peripheral slurry solids are arranged on the pile periphery of the pre-stressed pipe pile. The bottom end of the pre-stressed pipe pile is sealed through the bottom end plate, and anchor cable fixing ends for fixing the unbonded pre-stressed anchor cables are arranged on the bottom end plate. The top end plate is arranged at the top of the pre-stressed pipe pile and embedded in the foundation raft. An inserting groove for inserting of the top of the pre-stressed pipe pile is formed on the lower surface of the top end plate, and bonded pre-stressed anchor cables are arranged in a pile core of the pre-stressed pipe pile. The anti-floating pile structure of the pre-stressed pipe pile has good vertical bearing performance and pulling resistance, achieves sufficient whole pile body pulling resistance, and has good technical and economic benefits.

Owner:JIANGSU HUAJIANG CONSTR GROUP

Large-diameter cast-in-place concrete pile defect treatment reinforcing structure and construction method

InactiveCN112411642AShort construction periodLittle impact on project progressFoundation repairBulkheads/pilesPunchingRebar

The invention relates to a large-diameter cast-in-place concrete pile defect treatment reinforcing structure and a construction method. The large-diameter cast-in-place concrete pile defect treatmentreinforcing structure comprises defective large-diameter cast-in-place concrete piles, the defective large-diameter cast-in-place concrete piles comprise pile body defect sections, pile body punchingexcavation side boundaries and pile body punching excavation bottom boundaries are determined according to design requirements, after pile bodies are punched and excavated, core piles subjected to refilling treatment are arranged, core pile longitudinal bars and core pile stirrups are arranged on the core piles according to design requirements, and high-pressure jet grouting reinforcement sectionsare arranged in a certain range of the periphery of the pile body defect sections to form a waterproof curtain and an enclosure structure. Compared with the prior art, the original pile does not needwaste treatment, the construction period is short, the influence on the overall engineering progress is small, and the treatment cost is controllable; on the basis that an annular reinforced concretestructure outside the original pile body is complete, a core pile processing mode is additionally adopted, the hooping effect can be formed, and the bearing capacity of the pile body is improved; andthe mode of thoroughly chiseling away part of concrete of the defect sections is obvious in treatment effect, and no defect risk is left.

Owner:ZHEJIANG JIEDI ARCHITECTURAL DESIGN

Post mudjack construction technics for sidewal and bottom of bore of filling pile

A post-grouting technology and equipment for the side and bottom of bored grouting pile is disclosed. At least two grouting pipes are arranged around the reinforcing bar cage. At least two grouting pipes are arranged at bottom of pile. The slurry prepared from cement slurry, anhydrous calcium thioaluminate and gypsum is grouted via said grouting pipe, which has a conic head to connect with a perforated steel pipe sleeved by an elastic rubber sleeve, a grouting piston in it and a spring under said piston and fixed to bottom of grouting pipe.

Owner:北京城建中南土木工程集团有限公司

High-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method

InactiveCN111379253ARapid Consolidation SettlementTake full advantage of drainageBulkheads/pilesStructural engineeringCement slurry

The invention provides a high-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method. The high-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method comprises the steps that segmented drilling for hole forming is conducted; grouting pipes are placed in a drill hole in a segmented connection mode, and the grouting pipes are bent by 90 degrees and extend out of the two sides of a roadbed in the horizontal direction; a bulk material is put in the drill hole; a reinforced gravel cushion layer is laid on the surface of a foundation; layered filling of embankment soil is carried out on the cushion layer; foundation soil is subjected to consolidated drainage; and expanding cement slurry is injected into the grouting pipes to form rigid pile bodies. The drainage performance of the bulk material is fully utilized to enable inter-pile soil to be subjected to drainage consolidation during embankment filling, the carrying capacity of pile foundations is improved through the expanding cement slurry, properties of the inter-pile soil are improved, and the advantages such as small post-construction settlement are achieved.

