Patents

Literature

33results about How to "Thermally efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

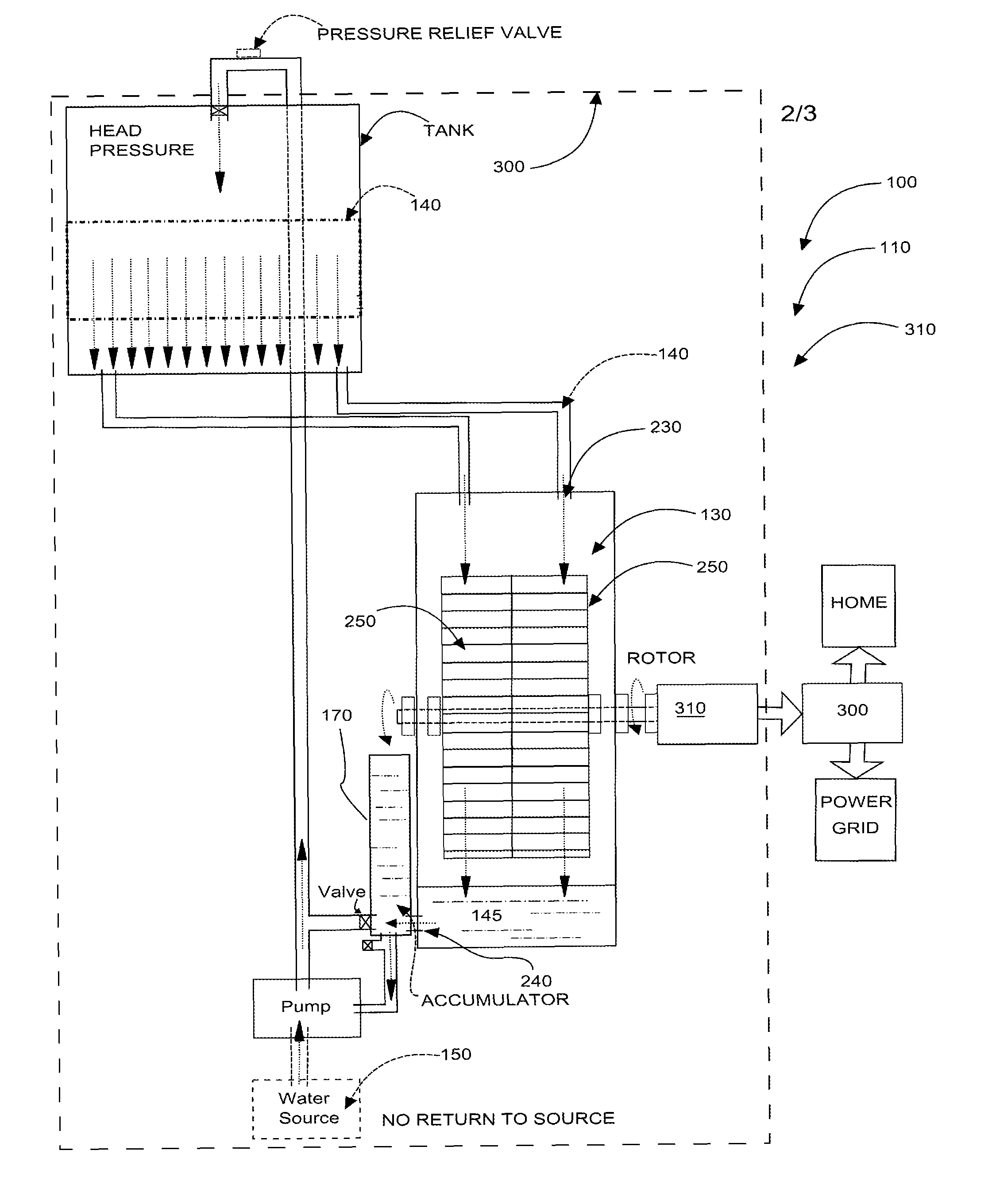

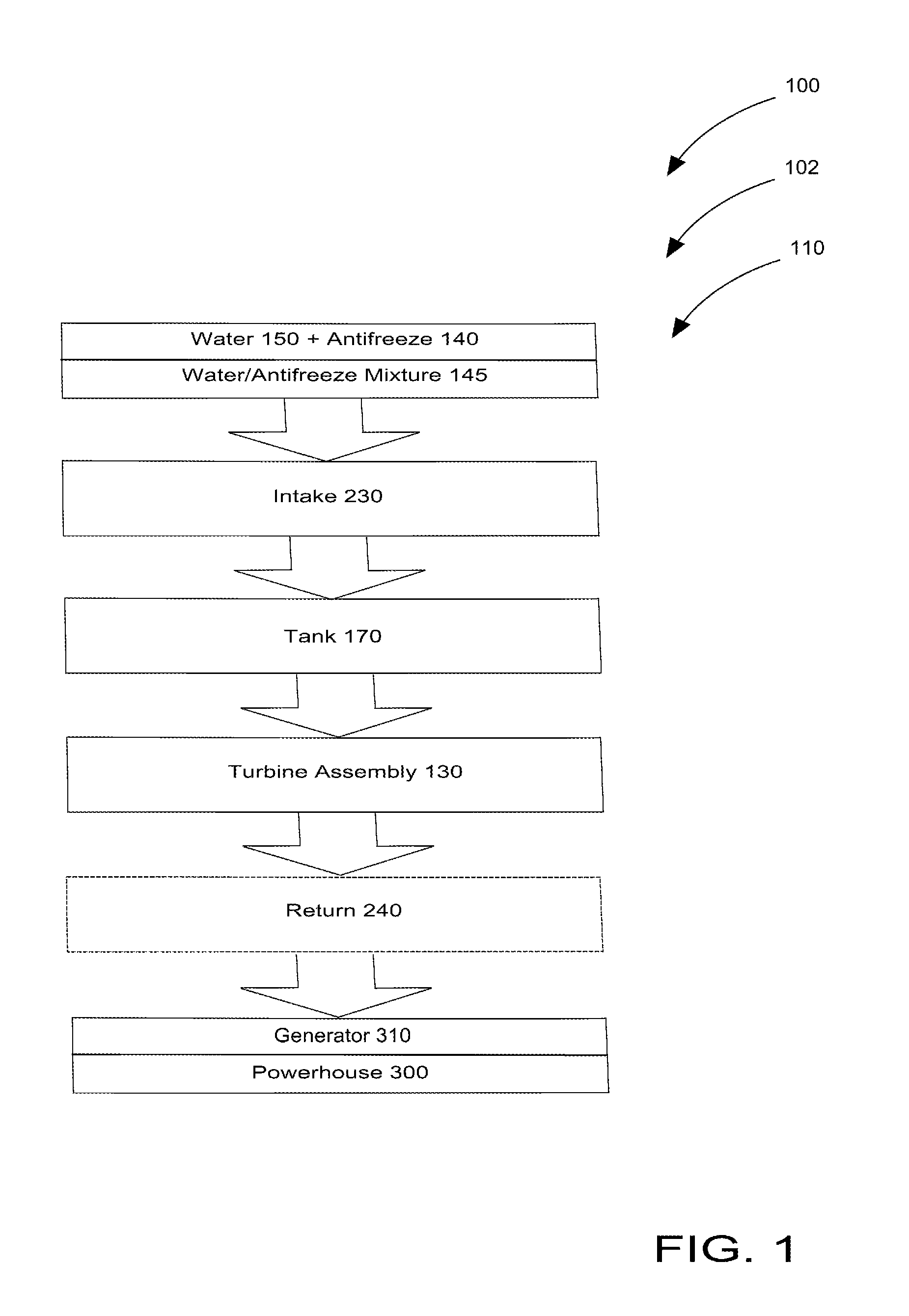

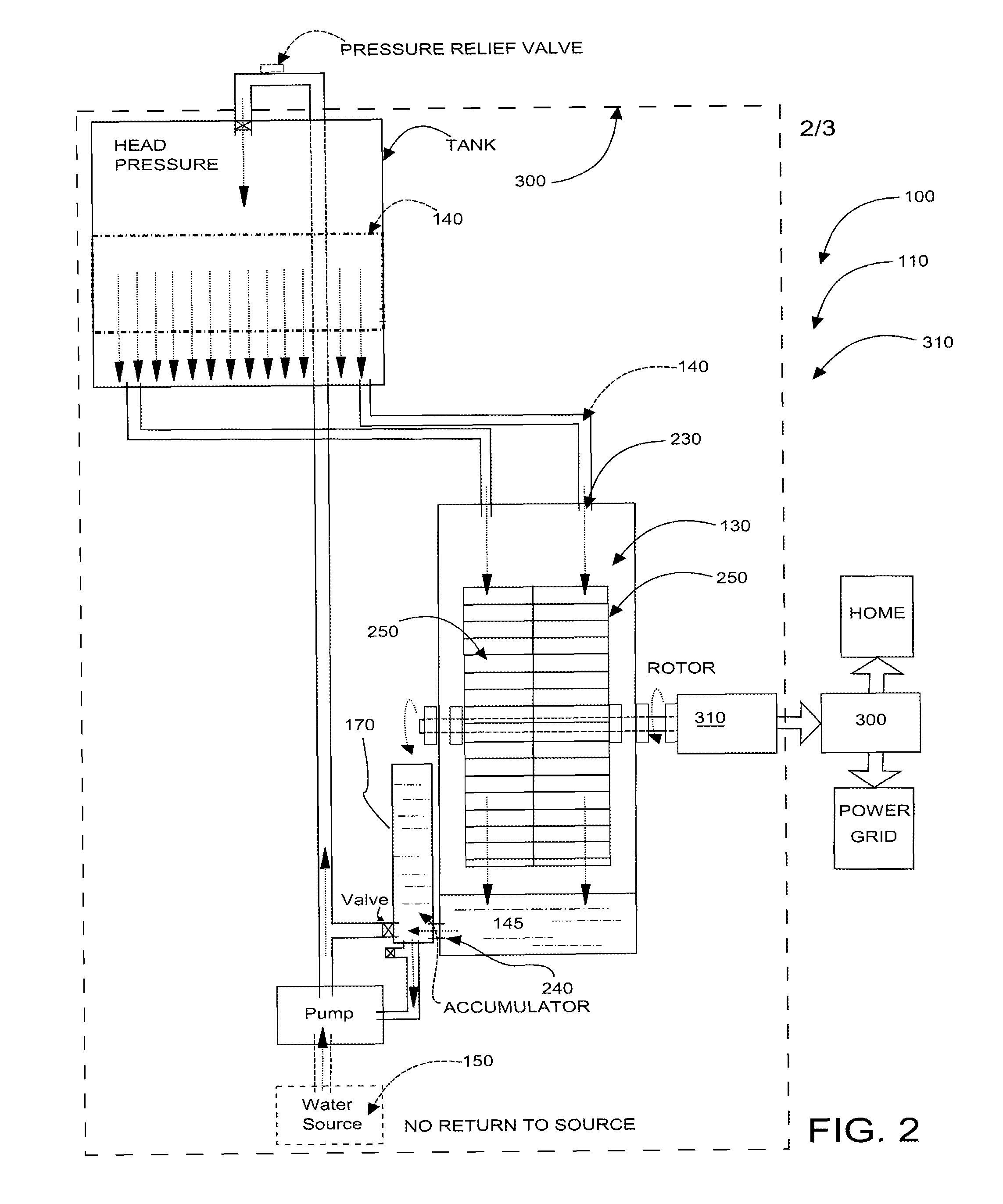

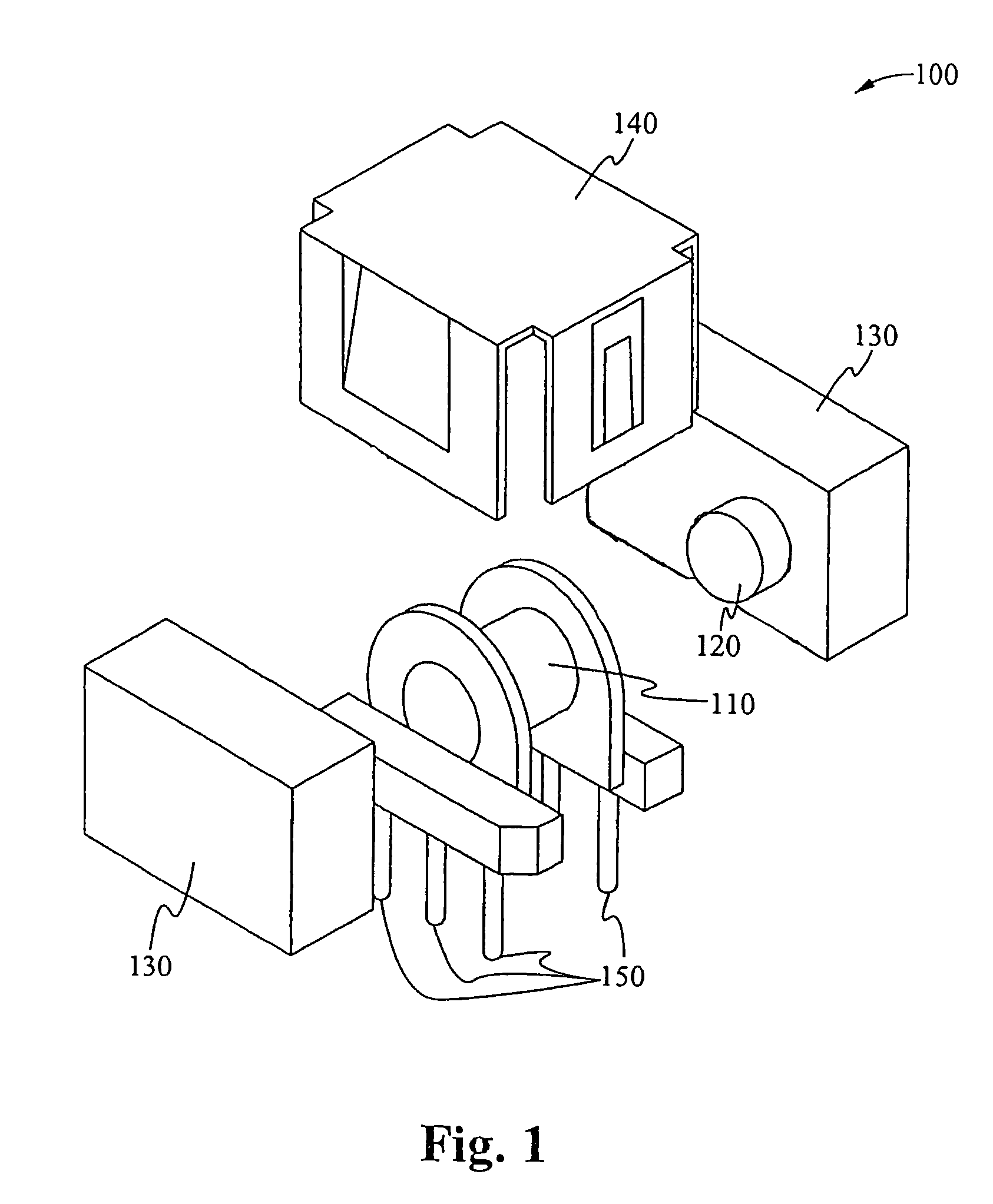

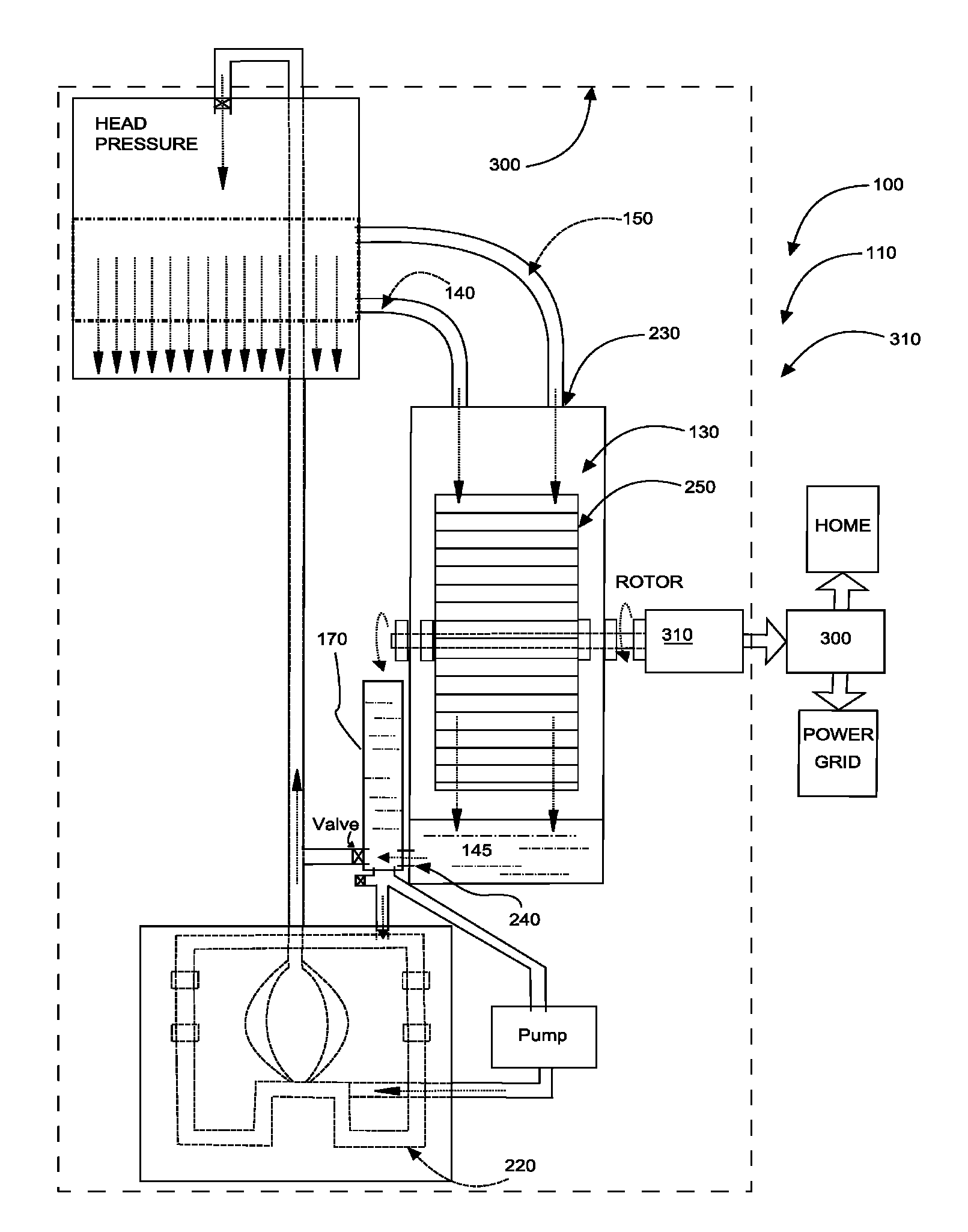

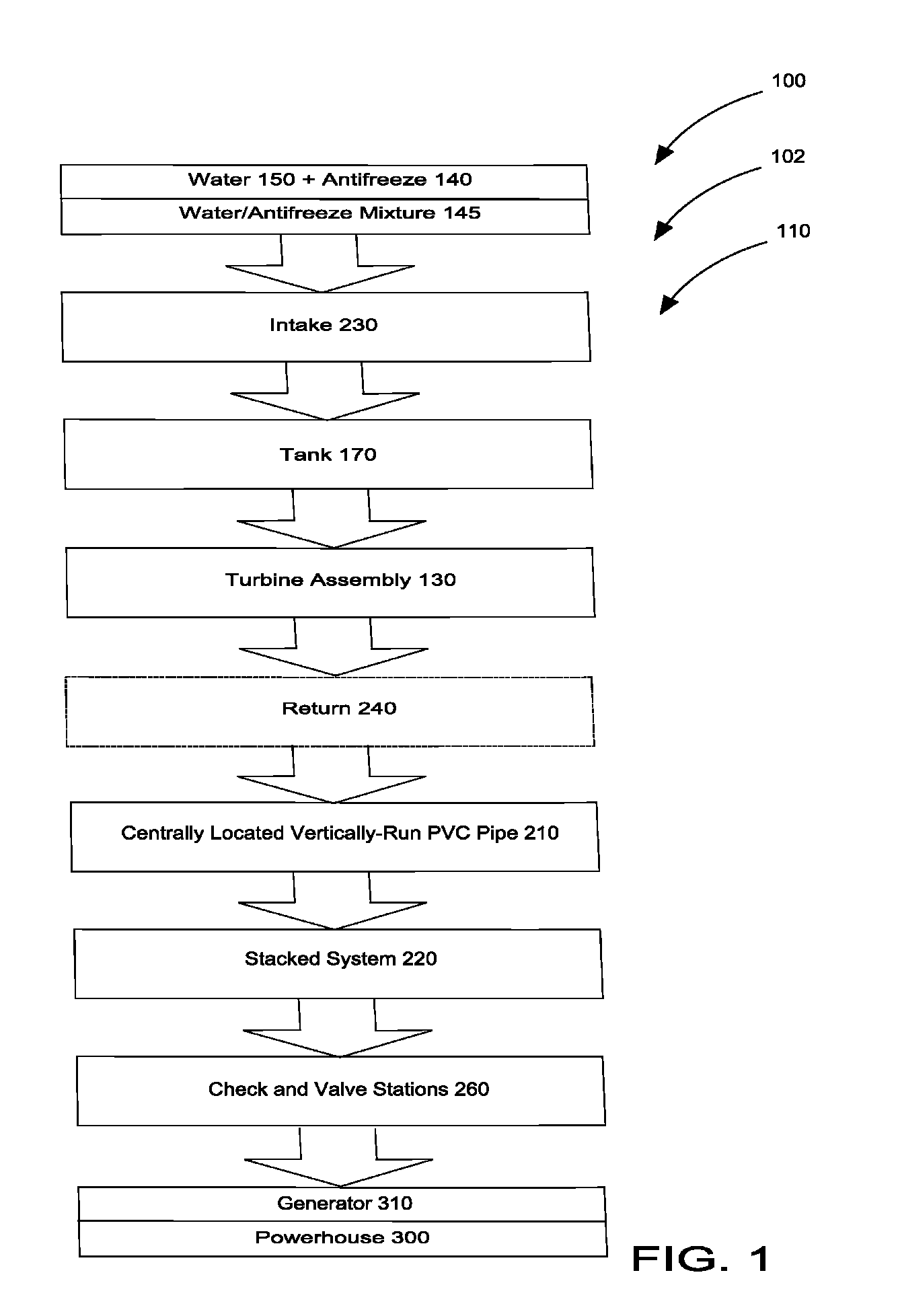

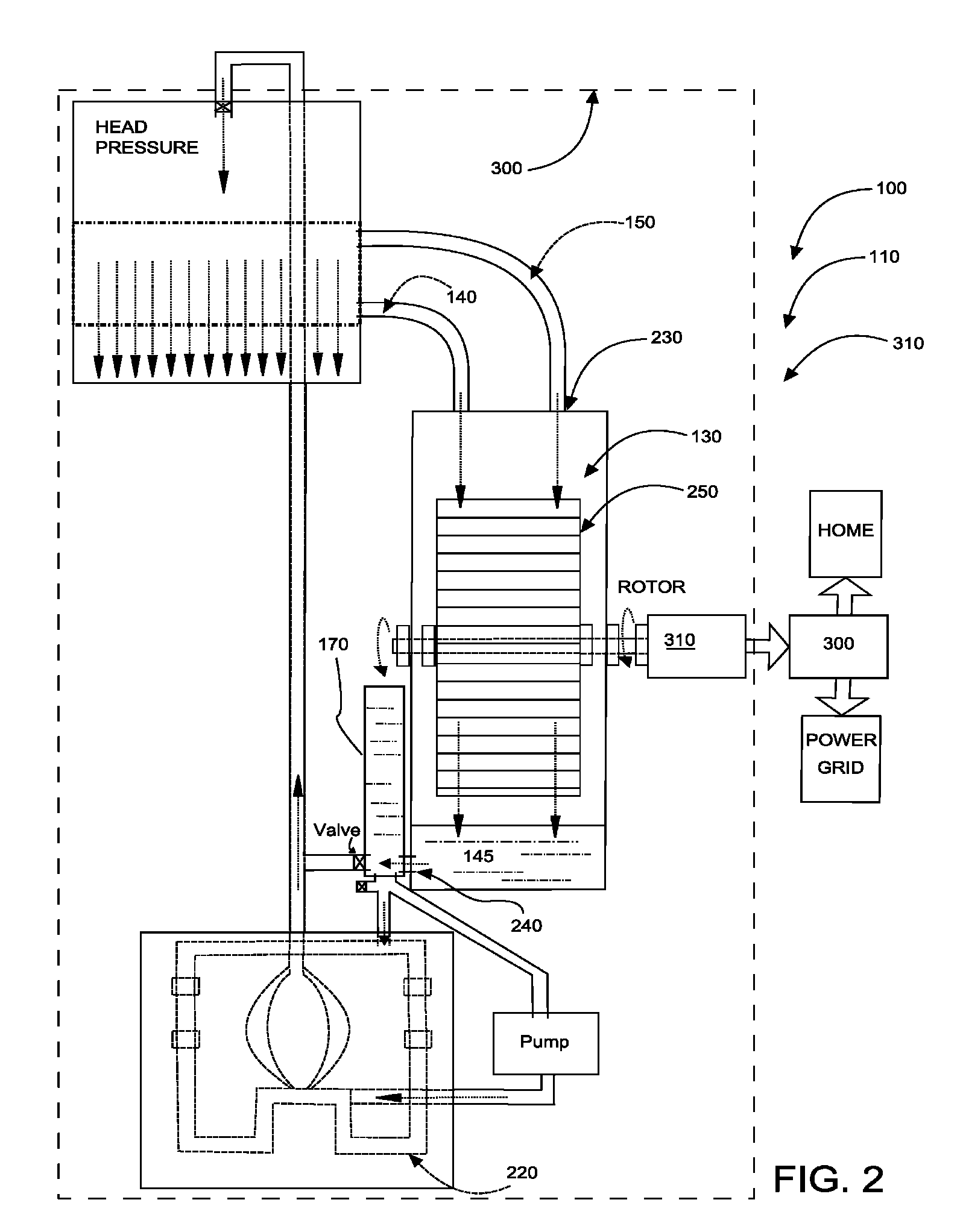

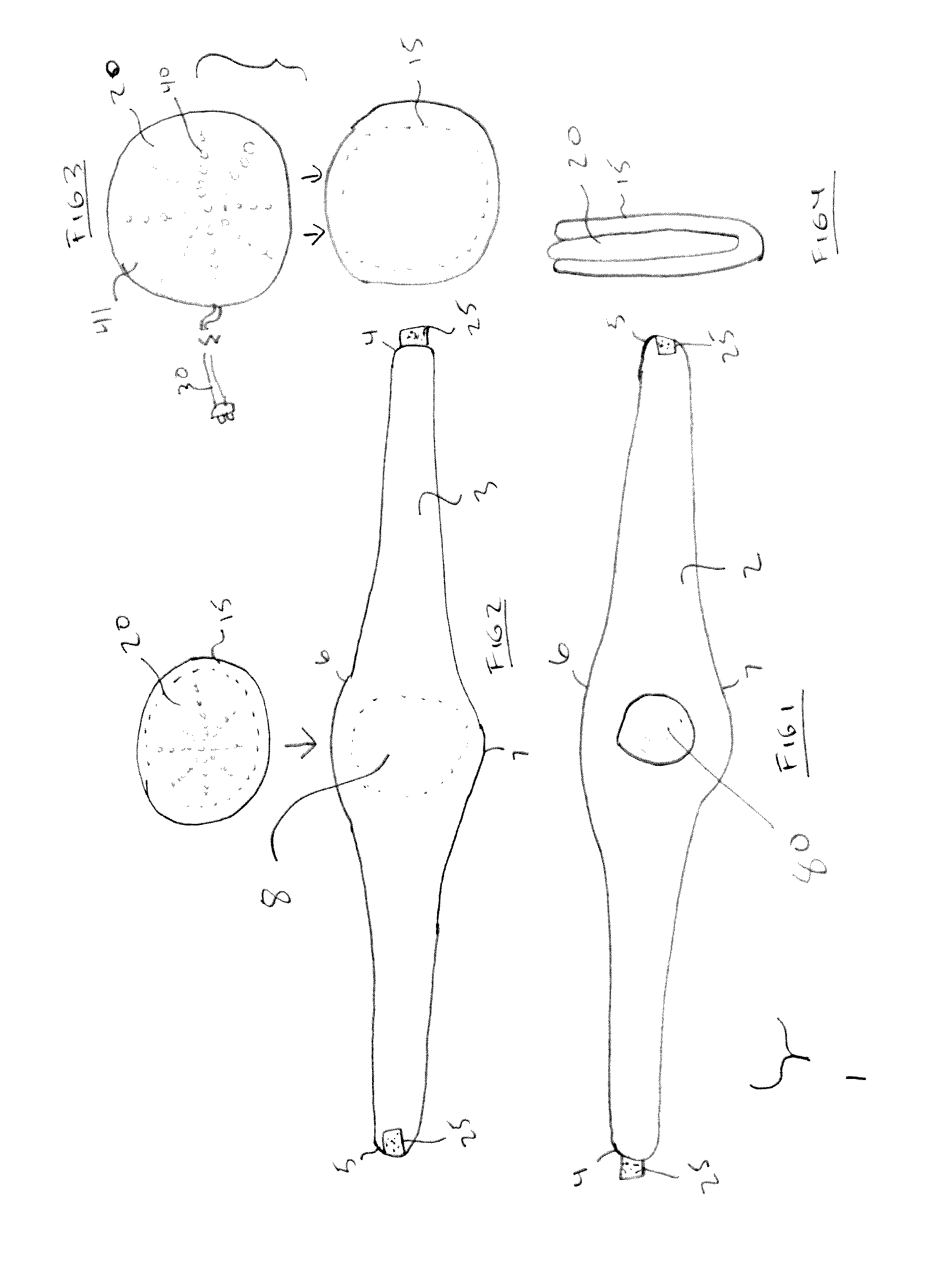

Portable hydroelectric generating system

InactiveUS8127542B1Strong pressure capacityIncrease volume capacityFluid couplingsWorking fluid for enginesWorking fluidWater source

