Patents

Literature

48results about How to "Economical and efficient processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid mine water treatment system

InactiveCN101830585ALarge specific surface areaImprove settlement performanceWaste water treatment from quariesMultistage water/sewage treatmentWater treatment systemManganese

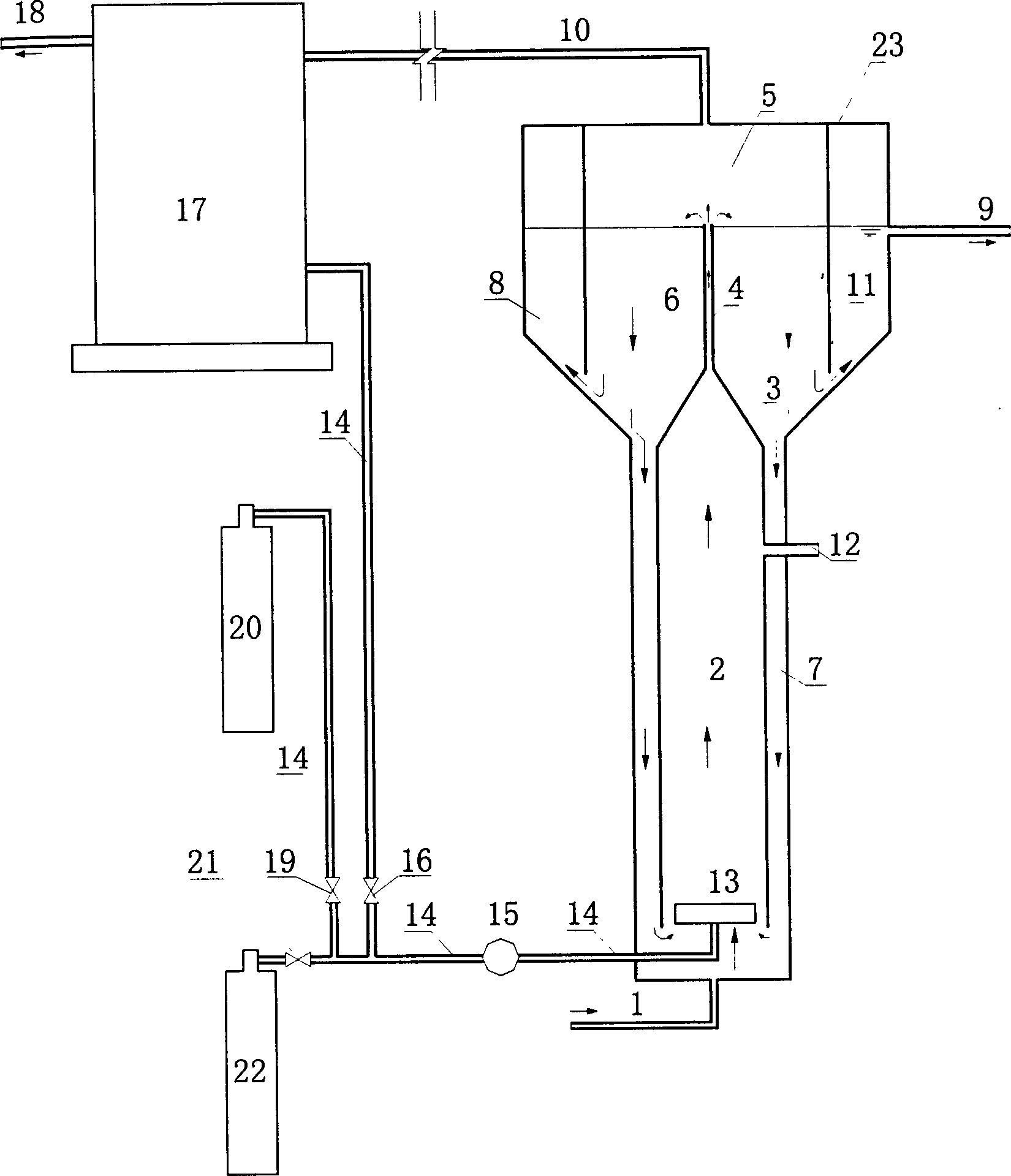

The invention discloses an acid mine water treatment system and belongs to the field of water treatment. The system consists of a neutralization system, a coagulation sedimentation system, a filtration system, a reverse osmosis system and a sterilization system which are connected in turn, wherein the coagulation sedimentation system comprises a mixing region, a reaction region, a transition region and a settling region; the mixing region is communicated with the reaction region, the transition region and the settling region in turn; the water inlet of the mixing region is communicated with the water outlet of the neutralization system; the water outlet of the settling region is communicated with the water inlet of the filtration system; and the filtration system comprises a manganese sand filter in which a modified manganese sand filter material modified by 1 to 7 mass percent potassium permanganate solution is arranged. Four regions are arranged in the coagulation sedimentation system of the system, so coagulation treatment effect is enhanced; and the modified manganese sand filter material is adopted in the manganese sand filter, so the effect of removing ferro-manganese ions in the mine water is enhanced and the aim of treating and recycling the acid mine water with high turbidity, high ferro-manganese content and high mineralization is fulfilled.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

