Condensation heat exchange pipe and manufacturing and using method thereof

A manufacturing method and technology of a heat exchange tube are applied to a condensation heat exchange tube, and a method for manufacturing and using the condensation heat exchange tube. It can solve problems such as unscientific methods, poor effects, and thinning, and achieve the effects of compact structure, stable operation, and water conservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

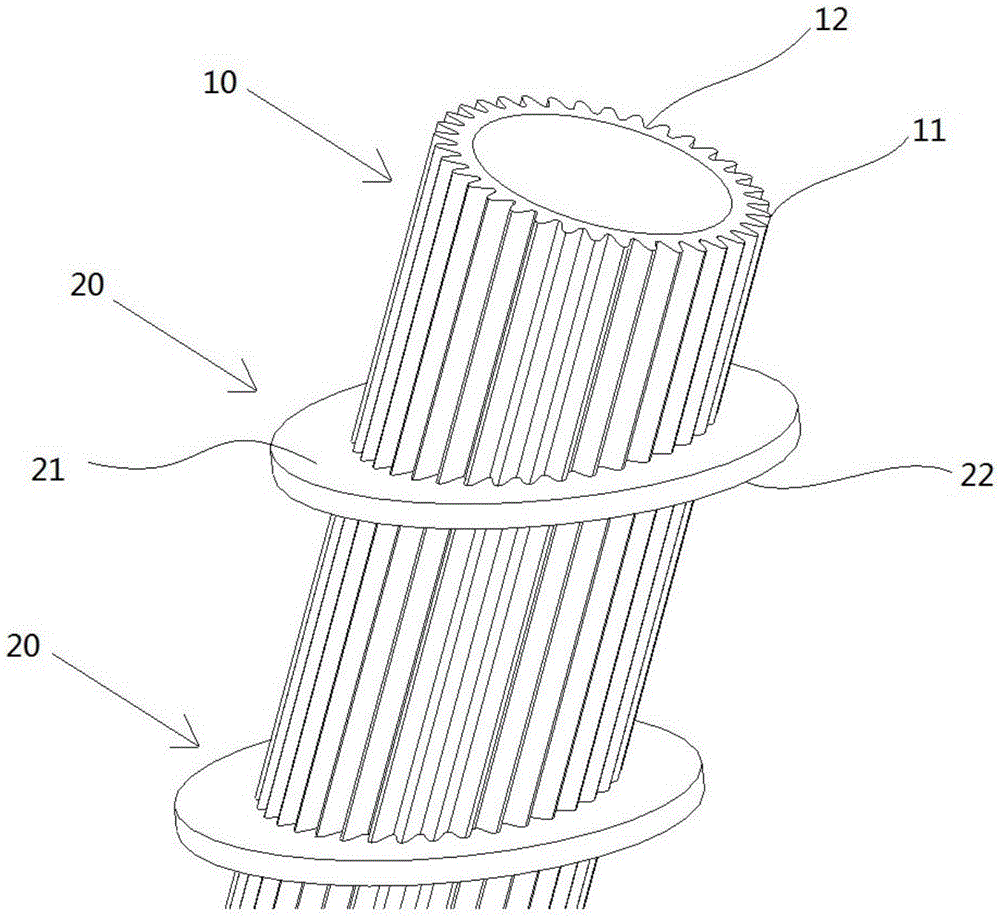

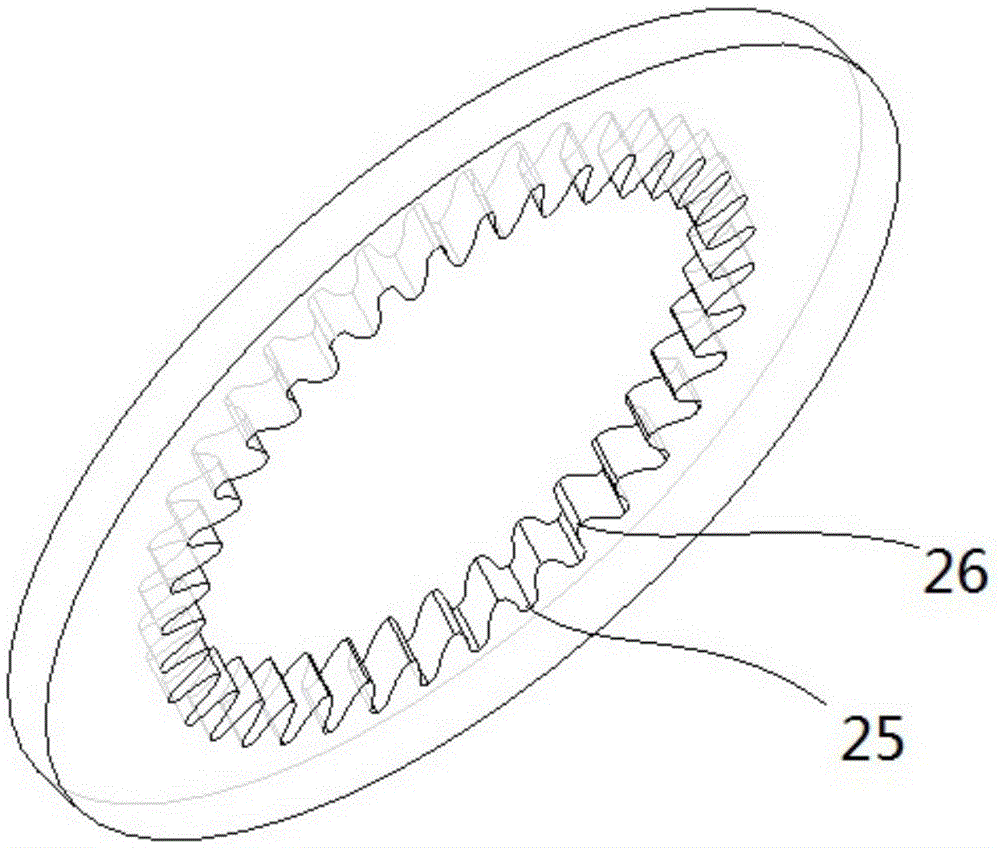

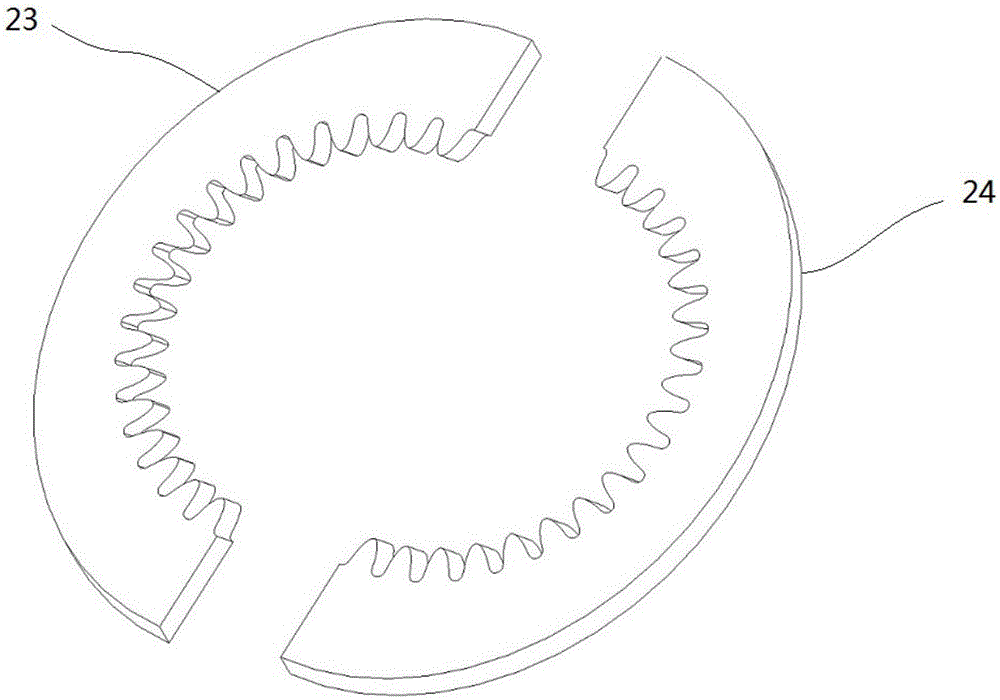

[0033] Figure 1-Figure 3 A preferred embodiment of the condensation heat exchange tube provided by the present invention is shown.

[0034] Such as Figure 1-Figure 3 As shown, the condensing heat exchange tube in this specific embodiment includes a heat exchange base tube 10 and a plurality of fins 20 , and the fins 20 are sleeved on the outside of the heat exchange base tube 10 . The fin 20 has a first surface 21 , the first surface 21 is a plane, the heat exchange base pipe 10 extends along the axis, and the plane where the first surface 21 of the fin 20 is located obliquely intersects with the axis of the heat exchange base pipe 10 . The included angle between the fin plane and the axis of the heat exchange base tube can be determined by experiments. After searching through the application, in order to obtain a better condensation heat transfer effect, the angle between the plane where the first surface 21 of the fin 20 is located and the axis of the heat transfer base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com