Method of manufacturing magnetic field shielding sheet and magnetic field shielding sheet formed thereby

a technology of magnetic field shielding and magnetic field, which is applied in the manufacture of magnetic cores, shielding materials, inductances, etc., can solve the problems of inability to satisfactorily perform the function of protective films, easy torn or scratched, and increased production costs, so as to enhance heat radiating performance, enhance protection function, and enhance rigidity of heat radiating members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071]Hereinafter, exemplary embodiments of the present disclosure will be described in detail with reference to the accompanying drawings, which will be readily apparent to those skilled in the art to which the present disclosure pertains. The present disclosure may be embodied in many different forms and is not limited to the embodiments described herein. In the drawings, parts not relating to the description are omitted for clarifying the present disclosure, and the same reference numerals are assigned to the same or similar components throughout the specification.

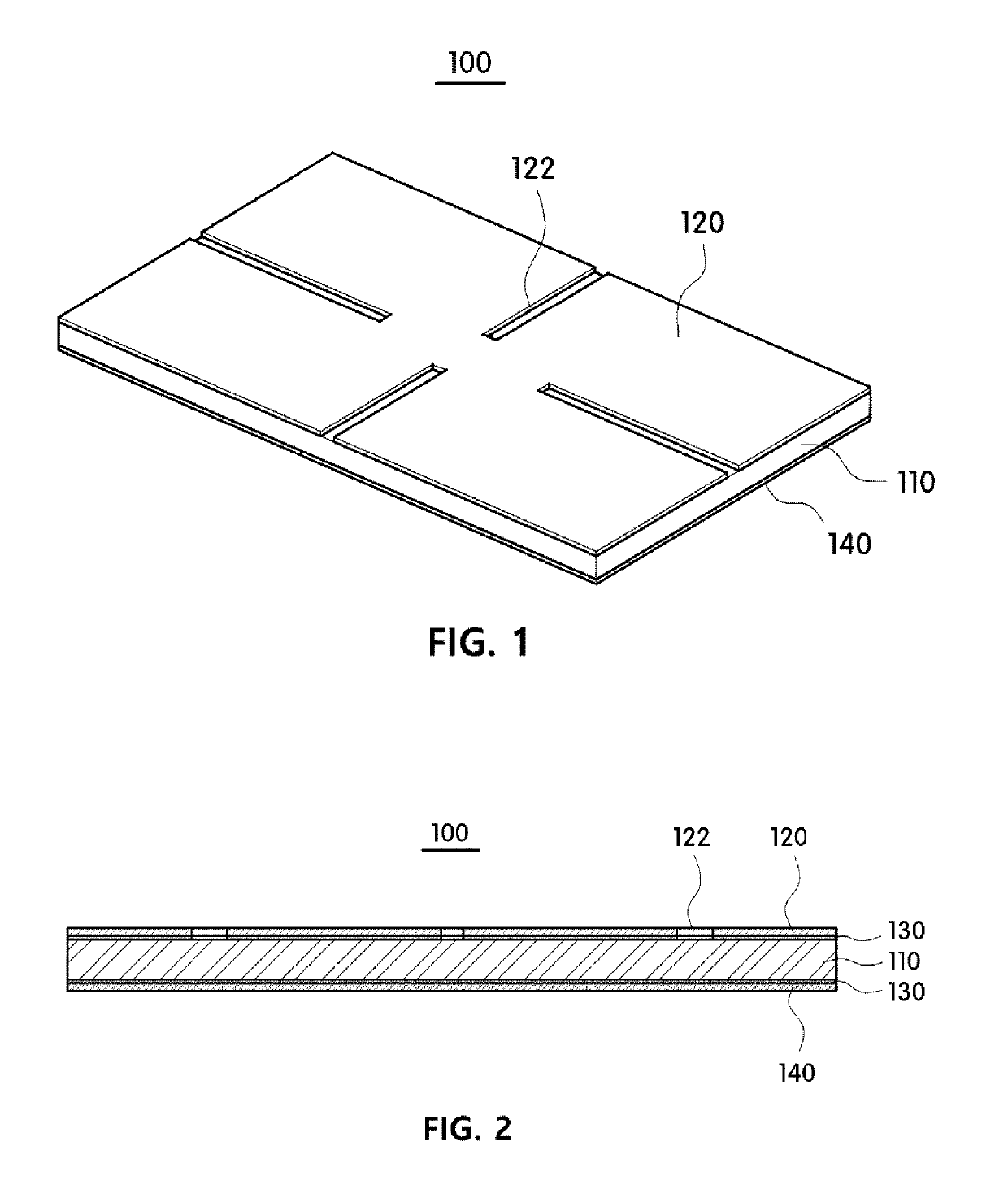

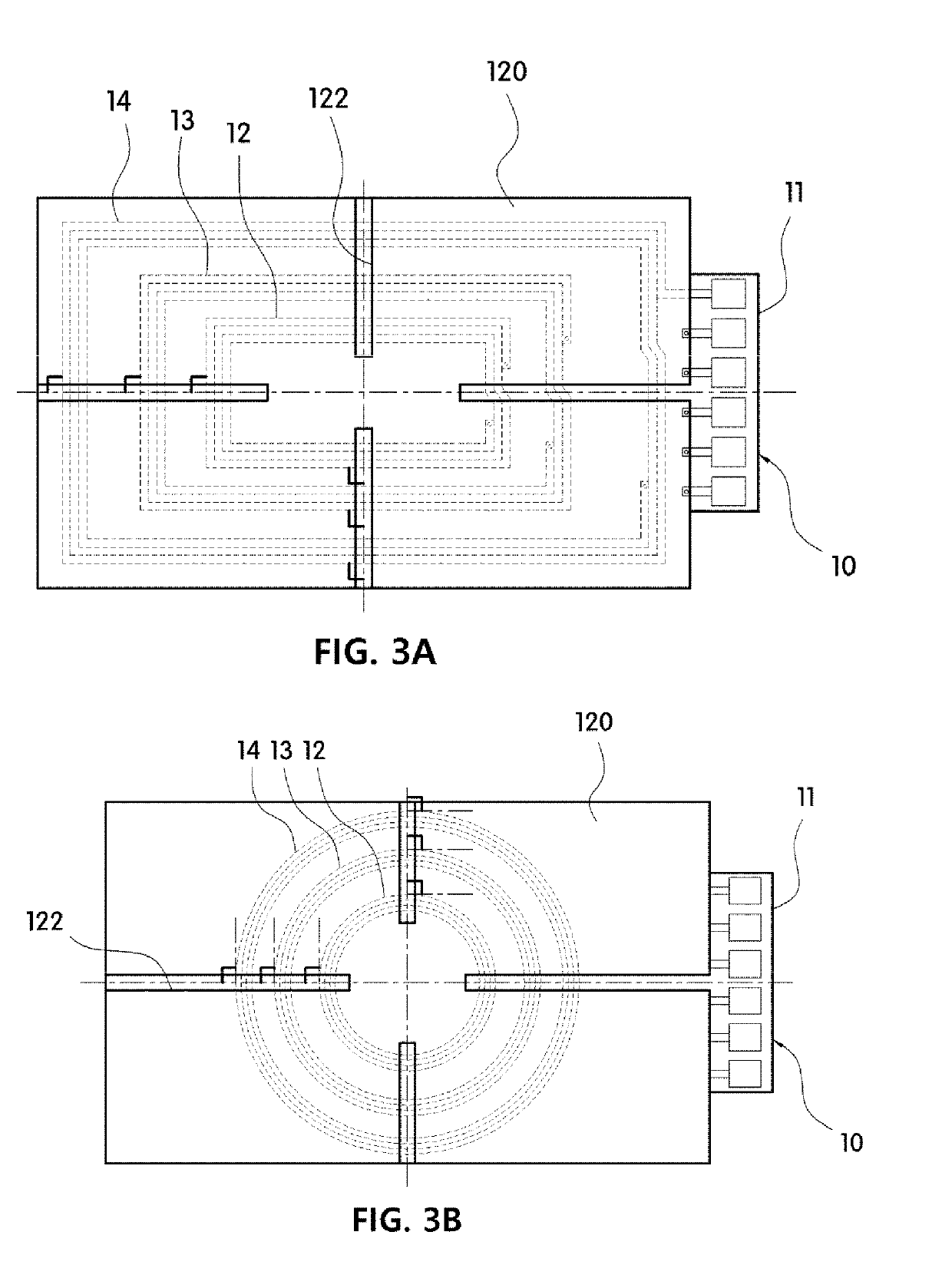

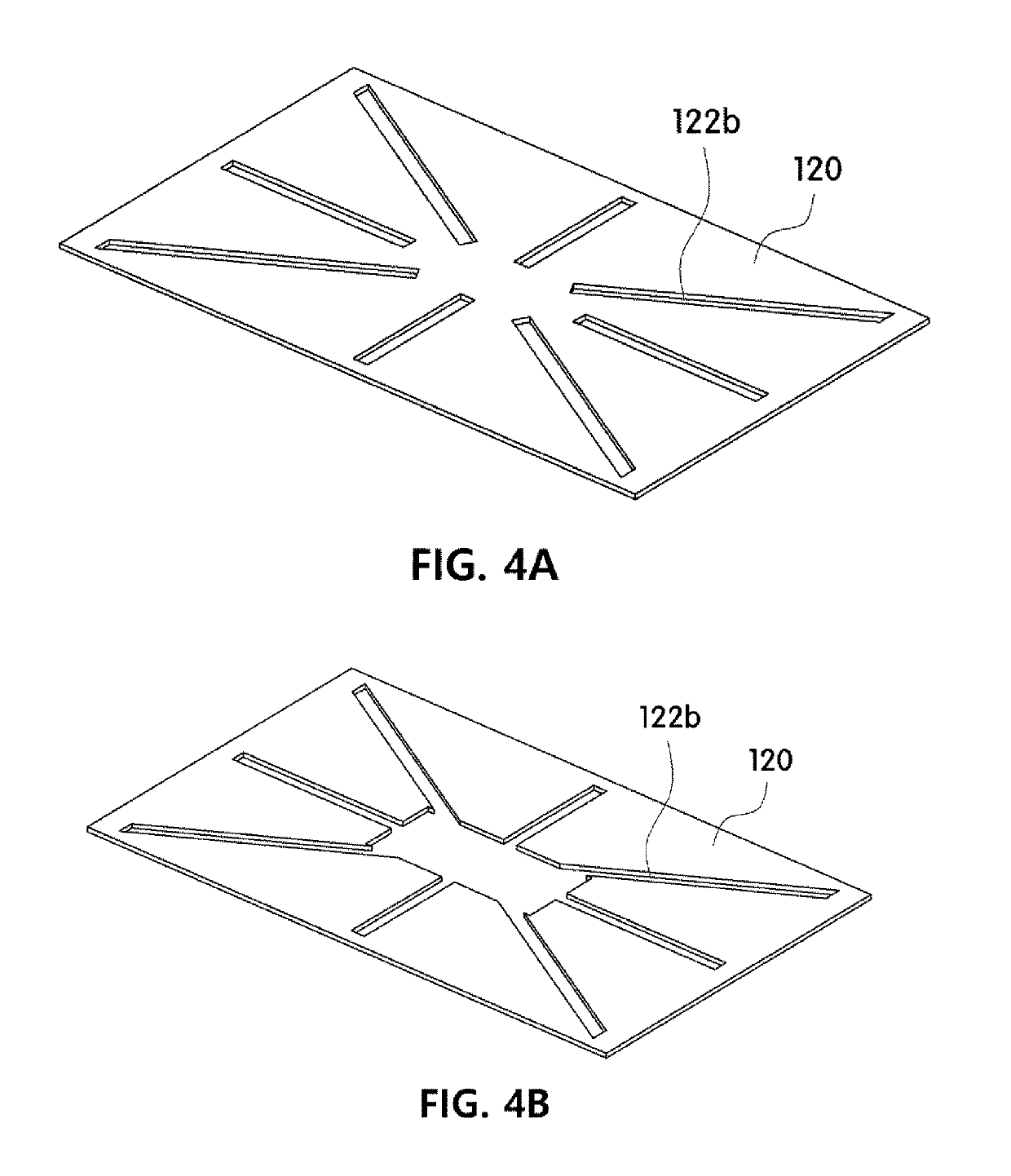

[0072]In an exemplary embodiment, a magnetic field shielding unit 100 may include a magnetic field shielding sheet 110 and a metallic protecting member 120 as shown in FIGS. 1 and 2.

[0073]The magnetic field shielding sheet 110 may enhance a performance of an antenna using a predetermined frequency band by shielding the magnetic field generated from the antenna to increase a condensing performance of the magnetic field.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com