Production process of polyamide 6 special-shaped air-textured yarns with high strength and low boiling shrinkage

A production process and high-strength technology, applied in the manufacture of hollow filaments, chemical characteristics of fibers, heat treatment of artificial filaments, etc., can solve the problems of low strength, poor boiling shrinkage performance, and unsatisfactory air-varying yarn performance, and achieve high the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

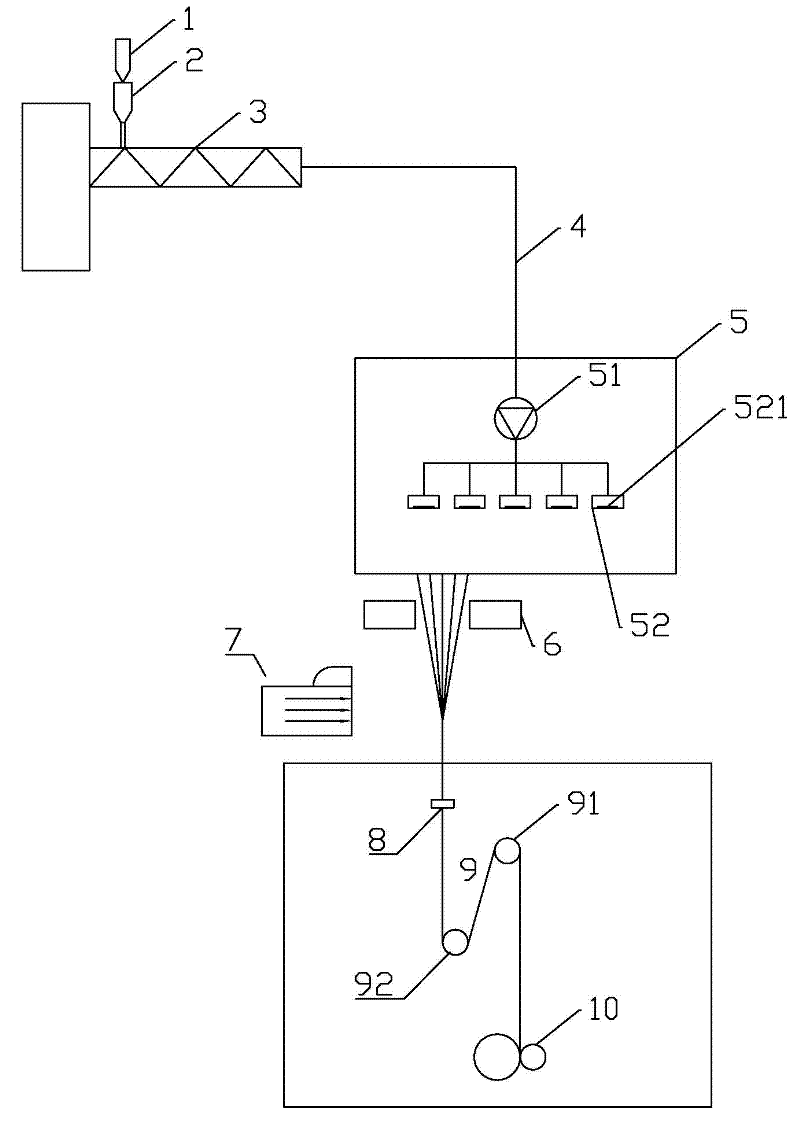

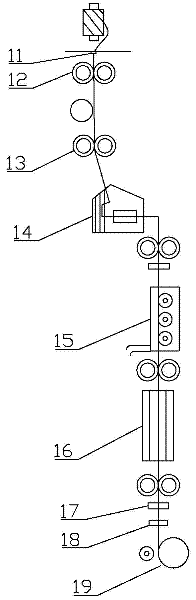

[0021] A production process of high-strength and low-boiling shrinkage nylon 6 special-shaped air-variable yarn (see figure 1 with figure 2 ), including the following steps:

[0022] 1) Add nylon 6 slices (relative viscosity 3.0, moisture content lower than 0.05ppm) into the storage tank 2 through the slice hopper 1, and the material in the storage tank 2 is fed into the extruder 3, and the temperature of each section of the extruder 3 is respectively 260°C, 270°C, 280°C, 290°C, 300°C;

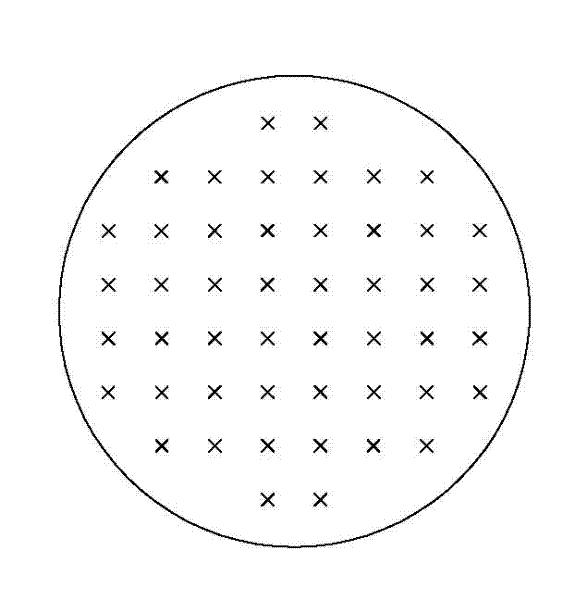

[0023] 2) The extruder 3 transports the molten material to the metering pump 51 in the spinning box 5 through the melt distribution pipe 4, and the metering pump 51 accurately injects the material into the spinning assembly 52 in the spinning box 5, and the material is sprayed The wire plate 521 forms a thin stream of melt; wherein, the shape of the nozzle holes in the spinneret is ten-lobed;

[0024] 3) The melt stream passes through the thermostat 6 (the temperature is controlled at 190~...

Embodiment 2

[0027] A production process of high-strength and low-boiling shrinkage nylon 6 special-shaped air-variable yarn (see figure 1 with figure 2 ), including the following steps:

[0028] 1) Add nylon 6 slices (relative viscosity 3.2, moisture content lower than 0.05ppm) into the storage tank 2 through the slice hopper 1, and the material in the storage tank 2 is fed into the extruder 3, and the temperature of each section of the extruder 3 is respectively 260°C, 270°C, 280°C, 290°C, 300°C;

[0029] 2) The extruder 3 transports the molten material to the metering pump 51 in the spinning box 5 through the melt distribution pipe 4, and the metering pump 51 accurately injects the material into the spinning assembly 52 in the spinning box 5, and the material is sprayed The wire plate 521 forms a thin stream of melt; wherein, the shape of the nozzle holes in the spinneret is five-lobed;

[0030] 3) The melt stream passes through the thermostat 6 (the temperature is controlled at 190...

Embodiment 3

[0033] A production process of high-strength and low-boiling shrinkage nylon 6 special-shaped air-variable yarn (see figure 1 with figure 2 ), including the following steps:

[0034] 1) Add nylon 6 slices (relative viscosity 3.6, moisture content lower than 0.05ppm) into the storage tank 2 through the slice hopper 1, and the material in the storage tank 2 is fed into the extruder 3, and the temperature of each section of the extruder 3 is respectively 260°C, 270°C, 280°C, 290°C, 300°C;

[0035] 2) The extruder 3 transports the molten material to the metering pump 51 in the spinning box 5 through the melt distribution pipe 4, and the metering pump 51 accurately injects the material into the spinning assembly 52 in the spinning box 5, and the material is sprayed The wire plate 521 forms a thin stream of melt; wherein, the shape of the orifice in the spinneret is a six-lobed shape;

[0036] 3) The melt stream passes through the thermostat 6 (the temperature is controlled at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Water rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com