High-speed railway expanding cement slurry post-grouting bulk material pile composite foundation construction method

A technology for bulk material piles and high-speed railways, which can be used in infrastructure engineering, sheet pile walls, buildings, etc., and can solve problems such as large post-construction settlement, unfavorable construction, and high clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

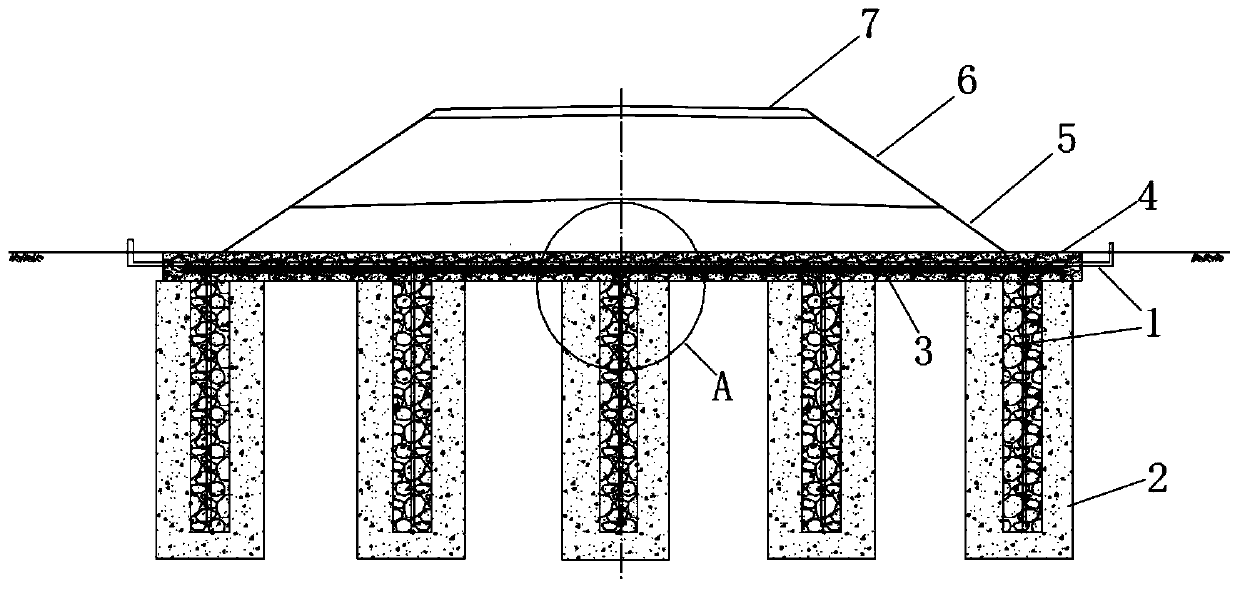

[0037] The construction method of composite foundation of high-speed railway expanded cement slurry post-grouting granular material pile is characterized in that it comprises the following steps:

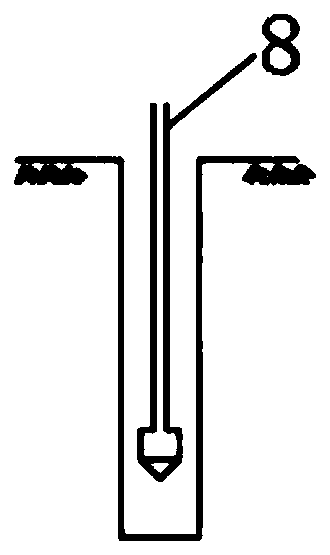

[0038] 1) Drilling in sections to form holes: Use a small gyroscopic drill to drill the hole, each drill rod is no more than 5 meters in length, and the first drill rod reaches the drilling depth and then connects to the second drill rod. After drilling the depth, connect the third drill rod, and so on, through the connection of the drill rod to form holes in sections until the design pile length is reached.

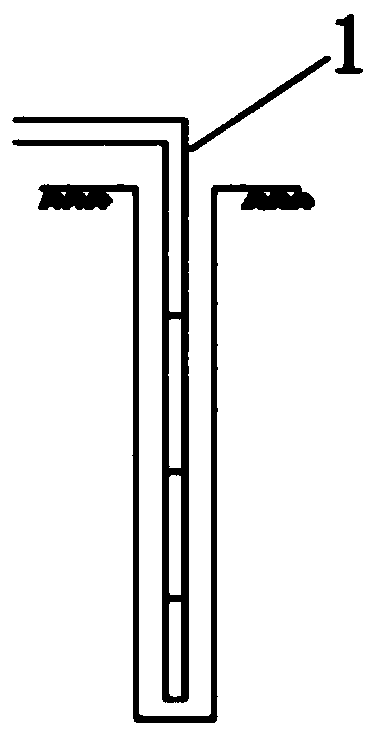

[0039] 2) Place a number of grouting steel pipes (1) of different lengths in the above-mentioned borehole; after the upper end of the grouting steel pipe (1) extends out of the ground, it is bent 90 degrees and protrudes from both sides of the subgrade in the horizontal direction (for convenience Grouting). In the embodiment, the grouting pipe adopts steel pipes, which are connect...

Embodiment 2

[0048] The main structure of this embodiment is the same as that of embodiment 1. Further, in step 1), the length of each drill rod is not more than 5 meters, and the first drill rod is connected to the second drill rod after reaching the drilling depth. After reaching the drilling depth, connect the third drill rod, and so on, through the connection of the drill rod to form holes in sections until the design pile length is reached.

Embodiment 3

[0050] The main structure of this embodiment is the same as that of Embodiment 1. Further, in step 1], the formed pile hole is divided into several sections, each section being no more than 5 meters in length.

[0051] In step 2], the number of grouting steel pipes 1 is the same as the number of pile hole sections, and each grouting steel pipe 1 extends to the bottom of the section, and a distance from the bottom section is 15-30cm (the longest one grouting steel pipe 1 , In the lowest section, should ensure that the lower end is 15-30cm away from the bottom of the hole).

[0052] Several grouting steel pipes of different lengths. In step 7], the grouting pressure and the amount of expansion agent can be adjusted according to the situation to form a reducing pile:

[0053] 1. For a homogeneous foundation, since the earth pressure increases linearly with depth, from the grouting steel pipe 1 extending to the bottom end to the grouting steel pipe 1 extending to the top, the grouting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com