Root pressure grouting pile and construction method thereof

A construction method and technology of cast-in-situ piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high construction cost, difficulty in construction, and difficulty in construction of pile foundations, so as to reduce construction costs and improve construction efficiency. The effect of low construction cost and less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

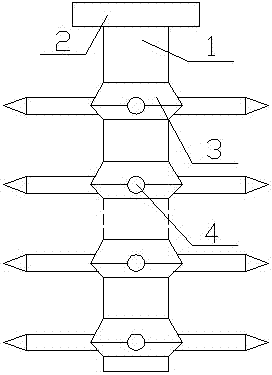

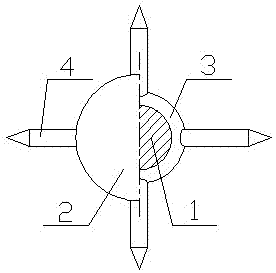

[0031] combine figure 1 with figure 2 As shown, the present invention includes a cylindrical pile foundation 1, and also includes a cap surface 2 arranged on the top of the pile foundation 1, and a plurality of root keys 4 are arranged on the cylindrical surface of the pile foundation 1; or the cylindrical surface of the pile foundation 1 A supporting plate 3 protruding from the center of the circle is provided, and the plurality of root keys 4 are connected to the supporting plate 3; the root keys 4 are perpendicular to the pile foundation 1; the end of the root key 4 away from the pile foundation 1 is a cone structure; the root keys 4 arranged on the cylindrical surface of the pile foundation 1 are arranged in multiple layers from top to bottom; the number of root keys 4 set on each support plate 3 is at least 3, and the root keys 4 are equally divided into a circle of the support plate 3; the distance between the root keys 4 of two adjacent layers is in the range of 1 to ...

Embodiment 2

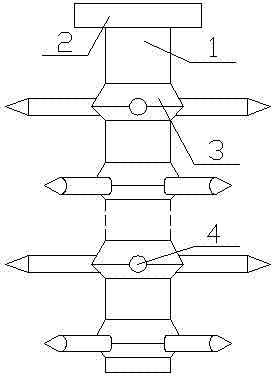

[0034] combine image 3 with Figure 4 As shown, the present invention includes a cylindrical pile foundation 1, and also includes a cap surface 2 arranged on the top of the pile foundation 1, and a plurality of root keys 4 are arranged on the cylindrical surface of the pile foundation 1; or the cylindrical surface of the pile foundation 1 A supporting plate 3 protruding from the center of the circle is provided, and the plurality of root keys 4 are connected to the supporting plate 3; the root keys 4 are perpendicular to the pile foundation 1; the end of the root key 4 away from the pile foundation 1 is a cone structure; the root keys 4 arranged on the cylindrical surface of the pile foundation 1 are arranged in multiple layers from top to bottom; the number of root keys 4 set on each support plate 3 is at least 3, and the root keys 4 are equally divided into a circle of the support plate 3; the distance between the root keys 4 of two adjacent layers is in the range of 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com