Temperature self-regulating soldering iron with removable tip

A cutting-edge, soldering iron technology, used in soldering irons, manufacturing tools, metal processing equipment, etc., can solve problems such as tip wear, and achieve the effects of easy disassembly, good heat transfer, and consistent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

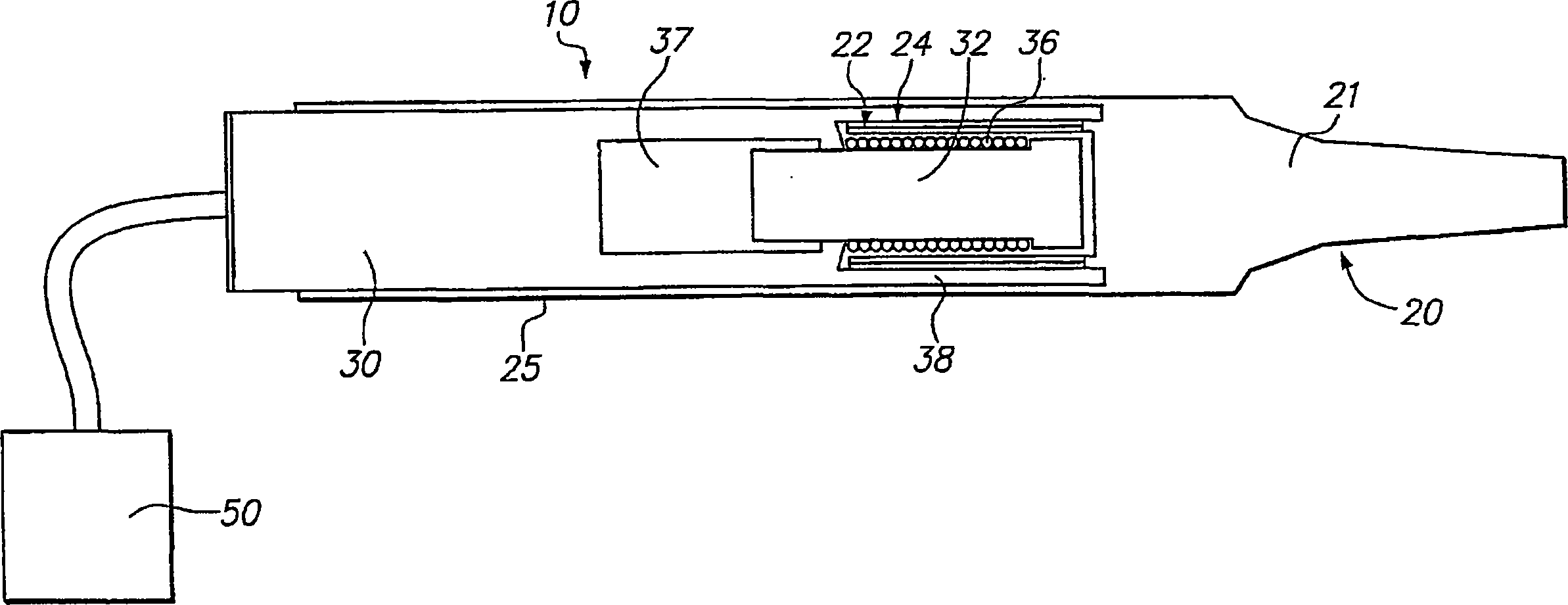

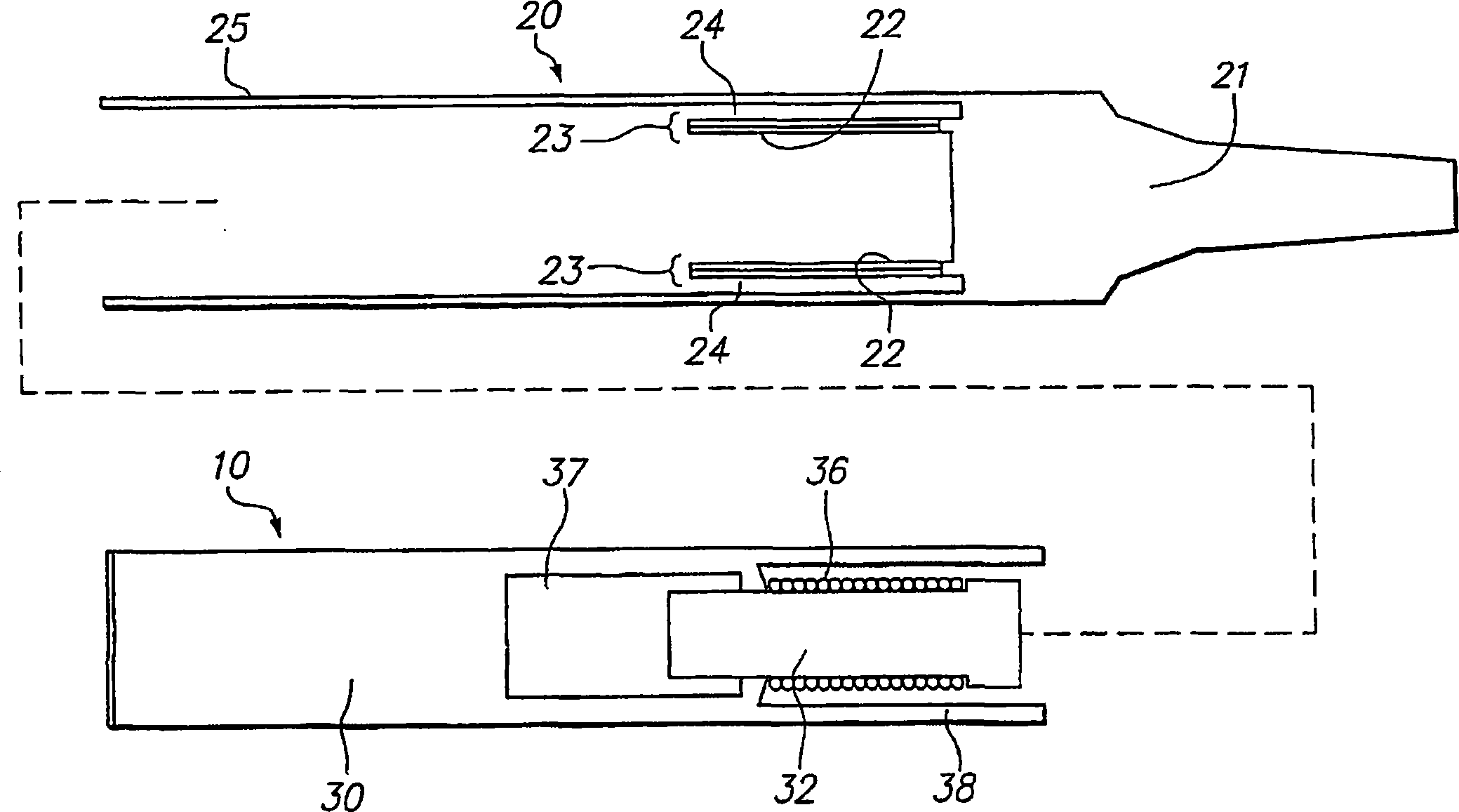

[0031] figure 1 It is an assembly drawing of a soldering iron shaft with a detachable tip located on it. figure 2 It is an exploded view with the tip removed.

[0032] The present invention provides a soldering iron 10 with a detachable tip 20. The soldering iron 10 includes a shaft 30 having a ferrite bobbin 32 mounted thereon. The magnetic coil 36 is wound around the ferrite bobbin 32.

[0033]A detachable tip 20 is also provided. The detachable tip 20 includes a main body 21 having a heating element 23 extending therefrom. Most preferably, the heating element 23 includes a cylindrical inner alloy heating layer 22 surrounding the cylindrical outer layer 24. When the detachable tip 20 is located on the soldering iron 10, the size of the heating element 23 is designed such that the inner alloy heating element 22 is accommodated around the magnetic coil 36.

[0034] By improving the magnetic circuit formed between the heating layer 22 and the magnetic coil 36, the ferrite bobbin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com