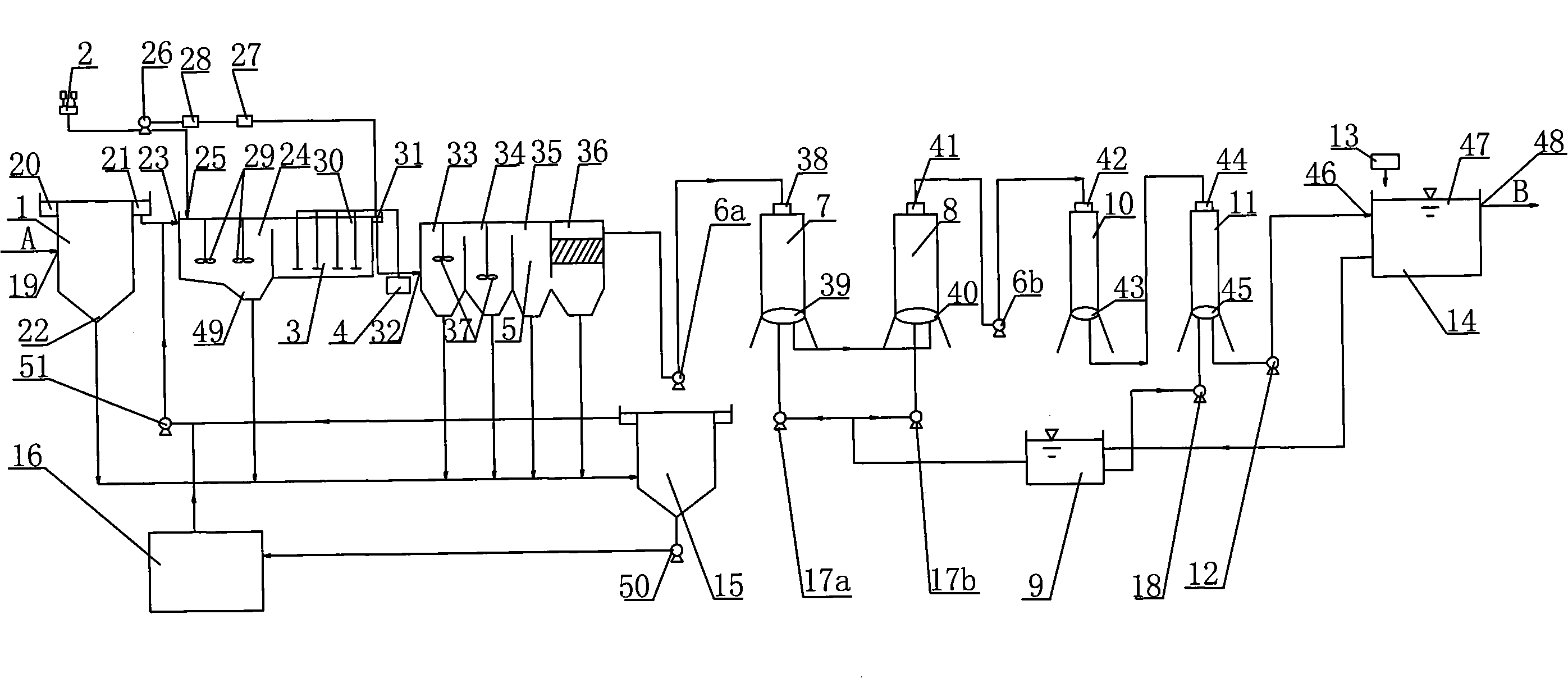

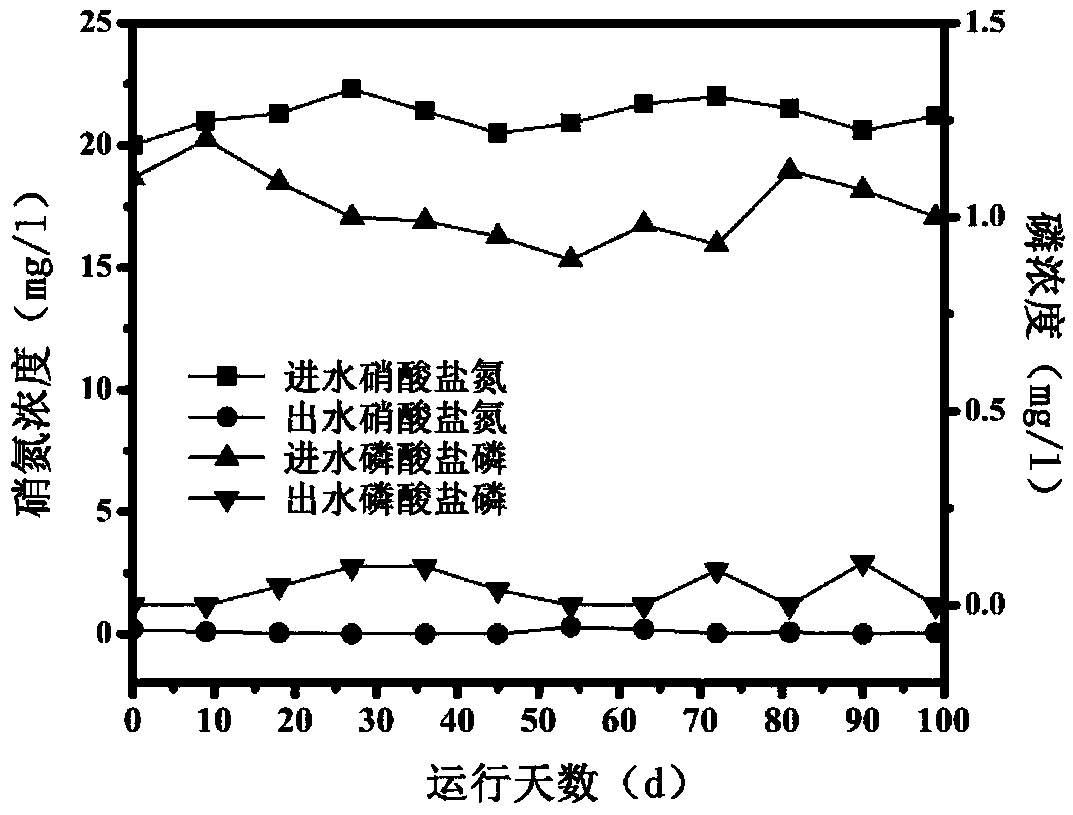

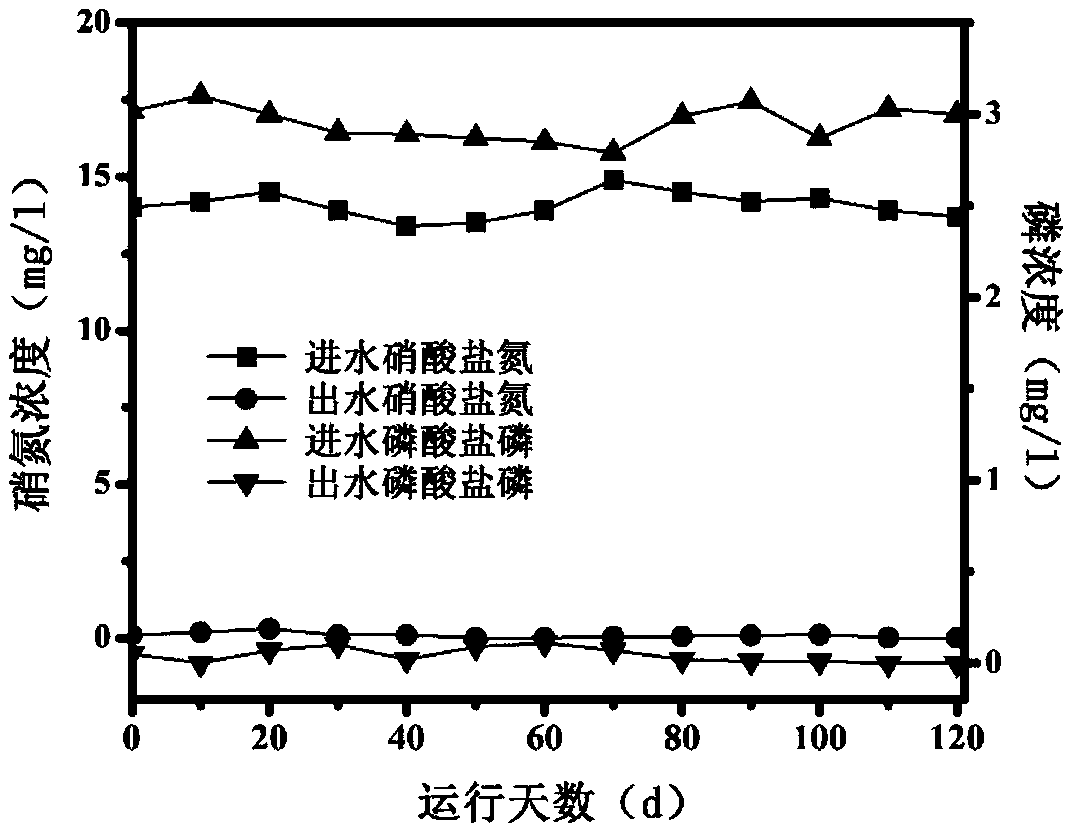

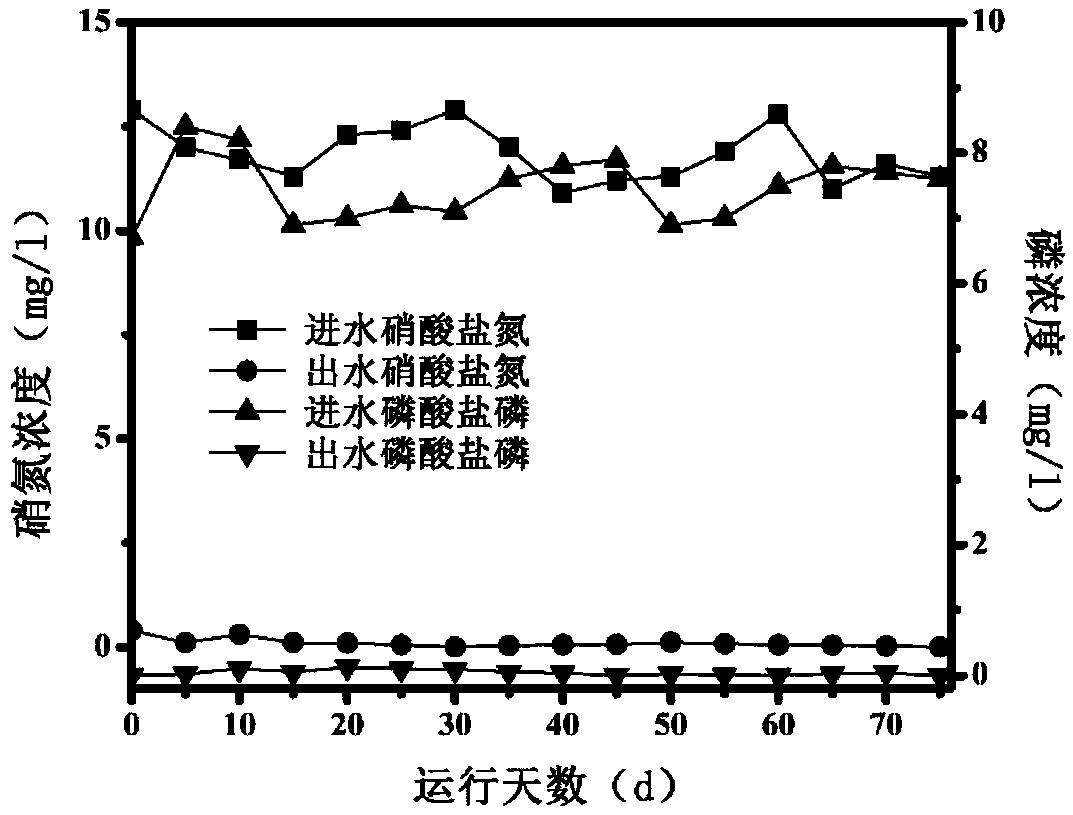

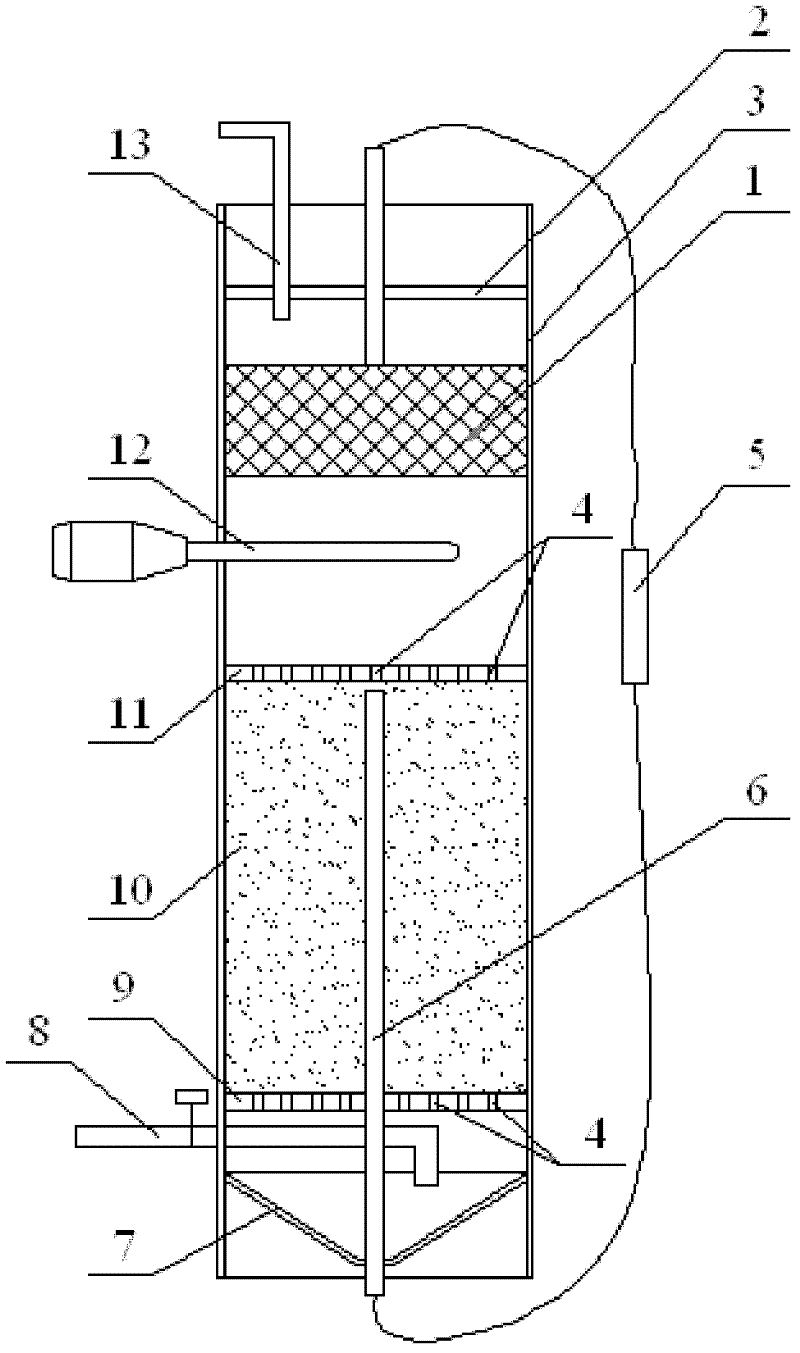

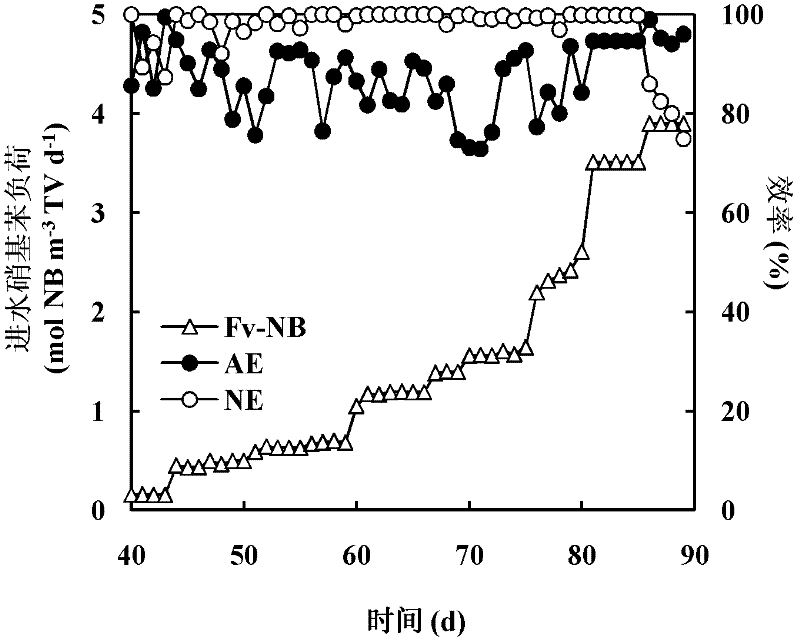

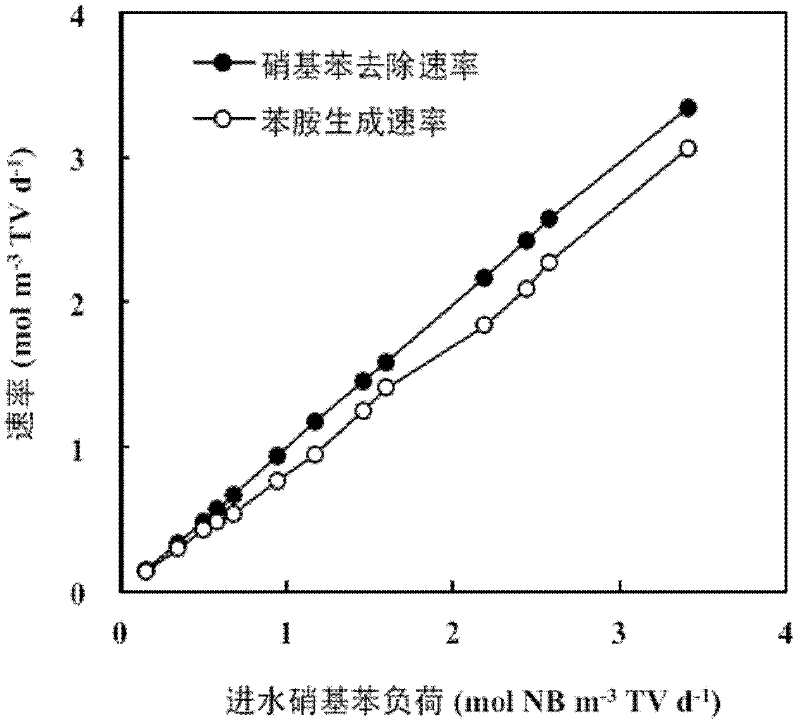

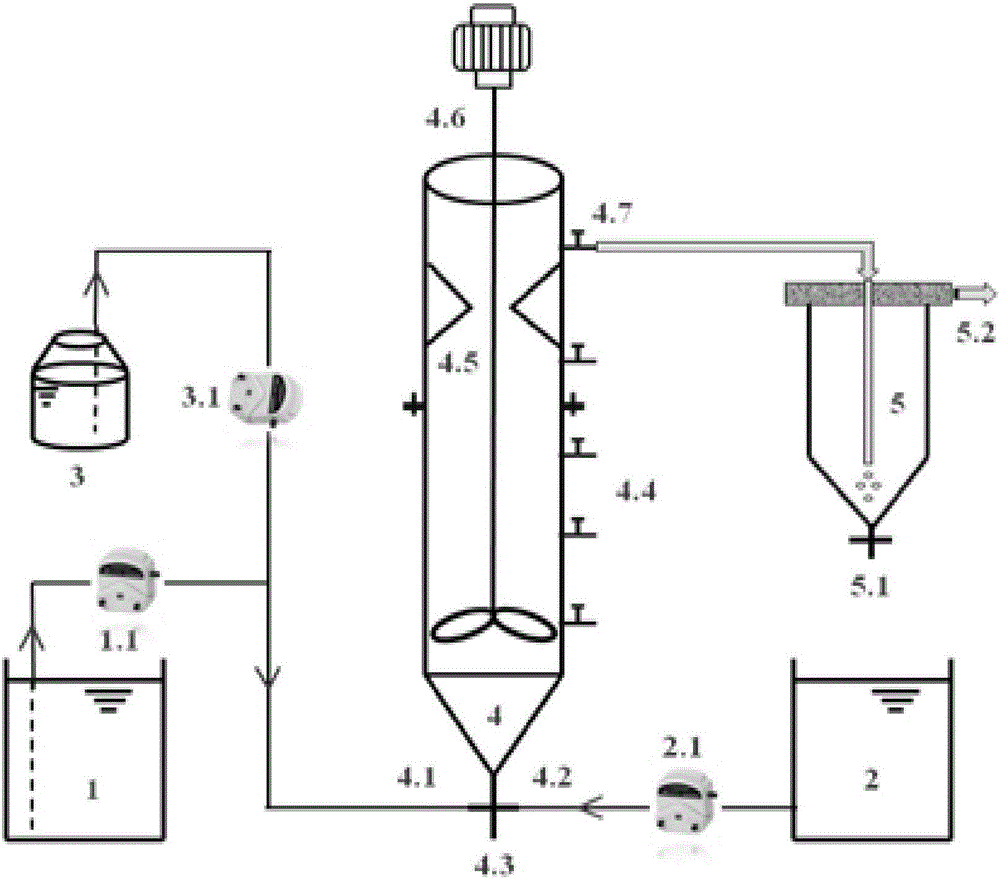

Coupling filler autotrophic denitrification biofilter and application

ActiveCN109052641ADifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiofilmSewage

