Patents

Literature

1203results about "Magnetic core manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

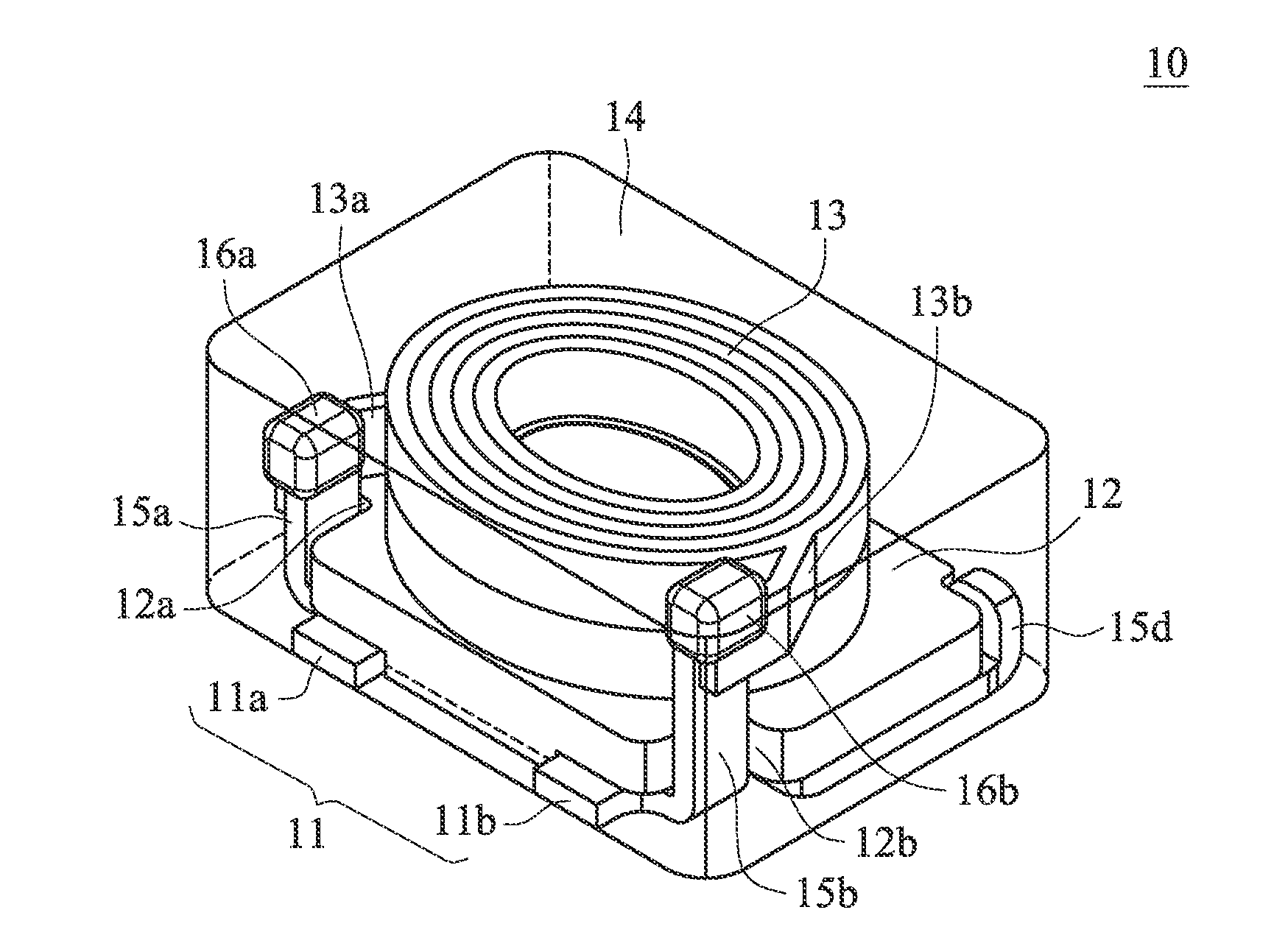

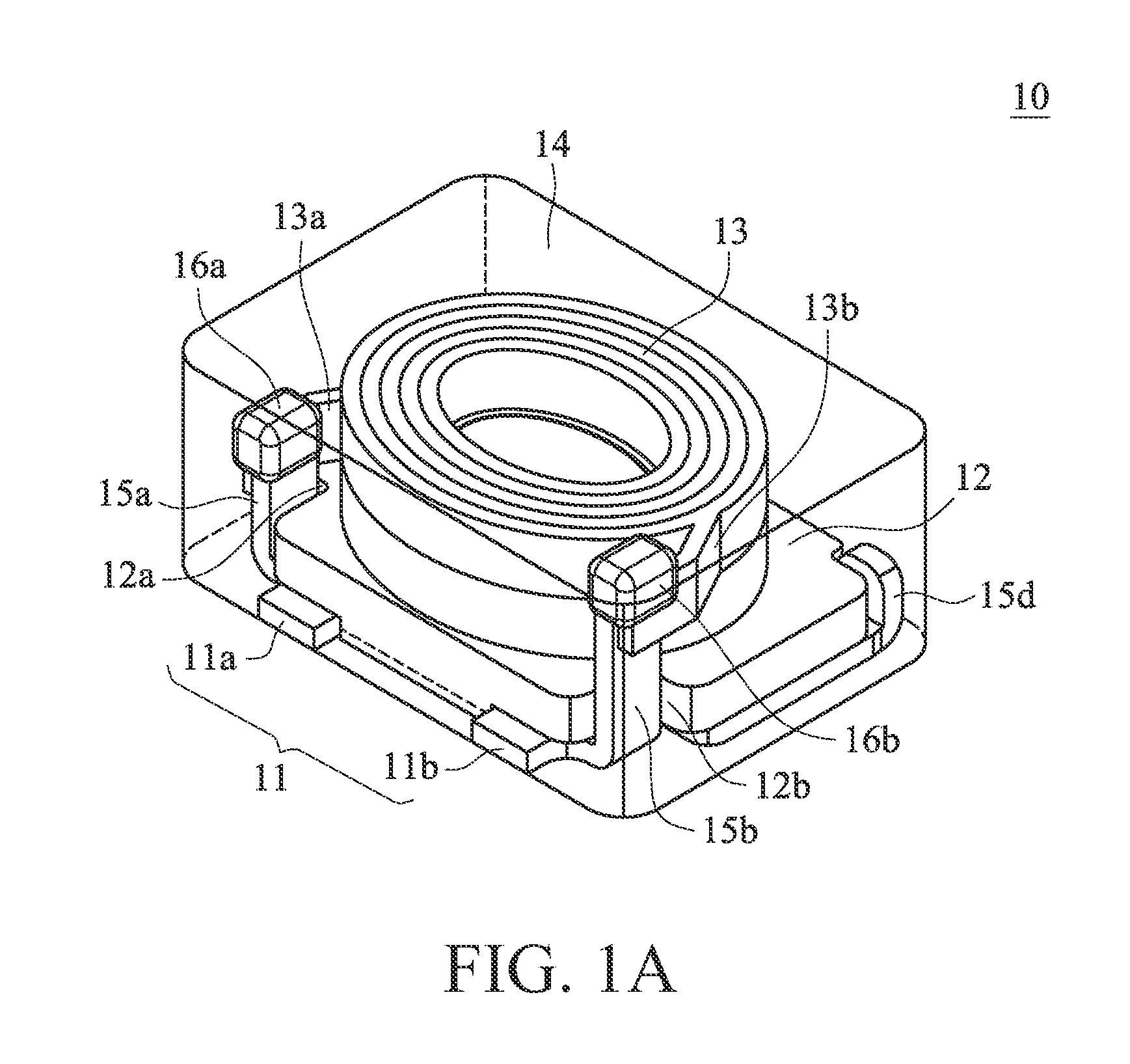

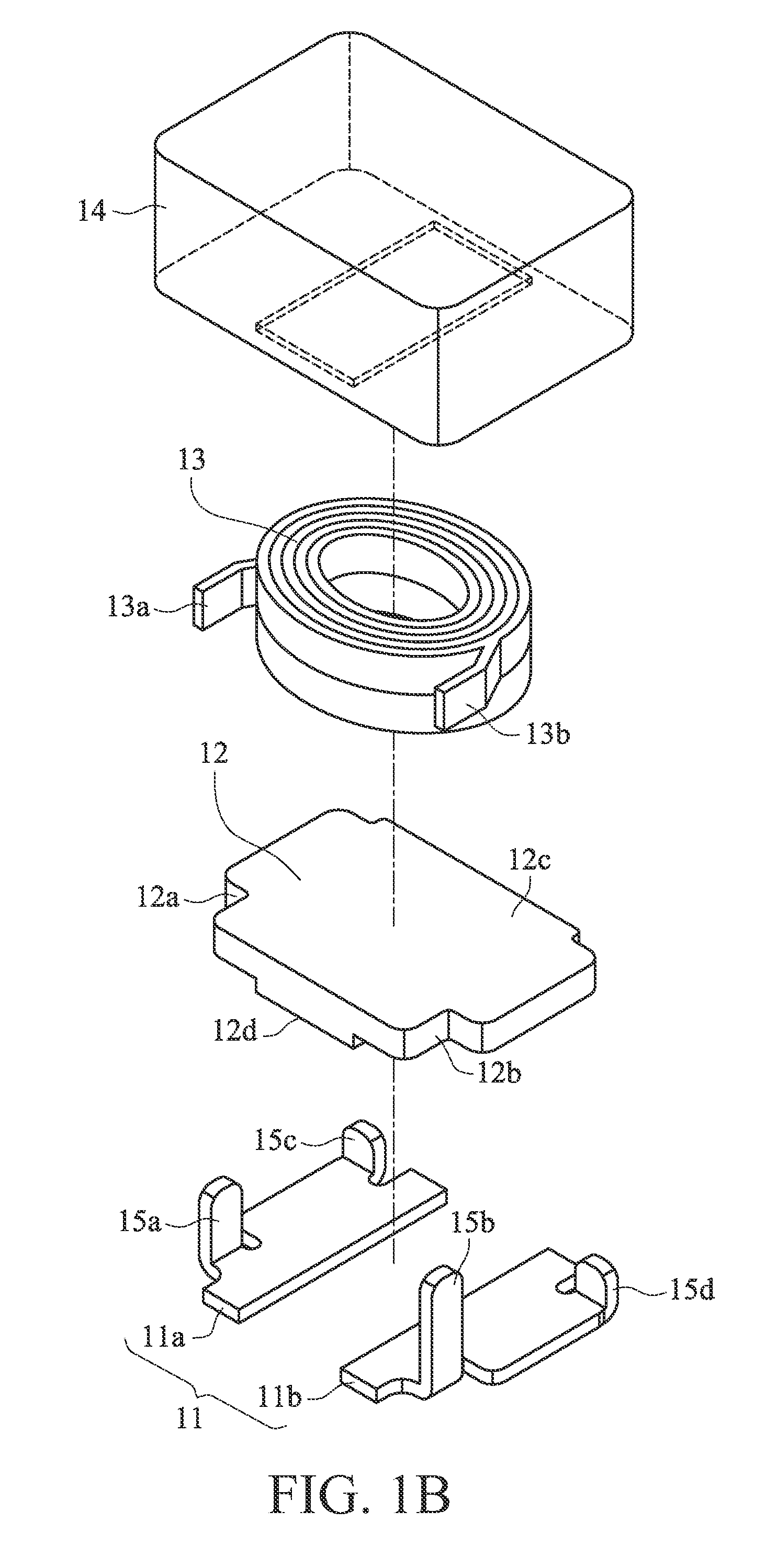

Magnetic device and method of manufacturing the same

ActiveUS20140002227A1High bonding strengthEasy to weldPrinted circuit assemblingTransformers/inductances coils/windings/connectionsEngineeringLead frame