Owner:CHONGQING UNIV +1

Spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile, construction method thereof and drilling machine

PendingCN108729440AImprove bearing capacityIncrease side frictionBulkheads/pilesThree stageHigh pressure

The invention discloses a spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile, a construction method thereof and a drilling machine. According to the stiff composite pile, the construction method thereof and the drilling machine, the technical problems of relatively low bearing capacity, high cost, certain quality defects and the like of an existing stiff composite pile are solved. The spiral high-pressure jetting wing-enlarged stirring bottom-expanded stiff composite pile comprises an outer pile body, an inner core pile body and a bottom-expanded base, wherein the outer pile body, the inner core pile body and the bottom-expanded base are combined into a whole, the strength composite pile further comprises a prefabricated pile tip installed at the lowerend of the inner core pile body, and the inner core pile body and the prefabricated pile tip are planted into the center of the outer pile body. According to the stiff composite pile, the construction method thereof and the drilling machine, firstly, the outer pile body is subjected to high-pressure grouting injection to carry out first-stage extrusion and compaction on pile periphery soil, whenguncreting is carried out on center concrete through the bottom-expanded base, second-stage extrusion and compaction are carried out on the outer pile body, third-stage extrusion and compaction are carried out on the outer pile body in the process of planting the inner core pile body, and the outer pile body which are formed through the three stages of extrusion and compaction is extruded and compacted with the surrounding soil layer, and the resistance of the side of the pile is greatly improved; and secondly, the three stages of extrusion and compaction are carried out on the bottom-expandedconcrete through high-pressure grouting bottom expanding, concrete guncreting bottom expanding and the prefabricated pile tip, so that the resistance of a pile end is further improved.

Owner:中航旭日(北京)岩土工程技术有限公司 +2

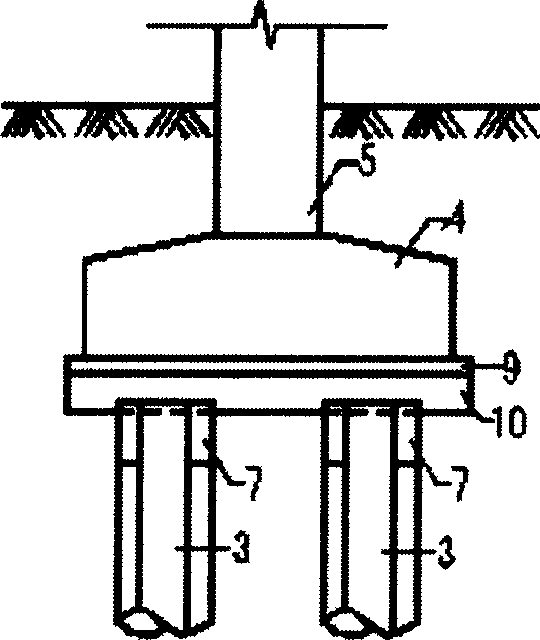

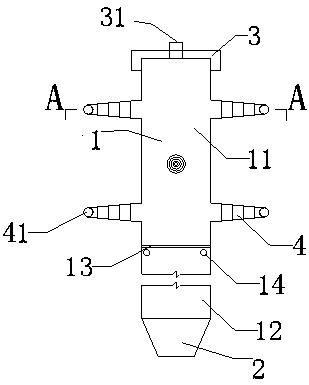

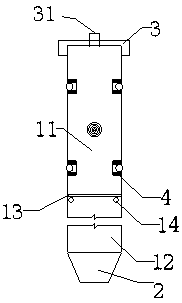

Construction Method of Cast-in-situ Reinforced Concrete Large Diameter Pipe Pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

Construction method of PCC (cast-in-place concrete large-diameter pipe) pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