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

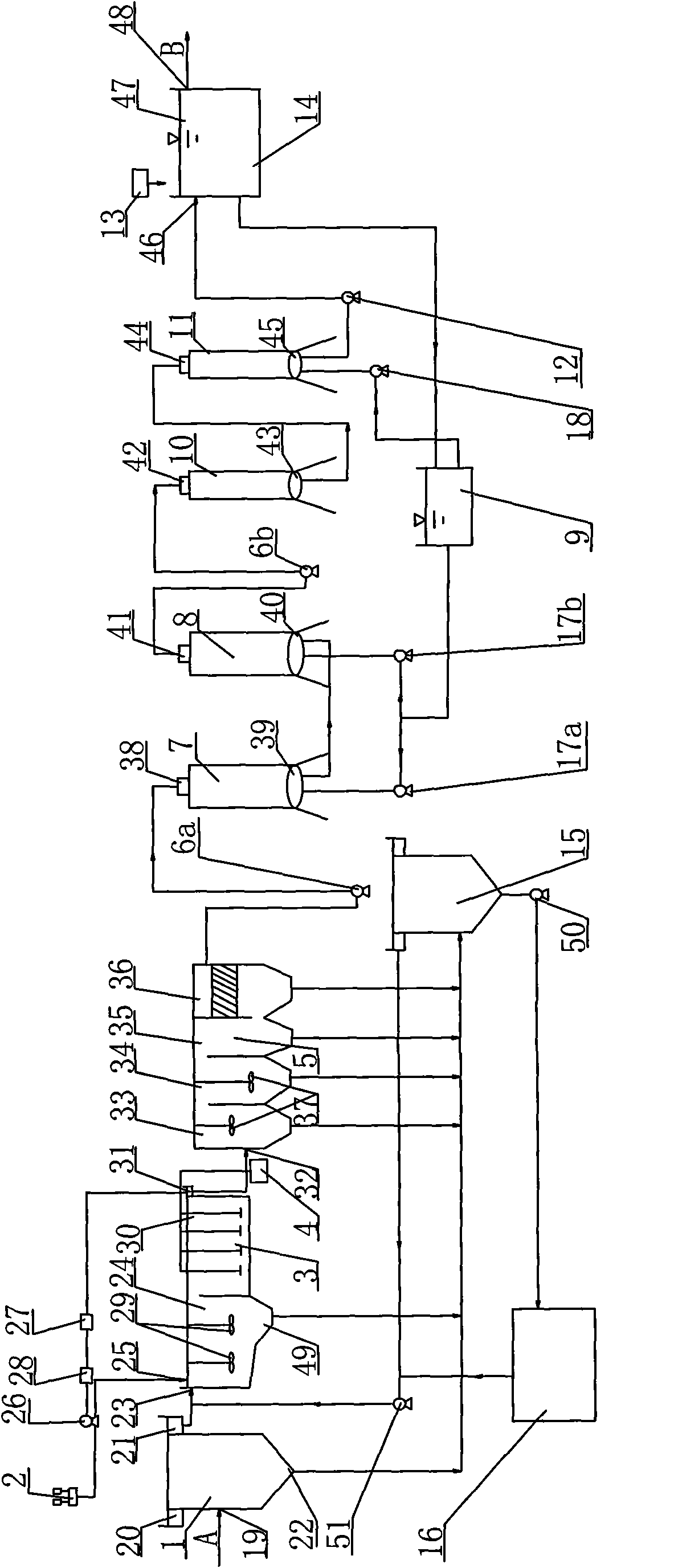

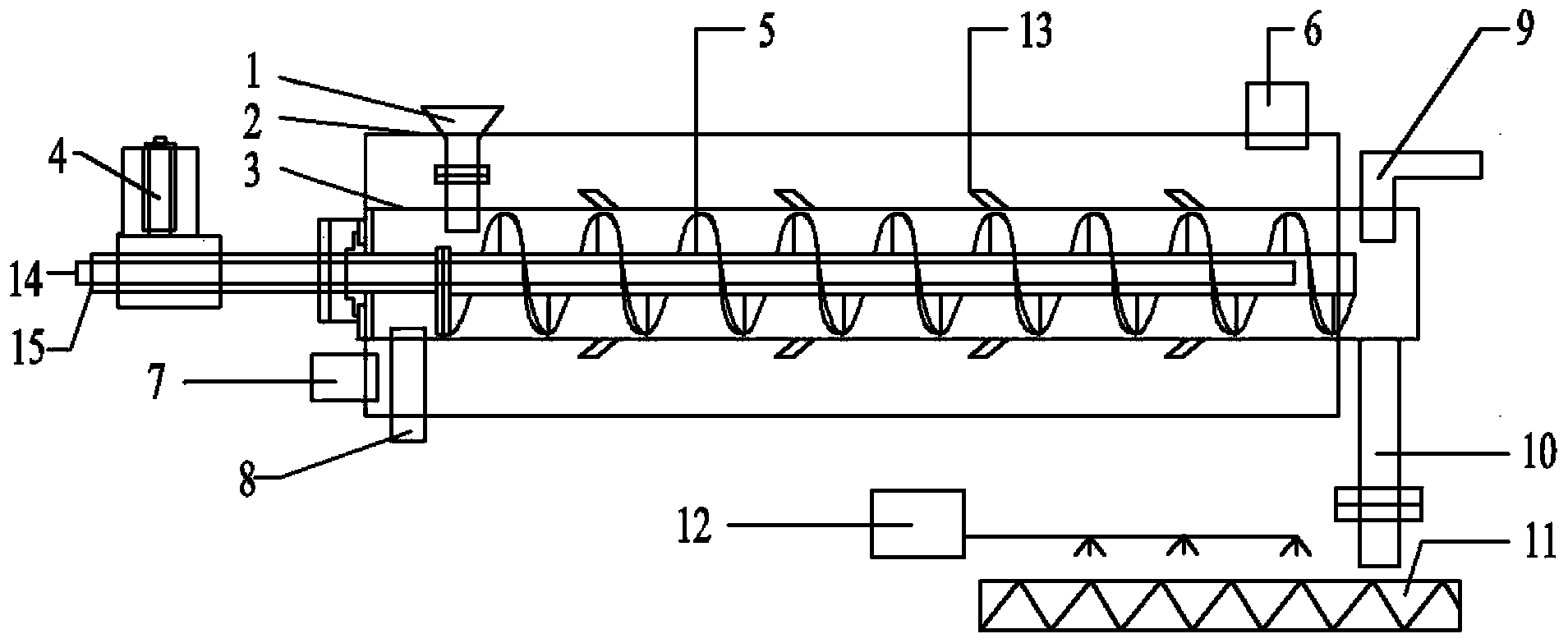

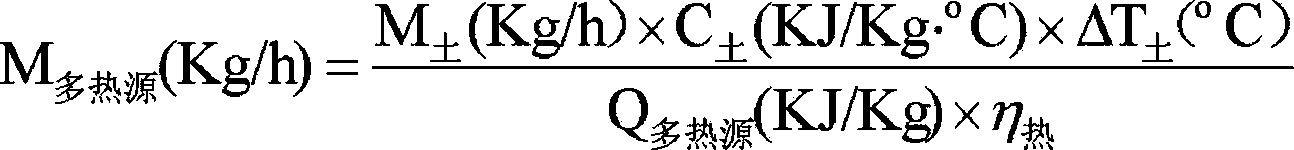

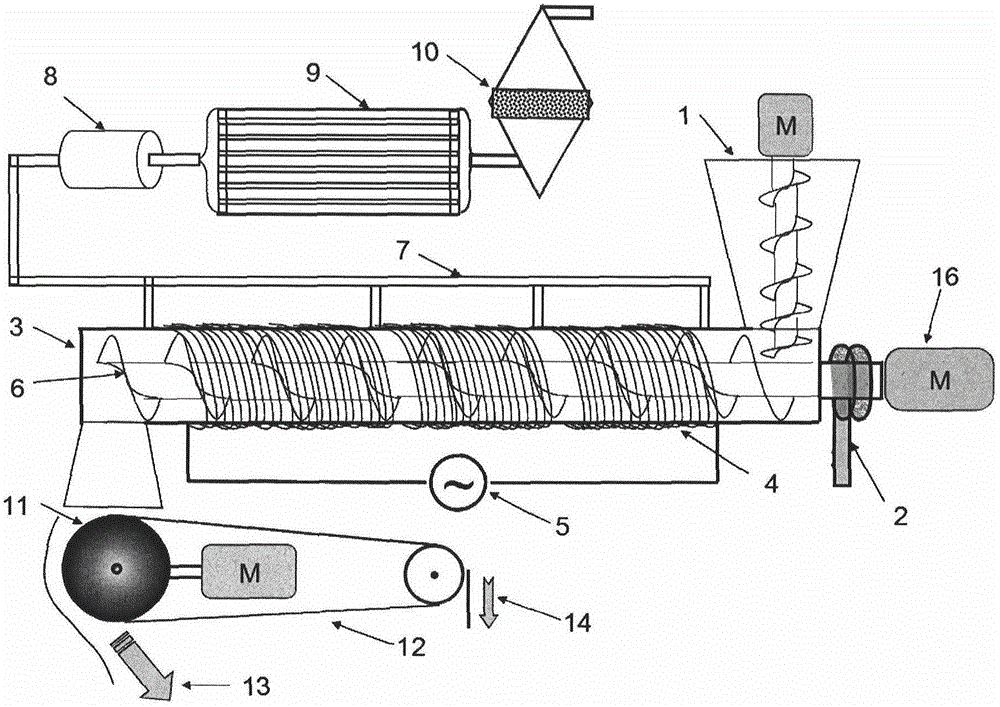

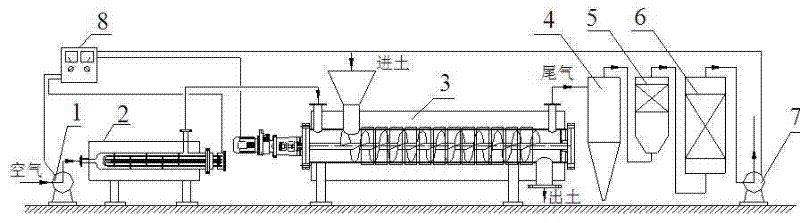

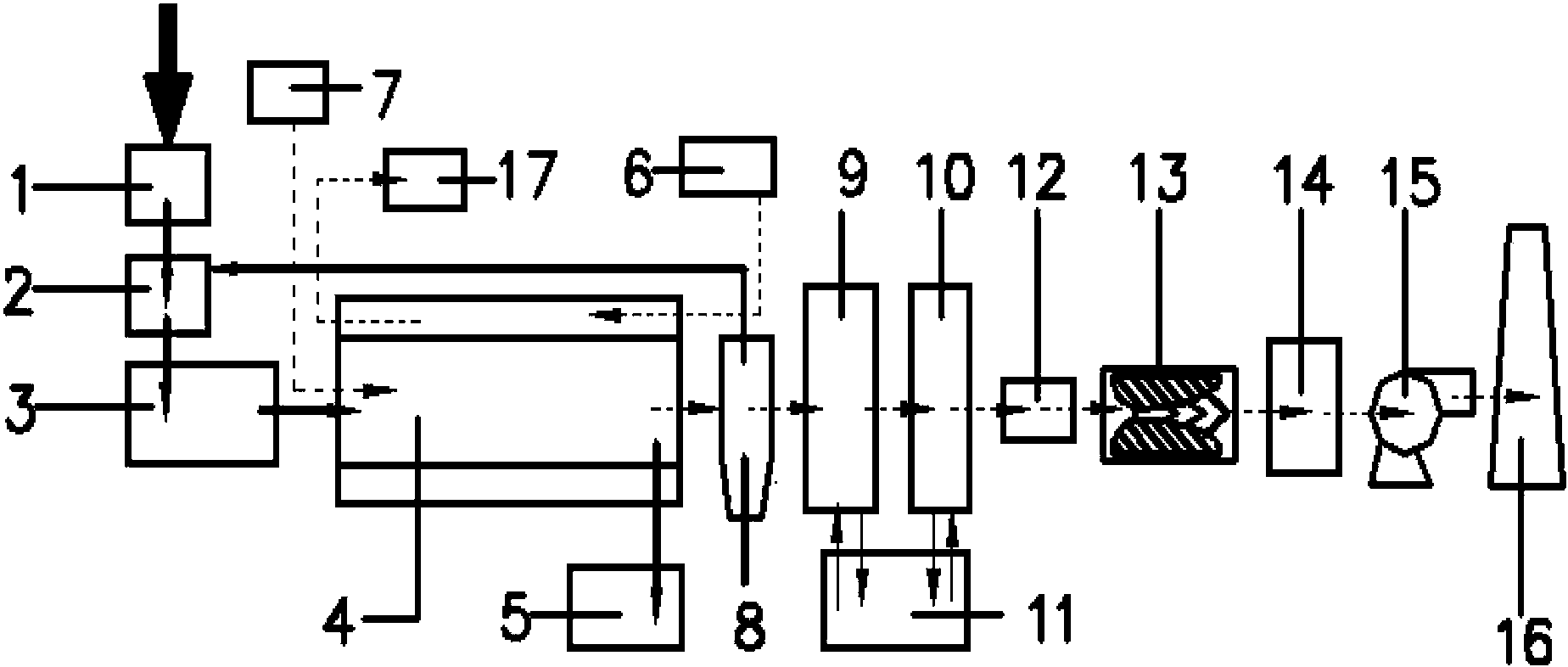

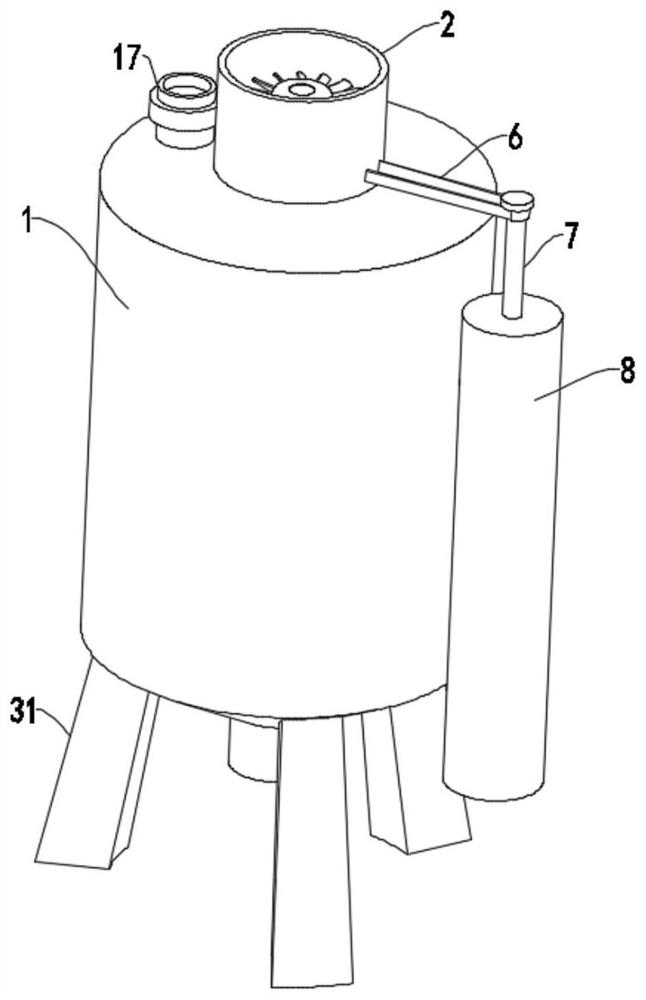

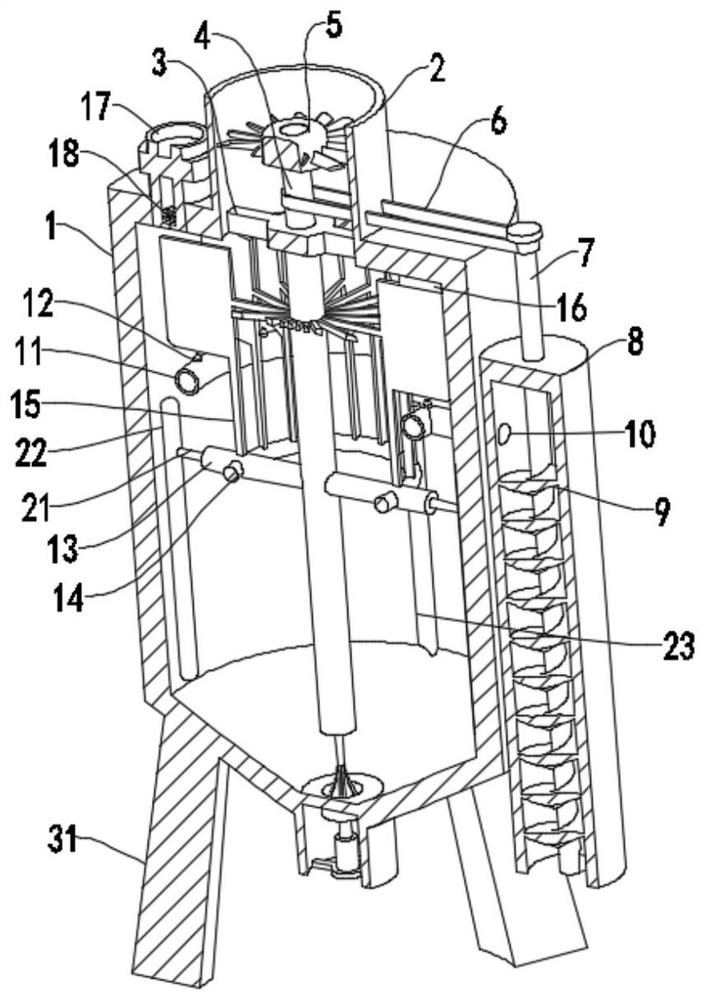

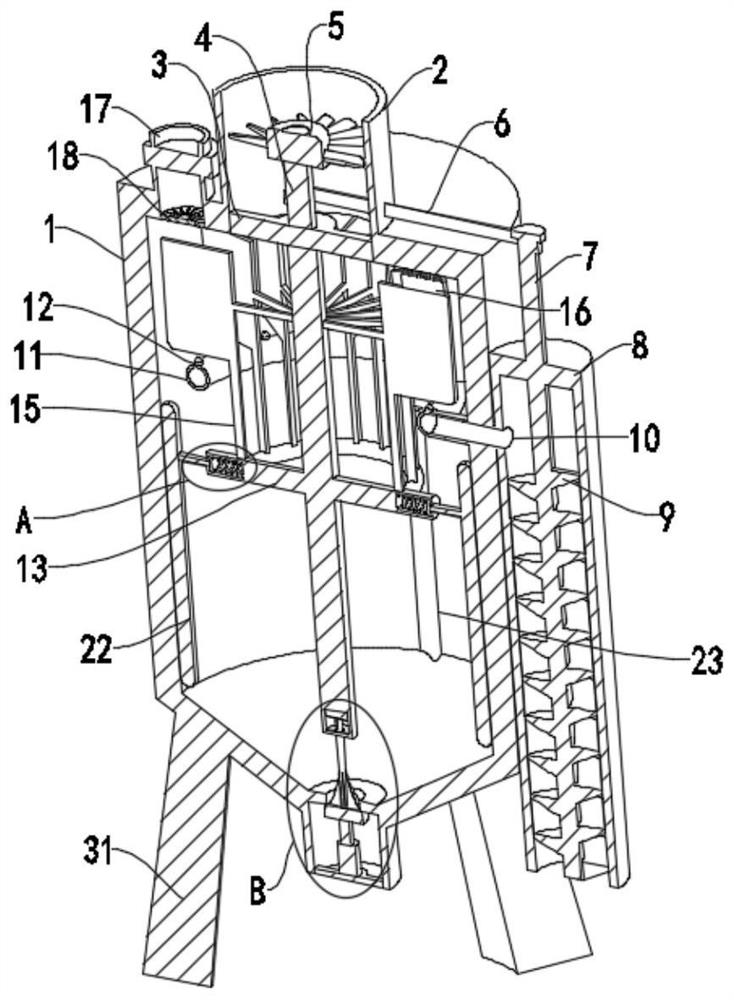

Multi-heat source and shaft intervallic heating type thermal desorption device for organic pollutant contaminated soil repair

ActiveCN103506378AEconomical and efficient processingRemove completelyContaminated soil reclamationHigh concentrationEngineering

The invention relates to the field of environmental protection, and aims to provide a multi-heat source and shaft intervallic heating type thermal desorption device for repairing organic pollutant contaminated soil. An intervallic heating type thermal desorption machine of the device is a jacket type heating furnace; a soil feeding port, an unearthing machine, a first multi-heat source inlet and a first multi-heat source outlet are formed in the outer cylinder; a carrier gas inlet and a carrier gas outlet are formed in the inner cylinder; and a hollow shaft type revolving shaft adopting a jacket structure is formed by an outer shaft sleeve and a hollow inner shaft sleeve; a second multi-heat source inlet and a second multi-heat source outlet respectively connected with the outer shaft sleeve or the inner shaft sleeve are formed in the hollow shaft type revolving shaft. The device can effectively treat the organic pollutant contaminated soil, is particularly suitable for repairing high-concentration and multi-component organic pollutant contaminated soil fields, has excellent adaptability to various heat sources, improves the synthetic utilization efficiency of the heat sources, has great soil processing capacity in unit time, and is particularly suitable for sandy contaminated soil. For the organic pollutant contaminated soil, the device can achieve the organic pollutant removing efficiency above 99.9%.