Owner:CYNTEC

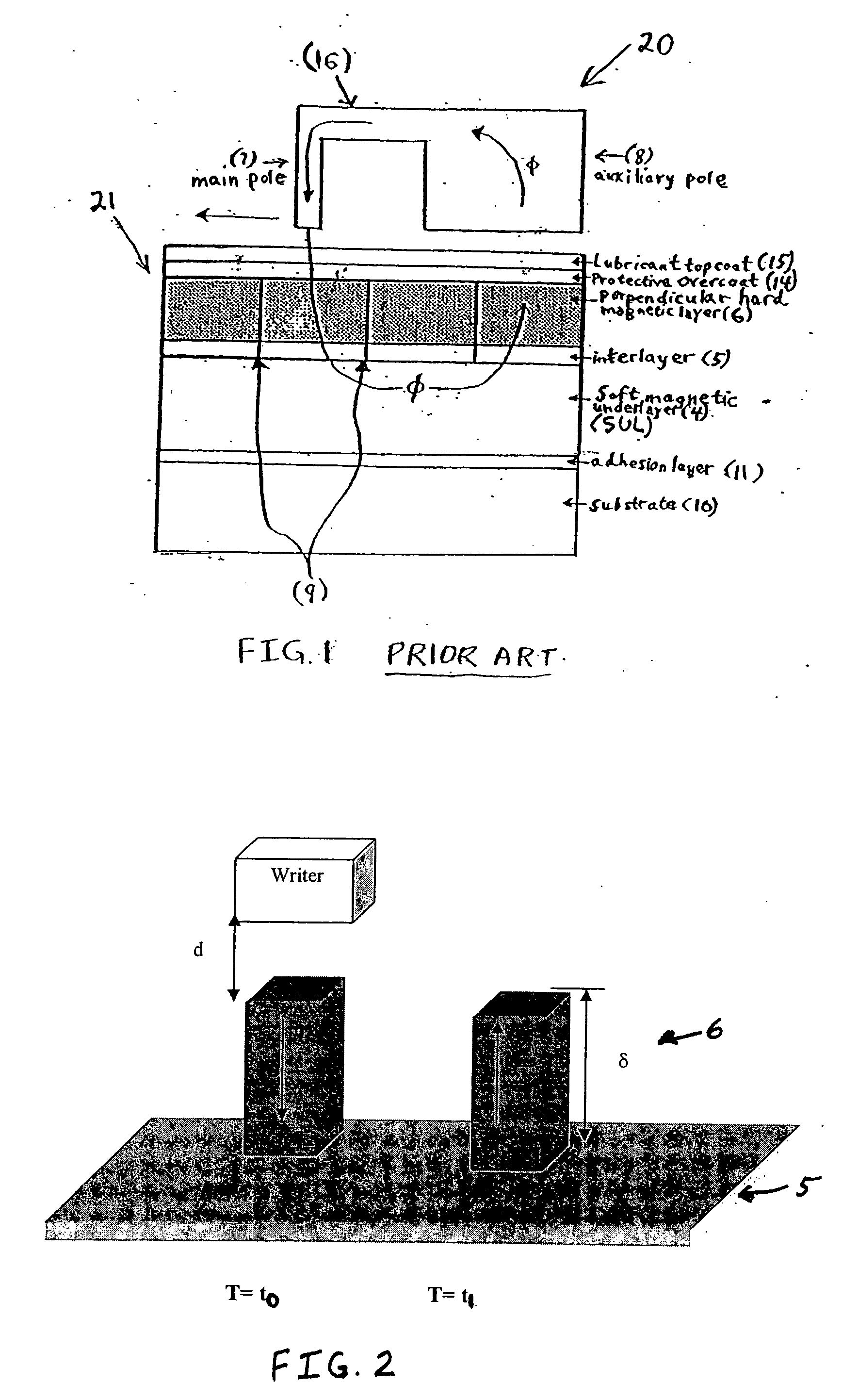

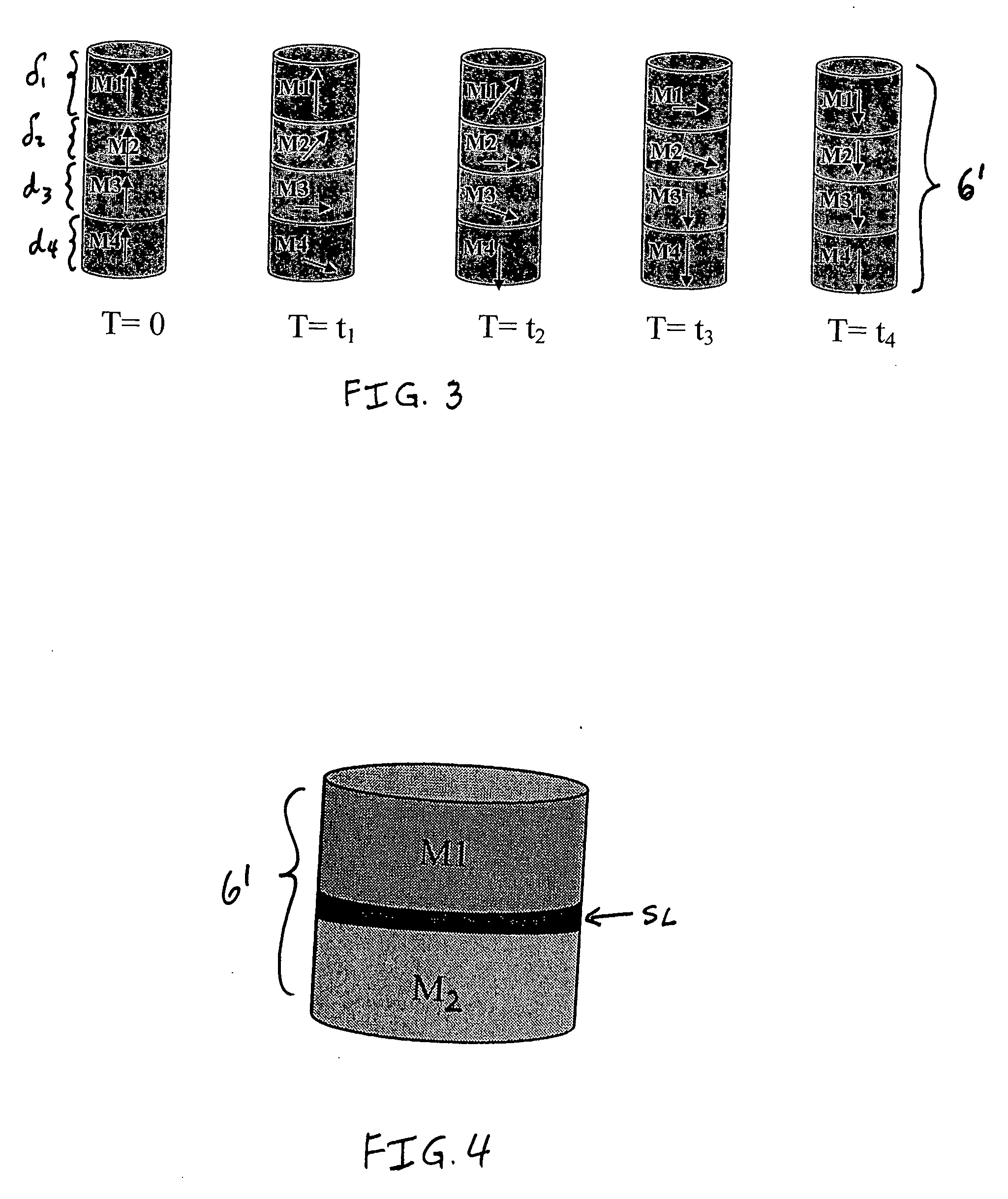

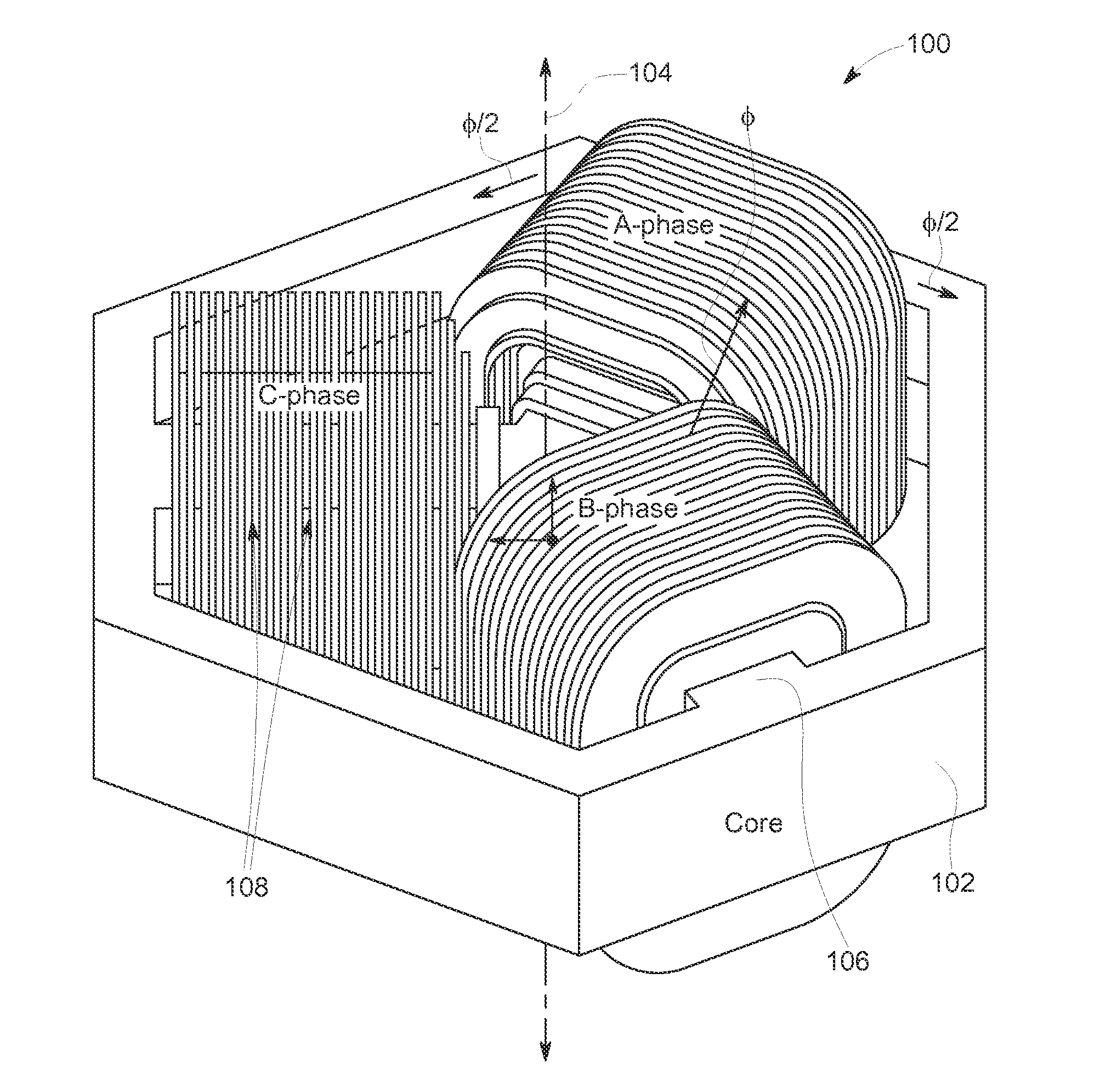

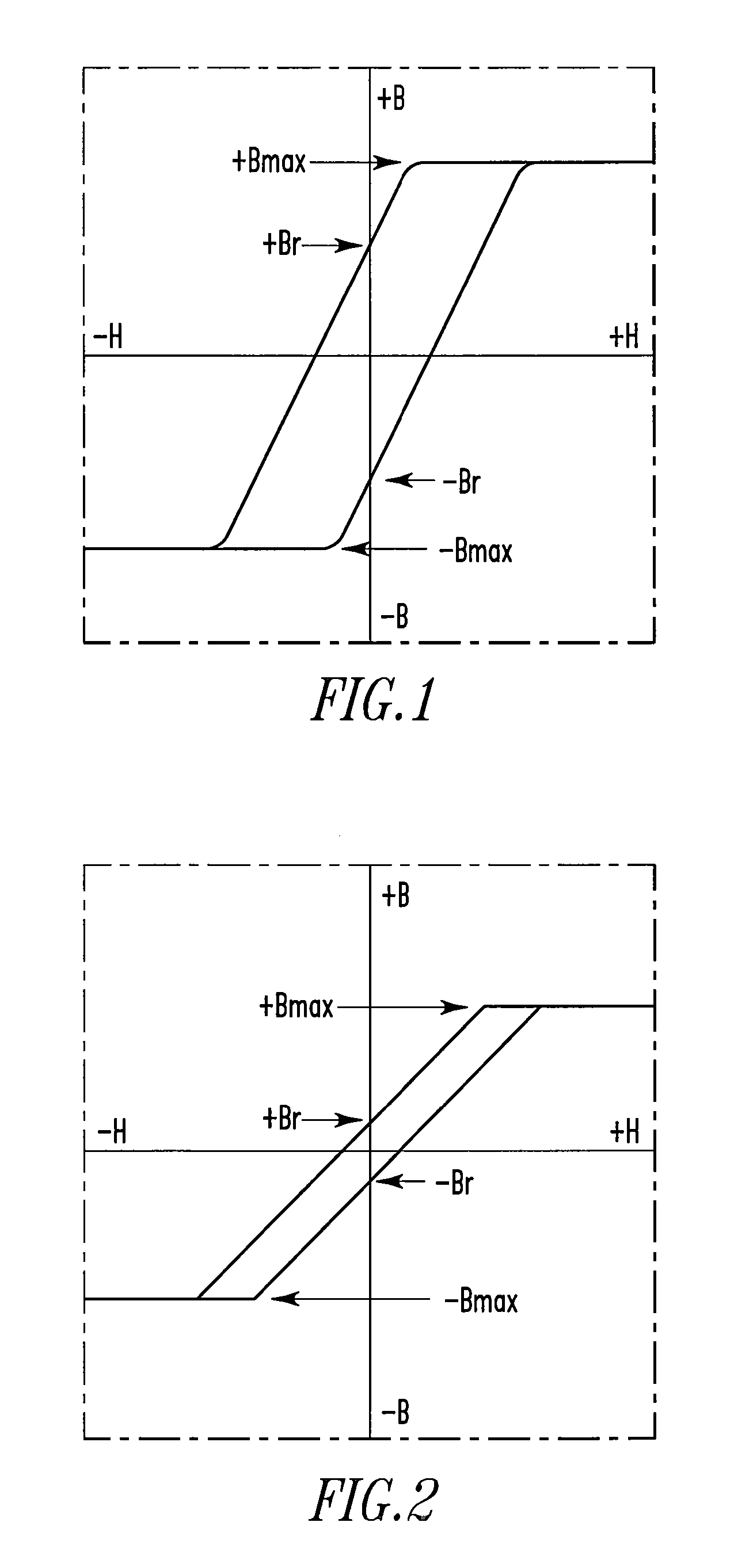

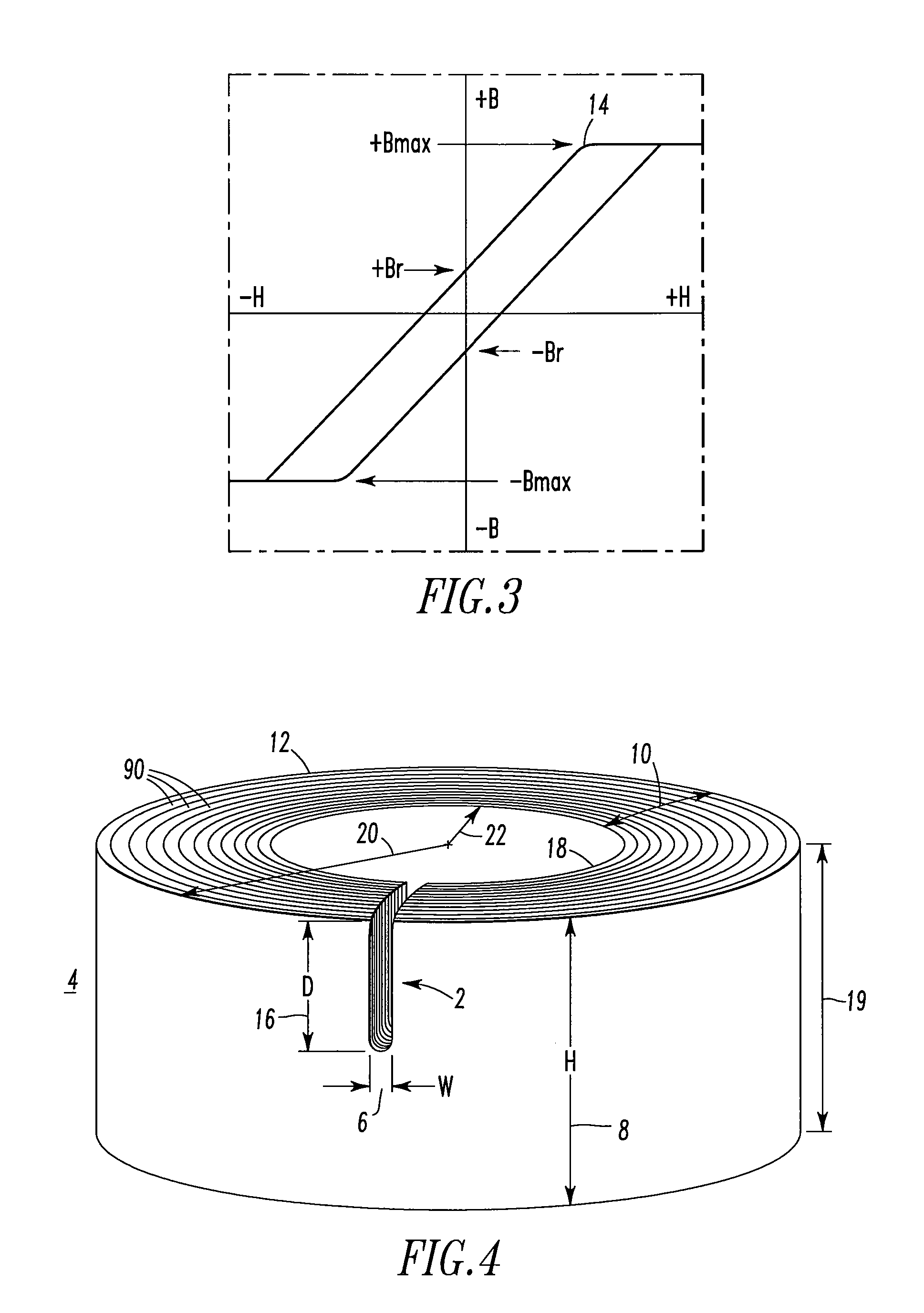

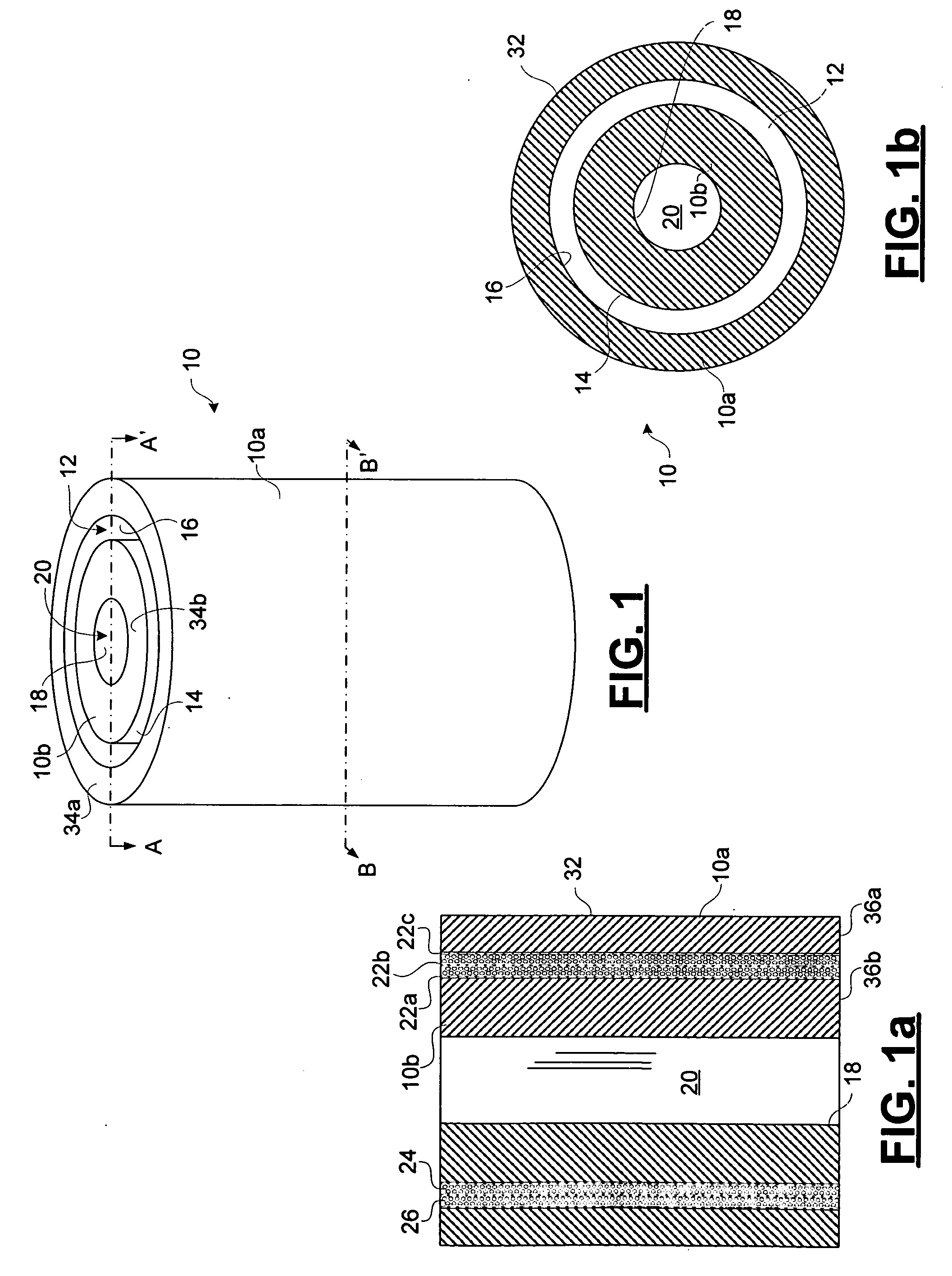

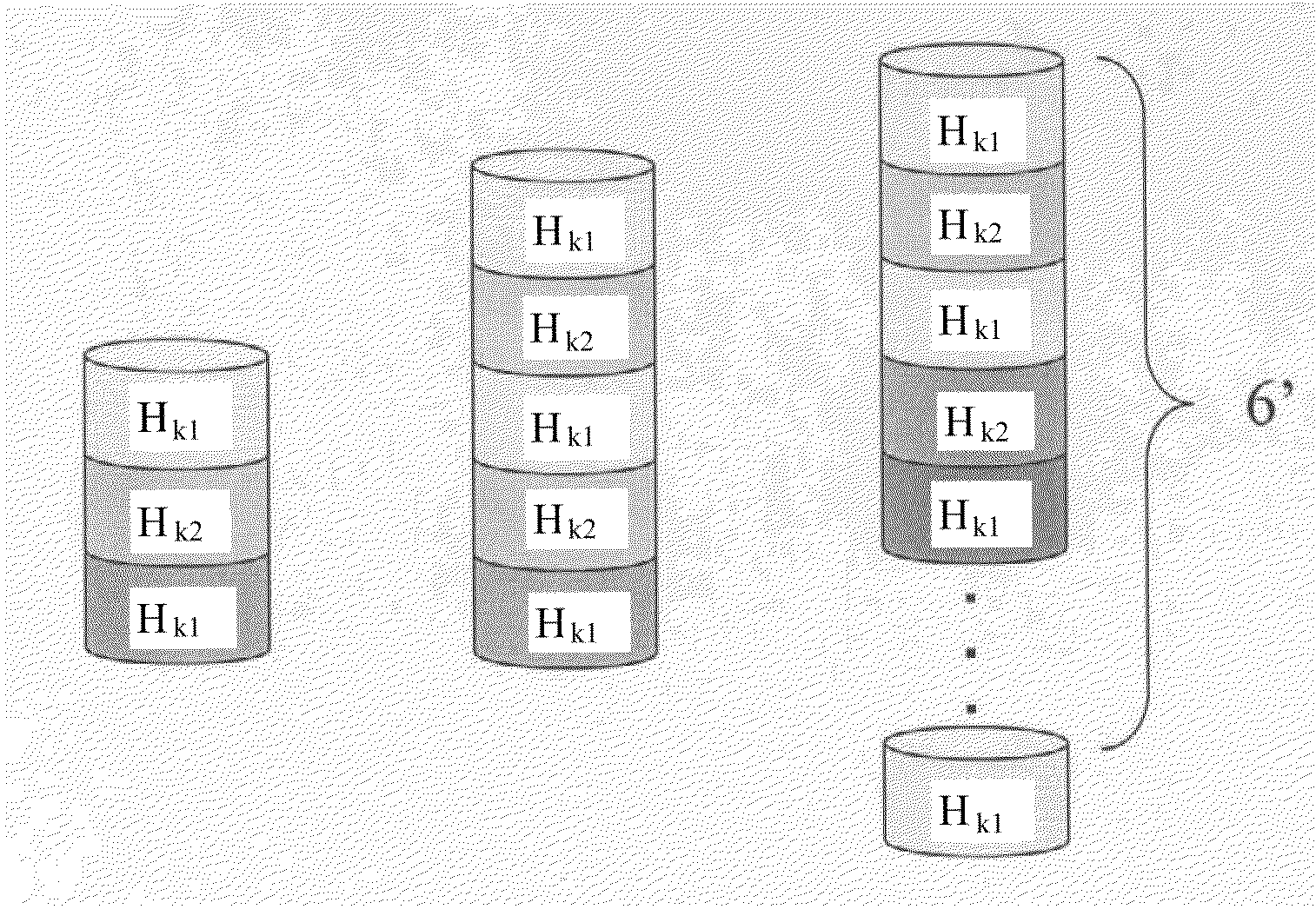

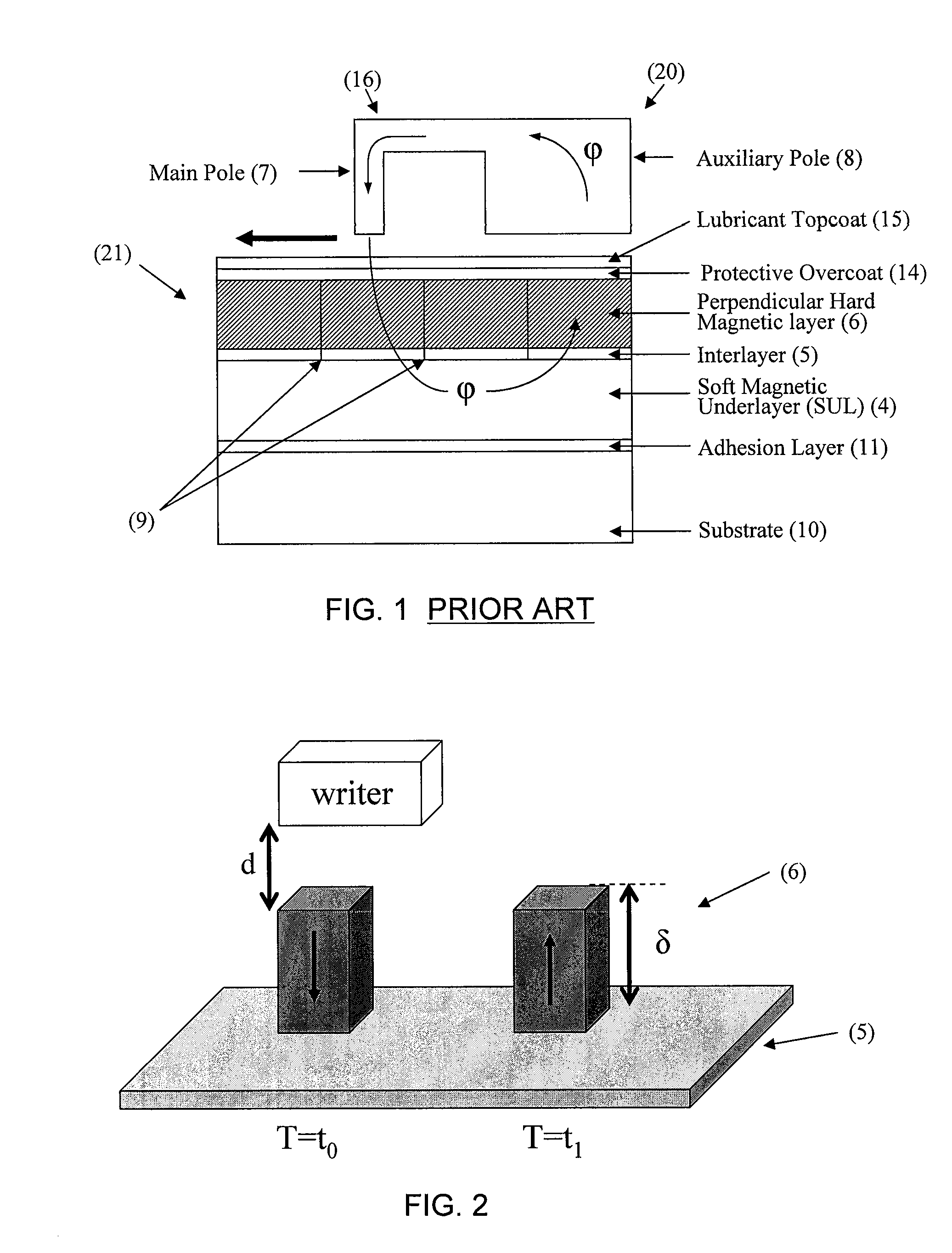

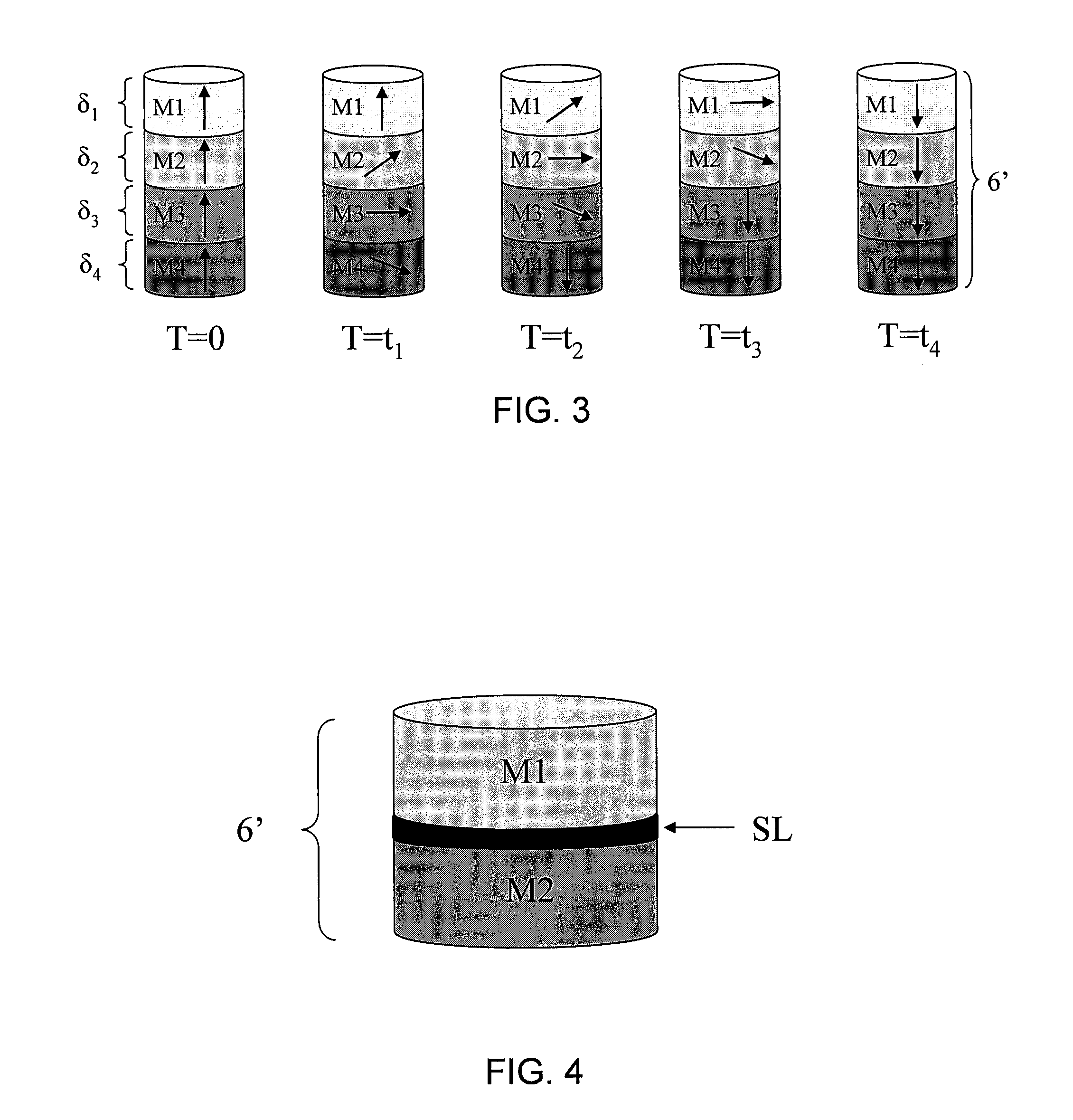

Perpendicular magnetic recording media with magnetic anisotropy/coercivity gradient and local exchange coupling

ActiveUS20070072011A1Improve recording densityHigh data recording ratePatterned record carriersNanoinformaticsMagnetic anisotropyRecording layer

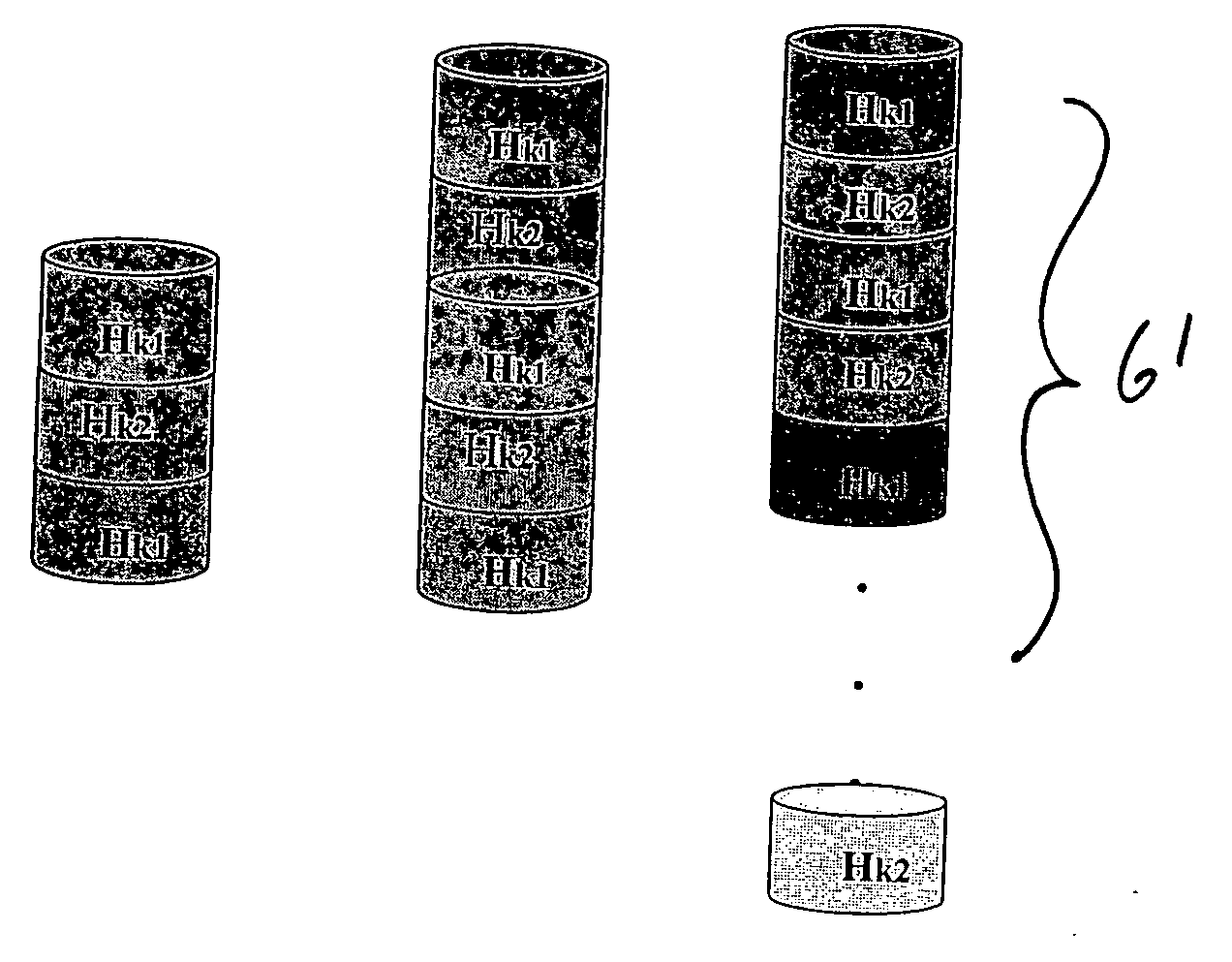

A perpendicular magnetic recording medium adapted for high recording density and high data recording rate comprises a non-magnetic substrate having at least one surface with a layer stack formed thereon, the layer stack including a perpendicular recording layer containing a plurality of columnar-shaped magnetic grains extending perpendicularly to the substrate surface for a length, with a first end distal the surface and a second end proximal the surface, wherein each of the magnetic grains has: (1) a gradient of perpendicular magnetic coercivity Hk extending along its length between the first end and second ends; and (2) predetermined local exchange coupling strengths along the length.

Owner:SEAGATE TECH LLC

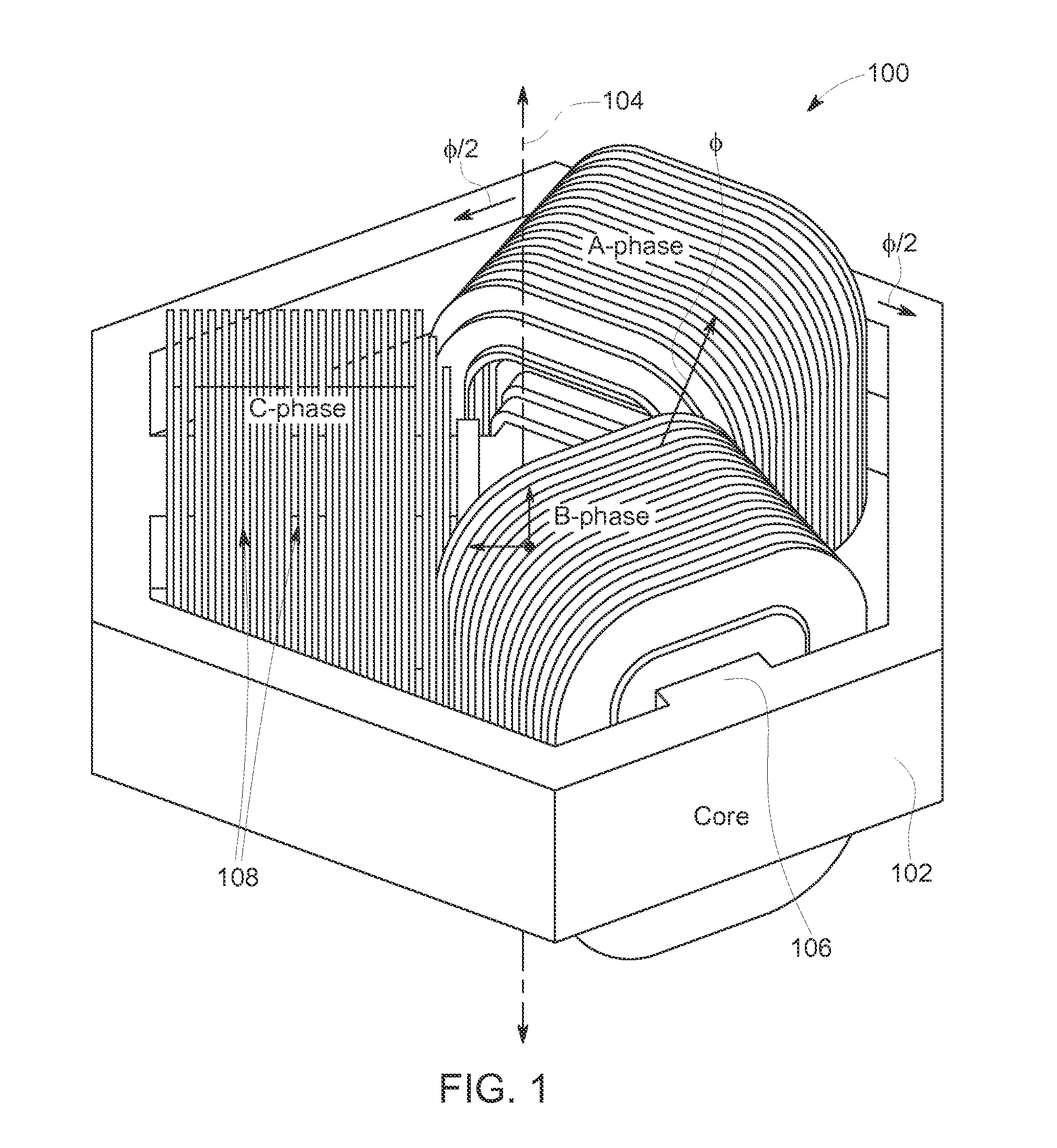

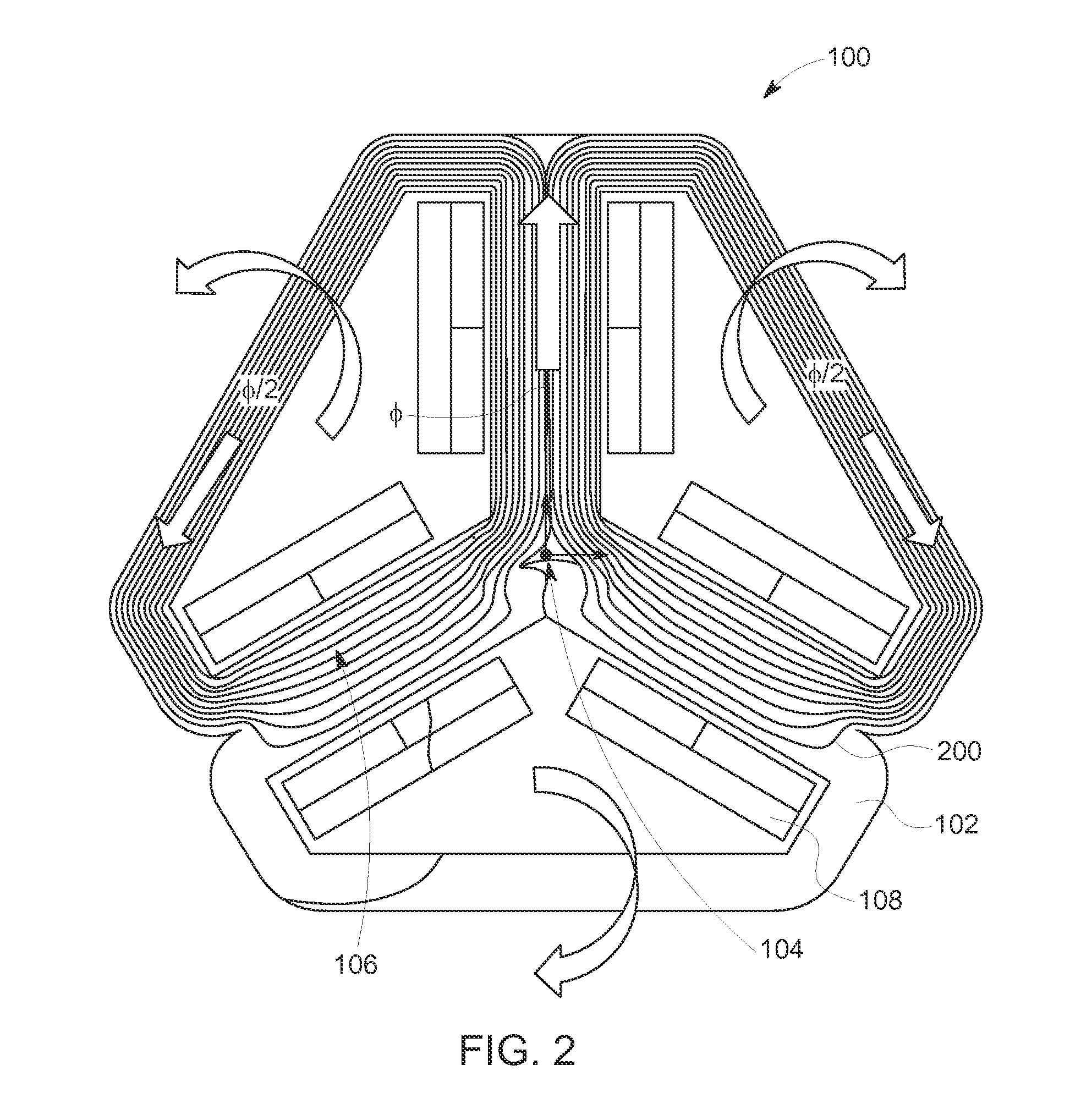

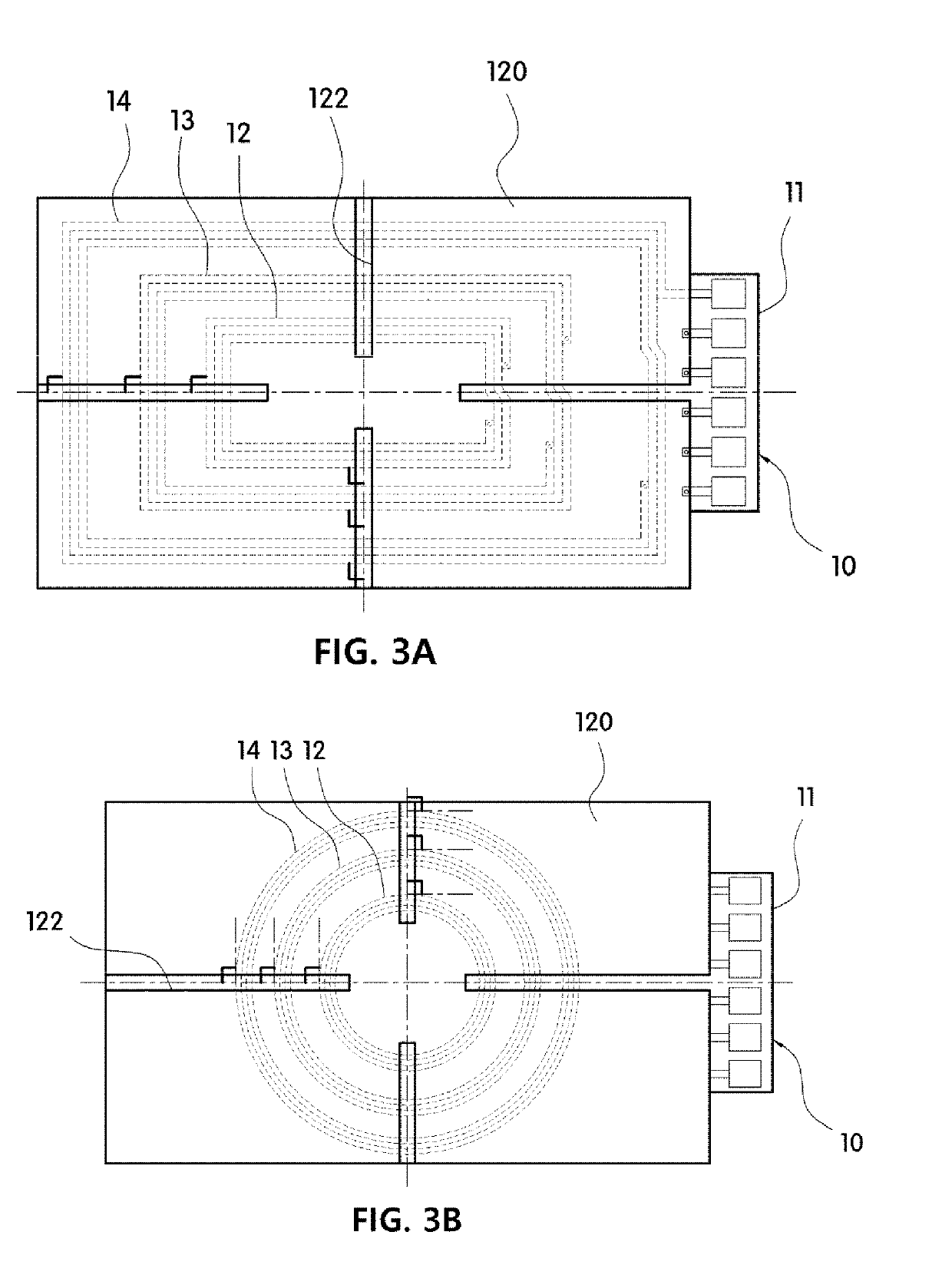

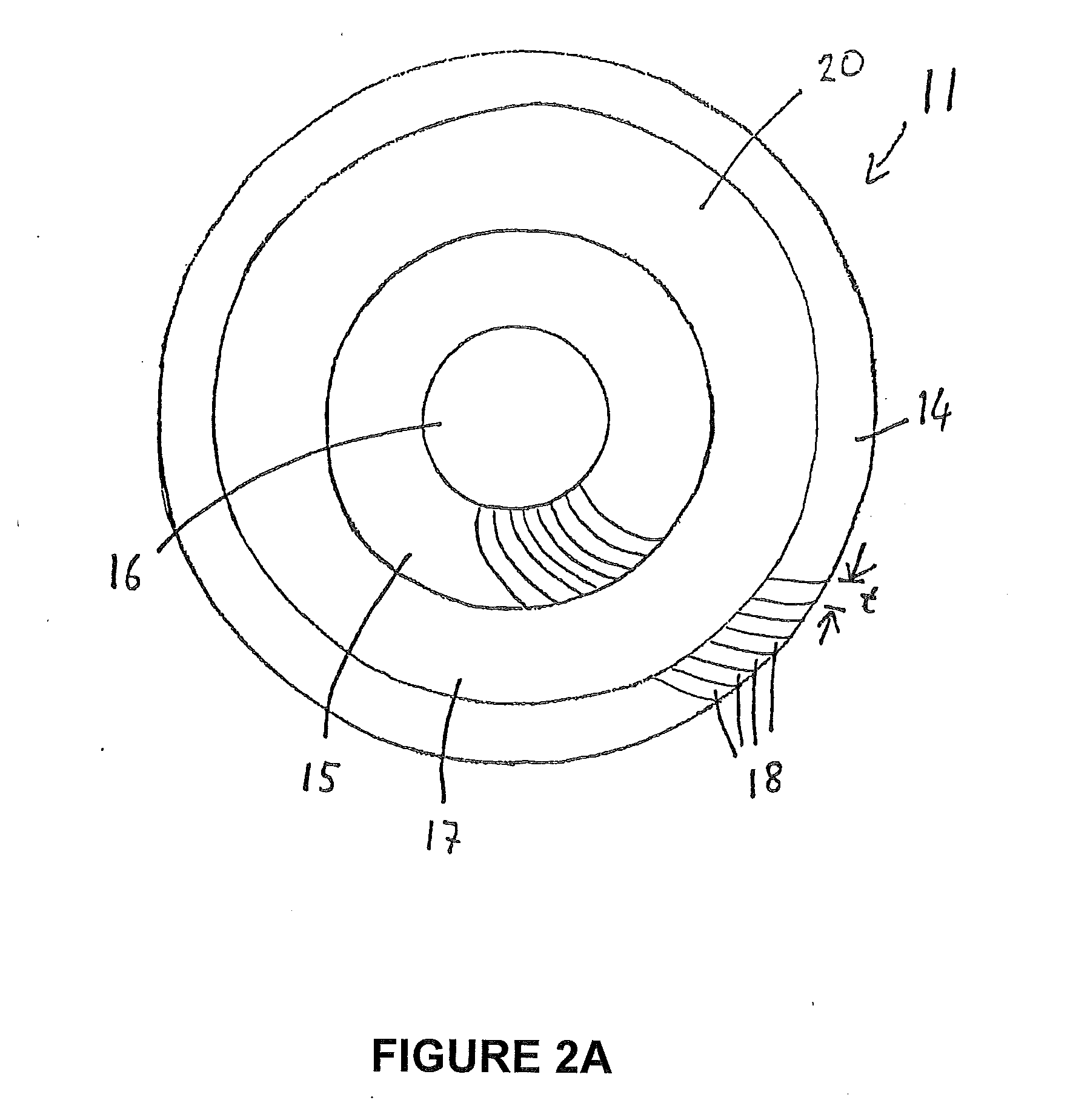

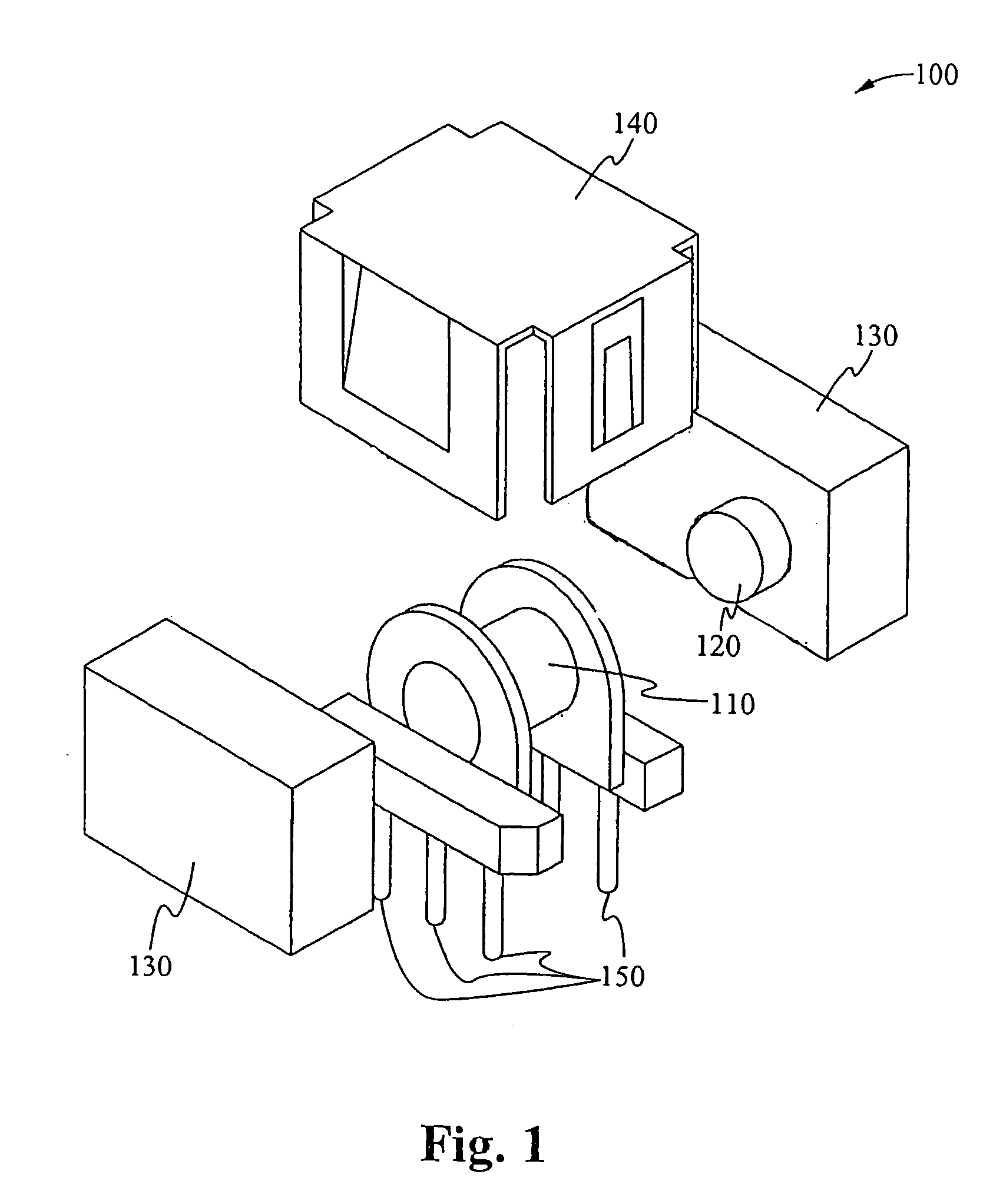

Filter assembly and method

ActiveUS20160125998A1Transformers/inductances coils/windings/connectionsFixed inductancesElectrical impedanceConductor Coil

An electronic filter assembly includes a magnetically conductive annular body extending around a center axis, a set of magnetically conductive prongs radially extending from the center axis toward the annular body, and conductive windings extending around the prongs. The conductive windings can be disposed around the prongs instead of the annular body to assist in conduction of common mode magnetic flux, to reduce impedance of the filter assembly, and / or to more evenly distribute temperature in the filter assembly. A method for forming an electronic filter assembly includes forming an electronic filter assembly having a magnetically conductive annular body extending around a center axis and a set of magnetically conductive prongs radially extending from the center axis toward the annular body. The annular body and the prongs can be formed by coupling plural layers of magnetically conductive bodies together.

