Post mudjack construction technics for sidewal and bottom of bore of filling pile

A technology of bored piles and construction technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of increasing the bearing capacity of the pile bottom, the lateral friction resistance, and the backflow of the grouting equipment, so as to improve the bearing capacity of the pile end. The effect of force, the expansion of the influence range, and the avoidance of grouting failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

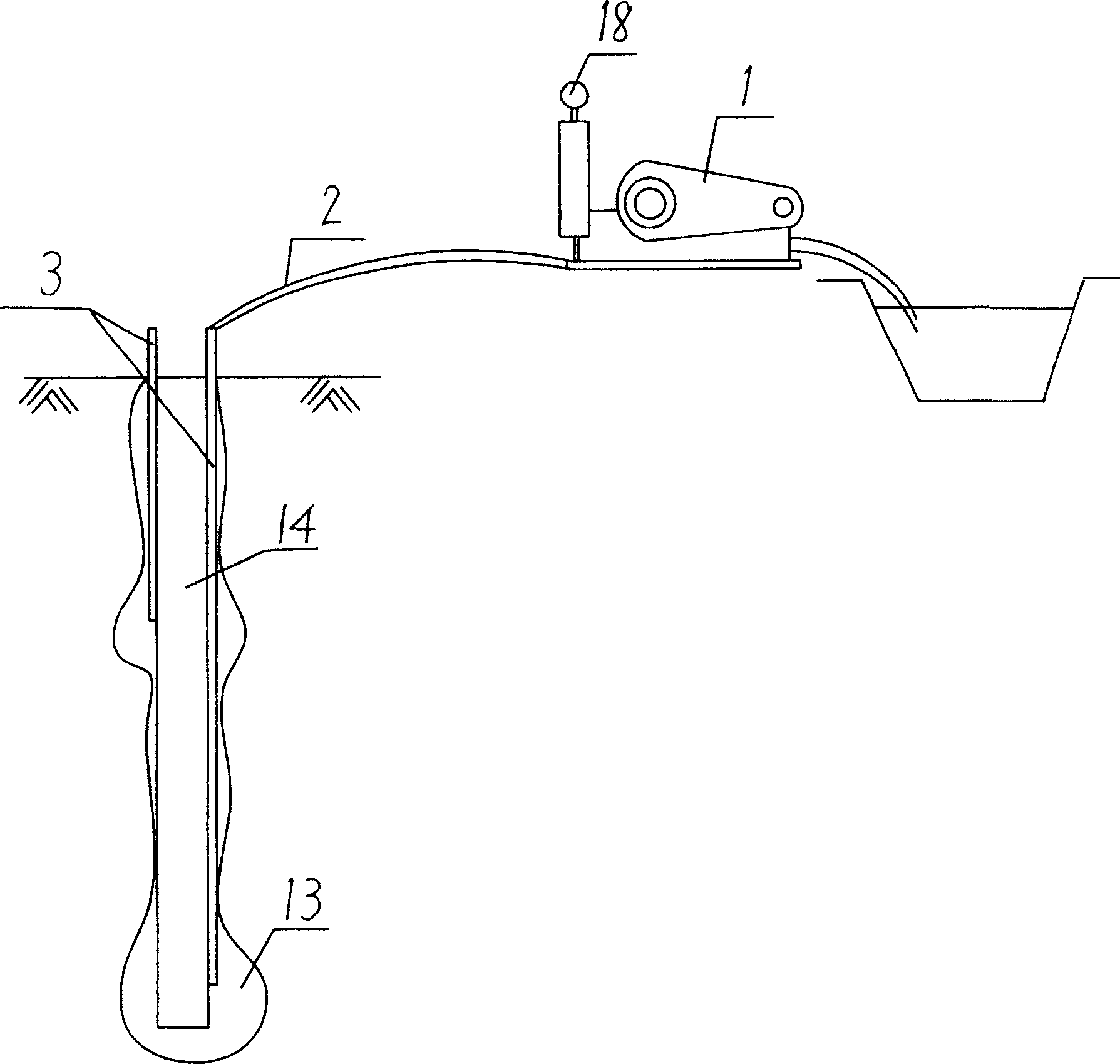

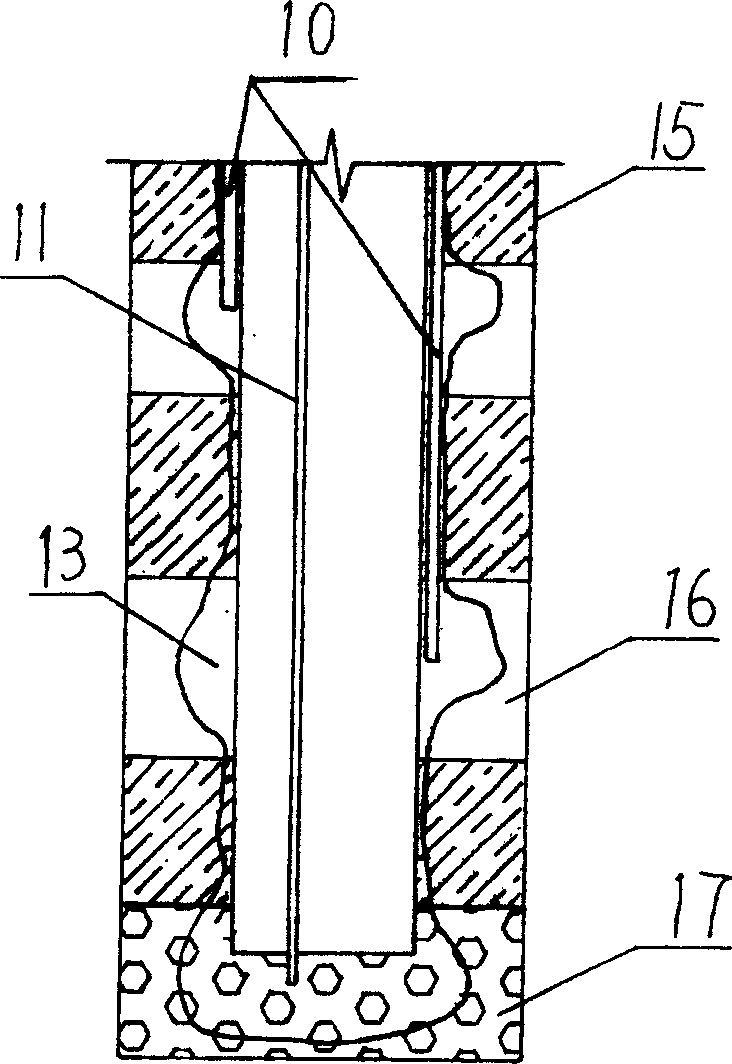

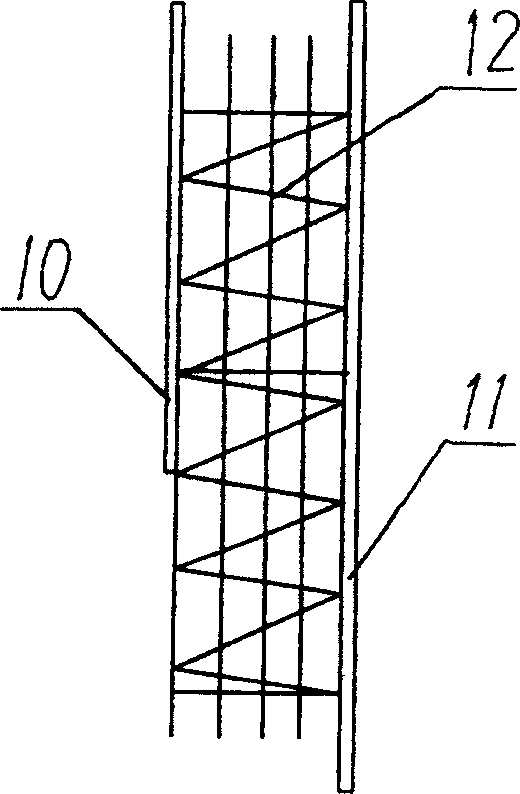

[0018] Example figure 1 , 2 , 3, the drilled cast-in-place pile pile side of the present invention, pile bottom back pressure grouting device comprises the grouting pump 1, the grouting hose 2 and the grouting pipe 3 that are connected in sequence, the grouting pump 1 and the pressure gauge 18 connections, the grouting pipe 3 includes three pile side grouting pipes 10 and two pile bottom grouting pipes 11, and the three pile side grouting pipes 10 are evenly arranged within the circumference of the reinforcement cage 12, basically in an equilateral triangle; The pile bottom grouting pipes 11 are symmetrically arranged, and one of them is a spare pipe or used as a secondary splitting grouting. The pile bottom grouting pipe 11 should grow 20-30cm out of the reinforcement cage, so that its root can penetrate into the soil layer within the influence range of the drill bit at the bottom of the hole and extend into the bearing layer, for example, it can extend to the pebble layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com