Owner:DOLCIMASCOLO JOSEPH

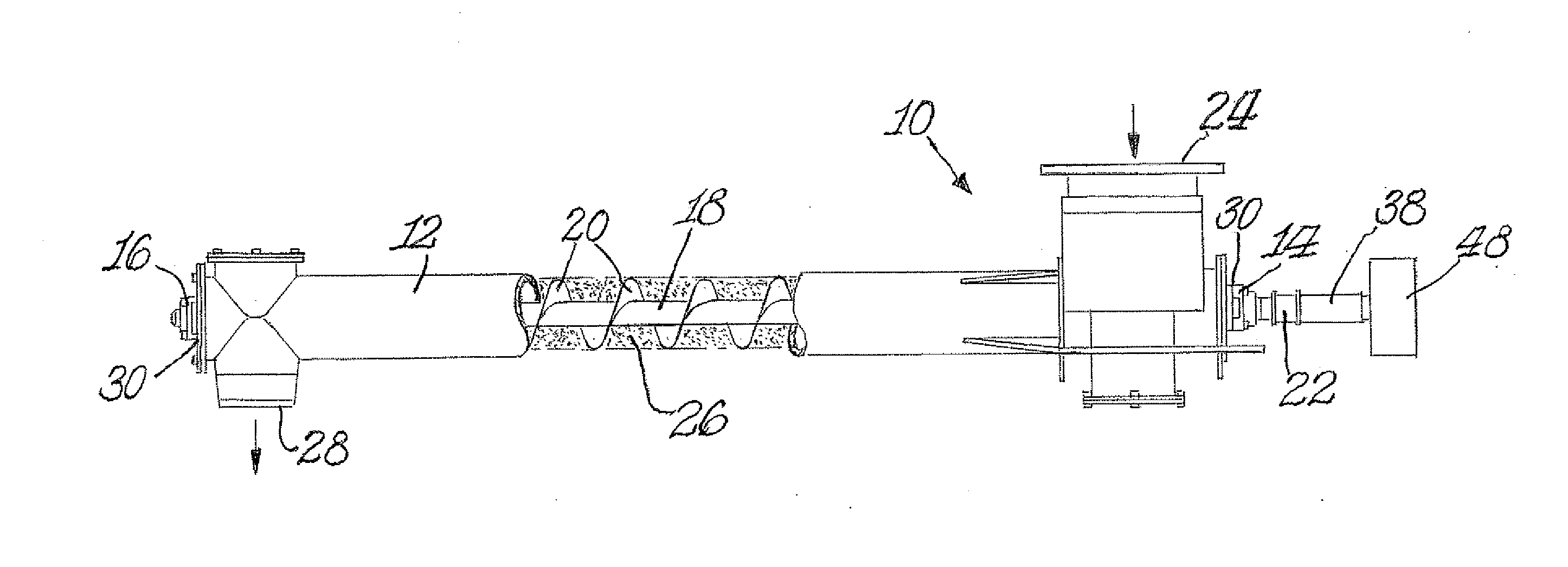

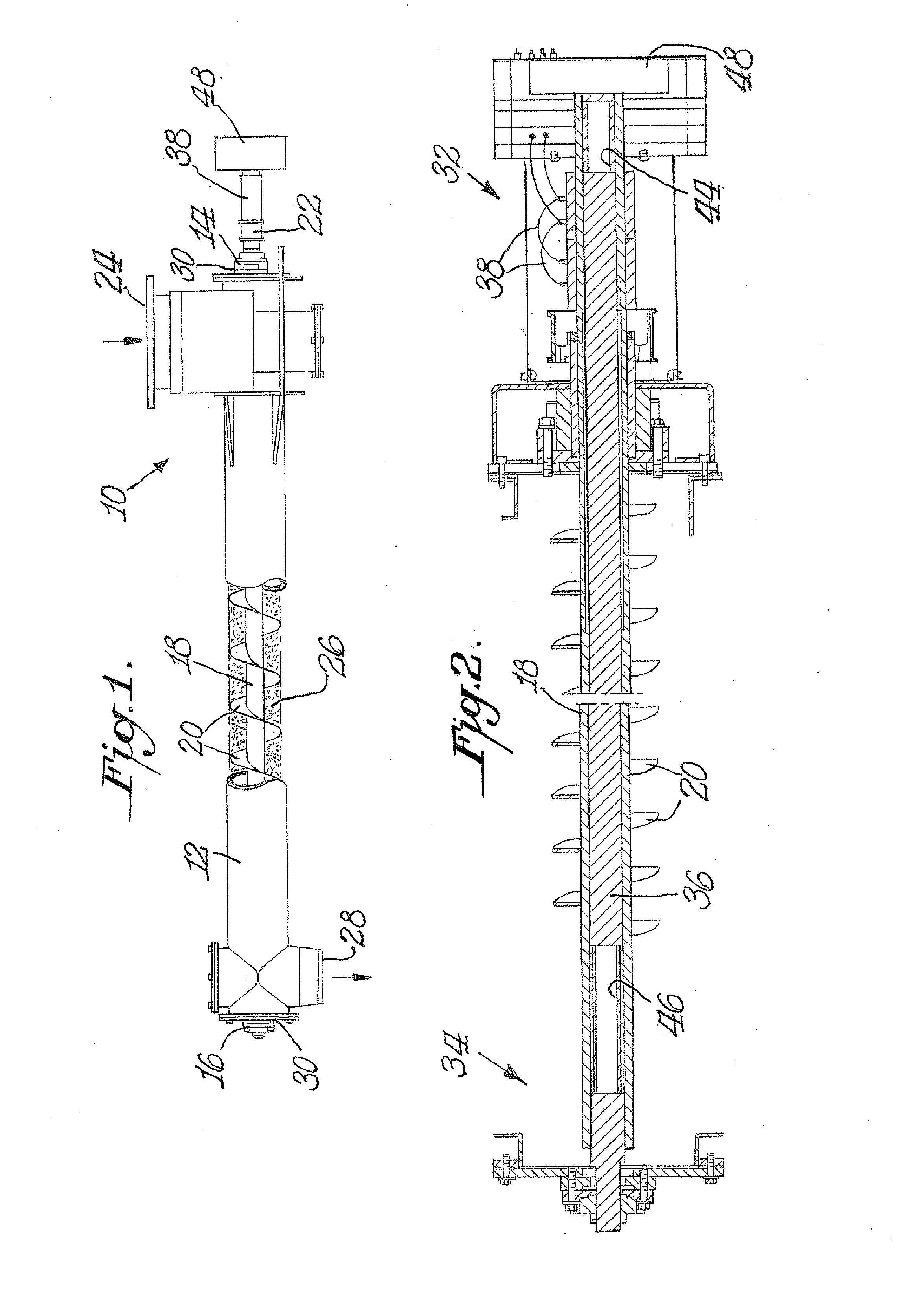

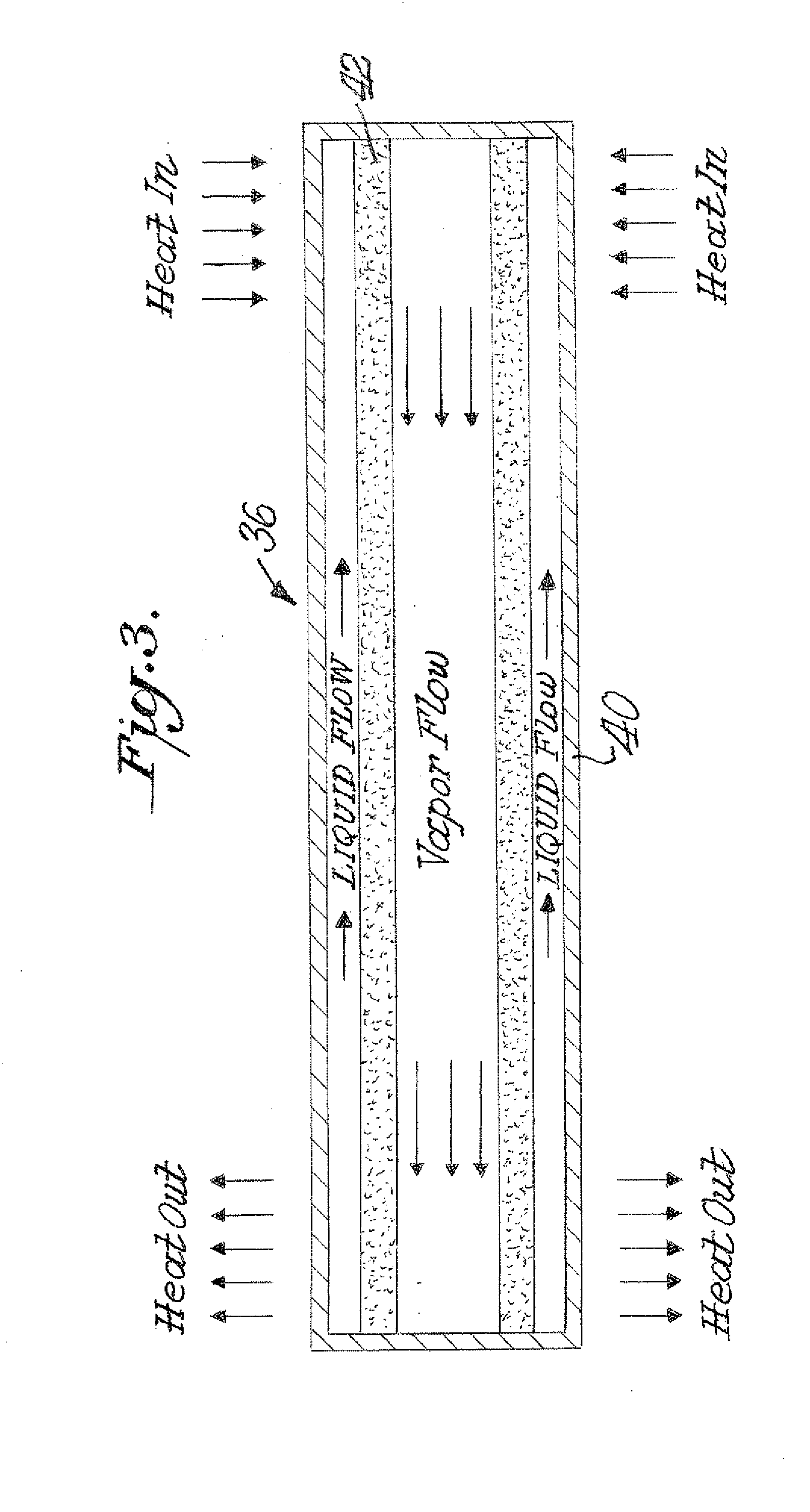

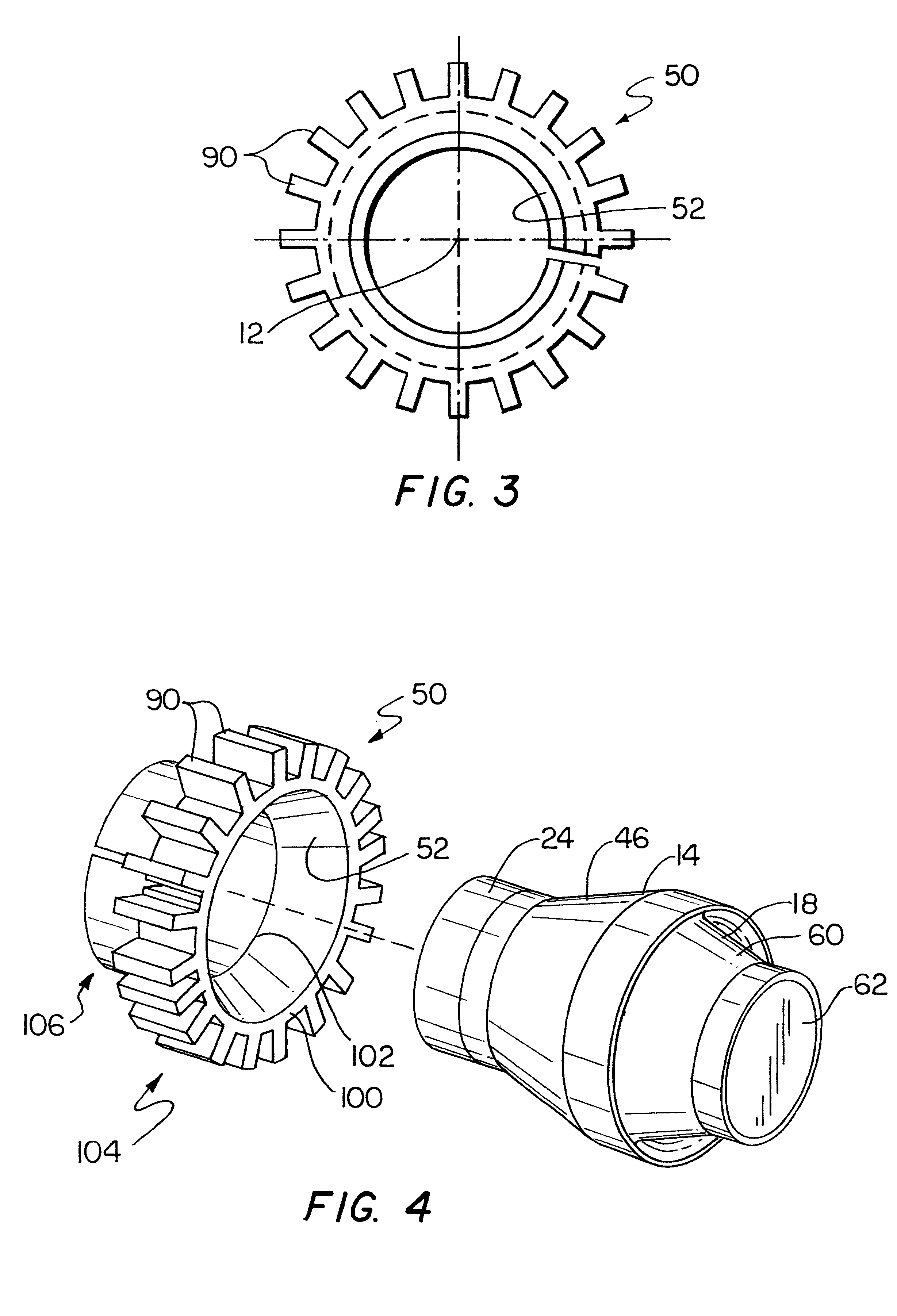

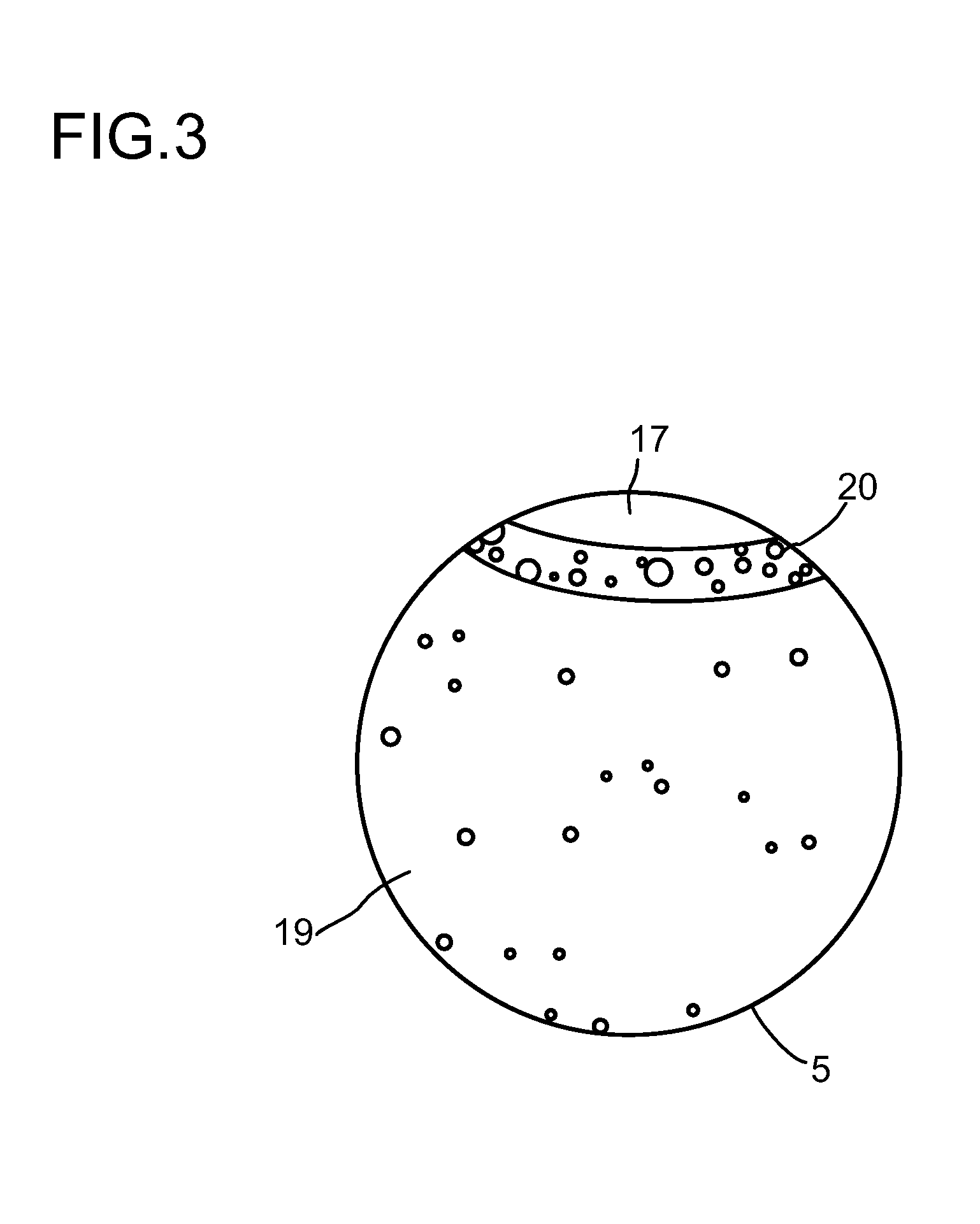

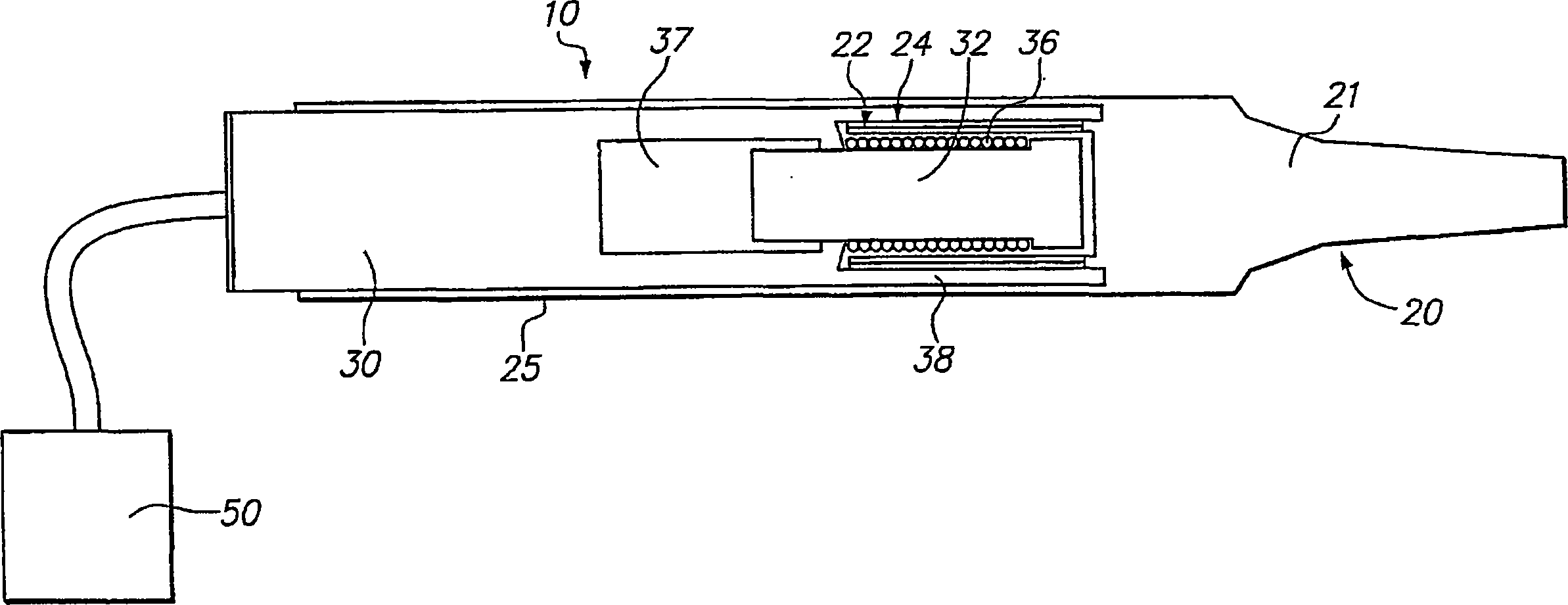

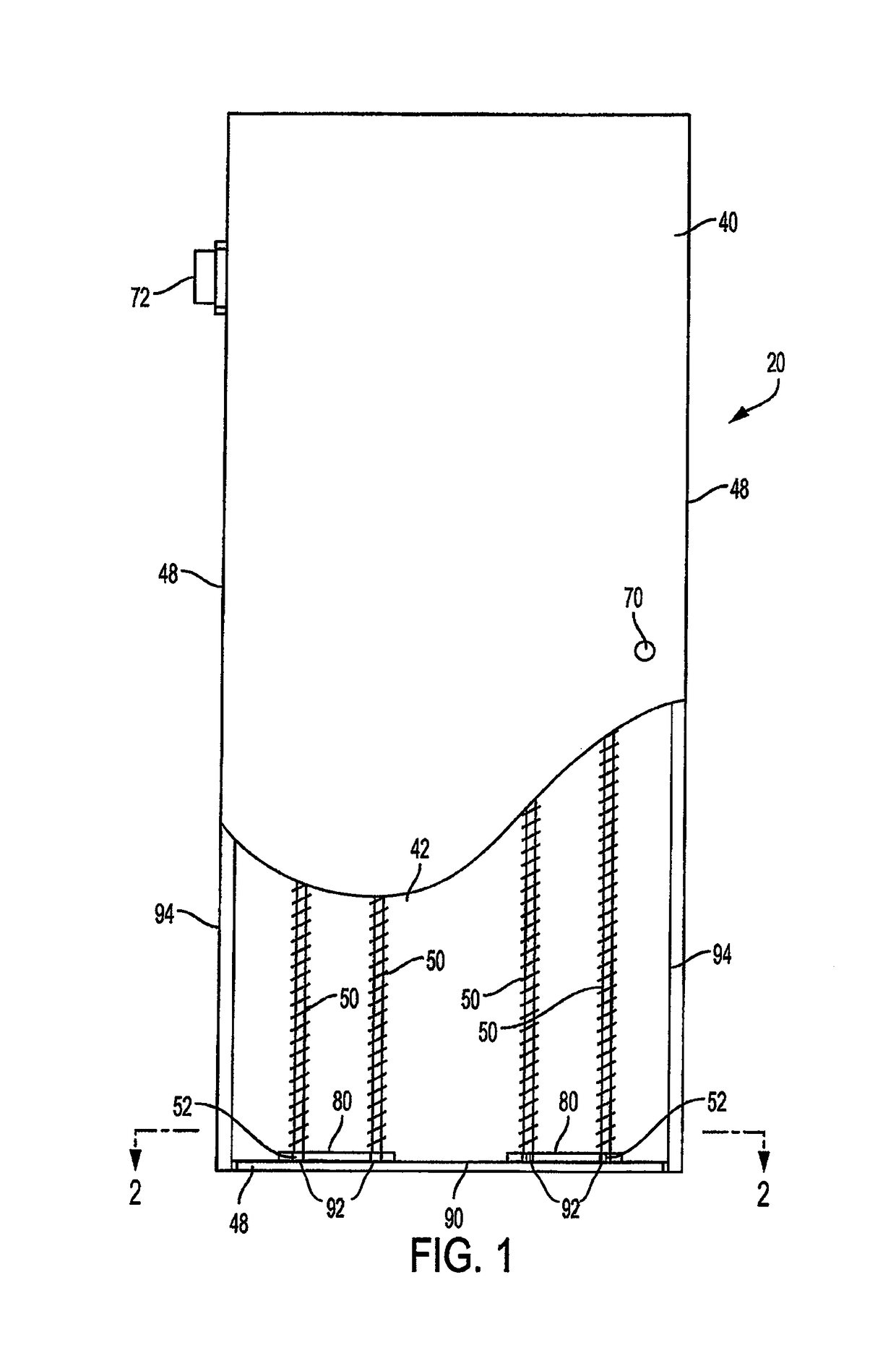

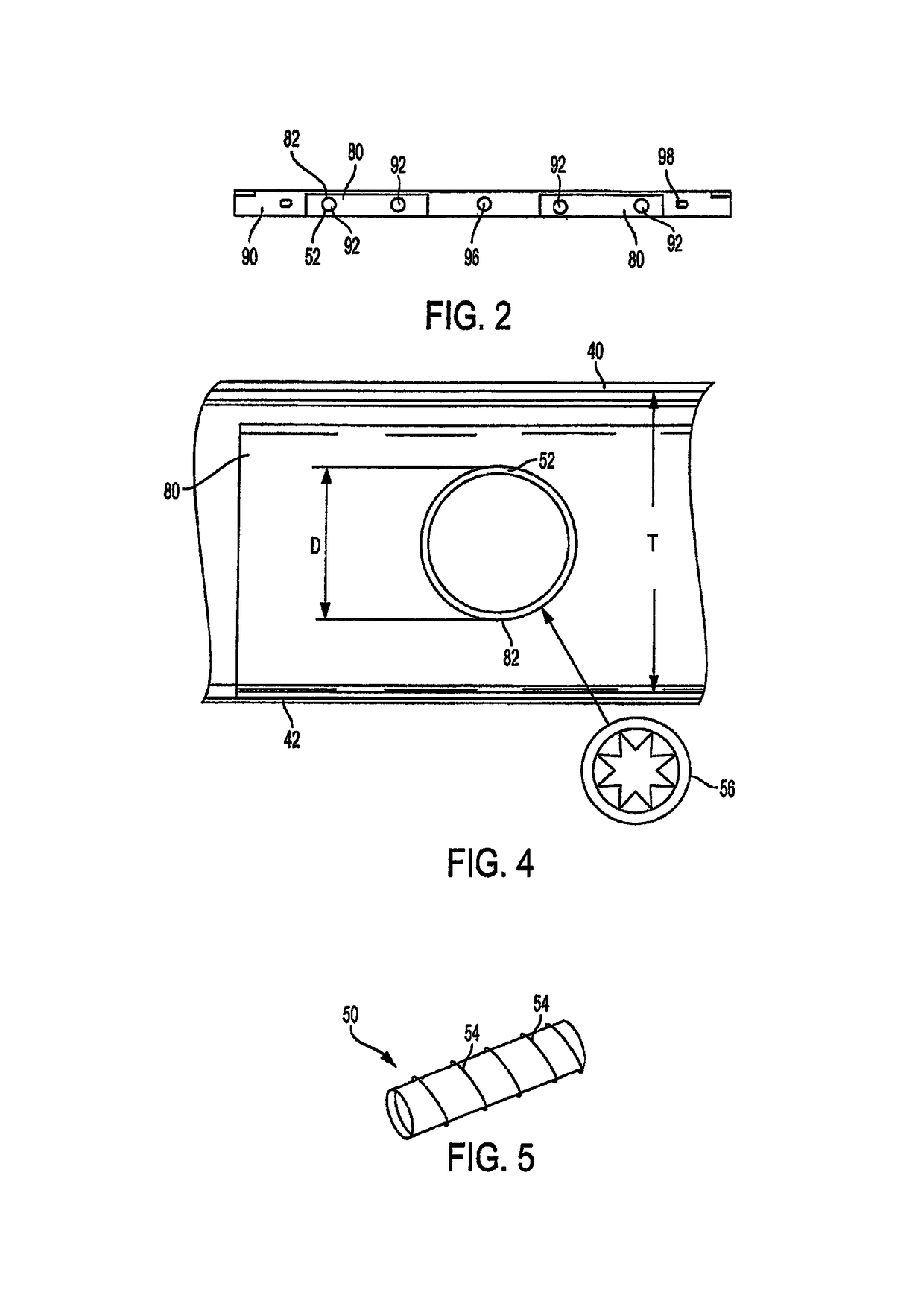

Heated/cool screw conveyor

InactiveUS20080121497A1Uniform temperatureThermally efficientCharge manipulationPackagingEngineeringScrew thread

A screw conveyor includes a hollow rotatable shaft having an externally mounted flight extending along a portion of its length. Thermal applicating structure is provided at one end of the shaft for heating or cooling the screw conveyor. A thermosyphon is mounted within the shaft. The thermosyphon includes a hollow tube mounted against and in direct surface to surface contact with the shaft to rotate co-jointly with the shaft.

Owner:ESTERSON CHRISTOPHER +1

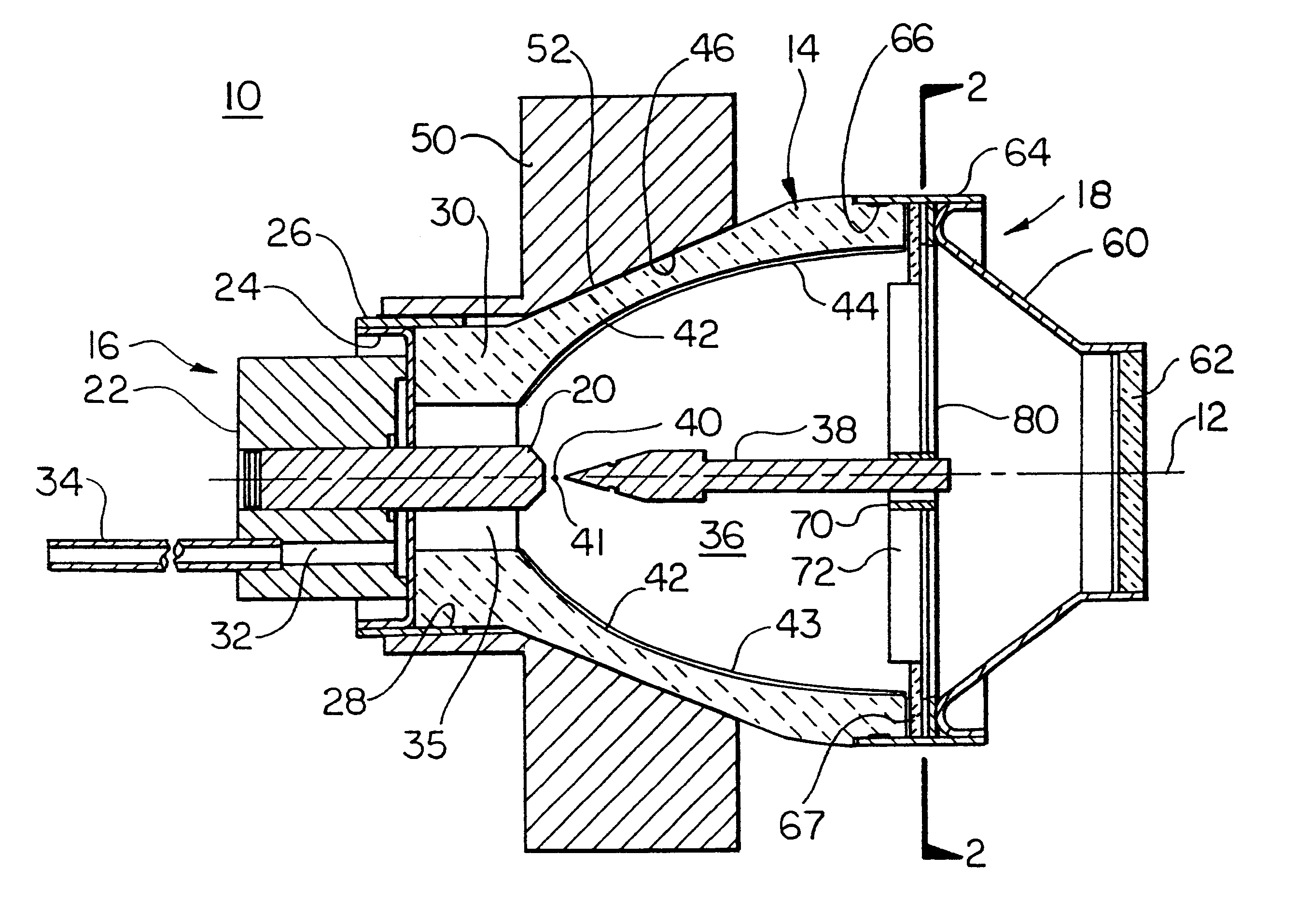

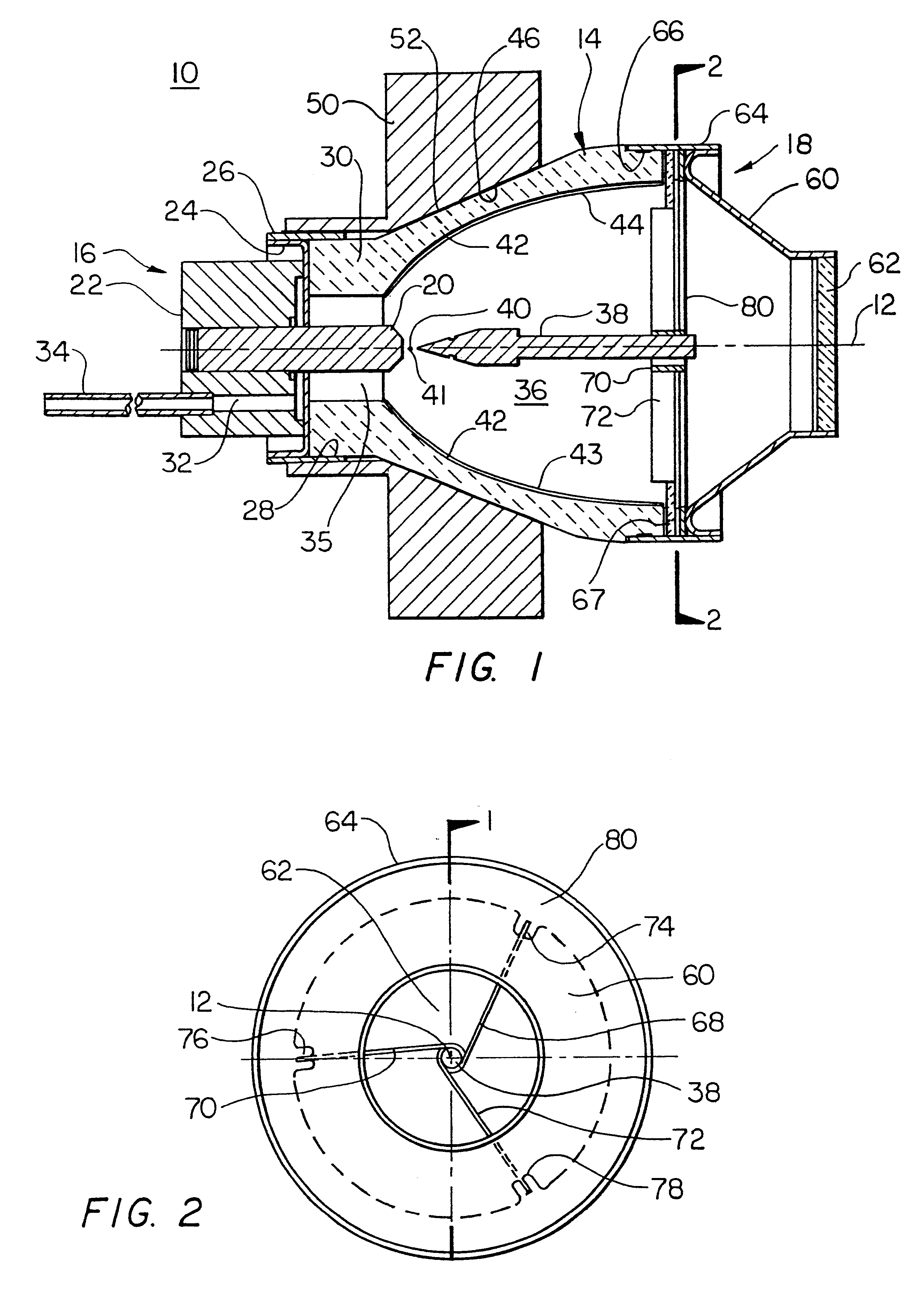

High power short arc discharge lamp with heat sink

InactiveUS6400067B1Reduce thicknessThermally efficientIncadescent screens/filtersElectric discharge tubesGas-discharge lampOptoelectronics

A high power short arc gas discharge lamp includes an electrically insulating reflector body having a concave internal reflector surface with a focal point; an anode and a cathode spaced from the anode to create an arc gap between them proximate the focal point; the reflector body having a conical external surface for reducing the thickness of the reflector body between the concave internal surface and the conical external surface; and an external electrically isolated heat sink mounted on the external conical surface proximate the arc gap.