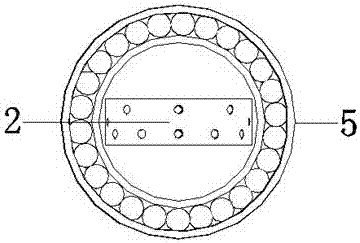

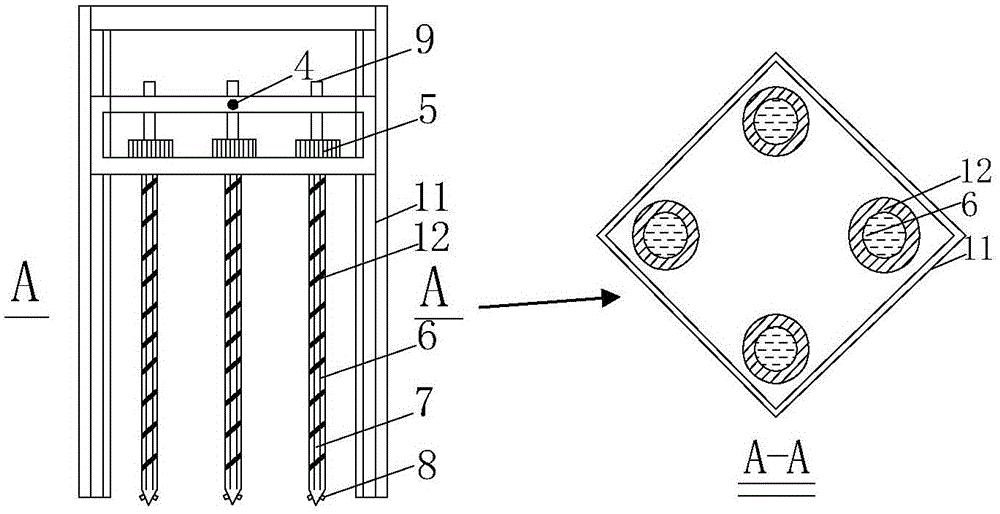

Multi-head minor-diameter long-spiral drilling machine and application thereof in construction of cast-in-situ major-diameter tubular pile

ActiveCN105113488AEvenly distributedIncrease contact areaDrilling rodsDrilling casingsTreatment systemDrilling machines

The invention discloses a multi-head minor-diameter long-spiral drilling machine. The multi-head minor-diameter long-spiral drilling machine comprises a main engine, a winding engine, a spiral drill pipe module, a locating rack, a powder device and a background concrete treatment system, wherein the winding engine is positioned on a base plate; 2-6 spiral drill pipes are symmetrically fixed on the top of the locating rack to form an annulus; during once drilling, the 2-6 spiral drill pipes work at the same time; the locating rack is connected with the power device in a rotating manner, so that the angle can be changed by rotation after construction every time. The multi-head minor-diameter long-spiral drilling machine has the following advantages that the head and tail of a long-spiral drill are annularly connected to form a cast-in-situ major-diameter tubular pile, and the inner and outer walls of the cast-in-situ major-diameter tubular pile are wavy, so that the contact area of the pipe with soil is greatly enlarged, and the side friction resistance of the pile is increased; as for the cast-in-situ major-diameter tubular pile, the problems that the soil compaction effect is increased due to the increased pile thickness, construction is difficult, and the like, are overcome, site construction soil compaction has relatively little influence on the ambient environment, and the problems like pile cutting are avoided; the construction cost is reduced, the construction technology is clear, the construction speed is high, the pile forming effect is good, the bearing capacity is high, and the construction cost is low.

