Vacuum type yarn steaming forming equipment and application method thereof

A vacuum and steamed silk technology, which is applied in the processing of textile material equipment configuration, liquid/gas/steam yarn/filament processing, liquid/gas/steam textile material processing, etc., can solve the large production cost expenditure, steaming machine To solve the problems of high cost, achieve the effect of optimizing treatment effect, improving yarn quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

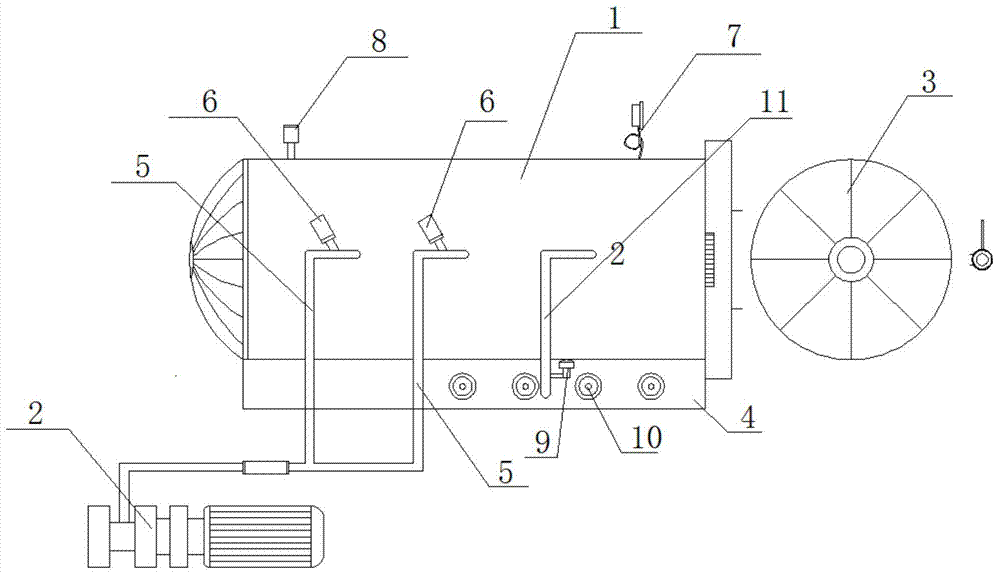

[0032] A kind of vacuum type steaming and setting equipment provided in this embodiment has a structure such as figure 1 As shown, it mainly includes a box body 1 and an SZB type water ring vacuum pump 2 arranged outside the box body 1. The box body 1 is a hollow cylindrical structure. One end of the box body 1 is sealed and the other end is open. The box door 3 is hinged on the box body On the open end of 1, the surface of the box body 1 and the box door 3 are covered with 70mm EPDM insulation layer, and the bottom of the box body 1 is connected to a water tank 4, wherein:

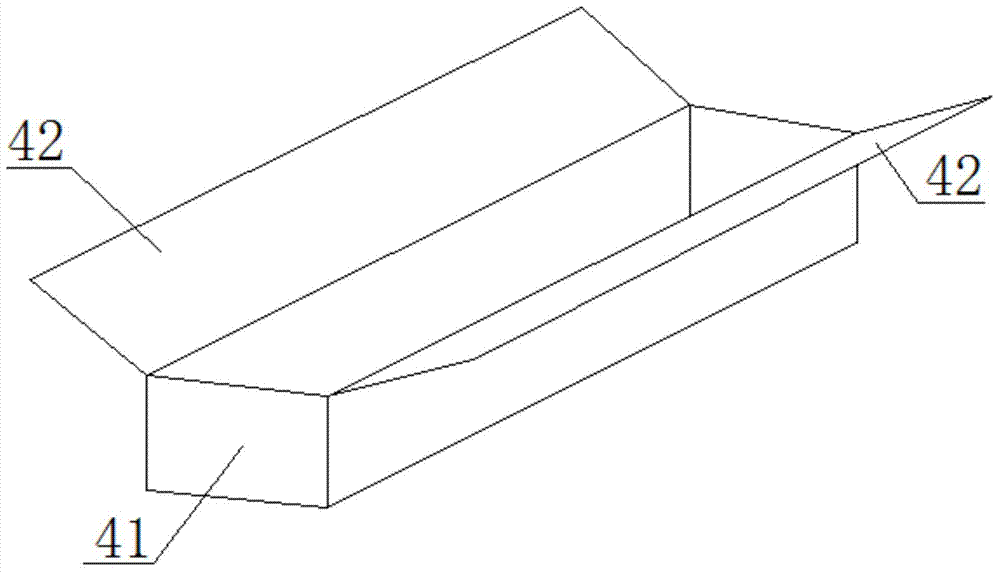

[0033] The side wall of the box body 1 is provided with a water inlet pipe and a water outlet pipe, and the water inlet pipe is higher than the water outlet pipe. The box body 1 is provided with an exhaust pipe 5, which is connected to the water ring vacuum pump 2 through a hose. There is a filter cover 6, the filter cover 6 is made up of a filter cover body and a filter screen, the filter screen includes...

Embodiment 2

[0036] This embodiment provides an application method of the vacuum-type silk steaming and shaping equipment in Embodiment 1, and the specific steps are as follows:

[0037] (1) Put the steamed silk on the matching steamed silk rack and push it into the box 1, close the box door 3, turn on the heating tube 10 and heat it for 10-15 minutes, preheat the box 1 and let it stand for 20-25 minutes;

[0038] (2) Inject water into the tank 1 through the water inlet pipe and use the water level gauge 9 to observe the water level, and then turn on the water ring vacuum pump 2 to vacuumize the tank 1 after water injection;

[0039] (3) The water in the water tank 4 becomes low-temperature saturated steam after vacuuming once, and the heating tube is used to heat the water in the water tank 4 once so that the low-temperature saturated steam in the box 1 penetrates into the steamed silk, and heat for 0.5-1h Keep the temperature in the box 1 at 80-90°C and then let it stand for 40-55 minutes;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com