A method for making an inductor and the product made therefrom

A technology of inductors and magnetic cores, which is applied in the field of passive components to reduce heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

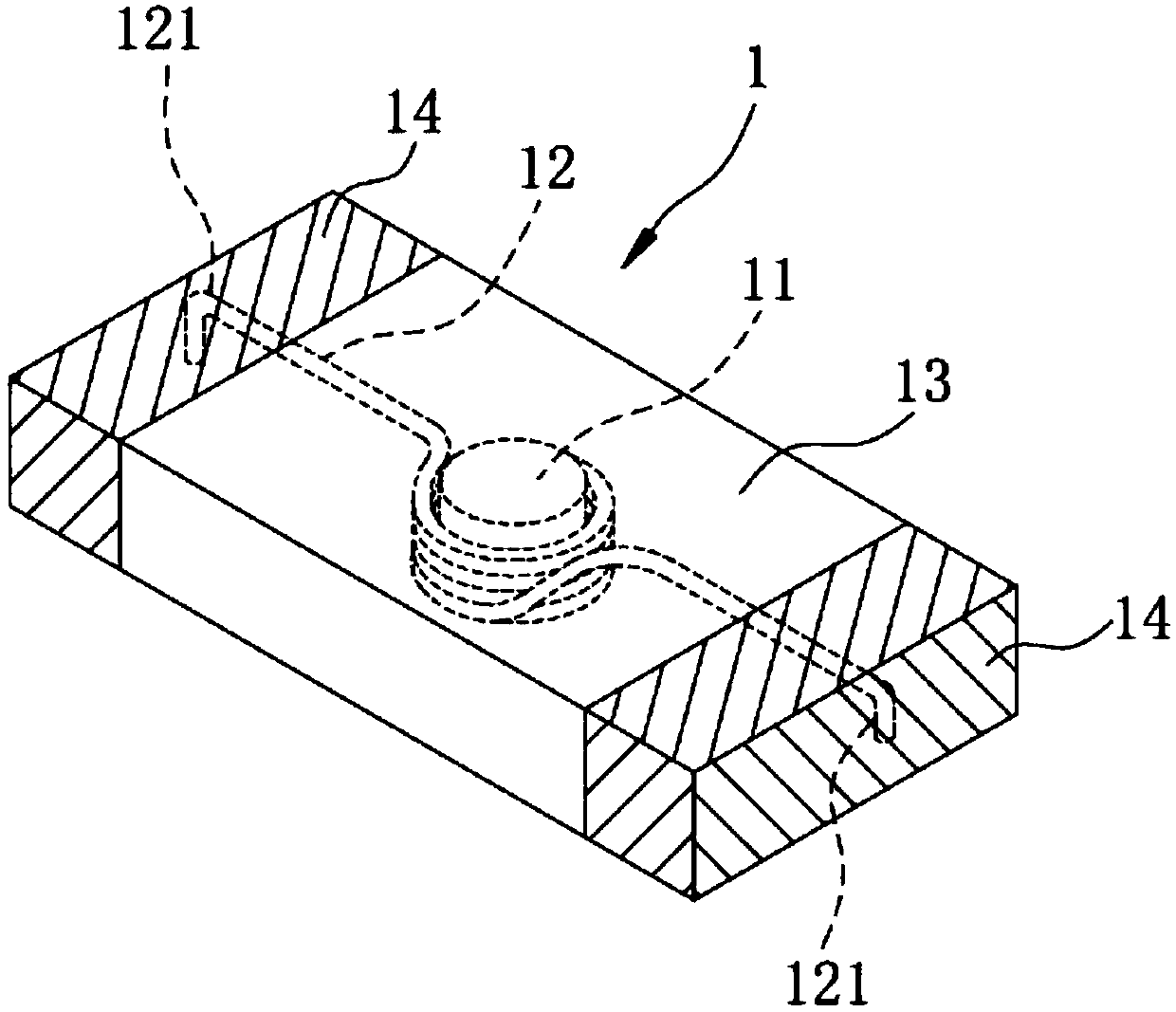

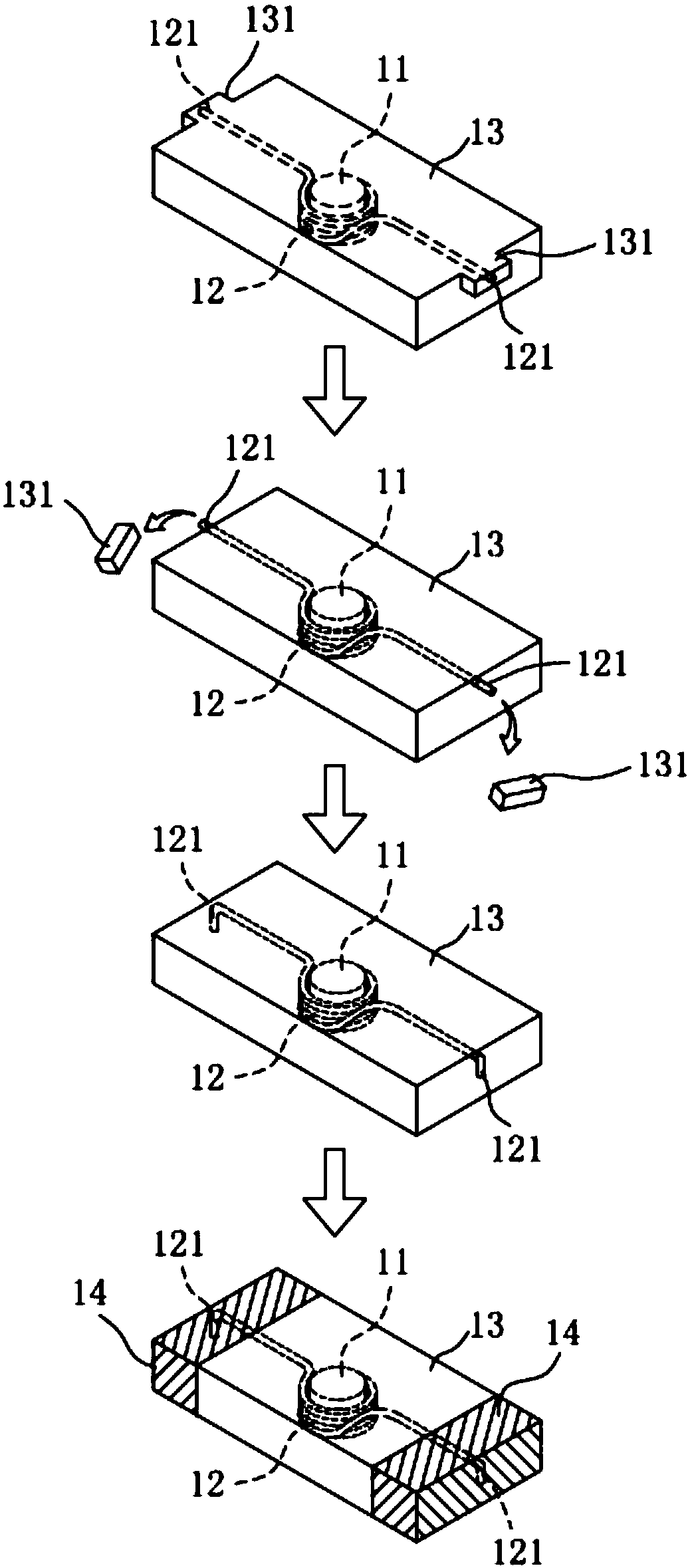

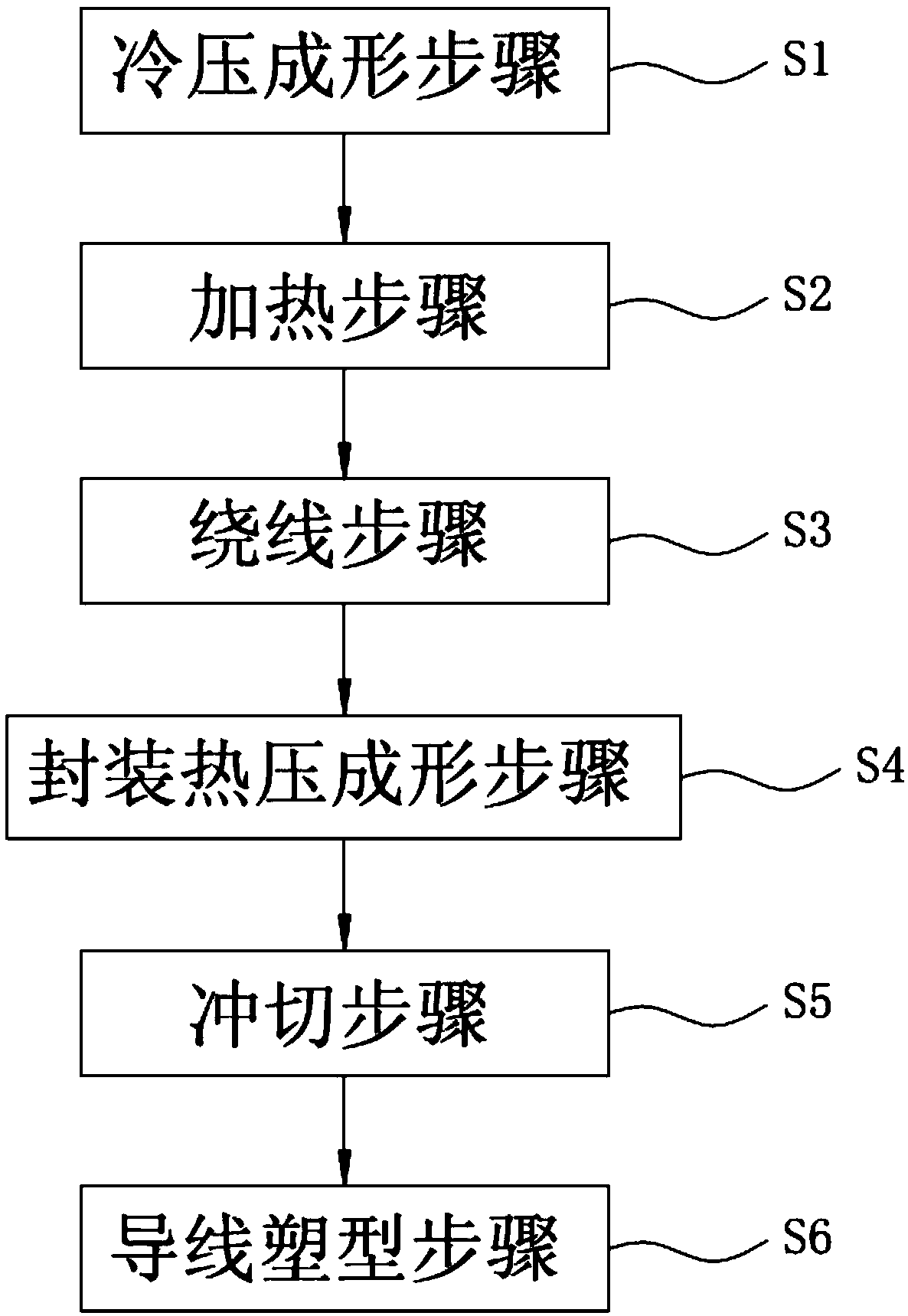

[0047] refer to image 3 , a first embodiment of the manufacturing method of the inductor of the present invention, comprising a cold forming step S1, a heating step S2, a winding step S3, a package hot pressing forming step S4, and a punching step S5 , and a wire shaping step S6.

[0048] Such as Figure 4 As shown, the cold forming step S1 is to form a magnetic core 2 by cold pressing a first magnetic component in a magnetic core mold 71 having a columnar mold cavity 710 . In the first embodiment of the present invention, the pressure implemented in the cold forming step S1 is between 3000kgw / cm 2 to 7000kgw / cm 2 . Core 2 is along the same as Figure 7 and Figure 8 The shown axis Y extends, and the cross-section of the magnetic core 2 along the vertical direction of the axis Y is an oblong circle; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com