A kind of preparation method of high-frequency soft magnet silicon-aluminum magnetic powder core

A technology of soft magnets and magnetic powder cores, applied in the manufacture of magnetic cores, inductors/transformers/magnets, magnetic objects, etc., can solve problems such as low magnetic permeability, rough surface, and more cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

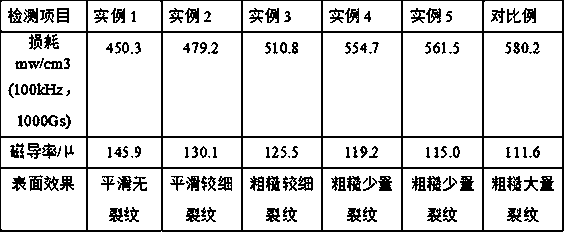

Examples

example 1

[0022]Put the sendust in the pulverizer, after mechanical crushing, use a 500-mesh round hole screen to classify, and carry out grading according to the following weight parts, 200 mesh accounts for 15 parts, 325 mesh accounts for 35 parts, and 500 mesh accounts for 75 parts. to obtain graded gold powder; mix graded gold powder and absolute ethanol at a mass ratio of 1:10 and pour it into a three-necked flask. Under the condition of an ultrasonic frequency of 50 kHz, ultrasonically disperse it for 60 minutes, and then add graded gold powder into the three-necked flask. Polyvinylpyrrolidone with 0.8 times the mass of gold powder and dopamine with 0.03 times the mass of graded gold powder were continued to be ultrasonically dispersed at a frequency of 50 kHz for 60 minutes, and then the ultrasonic wave was stopped. Feed nitrogen into the three-necked flask at a high rate, under nitrogen protection, at a temperature of 70°C and a rotation speed of 500r / min, heat and stir at a cons...

example 2

[0024] Put the sendust in the pulverizer, after mechanical crushing, use a 500-mesh round hole screen to classify, and carry out grading according to the following weight parts, 200 mesh accounts for 15 parts, 325 mesh accounts for 35 parts, and 500 mesh accounts for 75 parts. to obtain graded gold powder; mix graded gold powder and absolute ethanol at a mass ratio of 1:10 and pour it into a three-necked flask. Under the condition of an ultrasonic frequency of 50 kHz, ultrasonically disperse it for 60 minutes, and then add graded gold powder into the three-necked flask. Polyvinylpyrrolidone with 0.8 times the mass of gold powder and dopamine with 0.03 times the mass of graded gold powder were continued to be ultrasonically dispersed at a frequency of 50 kHz for 60 minutes, and then the ultrasonic wave was stopped. Nitrogen gas was passed into the three-necked flask at a high rate, under the condition of nitrogen protection, at a temperature of 70°C and a rotation speed of 500r / ...

example 3

[0026] Put the sendust in the pulverizer, after mechanical crushing, use a 500-mesh round hole screen to classify, and carry out grading according to the following weight parts, 200 mesh accounts for 15 parts, 325 mesh accounts for 35 parts, and 500 mesh accounts for 75 parts. to obtain graded gold powder; mix graded gold powder and absolute ethanol at a mass ratio of 1:10 and pour it into a three-necked flask. Under the condition of an ultrasonic frequency of 50 kHz, ultrasonically disperse it for 60 minutes, and then add graded gold powder into the three-necked flask. Polyvinylpyrrolidone with a mass of 0.8 times the gold powder was dispersed ultrasonically for 60 minutes at a frequency of 50 kHz, then the ultrasonic was stopped, and the three-necked flask was moved into a digital display speed measuring constant temperature magnetic stirrer, and nitrogen gas was introduced into the three-necked flask at a rate of 8 mL / min. Under nitrogen protection, at a temperature of 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com