Owner:HOHAI UNIV

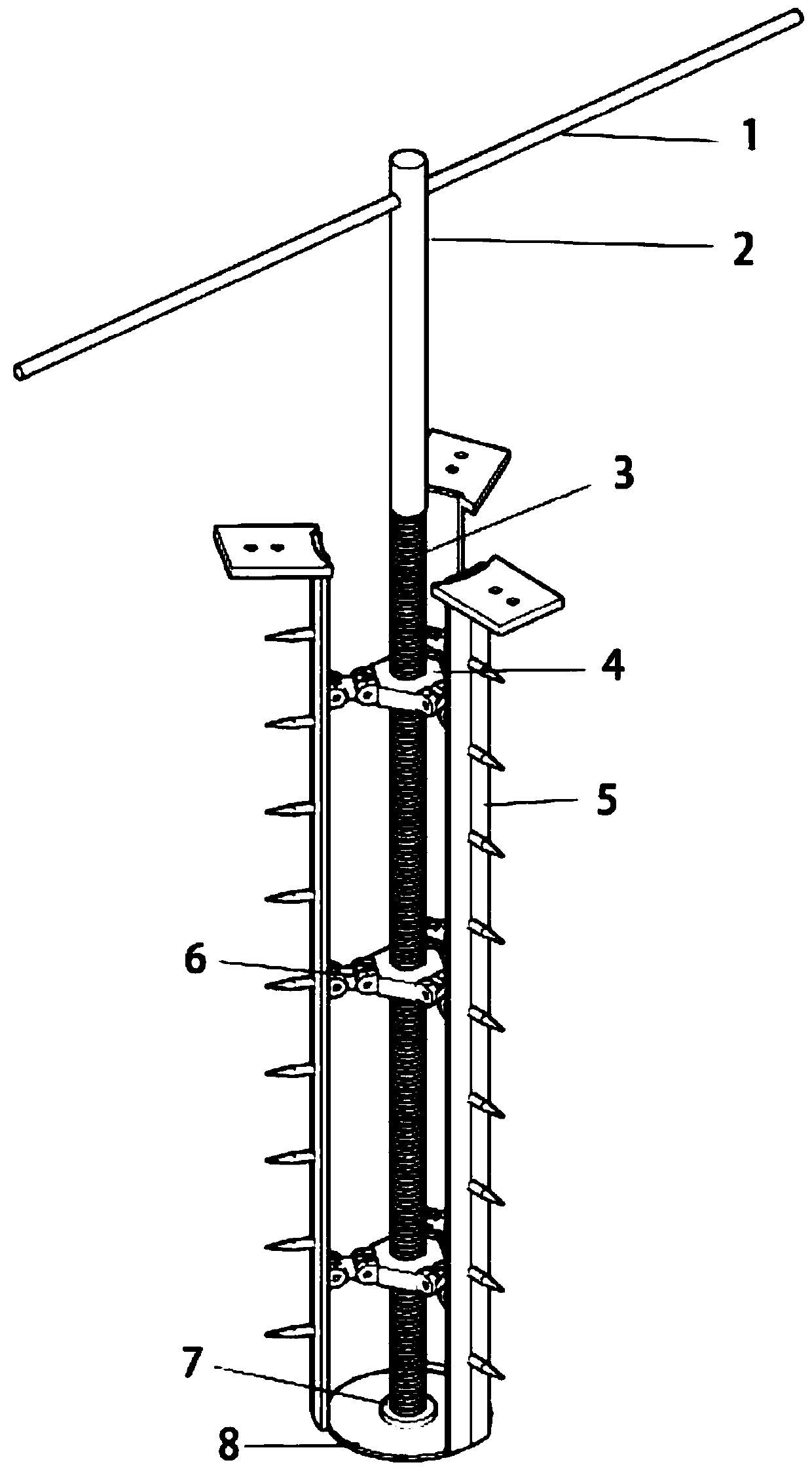

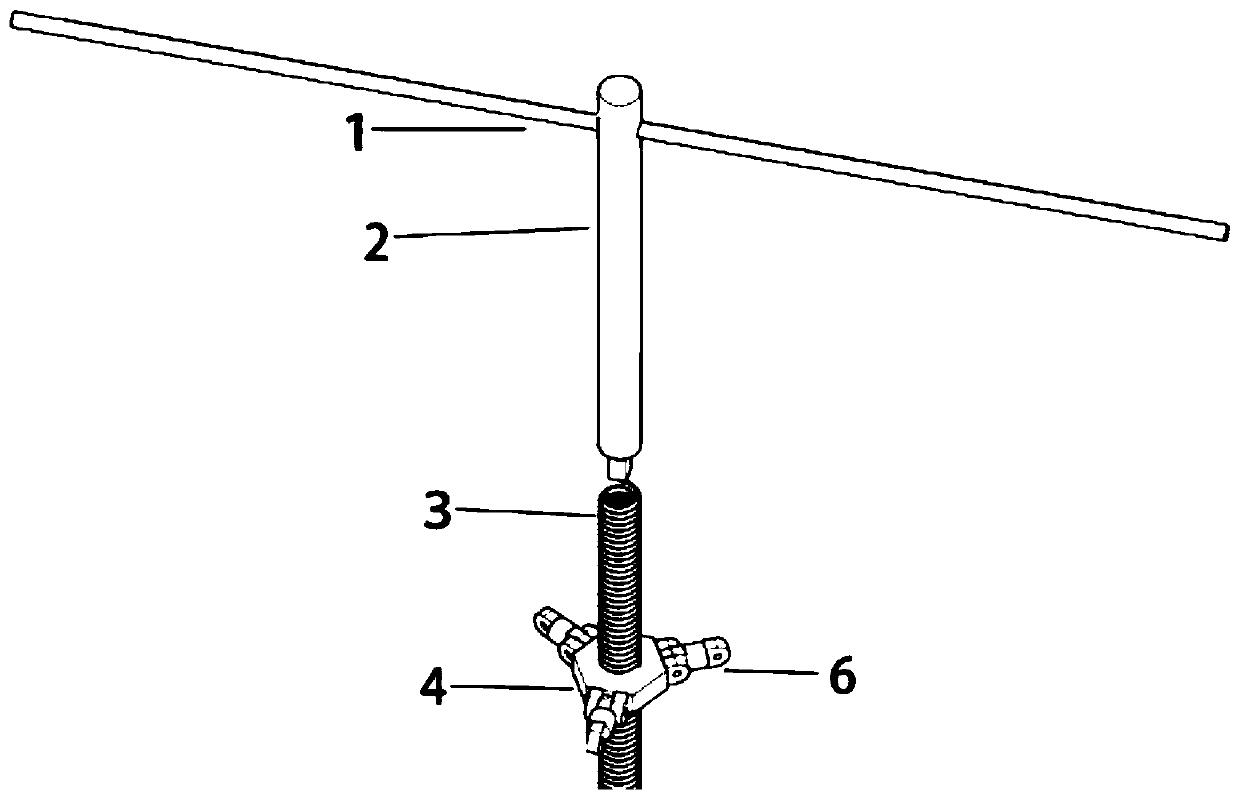

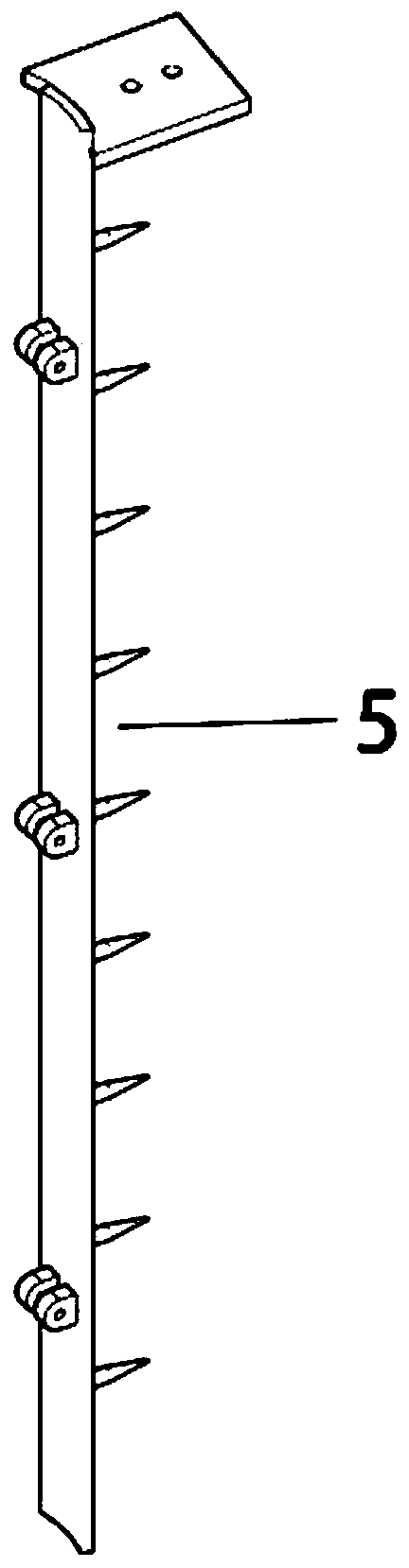

Frost heaving resisting device and construction method thereof

ActiveCN109944269AReduce disturbanceSmall operating radiusFoundation engineeringMortise and tenonButt joint

Provided are a frost heaving resisting device and a construction method thereof. The device comprises a chassis, a screw rod, a thrust bearing, a hexagon nut, a pushing needle plate, a chain rod, a butt joint rod and an inserting rod. The chain rod is an iron chain rod, and is hinged to a force bearing point of the nut and a force bearing point of the pushing needle plate. The butt joint rod is aniron rod, and is in butt joint with the upper portion of the screw rod through a mortise and tenon structure. The inserting rod is an iron rod, and is inserted into a round hole preserved in the upper portion of the butt joint rod to serve as a force arm to rotate the screw rod. All the parts of the device can be prefabricated, and can be fast assembled on site. According to the construction method, a gasoline portable drill is adopted for drilling a hole in advance, the device