Owner:EXCELITAS TECH

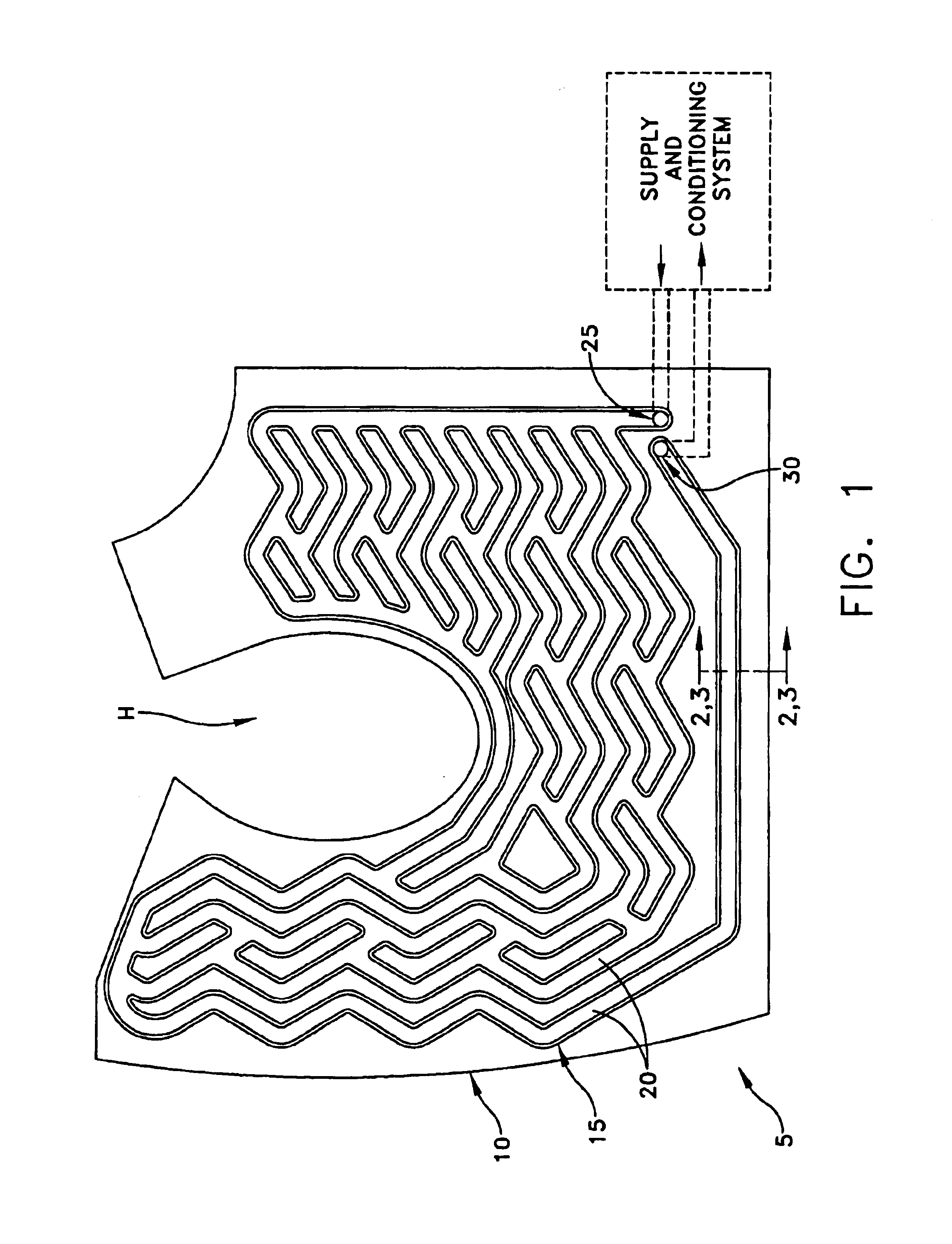

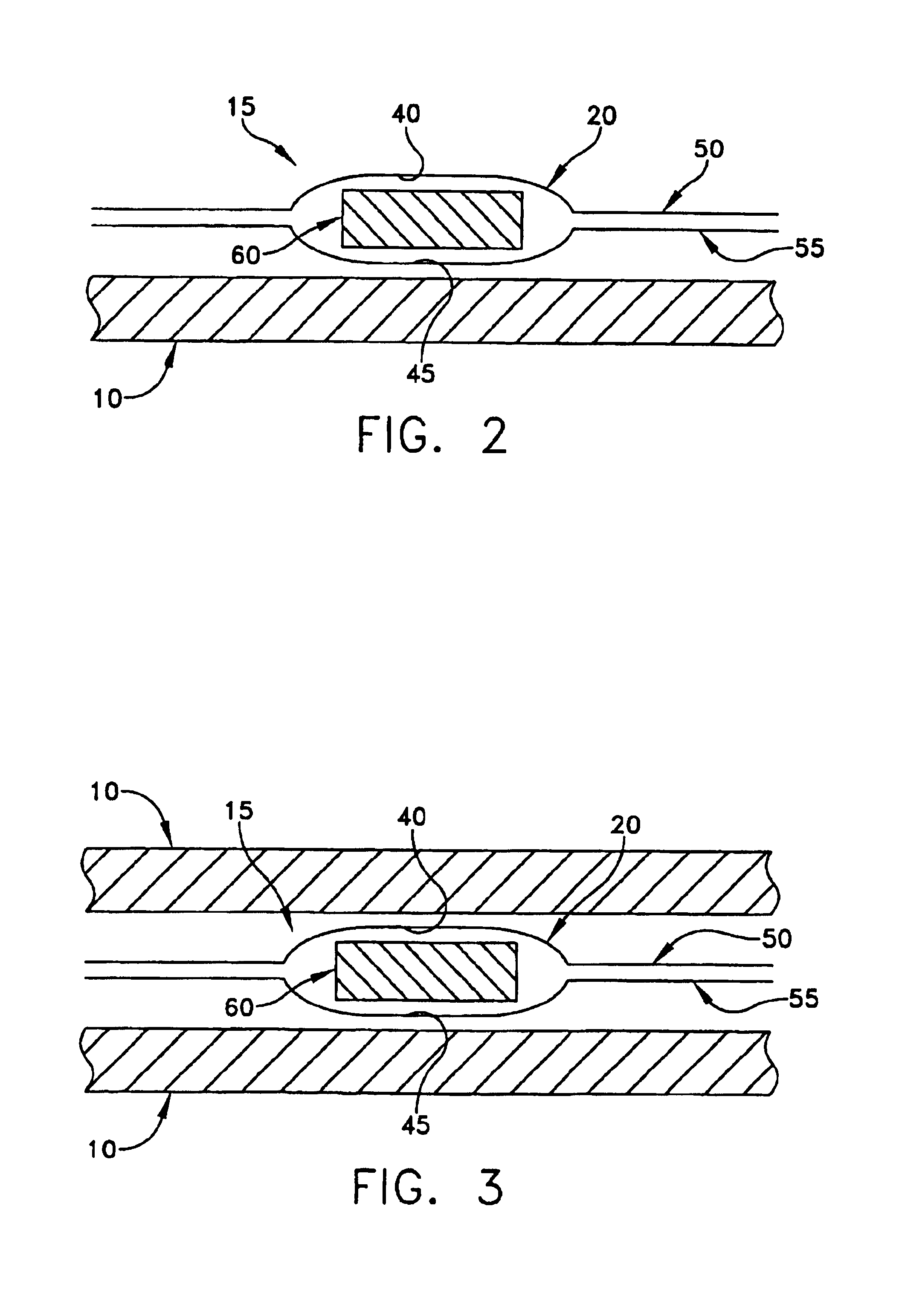

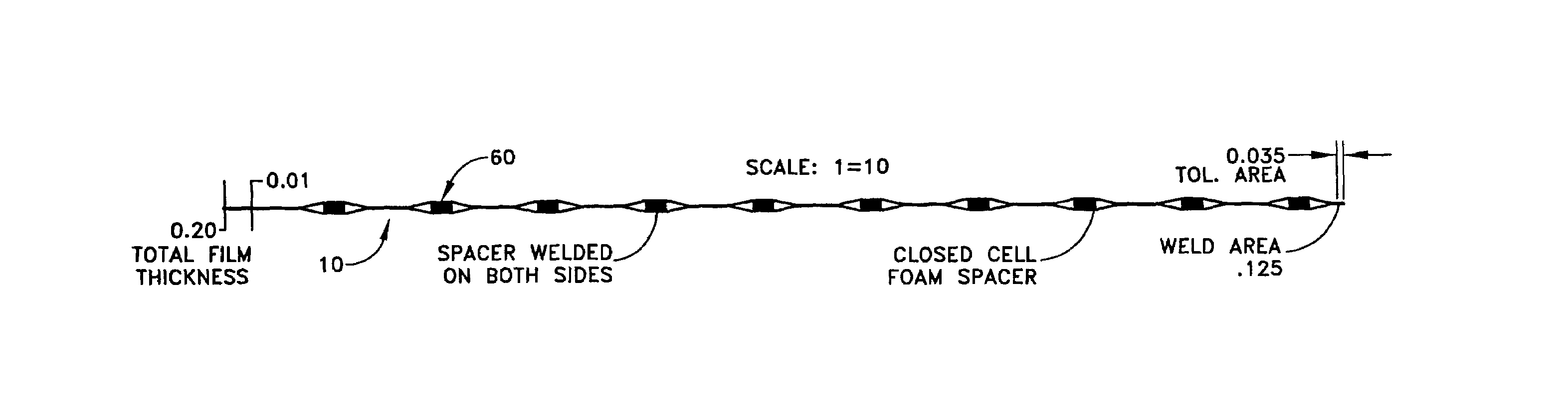

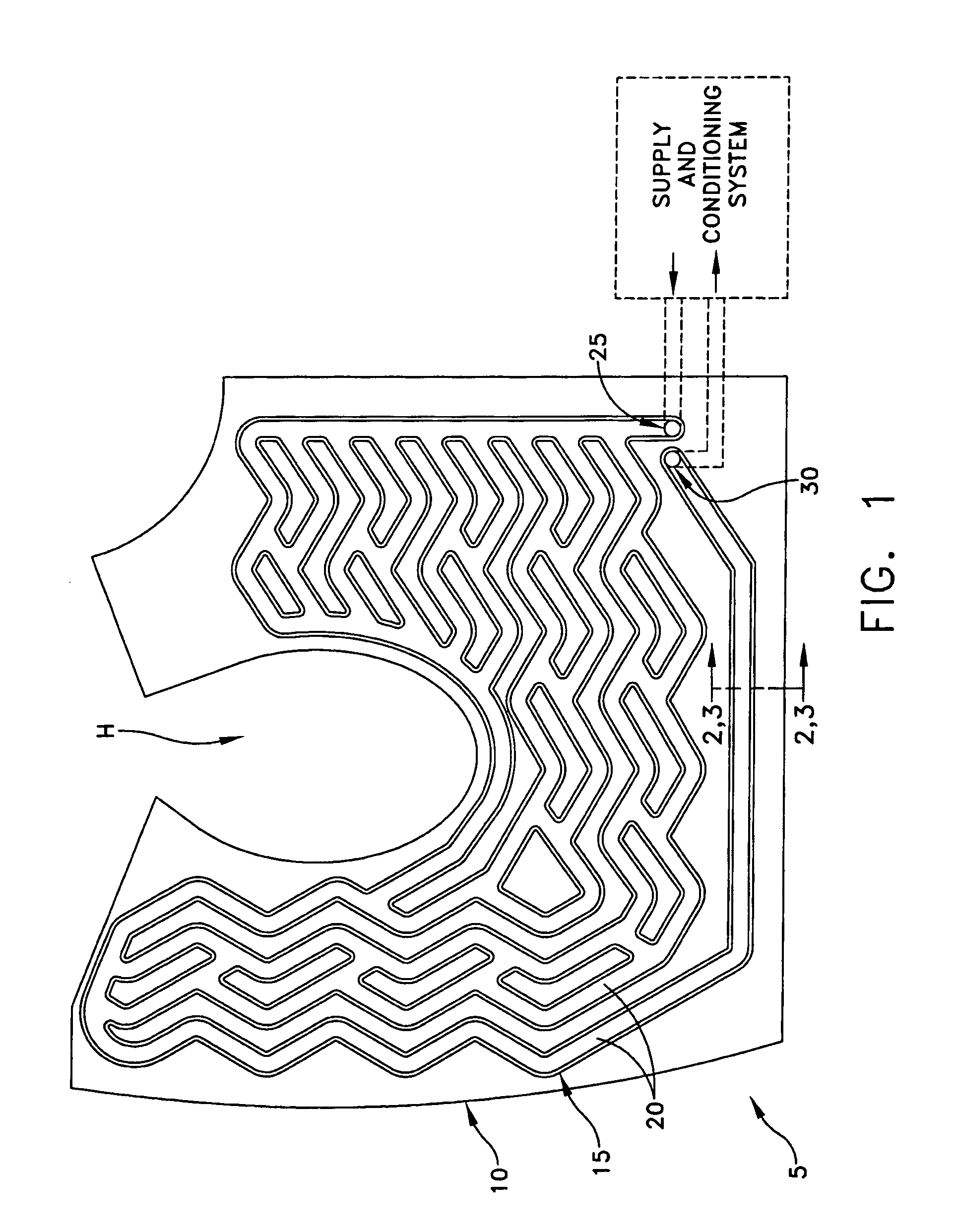

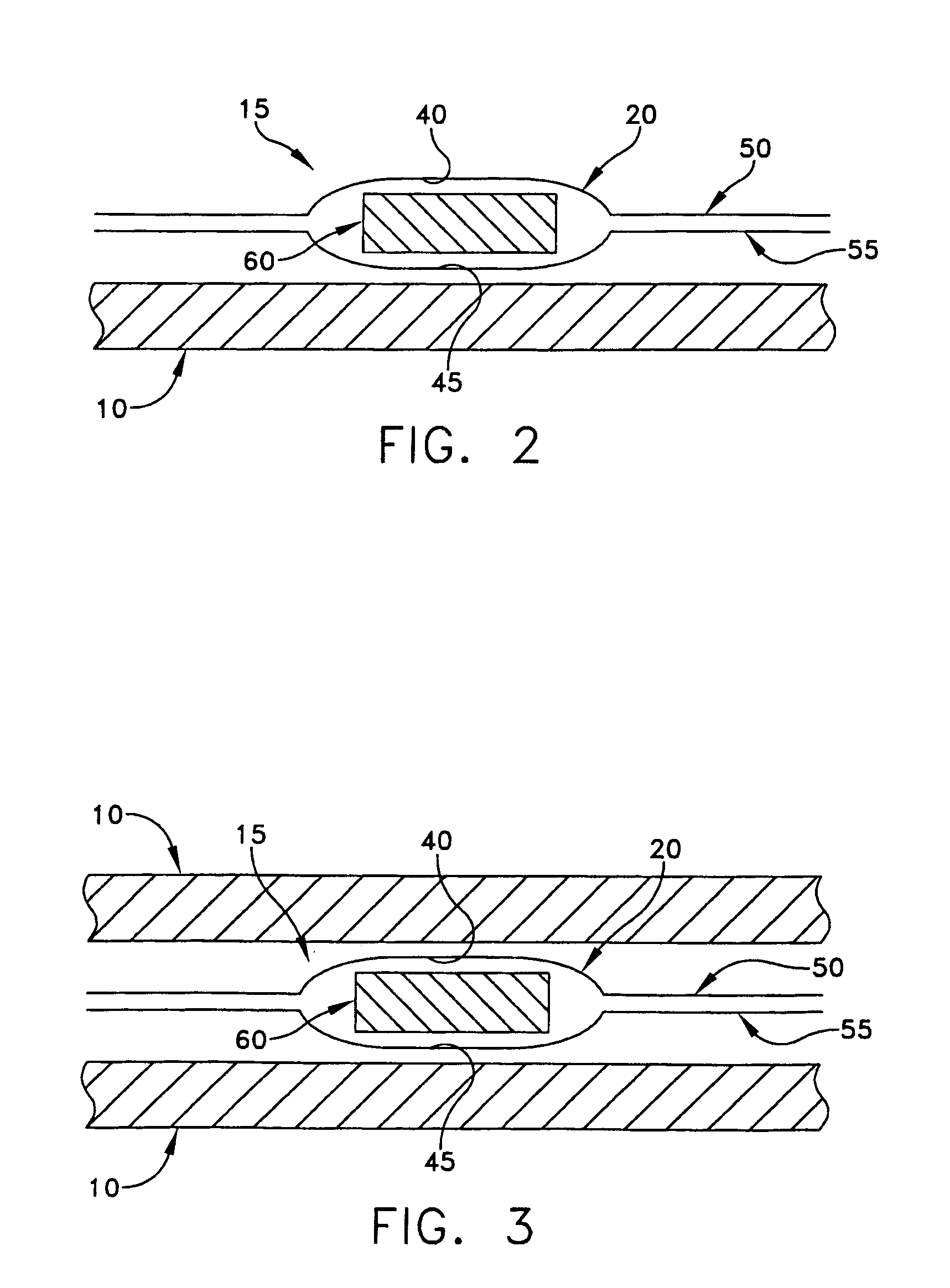

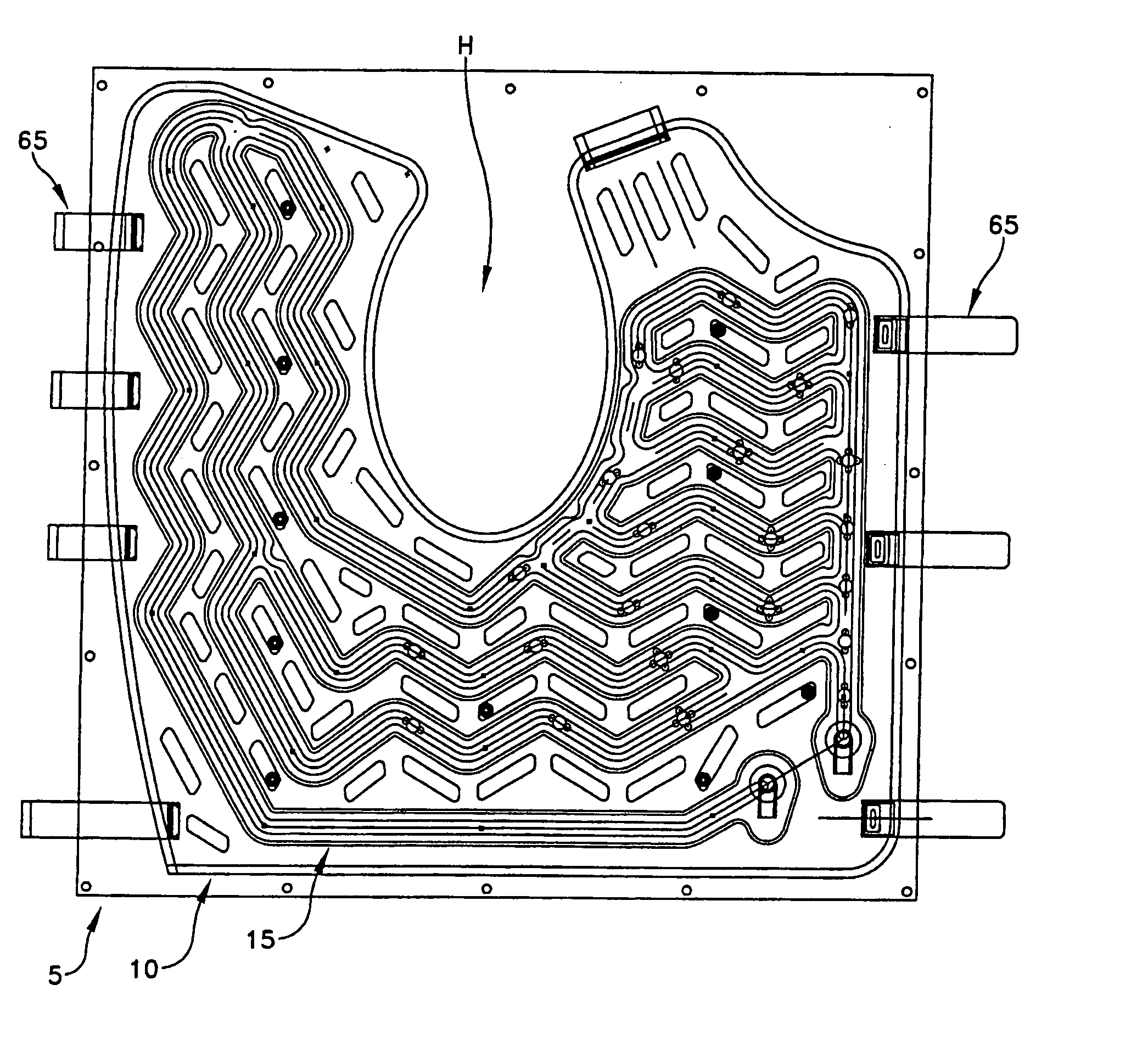

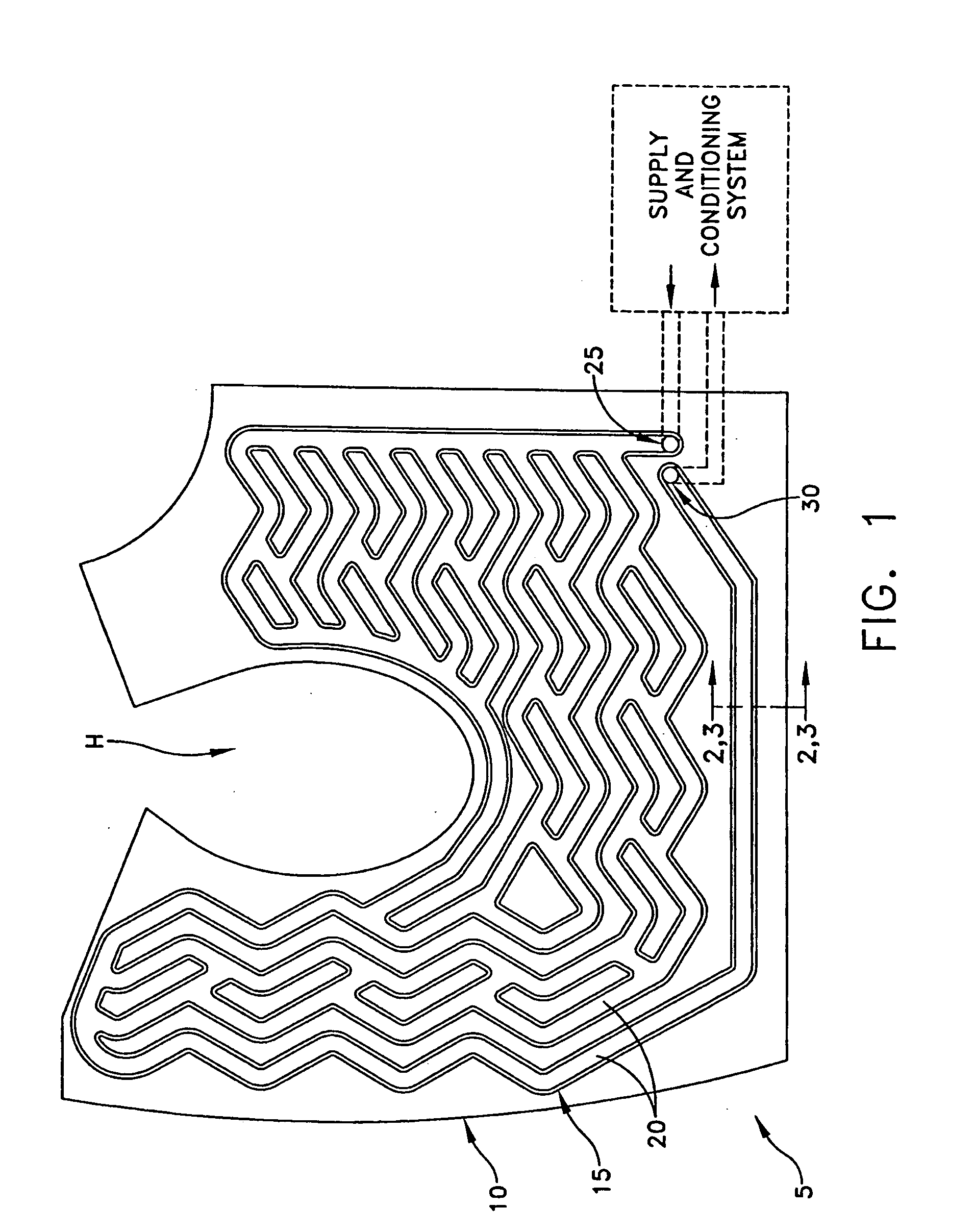

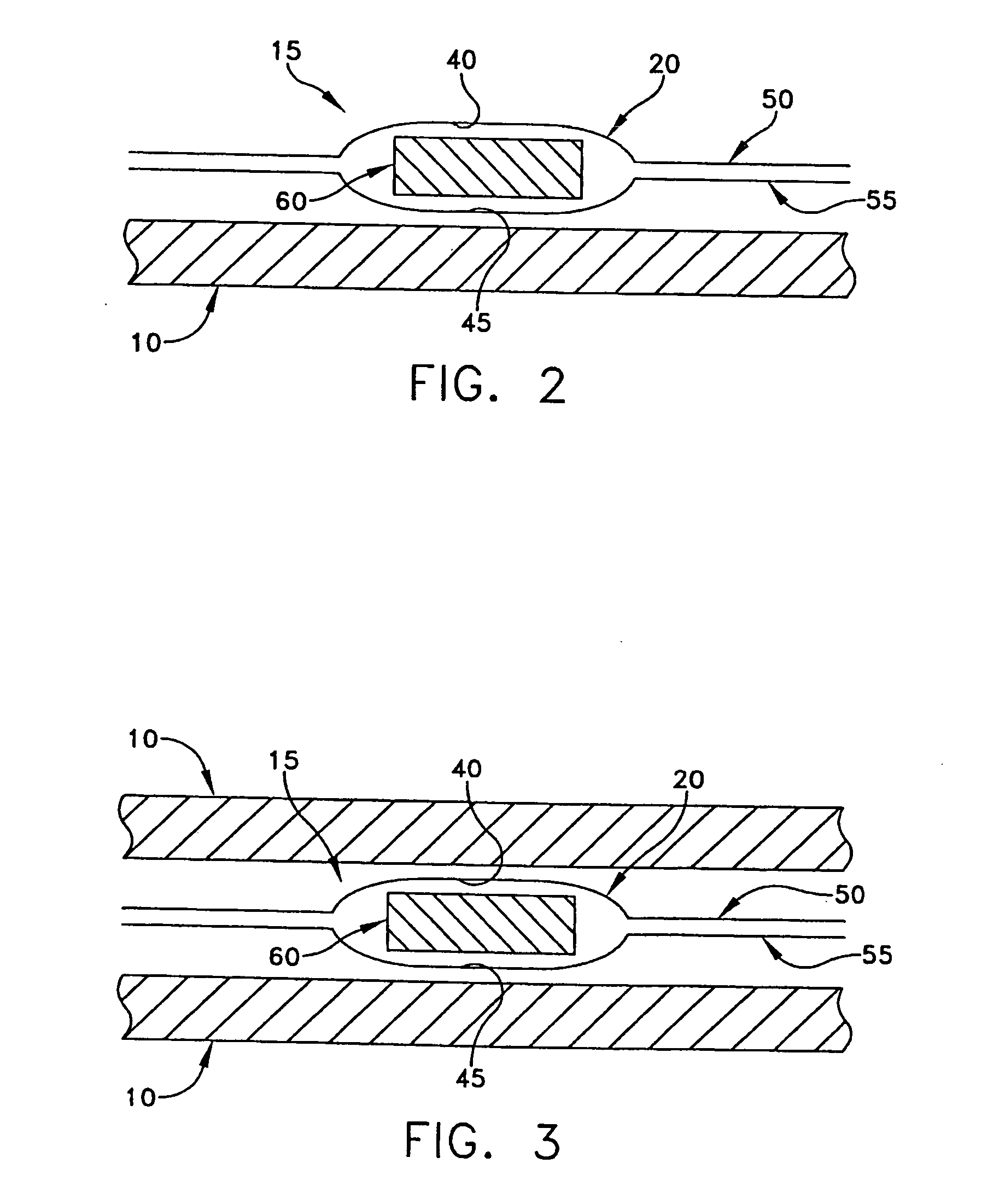

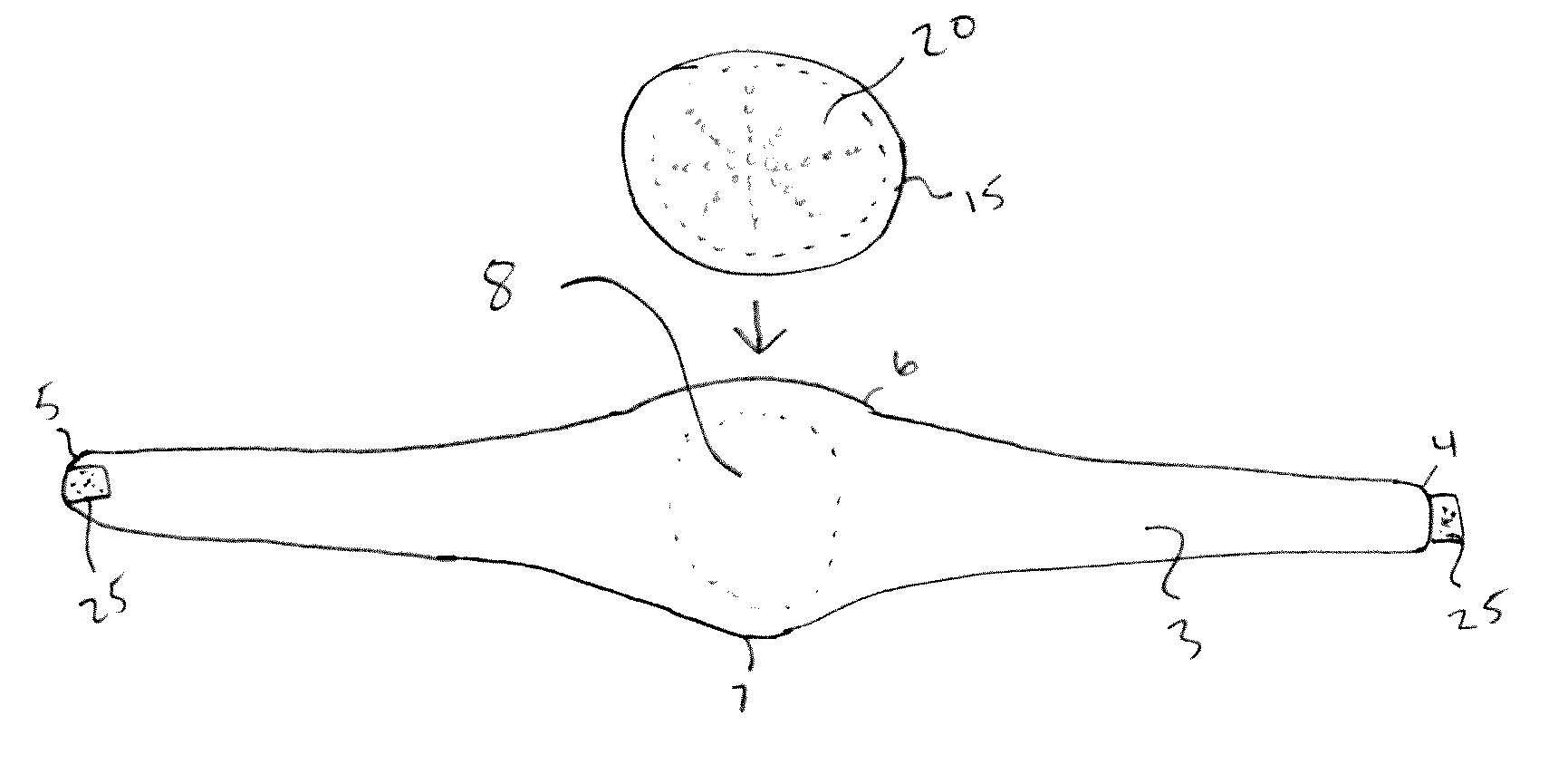

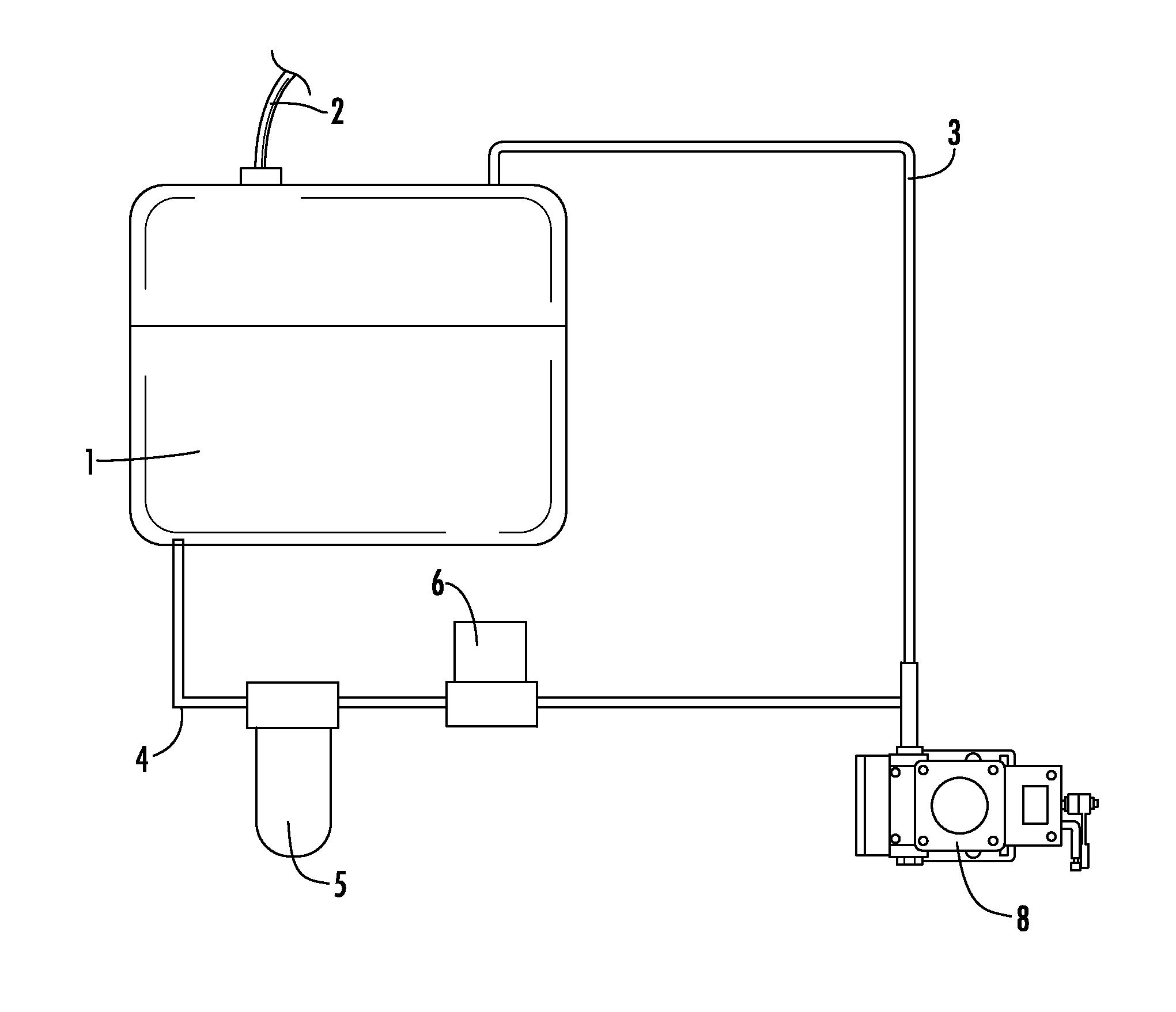

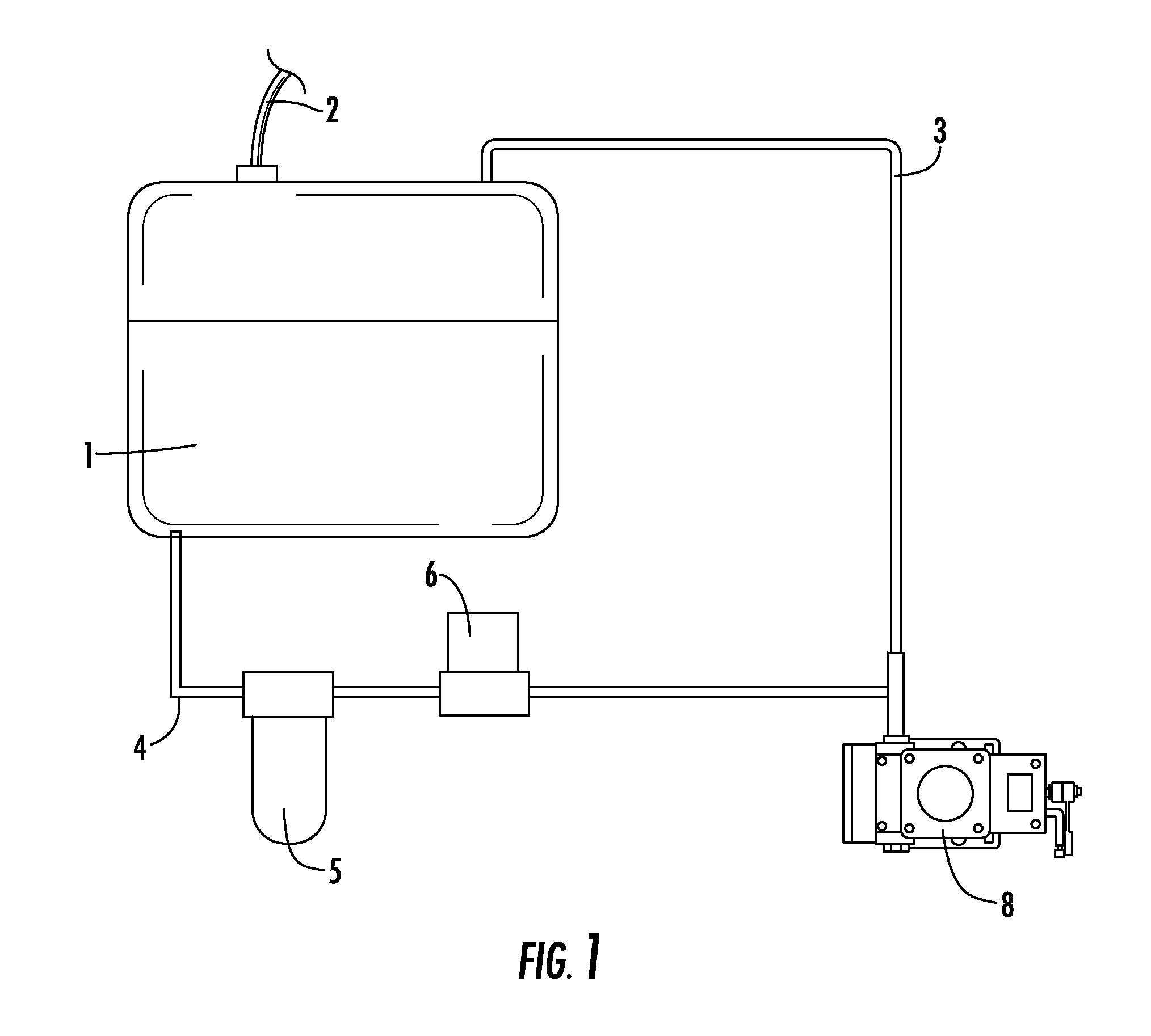

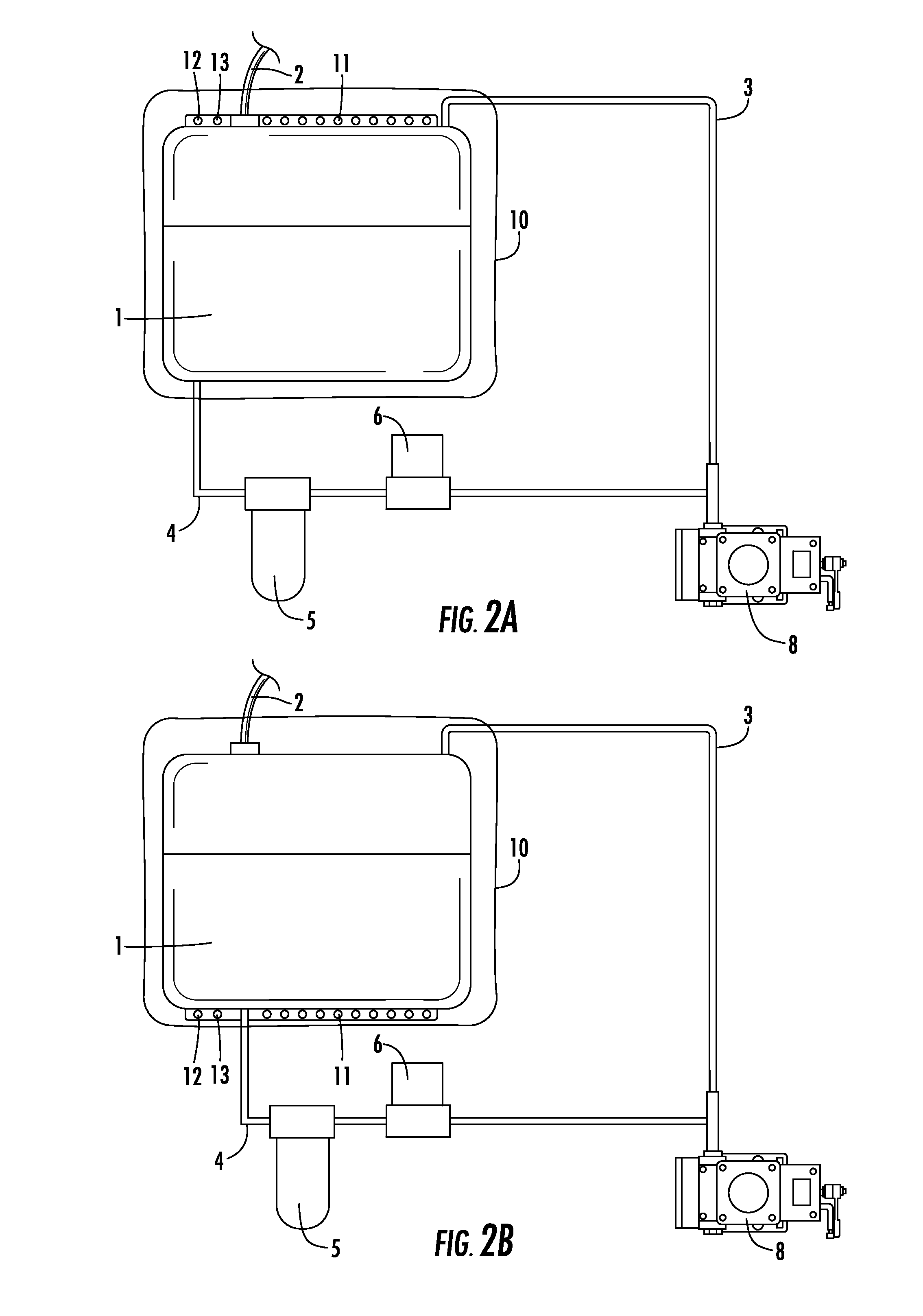

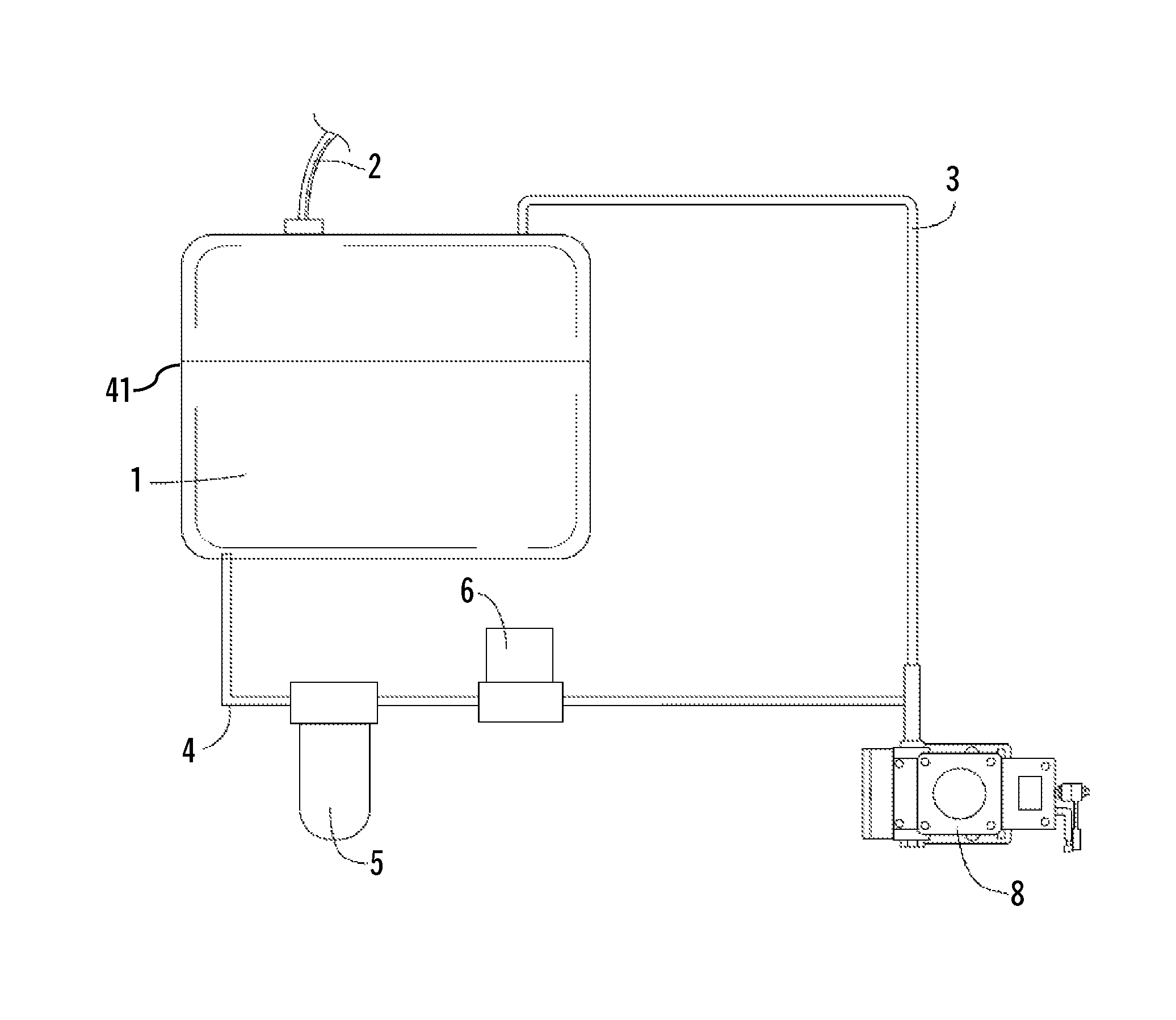

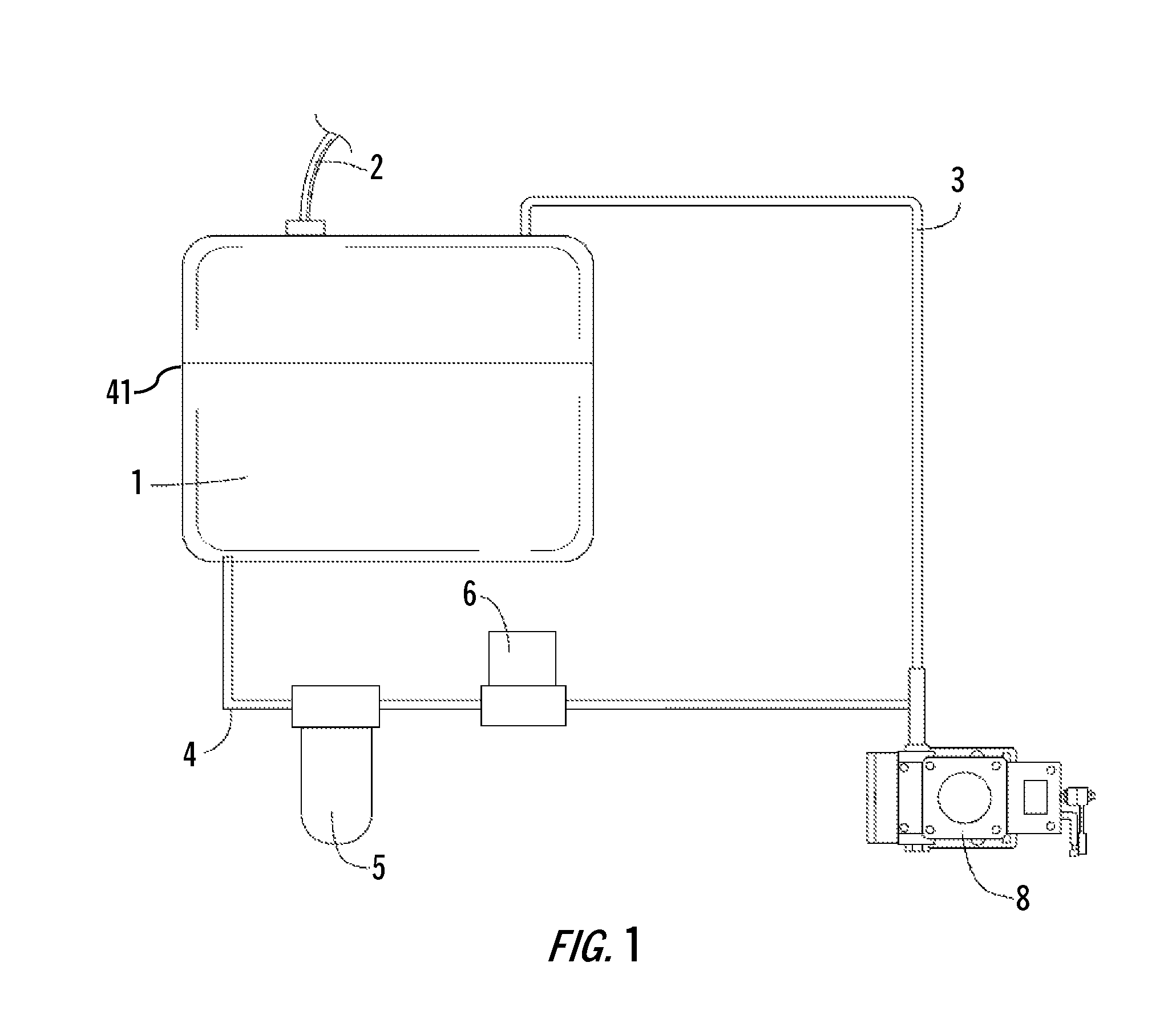

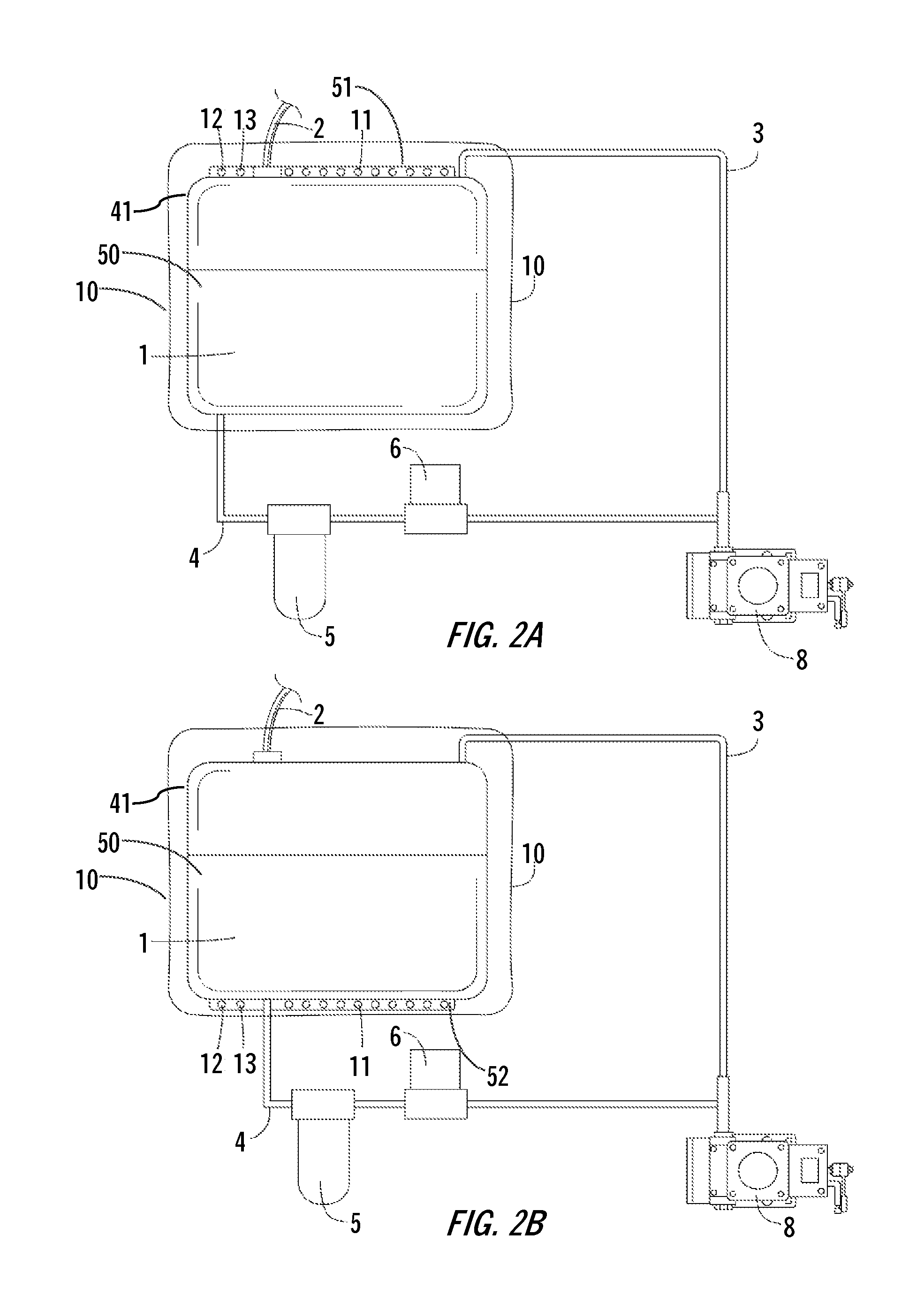

Personal cooling or warming system using closed loop fluid flow

InactiveUS6957697B2Simple and inexpensive to manufactureLightweight and comfortable for userChemical protectionHeat protectionClosed loopEngineering

A garment for a personal cooling or warming system, the garment comprising a carrier formed in the shape of the garment, and a bladder comprising at least two channel segments, wherein the channel segments have a substantially flat configuration so as to improve thermal efficiency.