Owner:GE GLOBAL SOURCING LLC

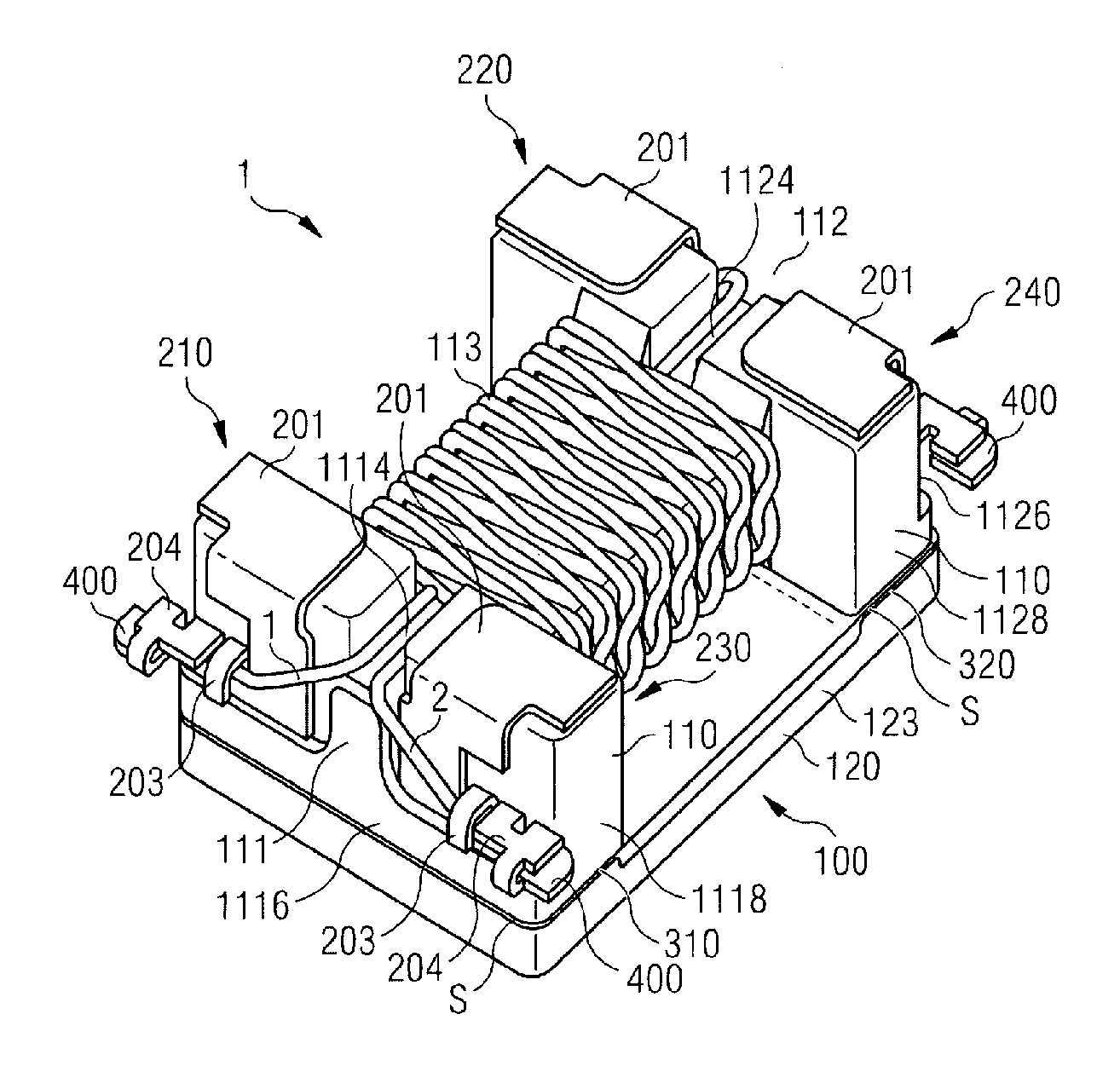

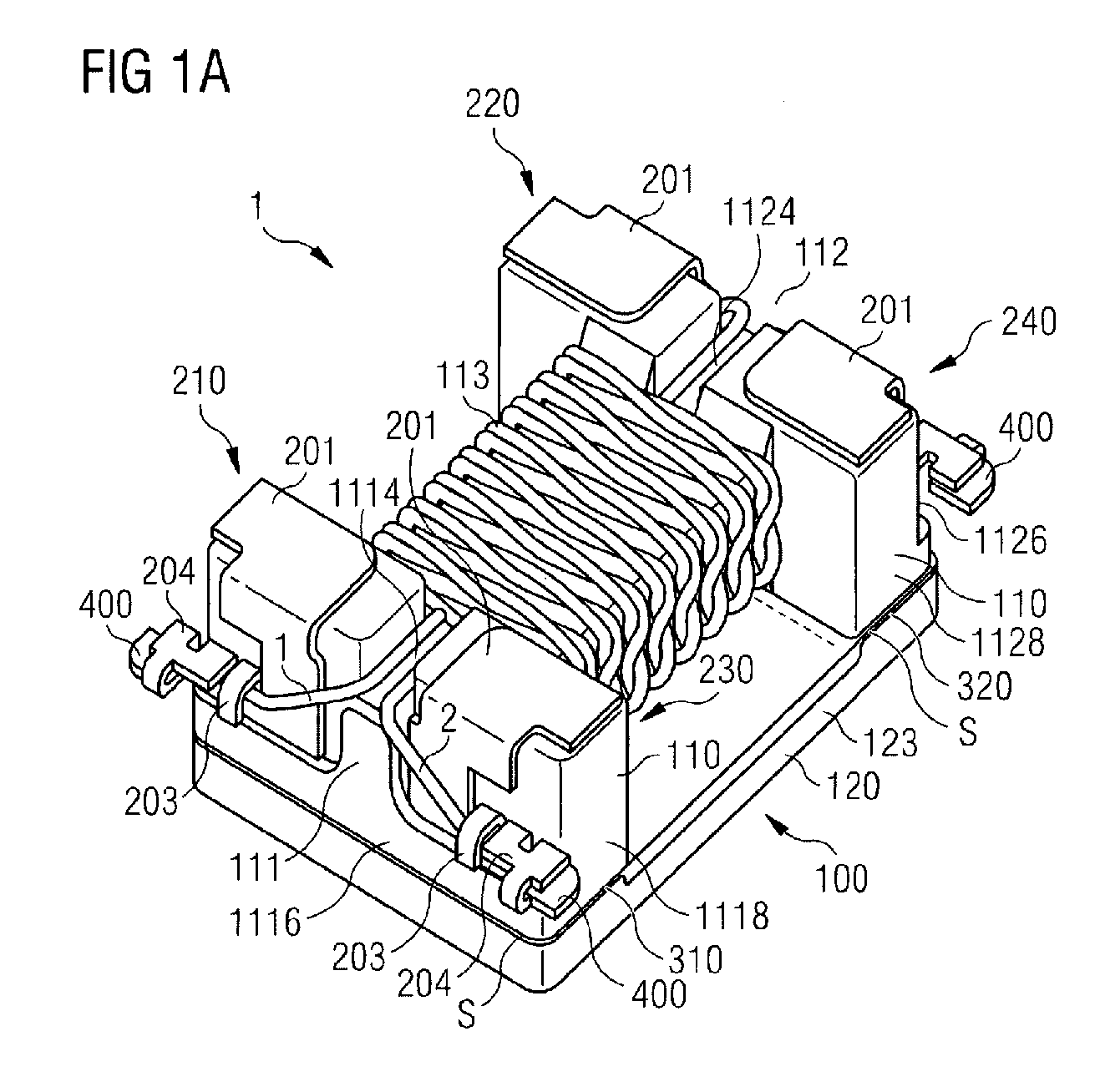

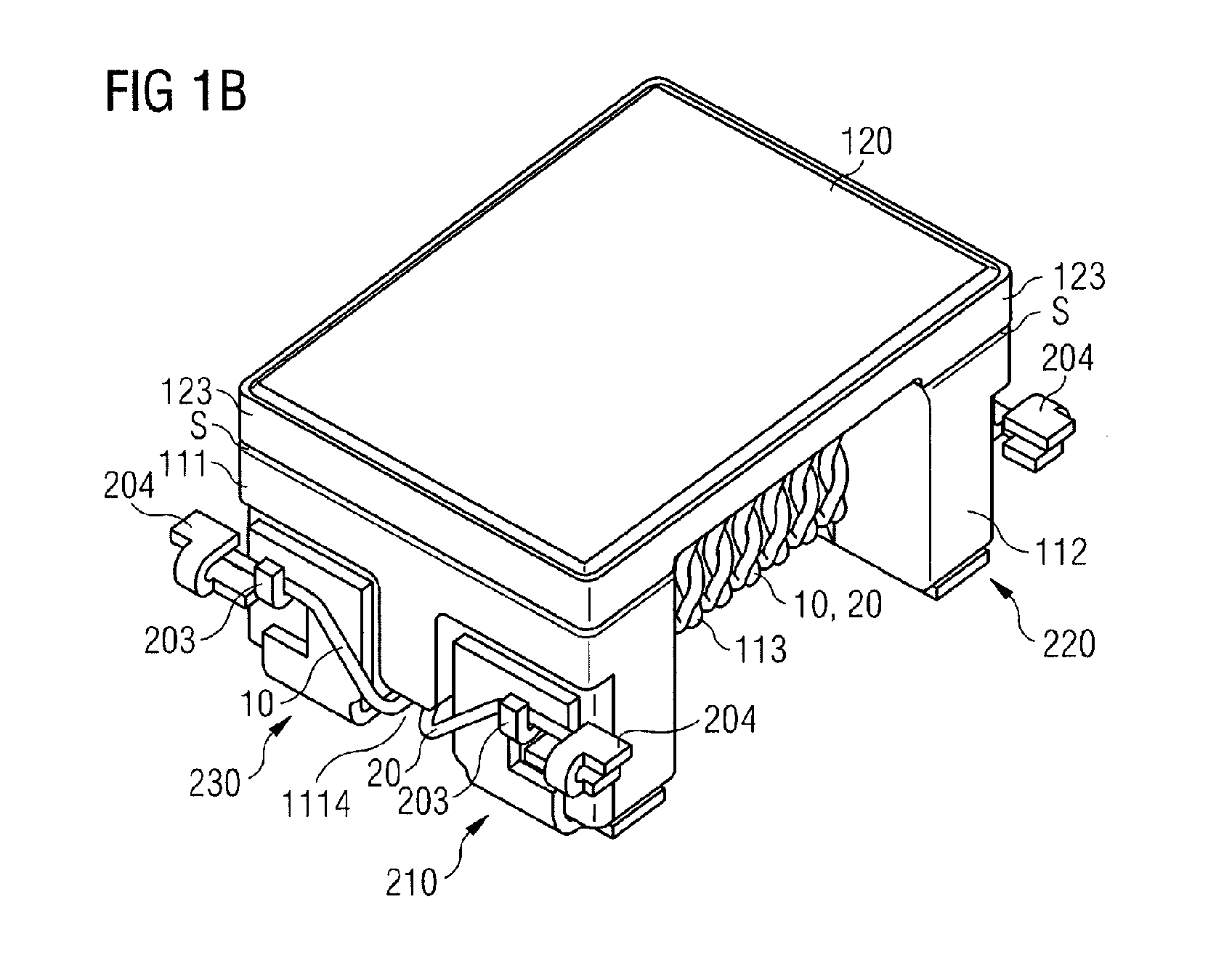

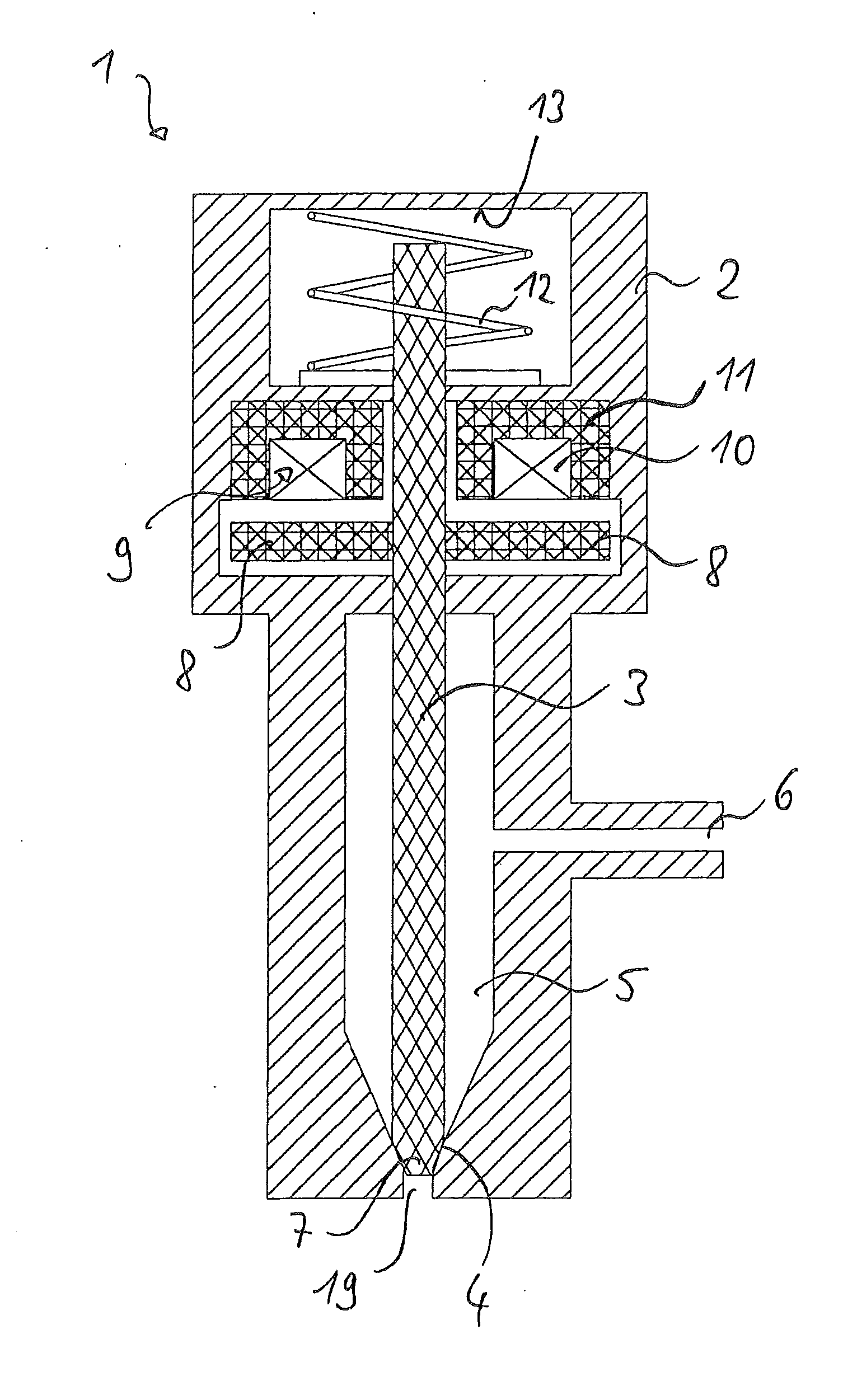

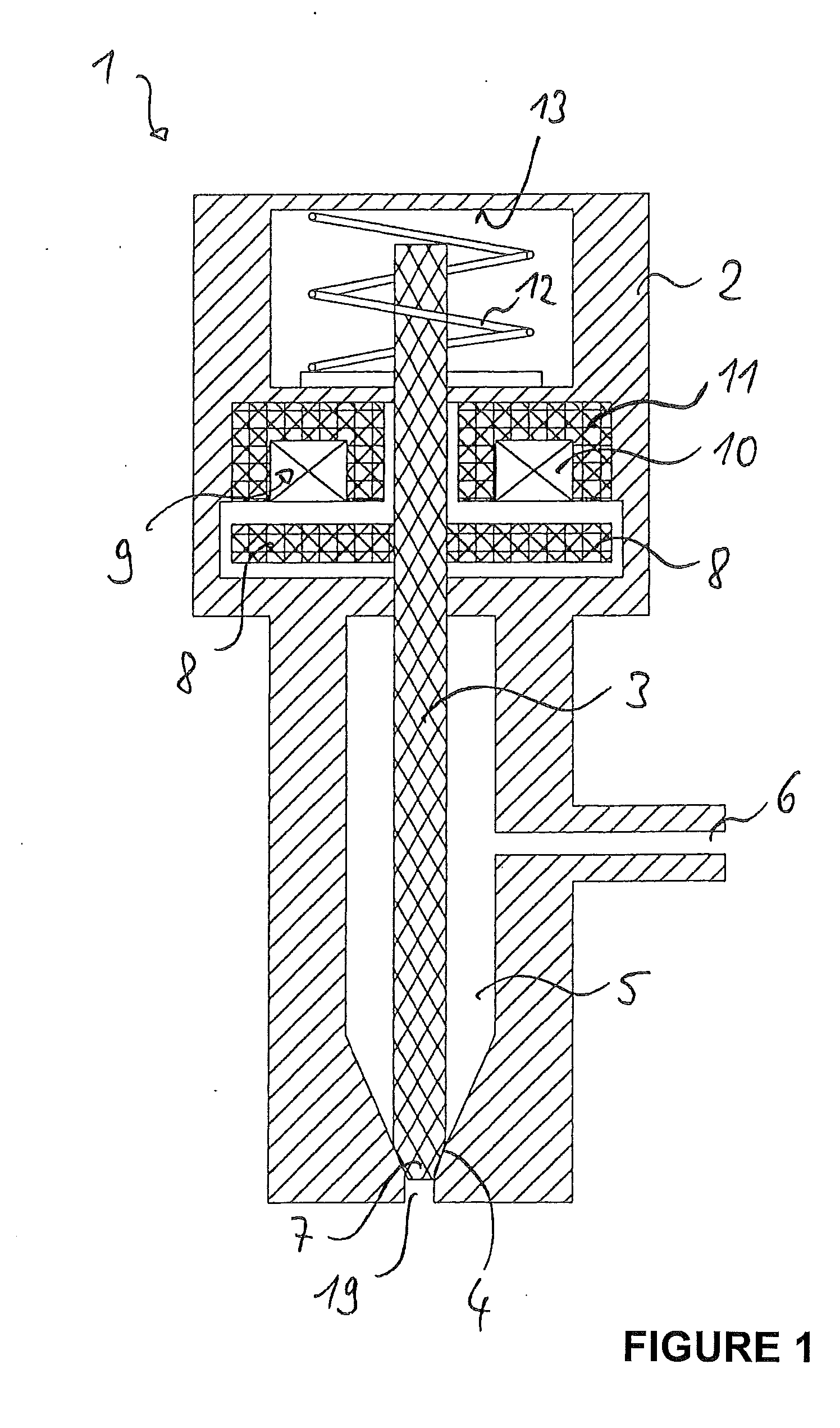

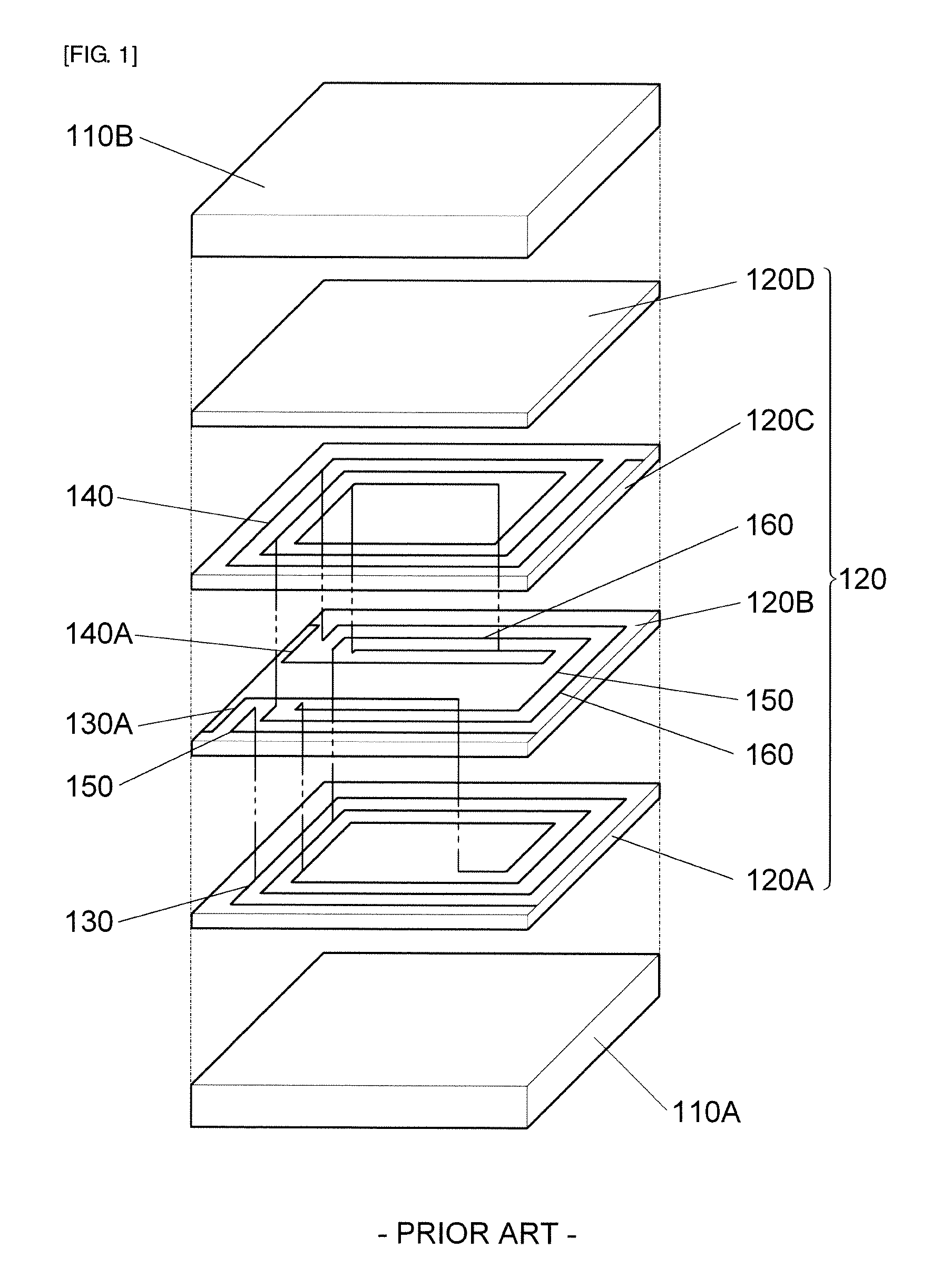

Inductive Component and Method for Producing an Inductive Component

ActiveUS20170025212A1Compact designTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesCapacitanceCapacitive coupling

An inductive component and a method for producing an inductive component are disclosed. In an embodiment, the inductive component includes a first core part having wound first and second wires and a second core part arranged on the first core part. In various embodiments the inductive component has a low mode conversion, a low inductance in differential-mode operation, a high inductance for common-mode signals, a constant characteristic impedance, a low capacitive coupling of the wires, and / or a low leakage inductance.

Owner:EPCOS AG

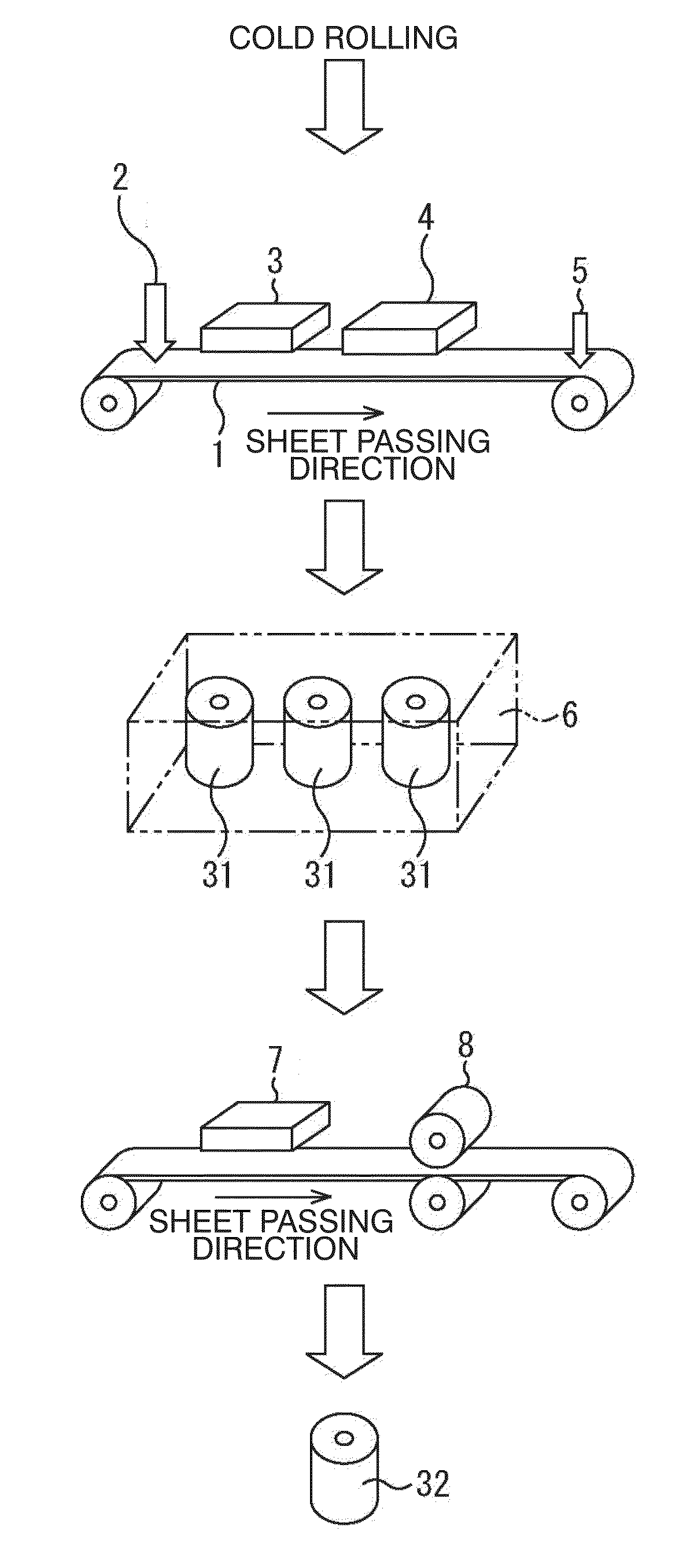

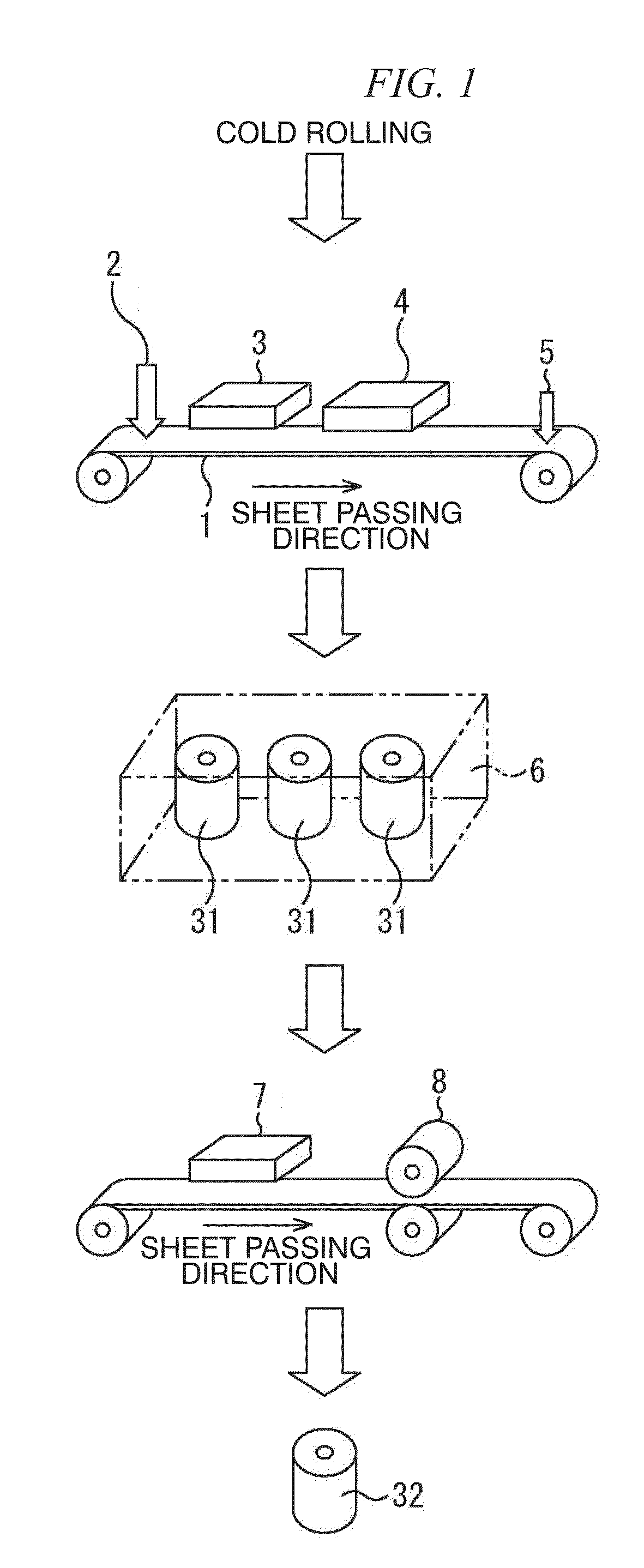

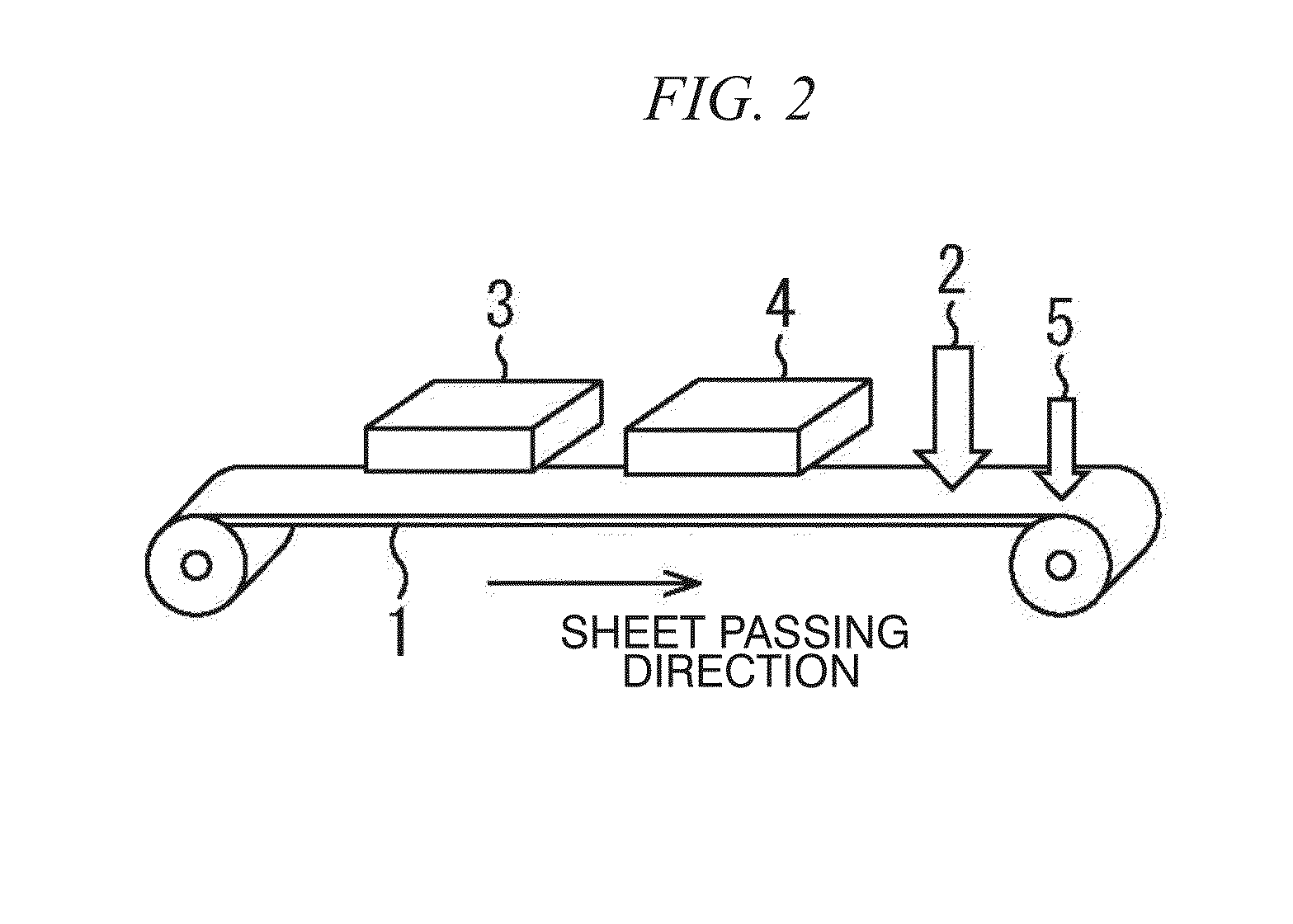

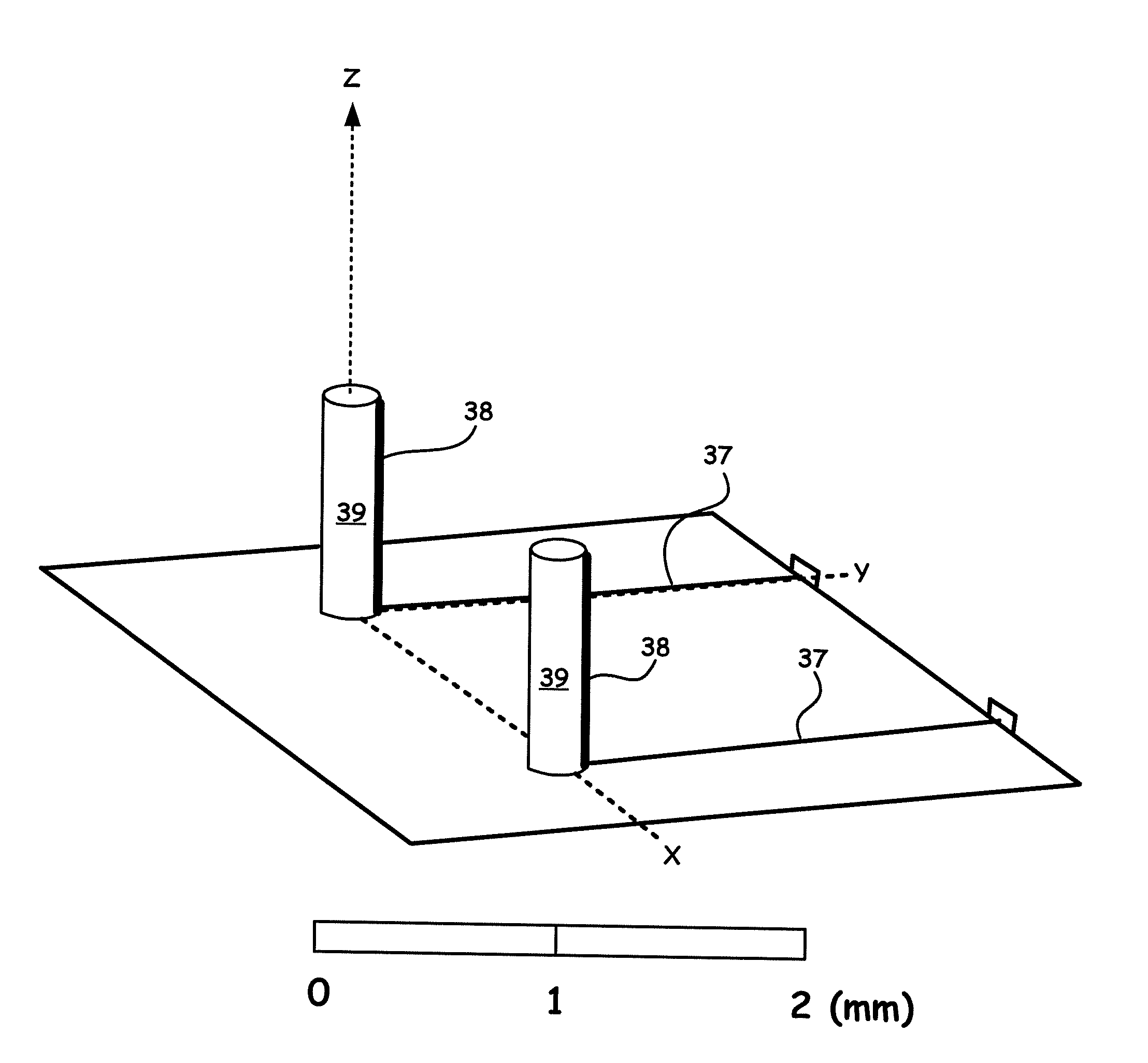

Grain-oriented electrical steel sheet and method of manufacturing the same

ActiveUS20130139932A1Low iron-lossInorganic material magnetismMagnetic core manufactureElectrical steelSheet steel

This method of manufacturing a grain-oriented electrical steel sheet includes, between a cold rolling process and a winding process, a groove formation process of irradiating the surface of a silicon steel sheet with a laser beam multiple times at predetermined intervals in a sheet passing direction, over an area from one end edge to the other end edge, in a sheet width direction of the silicon steel sheet, thereby forming a groove along a locus of the laser beam.