Owner:ZHEJIANG UNIV

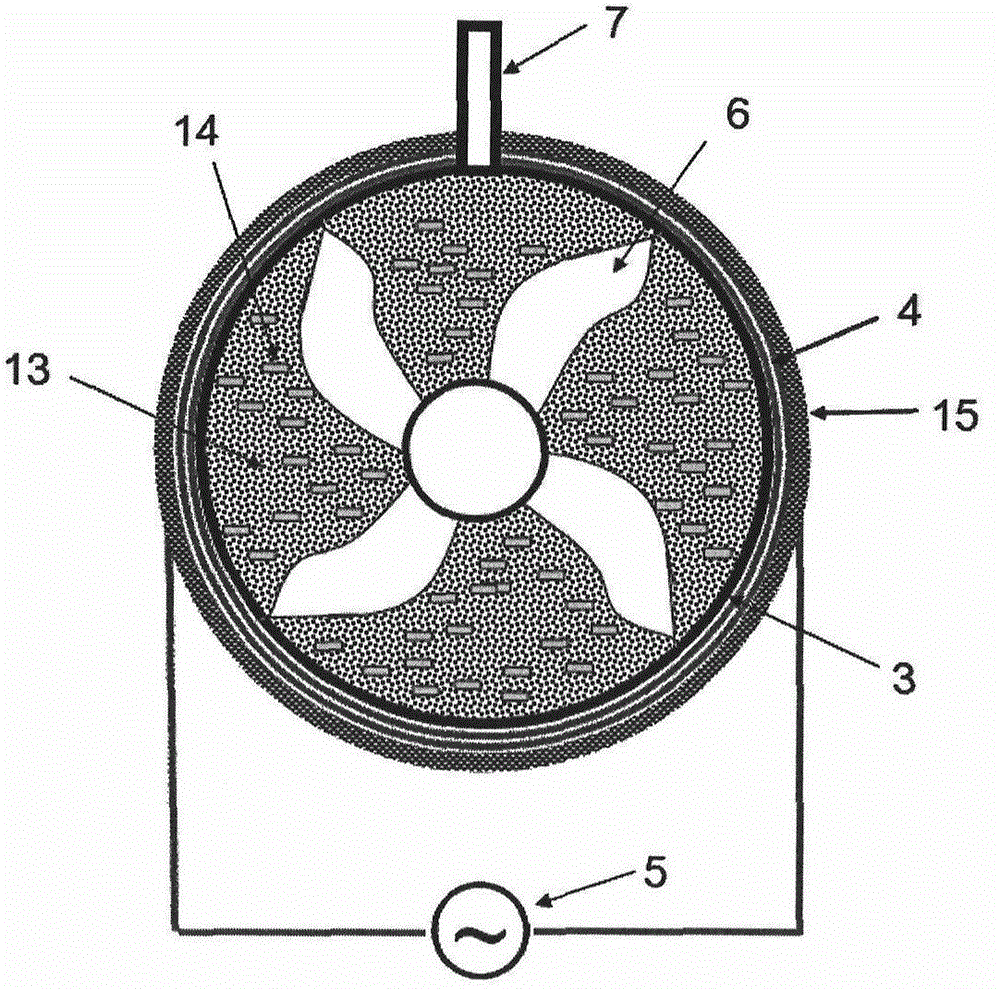

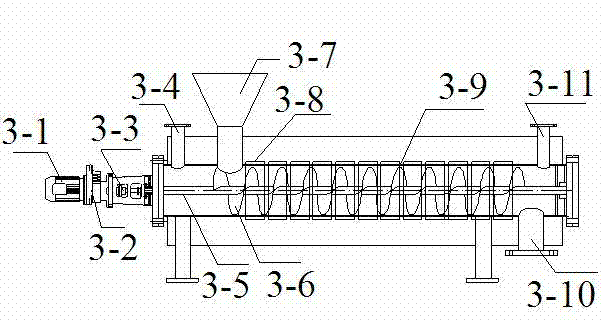

Magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating soil

InactiveCN105983569AFast temperature controlFast control timeContaminated soil reclamationElectromagnetic heatingThermal desorption

The invention provides a magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating contaminated sites. The method is characterized in that ferromagnetic materials, such as reducing iron powder, are doped into contaminated soil in an ex-situ mixing and stirring manner, the contaminated soil spirally stirred is heated by using electromagnetism, and a thermal desorption heat transfer gasifying effect is improved through the in-situ electromagnetic eddy heating of the ferromagnetic materials; the reaction activity and oxidation reduction capability of the ferromagnetic materials are improved when the ferromagnetic materials produce heat; after thermal desorption is finished, the ferromagnetic materials of which the surfaces react and adsorb pollutants can be separated from the contaminated soil through magnetic separation, recycled and reutilized; and the continuous remediation of contaminated soil is realized. The device also can be used for the in-situ remediation of contaminated soil. After the ferromagnetic materials are added to the soil in situ through a ploughing stirring device, the soil is heated in situ by utilizing an electromagnetic induction coil to carry out excitation eddy heating in the contaminated soil, pollutants are desorbed, and at the same time, the reaction activity of the magnetic materials(for example, reducing iron powder) can be improved; and after reaction is finished, the iron powder can be separated from the contaminated soil through a magnetic separation technology. The device also can be placed in soil to realize in-situ oxidation reduction degradation. The method and device are suitable for the in-situ thermal desorption remediation of circumjacent large area of low-concentration contaminated soil.

Owner:李泽唐

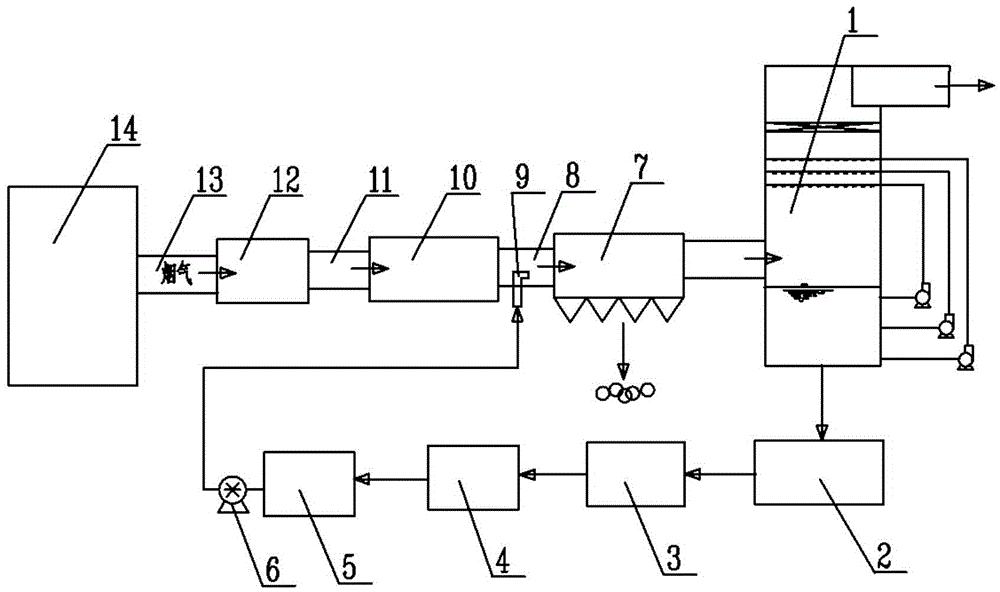

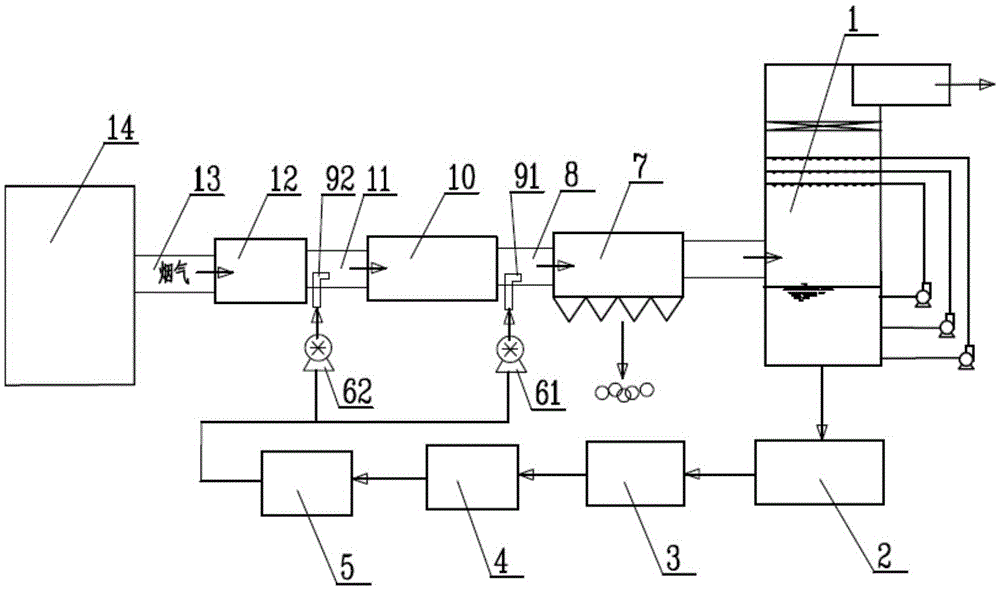

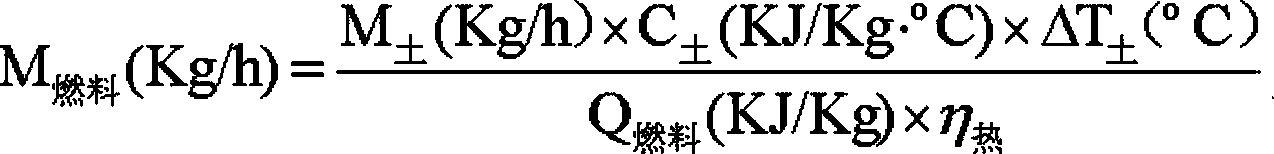

System and method for treating high salinity wastewater

ActiveCN105417817AEconomical and efficient processingAchieving zero emissionsWater contaminantsWaste water treatment from gaseous effluentsBoiling pointSalt water

The invention discloses a treatment system and evaporating treatment method for high salinity wastewater. The treatment system comprises a desulfurization waste water conventional treatment device, a high-salinity water concentration device, a concentrated high-salinity water storage pool and an atomizer which are connected in sequence. The treatment system further comprises a high-salinity water boiling point reducing device which is arranged at any appropriate position in front of the concentrated high-salinity water storage pool. The water spraying amount of concentrated high-salinity water sprayed out of the atomizer can be adjusted. The treatment method comprises the steps that 1, after desulfurization waste water is subjected to conventional treatment, upper-layer clear water, namely, high-salinity water is collected, the high-salinity water is concentrated to be reduced, and concentrated high-salinity water is formed and stored in the concentrated high-salinity water storage pool; 2, the concentrated high-salinity water in the concentrated high-salinity water storage pool is sprayed into a flue between a hearth and a dust remover and / or the hearth through the atomizer and subjected to atomization and evaporation, and crystal substances are mixed into coal ash to be removed together, wherein the water spray amount of the concentrated high-salinity water sprayed into the flue between the hearth and the dust remover and / or the hearth is adjusted according to flue gas temperature.

Owner:高境 +1

Non-diaphragm upflow type continuous flow bio-electrochemical apparatus for treating difficultly degraded waste water

ActiveCN102502973ALow costBalance accumulationBiological water/sewage treatmentContinuous flowAnodic oxidation

The invention discloses a non-diaphragm upflow type continuous flow bio-electrochemical apparatus for treating difficultly degraded waste water, which relates to an apparatus for treating waste water. The invention is used for solving the technical problems of high cost and low efficiency of BESs. A housing is fixedly connected with a base plate, a lower separator plate, a cathode, an upper separator plate, an anode and a top plate from the bottom to the top. According to the invention, present bio-electrochemical reactors are greatly improved, and according to the characteristics of waste water, the electrode positions are reasonably arranged, thereby pollutants which are difficult to be degraded in water are effectively detoxified at the cathode firstly, then the pollutants in water are further degraded by the effect of anodization, and the difficultly degraded waste water treatment efficiency is improved greatly. In addition, the invention employs a non-diaphragm design, thereby not only reducing internal resistance of the reactor, but also reducing cost, which are beneficial to the extension and engineering of the reactor.

Owner:HARBIN INST OF TECH

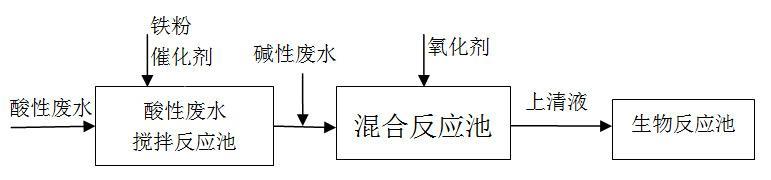

Method for pretreatment on industrial wastewater by nascent state ferrous iron reduction

ActiveCN102627360ARaise the pHSolve processing problemsMultistage water/sewage treatmentIndustrial waste waterPtru catalyst

The invention belongs to the technical field of environmental protection and especially relates to a method for pretreatment on industrial wastewater by nascent state ferrous iron reduction. The method is characterized in that acidic wastewater and zero-valent iron undergo a reaction in the presence of a catalyst to produce a large amount of high-activity nascent state ferrous iron and the acidity of the acidic wastewater is eliminated and a pH value of the acidic wastewater is improved; the high-activity nascent state ferrous iron and alkaline wastewater are mixed according to a certain ratio so that nascent state ferrous iron ions form a high-activity structural-state ferrous complex under alkaline conditions; through negative and positive ions and the catalyst in the wastewater, reduction performances of structural-state ferrous iron are improved; and through addition of a trace amount of an oxidizing agent, catalytic oxidation effects of residual ferrous iron are performed so that a ferrous iron structural form is changed and coagulating precipitation effects of ferrous iron are improved. The method realizes preparation of nascent state ferrous iron from acidic waste water, utilizes reduction effects of zero-valent iron and ferrous iron, realizes synchronous treatment on acidic wastewater and alkaline wastewater, realizes treatment of wastes with processes of wastes against one another and saves a treatment cost.