Owner:AVON PROTECTION SYST

Personal cooling or warming system using closed loop fluid flow

InactiveUS7000682B2Simple and inexpensive to manufactureLightweight and comfortable for userChemical protectionHeat protectionClosed loopEngineering

A garment for a personal cooling or warming system, the garment comprising a carrier formed in the shape of the garment, and a bladder comprising at least two channel segments, wherein the channel segments have a substantially flat configuration so as to improve thermal efficiency.

Owner:AVON PROTECTION SYST

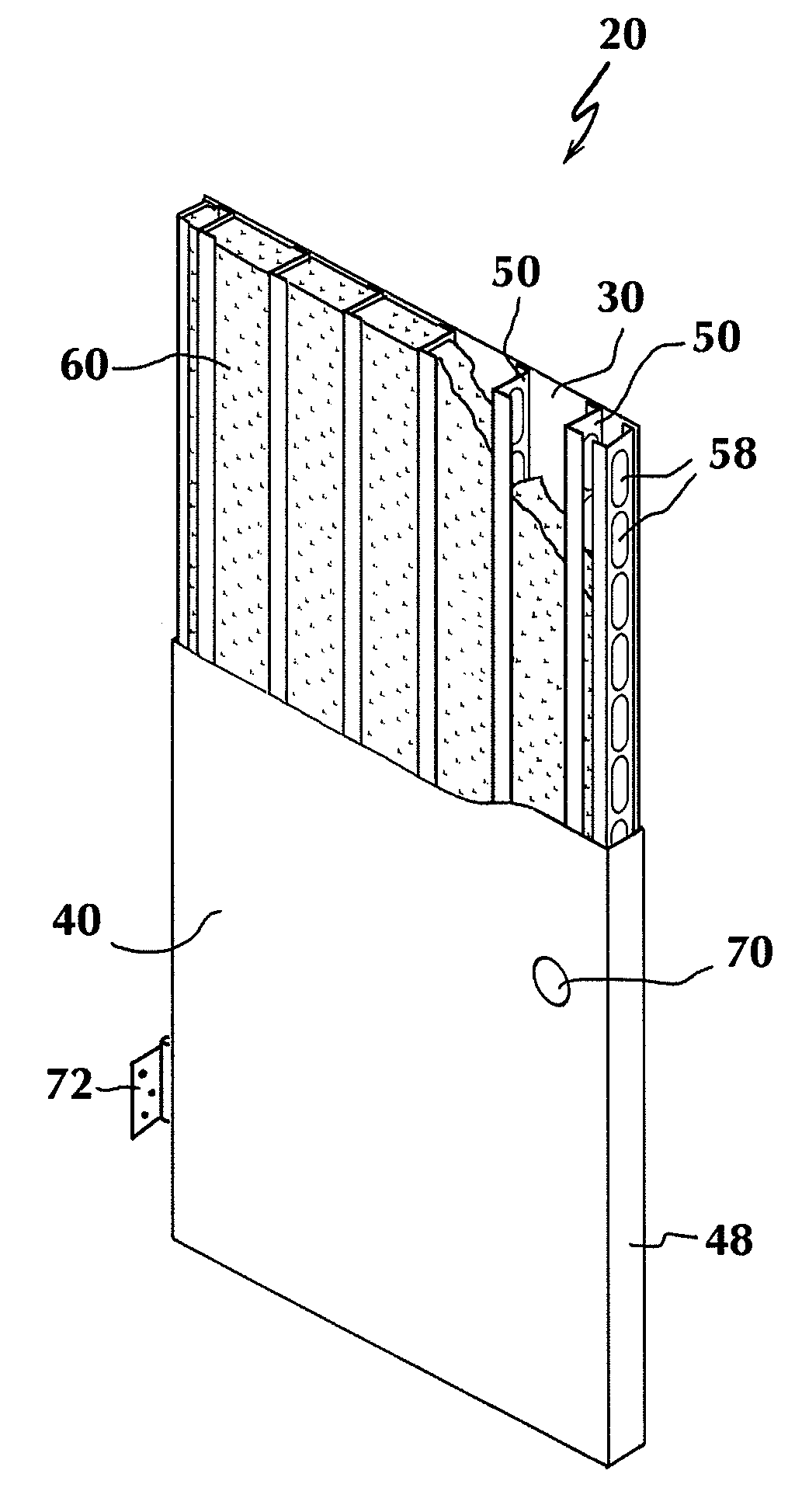

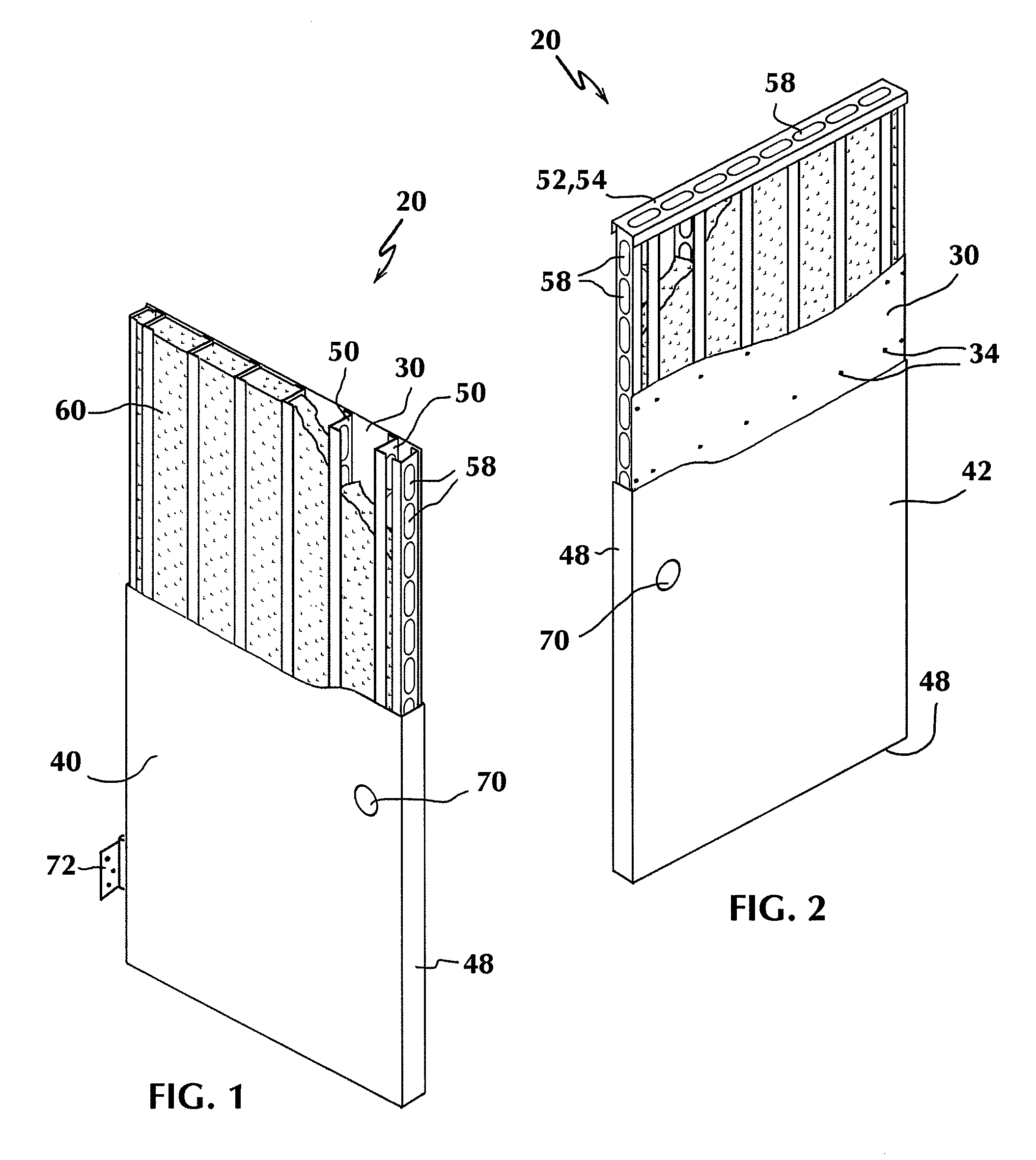

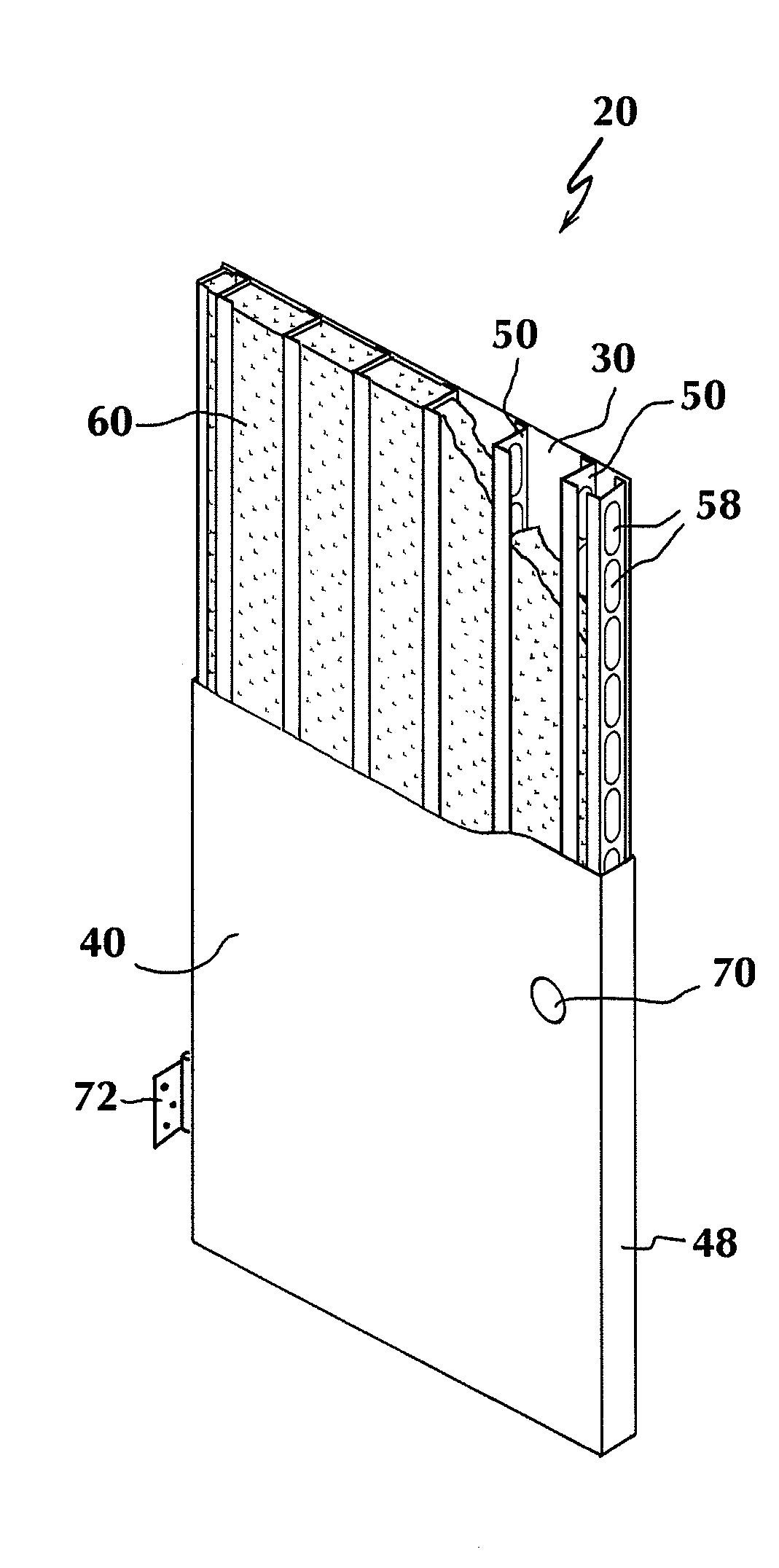

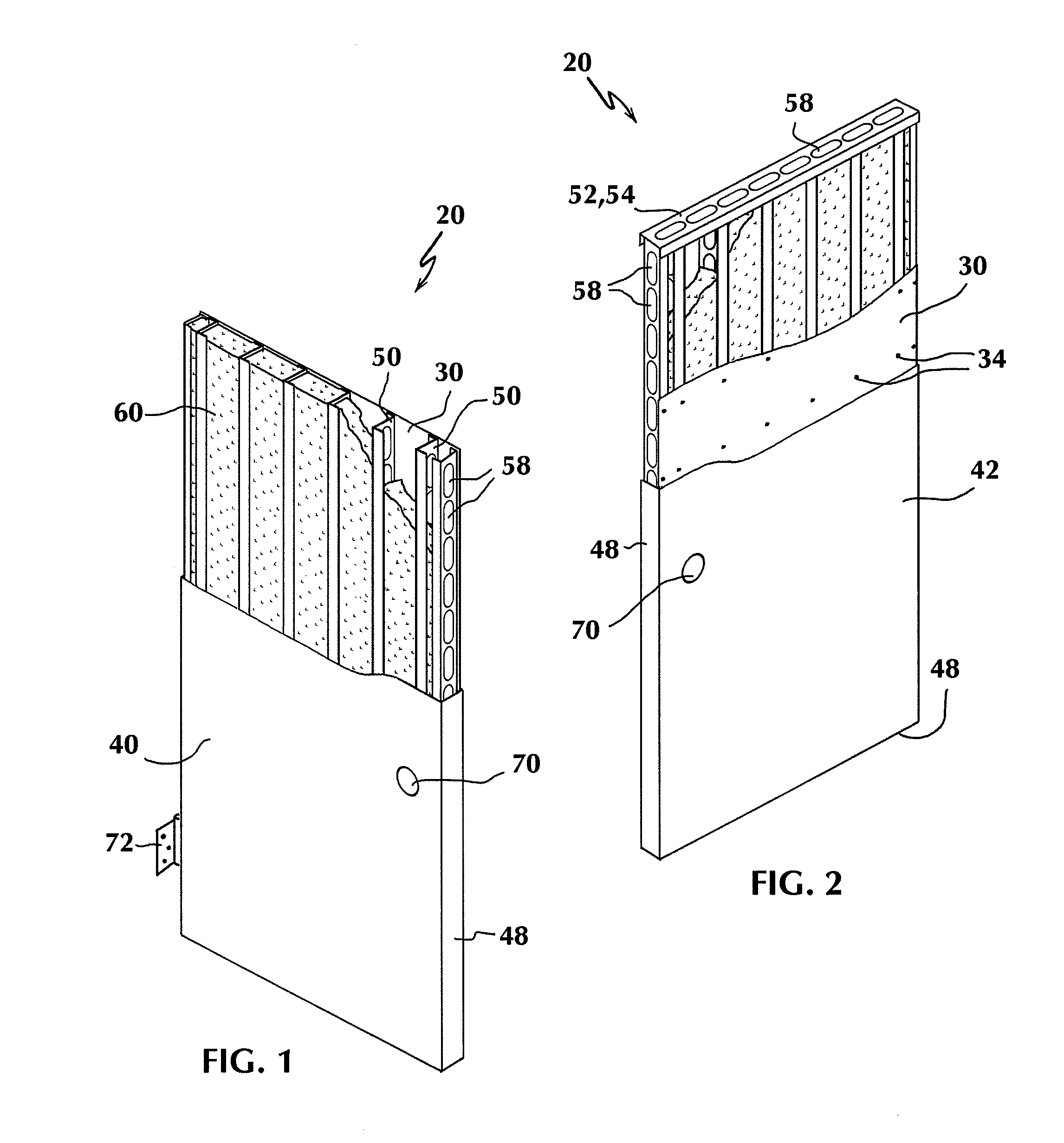

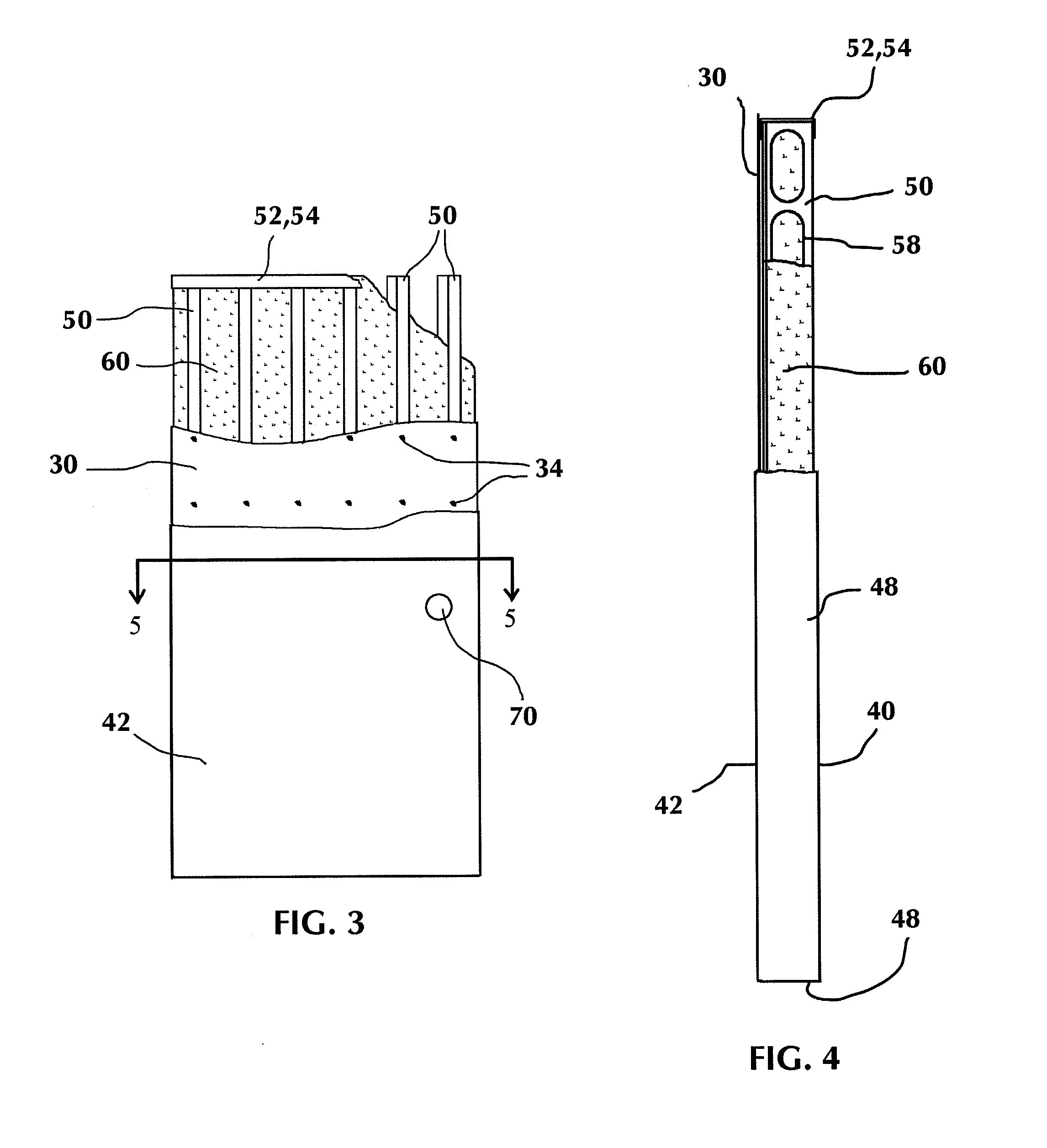

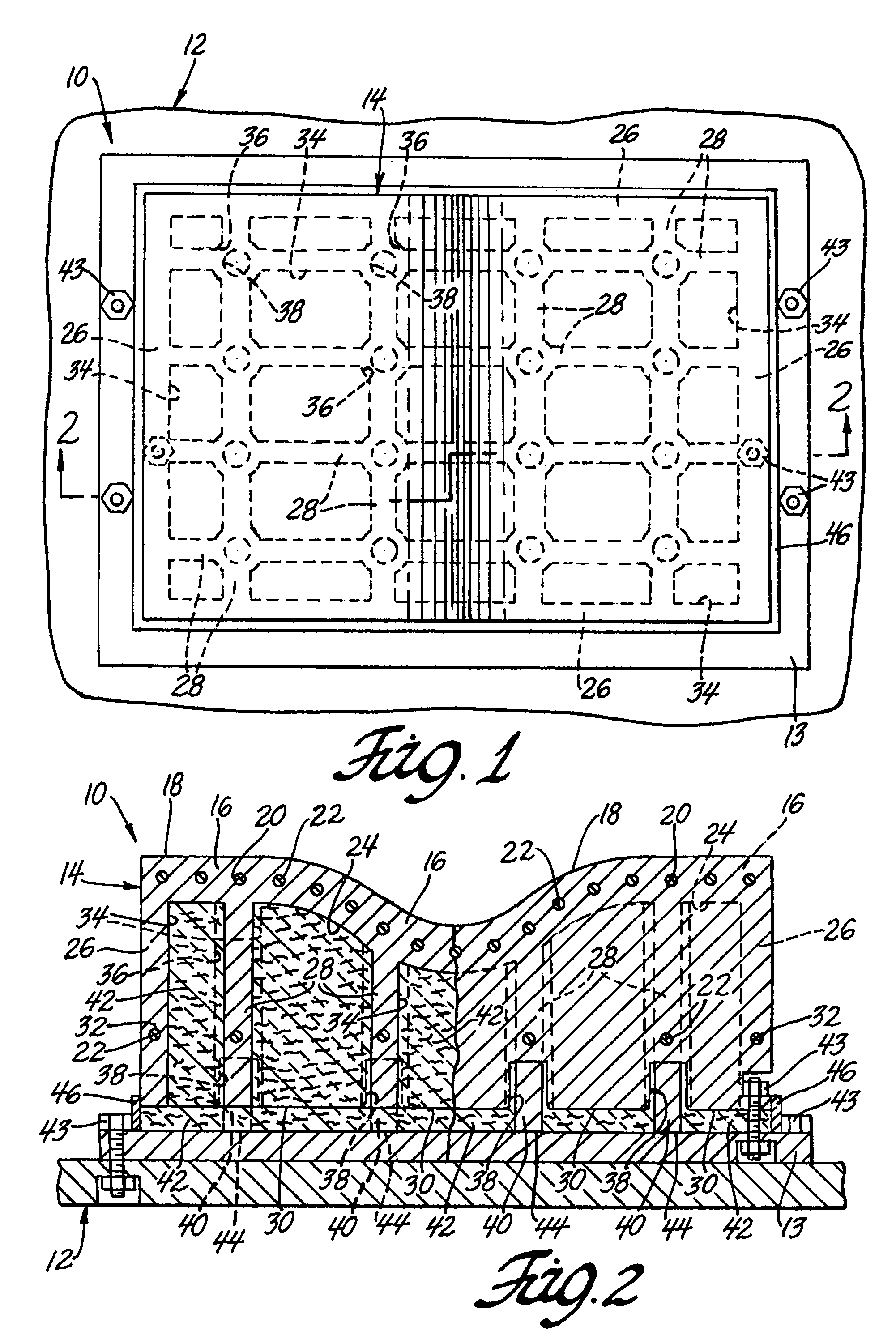

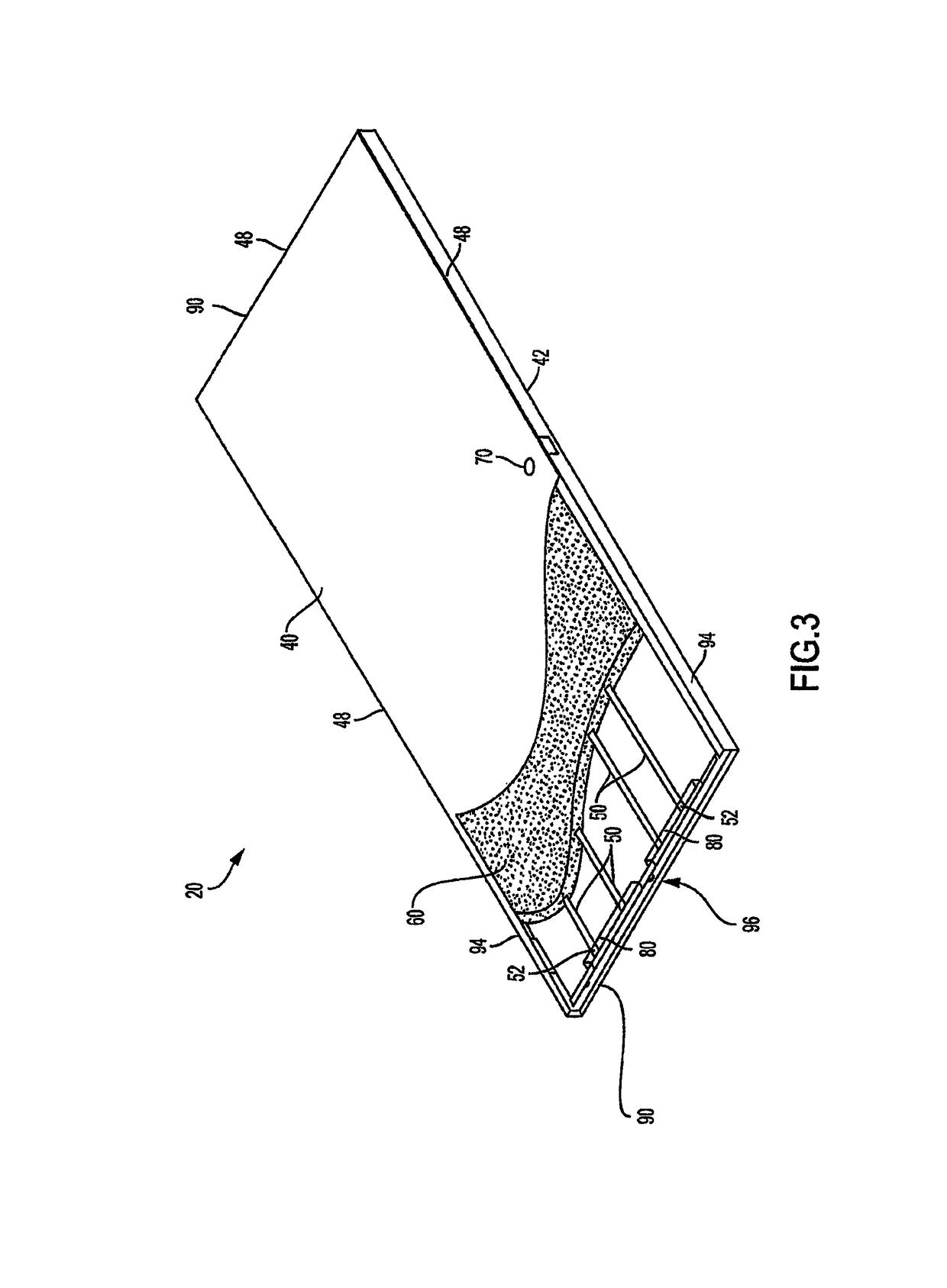

Insulated door and method of making same

ActiveUS8418427B2Improves Structural IntegrityThermally efficientBuilding repairsWindow/door framesThermal insulationElectrical and Electronics engineering

Owner:AADG INC

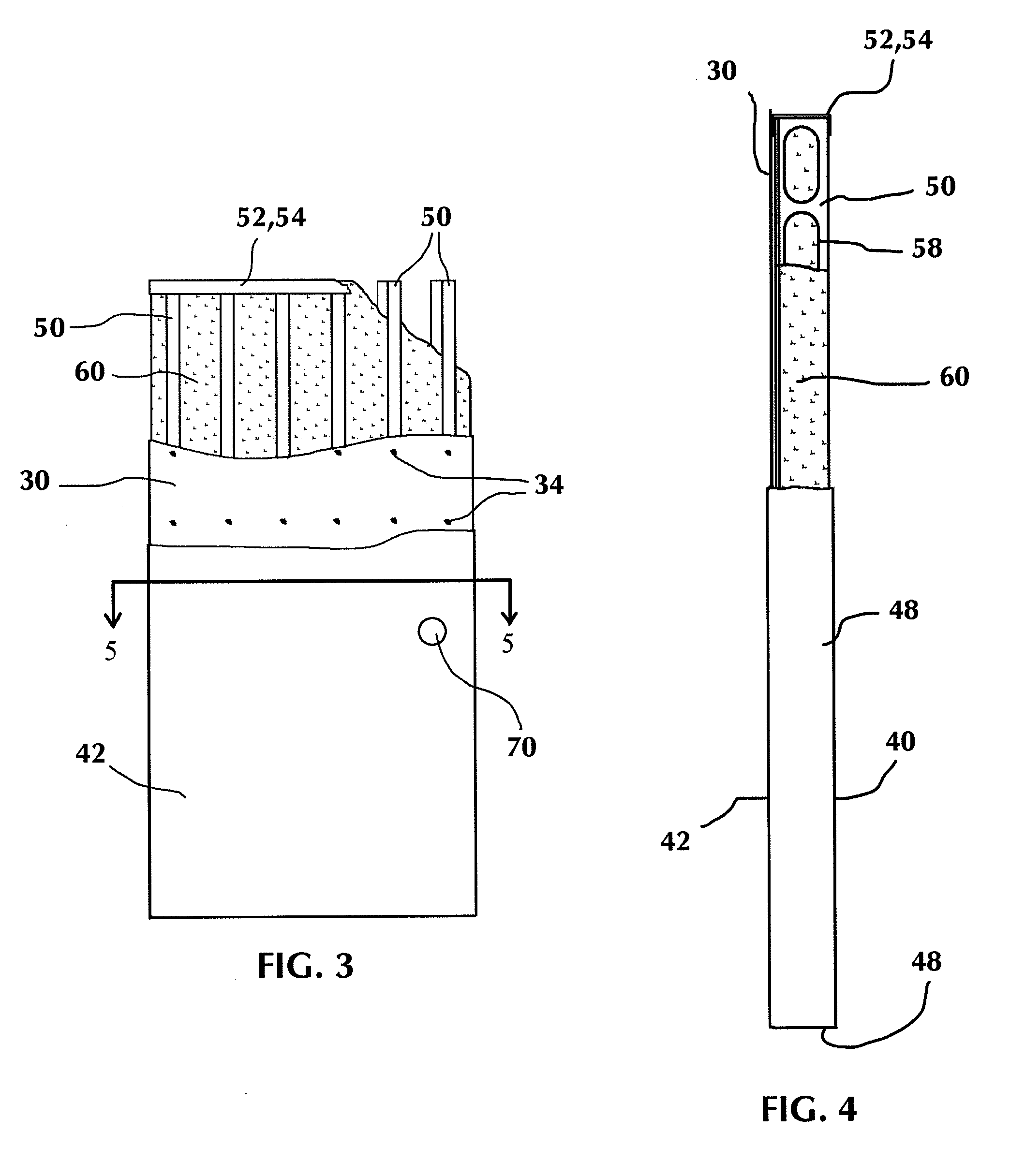

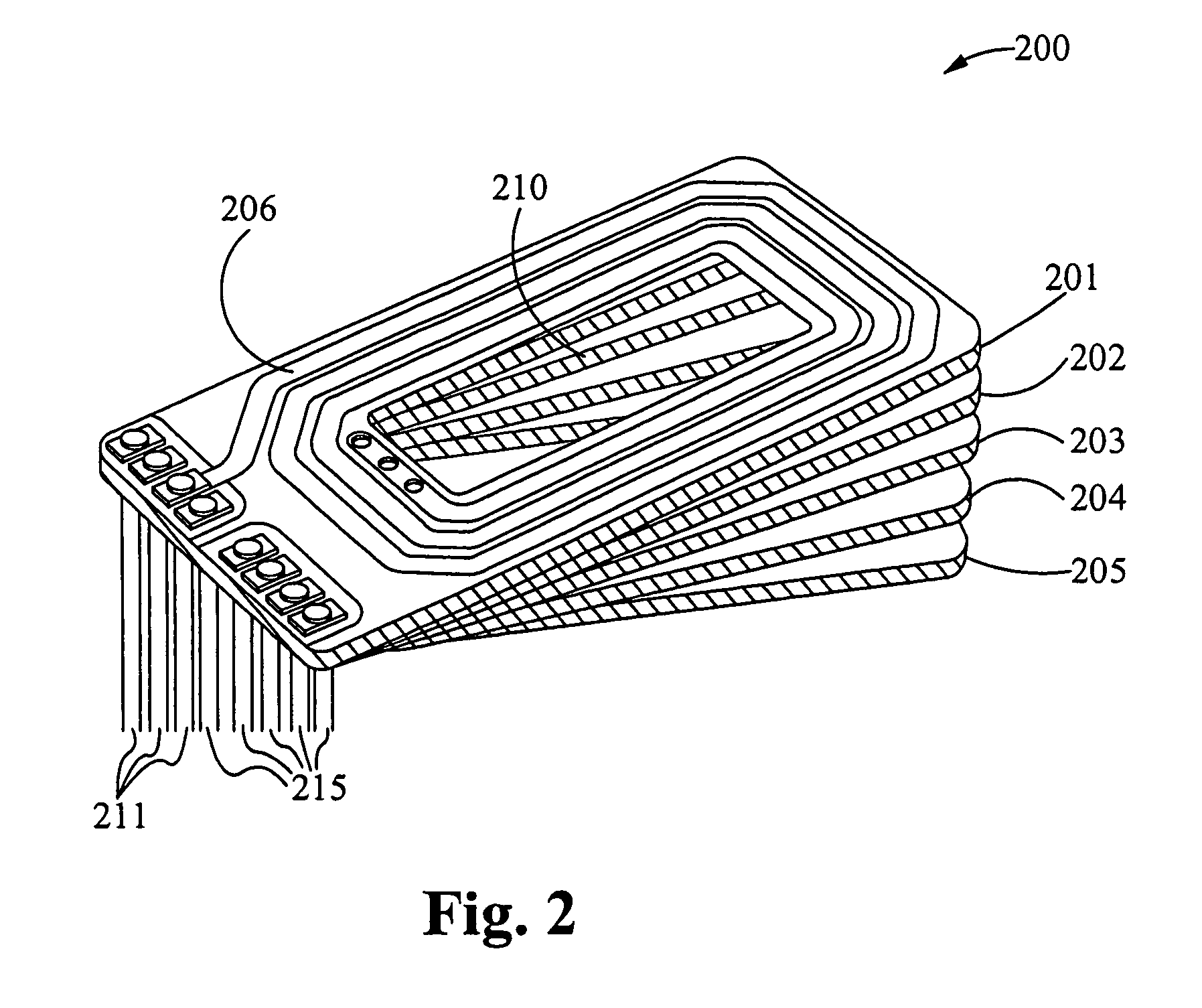

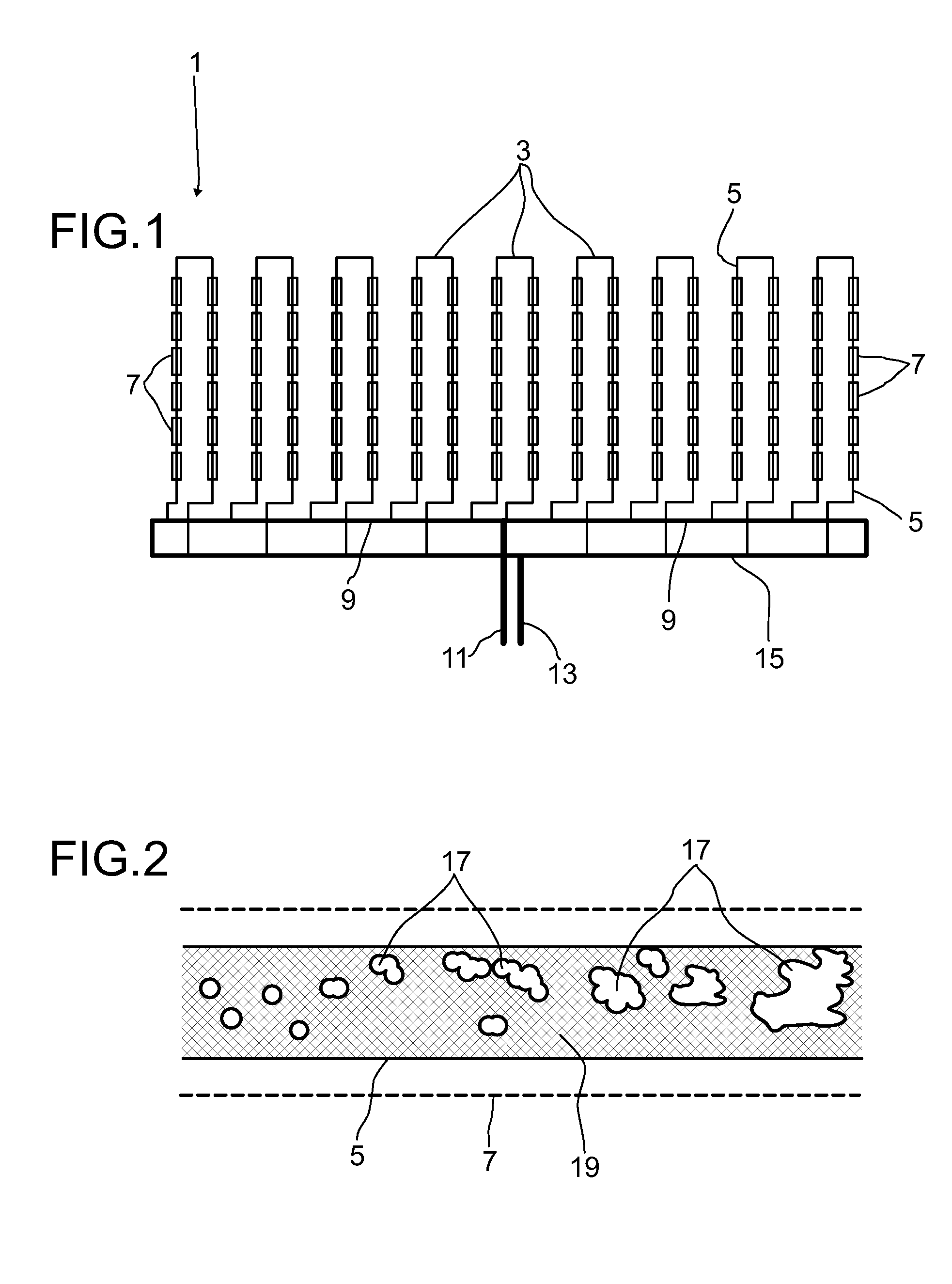

Thermally enhanced magnetic transformer

ActiveUS7920039B2Thermally efficientEliminate useTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEngineeringHeat sink

A planar transformer comprises a laminate substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, a core configured to fit inside the opening to enclose the laminate substrate. At least one heat sink fin is integrally formed with the top, bottom or both sides of the core. A method of forming a planar transformer comprises laminating a substrate having an opening with metal traces wound thereabout forming a primary and a secondary winding, fitting a core inside the opening, and enclosing the laminate substrate. One of the top, bottom or both sides of the core include one or more heat sink fins.

