Pile forming apparatus and method for mud-jacking inner-ramming pedestal pile

A bottom-expanding pile and pile-forming technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as failure to pull out the outer pipe, broken piles, side friction and poor pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

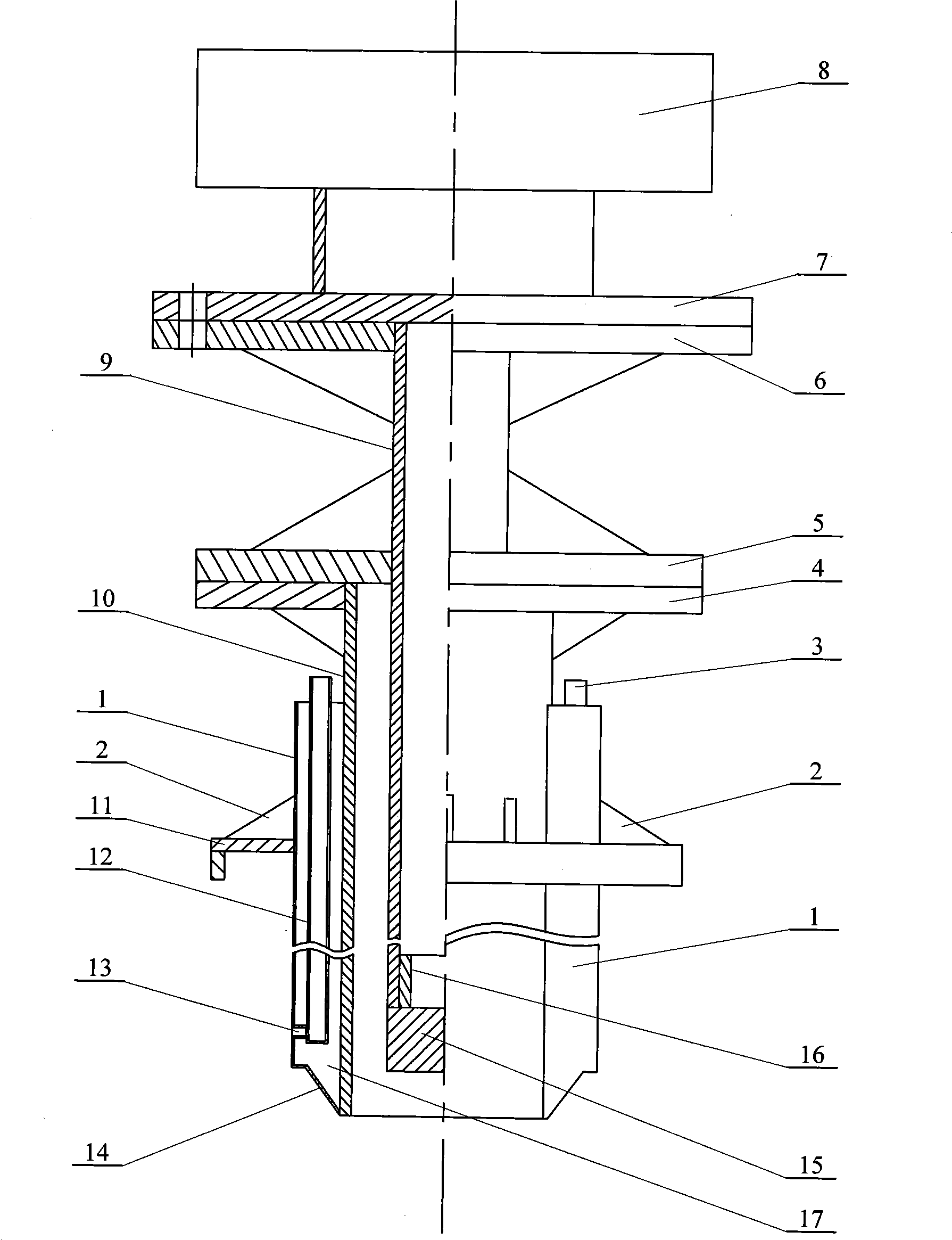

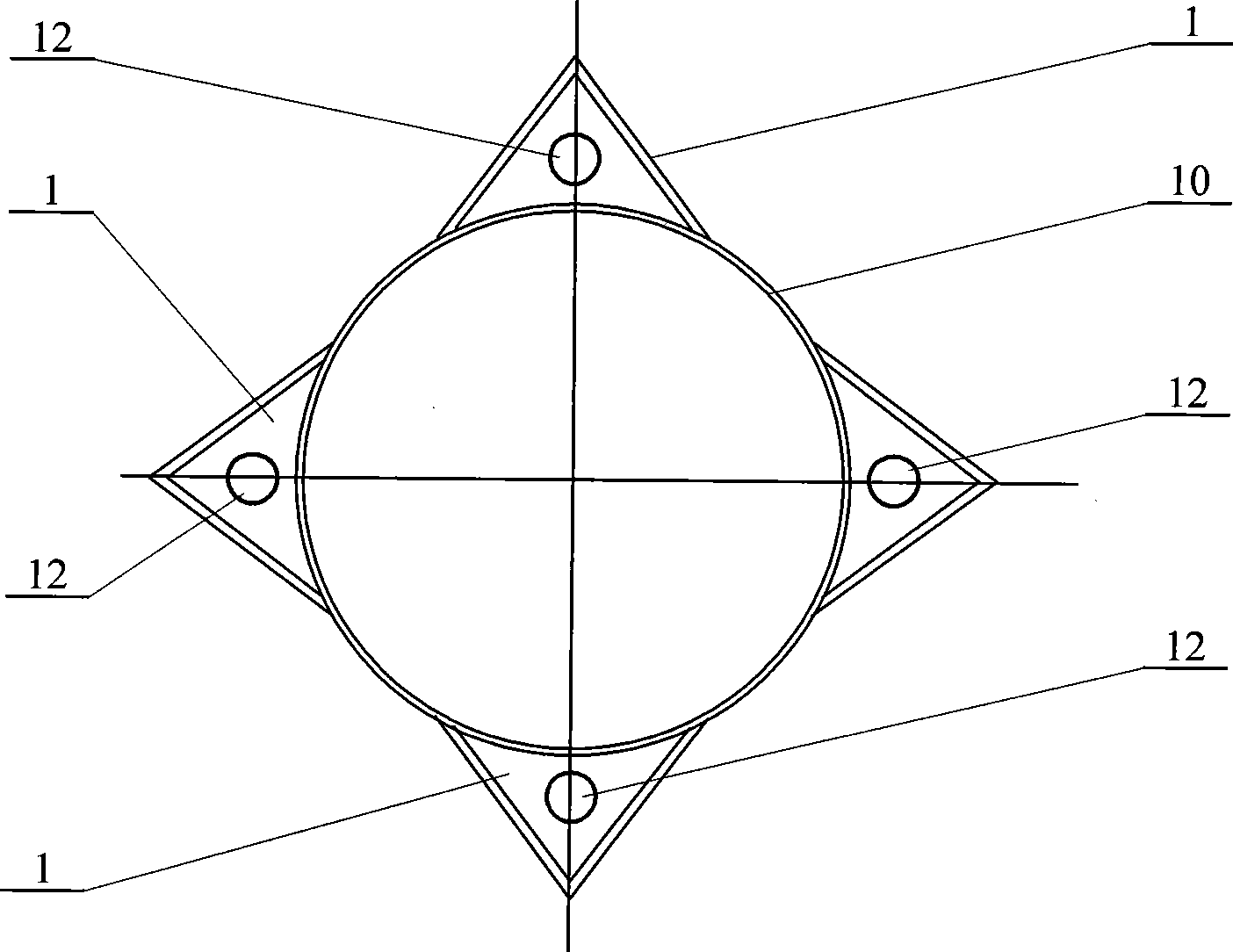

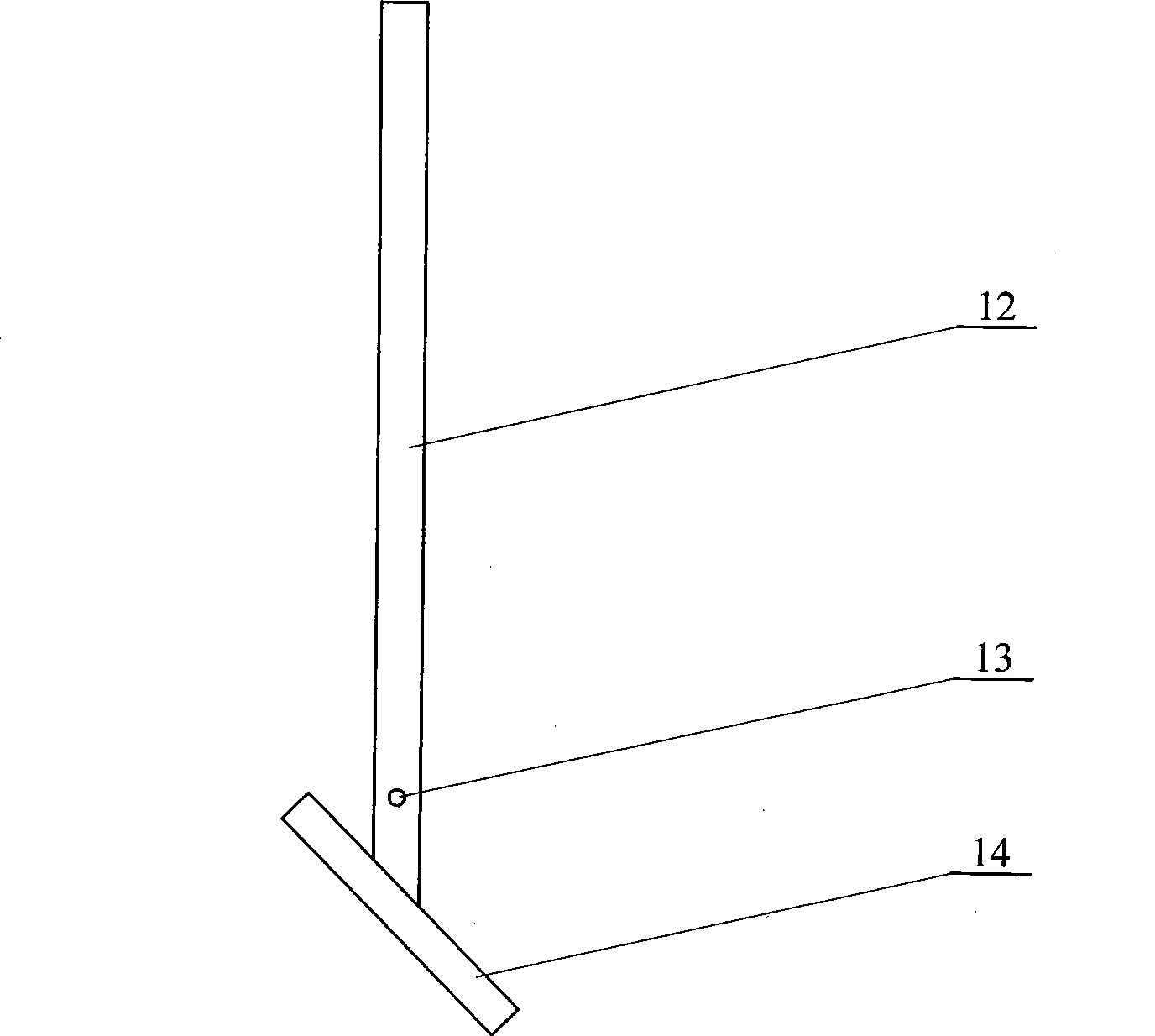

[0006] Specific implementation one: (see Figure 1 to Figure 3 ) This embodiment includes a closed cavity outer steel plate 1, a grouting port 3, an outer tube flange 4, an inner tube lower flange 5, an inner tube upper flange 6, a hammer body flange 7, a hammer 8, an inner tube flange Tube 