Owner:TONGJI UNIV

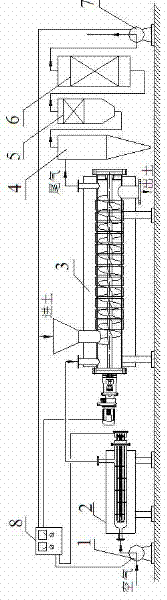

System for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption

ActiveCN101972773BEfficient repairSimple processContaminated soil reclamationAgricultural engineeringCyclonic spray scrubber

The invention provides a system for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption, which comprises an air preheating system, a spiral stirring thermal desorption system, a tail gas treatment system and a control system, wherein the air preheating system consists of a blower and an air heater, the spiral stirring thermal desorption system consistsof a spiral stirring thermal desorption device and a draft fan, the tail gas treatment system consists of a cyclone dust collector, a dehumidifier and an absorption tower, and the control system can realize the effective control of the rotation speed of a spiral stirrer, the air preheating temperature and the soil heating temperature. The system can be used for restoring soil contaminated by volatile / semi-volatile organic matters.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

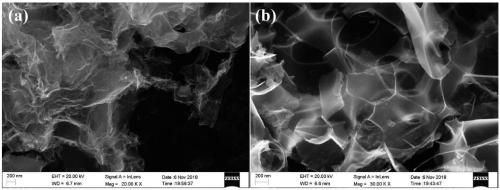

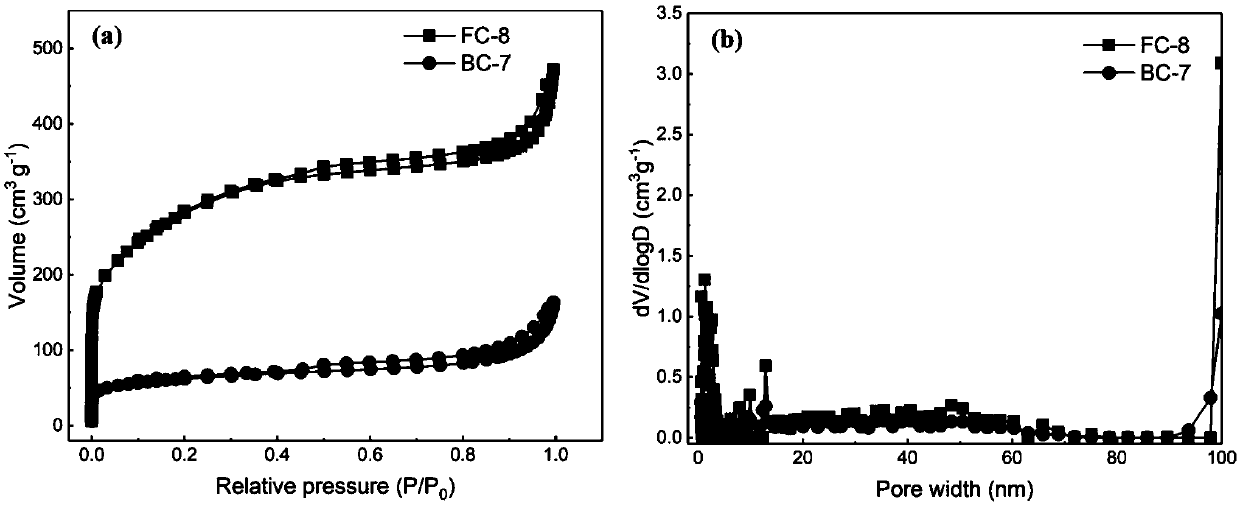

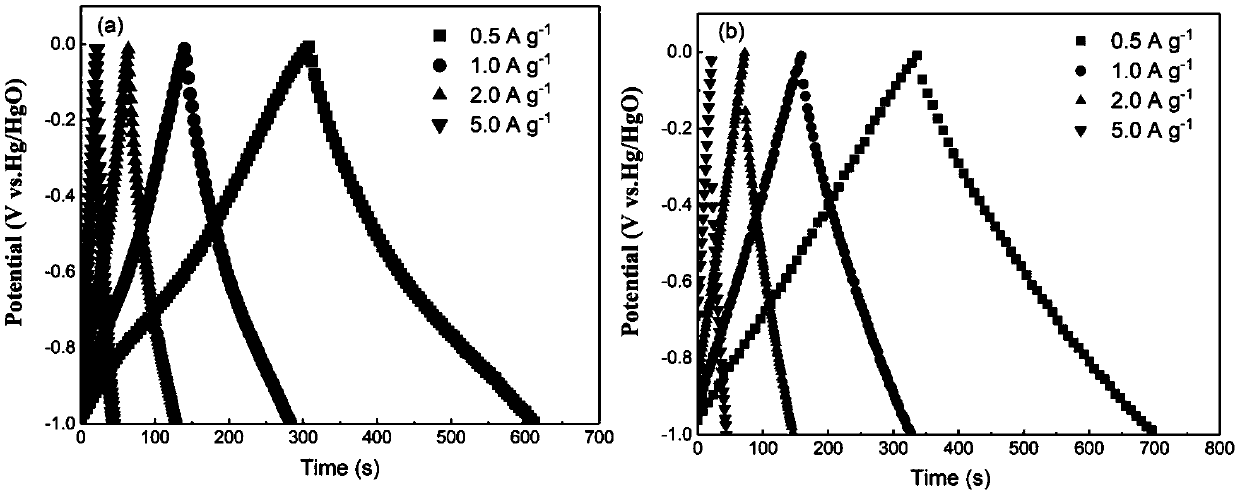

Method for auxiliary preparation of biomass-based functional active carbon material by using concentrated seawater and application thereof

PendingCN109650388AEfficient use ofAchieve metabolismPhysical/chemical process catalystsOther chemical processesSeawaterBiomass

The invention discloses a method for auxiliary preparation of a biomass-based functional active carbon material by using concentrated seawater, which comprises the following steps of: uniformly mixinga biomass material and concentrated seawater, drying, performing high-temperature carbonization under an oxygen-free condition to obtain the biomass-based functional active carbon material, and mixing the obtained first washing liquid with the biomass material again for recycling. The carbon material prepared by the method can be used as a super capacitor electrode, an adsorption material and thelike. According to the method, two difficult points that seawater is difficult to treat after desalination and an activator required by active carbon preparation is expensive are solved; meanwhile, the washing waste liquid can be combined with the chlor-alkali industry, the Hussein alkali preparation method and the seawater bromine extraction process to prepare other products, so that resources are saved, economic cost is controlled, pollution is reduced and the purposes of industry-to-industry metabolism and green circular economic process are achieved. The method for preparing the biomass-based functional active carbon has the advantages of simple operation, low cost, large specific surface area of the prepared carbon material, multiple pore structures, and excellent electrochemical, adsorption and catalytic performances.

Owner:WUHAN UNIV

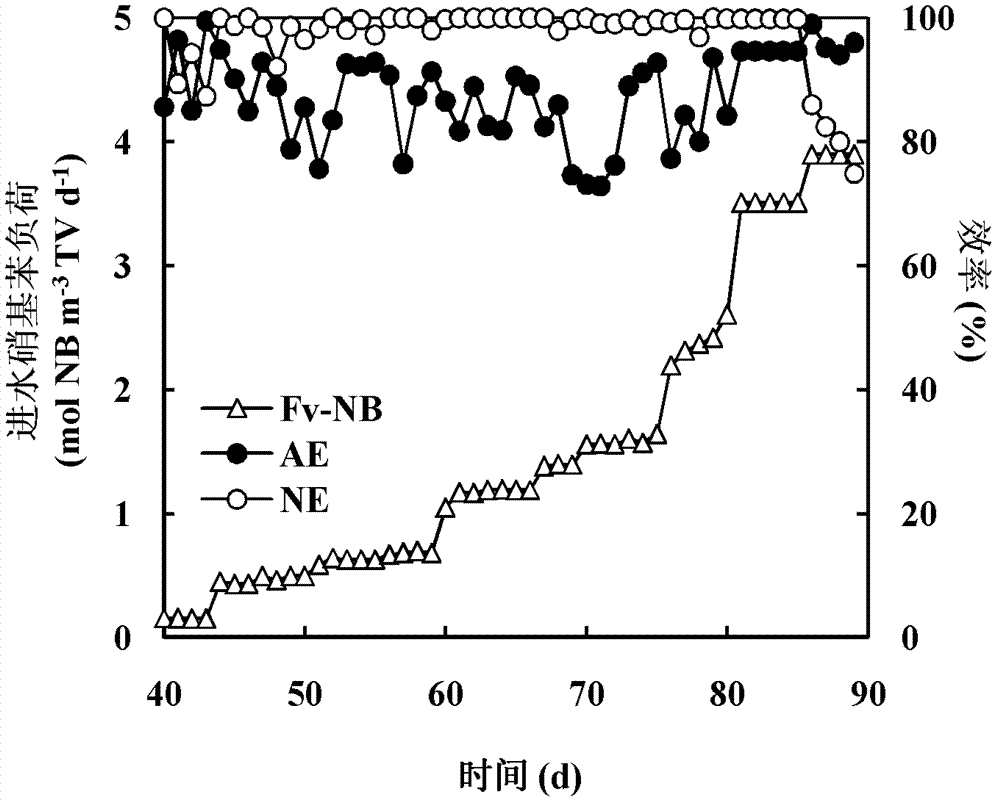

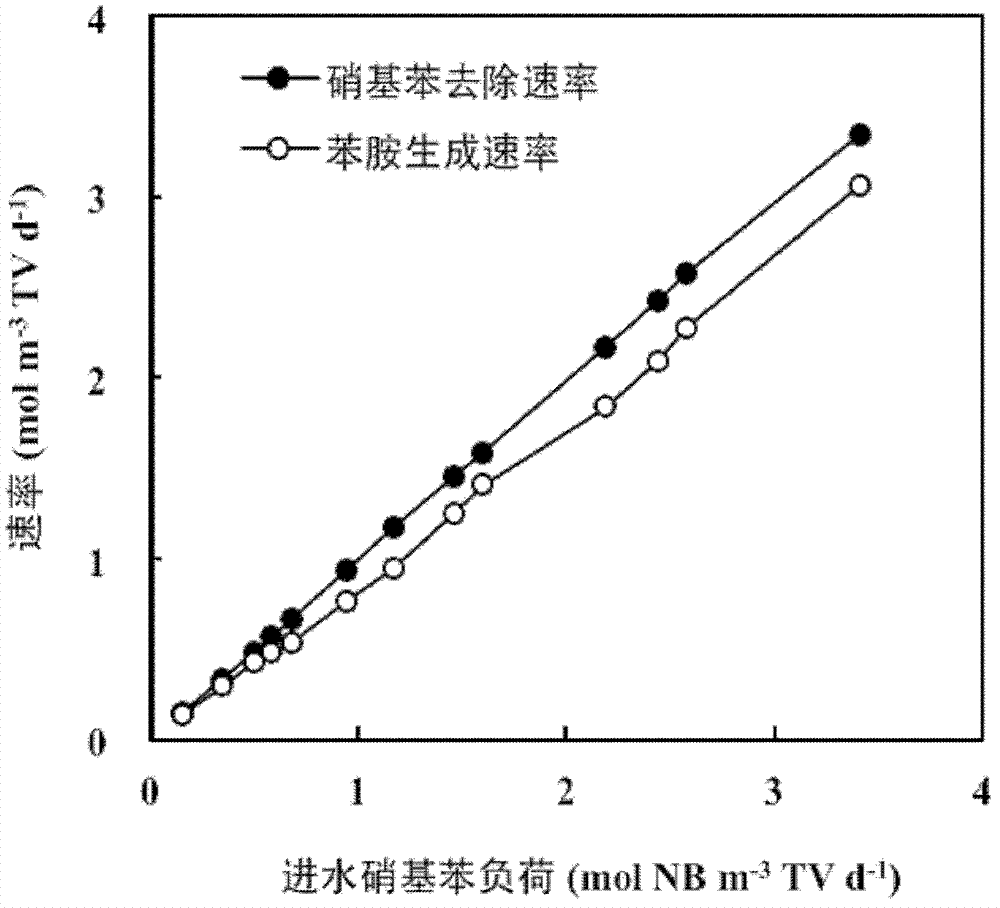

Device and method for treating high-concentration NO3-N wastewater or urban sewage by adopting improved DEAMOX continuous flow process

ActiveCN106145337AHigh nitrogen removal rateLow demand for external carbon sources and low sludge productionWater treatment parameter controlBiological treatment apparatusContinuous flowChemistry

The invention discloses a device and method for treating high-concentration NO3-N wastewater or urban sewage by adopting an improved DEAMOX continuous flow process. Short-process denitrifying granular sludge having good sedimentation performance and anaerobic ammonia oxidized granular sludge are put into a reactor, an oxygen-poor stirring strengthening substrate is added in the continuous flow reactor for mass transfer, and the problem of the poor denitrification effect caused by channeling and dead zone phenomena of a traditional continuous flow reactor is solved. Short-process denitrifying bacteria utilize organic matter and an external carbon source in urban sewage to convert NO3-N into NO2-N, then synchronous removal is performed through anaerobic ammonia oxidation reaction and NH4+-N in the urban sewage, and efficient removal of nitrogen is achieved by optimizing the flow of high-NO3-N-content wastewater, the urban sewage and the carbon source in inflow water. The device is high in nitrogen removal rate and nitrogen removal load, simple in structure and easy to optimize and control, the problem of difficult treatment of the high-NO3-N-content wastewater can be effectively solved, and the purpose of synchronous urban sewage treatment is achieved.