Owner:FLEXTRONICS AP LLC

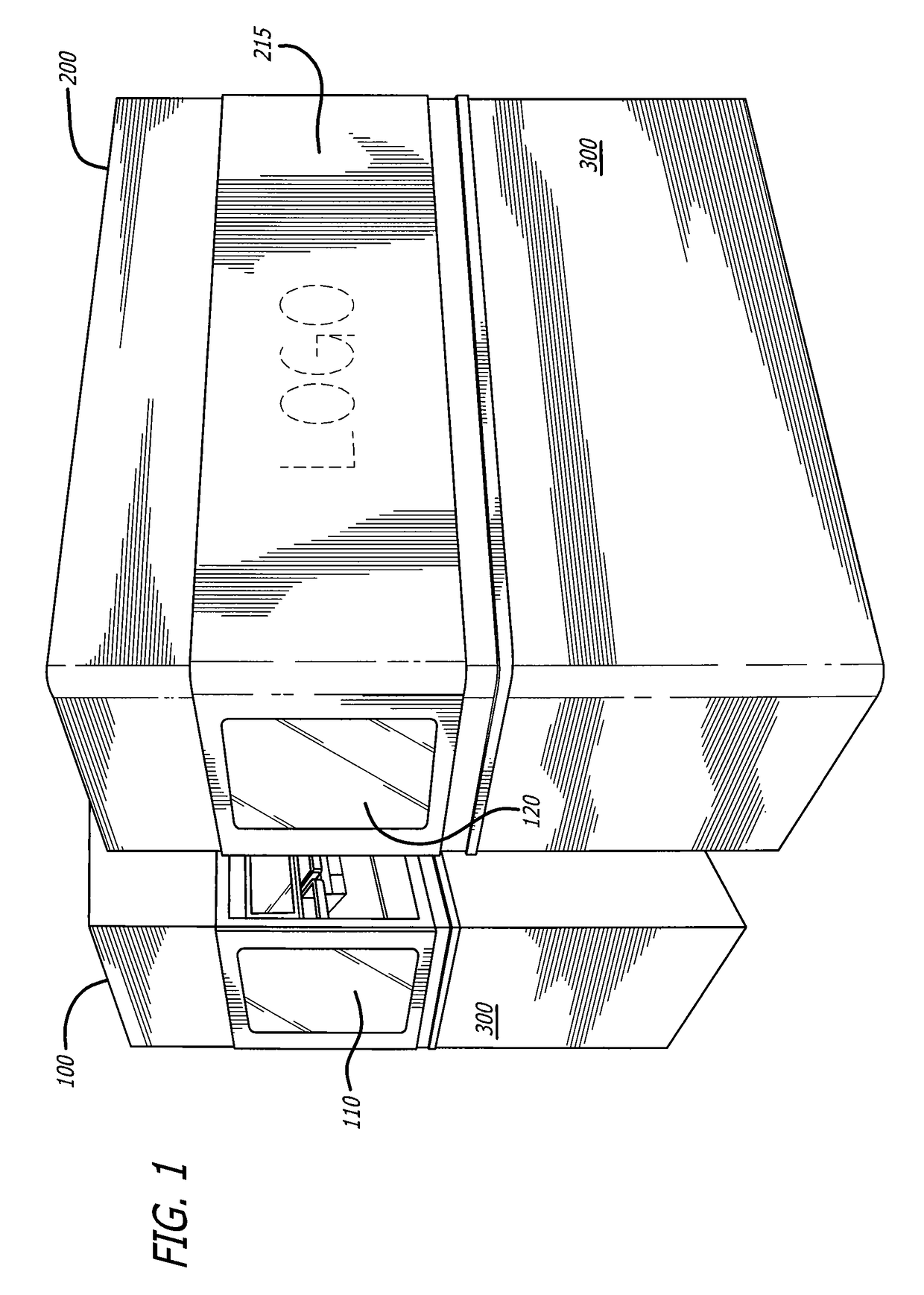

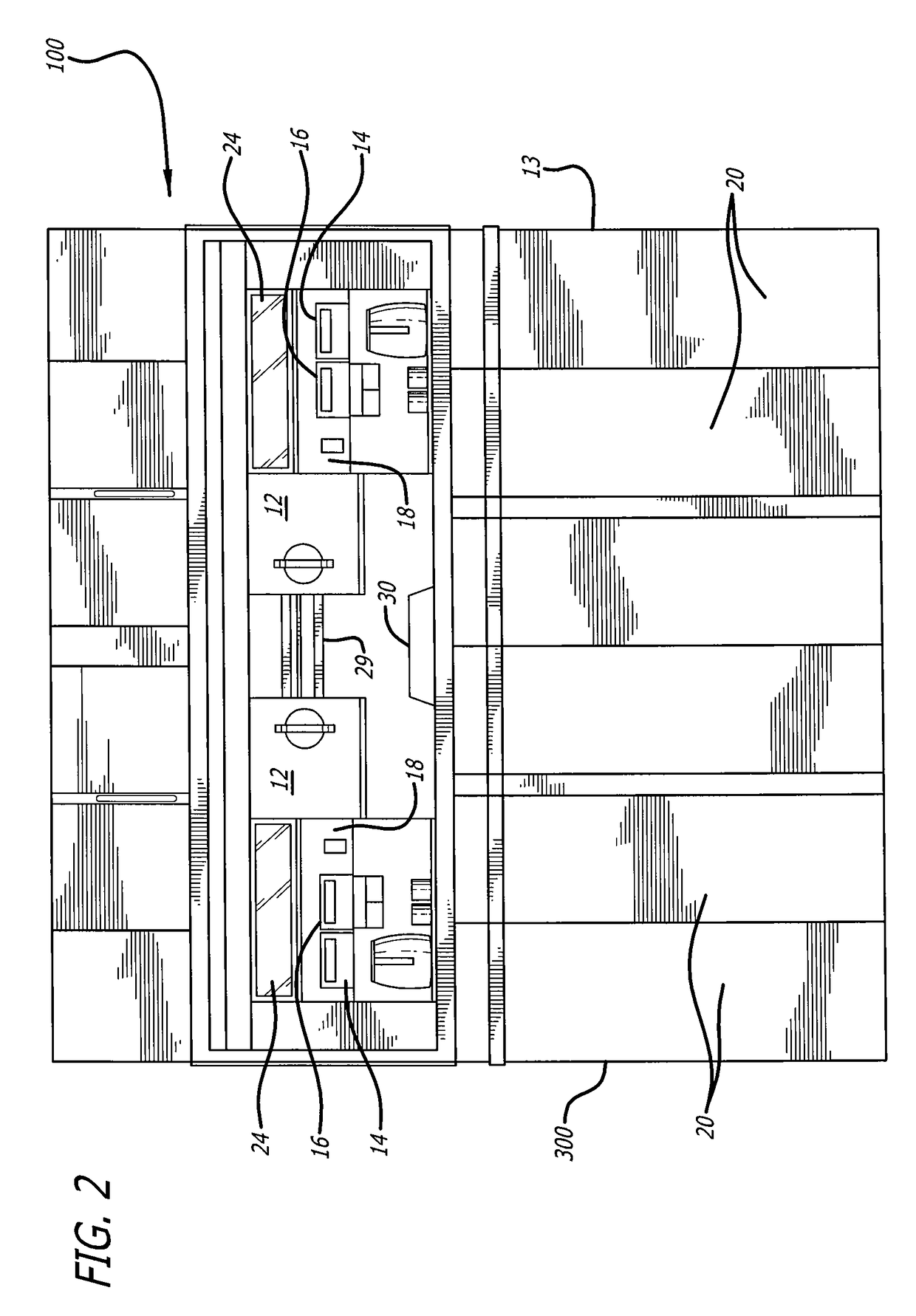

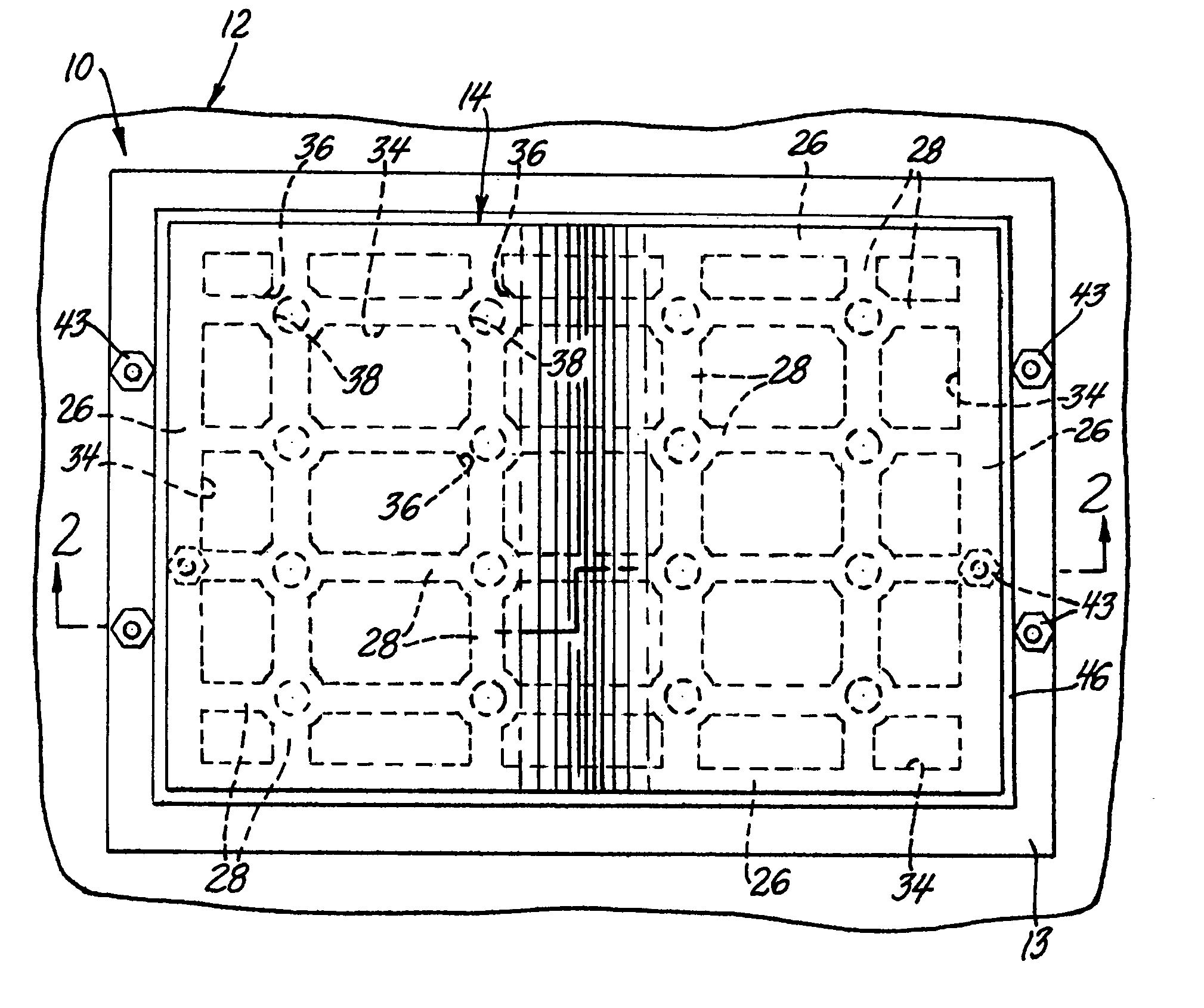

Insulated door and method of making same

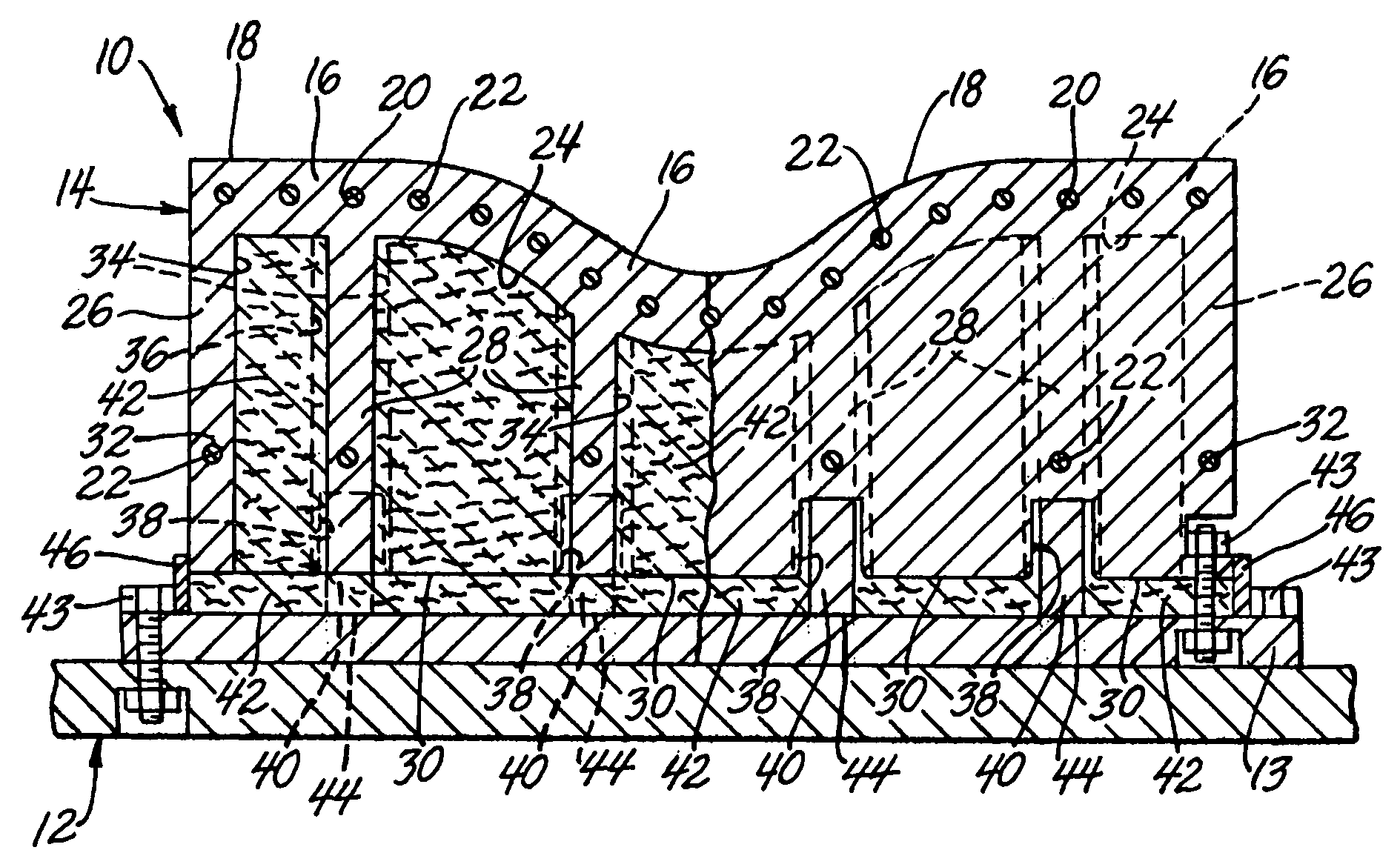

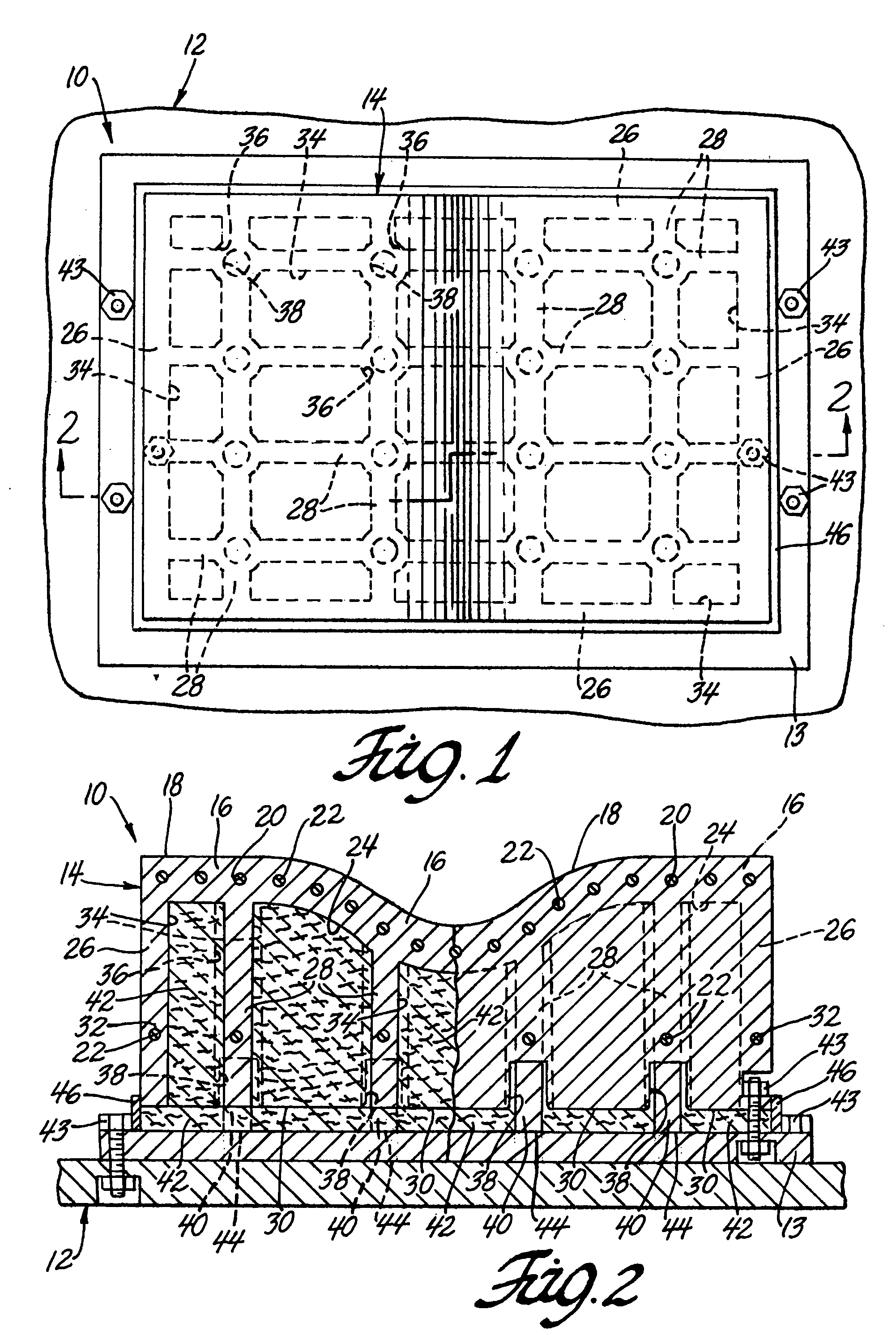

ActiveUS20100257802A1Improved structural integrityThermally efficientBuilding repairsWindow/door framesThermal insulationEngineering

An insulated door comprising a door shell having spaced first and second exterior panels. The door includes a plurality of stiffeners bonded to a liner panel, with thermal insulation between adjacent stiffeners, disposed within the door shell. The liner panel may extend along one side of the stiffeners and the thermal insulation along the liner panel between the stiffeners and the first and second exterior panels. The stiffeners and the liner panel are preferably made of steel and the stiffeners are welded to the liner panel. The stiffeners are preferably not welded to the first and second exterior panels of the door shell. The liner panel is preferably insertable into the first or second exterior panels of the door shell. The insulation material fills substantially all of the space between the liner panel and one of the first or second exterior panels.

Owner:AADG INC

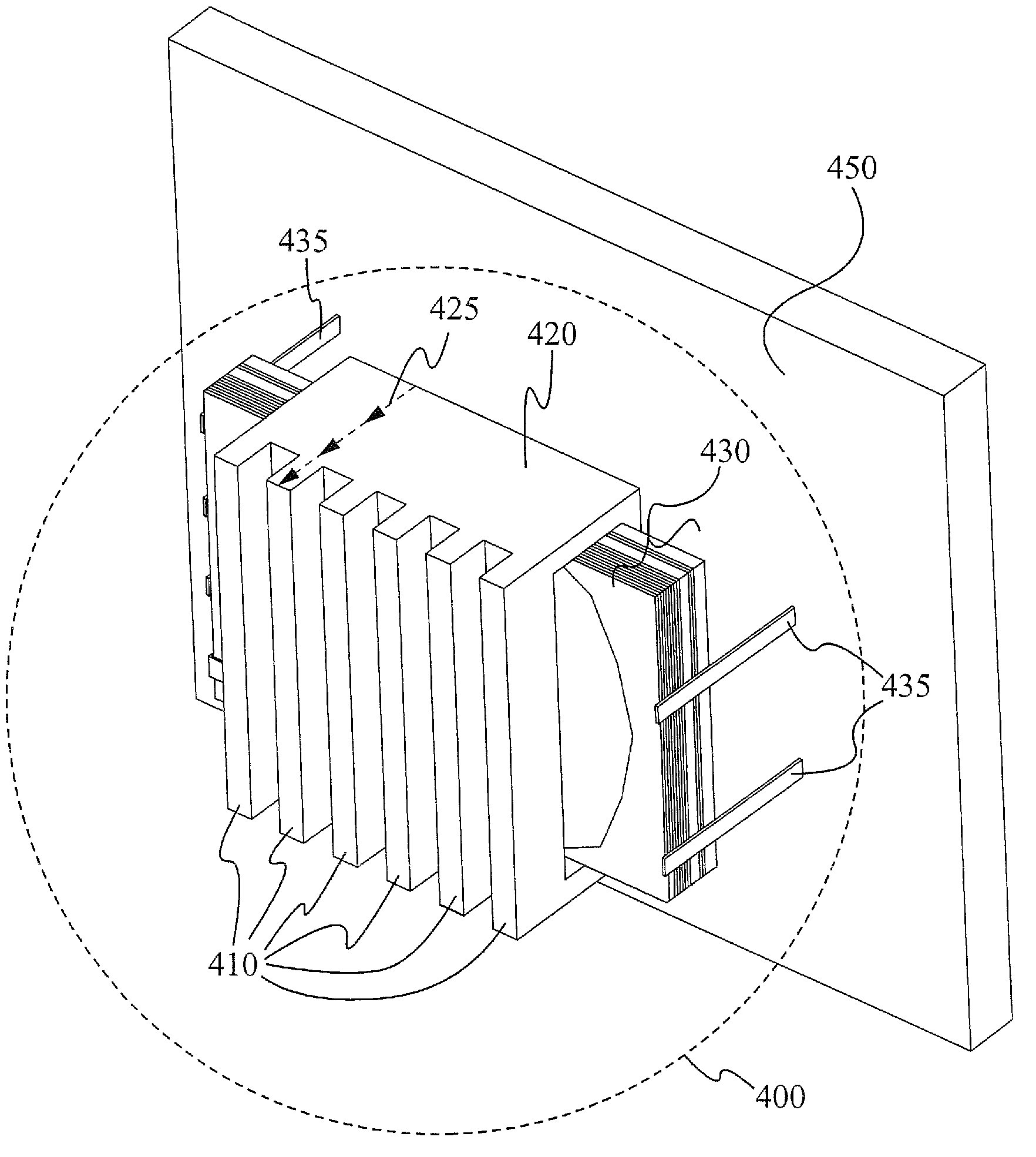

Forming tool apparatus for hot stretch-forming processes

ActiveUS20050199031A1Reduce heat lossImprove thermal efficiencyShaping toolsThermal insulationEngineering

A tooling assembly for hot stretch-forming of a sheet metal workpiece. A forming tool is attached to a plate and includes a shell having a forming surface, and support walls that extend away from the shell, that terminate in a rearward surface of the forming tool, and that define open cells between the support walls. Heating elements are embedded within the forming tool for integral and uniform heating thereof. To limit conductive thermal losses from the forming surface, through the forming tool, and to the plate and surrounding environment, the open cells are provided in the forming tool and insulative support posts are disposed between the forming tool and the plate within deep counterbores in the rearward surface of the forming tool. To limit radiative and convective thermal losses, thermal insulation is disposed within the cells and between the forming tool and plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Ancient hydroelectric company

InactiveUS20110266804A1Strong pressure capacityIncrease volume capacityWorking fluid for enginesMachines/enginesWorking fluidWater source

Ancient Hydroelectric Company comprises a portable hydroelectricity producing system. Consumers are provided with a cost-effective and reliable system for providing substantially clean electricity generation without obstructing the water source or negatively affecting the environment. The high efficiency portable hydro-electric producing system is for use with a moving water source. The system uses antifreeze with water to provide a more thermally efficient working fluid as used to improve the system's pressure and volume capacity in use.

Owner:DOLCIMASCOLO JOSEPH

Personal cooling or warming system using closed loop fluid flow

InactiveUS20050139351A1Simple and inexpensive to manufactureLightweight and comfortable for userChemical protectionHeat protectionClosed loopEngineering

A garment for a personal cooling or warming system, the garment comprising a carrier formed in the shape of the garment, and a bladder comprising at least two channel segments, wherein the channel segments have a substantially flat configuration so as to improve thermal efficiency.

Owner:AVON PROTECTION SYST

Process for the stabilization of soluble chromium contaminated solid by down draft sintering

InactiveUS6416251B1Faster rateThermally efficientTransportation and packagingSolid waste disposalSolid carbonMaterials science

The invention relates to a process for the stabilisation of soluble chromium in contaminated solids by down draft sintering by mixing chromium contaminated solids with different proportions of CaO, MgO, Al2O3, SiO2, SO4 and solid carbon bearing waste materials to maintain the desired ratio of CaO / SiO2, SiO2 / Al2O3+Fe2O3 and SO3 / Cr in the mixture. The Cr(VI) and chromates are converted into non-leachable compounds.

