Connector for flat cable

A technology of flat cables and connectors, applied in the direction of connection, circuit, contact parts, etc., can solve problems such as temperature rise, heat generation, and difficulty in miniaturization of electronic equipment, and achieve the effect of improving stability and reducing heat generation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

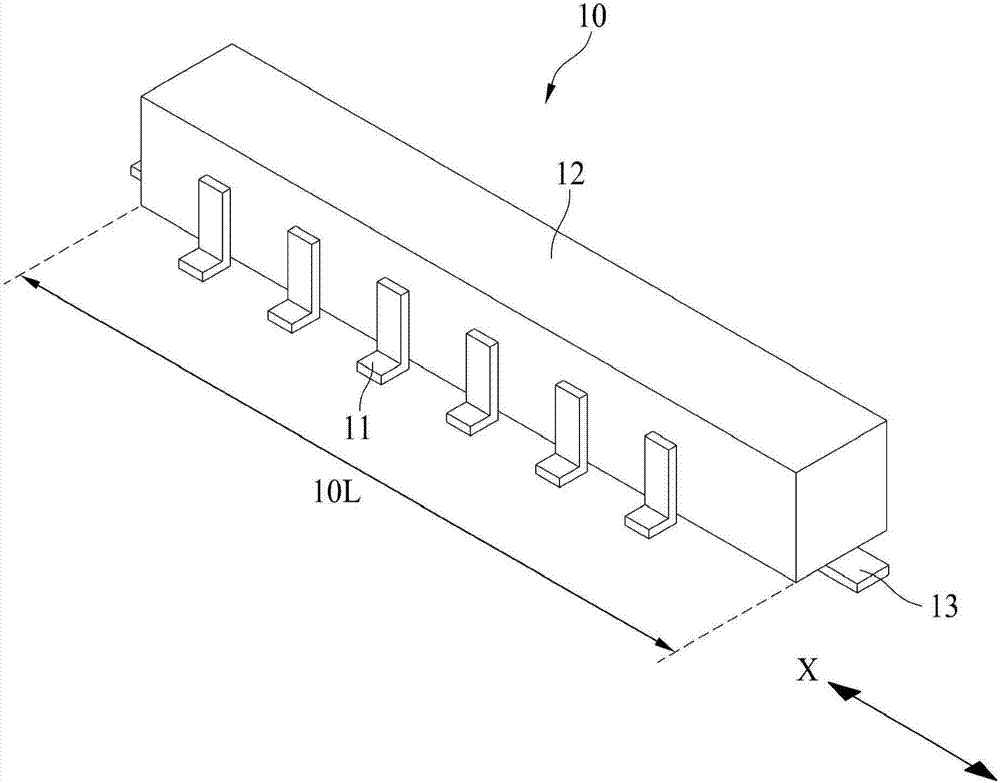

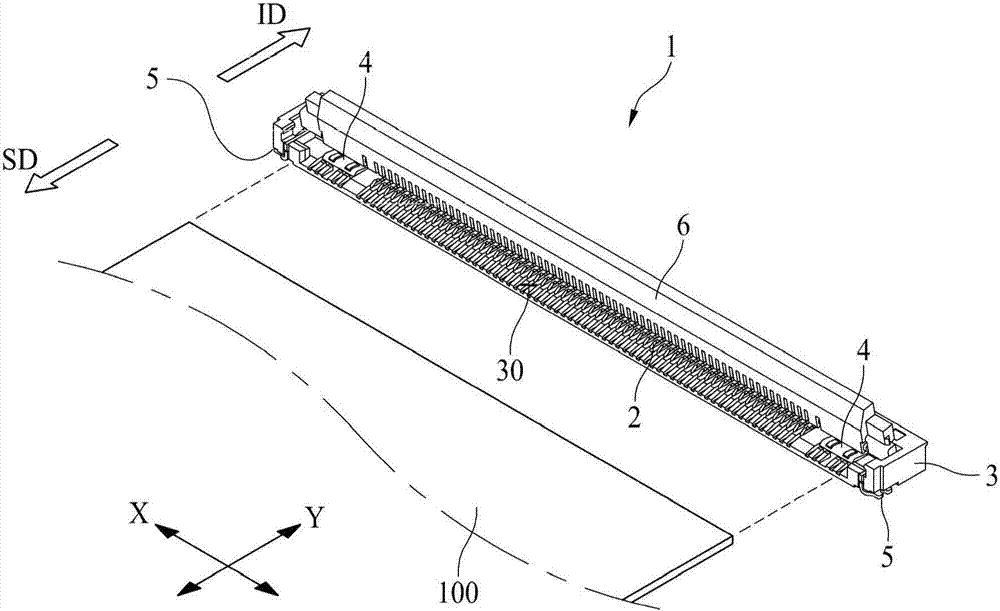

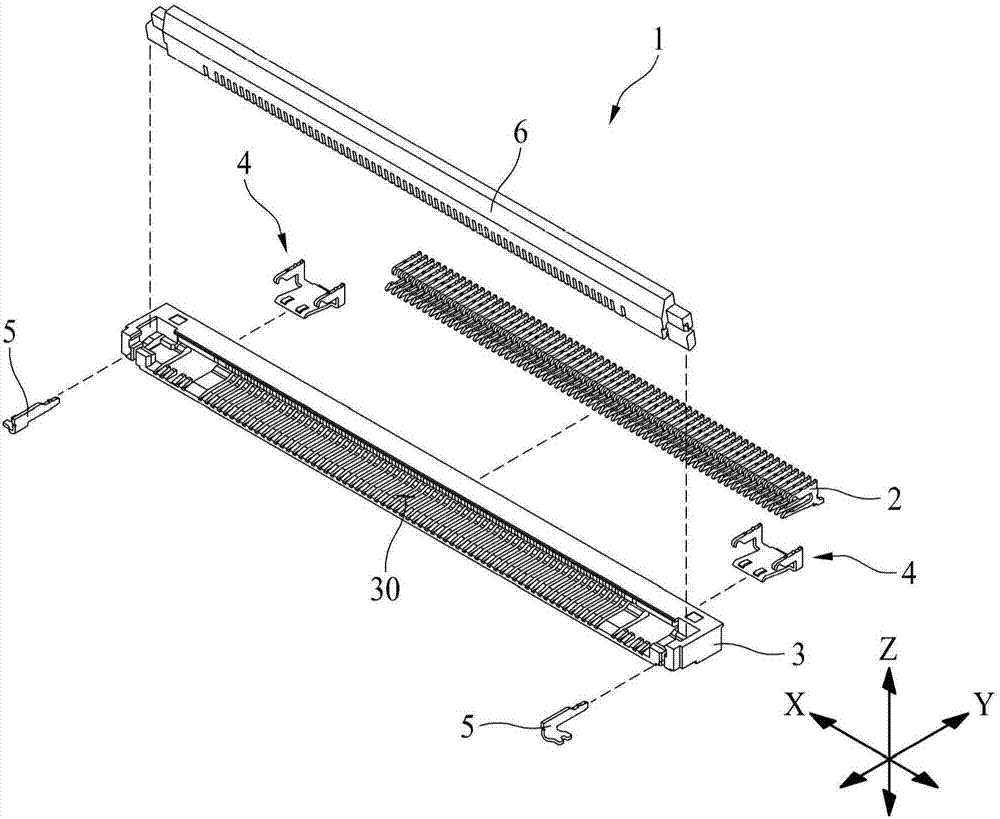

[0074] refer to Figure 2 to Figure 4 , the above-mentioned second contact piece 4 is formed to have a larger volume than each of the above-mentioned first contact pieces 2 , so as to have a larger allowable current than each of the above-mentioned first contact pieces 2 . For example, if Figure 4 As shown, the second contact 4 is formed to have a length 4L longer than the length 2L of each of the first contacts 2 on the basis of the first axis direction (X-axis direction), so that it can be formed to be consistent with each of the first contacts 2. Compared with a contact piece 2, it has a larger volume. Therefore, the flat cable connector 1 of the present invention electrically connects the flat cable 100 and the substrate using different types of contacts having different volumes.

[0075] Therefore, the flat cable connector 1 of the present invention is provided with the second contact 4 having a larger allowable current than each of the above-mentioned first contacts 2...

no. 2 example