Owner:NIPPON STEEL CORP

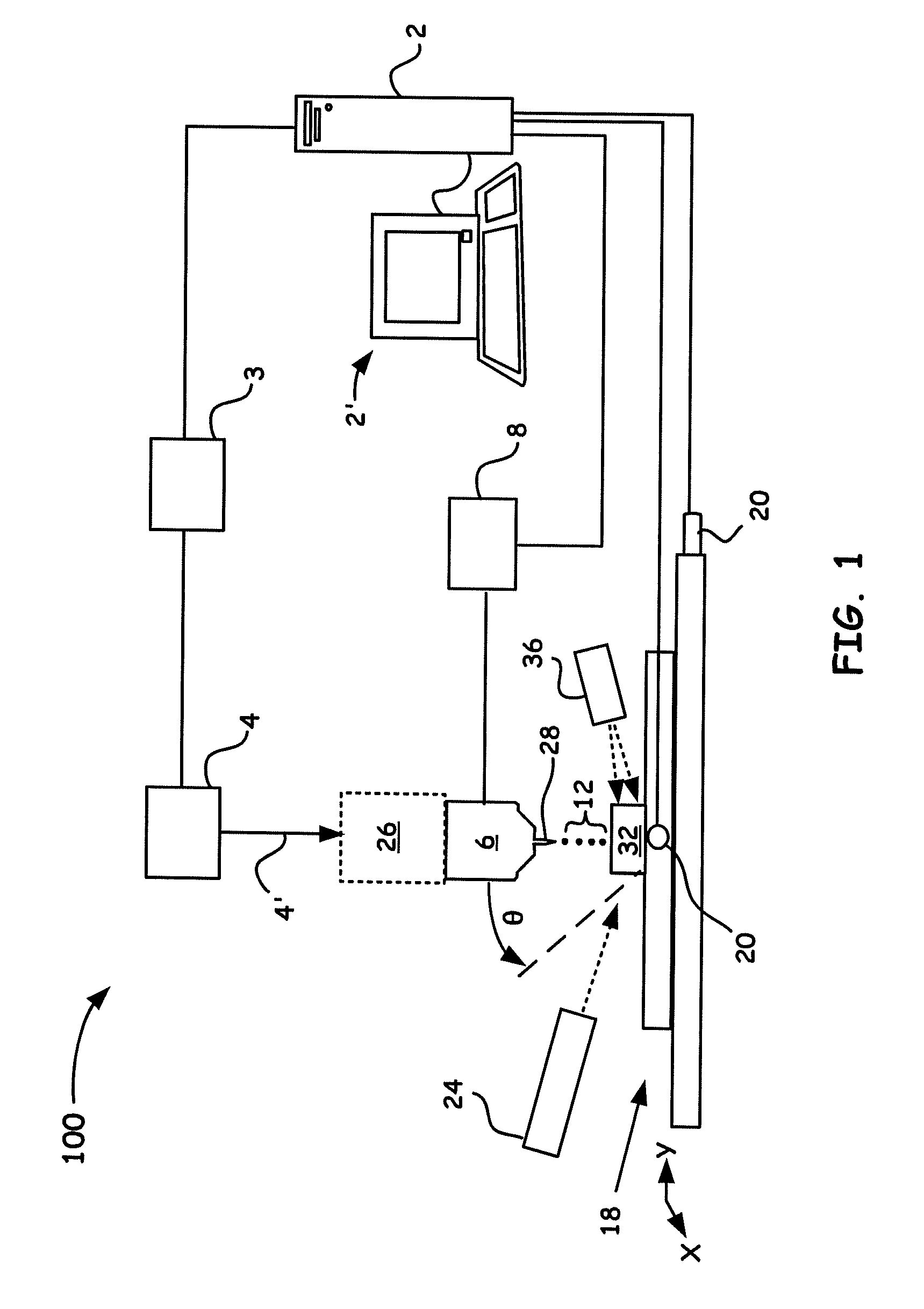

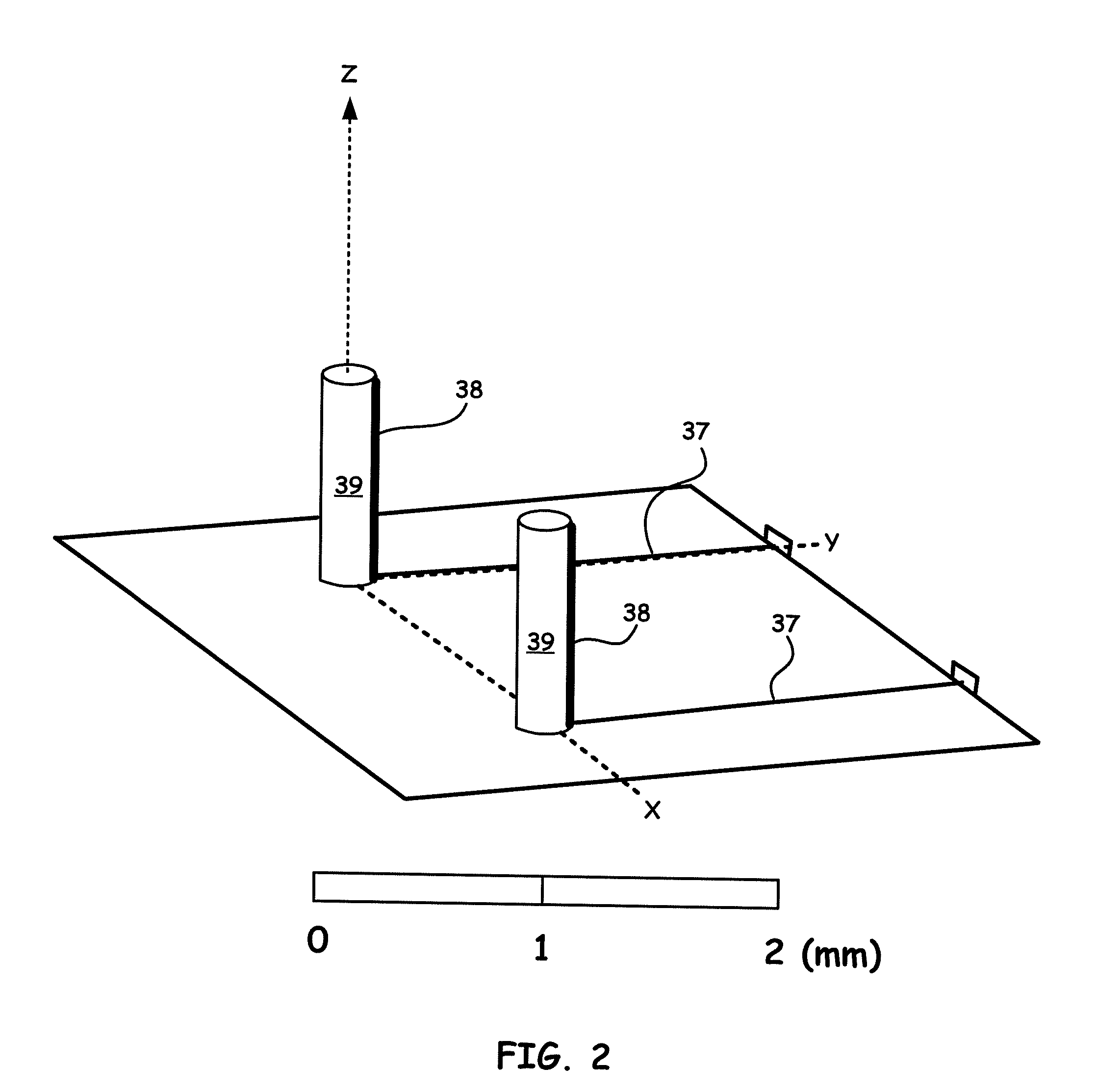

Three dimensional sub-mm wavelength sub-thz frequency antennas on flexible and uv-curable dielectric using printed electronic metal traces

ActiveUS20160172741A1High revenue streamCost-effective and versatile manufacturing processTransportation and packagingTransformers/inductances magnetic coresUltravioletLength wave

Novel methods for micro-additive manufacturing three dimensional sub-millimeter components are disclosed herein. The methods can include dispensing a dielectric at positions on a substrate so as to provide dielectric structures having an aspect ratio of up to 1:20. The methods can also include in-situ curing of the dielectric structure upon dispensing of the dielectric wherein the dispensing and curing steps provide for three dimensional configurations. Direct printing a metal nanoparticle solution on the dielectric to create conductive traces and thereafter sintering the printed nanoparticle solution so as to cure the conductive traces enables three dimensional conductive (antenna) elements having a length and width scale of down to 1 μm.

Owner:WASHINGTON STATE UNIVERSITY

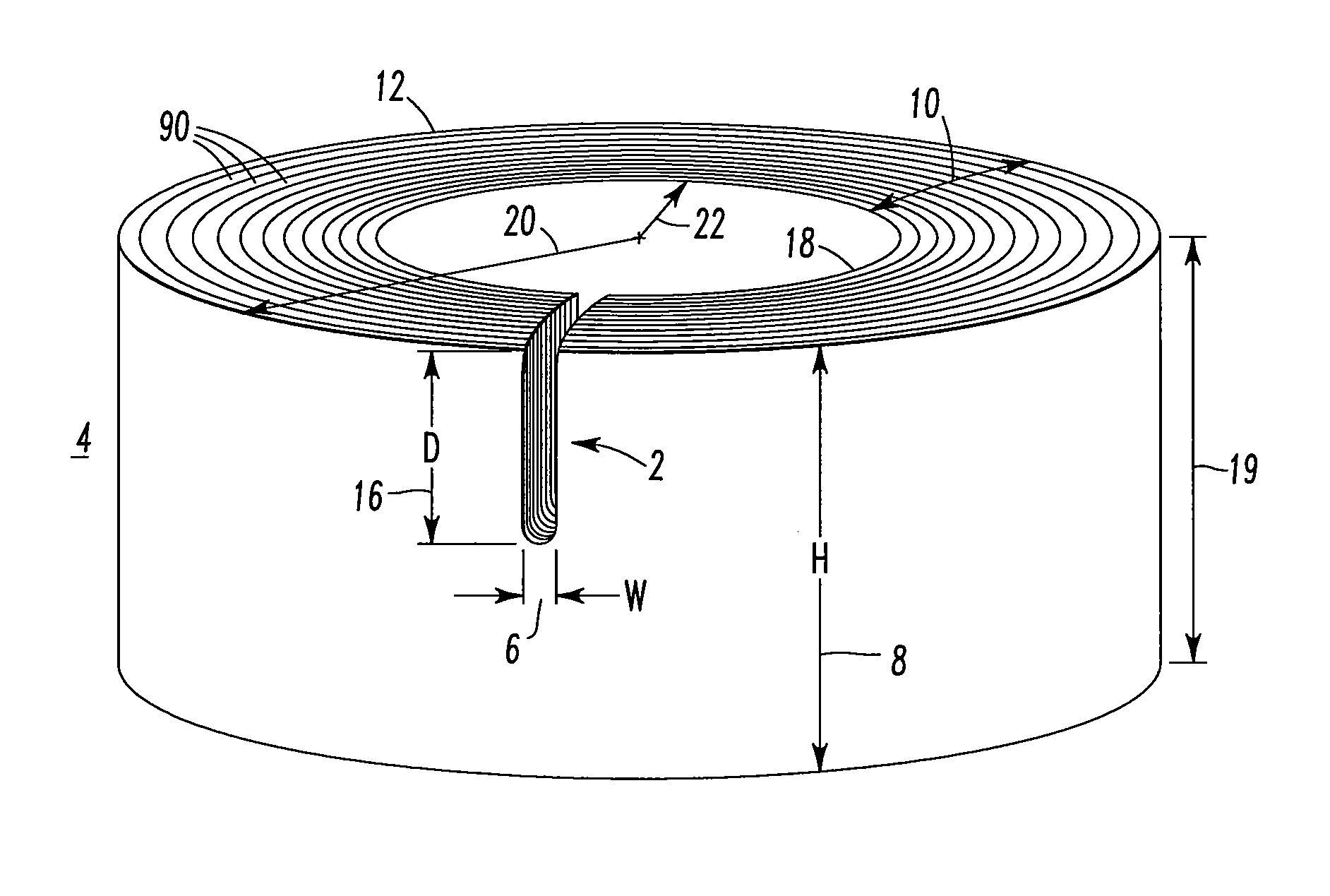

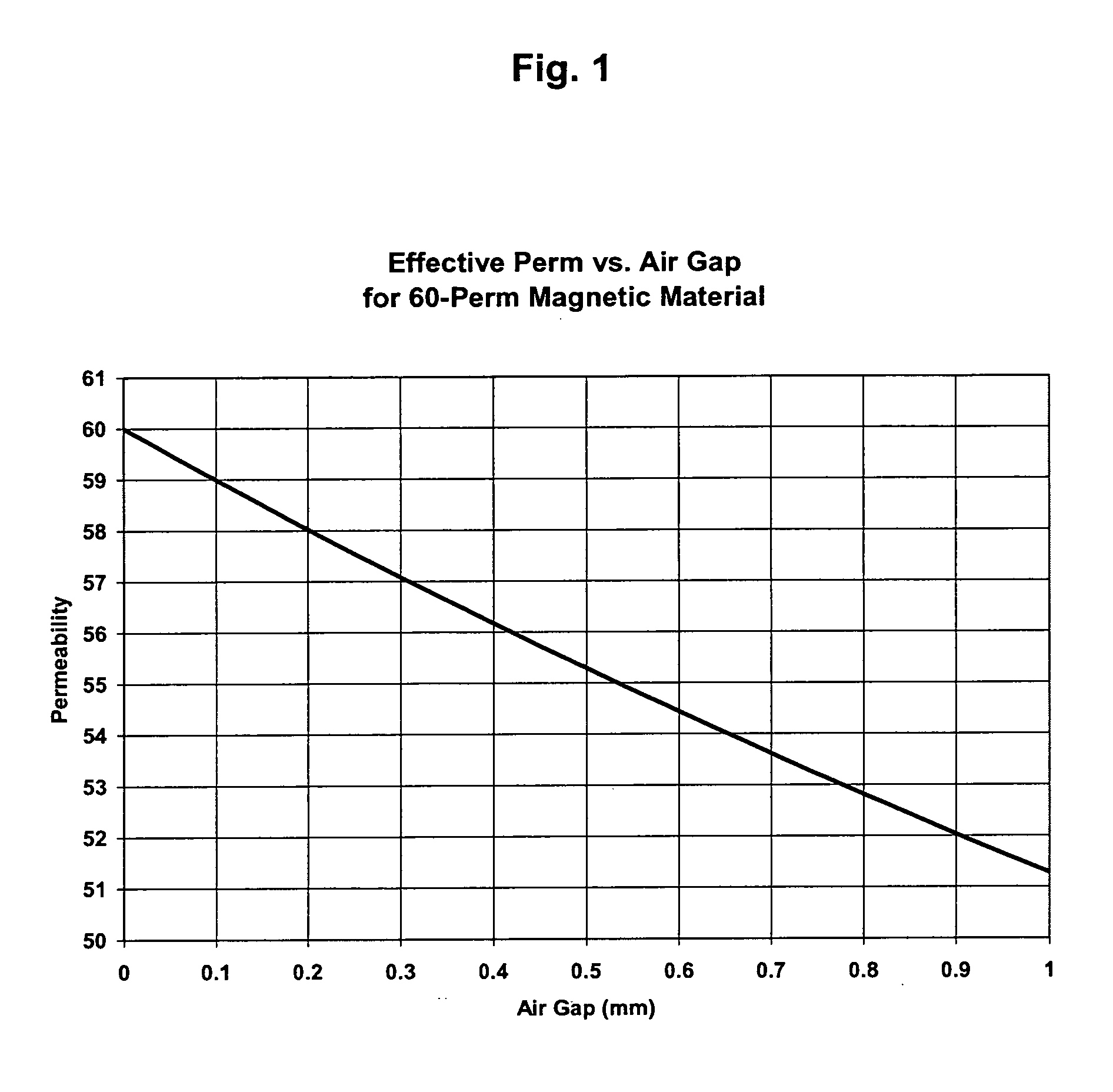

Current transformer, circuit interrupter including the same, and method of manufacturing the same

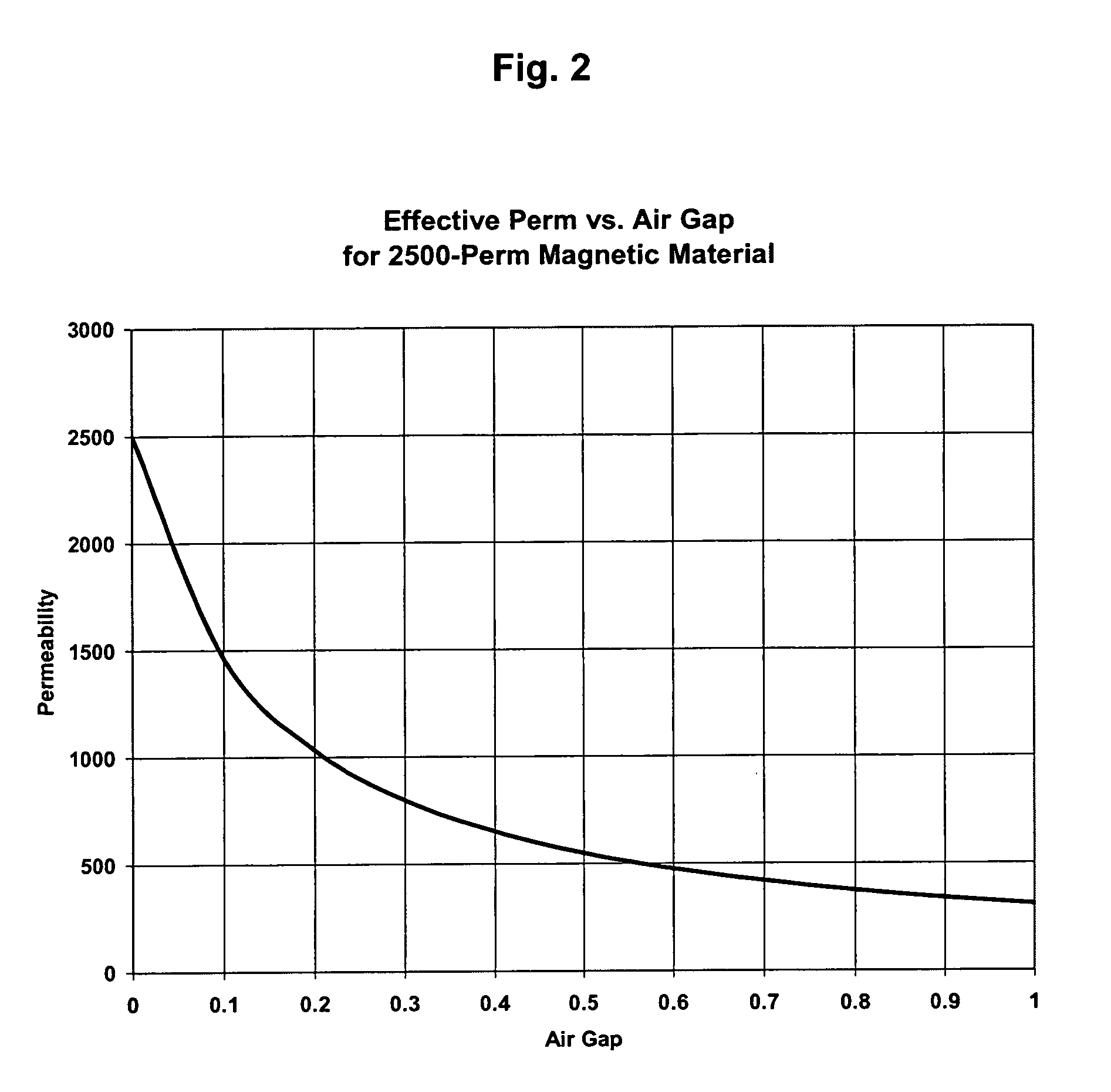

A current transformer includes a CT core having a central opening, a height, a width, inner and outer radii, and a secondary winding disposed about the CT core. The CT core is formed from a winding of an elongated length of taped steel having a reluctance and a width. The CT core height corresponds to the taped steel width. The CT core width is equal to the difference between the outer and inner radii. An air gap having a reluctance, a width and a depth is disposed in the CT core. The depth is along a portion of the CT core height. The air gap width is substantially smaller than the CT core height and width. The air gap reluctance is substantially greater than the taped steel reluctance. The CT core has a permeability resulting from being annealed at a temperature of 1450 to 1550° F. for one hour.

Owner:EATON INTELLIGENT POWER LTD

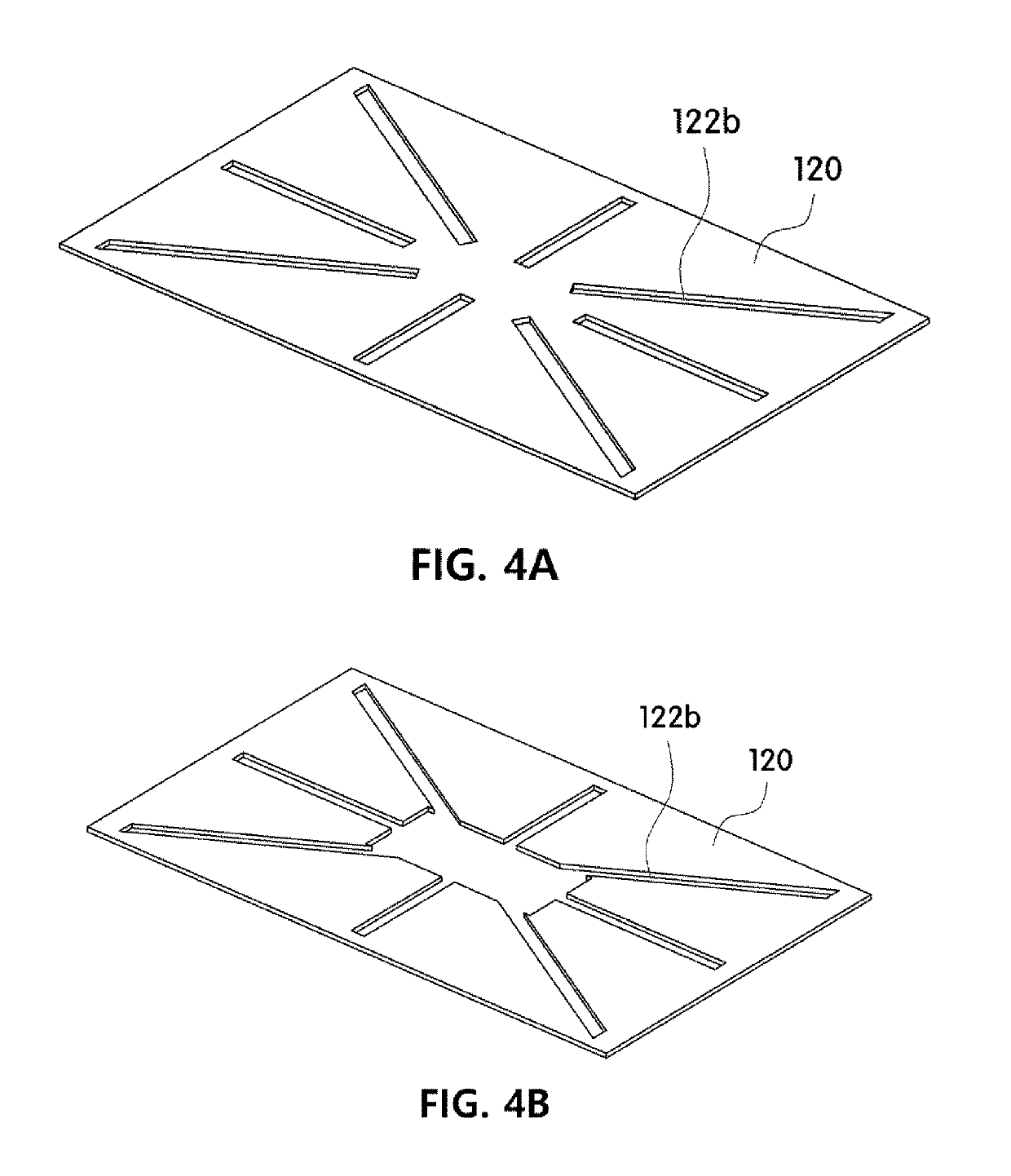

Method of manufacturing magnetic field shielding sheet and magnetic field shielding sheet formed thereby

ActiveUS20190148988A1Improve rigidityPrevent external impactShielding materialsBatteries circuit arrangementsPunchingEngineering

Disclosed is a method of manufacturing a magnetic field shielding sheet. The method of manufacturing a magnetic field shielding sheet formed as a plurality of divided pieces includes preparing a magnetic sheet formed of a magnetic material and having a first area and punching the magnetic sheet to form a shielding sheet using a mold such that the shielding sheet having a second area which is narrower than the first area is separated from the magnetic sheet, wherein the punching of the magnetic sheet to form the shielding sheet includes forming at least one linear slit in an inner region of the second area using the mold such that the shielding sheet is divided into a plurality of pieces while the shielding sheet is separated from the magnetic sheet to have the second area.

Owner:AMOSENSE

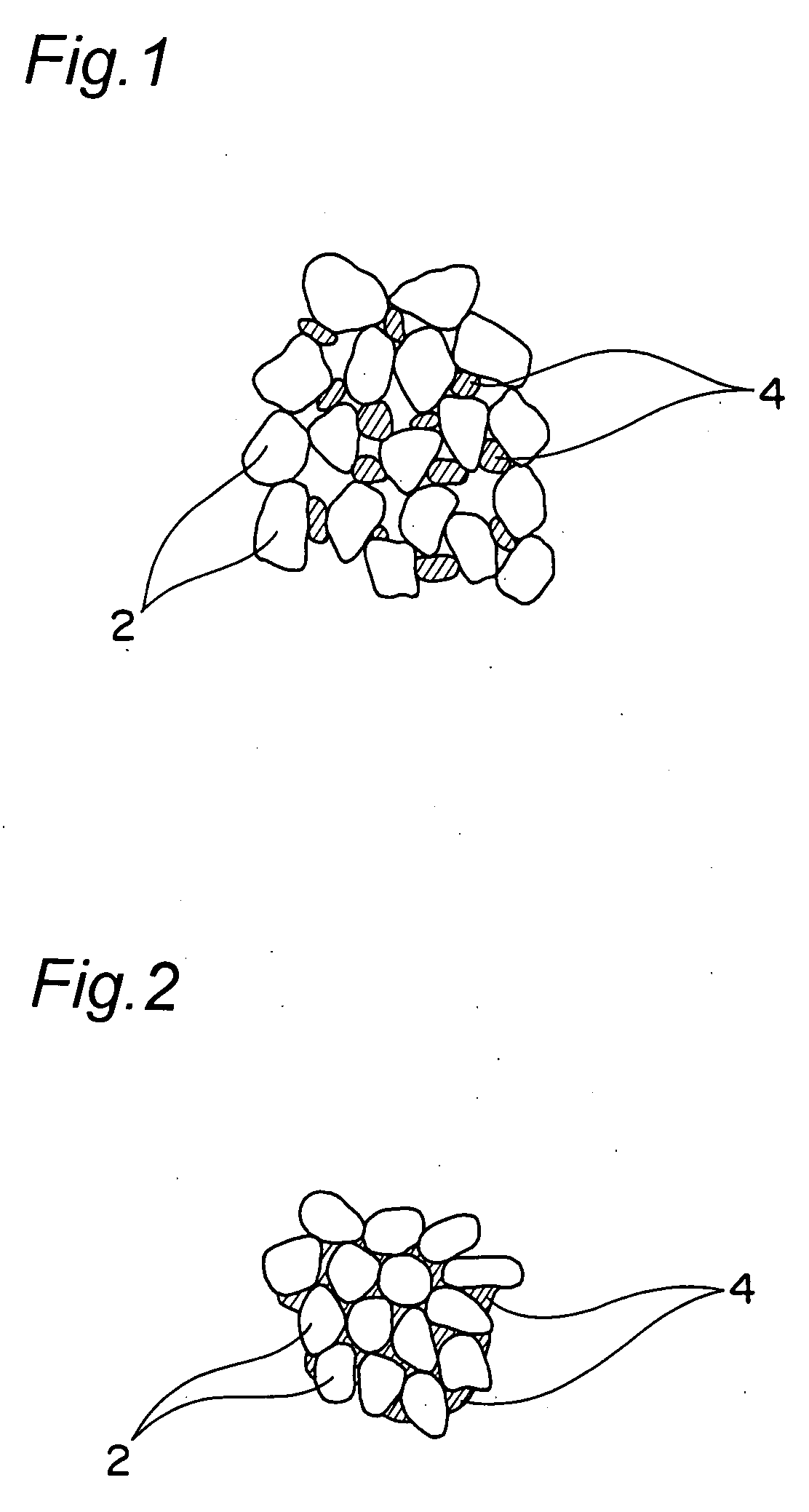

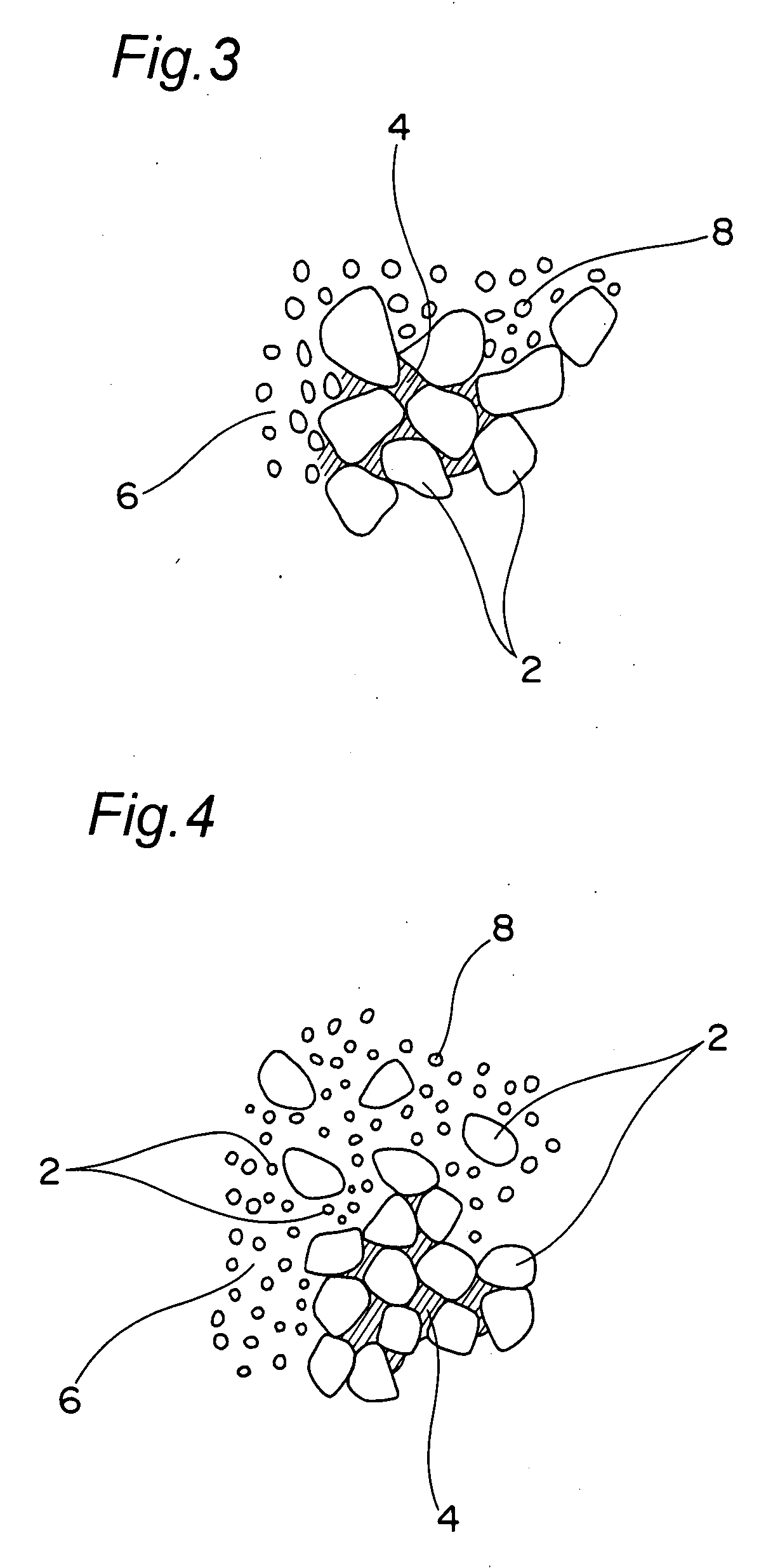

Method of Making a Magnetic Core Part

ActiveUS20070256759A1Small sizeHigh magnetic flux densityInorganic material magnetismTransformers/inductances detailsMaterials scienceMagnetic core

Magnetic powder contained in a resin composition for use in injection molding is coated with an insulating material, and a soft magnetic green compact or a hard magnetic green compact is insert molded into the resin composition.

Owner:NTN CORP

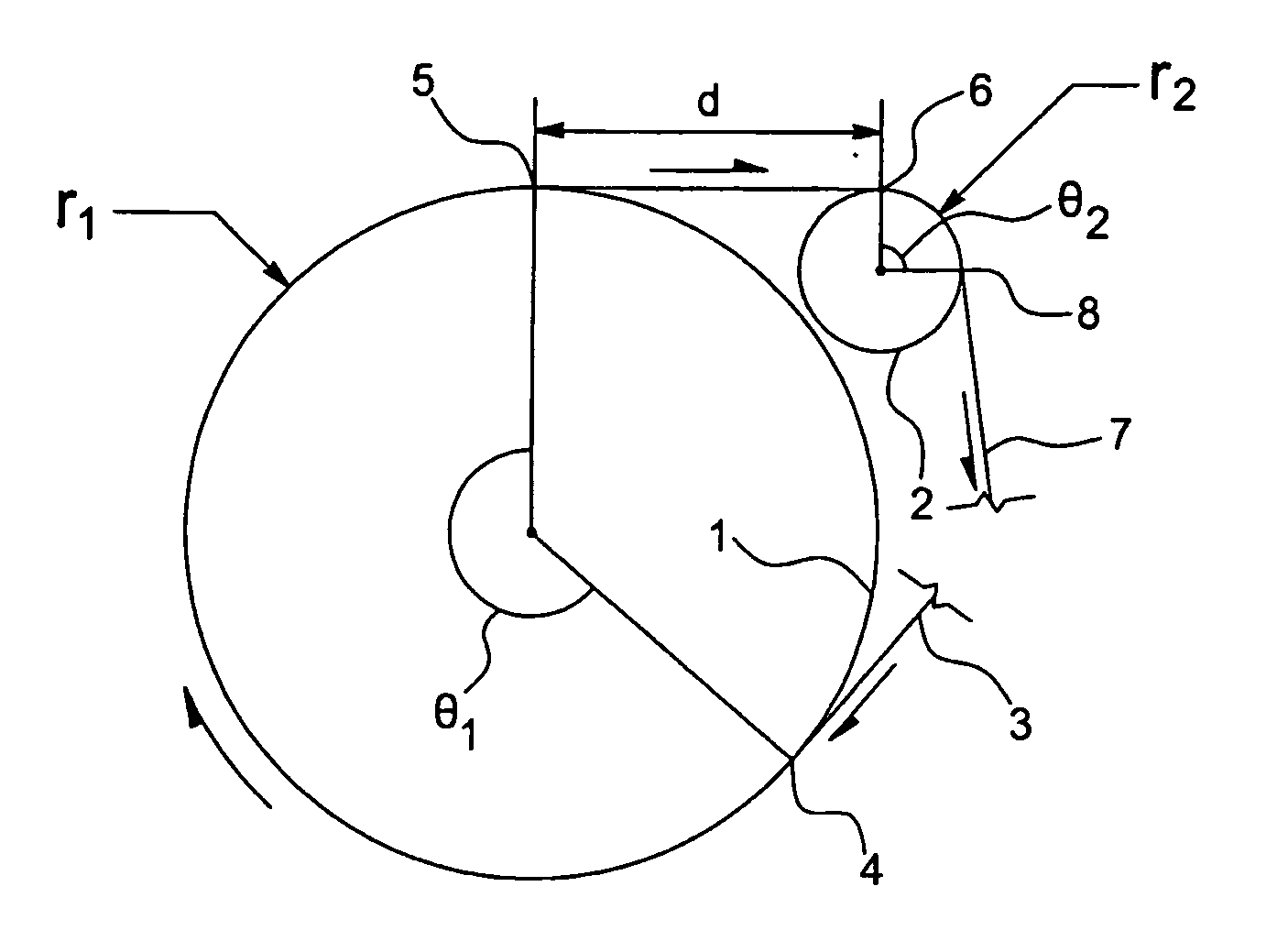

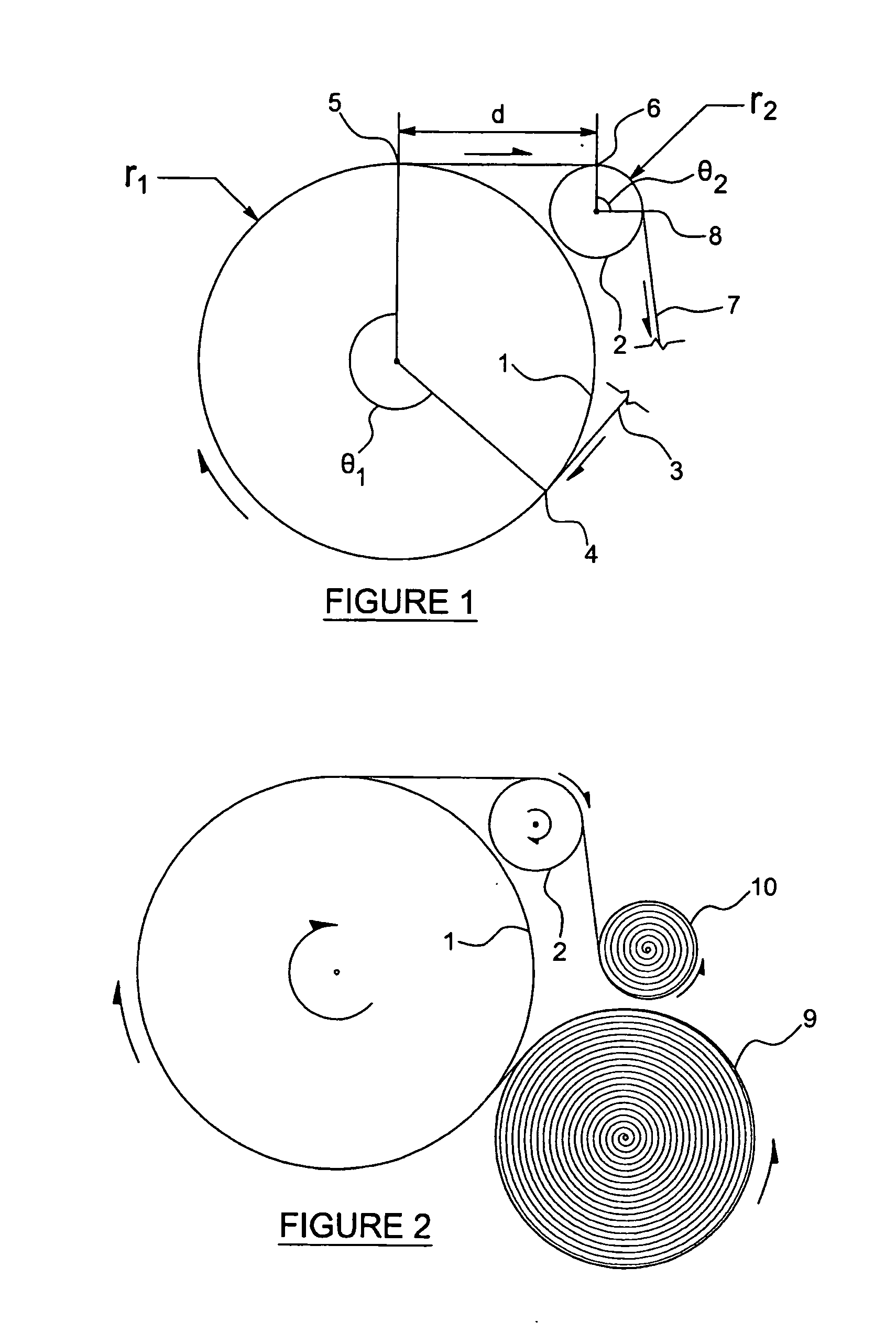

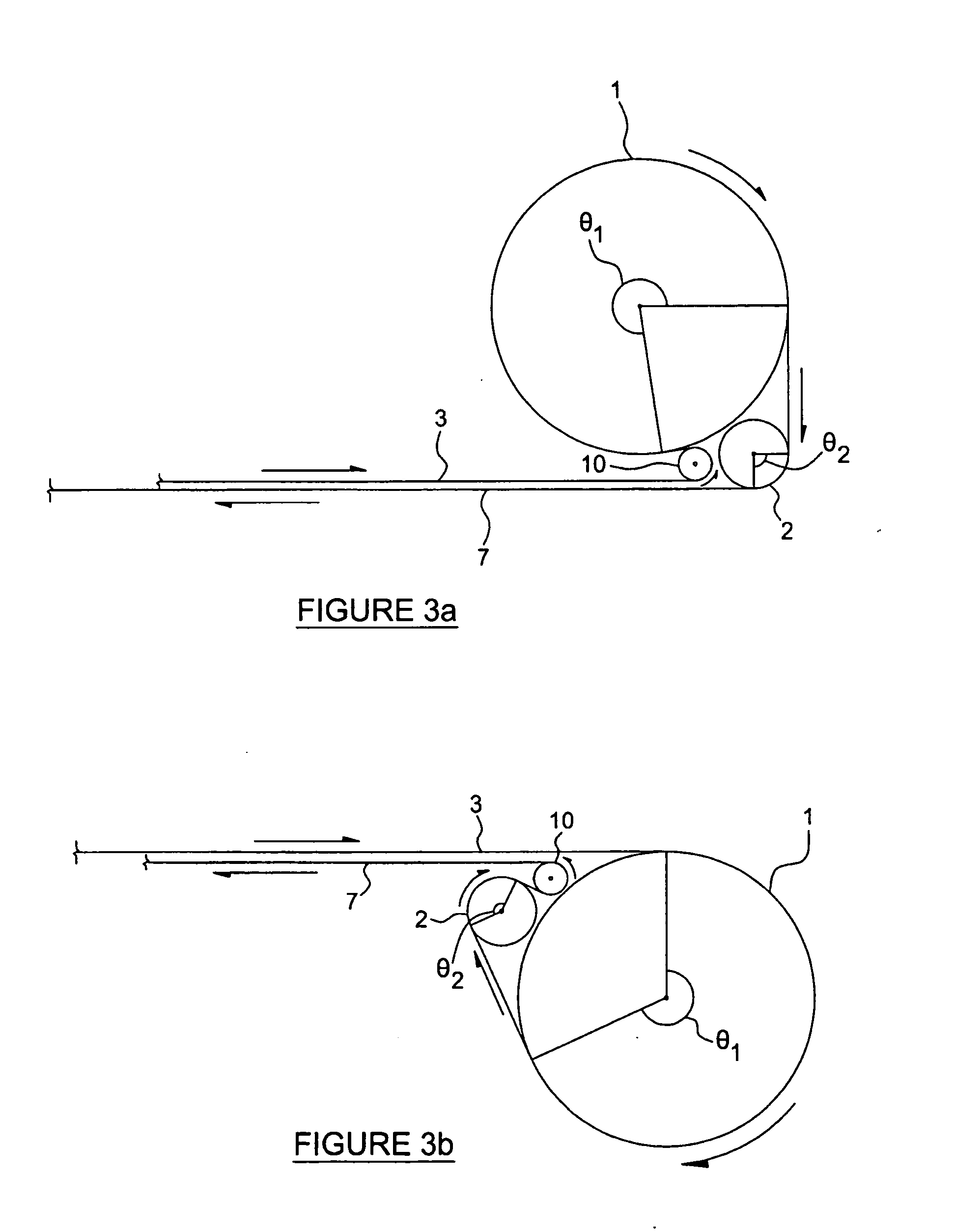

System and method for treating an amorphous alloy ribbon

ActiveUS20130139929A1Maximize contact angleReduce tensile stressTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsAlloyThermal treatment

A method and a system for continuously in-line annealing a forwarding ferromagnetic amorphous alloy ribbon in a curved shape to improve its magnetic properties without causing the ribbon to become brittle and which operates at significant high ribbon feeding rates. The amorphous alloy ribbon is fed forward, tensioned and guided along a path at a preset feeding rate and is heated at a point along the path at a rate greater than 103° C. / sec to a temperature to initiate a thermal treatment. Then the ribbon is initially cooled at a rate greater than 103° C. / sec until the thermal treatment ends. During the thermal treatment, a series of mechanical constraints is applied on the ribbon until the amorphous alloy ribbon adopts a specific shape at rest after the thermal treatment is ended. After the initial cooling, the amorphous alloy ribbon is subsequently cooled at a sufficient rate to a temperature that will preserve the specific shape.