9, outer tube 10, sealing disc 11, grouting tube 12, slurry outlet 13, lower sealing plate 14 of the sealing cavity, cylindrical body 15 and outer tube sealing cavity 17, the lower end of hammer 8 is fixedly connected with a hammer body flange Disc 7, the upper end of the inner tube 9 is fixedly connected with the inner tube upper flange 6, the inner tube upper flange 6 is connected with the hammer body flange 7, and the middle and upper part of the inner tube 9 is fixedly connected with the inner tube lower flange Plate 5, the upper end of the outer tube 10 is fixedly connected with the outer tube flange 4, the outer tube flange 4 is in contact with the lower flange 5 of the inner tube, an...

specific Embodiment approach 2

[0007] Specific implementation two: (see figure 1 ) The closed cavity outer steel plate 1 in this embodiment is composed of two to four outer closed cavity steel plates 1. Two to four closed cavity outer steel plates 1 are arranged on the outer wall of the outer tube 10, and each closed cavity outer steel plate 1 is provided with one to two grouting pipes. 12. Others are the same as the first embodiment.

specific Embodiment approach 3

[0008] Specific implementation three: (see figure 1 ) The closed cavity outer steel plate 1 in this embodiment consists of two closed cavity outer steel plates 1 symmetrically arranged on the outer wall of the outer tube 10 . Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com