Torque measurement sensing alarm system and method

A technology of torque measurement and alarm system, which is applied in signal transmission system, measuring device, torque measurement, etc., can solve the problems of complicated tools, incomplete management and control of high-altitude workers, and lack of quantitative standards for bolts, so as to improve work efficiency and reduce The effect of fever problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

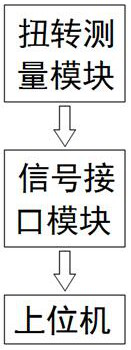

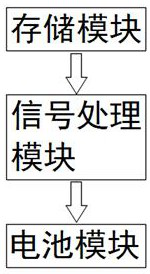

[0029] see Figure 1-2 , a torque measurement sensing alarm system, including a torque measurement device, a mounting device and a receiving device, the torque measuring device is fixed inside the spindle under test through the mounting device, the torque measuring device collects the spindle torque signal through a digital sensor, and the spindle torque signal passes through The monitoring data is sent to the receiving device by means of wireless communication. After receiving the monitoring data, the receiving device transmits the data to the host computer through the serial port. The torque measuring device is composed of a sensor module, a signal processing module, a wireless communication module, a power supply module and a storage module. The sensor module is composed of multiple sets of digital torque sensors, which are fixedly installed on the side wall of the installation device. The installation device makes the multiple sets of torque sensors fully contact with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com