Owner:HYDRO QUEBEC CORP

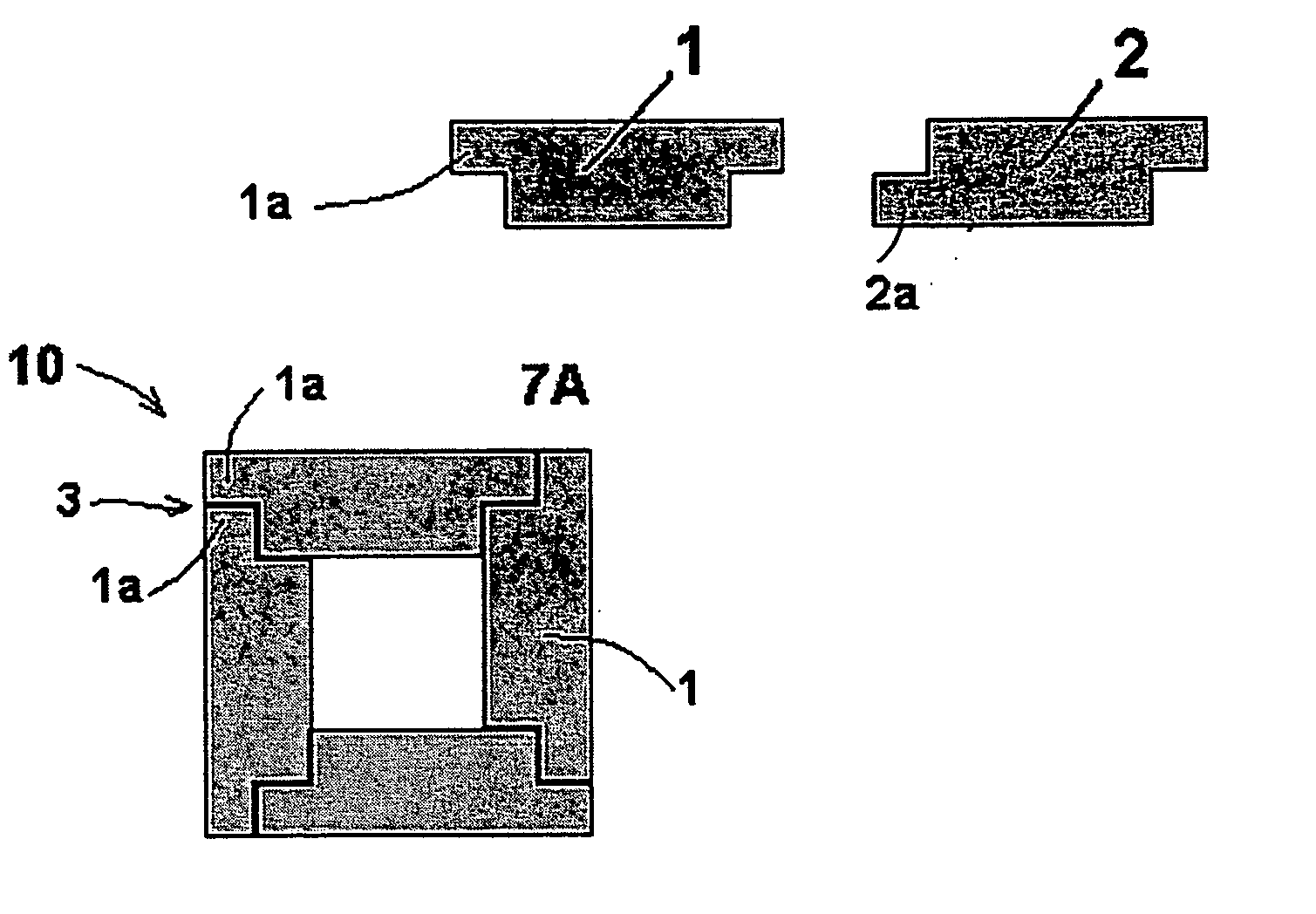

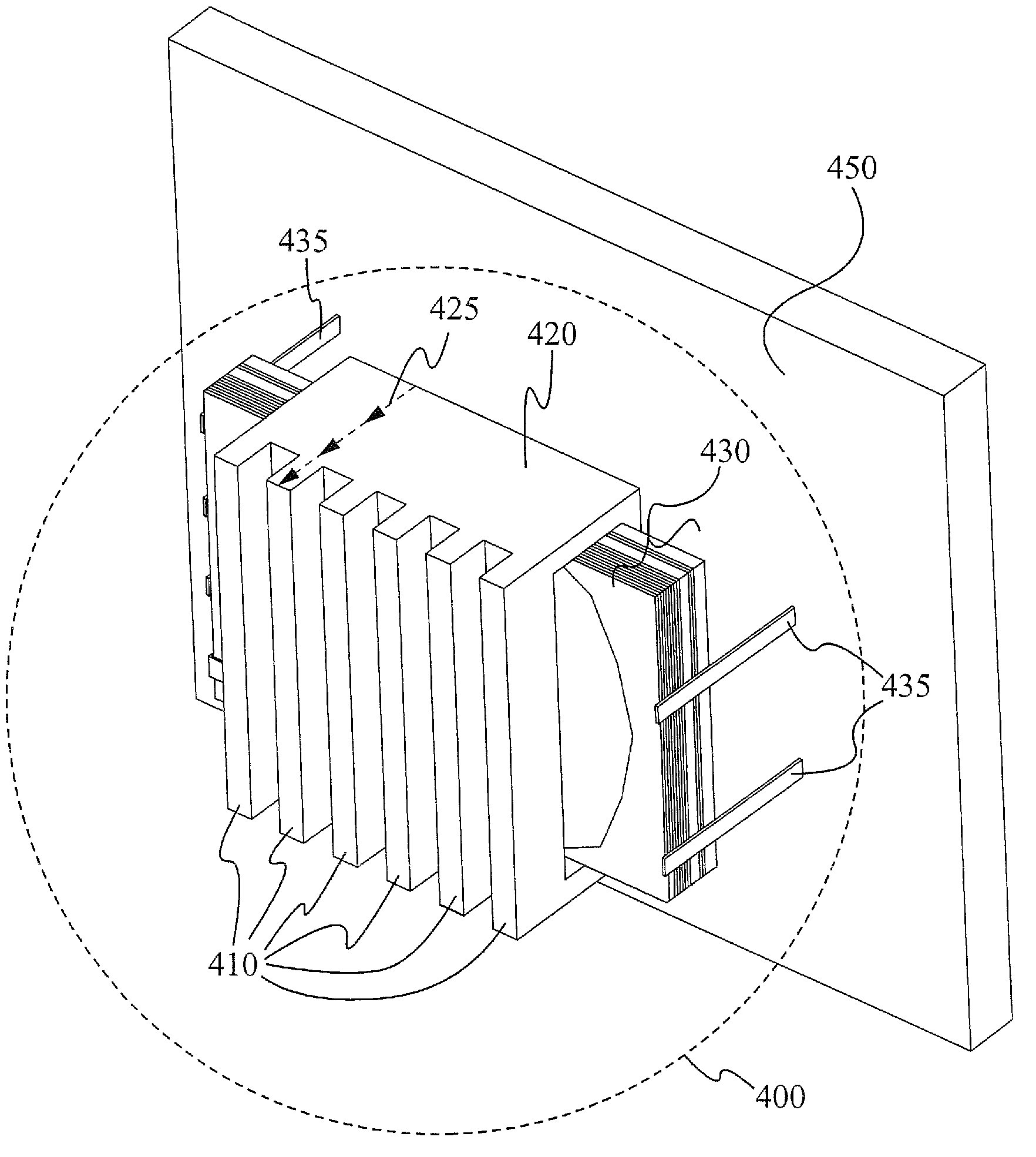

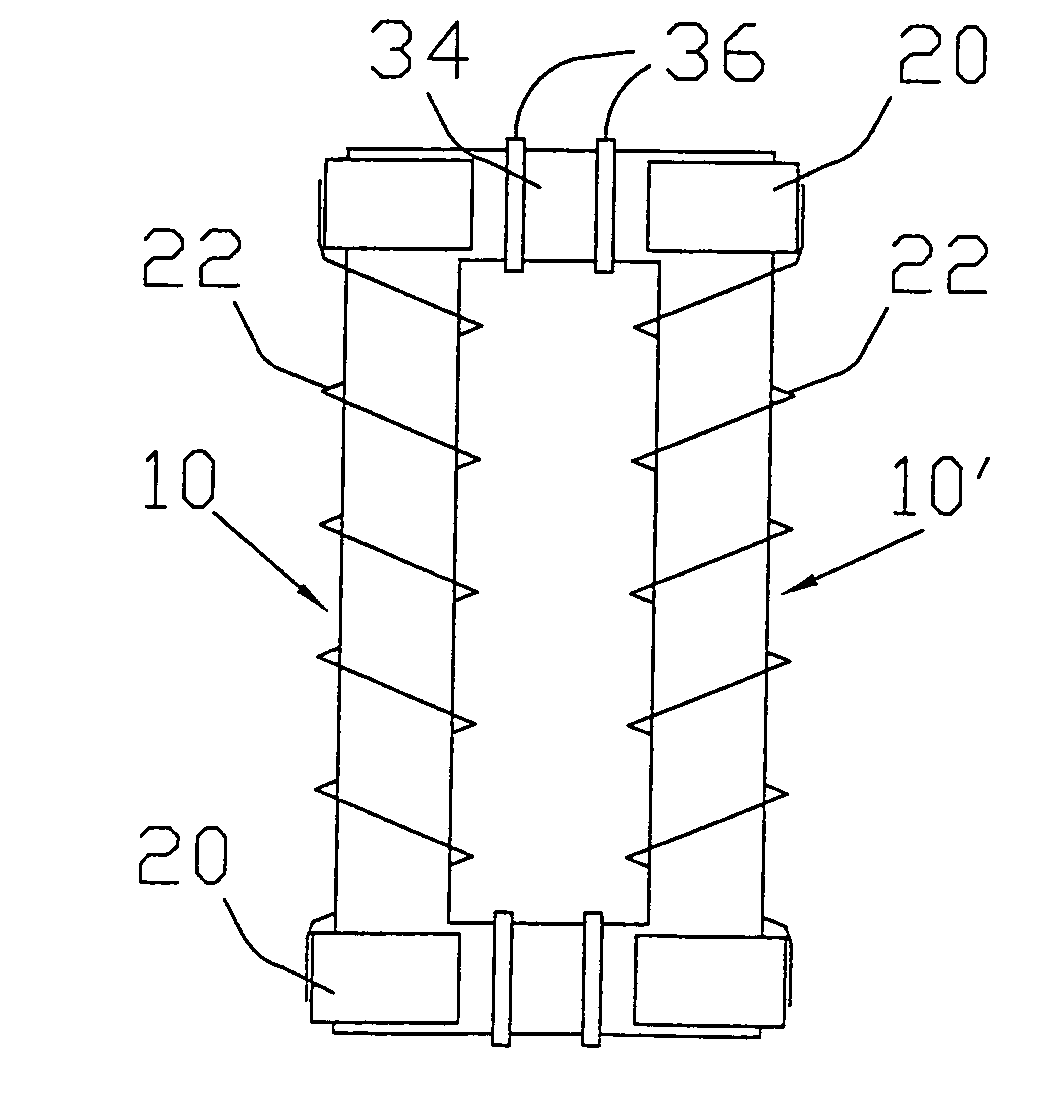

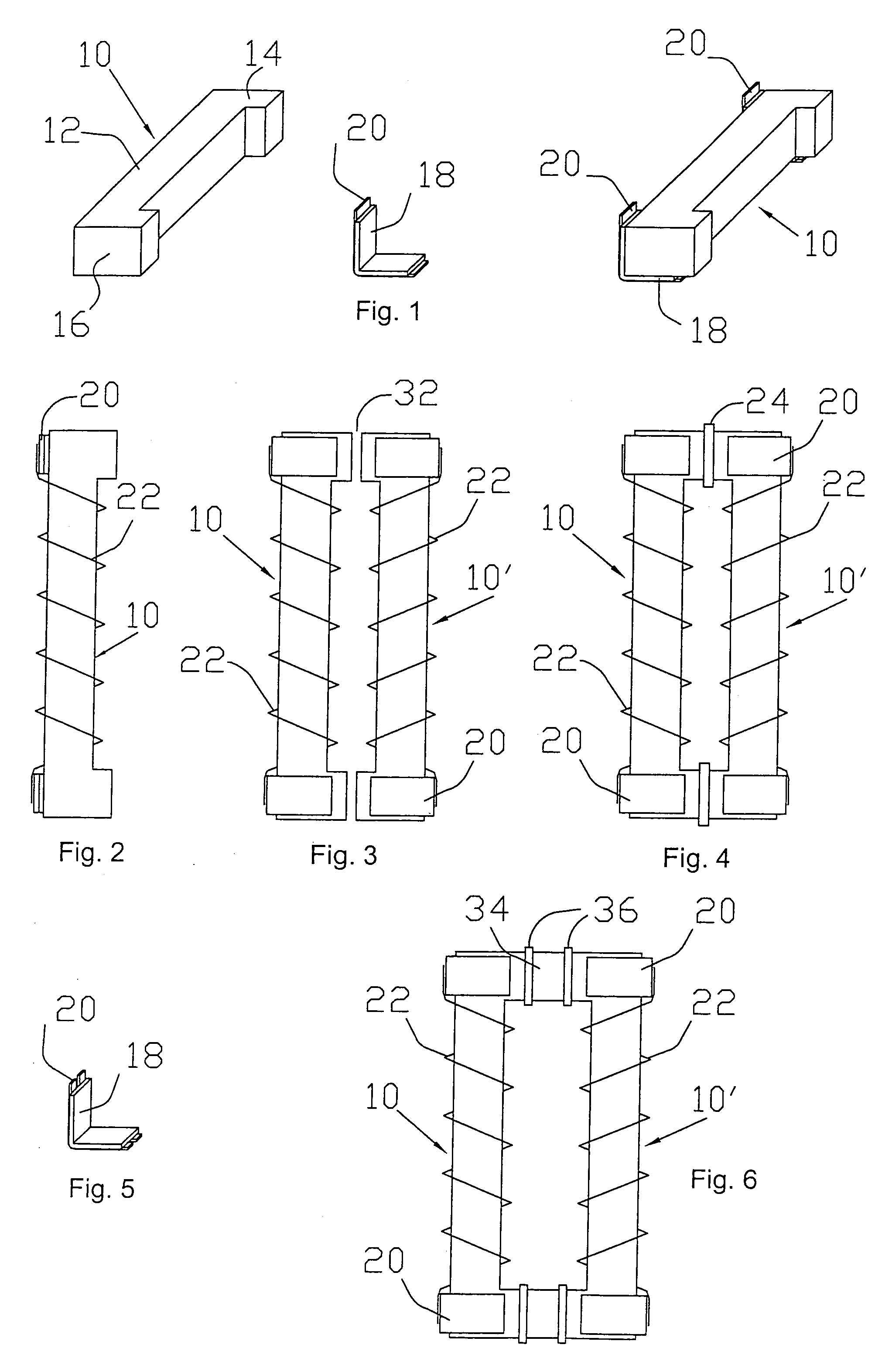

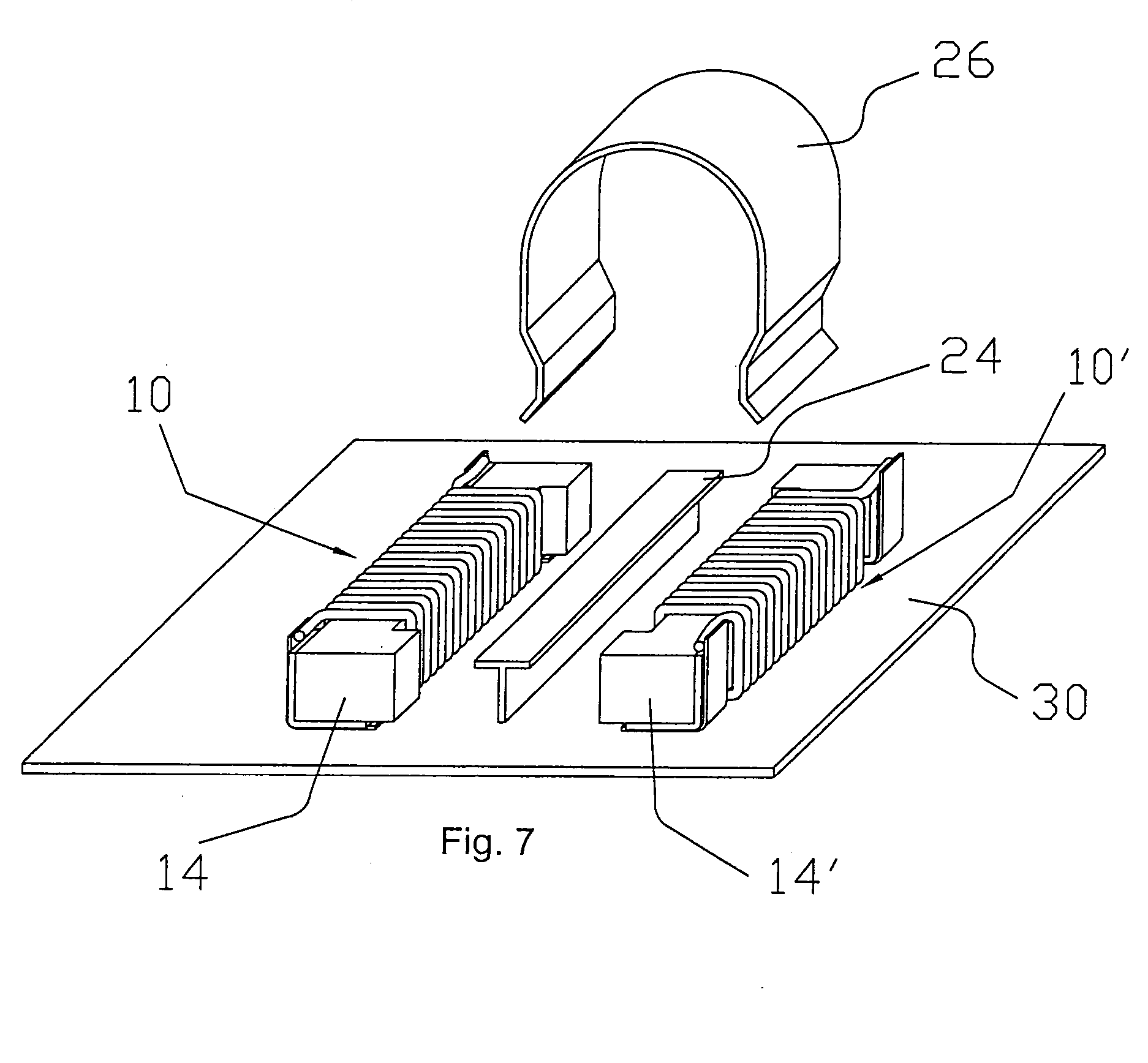

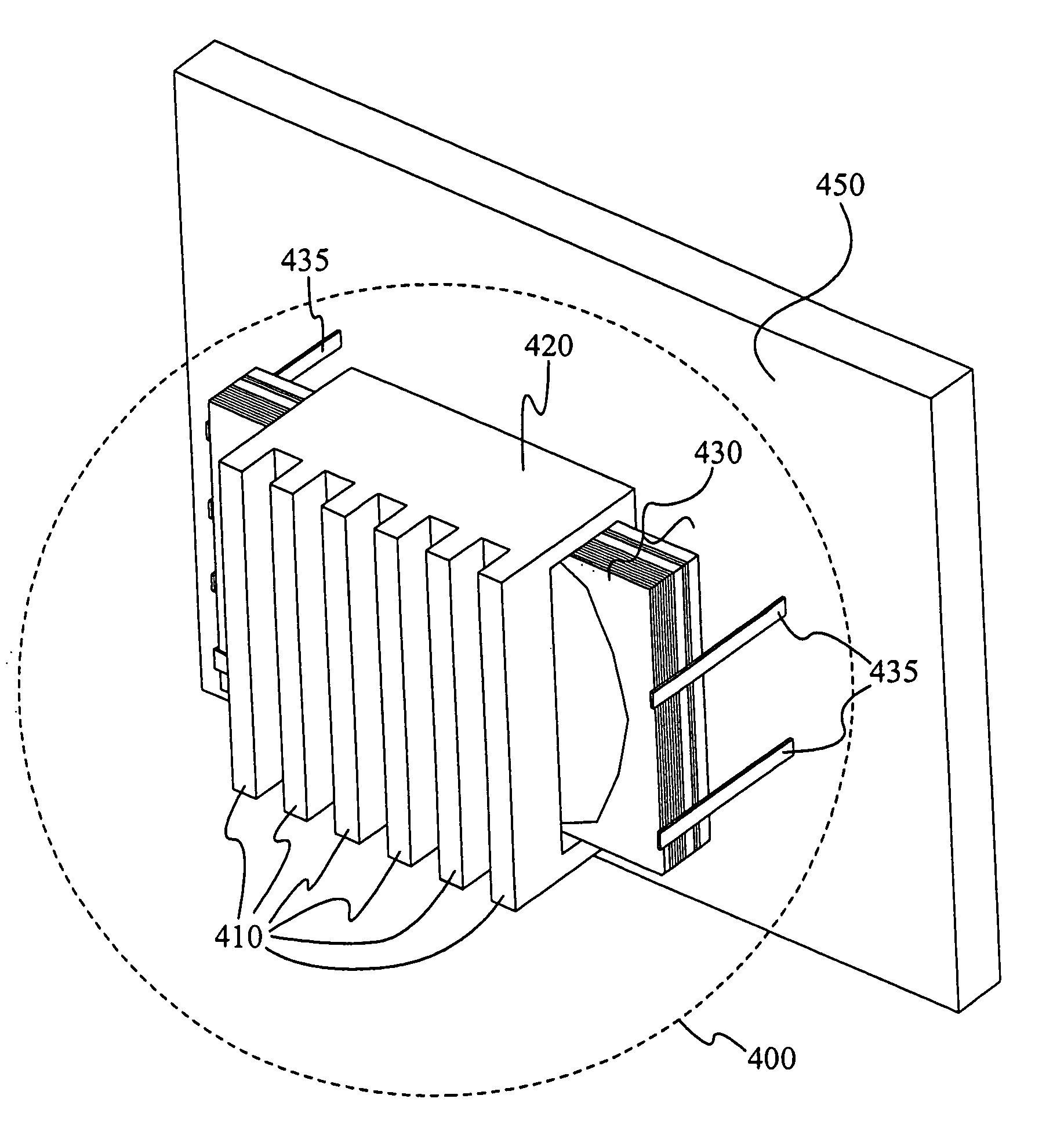

Methods of manufacturing and assembling electromagnetic assemblies and core segments that form the same

Electromagnetic assemblies, core segments that form the same, and their methods of manufacture. The segments have an interlocking engagement, whereby a variety of assemblies can be produced from a very small number of similar or complementary segments in a manner that provides excellent mechanical stability. The articles and methods of formation offer design flexibility and provide for a large variety of patterns from a small number of primary shapes, provide an economical manufacturing method for large transformer and inductor cores, and improve uniformity of magnetic properties of the assemblies when compared to conventional practices.

Owner:SPANG & CO

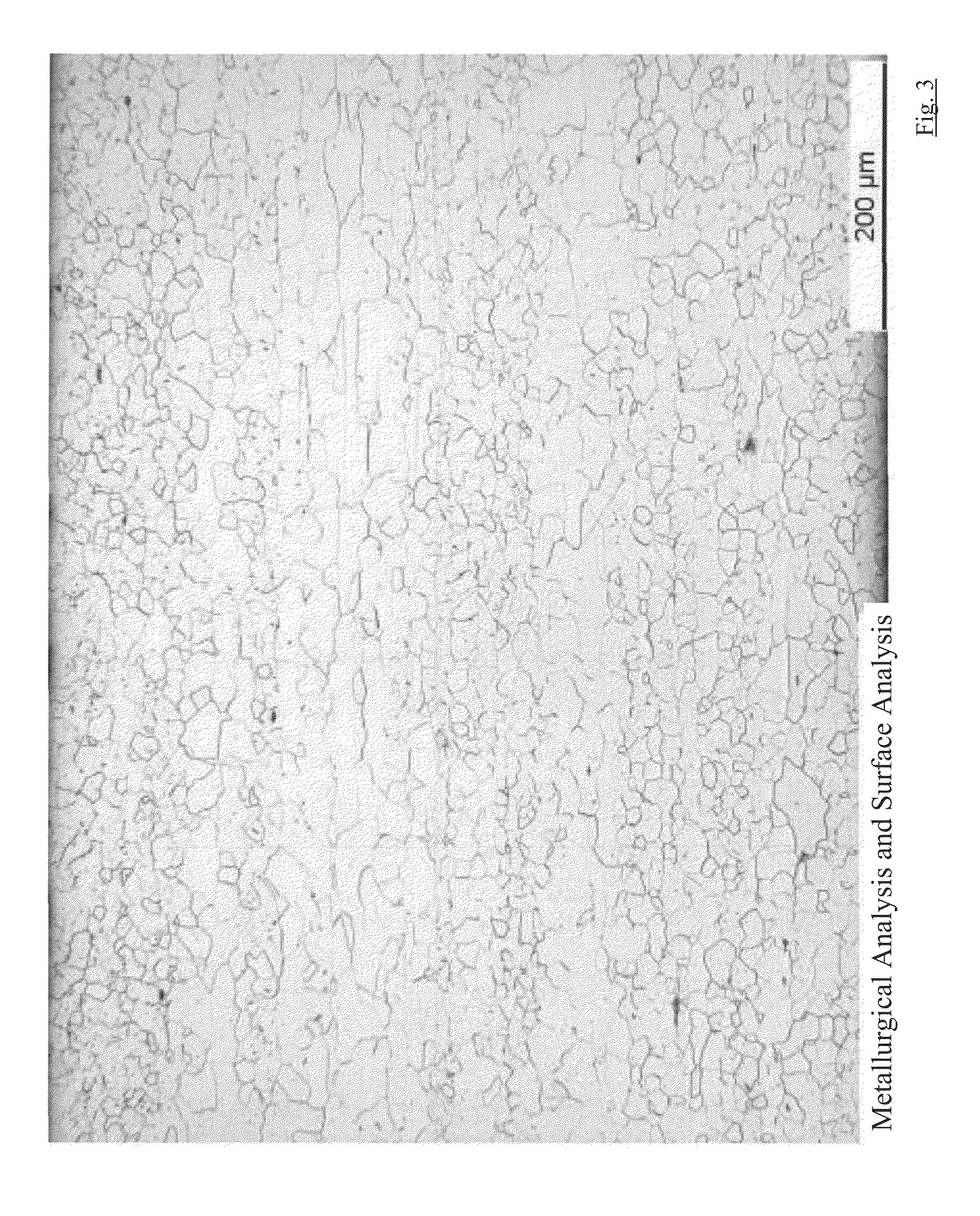

Non-grain-oriented higher-strength electrical strip with high polarisation and method for the production thereof

InactiveUS20140373340A1Negatively influenceImprove the immunityMaterial analysis by optical meansInorganic material magnetismAlloyHigh intensity

A higher-strength, non-grain-oriented electrical strip with high polarization, the electrical strip consisting of a steel alloy, wherein the limits of the following elements are maintained: Mn between 0.35 mass % and 0.65 mass %, Si between 2.0 mass % and 3.0 mass %, Al between 0.8 mass % and 1.4 mass %, and P between 0.14 mass % and 0.24 mass %; and a method for the production thereof.

Owner:VOESTALPINE STAHL GMBH

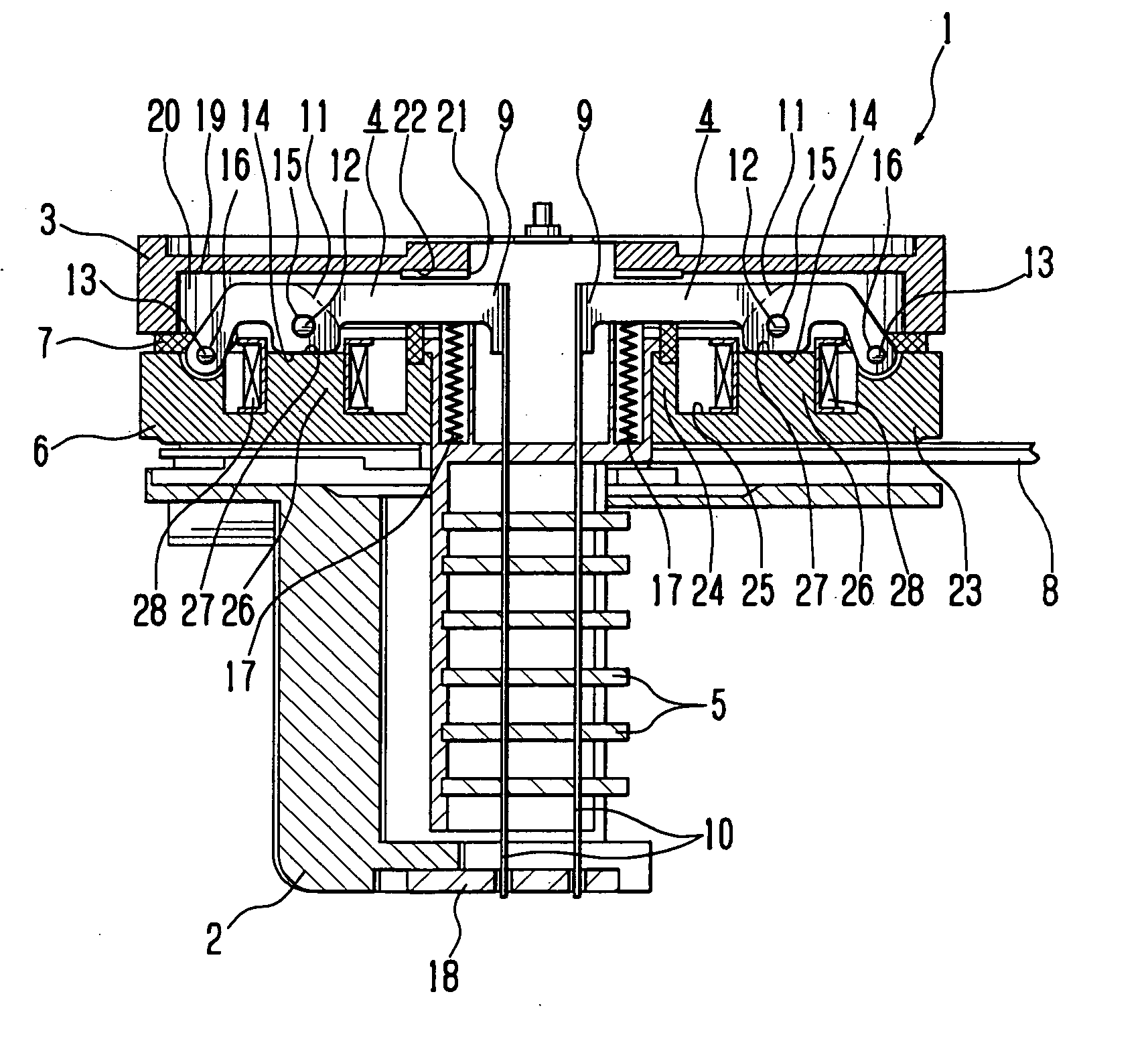

Laminate Stack Comprising Individual Soft Magnetic Sheets, Electromagnetic Actuator, Process for Their Manufacture and Use of a Soft Magnetic Laminate Stack

InactiveUS20110050376A1Improve magnetic propertiesLow eddy current lossActive material electrodesMachines/enginesBiomedical engineeringElectromagnetic actuator

A laminate stack having individual soft magnetic sheets. The individual sheets are involutely curved in the laminate stack. Each individual sheet has a first long side, a second long side opposite the first long side, a first short side and a second short side opposite the first short side. The first long side has a recess, said recess being rectangular and equidistant from the first short side, the second short side and the second long side when the individual sheet is in its uncurved state.