Owner:COUNCIL OF SCI & IND RES

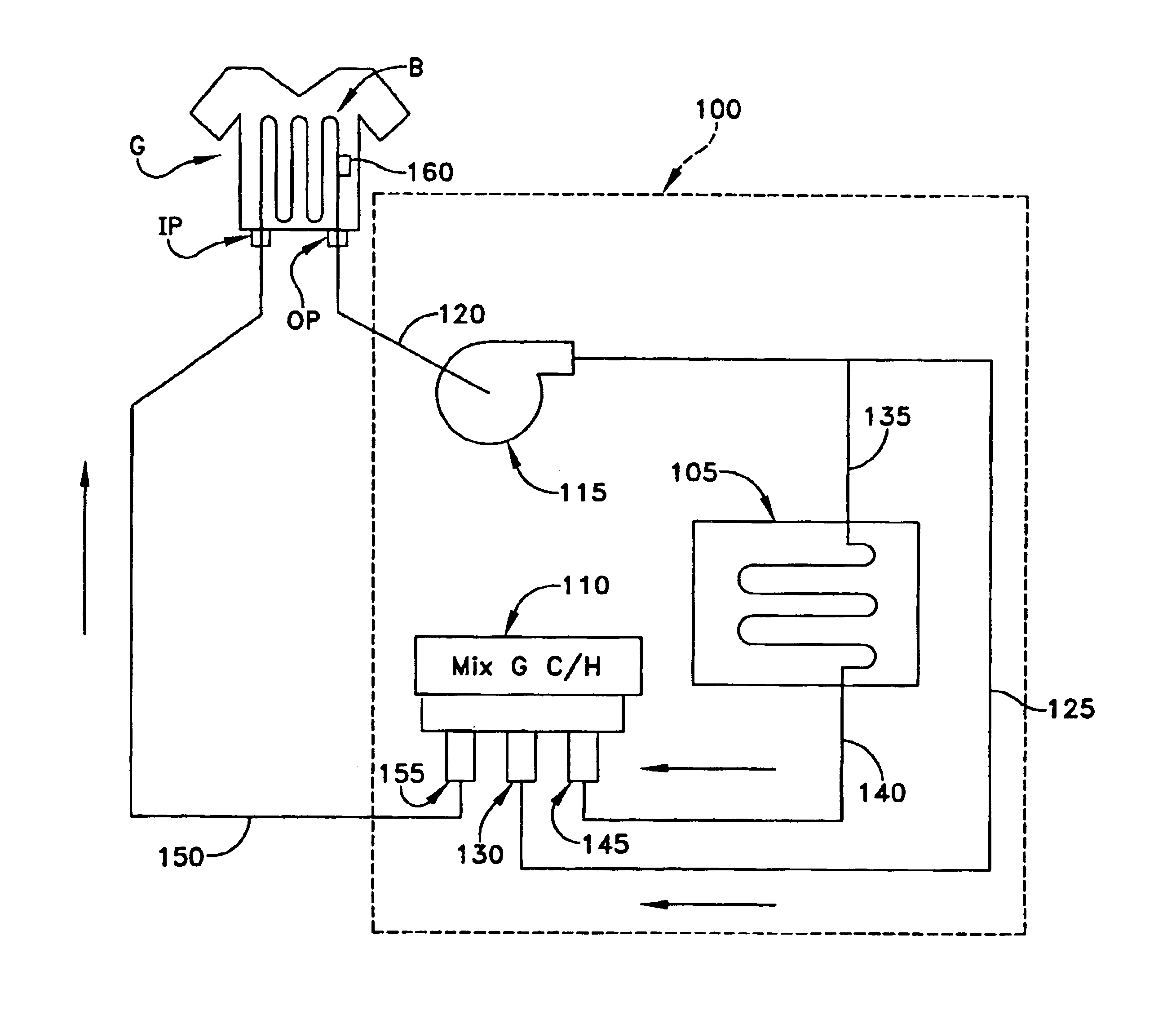

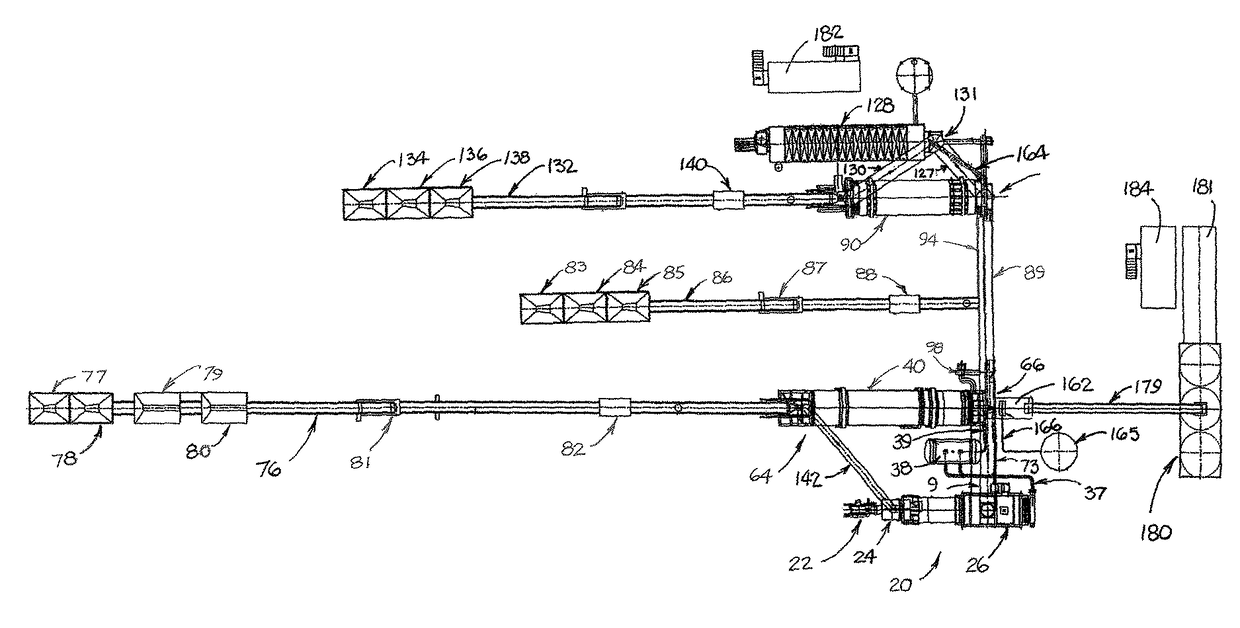

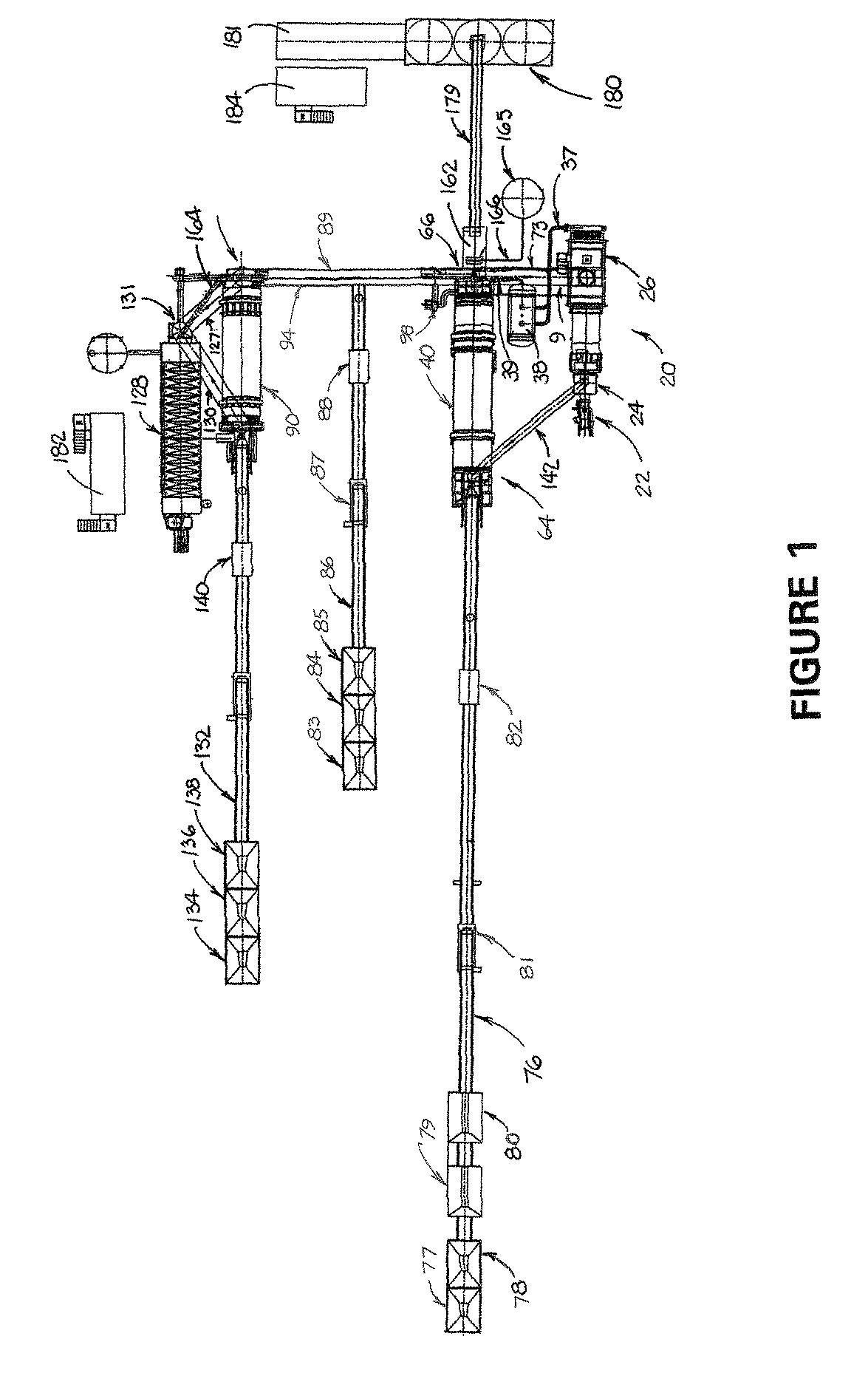

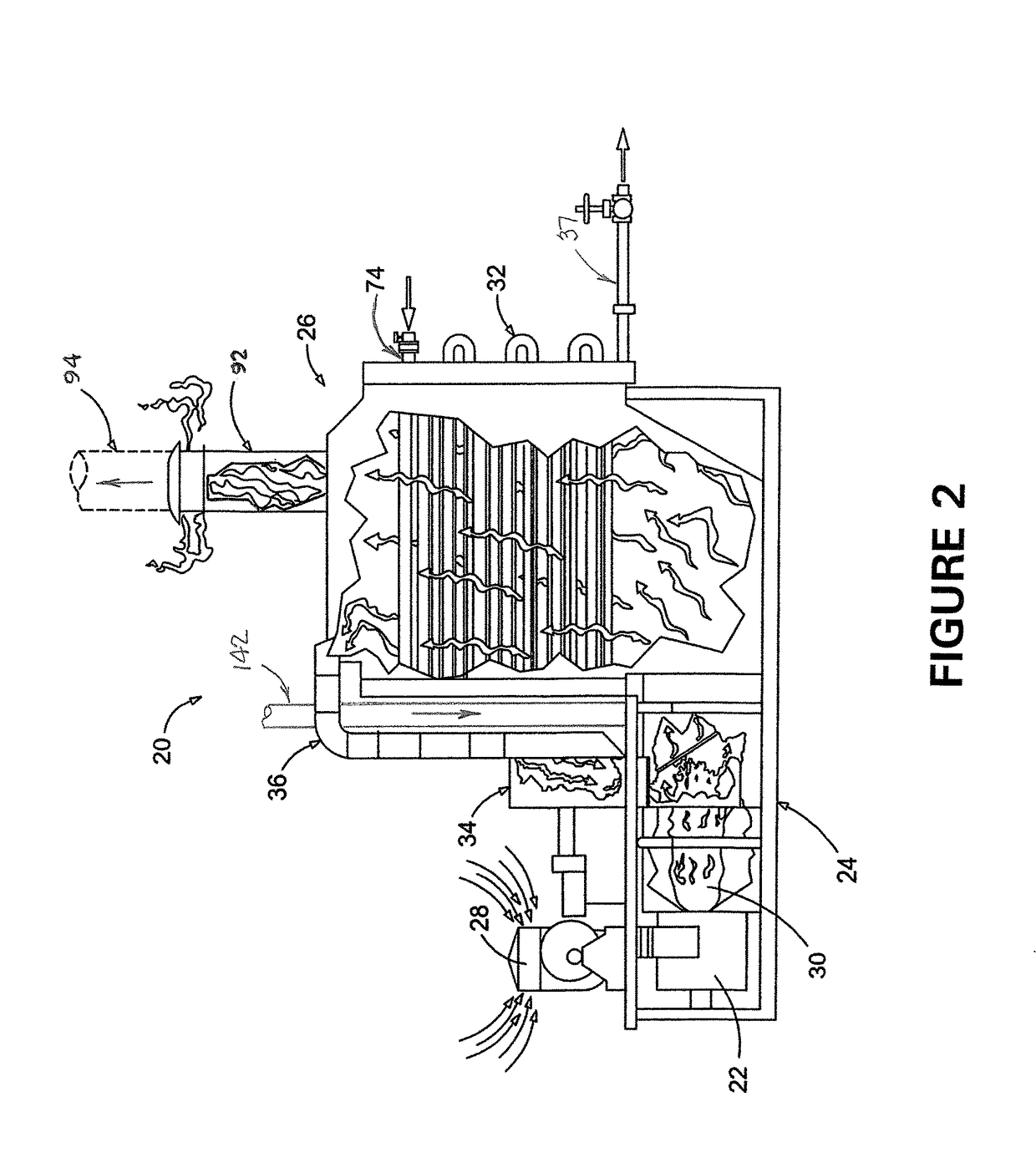

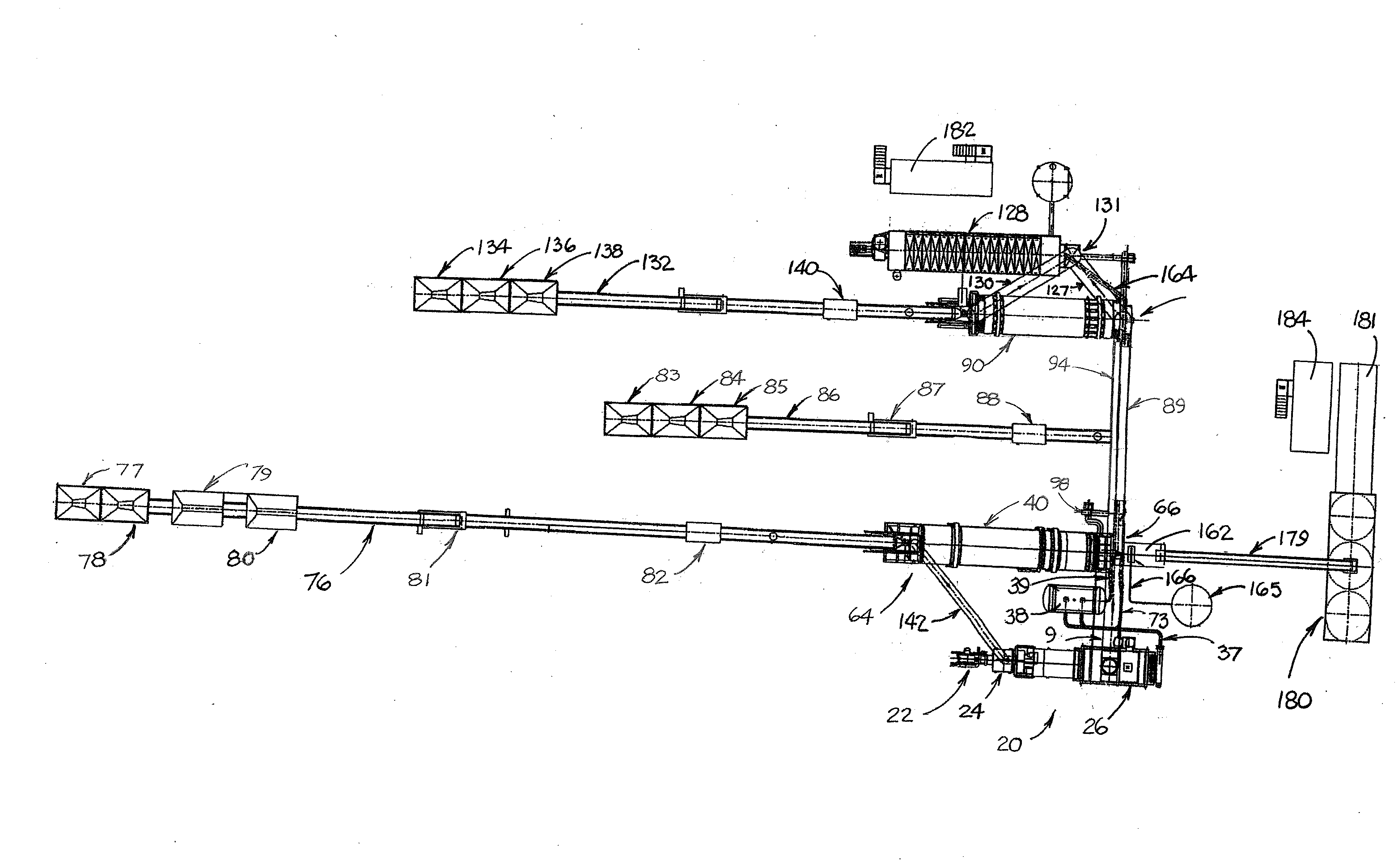

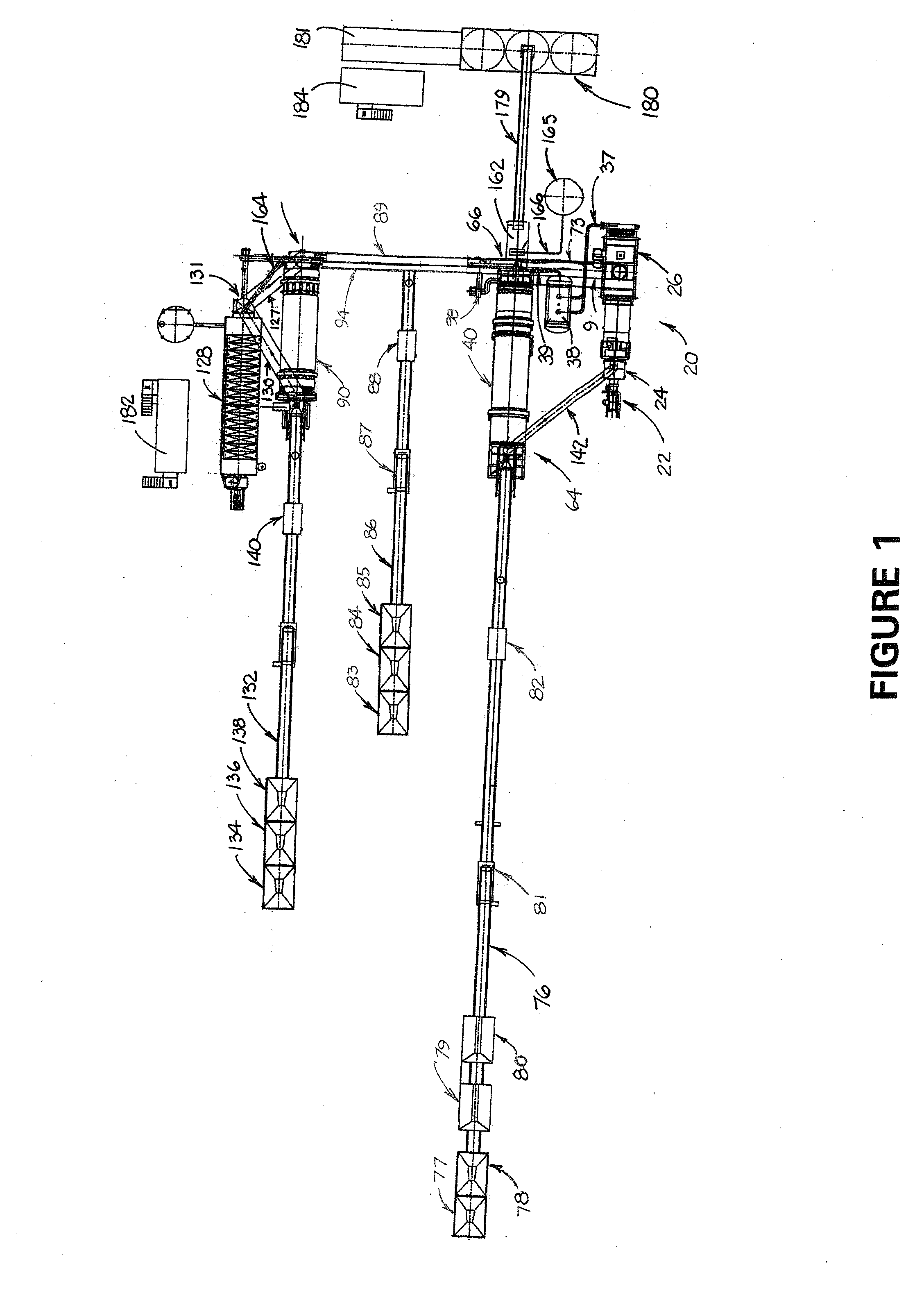

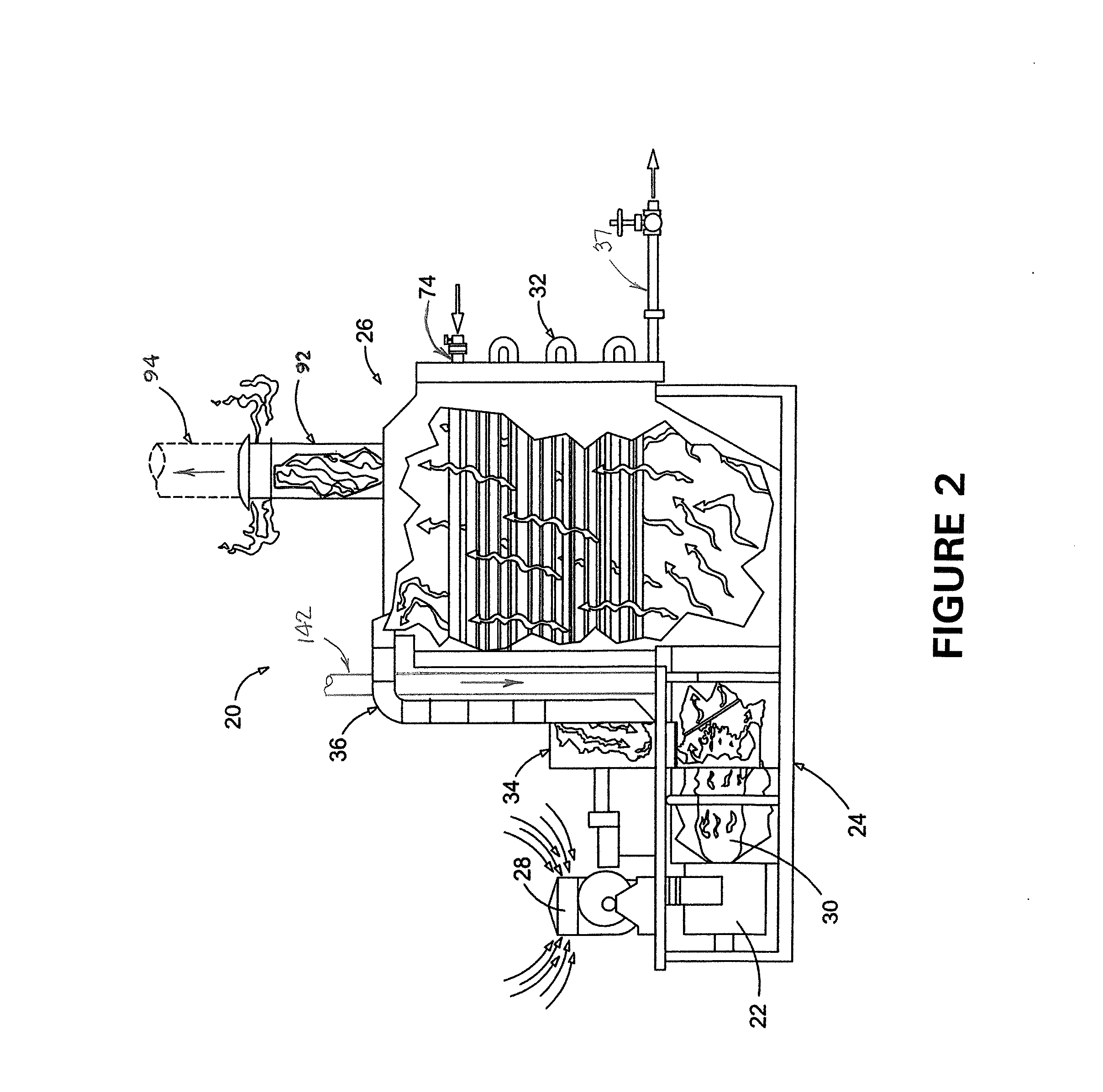

Method and apparatus for making asphalt concrete using aggregate material from a plurality of material streams

InactiveUS9855677B2Emission controlThermally efficientGranular material dryingRotary drum furnacesProcess engineeringMechanical engineering

A combination of components is provided for use in making asphalt concrete from a plurality of aggregate material streams. The combination includes an indirect dryer for heating aggregate material from a first material stream without directly exposing said first stream material to hot gases of combustion. The combination also includes a mixer for mixing aggregate material from the first material stream, aggregate material that has not been heated in the indirect dryer from a second material stream, and a binder component to produce asphalt concrete.

Owner:ASTEC

Method and apparatus for making asphalt concrete using aggregate material from a plurality of material streams

InactiveUS20150029809A1Emission controlThermally efficientGranular material dryingRotary drum furnacesCombustionMaterials science

A combination of components is provided for use in making asphalt concrete from a plurality of aggregate material streams. The combination includes an indirect dryer for heating aggregate material from a first material stream without directly exposing said first stream material to hot gases of combustion. The combination also includes a mixer for mixing aggregate material from the first material stream, aggregate material that has not been heated in the indirect dryer from a second material stream, and a binder component to produce asphalt concrete.

Owner:ASTEC

Spacecraft radiator systems

InactiveUS8157217B1Improve structural strengthEffective structureCosmonautic vehiclesCosmonautic power supply systemsSystems designHeat spreader

A spacecraft radiator system designed to provide structural support to the spacecraft. Structural support is provided by the geometric “crescent” form of the panels of the spacecraft radiator. This integration of radiator and structural support provides spacecraft with a semi-monocoque design.

Owner:PARAGON SPACE DEVMENT

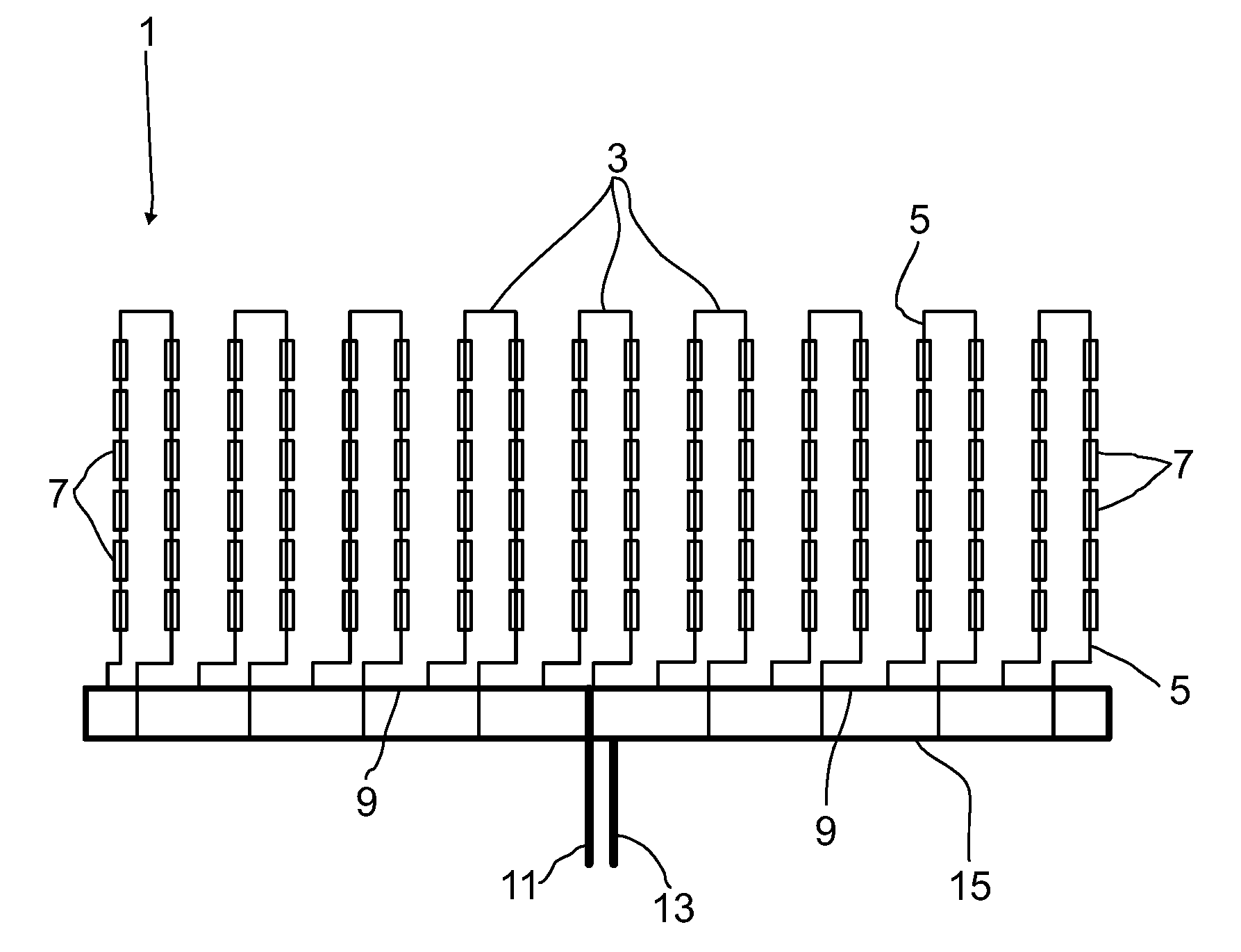

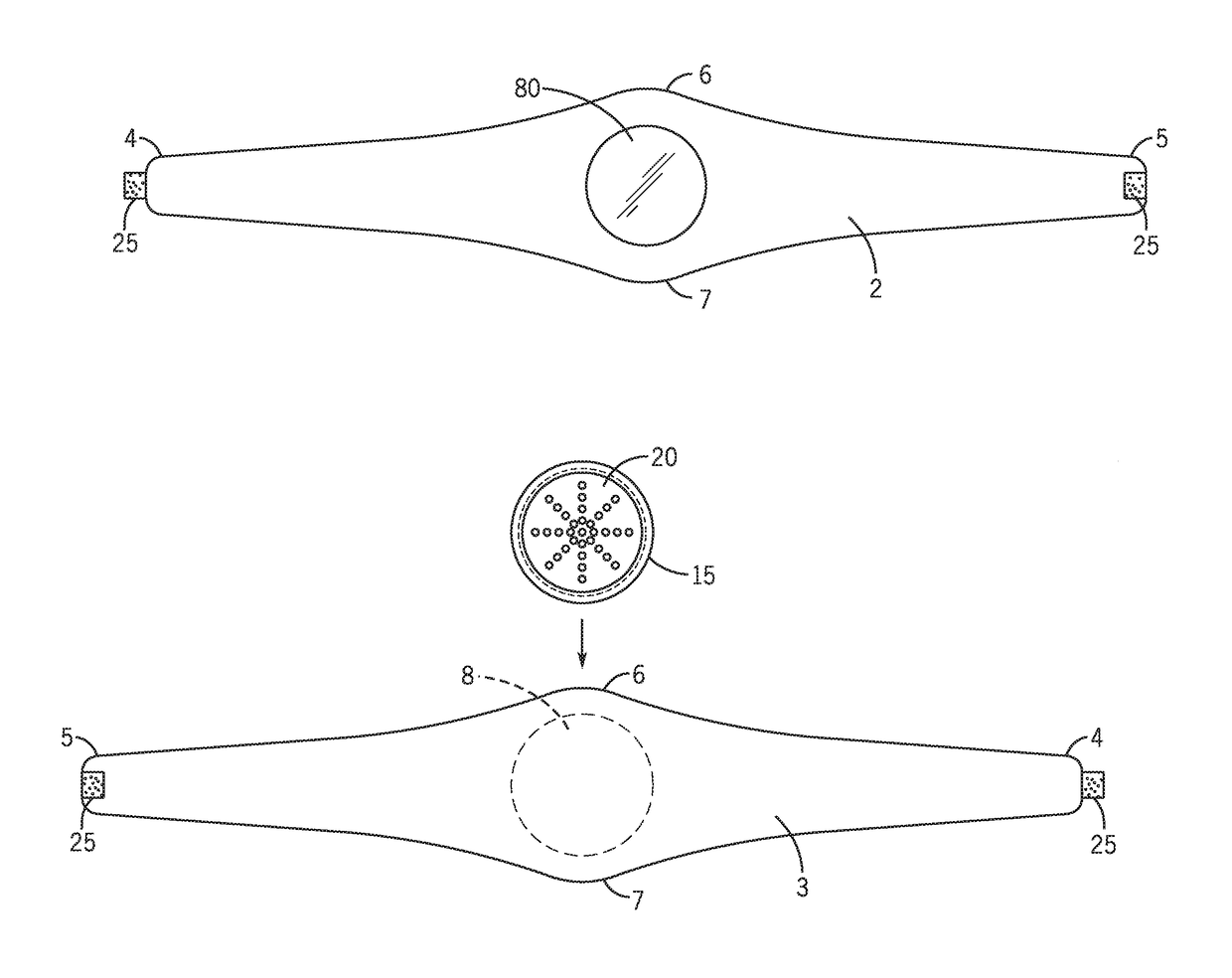

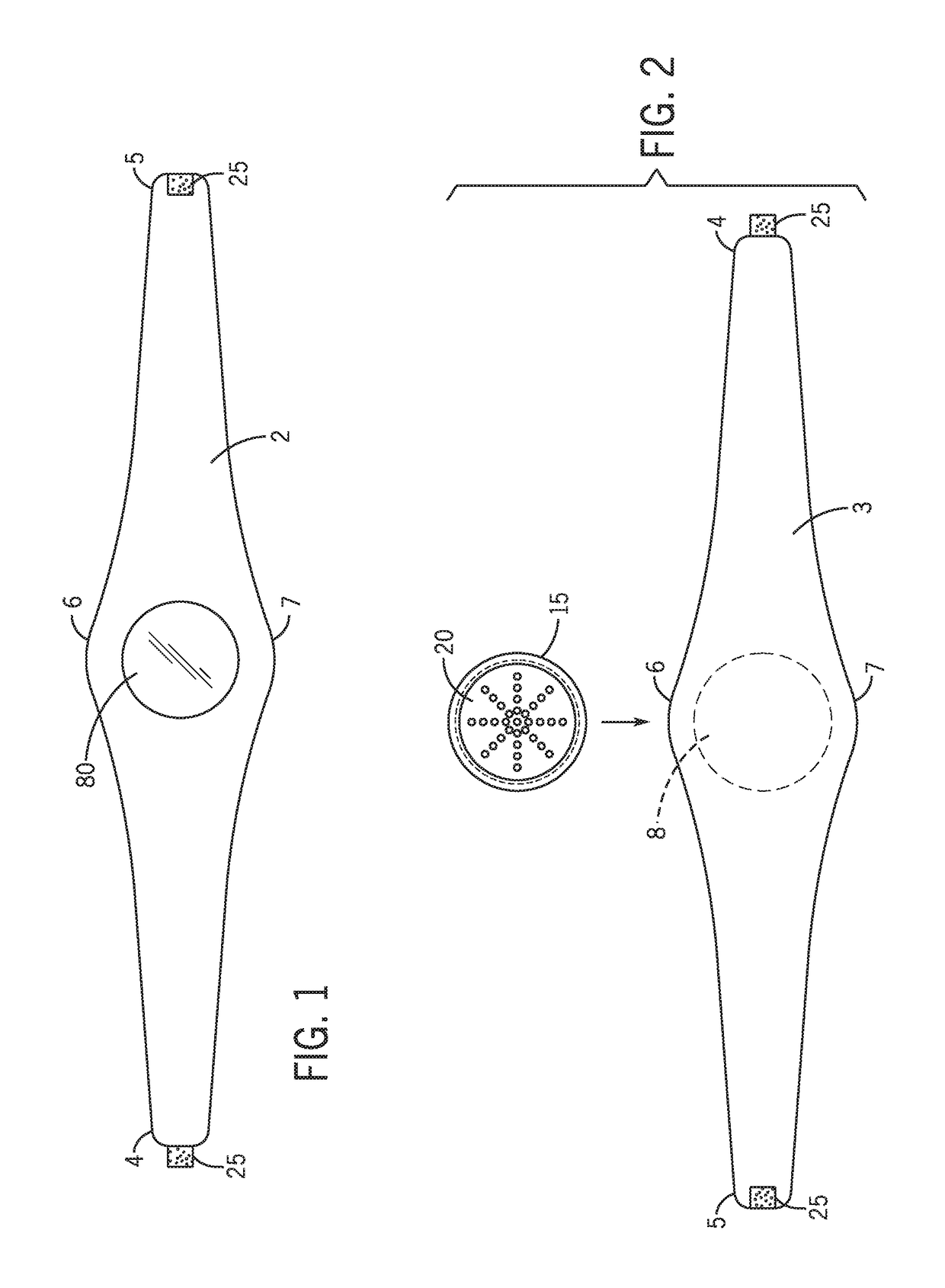

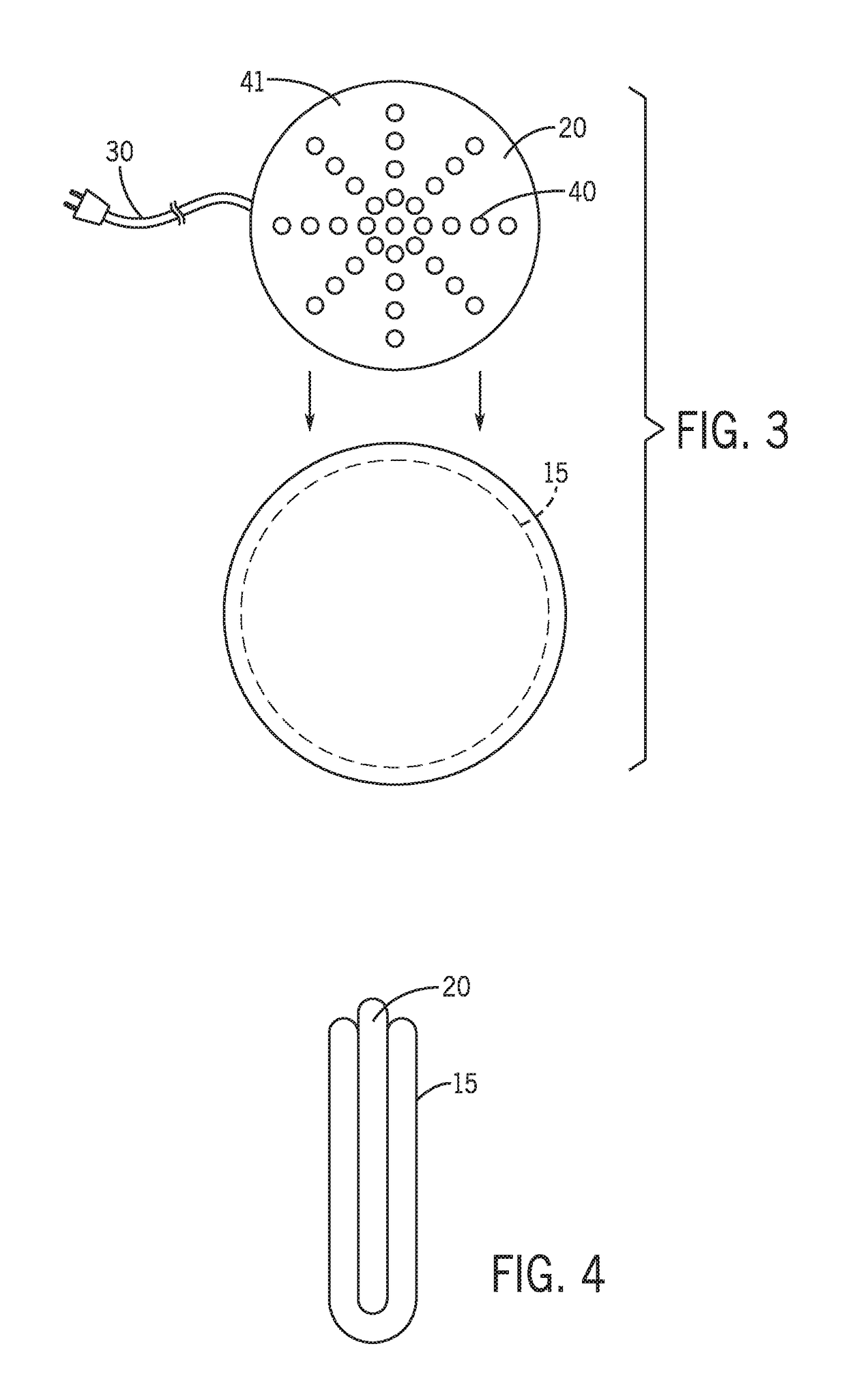

Photonic Wearable Apparatus Light Therapy Delivery System and Control System

InactiveUS20160367834A1Increase surface areaArea maximizationLight therapyHealth benefitsLight-emitting diode

A photonic apparatus made from a stretchable and flexible material is provided. The apparatus may be a garment is especially suitable for wearing around, for example, the torso of a person. The garment provides a wearer with light therapy within a specific wavelength range, which replicates the beneficial natural light of the sun therein providing health benefits which may include treatment of various medical conditions. The garment may take the form of a blanket, wrap, belt, cape, vest, hood, cap, headband, shirt or the like. The light source may include light emitting diodes (LEDs), optical fibers or solid state light emitting chips, which may be contained in a removable light transmitting pouch within the interior of the apparatus, so that the light may be powered by an internal power source to provide freedom of movement during treatment. In an embodiment, the light source is housed within the pouch wherein the pouch itself may be removed from the interior of the apparatus to be charged and replaced in the apparatus for wireless treatment use.

Owner:MEDISUN ORTHO LLC

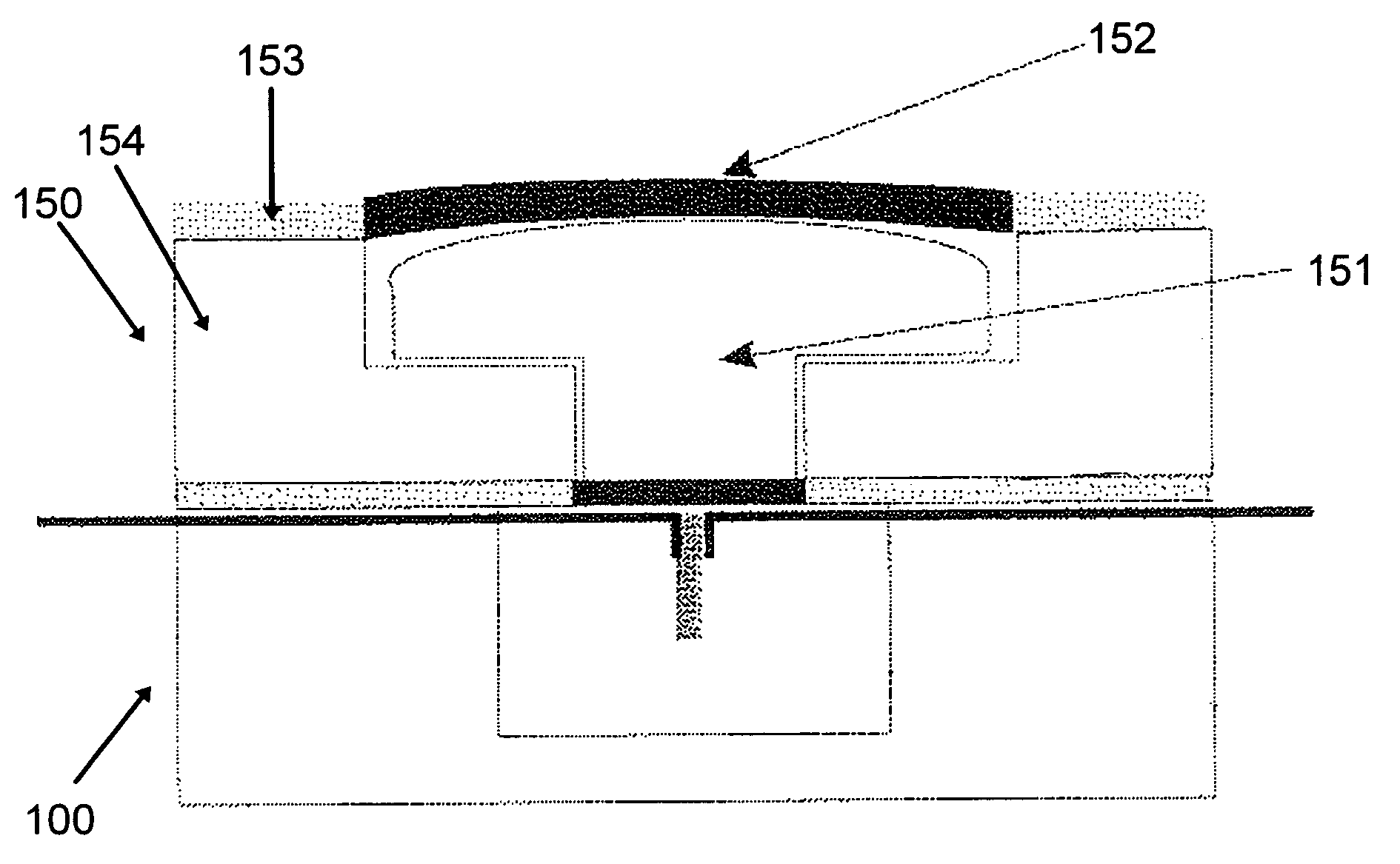

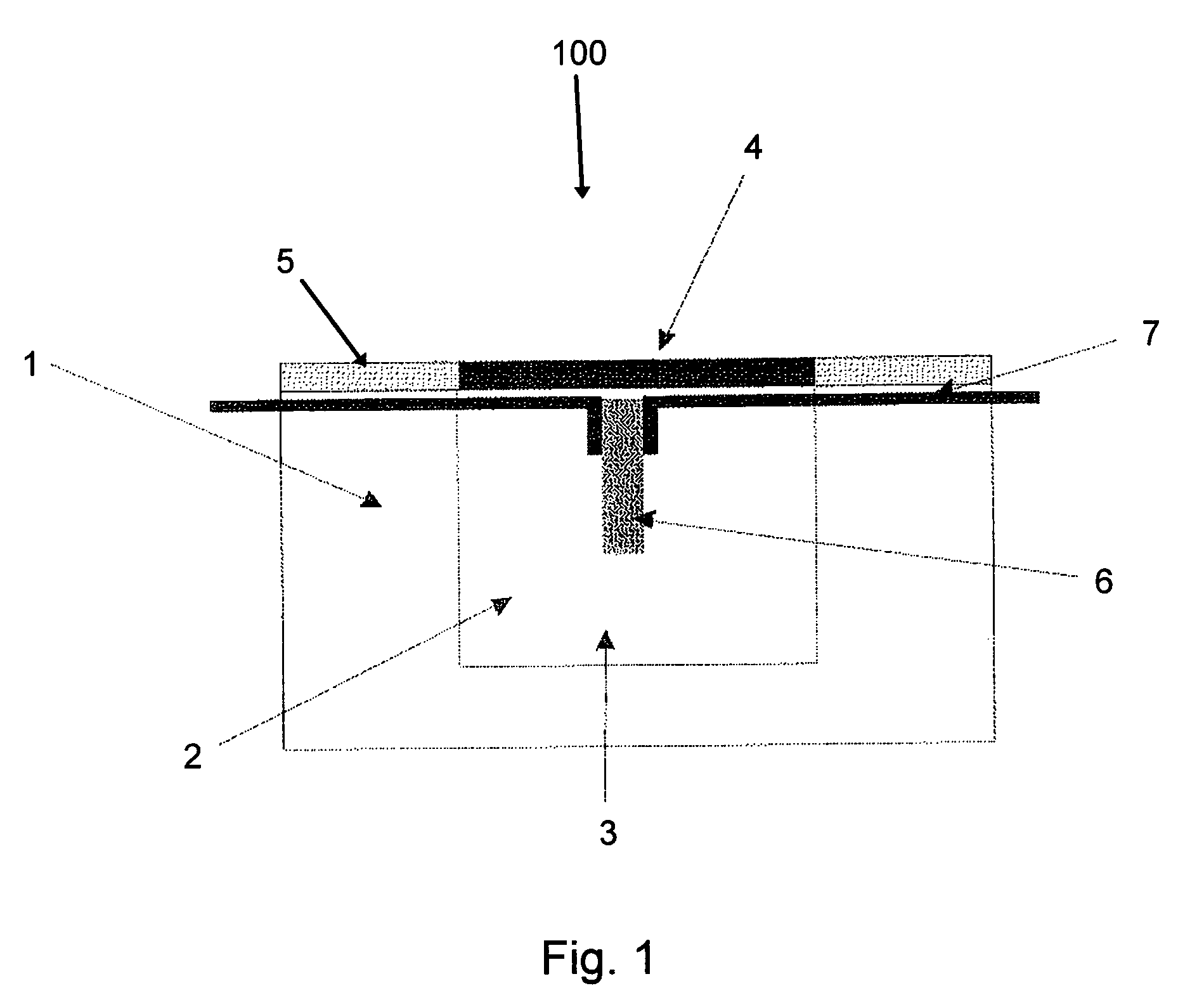

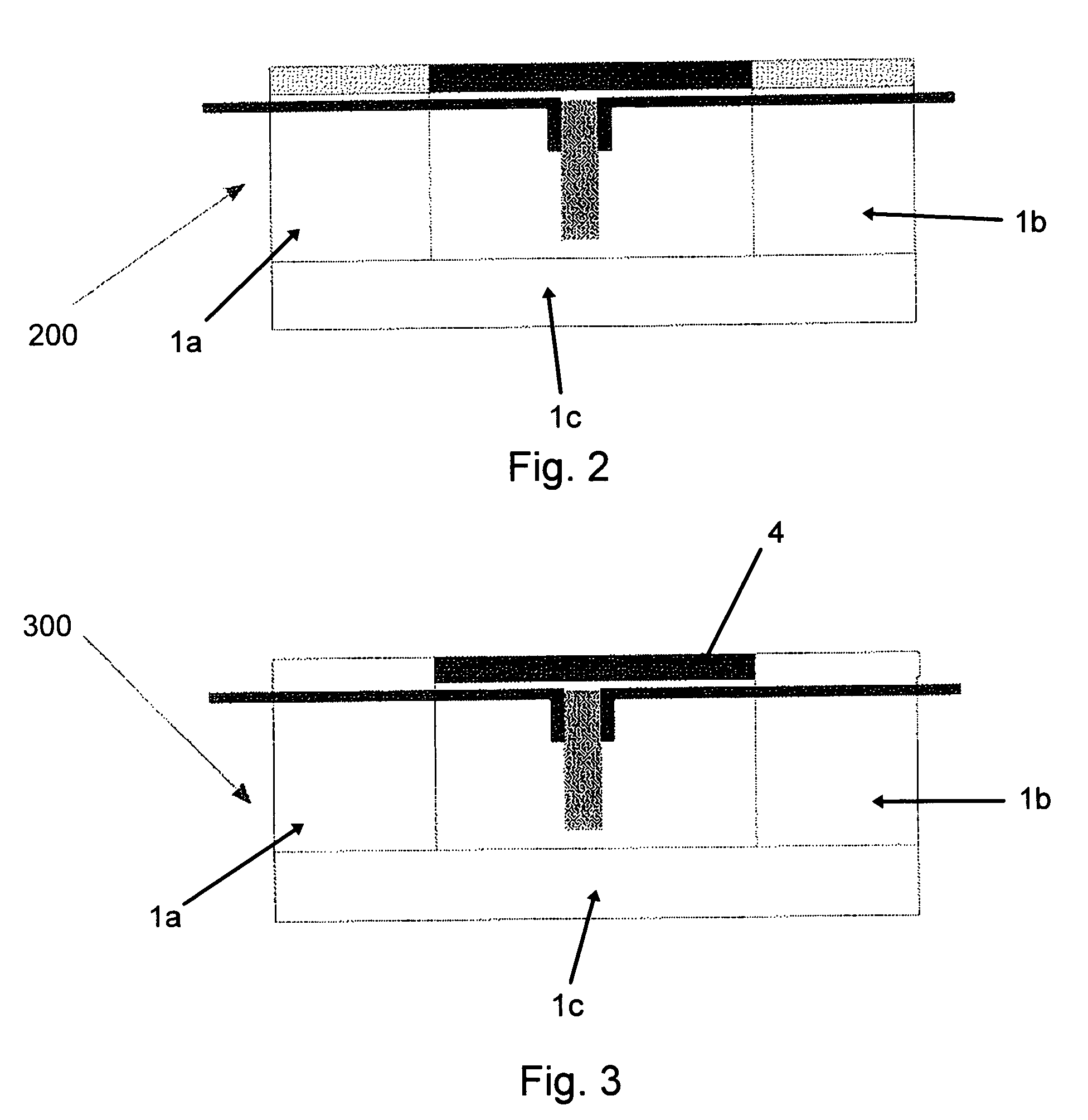

Wax Micro Actuator

ActiveUS20100145272A1Improve controlThermally efficientFlexible member pumpsWorking fluid for enginesWaxMicro actuator

An actuator comprises a cavity containing a working medium that reversibly expands as it undergoes a phase change from a solid to a liquid state, a diaphragm disposed adjacent the cavity such that expansion and contraction of the expandable working medium causes the diaphragm to deflect, and a semiconductor element disposed in the cavity, wherein the semiconductor element is adapted to heat the working medium to cause it to undergo the phase change into the liquid state. The actuator may be used in a pump for an infusion system.