Owner:BEIJING UNIV OF TECH

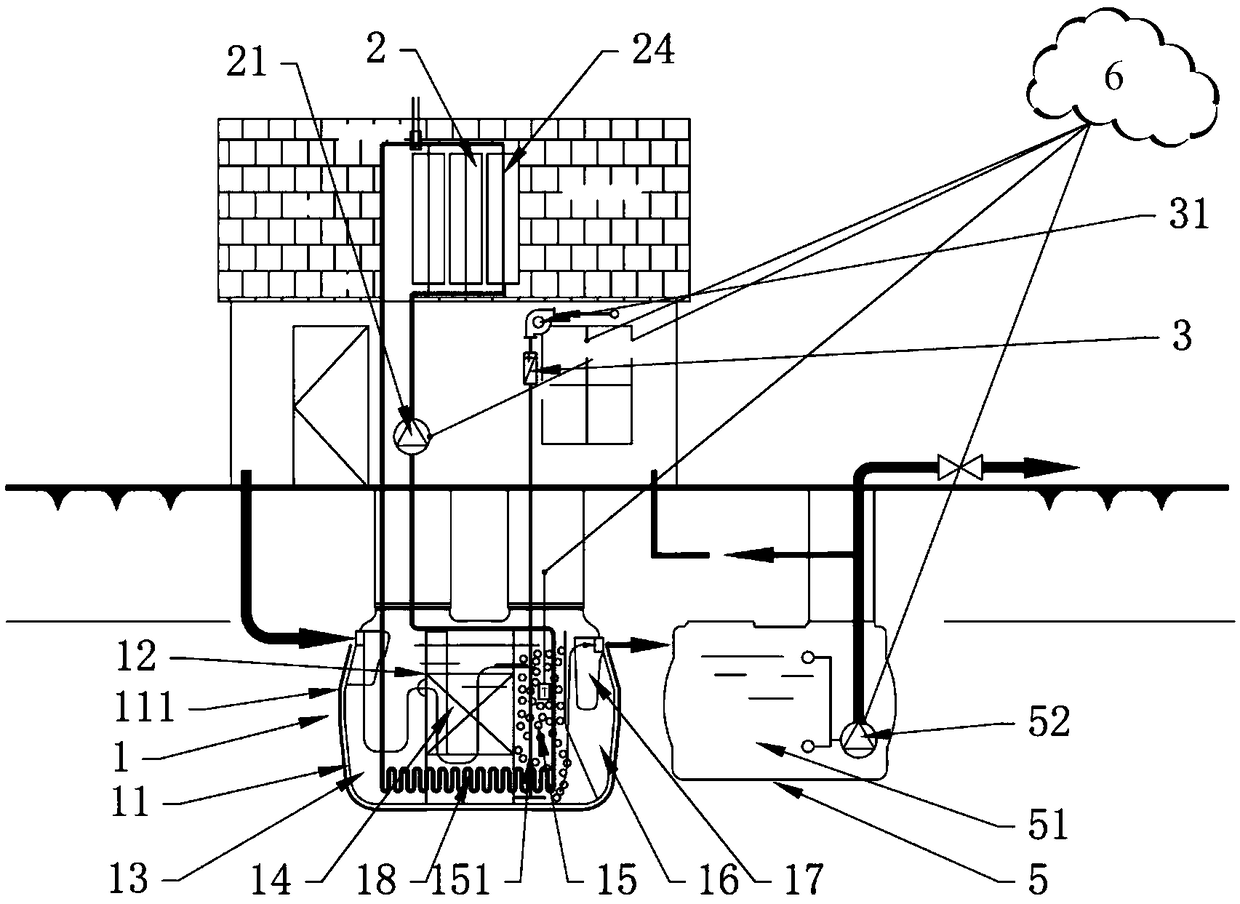

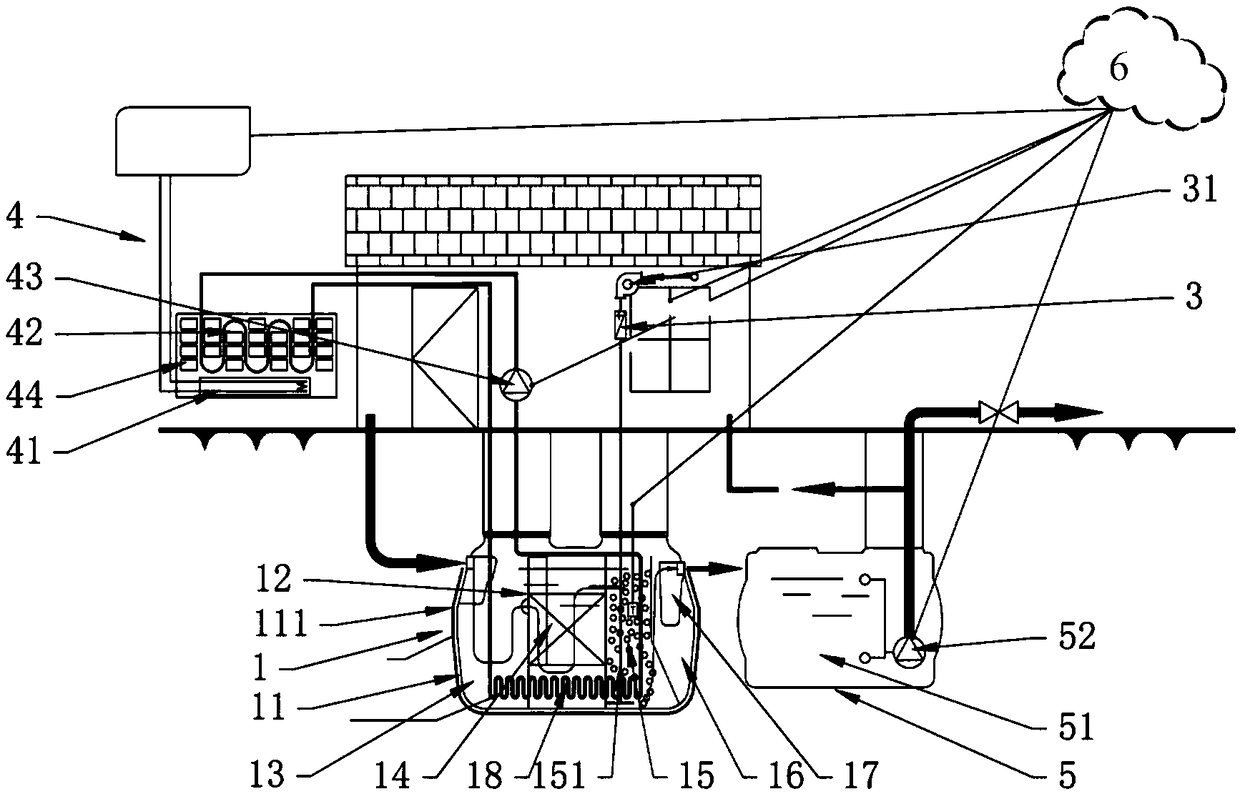

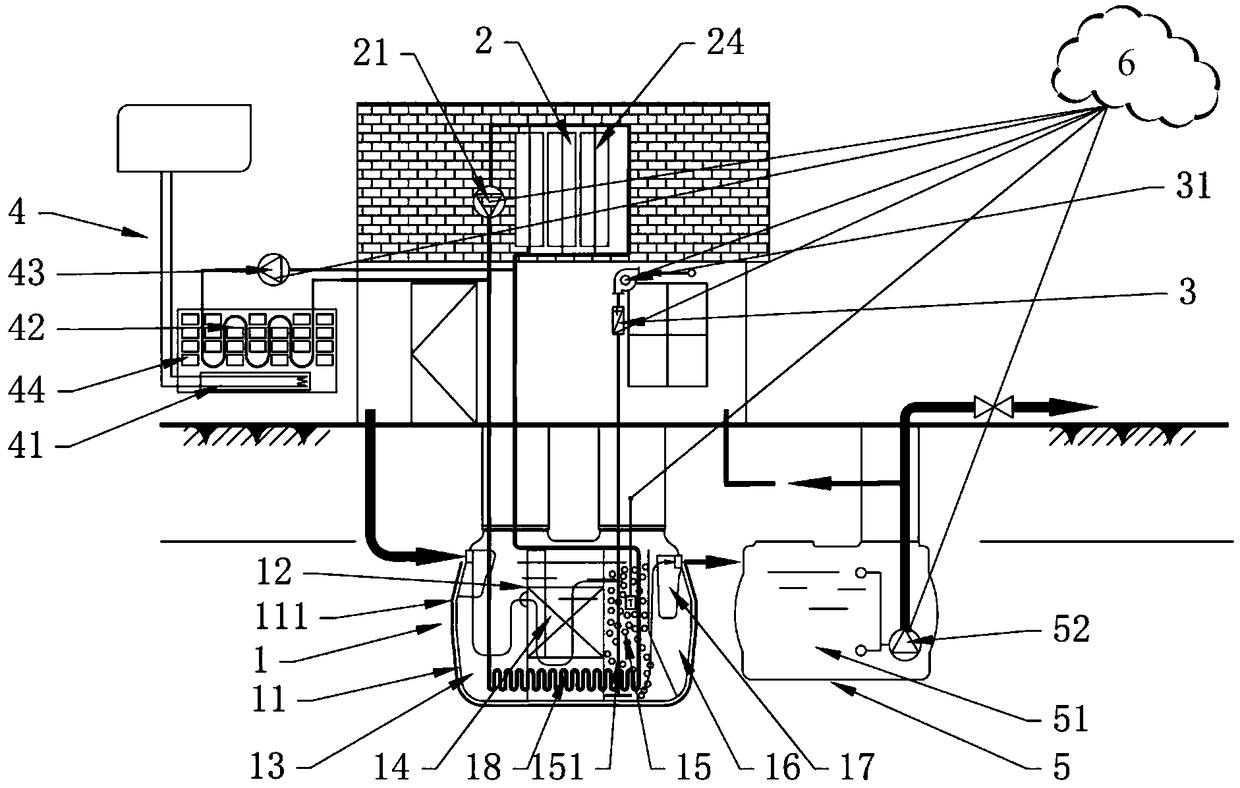

Rural domestic sewage treatment system

PendingCN109368942AGuaranteed uptimeWork reliablySpecific water treatment objectivesTreatment with aerobic and anaerobic processesThermal energyAnaerobic filter

The invention relates to a rural domestic sewage treatment system. The system comprises a purification tank, a wind-solar energy heating device, a solar energy heat collecting device, an air heating device and a cloud management platform; heat exchange pipes are arranged in an anaerobic filter tank and a carrier flowing tank of the purification tank, and the solar energy heat collecting device andthe wind-solar energy heating device are used for transforming wind energy and solar energy into heat energy of hot water, and inputting the hot water to the heat exchange pipes. The air heating device is connected with an air pump used for being configured indoors, and an air vent of the air pump is communicated with an aeration pipe of the carrier flowing tank through a breather pipe; moreover,based on nodes of the system, the cloud management platform monitors an operation strategy of a data remote intelligent control system. The domestic sewage treatment system is configured with multiple auxiliary heating means of solar heating, wind-solar energy heating, indoor air heating and the like, and according to local real-time working conditions, the operation strategy is chosen, so that the operation cost of heating is greatly reduced.

Owner:上海垒锦环境科技中心

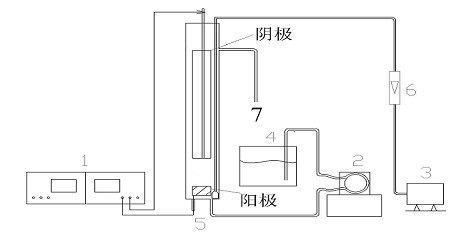

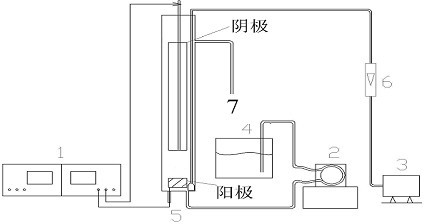

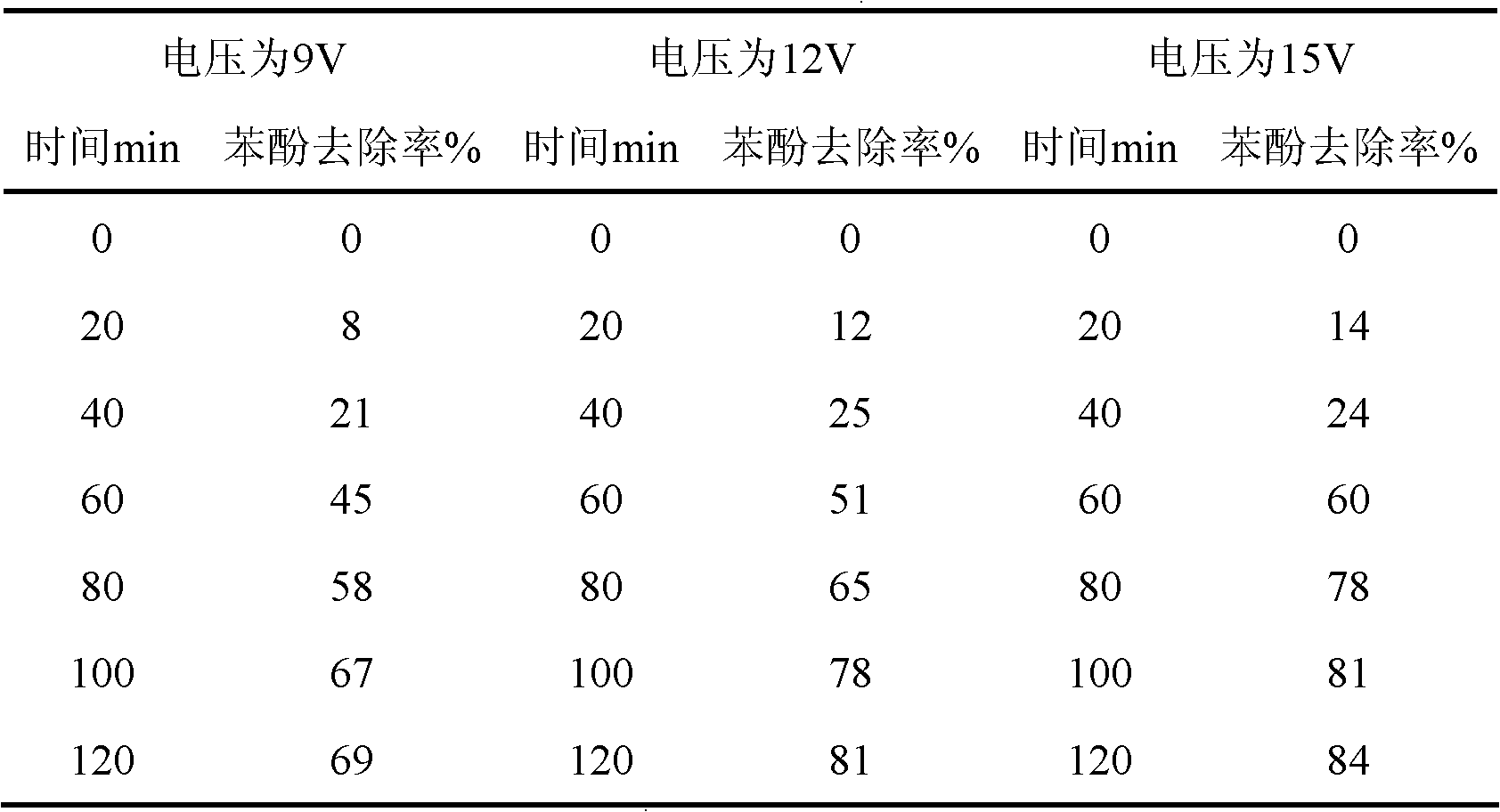

An electric fenton device for treating organic wastewater

InactiveCN102276025ALow running costEconomical and efficient processingWater/sewage treatment by oxidationFiberActivated carbon

The invention relates to an electric Fenton device for treating organic waste water, which comprises a reactor, which is a vertical container with an open top, and the cathode and anode of the reactor are connected with a DC stabilized voltage power supply; it also includes a storage tank for storing organic waste water, through The constant flow pump is connected to the bottom of the reactor; it also includes an air pump, the air output by the air pump passes through the gas flow meter, and enters the reactor from the top or bottom of the reactor; it also includes an external drain pipe, located on the upper part of the reactor, for processing Good clean water flows out from the outer drain. The cathode of the reactor uses activated carbon fiber, and the activated carbon fiber is fixed on the lead-antimony alloy wire and installed on the upper part of the reactor. Due to the adoption of the above structure, the present invention has simple structure, convenient operation and reliable operation, and can adjust the voltage, aeration rate and cathode area of the device according to the water quality of the influent to make the effluent quality meet the national wastewater discharge standard.

Owner:WUHAN UNIV

Method for treating tail gas produced by thermal desorption of contaminated soil through pulse heating

InactiveCN108815985AReduce energy consumptionLow costDispersed particle separationContaminated soil reclamationExhaust gasChemistry

The invention discloses a method for treating tail gas produced by thermal desorption of contaminated soil through pulse heating. The method comprises steps as follows: dust removal treatment, coolingtreatment, pulse heating type catalytic degradation and absorption treatment, wherein pulse heating type catalytic degradation is implemented as follows: the tail gas subjected to cooling and dust removal is sent into a catalysis treatment chamber for treatment, intermittent reactions of two stages of adsorption and heating are accompanied in the treatment process, and the adsorption process is implemented as follows: firstly, pollutants are adsorbed on a catalyst at the low temperature, a catalyst is heated to 150-500 DEG C after adsorption saturation is met through detection, and catalyticdegradation time is 2 seconds or longer; all the adsorbed pollutants are completely decomposed, a catalyst is regenerated in situ, and the regenerated catalyst can be continuously used for the next pulse adsorption stage.

Owner:JINGMEN TUODA TECH CO LTD

Water resource double-circulation feedback control system and method

ActiveCN113087030AGuaranteed removal rateEconomical and efficient processingWater treatment parameter controlTreatment control/steeringControl systemFeedback controller

The invention discloses a water resource double-circulation feedback control system and method. The system comprises a double-circulation feedback control machine. The output end of the double-circulation feedback control machine is connected with the input end of a double-circulation temperature feedback controller and the input end of a double-circulation flow feedback controller. The output end of the double-circulation temperature feedback controller is connected with the input end of a double-circulation COD feedback controller and the input end of a double-circulation BOD feedback controller, and the output end of the double-circulation COD feedback controller and the output end of the double-circulation BOD feedback controller are connected with the input end of the double-circulation feedback control machine.

