Multi-section type variable cross-section dynamic compaction method

A technology of variable cross-section and dynamic ramming, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve the problems of large subsidence, shallow effective reinforcement thickness, and poor reinforcement effect of weak foundation soil, etc., reaching the settlement value The effect of reducing the difference value of settlement and settlement, widening the applicable conditions and scope, and good co-action characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

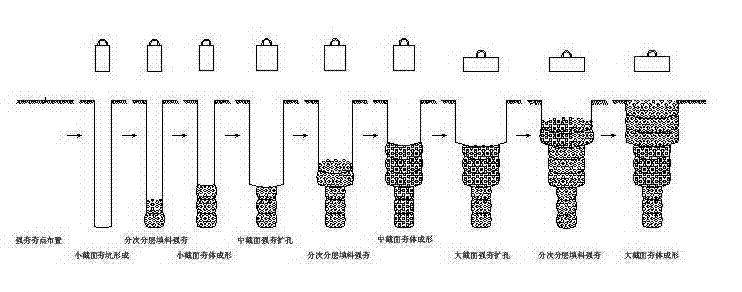

[0036] The inventive method comprises the following steps:

[0037] (1) Clean up and level the construction site

[0038] (2) Dynamic tamping construction of the first tamping body with small cross-section

[0039] ① Measuring and setting of dynamic compaction points: Arrange dynamic compaction points on the construction site according to the design requirements.

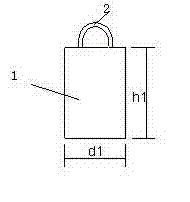

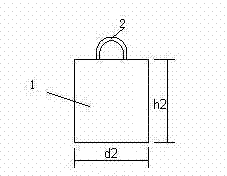

[0040] ② Formation of the ramming pit: the dynamic ramming machine is in place, and the type I rammer (ratio of hammer height h1 to hammer diameter d1 is 1.5, hammer diameter d1=1.2m, static ground pressure value of hammer bottom is 140kPa) is placed at the ramming point, Lift the type I rammer to a set height of 13.0 m, automatically unhook it and drop it to ram the soil, and repeat the ramming to form a ramming pit. When the depth of the designed ramming pit is ≤50cm, backfill the ramming pit with 1.5m thick backfill material and continue to ram until the bottom of the ramming pit is compacted by tamping.

...

Embodiment 2

[0060] The rammers and construction techniques used in the multi-stage variable section dynamic compaction method in Example 2 are the same as those in Example 1.

[0061] The difference is that when the thickness of the weak foundation soil layer is less than 9 m, the lower part of the foundation soil layer shall be constructed with a small cross-section or directly with a medium cross-section to make the filling layer or the lower part of the weak foundation soil layer compacted by dynamic compaction, and then The large cross-section construction is adopted to achieve the reinforcement effect of the upper soil layer, so that the upper and lower sections are constructed into a variable cross-section dynamic ramming body or a replacement pier with an inverted convex shape.

[0062] Full ramming construction: After the overall construction of the multi-stage variable cross-section dynamic ramming body in the dynamic ramming area, the entire dynamic ramming area uses Type III ram...

Embodiment 3

[0064] The construction technology used in the multi-stage variable section dynamic compaction method of embodiment 3 is the same as that of embodiment 1.

[0065] The difference is that: for the weak foundation soil layer with a layer thickness of 15-25 m, the first section of the rammed body of the small cross-section is firstly rammed for the deep soil mass of the weak foundation soil layer, and then the middle part of the weak foundation soil layer is Divided into n-2 sections, use rammers with increasing cross-sections from bottom to top to carry out n-2-section variable-section segmental ramming construction, and finally carry out large-cross-section n-section ramming on the soft foundation soil layer soil The dynamic tamping construction is thus constructed into n (n=4 or 5 or 6) sections of multi-section variable cross-section dynamic tamping ramming body or replacement pier body.

[0066] Full ramming construction: After the overall construction of the multi-stage var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com