Owner:INSULET NETHERLANDS BV

Pipeline for carrying a molten salt

ActiveUS8895901B2Reduce heat dissipationLower operating temperatureSolar heating energySolar heat devicesElectrical conductorMolten salt

The invention relates to a pipeline for carrying a molten salt, with a pipe wall that is stable with respect to the temperatures occurring. A heating conductor (21) is provided inside the pipeline (5) for heating, the heating conductor (21) preferably not lying against the inner wall of the pipeline (5).

Owner:BASF AG

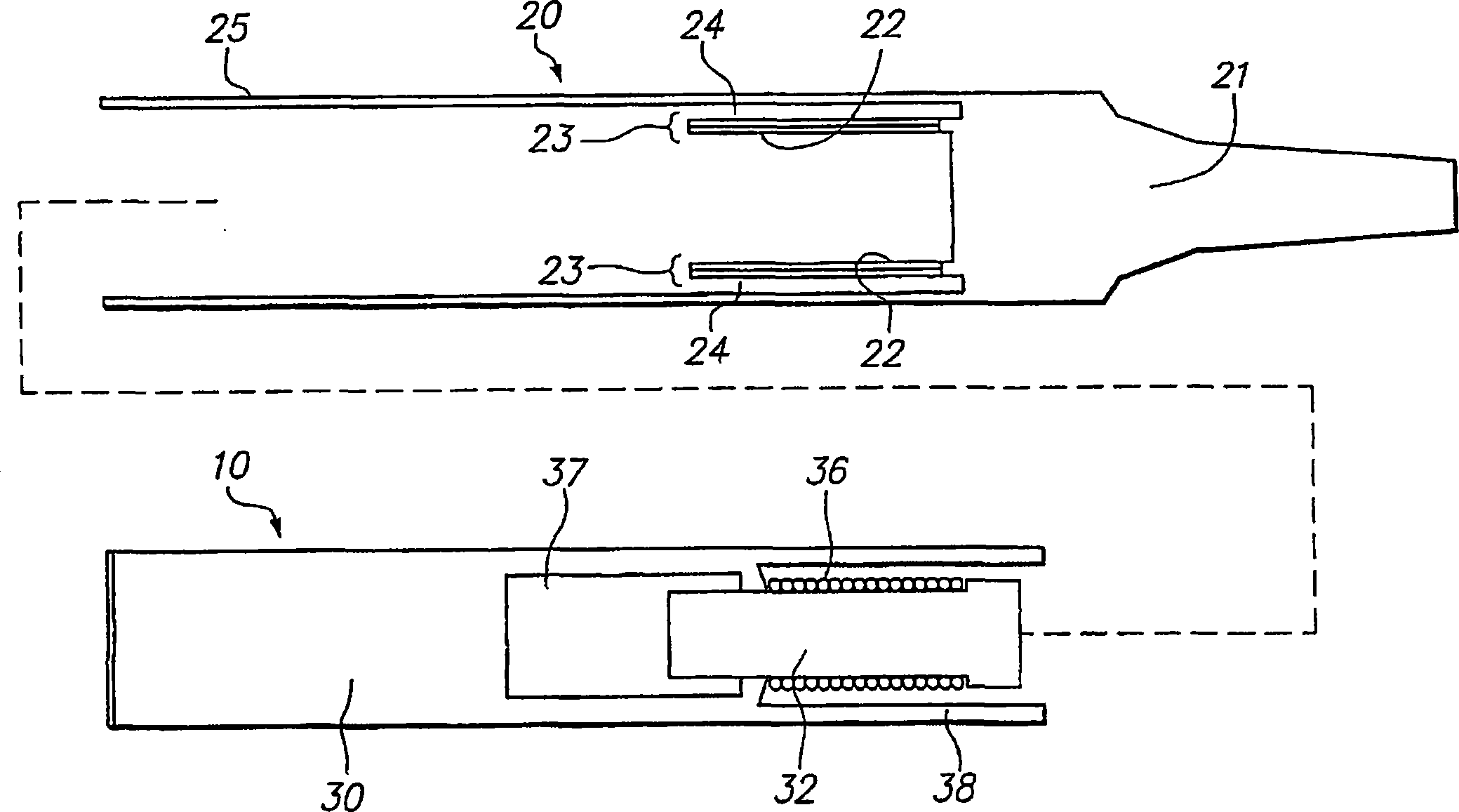

Temperature self-regulating soldering iron with removable tip

ActiveCN1894069AEasy to disassembleFor quick replacementHeating appliancesSoldering ironBobbinEngineering

A soldering iron (10) with a detachable tip (20), comprising: a soldering iron (10) comprising: a shaft (30); a ferrite bobbin (32) positioned on the shaft (30); wound on a magnetic coil (36) around a ferrite bobbin (32); and a removable tip (20) with a heating element (23) located thereon, wherein the heating element (23) is sized to be When the tip (20) is on the soldering iron (10), it fits around the magnetic coil (36).

Owner:OK INT

Acoustically and thermally insulated galley shell

ActiveUS9868530B2Easy to installEfficiently and economically meet its target temperatureGalleysLayered productsHeat lossesFace sheet

Owner:BE AEROSPACE INCORPORATED

Forming tool apparatus for hot stretch-forming processes

ActiveUS7066000B2Reduce heat lossImprove thermal efficiencyShaping toolsThermal insulationEngineering

A tooling assembly for hot stretch-forming of a sheet metal workpiece. A forming tool is attached to a plate and includes a shell having a forming surface, and support walls that extend away from the shell, that terminate in a rearward surface of the forming tool, and that define open cells between the support walls. Heating elements are embedded within the forming tool for integral and uniform heating thereof. To limit conductive thermal losses from the forming surface, through the forming tool, and to the plate and surrounding environment, the open cells are provided in the forming tool and insulative support posts are disposed between the forming tool and the plate within deep counterbores in the rearward surface of the forming tool. To limit radiative and convective thermal losses, thermal insulation is disposed within the cells and between the forming tool and plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Photonic wearable apparatus light therapy delivery system and control system

Owner:MEDISUN ORTHO LLC

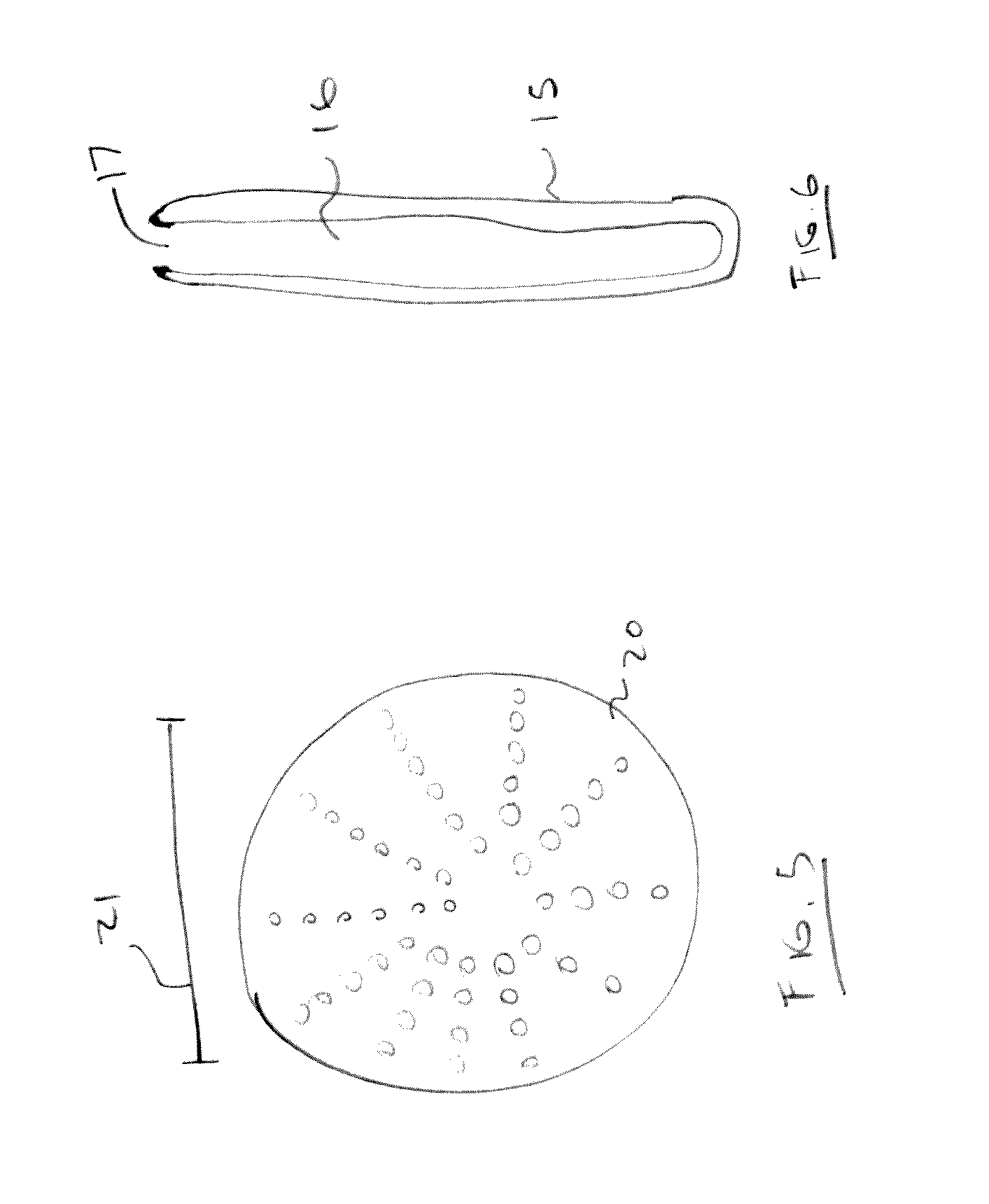

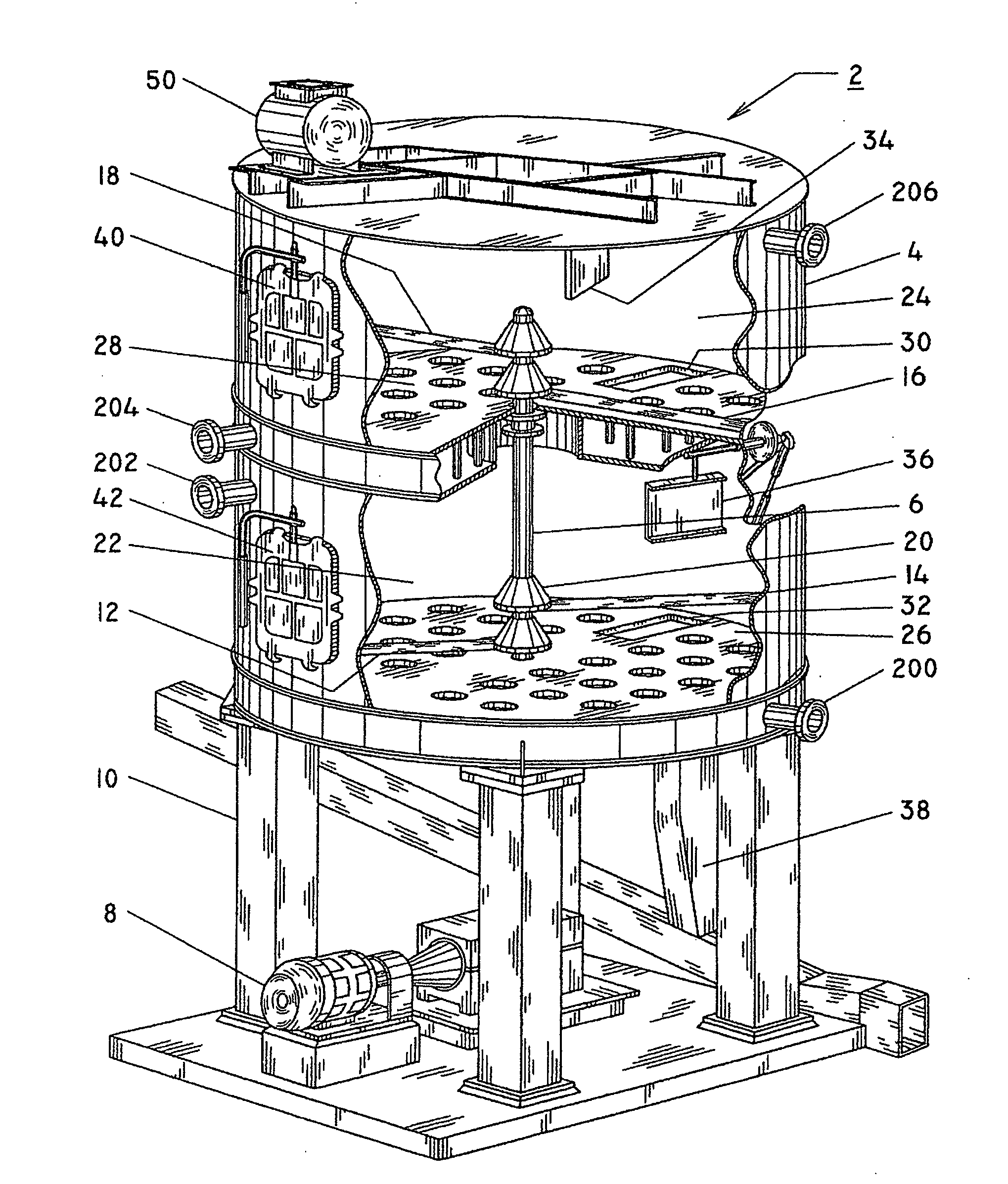

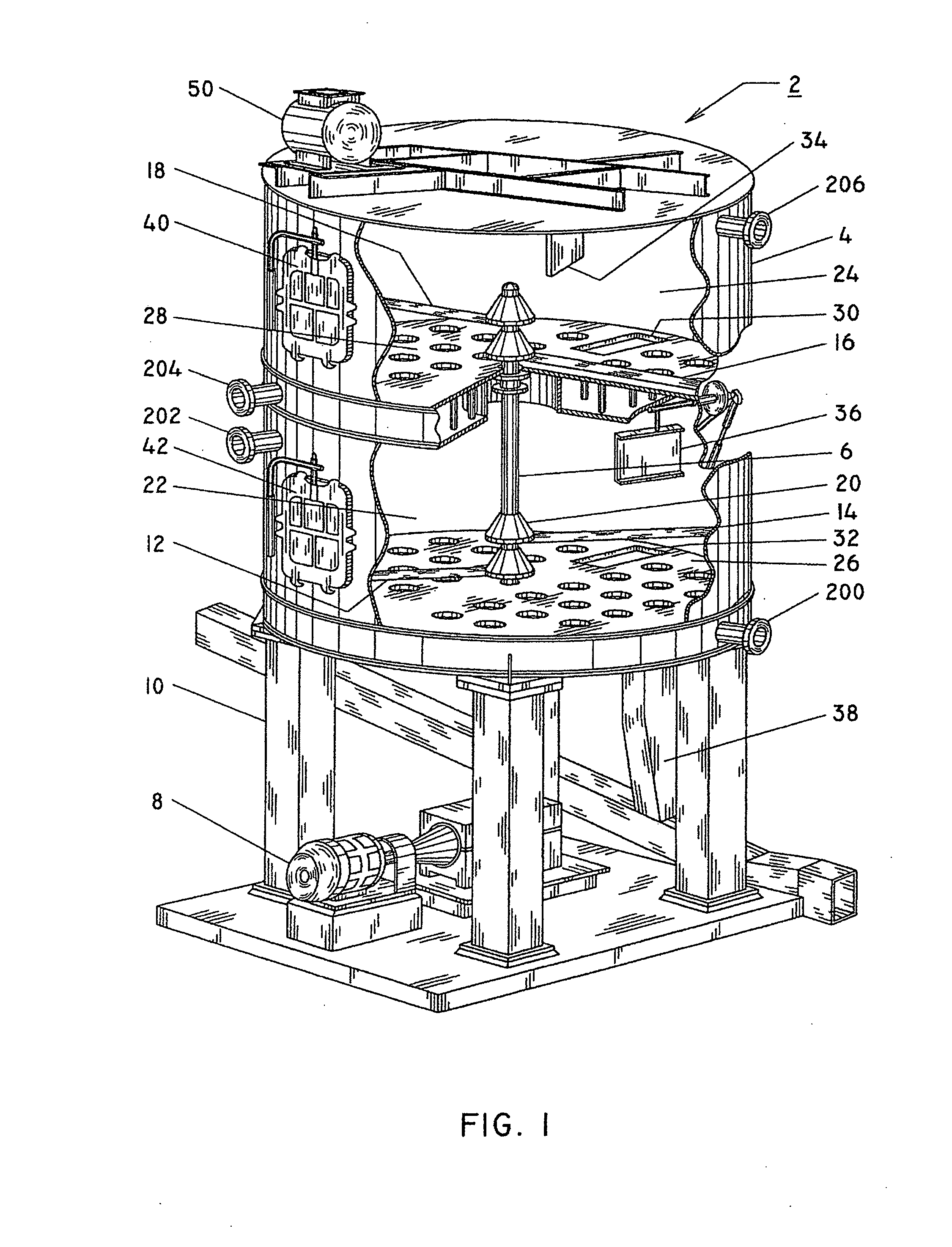

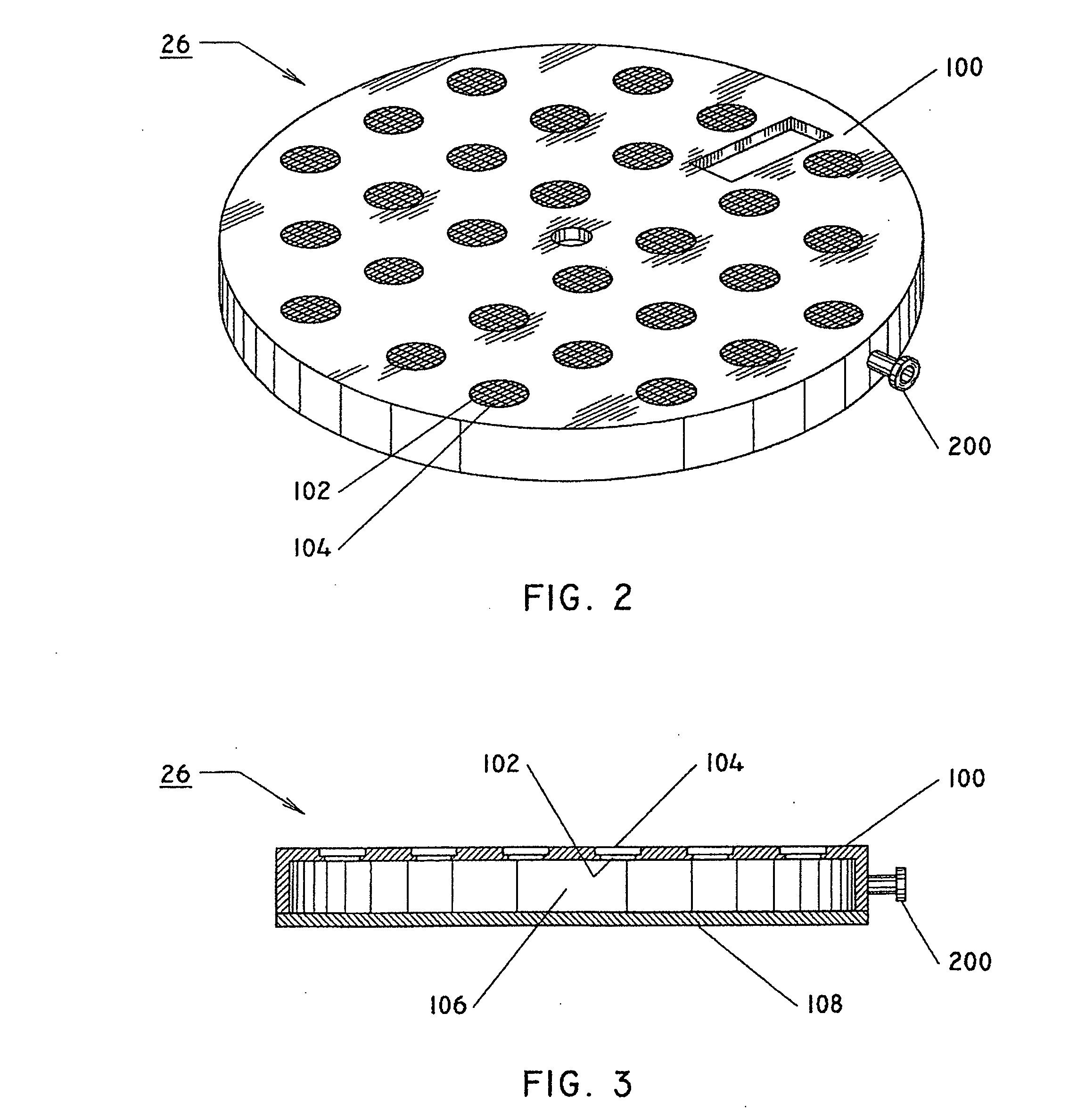

Meal dryer/cooler

InactiveUS20100088923A1Maintain thermal efficiencyThermally efficientDrying using combination processesDrying machinesVegetable matterChiller

Dryer / cooler (2) for oil bearing vegetable matter meal is provided wherein the dryer / cooler (2) has a cooling zone (22) and a drying zone (24) separated by a double bottom air plenum (28). The first surface (100) of the air plenum comprises a plurality of countersink bores (102) each receiving a slotted disc member (104) therein to provide open communication between the air plenum (26, 28) and one of the cooling or drying zones (22, 24).