Owner:VACUUMSCHMELZE GMBH & CO KG

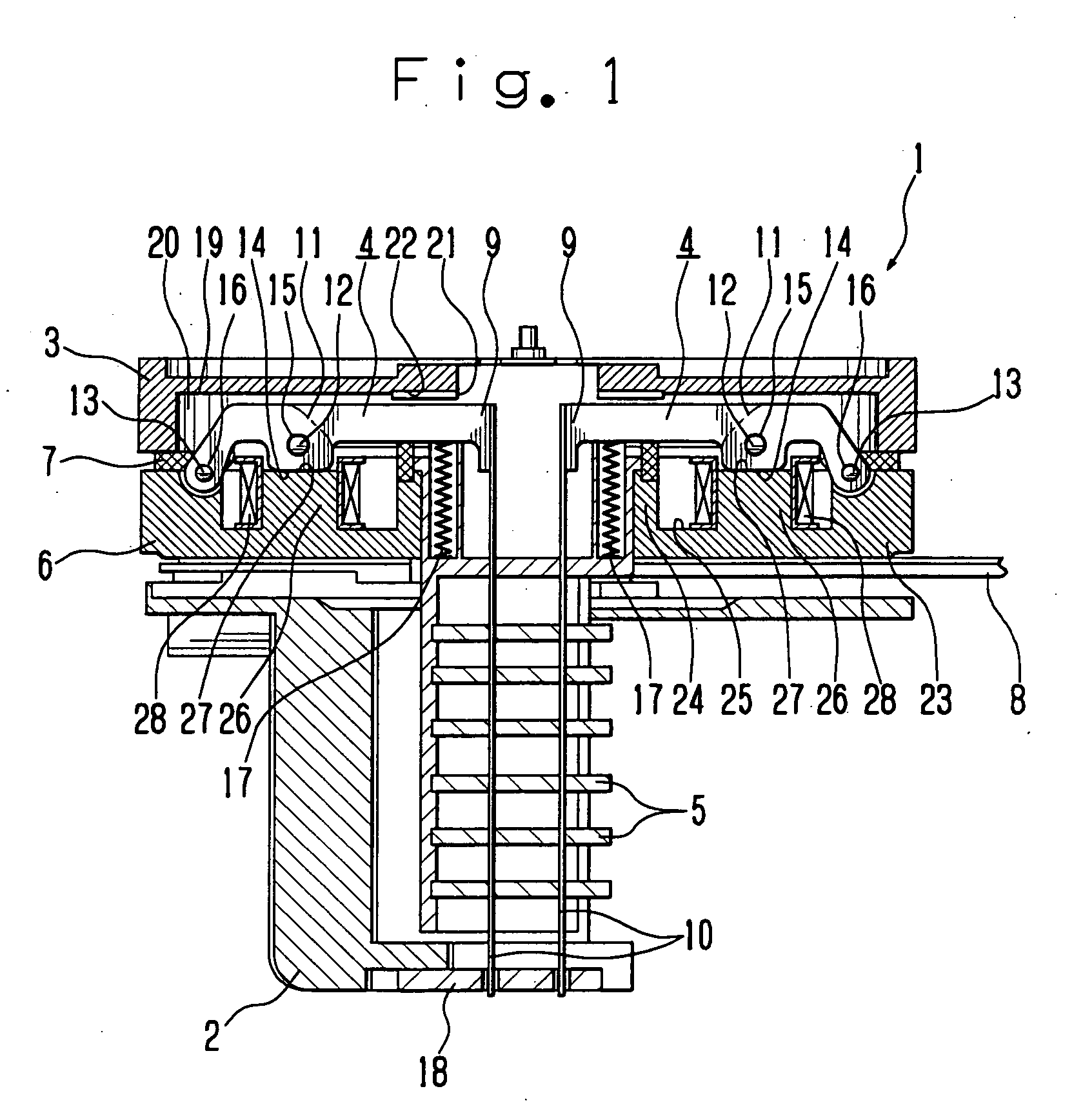

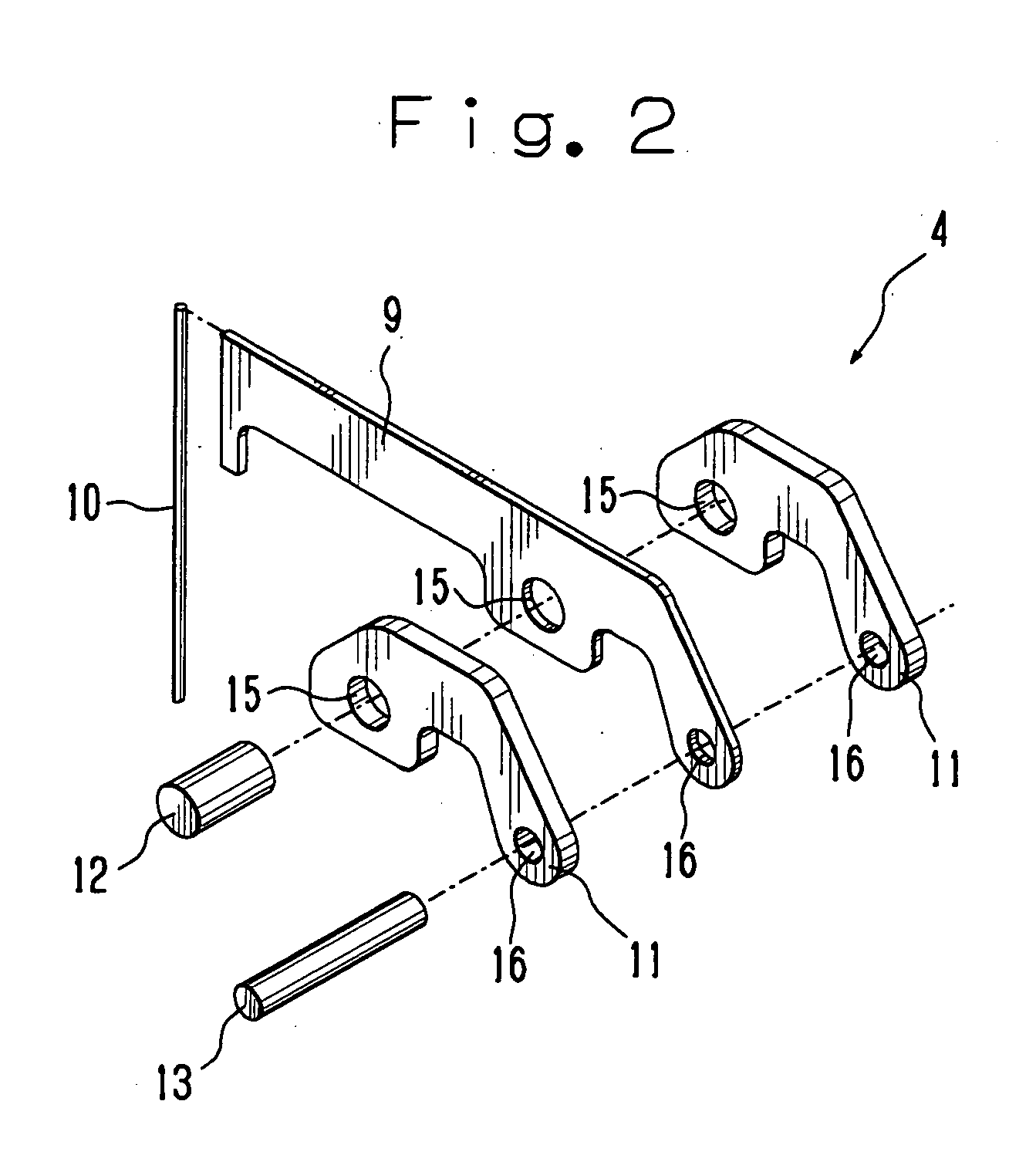

Method for manufacturing an armature

ActiveUS20050160576A1Improve joint strengthTypewritersPrinted circuit manufactureElectrical resistance and conductanceEngineering

An armature manufacturing method of forming an armature including an arm holding a printing wire, and magnetic circuit forming members attached to the arm places the magnetic circuit forming members on the arm with a resistive layer of a resistive material having high electric resistance sandwiched between the arm and each of the magnetic circuit forming members, and welds together the arm and the magnetic circuit forming members with the resistive films sandwiched between the arm and the magnetic circuit forming members by spot welding. The arm and the magnetic circuit forming members of the armature can be joined together by welds having a high weld strength.

Owner:TOSHIBA TEC KK

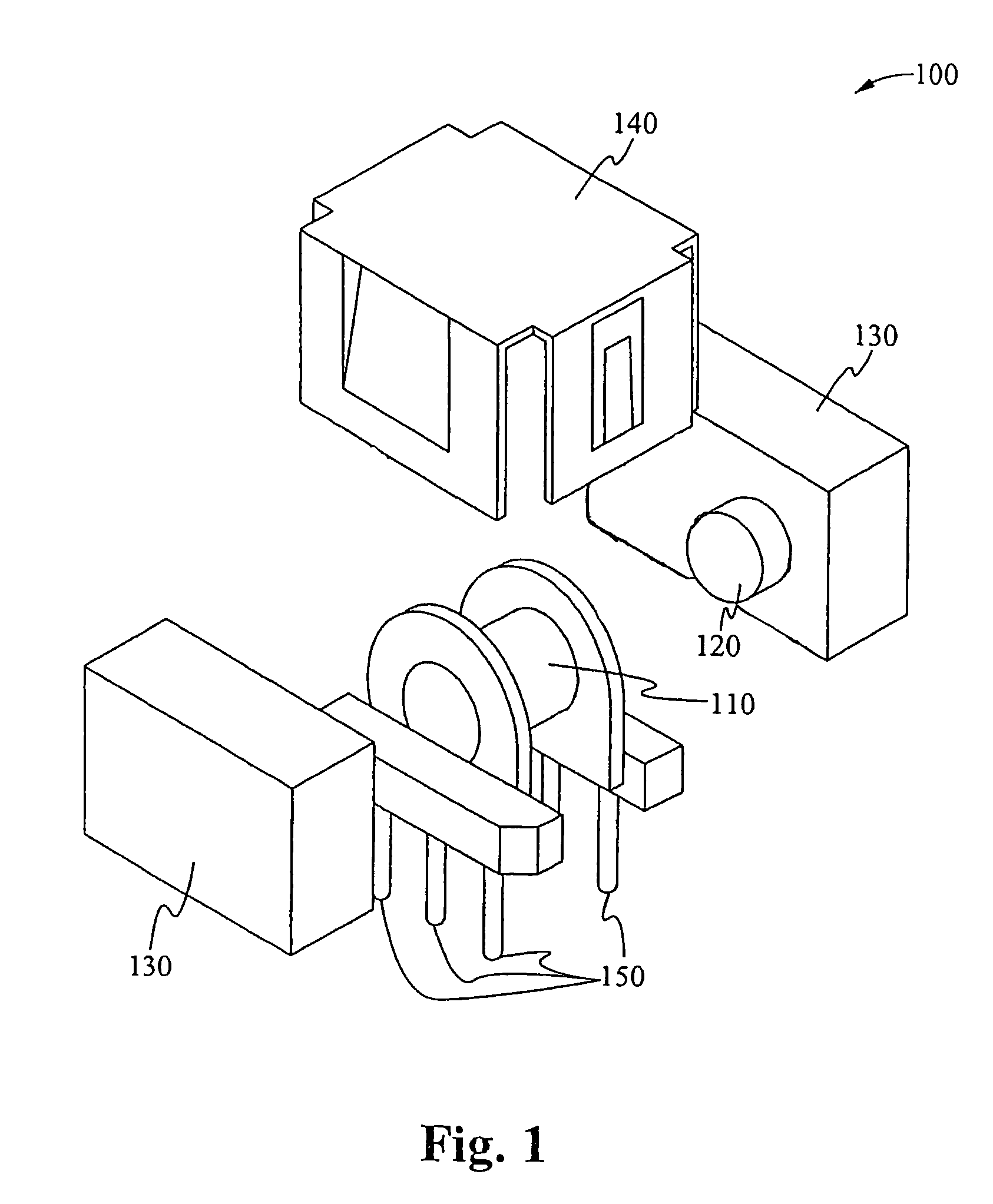

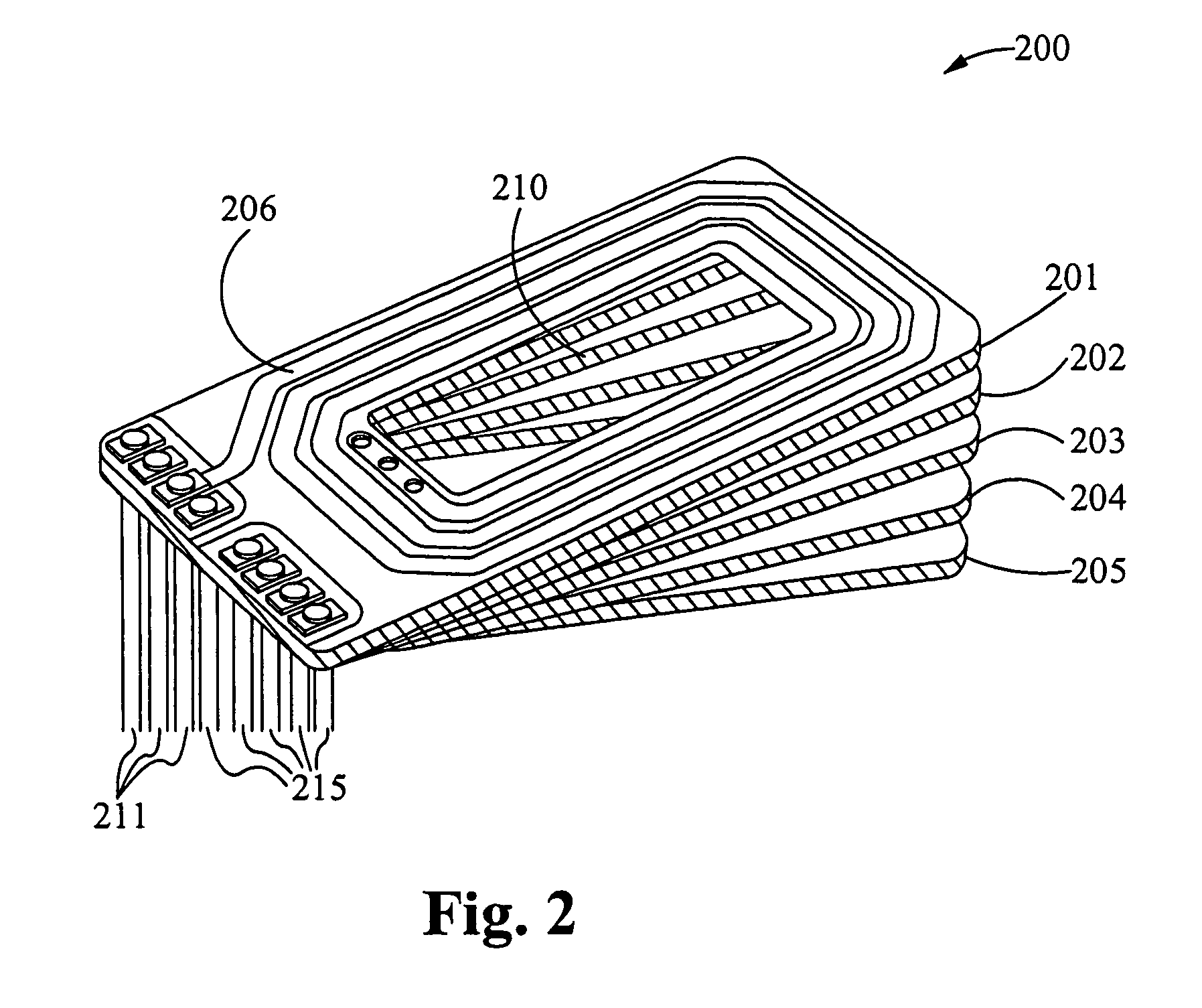

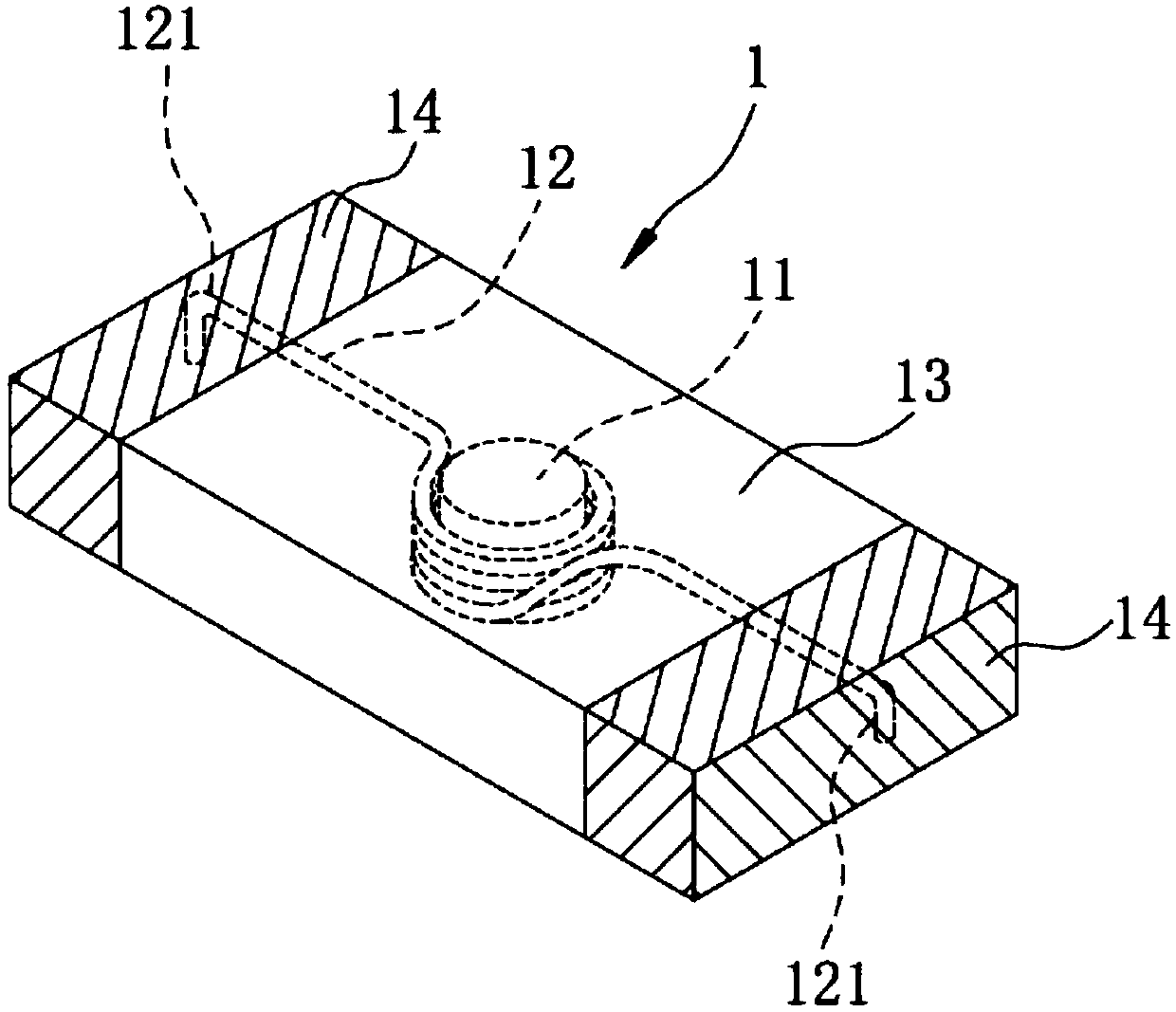

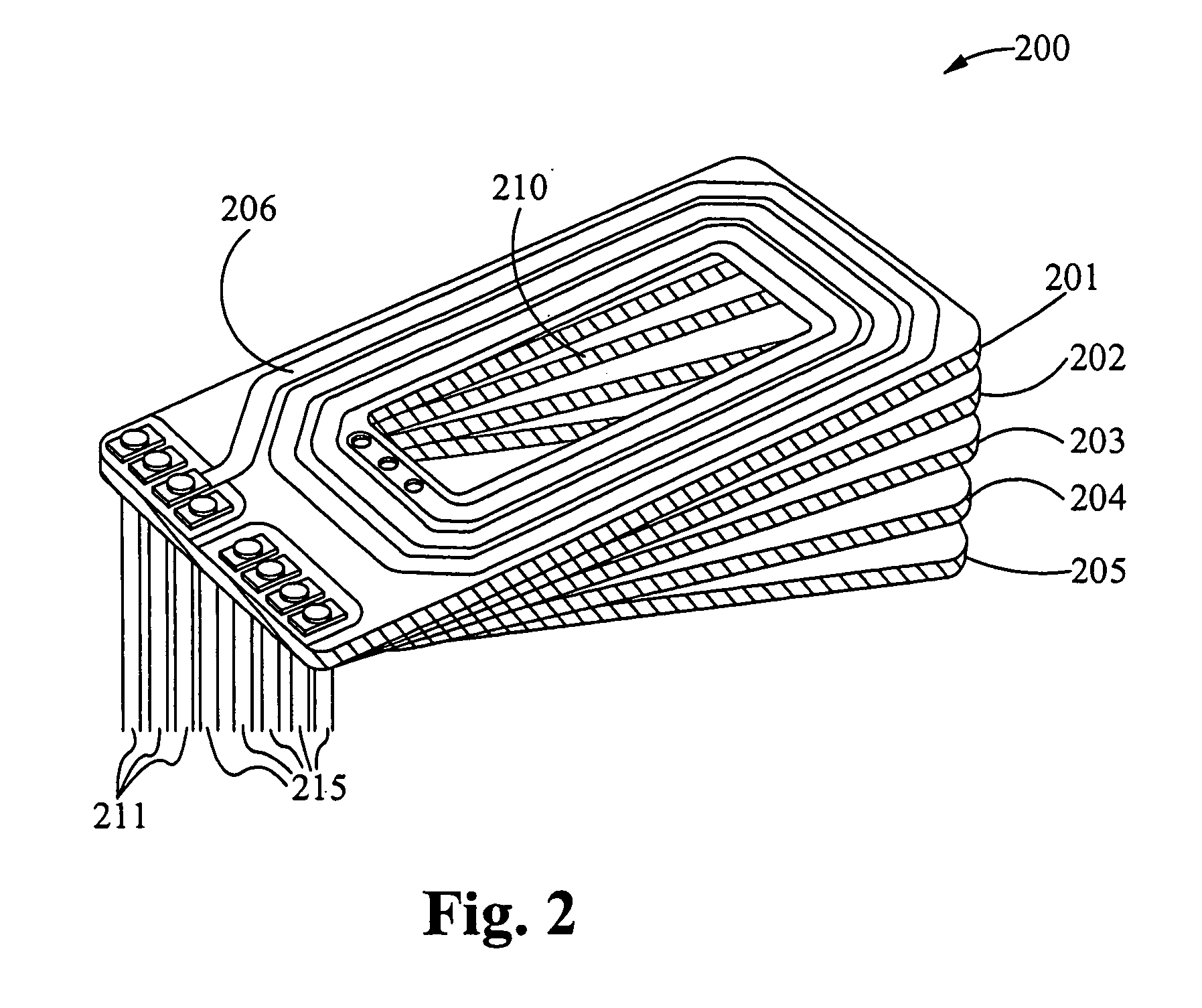

Thermally enhanced magnetic transformer

ActiveUS7920039B2Thermally efficientEliminate useTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEngineeringHeat sink

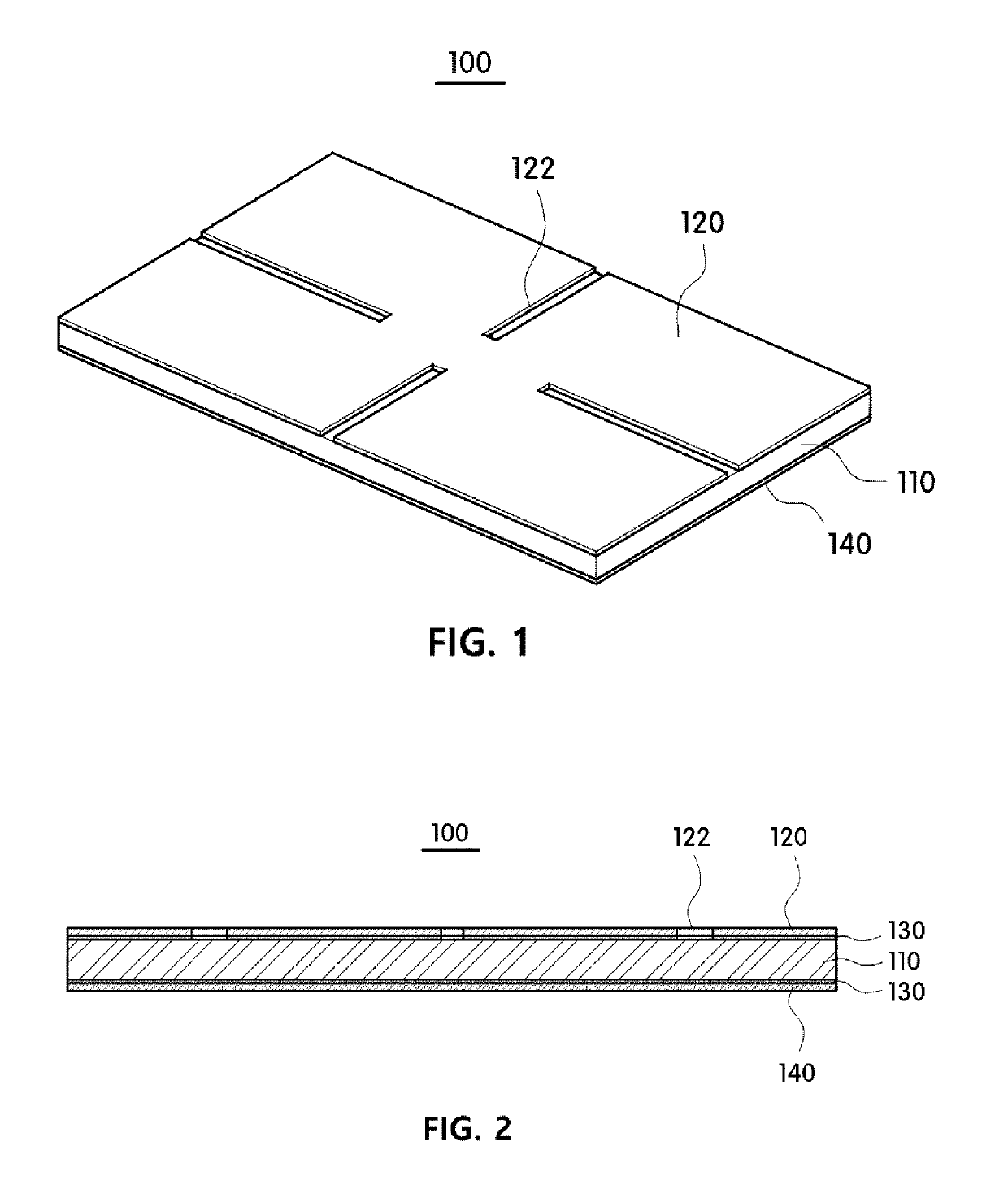

A planar transformer comprises a laminate substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, a core configured to fit inside the opening to enclose the laminate substrate. At least one heat sink fin is integrally formed with the top, bottom or both sides of the core. A method of forming a planar transformer comprises laminating a substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, fitting a core inside the opening, and enclosing the laminate substrate. One of the top, bottom or both sides of the core include one or more heat sink fins.

Owner:FLEXTRONICS AP LLC

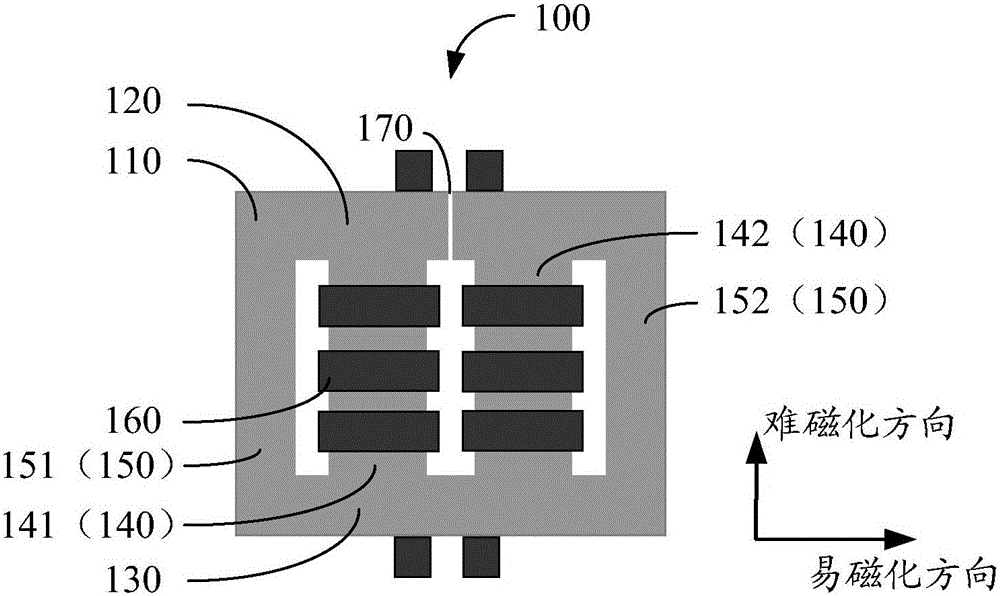

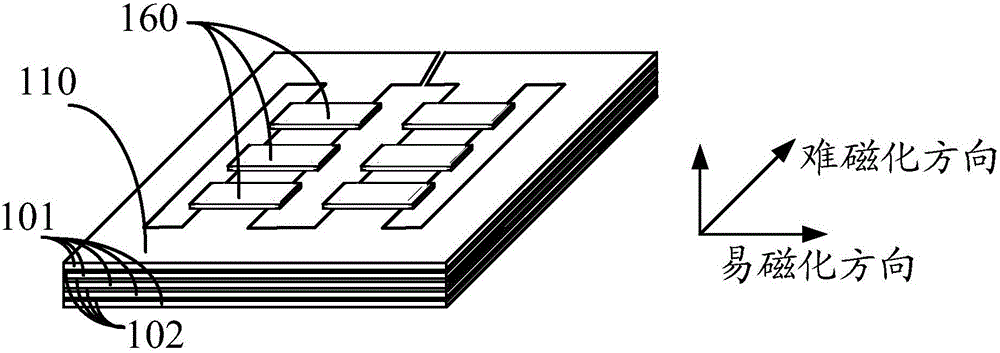

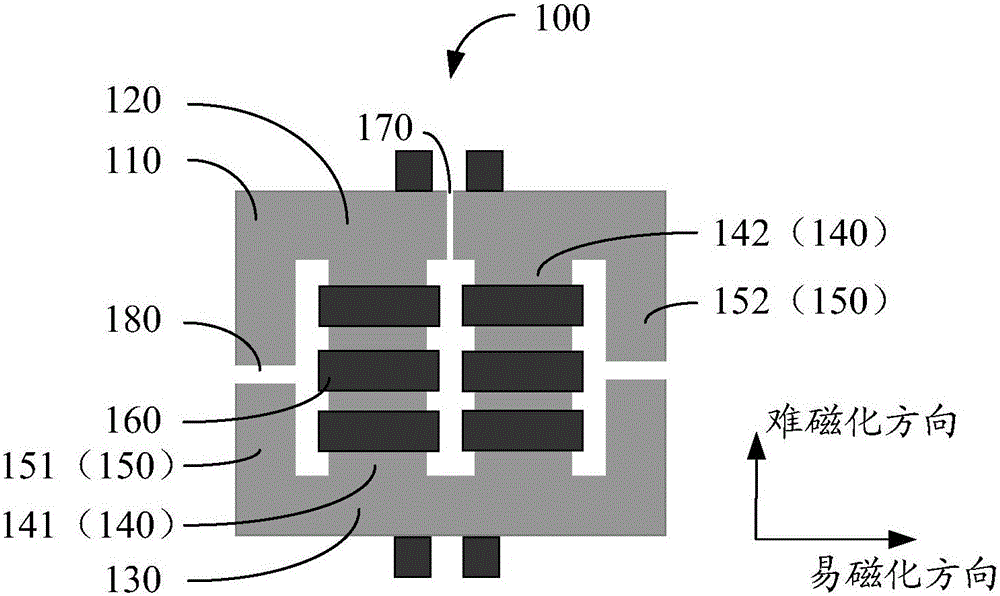

Thin film inductor and power switching circuit

ActiveCN105761880ASolve the real problemTransformers/inductances coils/windings/connectionsDc-dc conversionPower switchingMagnetization

The invention discloses a thin film inductor which comprises a thin film magnetic core. The thin film magnetic core comprises multiple magnetic columns, a first end and a second end. The multiple magnetic columns are arranged at intervals and are in a rod shape. One end of each magnetic column makes contact with the first end, and the other end of each magnetic column makes contact with the second end. The multiple magnetic columns comprise two or more winding magnetic columns and one non-winding magnetic column which is located on one side of the winding magnetic columns; or the multiple magnetic columns comprise two or more winding magnetic columns and two non-winding magnetic columns, wherein the winding magnetic columns are located between the two non-winding magnetic columns. The thin film magnetic core comprises at least one layer of magnetic thin film. The area, located at the first end and the second end and located between the adjacent winding magnetic columns, in each layer of magnetic thin film is provided with at least one first gap. The length direction of each first gap is parallel to the difficult magnetization direction of the corresponding magnetic thin film. The magnetic thin films are stacked and overlaid, and the sum of the widths of all the first gaps in each layer of magnetic thin film is the same.