[0191] refer to Figure 17 to Figure 19 , the above-mentioned second contact piece 4 is formed to have a larger volume than each of the above-mentioned first contact pieces 2 , so as to have a larger allowable current than each of the above-mentioned first contact pieces 2 . For example, if Figure 19 As shown, the second contact 4 is formed to have a length 4L longer than the length 2L of each of the first contacts 2 on the basis of the first axis direction (X-axis direction), so that it can be formed to be consistent with each of the first contacts 2. A larger volume compared to contact piece 2. Therefore, the flat cable connector 1 of the present invention electrically connects the flat cable 100 and the substrate using different types of contacts with different volumes.

[0192] Therefore, the flat cable connector 1 of the present invention is provided with the second contact 4 having a larger allowable current than each of the above-mentioned first contacts 2, so that t...

no. 3 example

[0328] refer to Figure 33 to Figure 35 , the above-mentioned second contact piece 4 is formed to have a larger volume than each of the above-mentioned first contact pieces 2 , so as to have a larger allowable current than each of the above-mentioned first contact pieces 2 . For example, if Figure 35 As shown, the second contact 4 is formed to have a length 4L longer than the length 2L of each of the first contacts 2 on the basis of the first axis direction (X-axis direction), so that it can be formed to be consistent with each of the first contacts 2. A contact piece 2 has a larger volume. Thus, the flat cable connector 1 of the present invention electrically connects the flat cable 100 and the substrate using different types of contacts having different volumes.

[0329] Therefore, the flat cable connector 1 of the present invention is provided with the second contact 4 having a larger allowable current than each of the above-mentioned first contacts 2, so that the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com