Owner:TIANJIN UNIV

Method and device for remediation of persistent organic pollutant-contaminated soil

ActiveCN103272838BAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

Non-diaphragm upflow type continuous flow bio-electrochemical apparatus for treating difficultly degraded waste water

ActiveCN102502973BBalance accumulationEconomical and efficient processingBiological water/sewage treatmentInternal resistanceContinuous flow

The invention discloses a non-diaphragm upflow type continuous flow bio-electrochemical apparatus for treating difficultly degraded waste water, which relates to an apparatus for treating waste water. The invention is used for solving the technical problems of high cost and low efficiency of BESs. A housing is fixedly connected with a base plate, a lower separator plate, a cathode, an upper separator plate, an anode and a top plate from the bottom to the top. According to the invention, present bio-electrochemical reactors are greatly improved, and according to the characteristics of waste water, the electrode positions are reasonably arranged, thereby pollutants which are difficult to be degraded in water are effectively detoxified at the cathode firstly, then the pollutants in water are further degraded by the effect of anodization, and the difficultly degraded waste water treatment efficiency is improved greatly. In addition, the invention employs a non-diaphragm design, thereby not only reducing internal resistance of the reactor, but also reducing cost, which are beneficial to the extension and engineering of the reactor.

Owner:HARBIN INST OF TECH

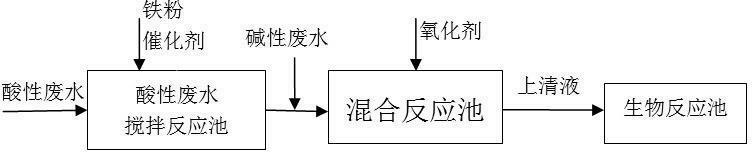

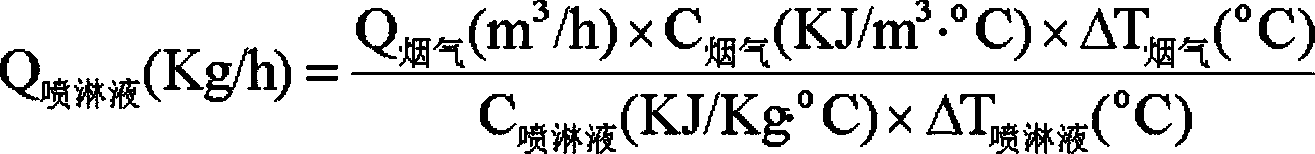

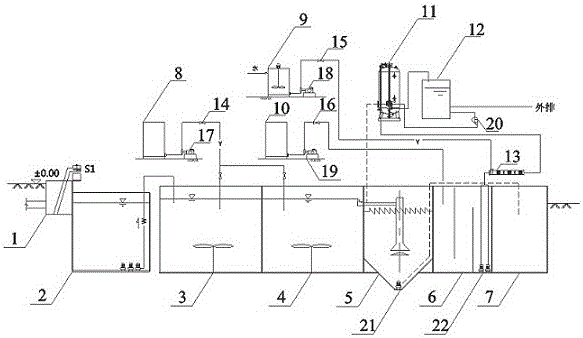

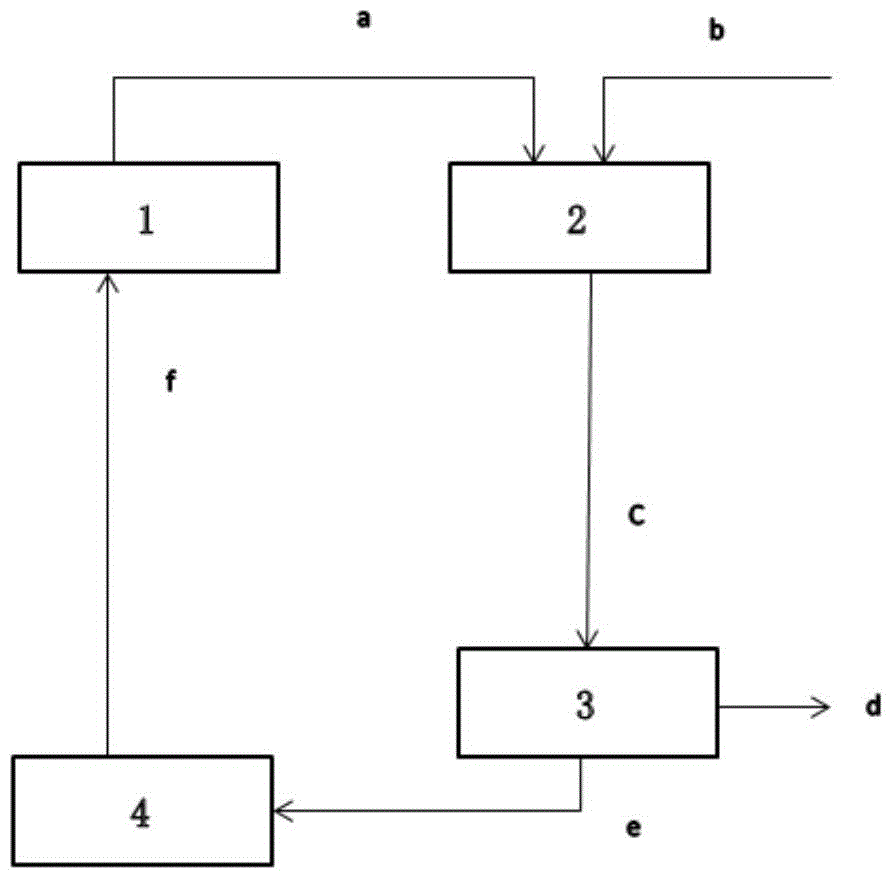

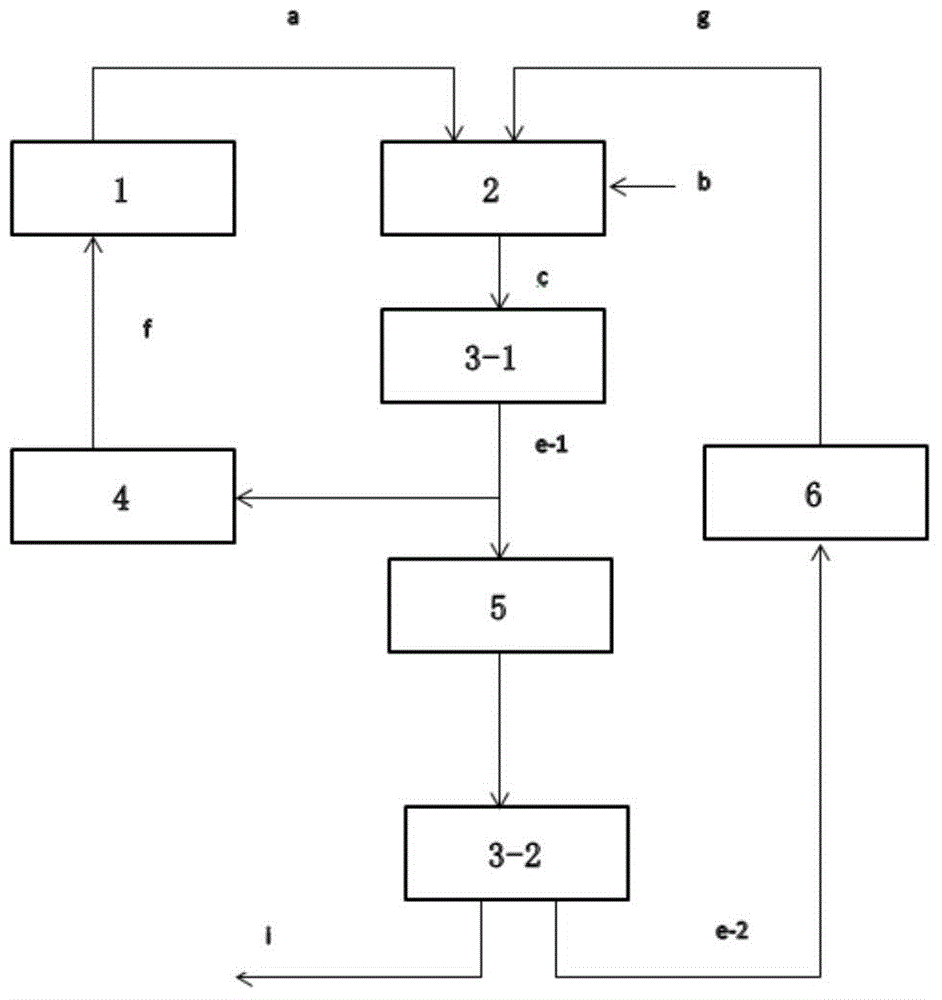

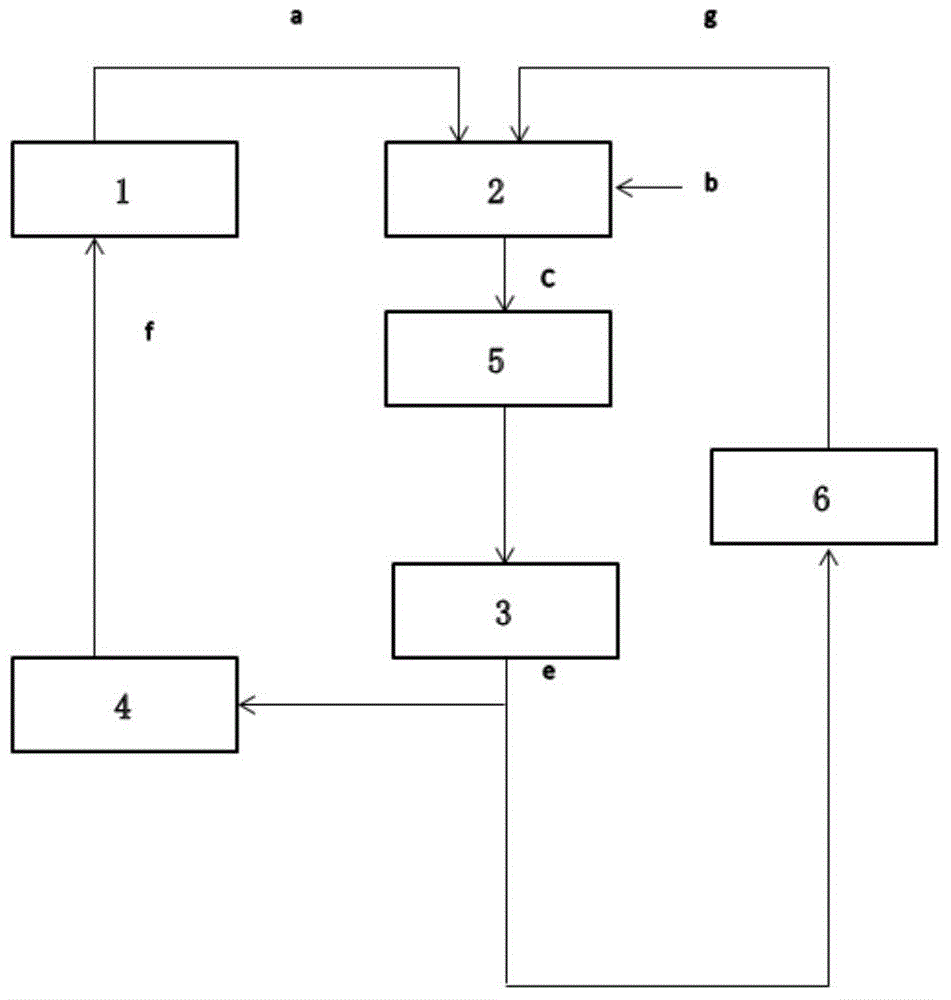

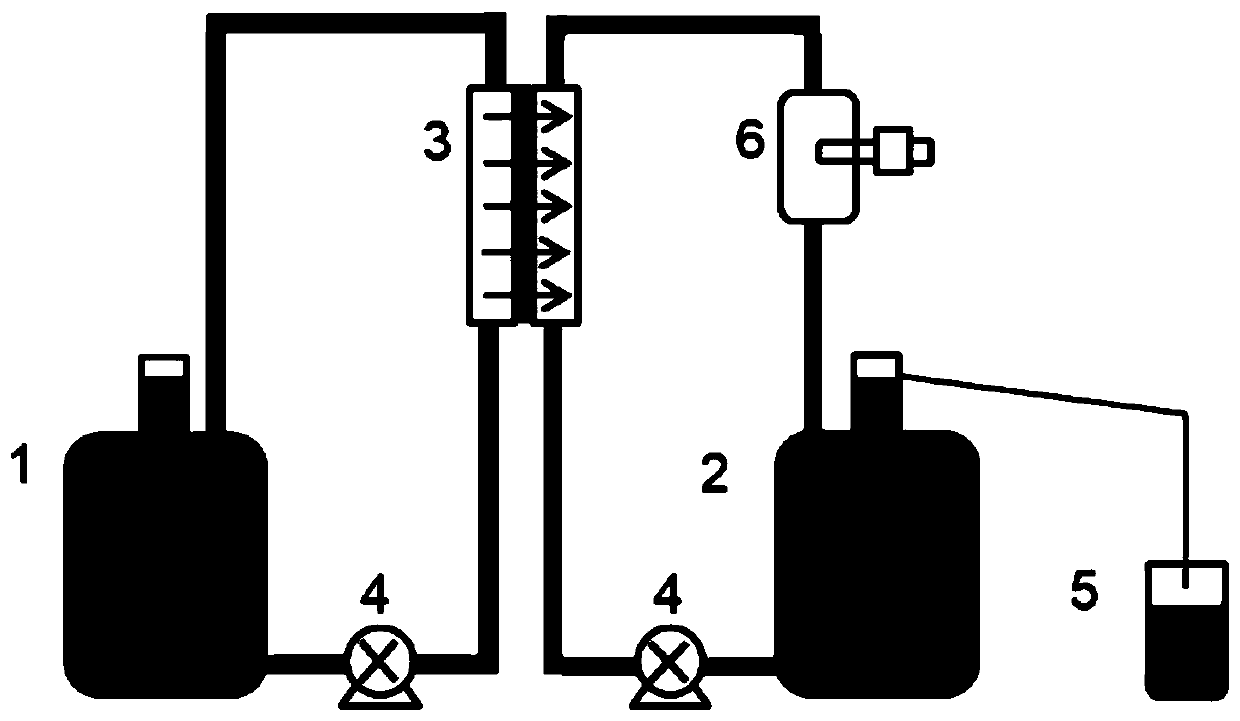

Treatment device and method for mercury-containing wastewater in chlor-alkali industry

InactiveCN105948329AEfficient removalStable emissionsWater contaminantsTreatment involving filtrationSludgeFirst-order reaction

The invention relates to a treatment device and a method for mercury-containing wastewater in the chlor-alkali industry. The treatment device comprises a grid tank 1, an adjusting tank 2, a first-order reaction tank 3, a second-order reaction tank 4, a settling pond 5, a disinfecting tank 6 and a sludge tank 7 which are connected in series in sequence, and further comprises a nano zero-valent iron preparation tank 8, wherein the nano zero-valent iron preparation tank 8 is connected with the first-order reaction tank 3 and the second-order reaction tank 4 through pipelines respectively; a coagulant preparation tank 9 and a tank type filter 11 are connected with a sterilization tank 6 through a pipeline mixer 13; the tank type filter 11 is connected with a storage tank 12 later. A materialization treatment process is adopted, so that the heavy metal mercury in wastewater can be efficiently removed, and stable up-to-standard emission can be achieved; the treatment device is good in impact resistance, so that variation of water amounts and water quality can be adapted; due to concentrated control and automatic operation, the treatment device is easy to manage; the mercury-containing wastewater can be economically and efficiently treated to meet the standard, and the purposes of energy conservation, consumption reduction and emission reduction can be met.

Owner:中钢集团天澄环保科技股份有限公司

Method for treating organic chemical wastewater

ActiveCN108083553AIncrease concentrationEasy to removeTreatment using aerobic processesWater treatment compoundsWastewaterRefractory

The invention provides a method for treating organic chemical wastewater. The method comprises the steps of S1, adjusting pH of wastewater to 6-8; S2, subjecting the wastewater treated in step S1 to contact with a polyurethane bioactive carrier to carry out first reaction; S3, subjecting the wastewater treated in step S2 to contact with an immobilized microbial carrier to carry out second reaction; S4, subjecting the wastewater treated in step S3 to contact with a heterogeneous Fenton catalyst and an oxidant to carry out third reaction. A microbial immobilization technique is used herein, thusincreasing microbial content in unit volume and increasing bioreaction speed; the heterogeneous catalytic oxidation is carried out to further catalytically and oxidatively degrade refractory organicsunable to be treated in the microbial immobilization phase, so that system effluent meets the emission standard.