Owner:HUAWEI TECH CO LTD

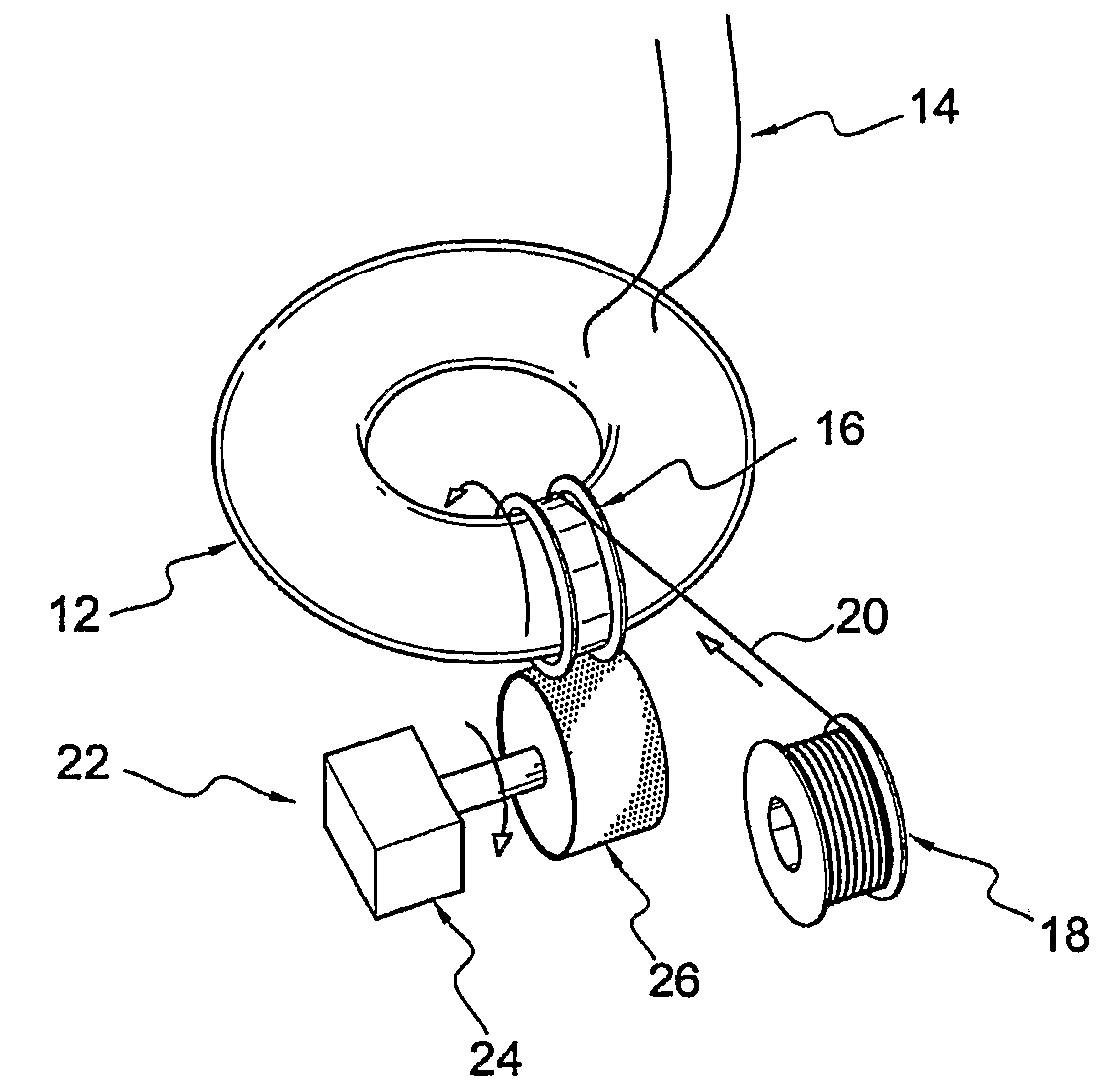

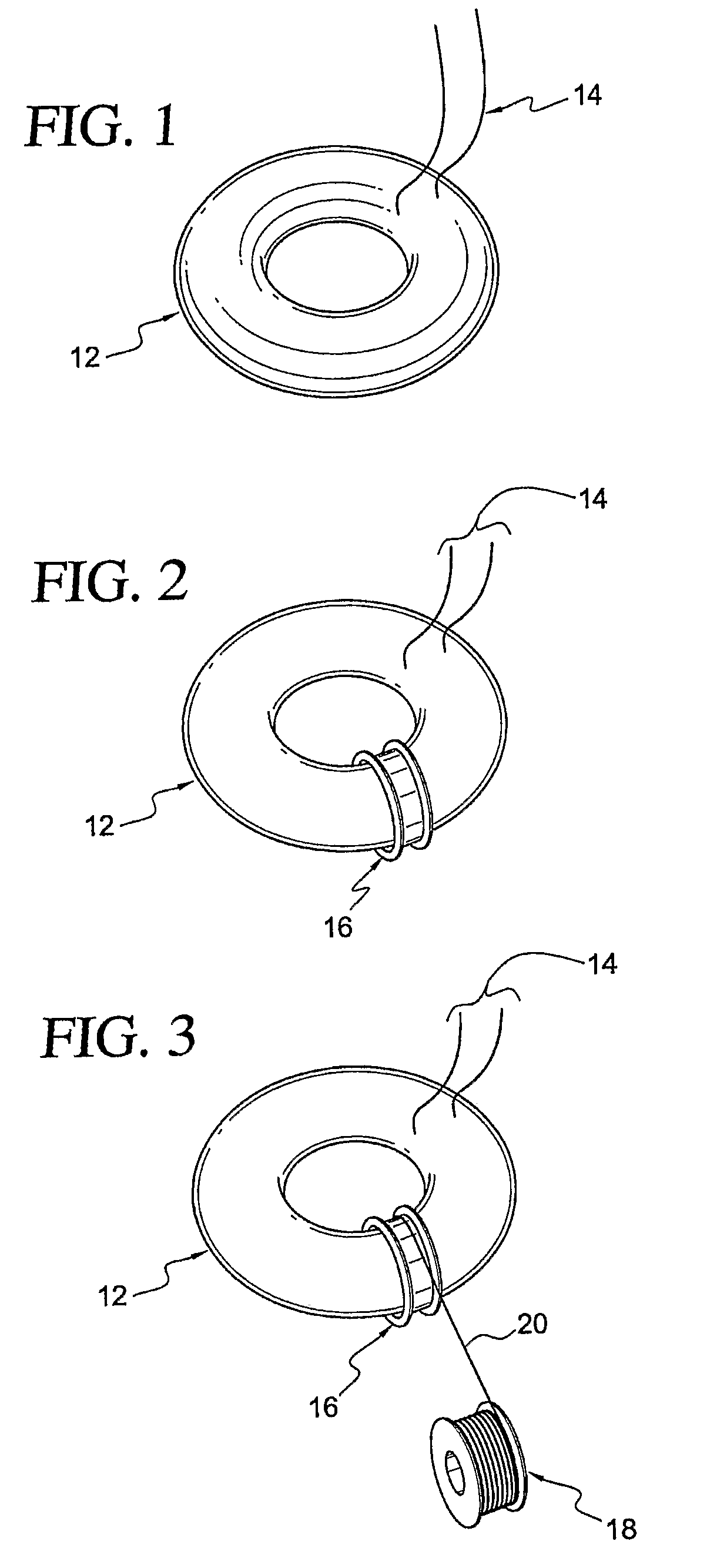

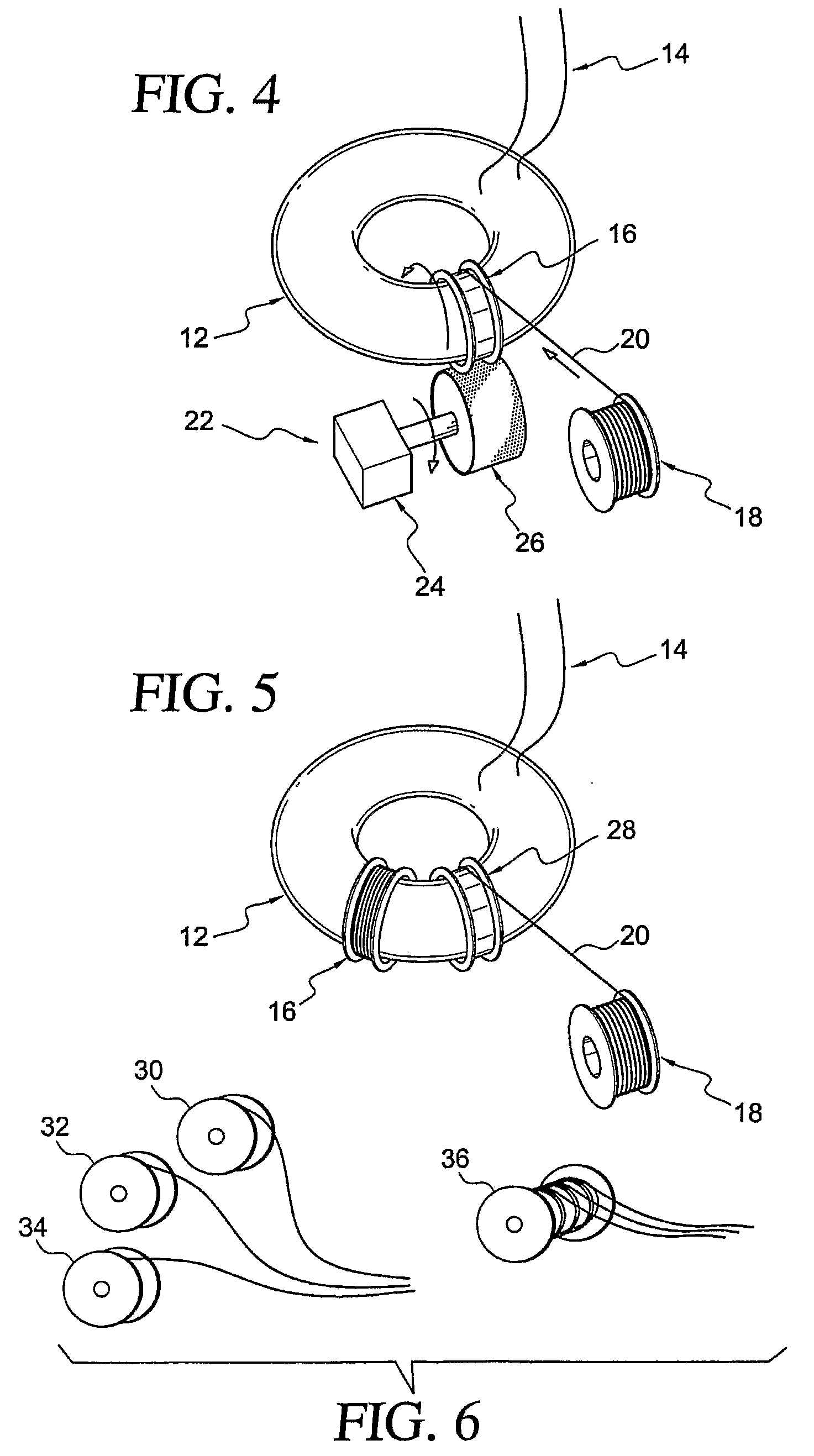

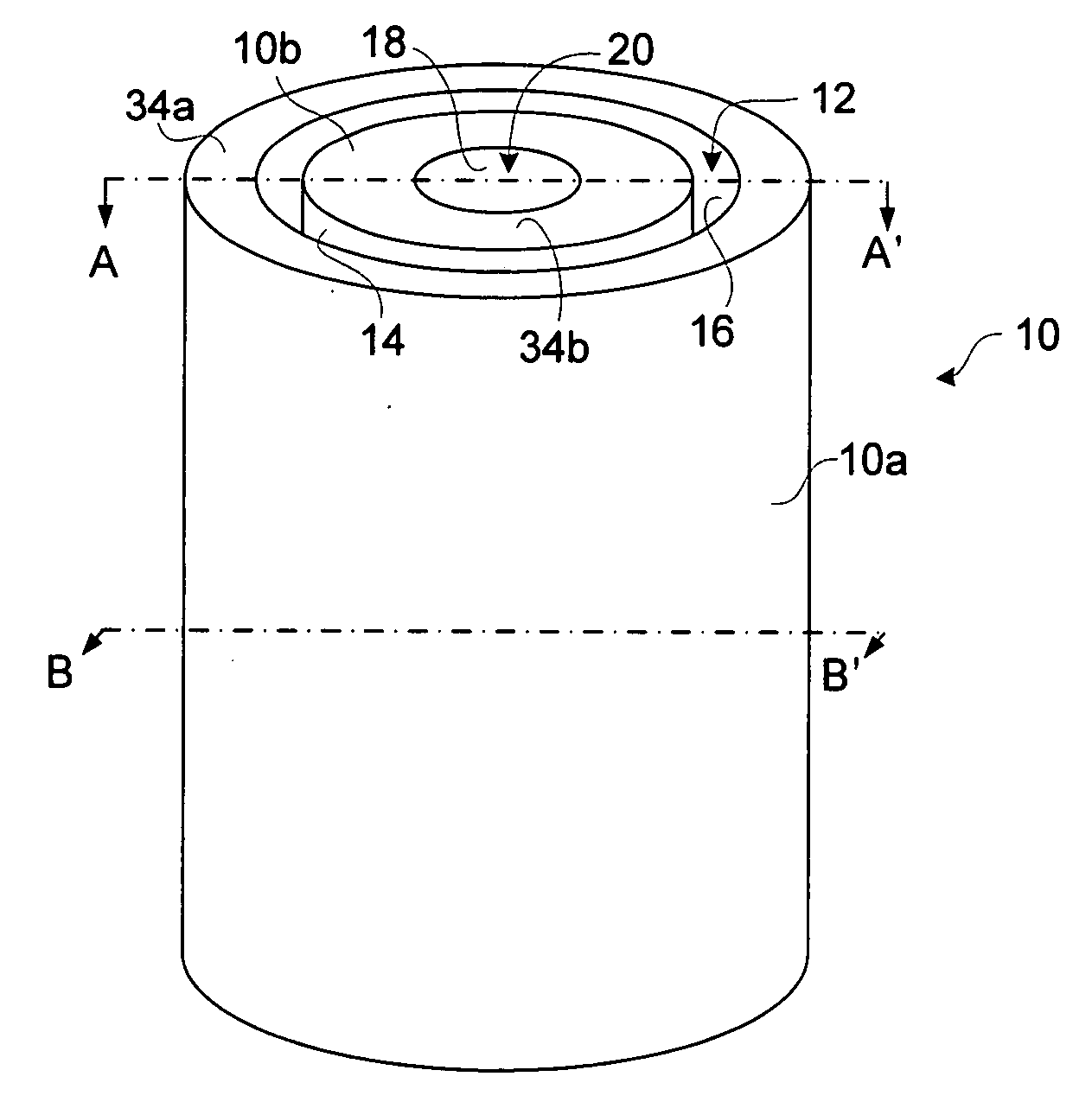

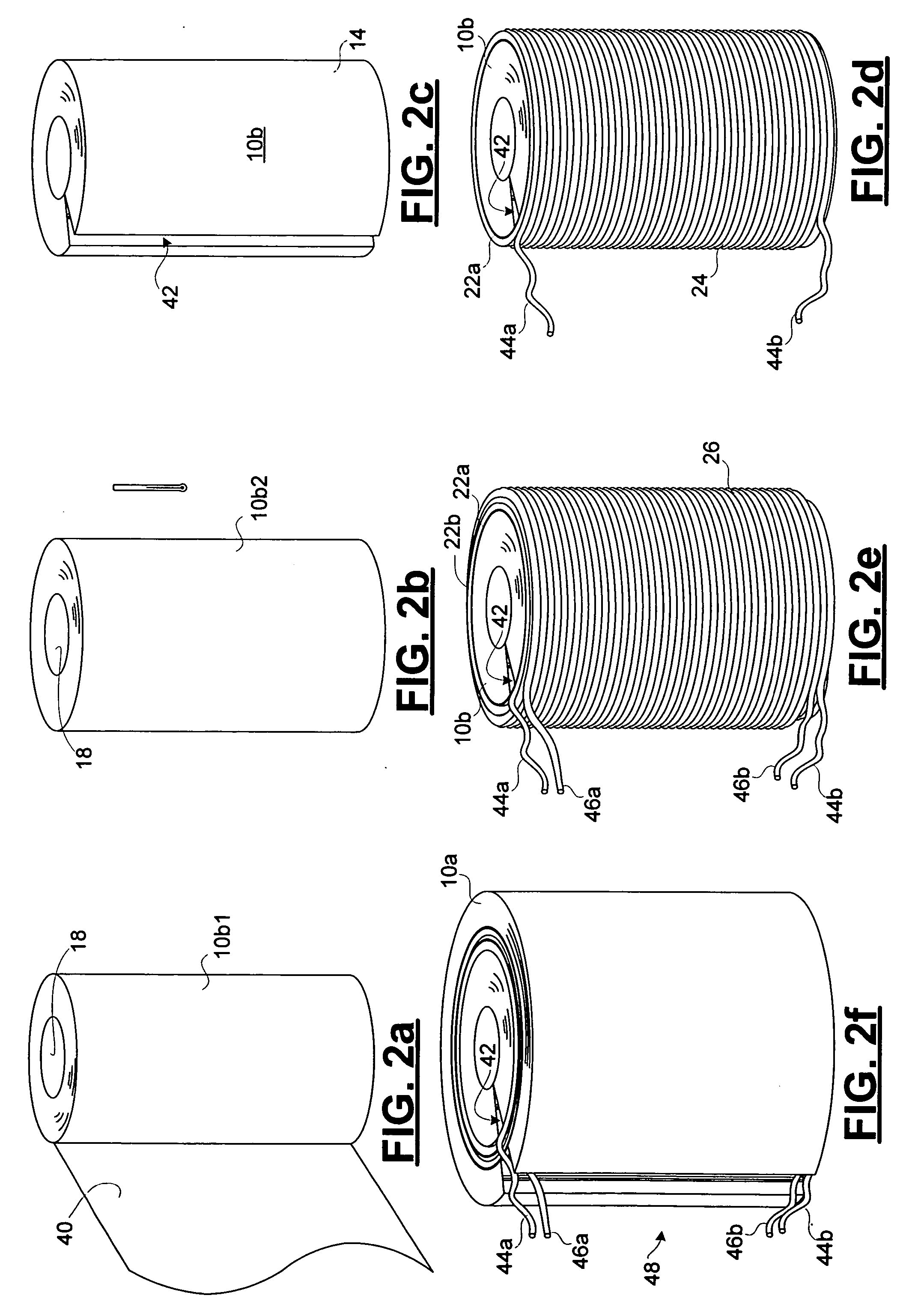

Inductive devices and methods of making the same

InactiveUS20090278647A1Easy to assembleReduce obstaclesTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinEngineering

Toroidal inductive devices are manufactured with high efficiency through the use of bobbin winding techniques or wound magnetic pattern members.

Owner:BUSWELL HARRIE R

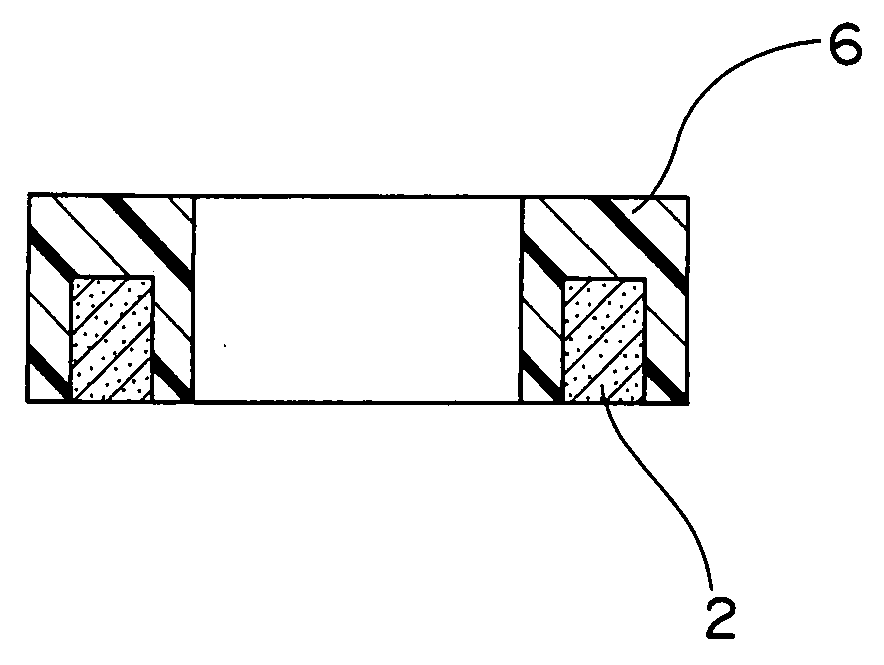

Two part transformer core, transformer and method of manufacture

InactiveUS20060125593A1Improve efficiencyArrange moreTransformers/inductances coolingTransformers/inductances coils/windings/connectionsElectricityTransformer

A toroidal transformer core topology having improved thermal and electrical properties has a two part core, one part concentrically disposed within the other, with the windings wound between the two. Less expensive materials and less material can be used to construct the core. The core can be constructed using inexpensive and efficient methods.

Owner:DELTA TRANSFORMERS +1

Coil arrangement and method for its manufacture

InactiveUS20050258926A1Excellent characteristicsImprove efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEngineeringConductor Coil

Owner:MINEBEA CO LTD

Perpendicular magnetic recording media with magnetic anisotropy/coercivity gradient and local exchange coupling

ActiveUS7846564B2Improved perpendicular magnetic recording mediumImprove recording densityNanoinformaticsPatterned record carriersNon magneticData recording

A perpendicular magnetic recording medium adapted for high recording density and high data recording rate comprises a non-magnetic substrate having at least one surface with a layer stack formed thereon, the layer stack including a perpendicular recording layer containing a plurality of columnar-shaped magnetic grains extending perpendicularly to the substrate surface for a length, with a first end distal the surface and a second end proximal the surface, wherein each of the magnetic grains has: (1) a gradient of perpendicular magnetic anisotropy field Hk extending along its length between the first end and second ends; and (2) predetermined local exchange coupling strengths along the length.

Owner:SEAGATE TECH LLC

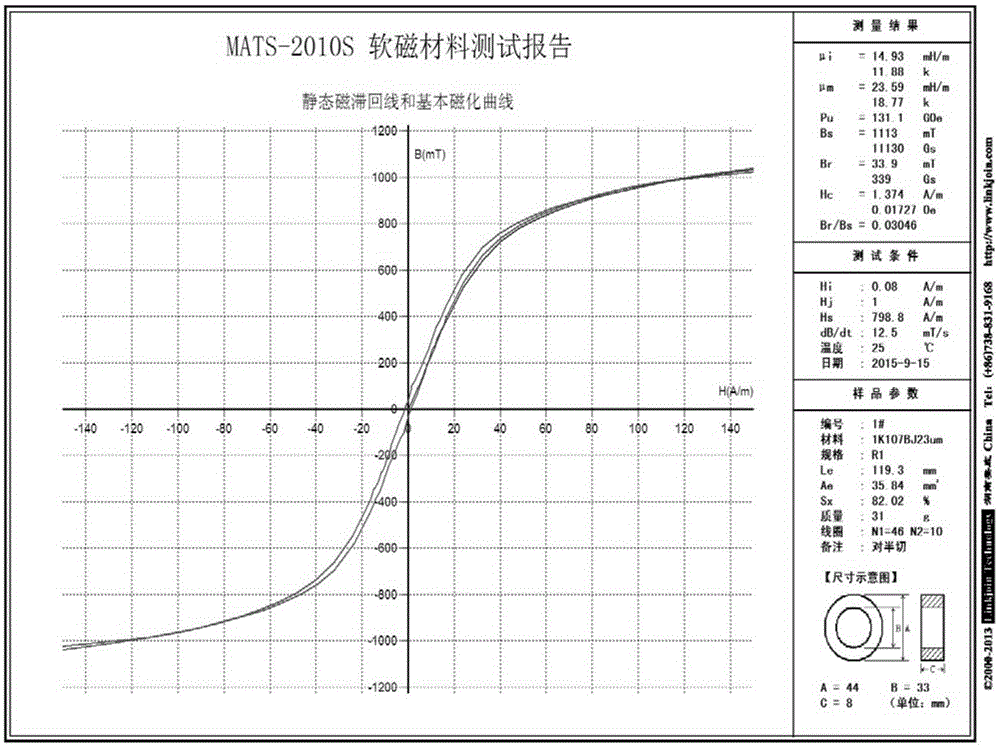

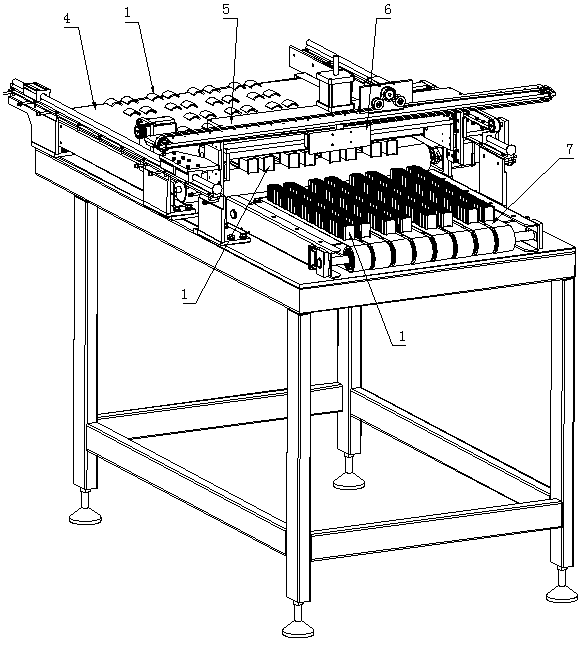

Method for precisely preparing nanocrystalline magnetic core with high magnetic permeability

ActiveCN105428053AImprove permeabilityIncreased accuracy levelMagnetic core manufactureEpoxyControl system

The invention provides a method for precisely preparing a nanocrystalline magnetic core with high magnetic permeability. The method comprises a step of nanocrystalline magnetic core curing and a step of nanocrystalline magnetic core cutting, wherein nanocrystalline magnetic core curing is realized by taking epoxy resin as varnish gum in a vacuum impregnation manner, particularly, a magnetic core and the varnish gum are preheated to 60-70 DEG C before impregnation, the epoxy resin varnish gum is mixed with acetone, then diluted and kept at the temperature for impregnation, the cured magnetic core has a clean and smooth surface, and the varnish gum can be kept in the magnetic core and doesn't overflow; the step of magnetic core cutting is implemented as follows: a grinding wheel machine cutting mechanism is adopted for cutting, meanwhile, a PLC (programmable logic controller) control system is adopted for controlling working feed, a self-made chemical corrosive agent is adopted for protecting a cutting site, and a tidy and smooth cutting surface of the magnetic core is guaranteed. The nanocrystalline magnetic core prepared with the method has the excellent characteristic that the magnetic permeability of the nanocrystalline magnetic core is 10 times higher than that of a conventional magnetic core and the nanocrystalline magnetic core has good temperature resistance and toughness.

Owner:FOSHAN CITY ZHONGYAN AMORPHOUS TECH

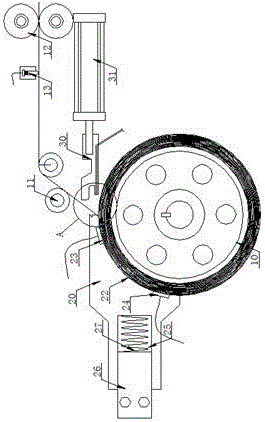

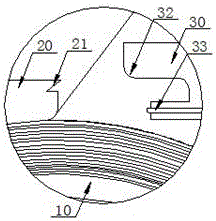

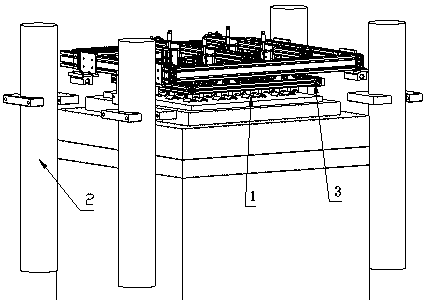

Full-automatic mutual inductor magnetic core strip winding device

ActiveCN106710864AIncrease productivityReduce labor intensityTransformers/inductances magnetic coresMagnetic core manufactureInductorConductor Coil

The invention discloses a full-automatic mutual inductor magnetic core strip winding device. The device comprises a mutual inductor magnetic core winding roll, a magnetic core winding cutting fixed block and a magnetic core winding cutting movable block, wherein a magnetic core strip fixed cutting disc is arranged at the top of one end, toward the mutual inductor magnetic core winding roll, of the magnetic core winding cutting fixed block; a magnetic core strip movable cutting disc is arranged at the end, toward the magnetic core strip fixed cutting disc, of the magnetic core winding cutting movable block and is matched with the magnetic core strip fixed cutting disc; a strip winding arc inductive face is arranged on the magnetic core winding cutting fixed block, and faces the surface of the mutual inductor magnetic core winding roll; an upper winding terminal inductor and a lower winding terminal inductor are respectively arranged at the upper end and the lower end of the strip winding arc inductive face. The device can be used for cutting of a continuous mutual inductor magnetic core strip and adhering the mutual inductor magnetic core strip to the magnetic core roll surface, and can accurately determine the quantitative winding terminal of the mutual inductor magnetic core strip.

Owner:江苏二互电气有限公司

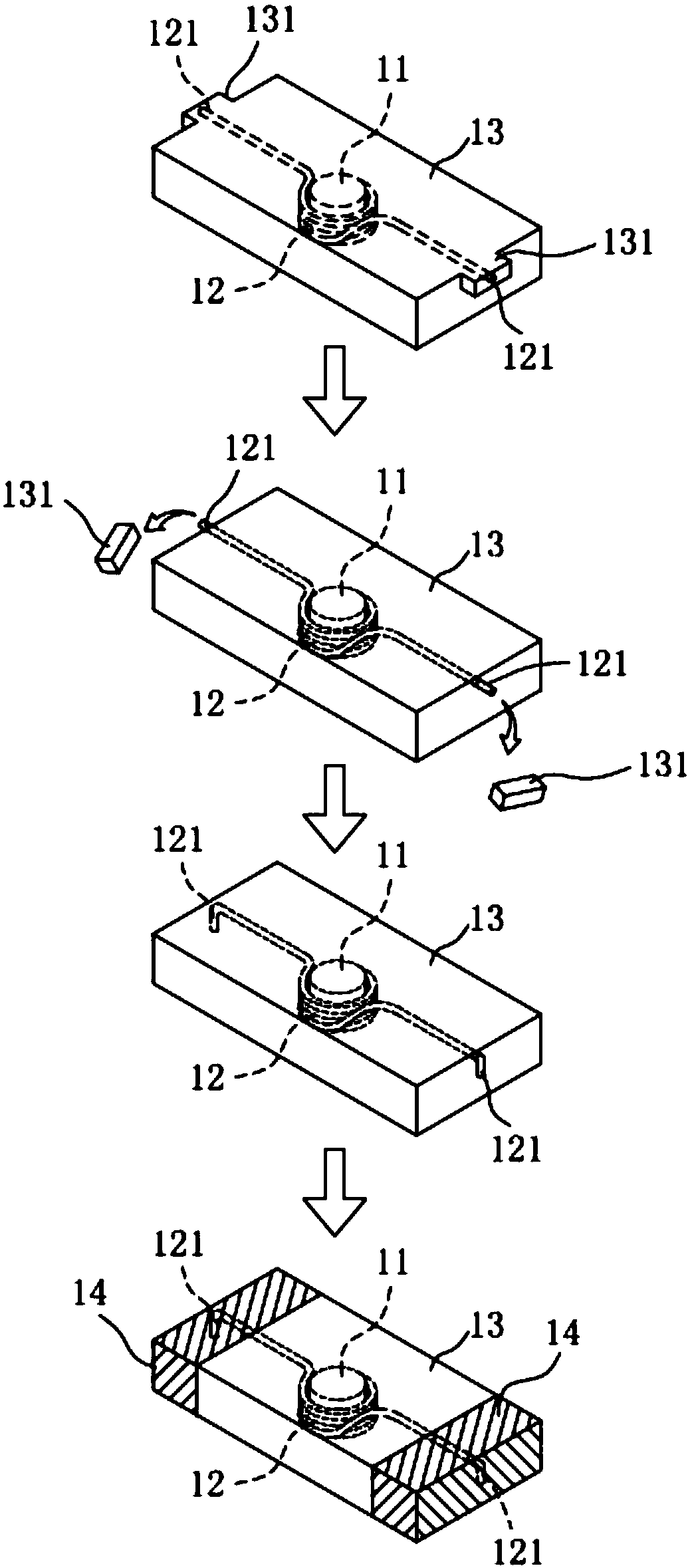

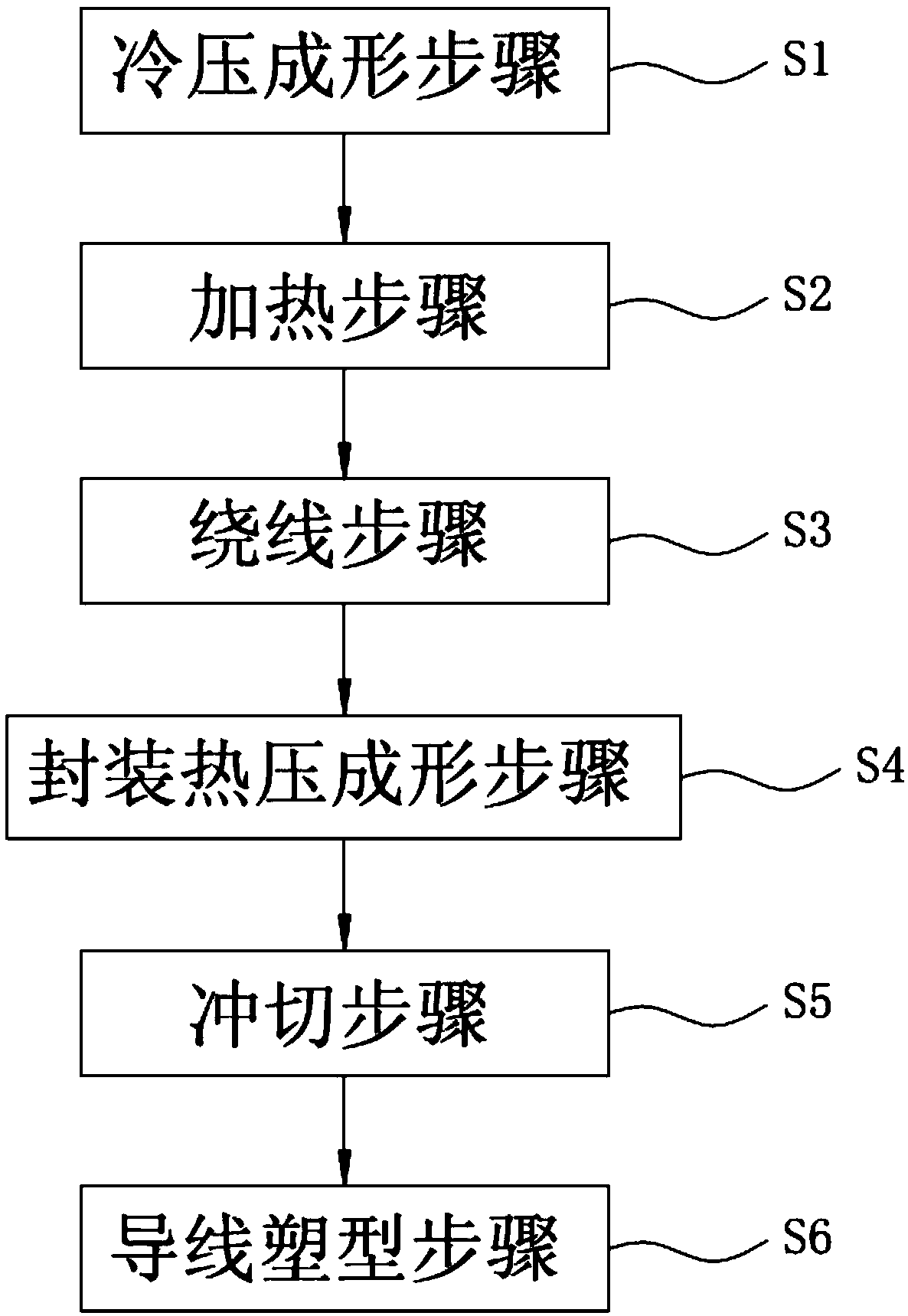

A method for making an inductor and the product made therefrom

InactiveCN109585149AReduce heat problemsHigh saturation current valueEncapsulation/impregnationCoils manufactureInductorInductance

A method for making an inductor comprises following steps: (a) preparing a magnetic core from a first magnetic component through cold pressing and moulding; (b) heating the magnetic core; (c) windingthe coil section of a wire around the heated magnetic core so that opposite bonded sections of the wire can extend in a direction opposite to the magnetic core from two opposite ends of the coil section; and (d), after the step (c), putting the wire wound magnetic core in a die, filling a second magnetic component in the die, and carrying out hot pressing moulding to form a magnetic shell that wraps the magnetic core and the coil section of the wire. The invention also provides an inductor prepared by the method mentioned above. The cold-press moulded magnetic core has the advantages of low relative magnetic permeability and high saturated current value. The hot-press moulded magnetic hell has high relative magnetic permeability and wraps the magnetic core and the coil section. The numberof turns of the coil section is not increased, the required inductance is reached, the heat caused by DC resistance is reduced, and the saturated current value is compensated at the same time.

