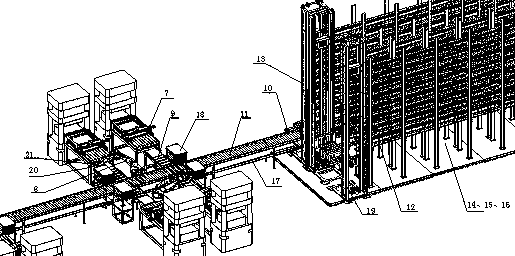

Magnetic material automated production line

A technology for automated production lines and magnetic materials, which is used in magnetic core manufacturing, inductor/transformer/magnet manufacturing, conveyor objects, etc. It can solve problems such as damage to semi-finished products, storage and scrapping of semi-finished products, and difficulty in product traceability. Product yield, effective specification and the effect of controlling product information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make a corresponding combination of features in the implementations in this document and in different implementations according to the descriptions in this document.

[0033] In this embodiment of the magnetic tile automatic production line, the functions or functions of each component are as follows:

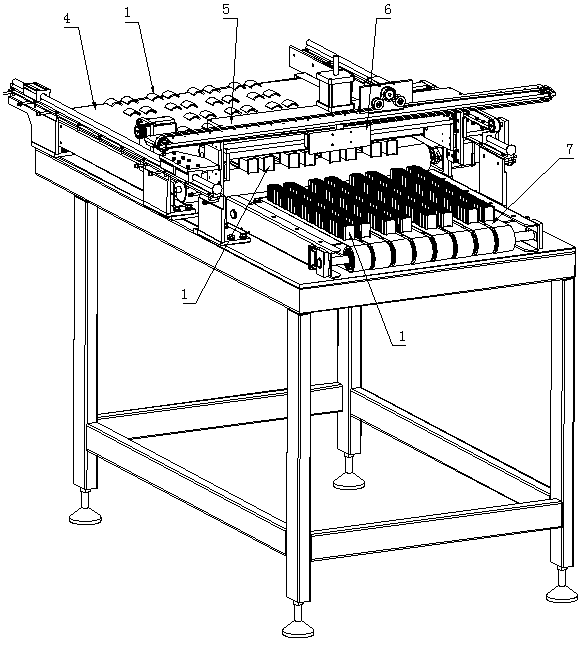

[0034] 1. Magnetic tile

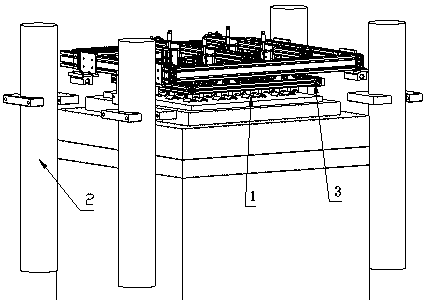

[0035] 2. Press machine, hydraulic press for pressing magnetic tiles

[0036] 3. Suction cup frame, a mechanism for sucking magnetic tiles between the upper and lower molds of the horizontal reciprocating press

[0037] 4. The platform to be inspected, the platform where the magnetic tiles are taken out from between the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com