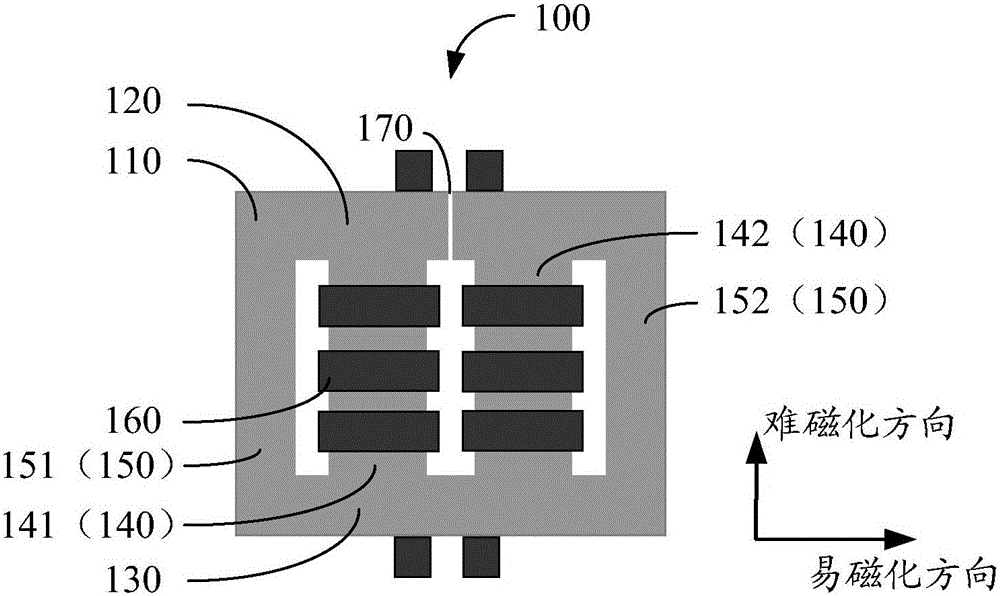

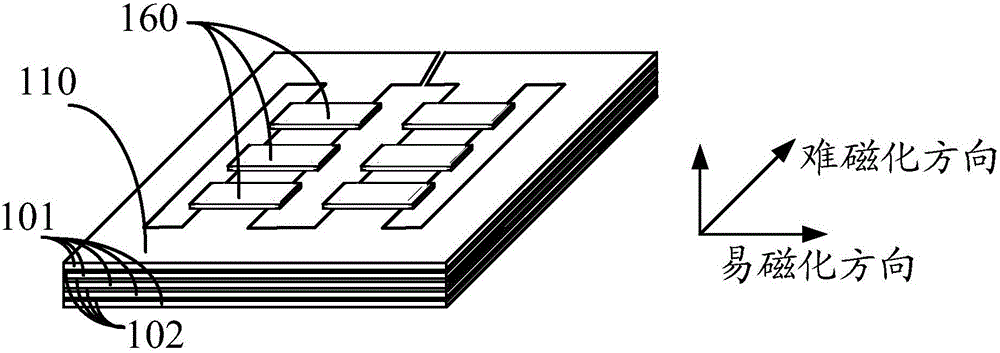

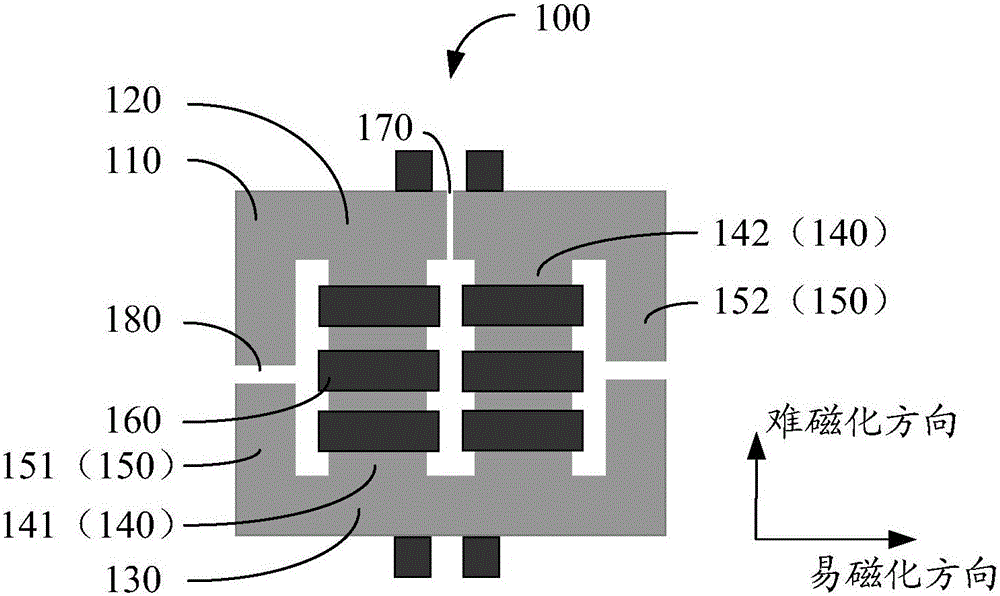

Thin film inductor and power switching circuit

A technology of thin film and inductance, which is applied in the direction of circuits, inductors, printed inductors, etc., can solve the problem of easy saturation of the magnetic core of magnetic thin film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0200] Figure 10 is a schematic flowchart of a method 900 for manufacturing a thin film inductor according to an embodiment of the present invention. Such as Figure 10 As shown, the preparation method 900 includes:

[0201] S910, forming more than two lower layer windings;

[0202] S920, forming a thin film magnetic core, the thin film magnetic core includes a plurality of magnetic columns, a first end and a second end opposite to the first end, the plurality of magnetic columns are isolated from each other, and the plurality of magnetic columns The magnetic columns are all rod-shaped. One end of each magnetic column in the plurality of magnetic columns is in contact with the first end, and the other end is in contact with the second end. The plurality of magnetic columns include more than two winding magnetic columns and more than one non-winding magnetic columns; the thin film magnetic core includes at least one layer of magnetic film, each layer of magnetic film is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com