Owner:TAIWAN GREEN POINT ENTERPRISE

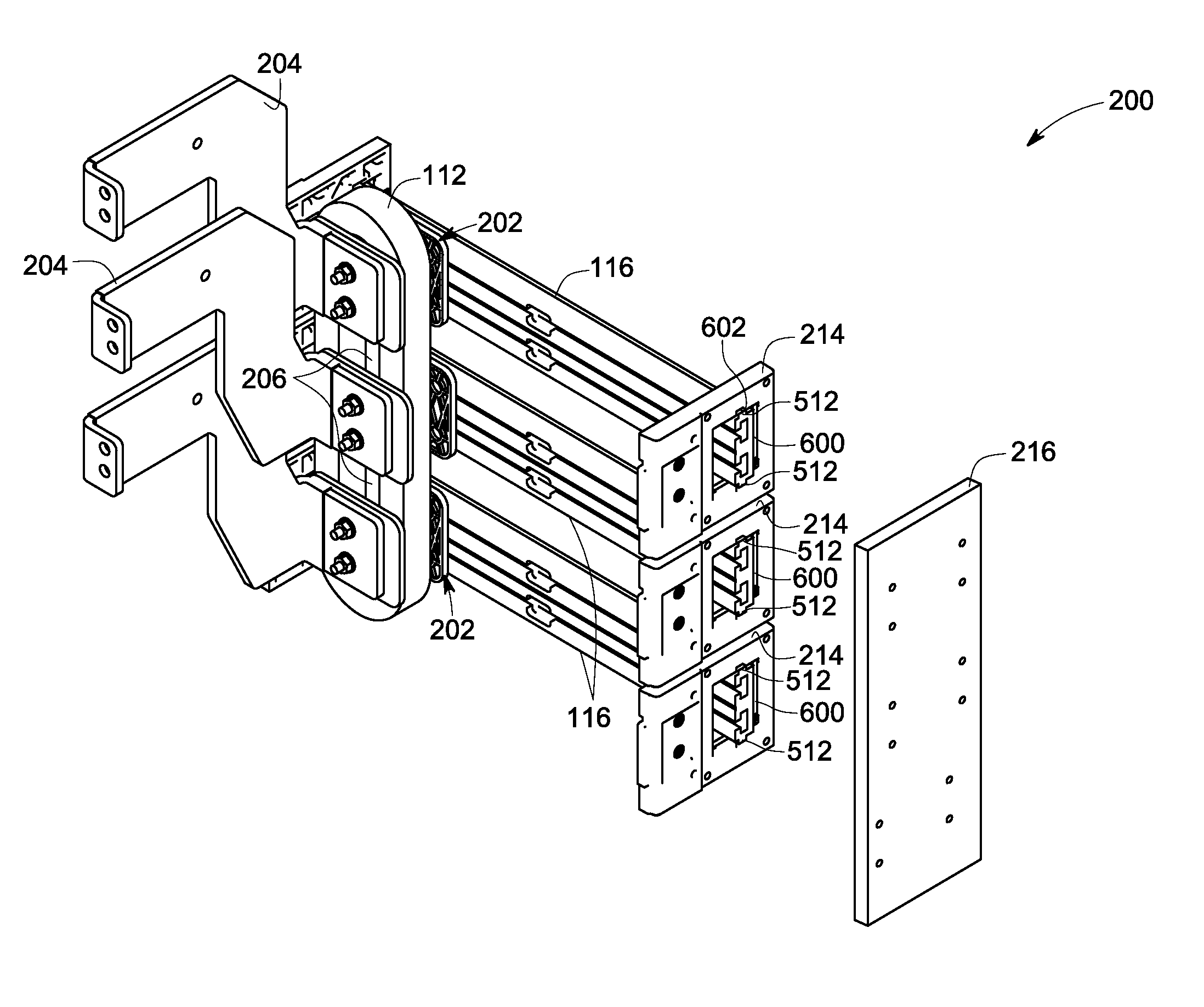

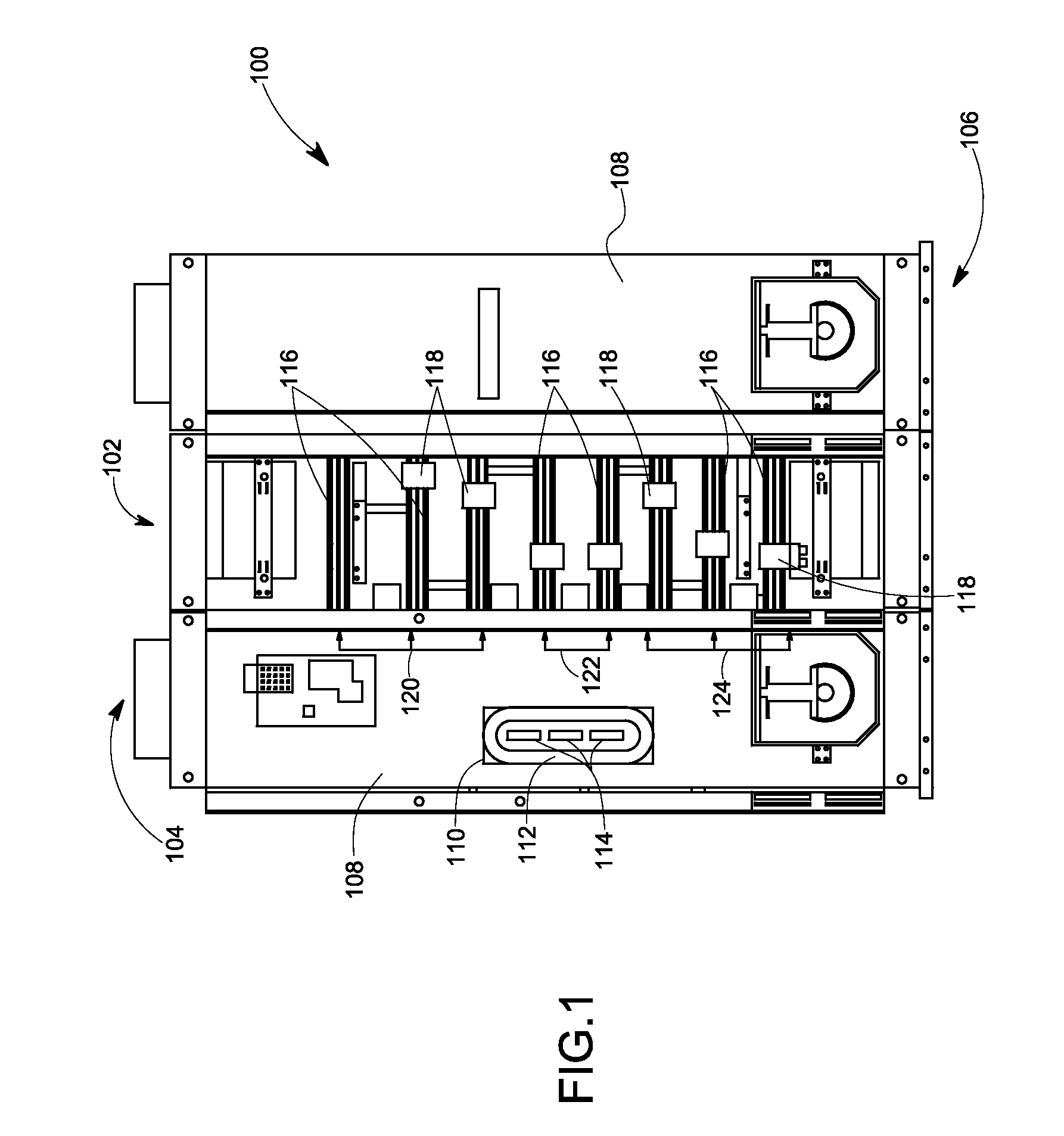

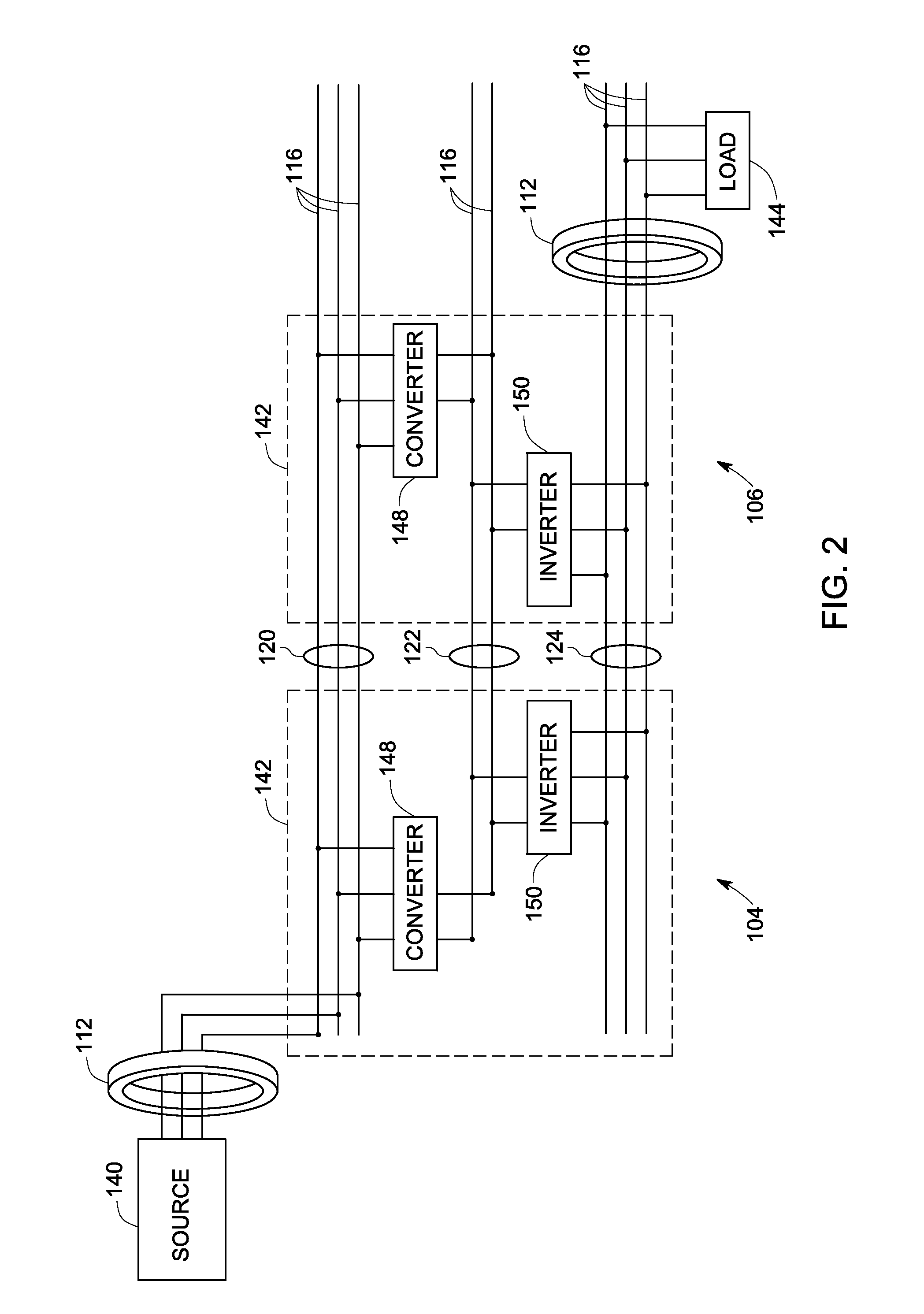

Common mode magnetic device for bus structure

InactiveUS8456807B2Enhanced interactionCooperate wellCoupling device connectionsDigital data processing detailsEngineeringElectric power

A magnetic device mounting system is disclosed, such as for use in electrical cabinets for distribution of power via power bus bars. The system includes a common mode magnetic device that has an opening configured to receive extensions of a set of parallel bus bars. A non-conductive support is provided, along with a conductive extension, the non-conductive support and extension being configured to coordinate to engage the opening and to support the common mode magnetic device via attachment to the bus bar.

Owner:ROCKWELL AUTOMATION TECH

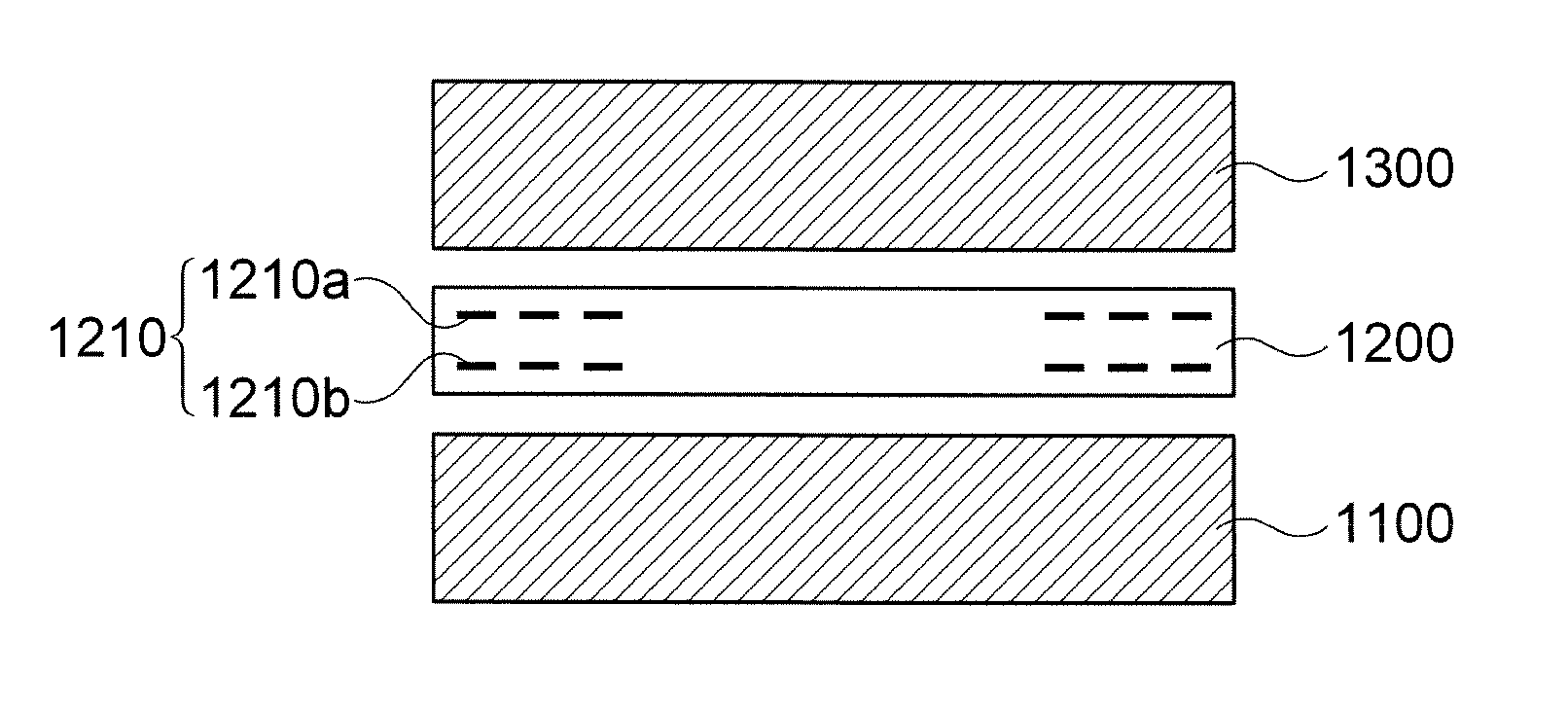

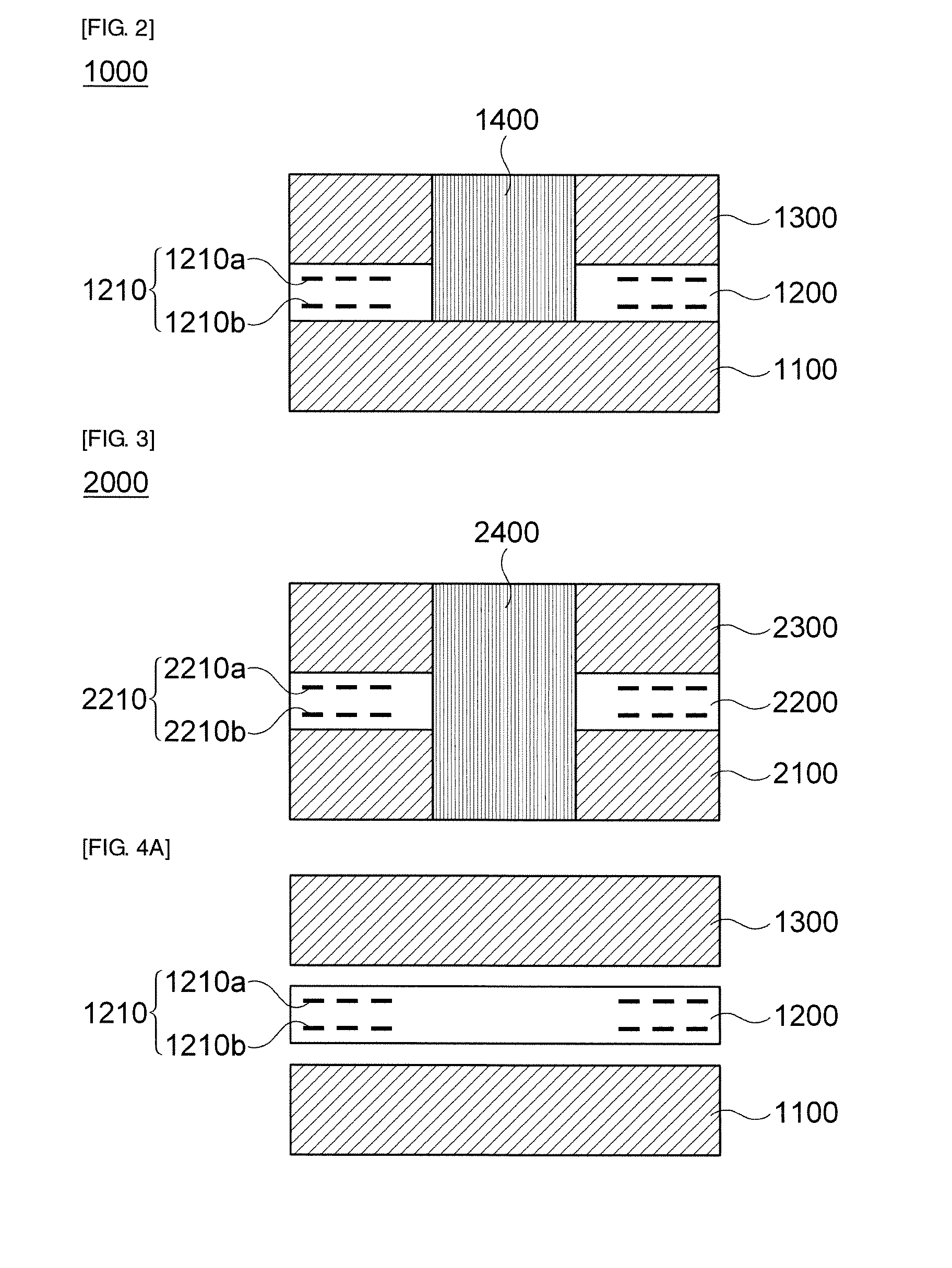

Common mode filter and method of manufacturing the same

InactiveUS20130169381A1Multiple-port networksLamination ancillary operationsElectrical conductorEngineering

The present invention relates to a common mode filter and a method of manufacturing the same. In order to implement a common mode filter with low shrinkage, high substrate sintered density, and high strength, the present invention provides a common mode filter including: a lower substrate; an insulating layer having a conductor pattern inside and provided on the lower substrate; an upper substrate provided on the insulating layer; and a ferrite core made of ferrite and provided in the center of the insulating layer, the lower substrate, and the upper substrate by penetrating the insulating layer, the lower substrate, and the upper substrate, and a method of manufacturing the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

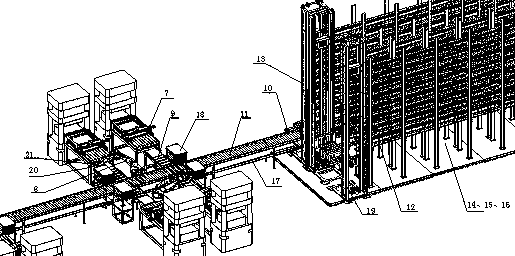

Magnetic material automated production line

PendingCN110289162AEfficient recyclingImprove yieldConveyorsStacking articlesProduction lineScheduling function

The invention relates to a magnetic material automated production line and is in the order of magnetic tile pressing, detecting, conveying, warehouse entry and sintering. The production line is characterized in that a pressing machine 2, a sorting table, a visual defect detecting mechanism 6 used for detecting magnetic tiles 1 on the sorting table, a robot 8 used for taking the magnetic tiles 1, a palletizing platform 9 used for disposing the magnetic tiles 1 and an ID card in a tray, a tray scanner 10 used for scanning the tray ID card information, a conveyor belt 11 used for conveying the tray (the magnetic tile tray, the same below) loaded with the magnetic tiles 1 to a sintering furnace, the sintering furnace 15, a printer system 16, an empty tray return system and a control system having the system scheduling function, wherein the control system includes a server connected with a PC industrial control computer, a tray scanner system, a PLC controller, and a defect identification system and a label printing system connected with the server, motion parts are respectively controlled by PLC, and the control system is used for acquiring and analyzing PLC controller instructions and the induction information and making instructions. The production line is advantaged in that production cost is reduced, production efficiency is improved, product consistency is improved, inspection standards are unified, and the information management level is improved.

Owner:江门市蓬江区联诚达科技发展有限公司

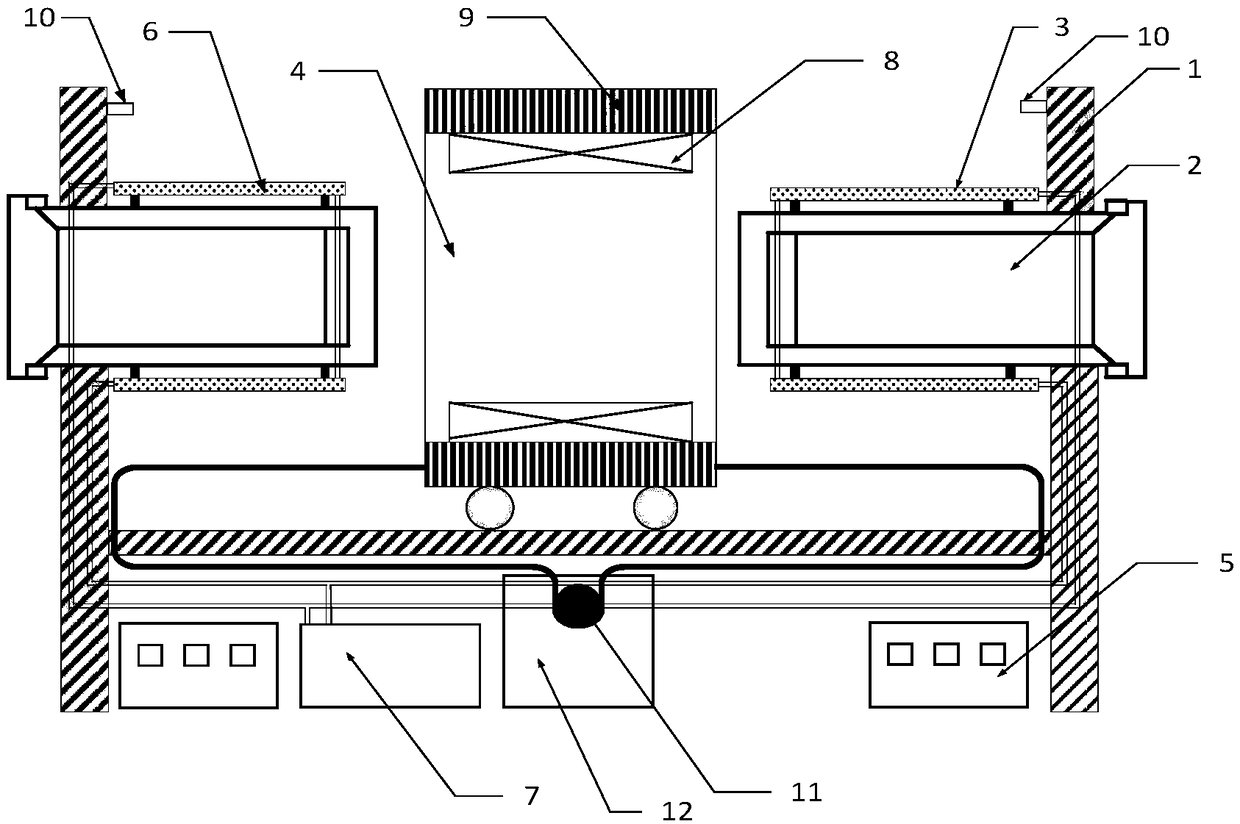

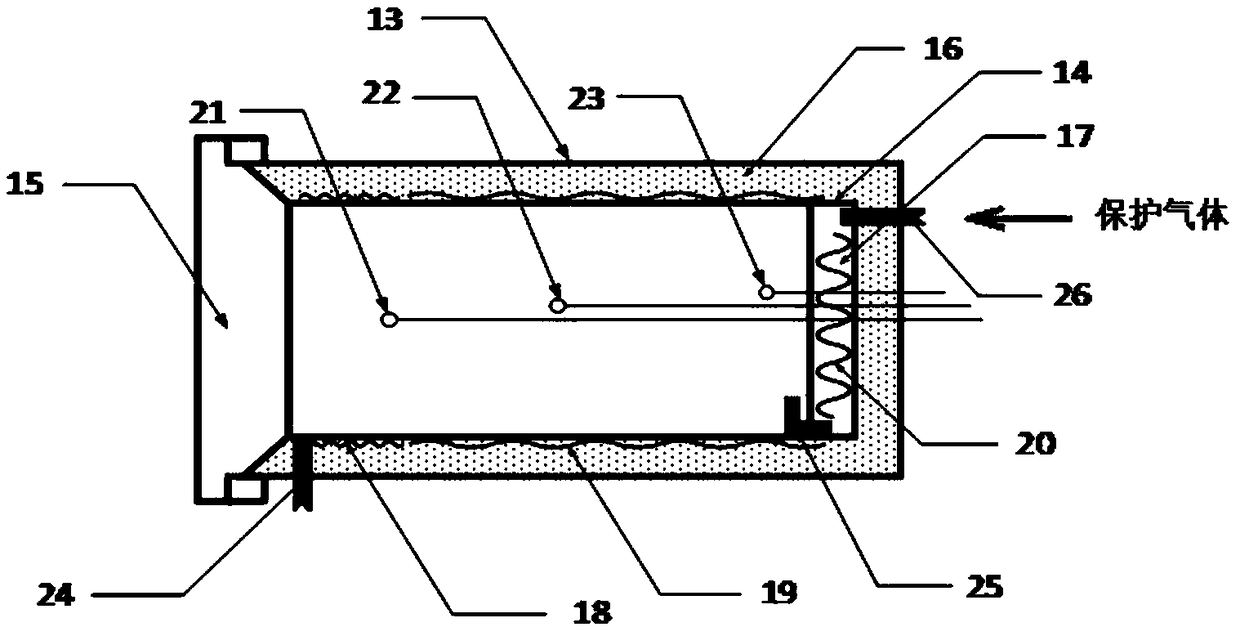

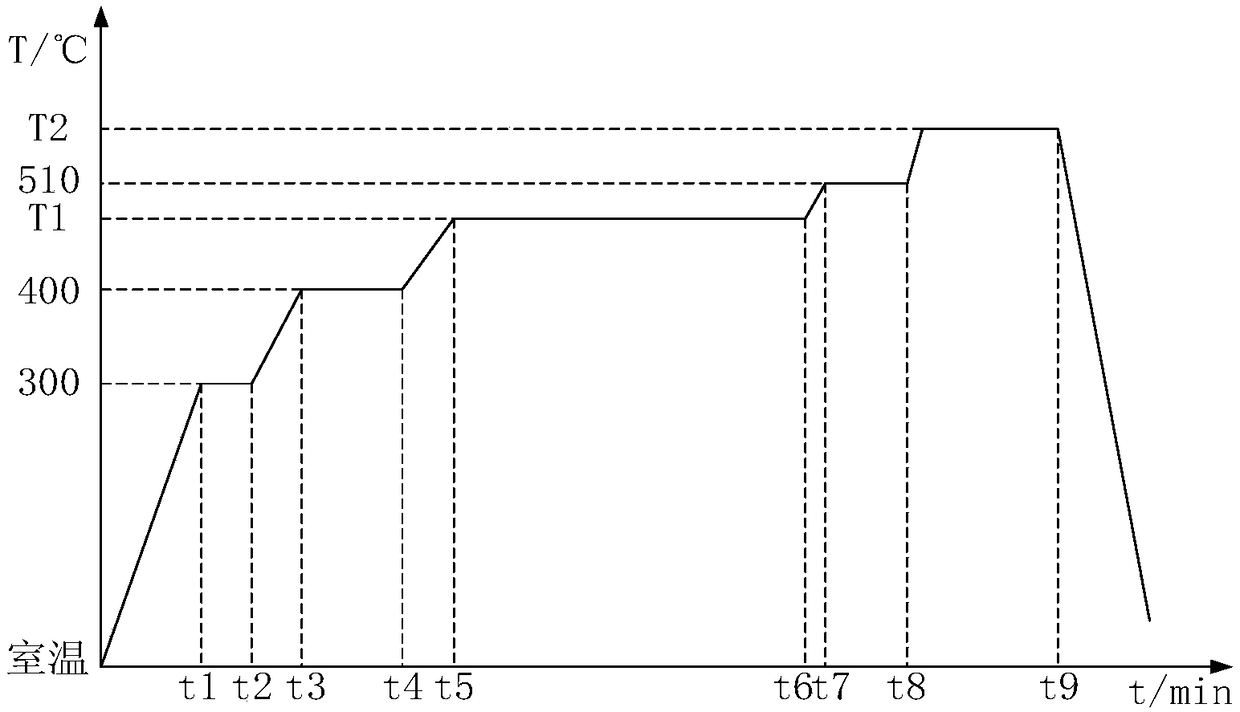

Amorphous nanocrystalline magnetic core heat treatment method

ActiveCN108998633AHigh initial permeabilityLow coercivityFurnace typesMagnetic materialsShielding gasRoom temperature

The invention discloses an amorphous nanocrystalline magnetic core heat treatment method. The amorphous nanocrystalline magnetic core heat treatment method comprises the steps that (1) a to-be-treatedmagnetic core is placed into a transverse magnetic field heat treatment furnace, and protective gas is led in; (2) heat treatment and magnetic treatment are carried out, wherein in the first stage, the temperature rises to about 300 DEG C from the room temperature, the wasted time is about 60 min, heat preservation is carried out for about 30 min, then the temperature rises to about 400 DEG C, the wasted time is about 30 min, and heat preservation is carried out for about 60 min; in the second stage, the temperature rises to T1 from about 400 DEG C, the wasted time is about 30 min, heat preservation is carried out at T1 for about 210 min, and meanwhile, a transverse magnetic field is applied in the second stage; in the third stage, the magnetic field is removed, meanwhile, the temperaturerises to about 510 DEG C from T1, the wasted time is about 20 min, heat preservation is carried out for about 40 min, then the temperature rises to T2 to be subjected to heat preservation, and the wasted time is about 90 min; and in the fourth stage, heating is stopped, cooling is carried out to the room temperature, wherein the T1 is 460 DEG C-480 DEG C, and the T2 is 560 DEG C-570 DEG C.

Owner:YANGZHONG INTELLIGENT ELECTRICAL INST NORTH CHINA ELECTRIC POWER UNIV

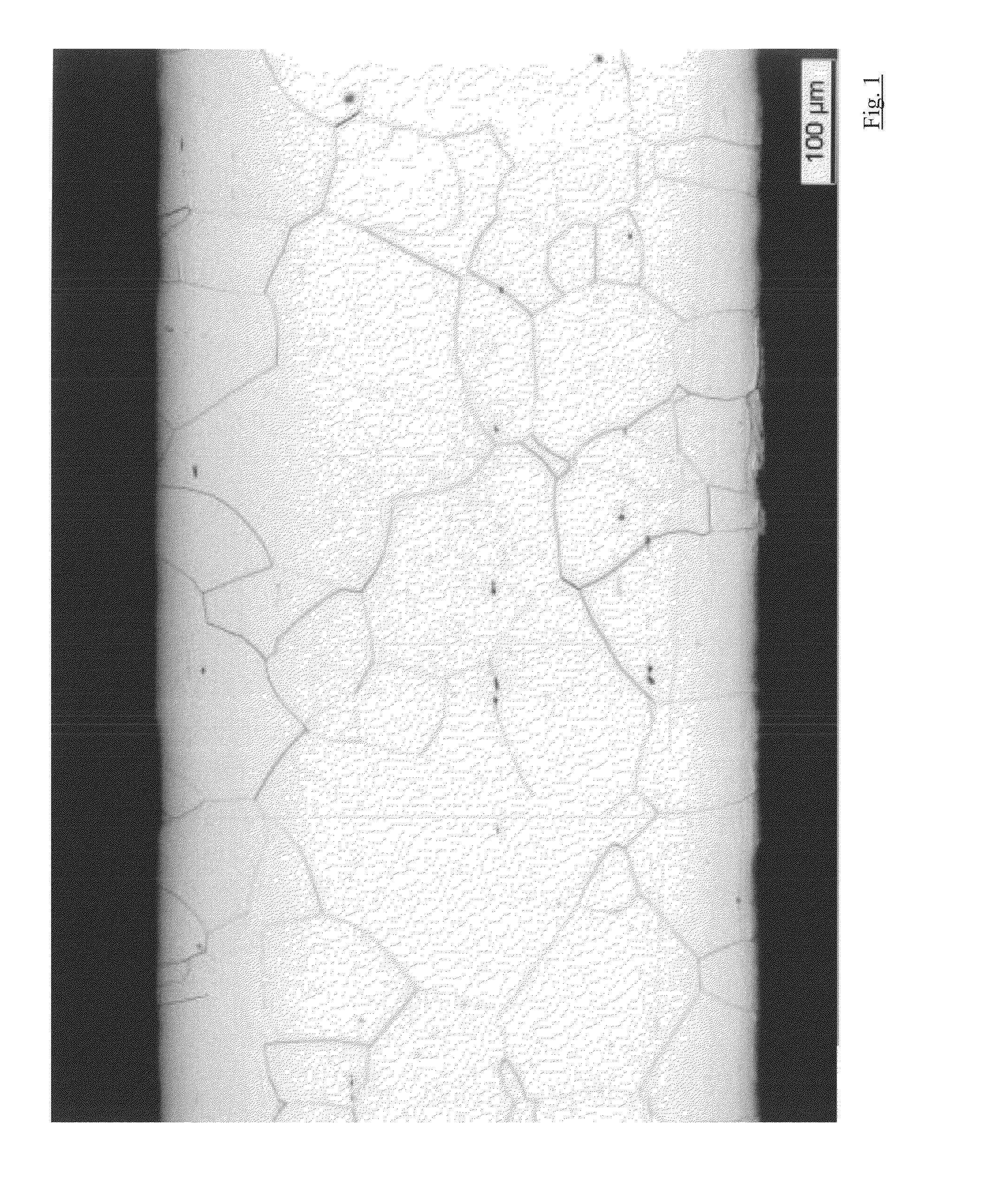

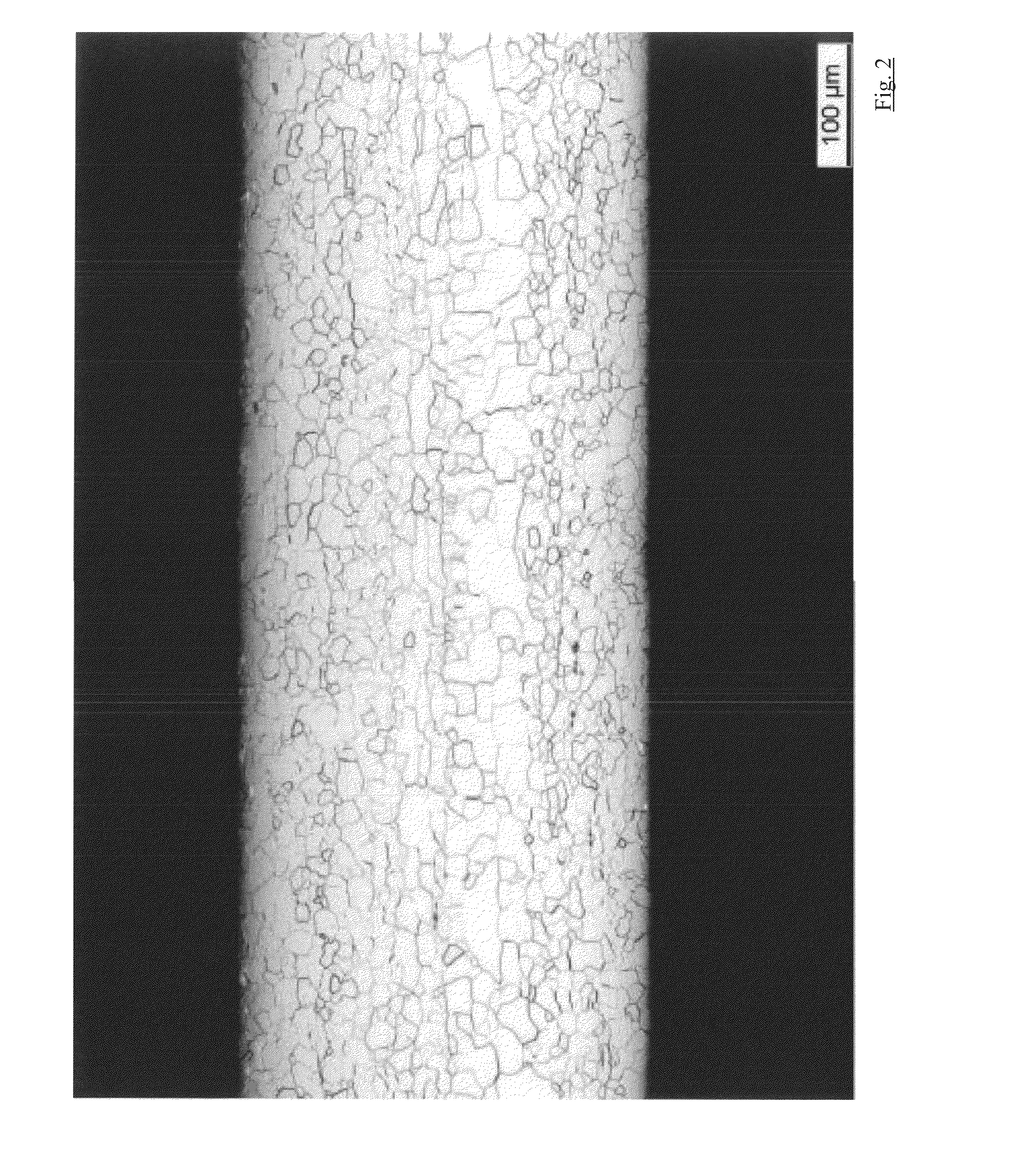

Soft magnetic iron-cobalt-based alloy and process for manufacturing it

A soft magnetic alloy consists essentially of 10 percent by weight ≦Co≦22 percent by weight, 0 percent by weight ≦V≦4 percent by weight, 1.5 percent by weight ≦Cr≦5 percent by weight, 0 percent by weight <Mn<1 percent by weight, 0 percent by weight ≦Mo≦1 percent by weight, 0.5 percent by weight ≦Si≦1.5 percent by weight, 0.1 percent by weight ≦Al≦1.0 percent by weight and the remainder iron, the content of the elements chromium and manganese and molybdenum and aluminium and silicon and vanadium being 4.0 percent by weight ≦(Cr+Mn+Mo+Al+Si+V)≦9.0 percent by weight.

Owner:VACUUMSCHMELZE GMBH & CO KG

Thermally enhanced magnetic transformer

ActiveUS20090079528A1Thermally efficientEliminate useTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEngineeringHeat sink

A planar transformer comprises a laminate substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, a core configured to fit inside the opening to enclose the laminate substrate. At least one heat sink fin is integrally formed with the top, bottom or both sides of the core. A method of forming a planar transformer comprises laminating a substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, fitting a core inside the opening, and enclosing the laminate substrate. One of the top, bottom or both sides of the core include one or more heat sink fins.

Owner:FLEXTRONICS AP LLC

Electromagnetic assemblies, core segments that form the same, and their methods of manufacture

Electromagnetic assemblies, core segments that form the same, and their methods of manufacture. The segments have an interlocking engagement, whereby a variety of assemblies can be produced from a very small number of similar or complementary segments in a manner that provides excellent mechanical stability. The articles and methods of formation offer design flexibility and provide for a large variety of patterns from a small number of primary shapes, provide an economical manufacturing method for large transformer and inductor cores, and improve uniformity of magnetic properties of the assemblies when compared to conventional practices.

Owner:SPANG & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com