Owner:DESMET BALLESTRA NORTH AMERICA INC

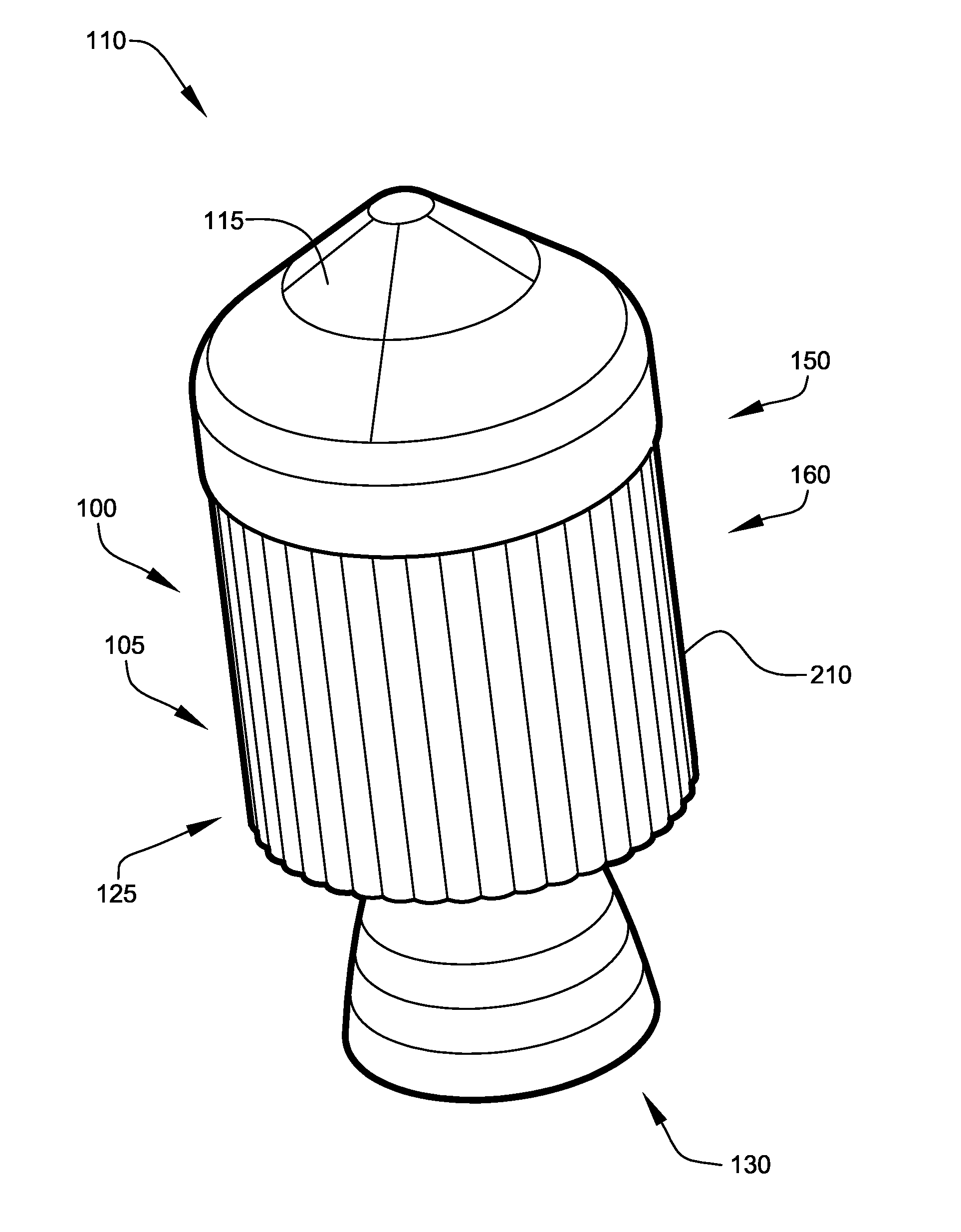

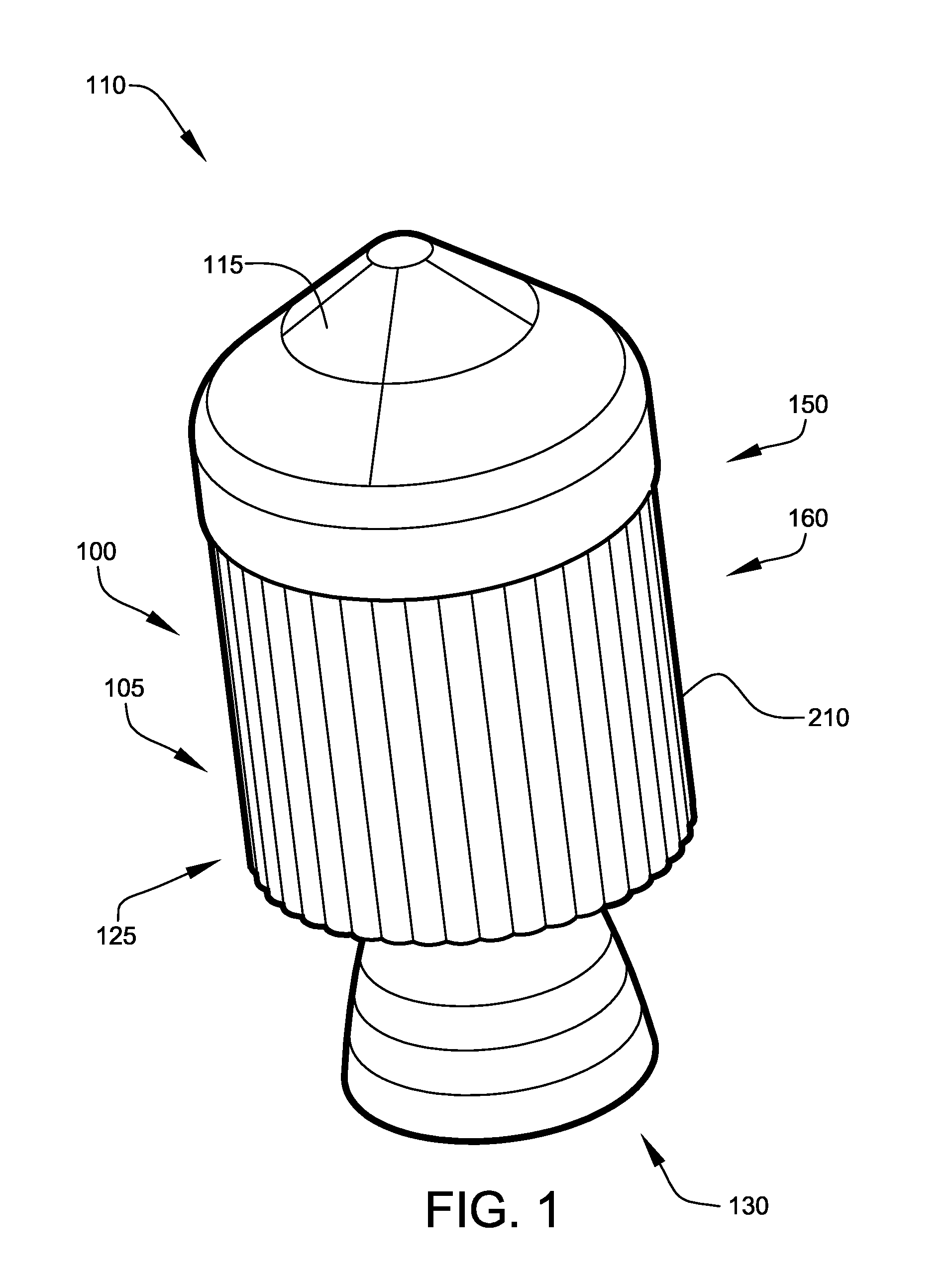

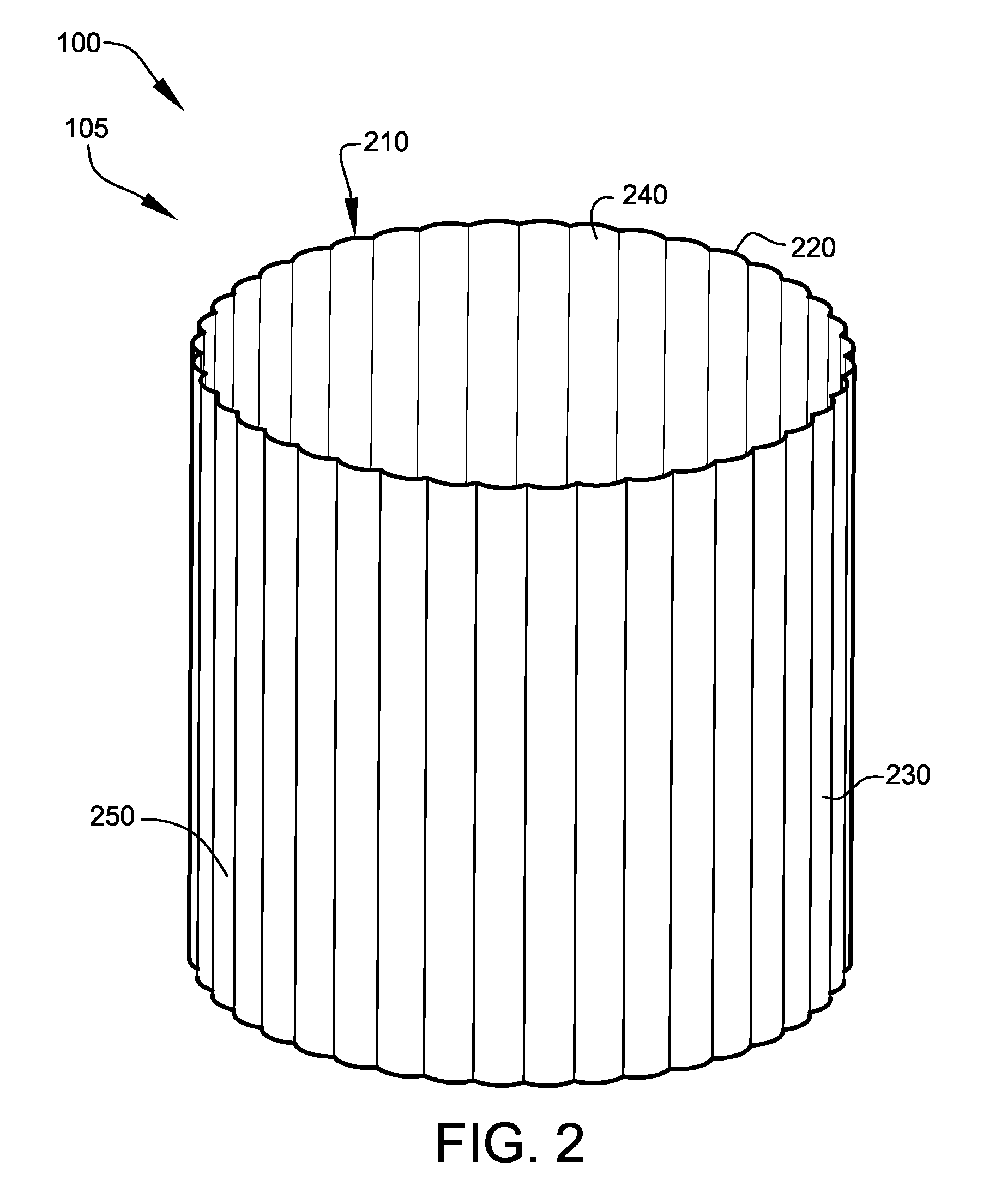

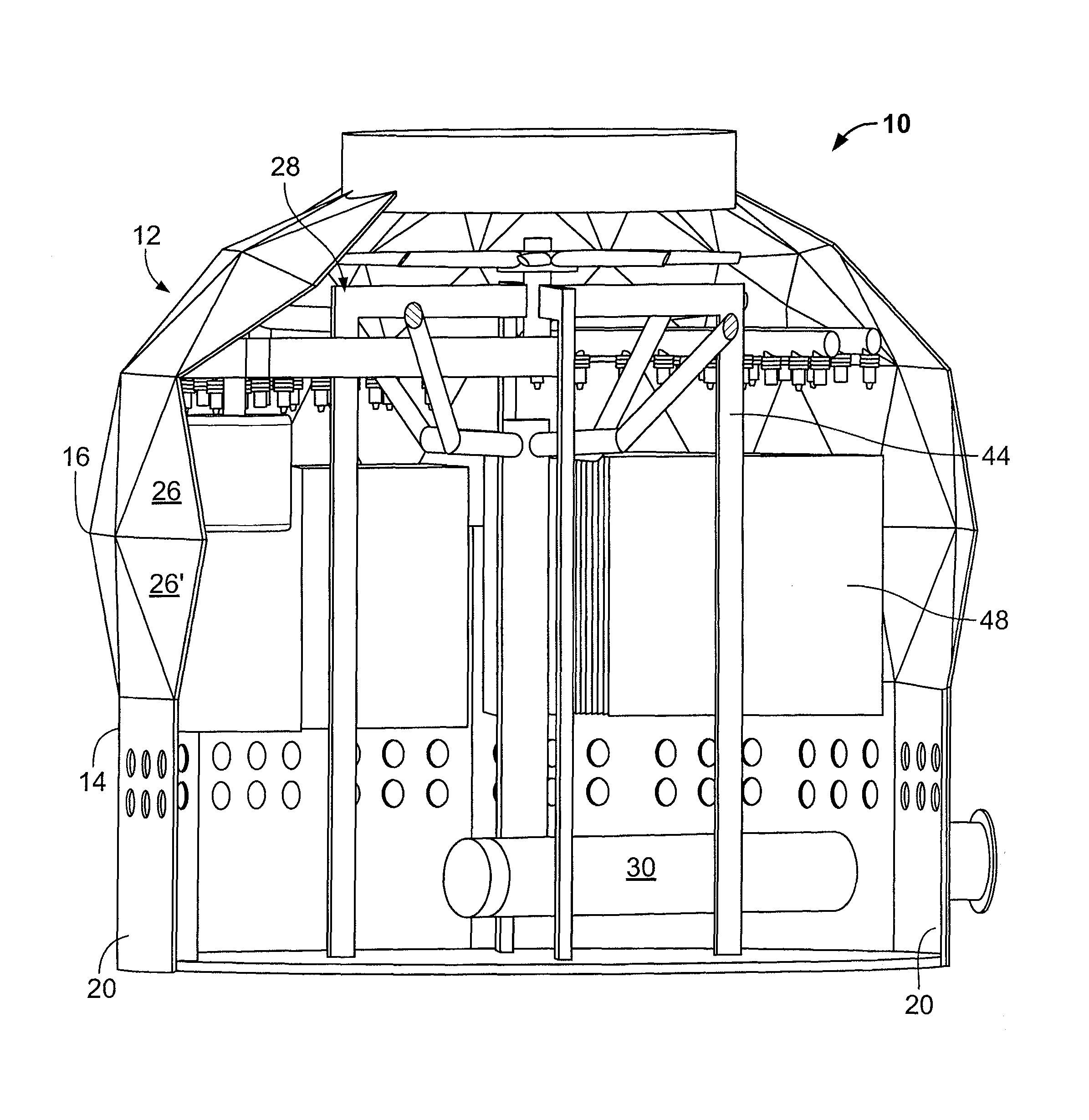

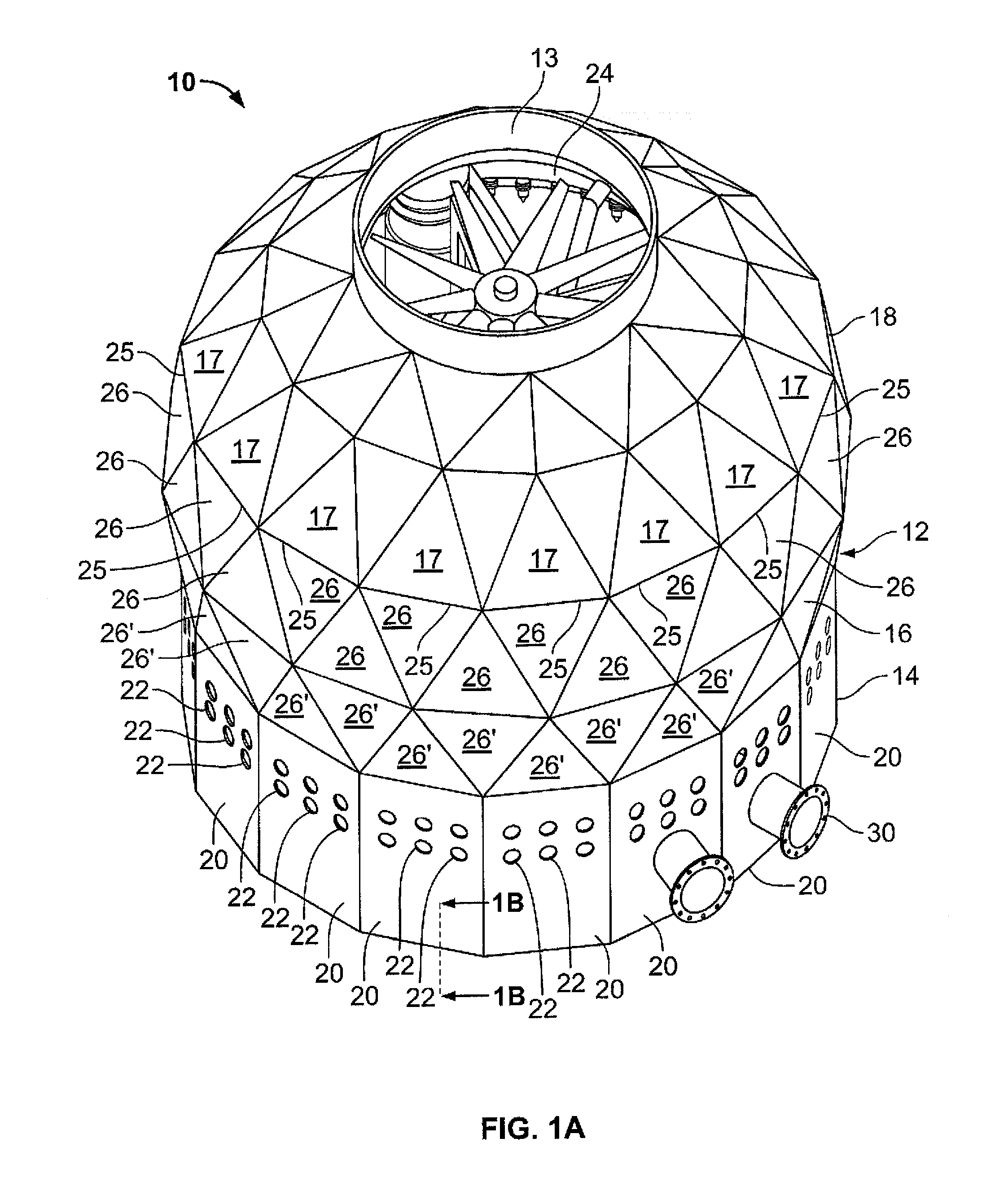

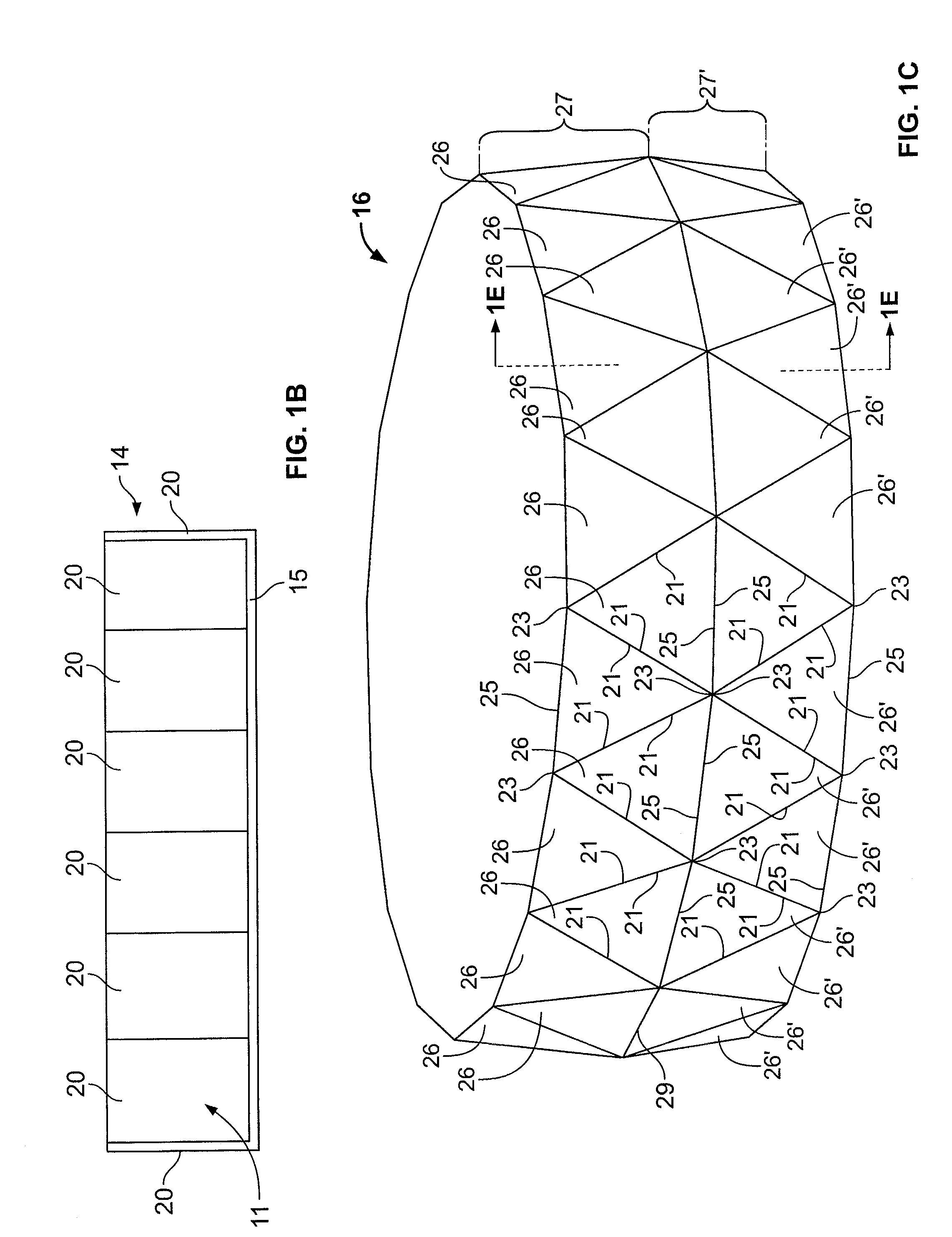

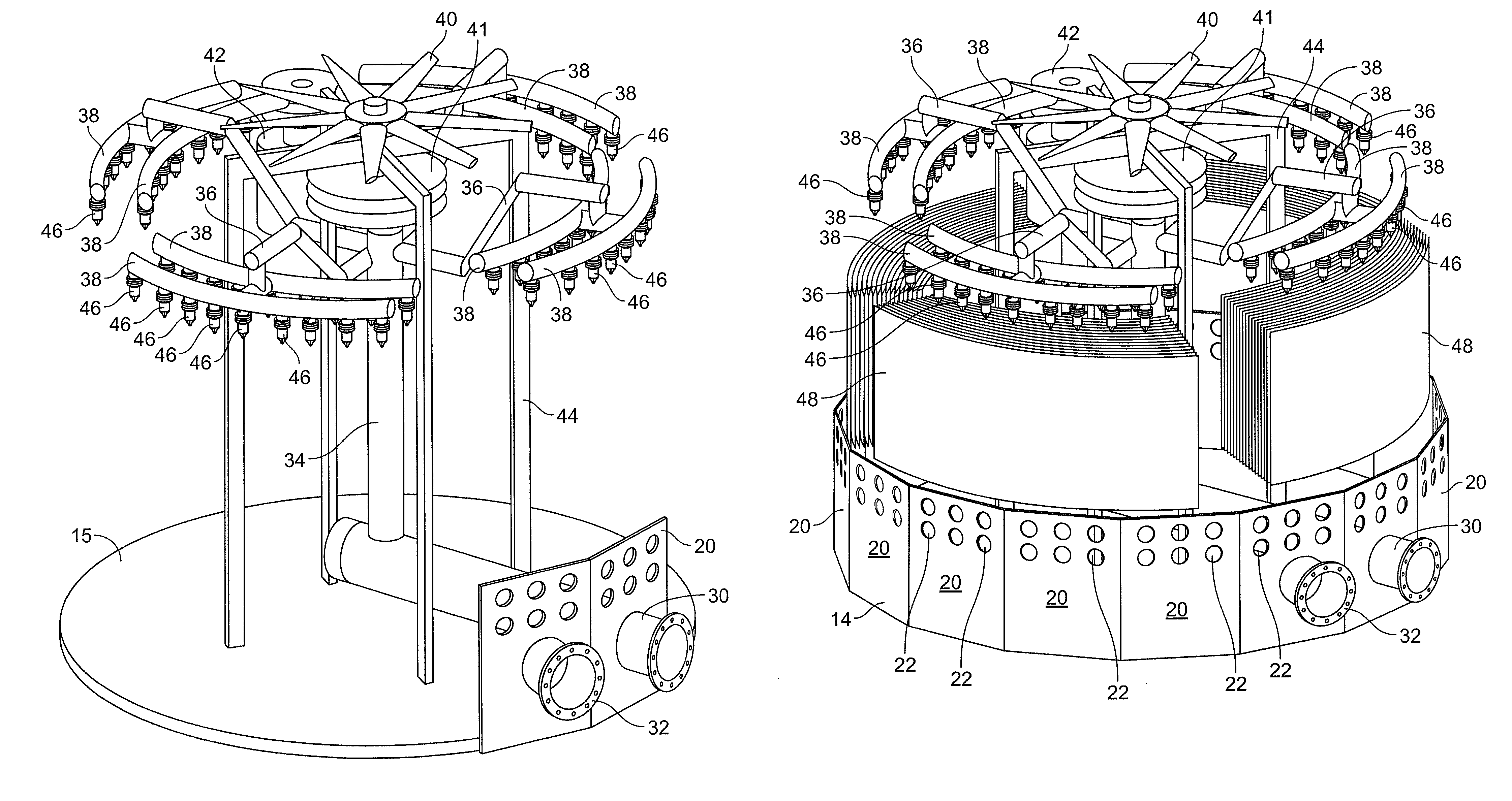

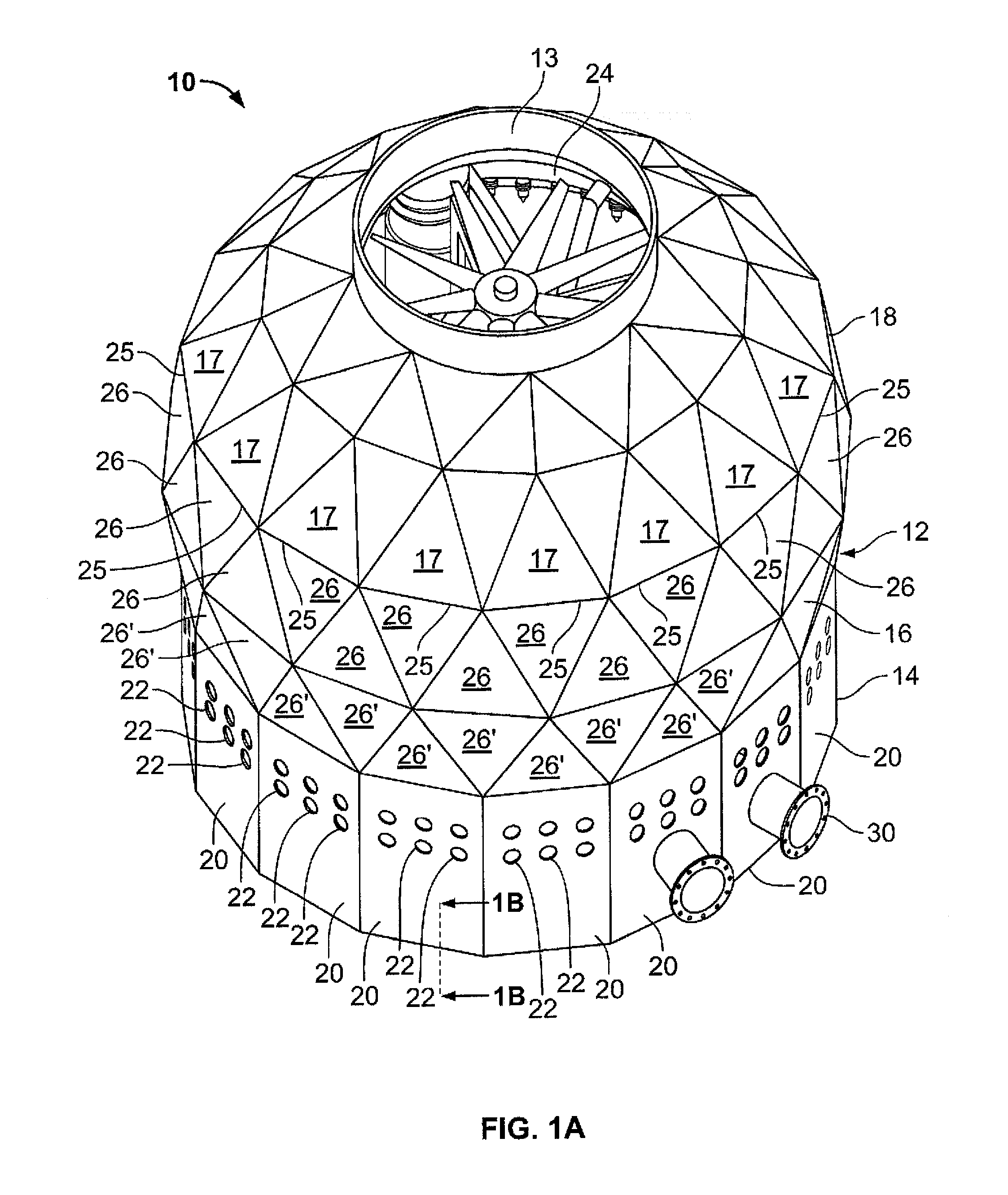

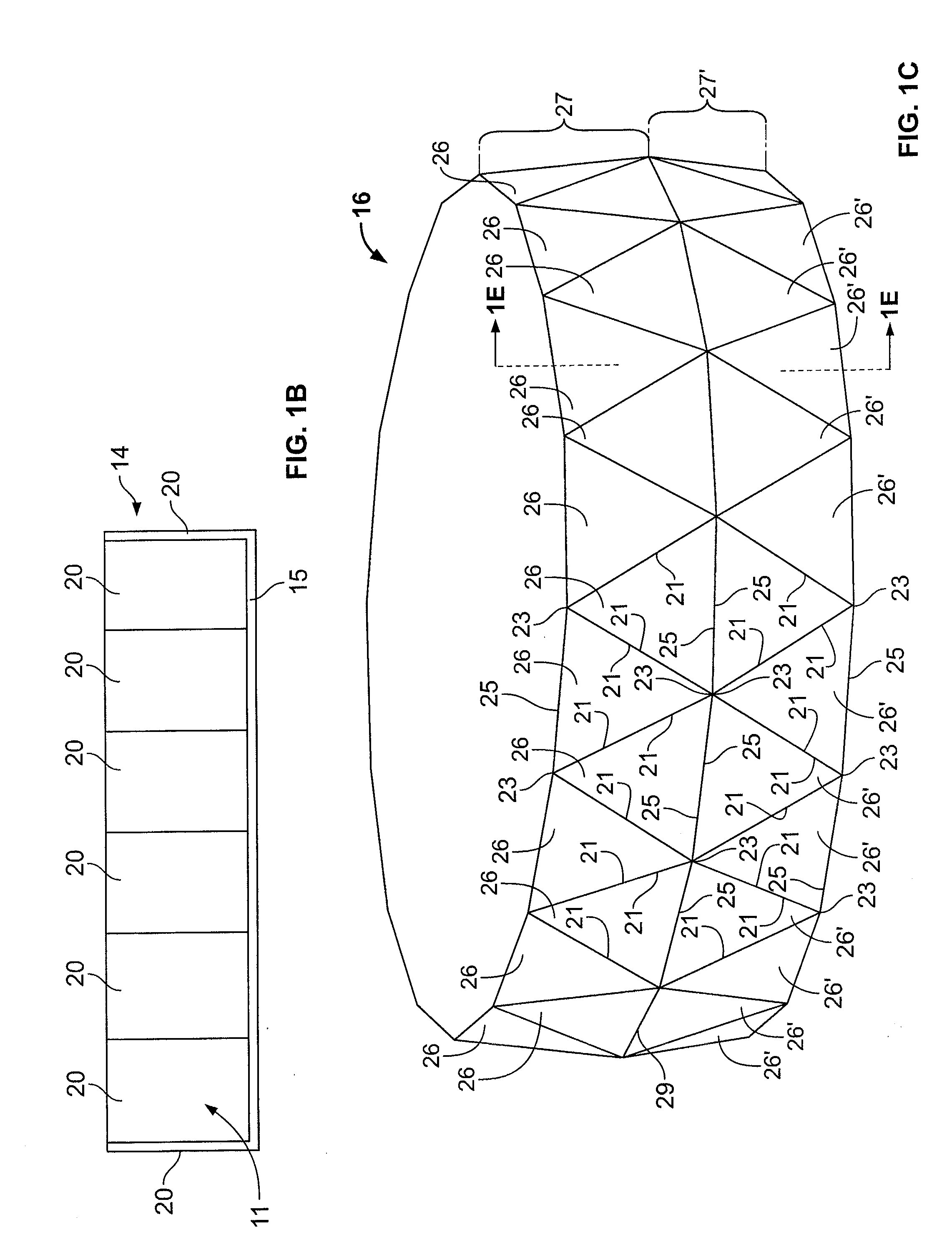

Cooling tower with geodesic shell

ActiveUS9366480B2Made lighterAppealing appearanceEfficient regulation technologiesTrickle coolersCooling towerEngineering

A cooling tower with a self-supported shell, and a cooling apparatus residing inside the shell. The shell includes a base section, a cap section and an annular wall residing between the base section and the cap section, the annular wall including a plurality of geometric bodies that are joined to one another and giving the shell a geodesic configuration.

Owner:ROSENWACH TANK CO

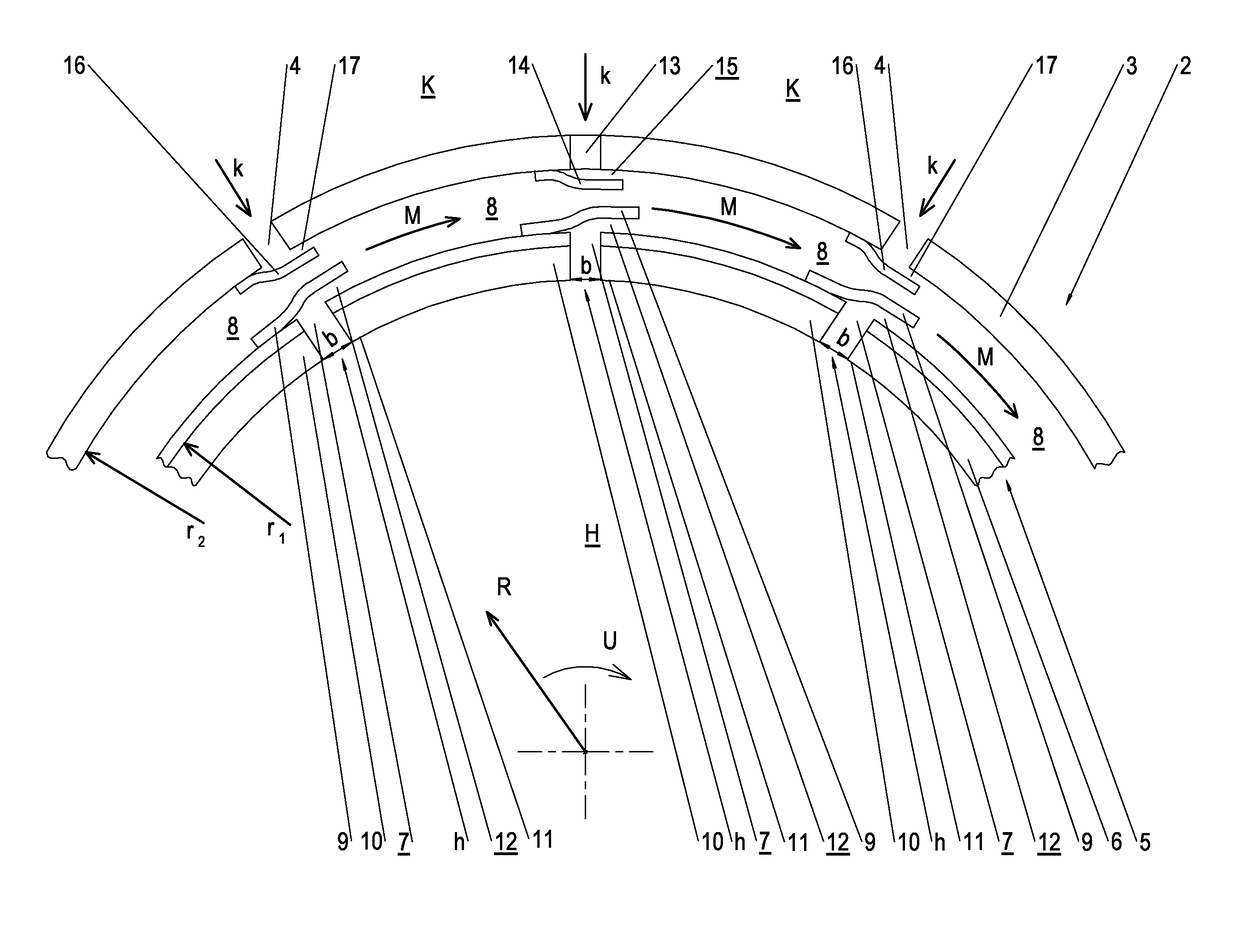

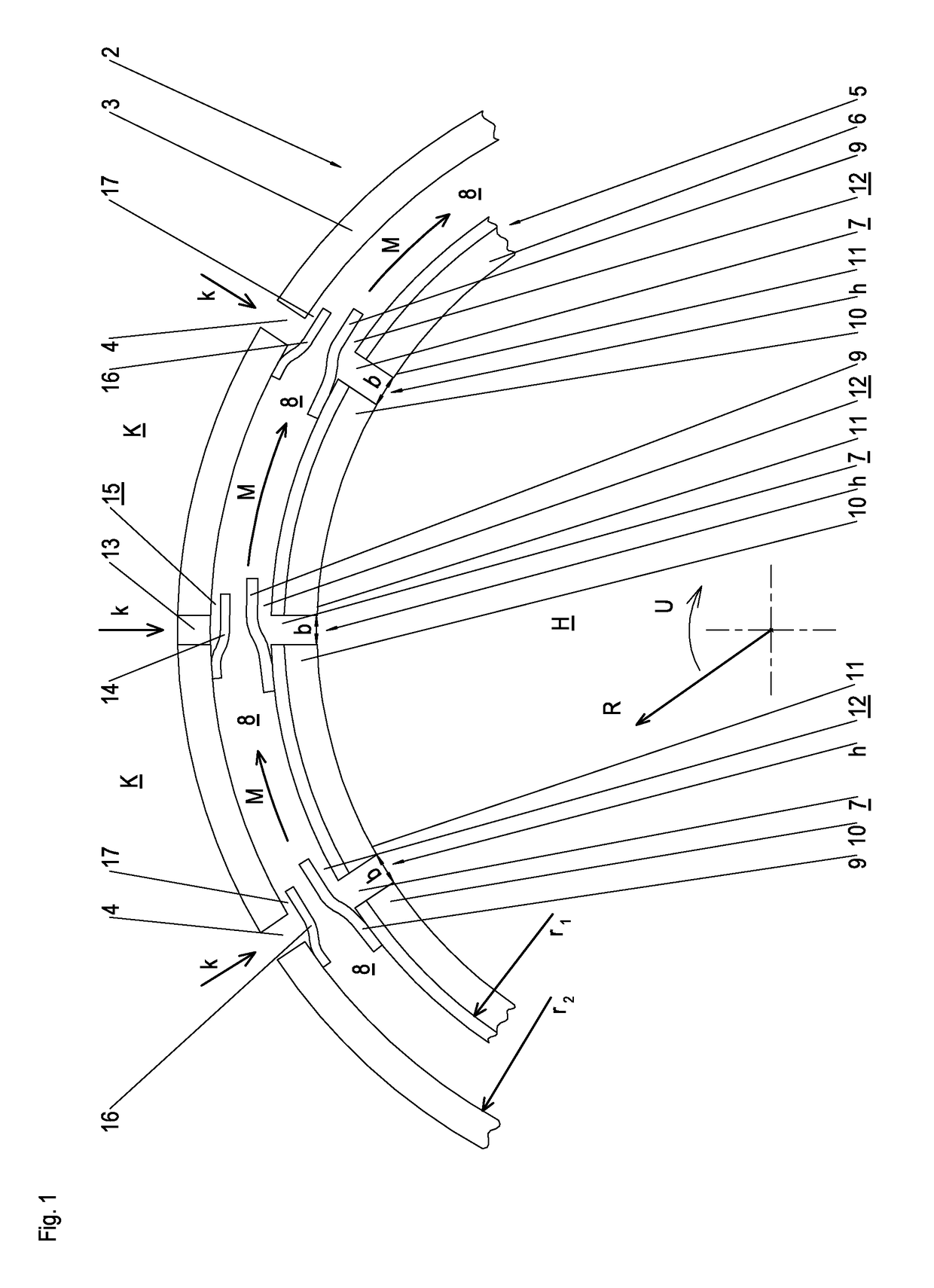

Device and method for influencing the temperatures in inner ring segments of a gas turbine

ActiveUS20170138209A1Efficient and low-loss mixingInhibits the formation of cracksGas turbine type power plantsEngine fuctionsEngineeringGas turbines

A device for influencing the temperatures in inner ring segments of a gas turbine is provided, which includes in the circumferential direction of the gas turbine, at least one outer shell assembly having a plurality of outer ring segments and at least one inner shell assembly having a plurality of inner ring segments. The inner ring segments are equal to or greater in number than the outer ring segments. An outer ring segment gap is between each two adjacent outer ring segments. An inner ring segment gap is between each two adjacent inner ring segments. An outer ring segment gap, or at least a radial cooling air passage, is located opposite each inner ring segment gap in the radial direction of the gas turbine.

Owner:MTU AERO ENGINES GMBH

Chilled vehicle fuel storage tank

ActiveUS20160039279A1Improve thermal efficiencyReduce heat transferLighting and heating apparatusUnderstructuresCombustionExternal combustion engine

A method and system for cooling the fuel contained in the fuel storage tank of motor vehicles using internal combustion engines. The method and system uses tubing in intimate contact with the exterior of the fuel tank to cool the fuel tank. The method and system may optionally employ an insulating wrap or shell to improve thermal efficiency.

Owner:BILLS ANTWANETTE +1

Insulated fiber reinforced door panel and method of making same

ActiveUS10151137B2Reduce quality problemsImproves Structural IntegrityDomestic articlesDoor leavesEngineeringPolycarbonate

An insulated door panel comprises a shell having spaced first and second exterior panels and frame members adjacent edges of the panels, a plurality of stiffeners in a shell interior portion extending along a length or width of the panels, and a hardenable insulation material creating a bond between the exterior panels, stiffeners, and frame members in the shell interior portion. The stiffeners comprise a thermally non-conductive fiber reinforced polymer. The hardenable insulation fills substantially all of the space between the adjacent exterior panels, stiffeners, and frame members. The door panel also comprises end cap members composed of thermoplastic polycarbonate material, and has openings therein to receive the ends of the stiffeners.

Owner:AADG INC

Chilled vehicle fuel storage tank

ActiveUS9493051B2Improve thermal conductivityProtection from damageAir-treating devicesUnderstructuresMobile vehicleCombustion

A method and system for cooling the fuel contained in the fuel storage tank of motor vehicles using internal combustion engines. The method and system uses tubing in intimate contact with the exterior of the fuel tank to cool the fuel tank. The method and system may optionally employ an insulating wrap or shell to improve thermal efficiency.

Owner:BILLS ANTWANETTE +1

Cooling tower with geodesic shell

ActiveUS20150176908A1Made lighterAppealing appearanceCarburetting airUsing liquid separation agentEngineeringMechanical engineering

A cooling tower with a self-supported shell, and a cooling apparatus residing inside the shell. The shell includes a base section, a cap section and an annular wall residing between the base section and the cap section, the annular wall including a plurality of geometric bodies that are joined to one another and giving the shell a geodesic configuration.

Owner:ROSENWACH TANK CO

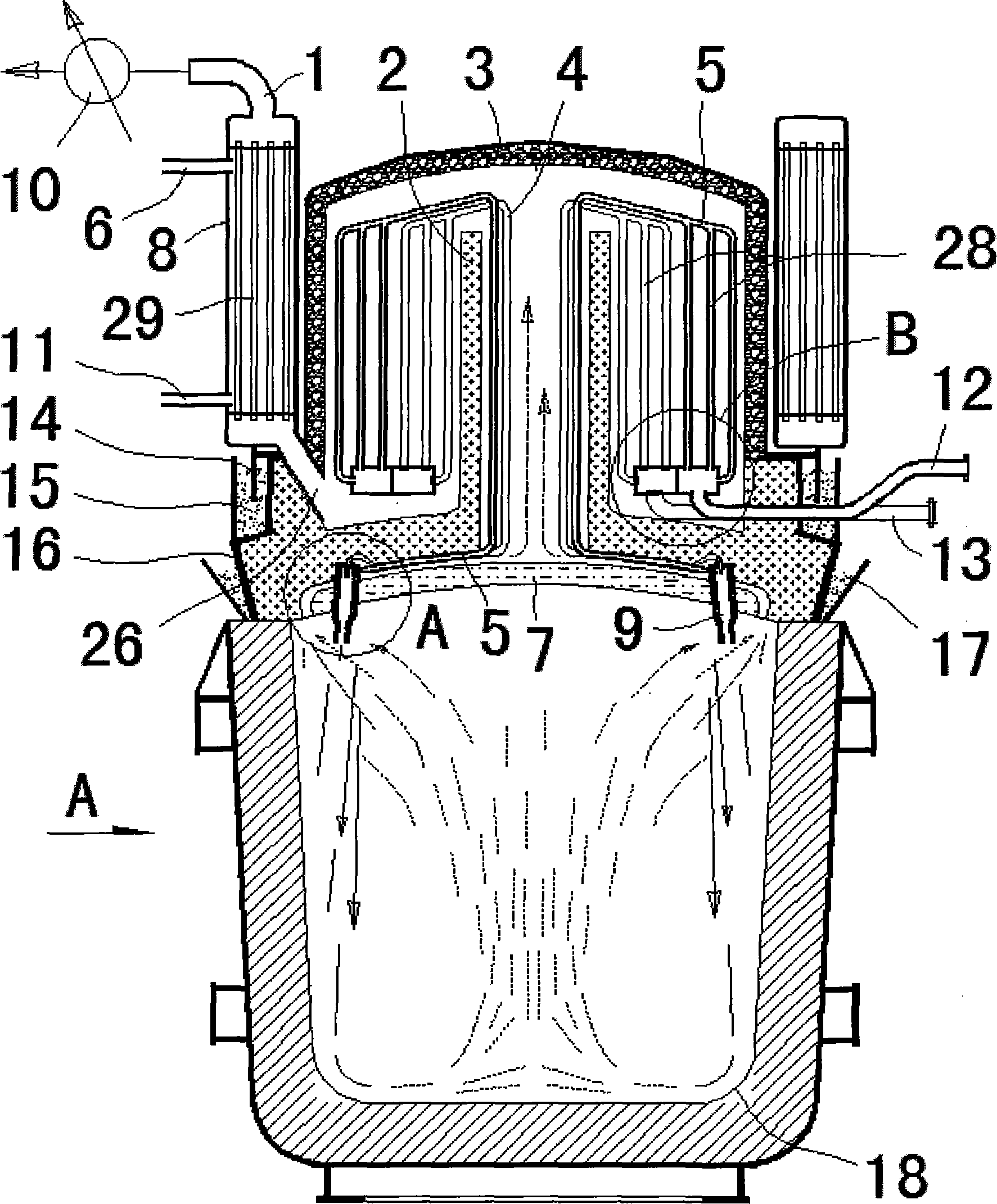

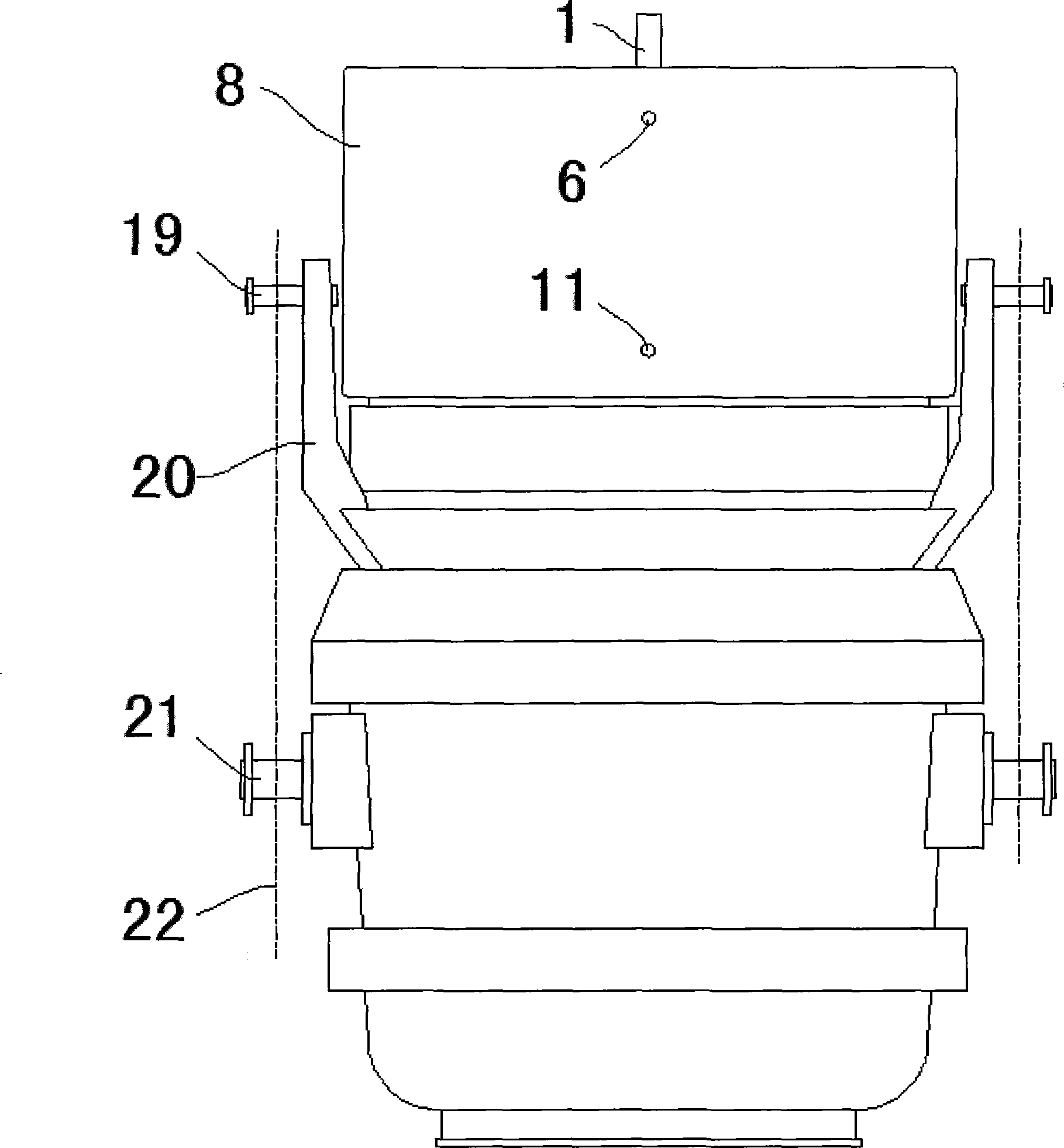

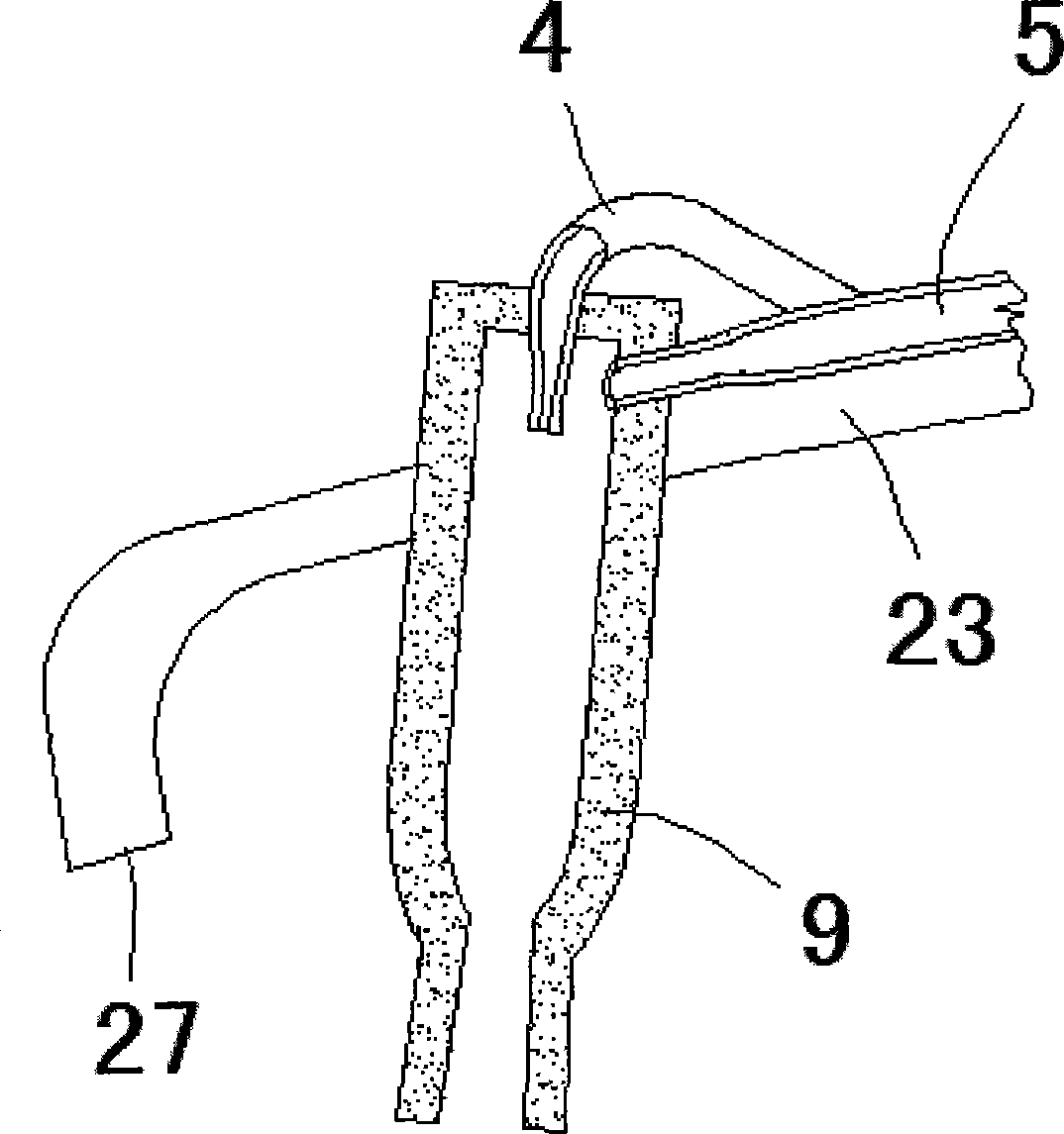

Cover for barrel roasting heat exchanging

ActiveCN104070155AIncrease the ratio of absorbed heat transferImprove temperature and energy efficiencyMelt-holding vesselsExhaust gasCombustion chamber

The invention discloses a cover for barrel roasting heat exchanging. A center hole is formed in the middle of the cover arch of the cover and is communicated with a flame path (23). The center hole is connected with a vertical flow guiding cylinder (2). Fuel gas heat exchanging pipelines (4) and hot air pipes (5) are arranged in the flow guiding cylinder (2). The heat exchanging pipelines (4) and the hot air pipes (5) are arrayed in a distributing mode to form a heat exchanging longitudinal pipe group. The number of the pipelines (4) and the number of the air pipes (5) of the heat exchanging longitudinal pipe group are the same. The lower portion of the heat exchanging longitudinal pipe group is communicated with the horizontal sections of the pipelines (4) and the air pipes (5) in the flame path (23). The horizontal section pipelines (4) and the air pipes (5) are arrayed in the flame path (23) in a radiation mode. Fluid of each pipeline (4) and each air pipe (5) in the flame path (23) is communicated with the same combustion chamber (9). Flames and smoke can go to an upper cavity through a gasification pipe (29). The upper cavity is communicated with a tail gas outlet (1). A gasification section is provided with a water replenishing opening (11). A steam outlet (6) is formed above the water replenishing opening (11), so that steam is discharged.

Owner:武安市飞翔金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com