is overall placed in the drilled hole, and pushing force for the pushing needle plate is generated through the spiraling of the screw rod, so the pushing needle plate is stuck into the a hole side wall soil body. According to the frost heaving resisting device and the construction method thereof, the construction difficulty of a frost heaving resisting measure, the construction period is shortened, the comprehensive building cost is reduced, and the basic tensile capacity is improved.

Owner:国网内蒙古东部电力有限公司经济技术研究院 +1

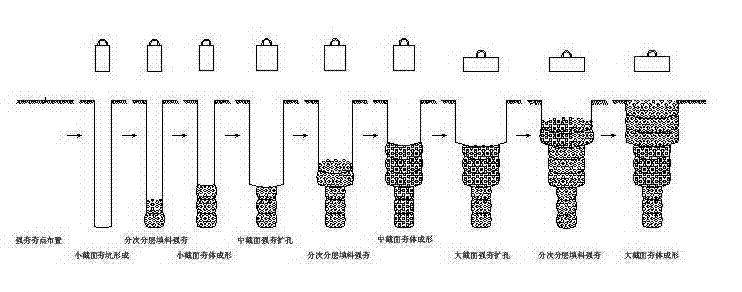

Multi-section type variable cross-section dynamic compaction method

The invention discloses a multi-section type variable cross-section dynamic compaction method, which is the method for treatment of a building foundation, clearing and leveling are firstly performed on a soft foundation space, and multi-section type variable cross-section dynamic compaction construction is further performed on dynamic compaction tamping points which are arranged according to the construction process flow and the technical specifications. During the process of forming a tamping pit and forming tamping bodies, more than two rams in cross sections which are increased gradually are adopted for ramming a soil body of a soft foundation from bottom to top respectively for forming the tamping pit or an expanded hole, dry soil or aggregate is further backfilled into the tamping pit and rammed, tamping of the tamping pit and the backfilled materials is completed section by section, then more than two sections of the dynamic compaction tamping bodies or replacement pier bodies in the cross sections which are gradually increased are formed from the bottom to the top and full compaction operation in a dynamic compaction region is finally performed. After the method is adopted for dynamic compaction and reinforcement, the overall compactness, the strength of the foundation and the bearing capacity are greatly improved, and the foundation is uniform at the upper part and the lower part. The stress stability, the uniformity and the overall rigidity of the foundation soil are significantly increased. The construction quality is more stable, the compression modulus of the foundation is high, and the settlement value and the settlement difference value are obviously reduced.

Owner:谢开生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com