Method for precisely preparing nanocrystalline magnetic core with high magnetic permeability

A technology with high magnetic permeability and nanocrystals, which is applied in the manufacture of magnetic cores, inductors/transformers/magnets, and electrical components. Satisfy the transformer accuracy level, temperature characteristics and miniaturization requirements and other issues, achieve the effect of good temperature stability and high precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

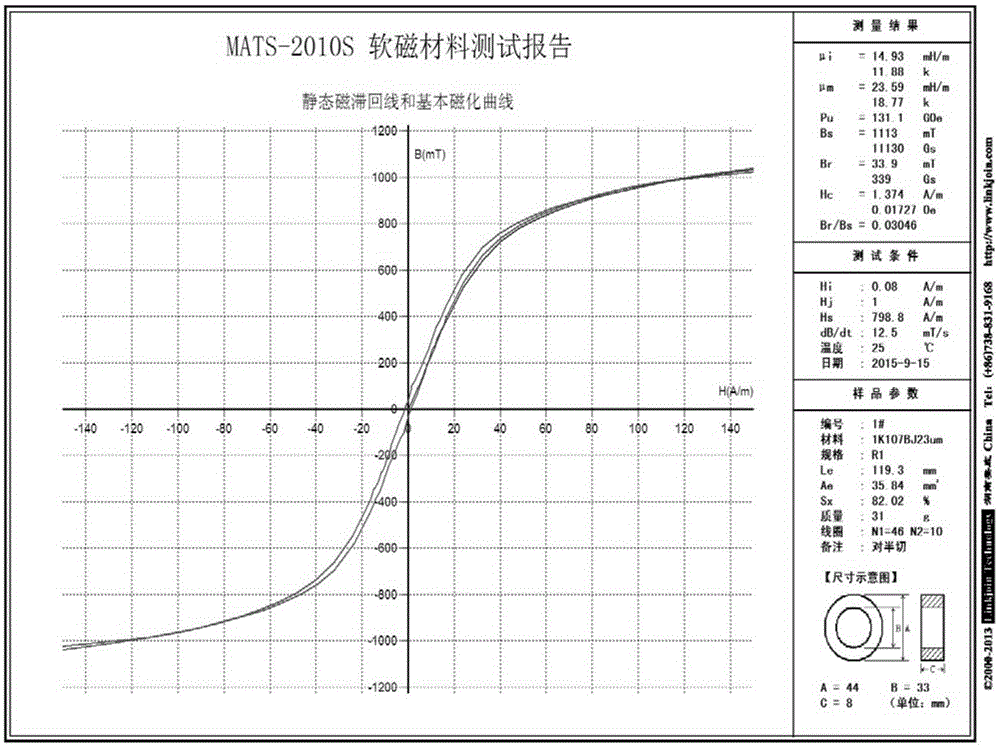

Image

Examples

Embodiment 1

[0035] The method for precisely preparing a nanocrystalline magnetic core with high magnetic permeability comprises the following steps:

[0036] (1) Use the single-roll quick quenching method to prepare iron-based nanocrystalline magnetic cores with good toughness according to the following components and ratios: Fe82.8%, Si8.4%, B1.66%, Cu1.18%, Nb5 .2%, Ni0.05%.

[0037] (2) After the heat-treated iron-based nanocrystalline strip is wound into a magnetic core, then annealed under nitrogen protection;

[0038] (3) The nanocrystalline magnetic core after the annealing treatment is subjected to dipping and curing treatment; the specific steps of the dipping and curing treatment are as follows:

[0039] ①Preheat the nanocrystalline magnetic core at 60°C;

[0040] ②Use epoxy resin lacquer as curing agent, heat the epoxy resin varnish in a water bath at 70°C; and use acetone to mix the diluted lacquer at a ratio of 1:1; keep the diluted lacquer at 70°C 60 minutes;

[0041] ③I...

Embodiment 2

[0053] Follow the steps below to prepare high permeability nanocrystalline magnetic cores:

[0054] (1) With the single-roll quick quenching method, the iron-based nanocrystalline magnetic core with good toughness is prepared according to the following components and ratios: Fe80%, Si9%, B1.%, Cu2%, Nb4.5%, Ni0.12 %.

[0055] (2) After the heat-treated iron-based nanocrystalline strip is wound into a magnetic core, then annealed under nitrogen protection;

[0056] (3) The nanocrystalline magnetic core after the annealing treatment is subjected to dipping and curing treatment; the specific steps of the dipping and curing treatment are as follows:

[0057] ①Preheat the nanocrystalline magnetic core at 65°C;

[0058] ②Use epoxy resin lacquer as curing agent, heat the epoxy resin varnish in a water bath at 70°C; and use acetone to mix the diluted lacquer at a ratio of 1:1; keep the diluted lacquer at 70°C About 60 minutes;

[0059] ③Immerse the preheated nanocrystalline magnet...

Embodiment 3

[0070] Follow the steps below to prepare high permeability nanocrystalline magnetic cores:

[0071] (1) Using the single-roll quick quenching method, an iron-based nanocrystalline magnetic core with good toughness was prepared according to the following components and ratios: Fe83.5%, Si7.3%, B3%, Cu1%, Nb6%, Ni0. 2%.

[0072] (2) After the heat-treated iron-based nanocrystalline strip is wound into a magnetic core, then annealed under nitrogen protection;

[0073] (3) The nanocrystalline magnetic core after the annealing treatment is subjected to dipping and curing treatment; the specific steps of the dipping and curing treatment are as follows:

[0074] ①Preheat the nanocrystalline magnetic core at 70°C;

[0075] ②Use epoxy resin lacquer as curing agent, heat the epoxy resin varnish in a water bath at 70°C; and use acetone to mix the diluted lacquer at a ratio of 1:1; keep the diluted lacquer at 70°C About 60 minutes;

[0076] ③Immerse the preheated nanocrystalline magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com