Owner:兰州大学白银产业技术研究院 +1

Method and device for treating iron-containing waste sulfuric acid

InactiveCN104692338AEfficient regenerationEconomic recyclingSulfur-trioxide/sulfuric-acidSulfateRoom temperature

The invention discloses a method for treating iron-containing waste sulfuric acid. The method comprises the following steps: adding concentrated sulfuric acid into the iron-containing waste sulfuric acid until the sulfuric acid concentration in the mixed solution is higher than 45wt%; at room temperature, separating out dissolved iron in the mixed solution basically in the form of ferrous sulfate crystal; separating solid and liquid mixtures; discharging solid ferrous sulfate; diluting a part of the liquid or the entire liquid by using water to obtain regenerated diluted sulfuric acid; freezing the other part; subsequently performing solid and liquid separation; discharging water from the solid; taking the liquid as regenerated concentrated sulfuric acid; or directly freezing the solid and liquid mixtures and then performing solid and liquid separation; discharging the water of the solid and the ferrous sulfate crystal; diluting a part of the liquid by water to obtain regenerated diluted sulfuric acid, and taking the other part as regenerated concentrated sulfuric acid. The invention also discloses a device for treating the iron-containing waste sulfuric acid. The sulfuric acid treated by the method and the device disclosed by the invention is basically free of iron component, can be effectively reutilized, is high in concentration and can be used as mixed concentration sulfuric acid or reused for acid washing after being diluted, so that economical and high-efficiency treatment of the waste sulfuric acid is realized.

Owner:金大一

Method for treating washing wastewater by using composite-film modified sintered gangue ceramsite

InactiveCN102923836AEconomical and efficient processingReduce dosageWater/sewage treatment by oxidationChemical oxygen demandPtru catalyst

The invention discloses a method for treating washing wastewater by using composite-film modified sintered gangue ceramsite, belonging to the technical field of wastewater treatment in explosives industries. The method comprises the following steps: using the sintered gangue ceramsite modifiedx by using a TiO2 / SiO2 composite film as a filling substance; using ultraviolet as a potential radiation source; stimulating a catalyst to produce holes and duplets, and making use of the strong oxidation-reduction function to treat the washing wastewater produced in the dinitrodiazophenol production process. The method provided by the invention not only overcomes the problem of long photo-catalytic oxidation time of pure TiO2-modified ceramsite for treating the dinitrodiazophenol washing wastewater, but also has small dosage of raw materials compared with a traditional catalytic oxidation method, the chromaticity and the COD (chemical oxygen demand) have good removal effects; the effluent quality can meet the discharge requirement of Discharge Standard for Water Pollutants from Ordance Industry Ammunition Loading (GB14470.3-2002), the operation is rather concise, the reaction process cannot generate colored ions, and the effluent chromaticity is also reduced.

Owner:CHANGZHOU UNIV

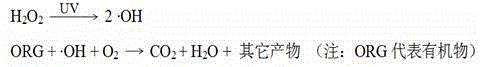

Method of treating aniline waste water through photo-catalytic oxidation

InactiveCN105036238AImprove degradation efficiencyQuick responseWater/sewage treatment by irradiationWater/sewage treatment by oxidationIndustrial waste waterCatalytic oxidation

The invention provides a method of treating aniline waste water through photo-catalytic oxidation and belongs to the technical field of industrial waste water treatment. The method includes the step of catalytically oxidizing the aniline pollutant into CO2, H2O and small-molecular organic substances in the presence of an oxidizing agent under irradiation of ultraviolet light. The method can be used for treating the aniline waste water in the fields of refining chemical engineering, printing and dyeing, pharmacy and the like. The method is quick in reaction speed, is complete in deep oxidization, is economic and high-effective in treatment process and is free of secondary pollution. A test proves that the method is higher than 90% in removal rates of both the aniline substances and chromaticity in the aniline waste water in various industries, and treated water satisfies the first-grade standard requirement in national pollutant integrated emission standard (GB8978-1996).

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

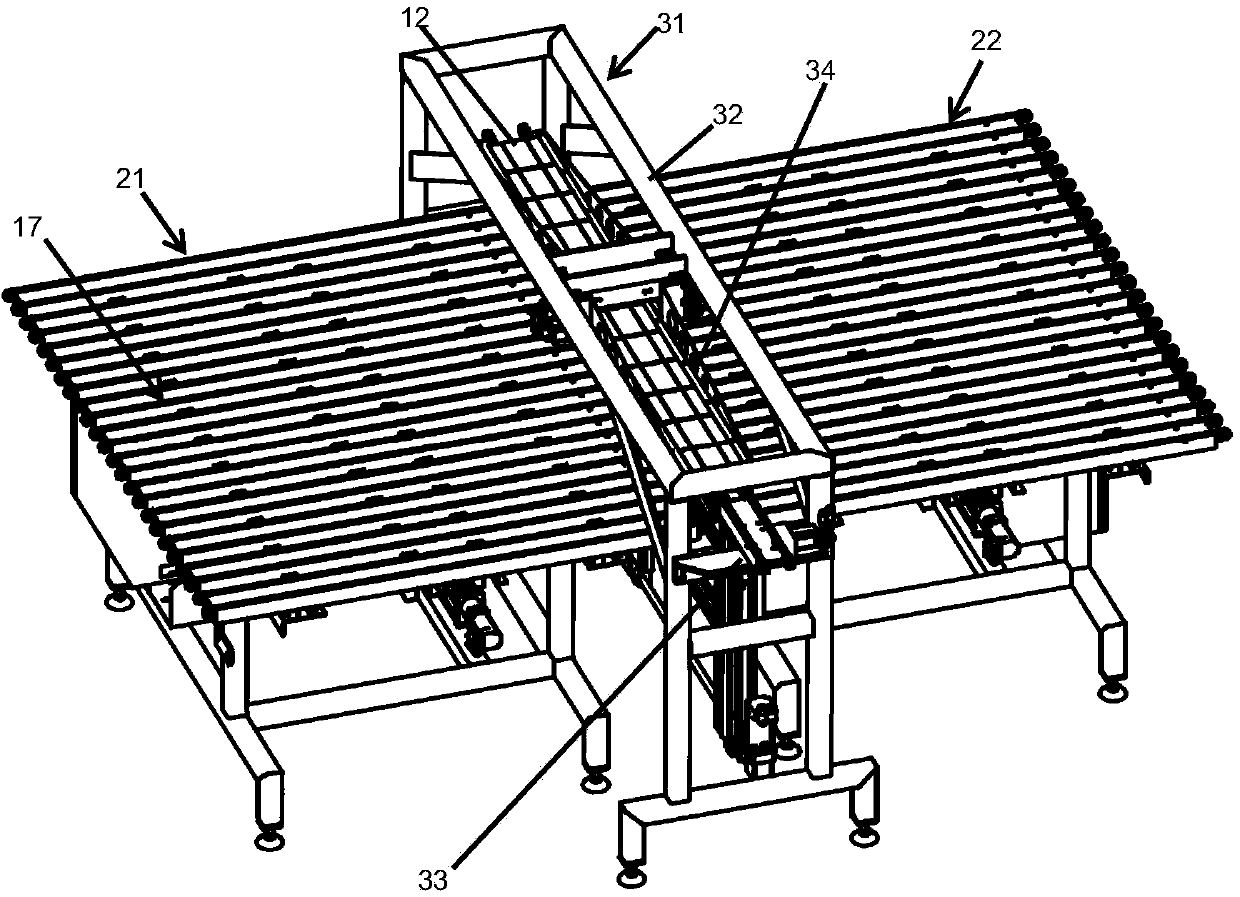

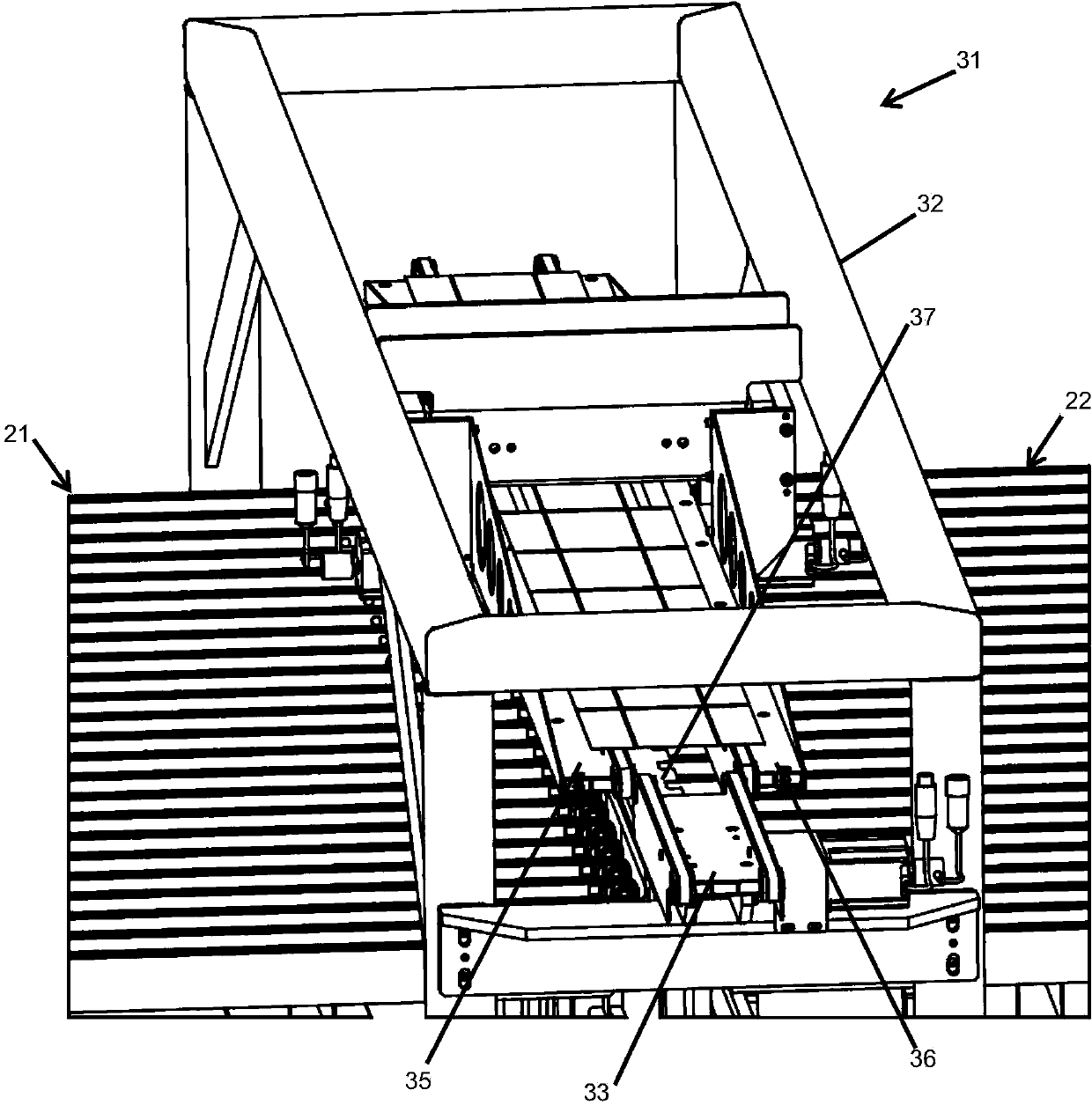

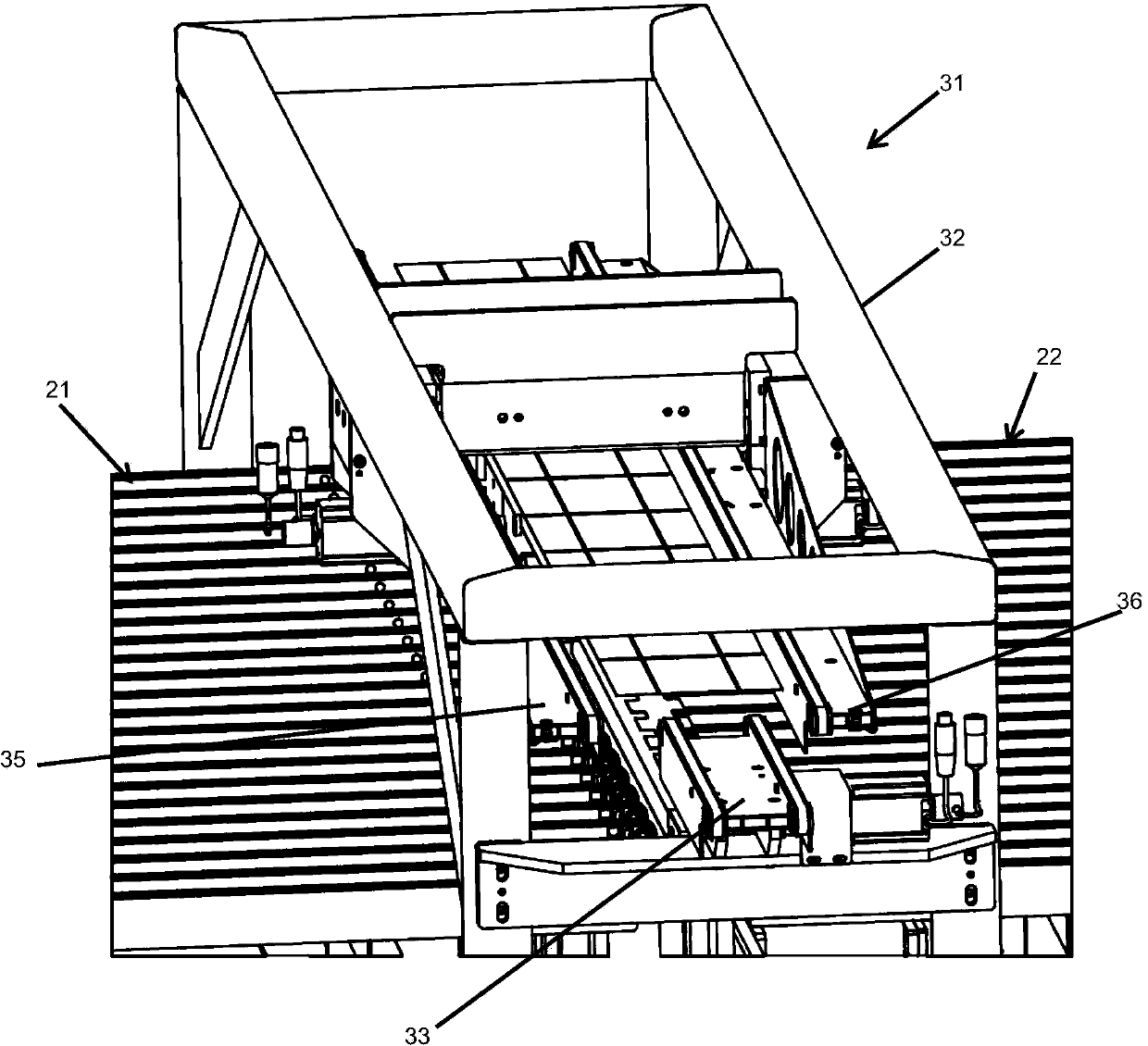

System and method for assembling a solar cell matrix

InactiveCN104011880AEasy to operateSafe handlingPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention refers to a system (11) for the formation of a matrix(13)of solar cells, having a unit (16) with an input area (17) and an output area(18). Between the input area (17) and the output area (18) the strings (12) are conveyed on the conveying unit (16)in a conveying direction(19). The system (11) further comprising means (31) for placing strings (12) on the input area(17) and rotating means (41, 51, 61) designed to lift a string (12) from the conveying unit (16), rotate that string about axes and lower it onto the same conveying unit (16).The invention refers further to a method using such a system (11).

Owner:佐蒙特股份有限公司

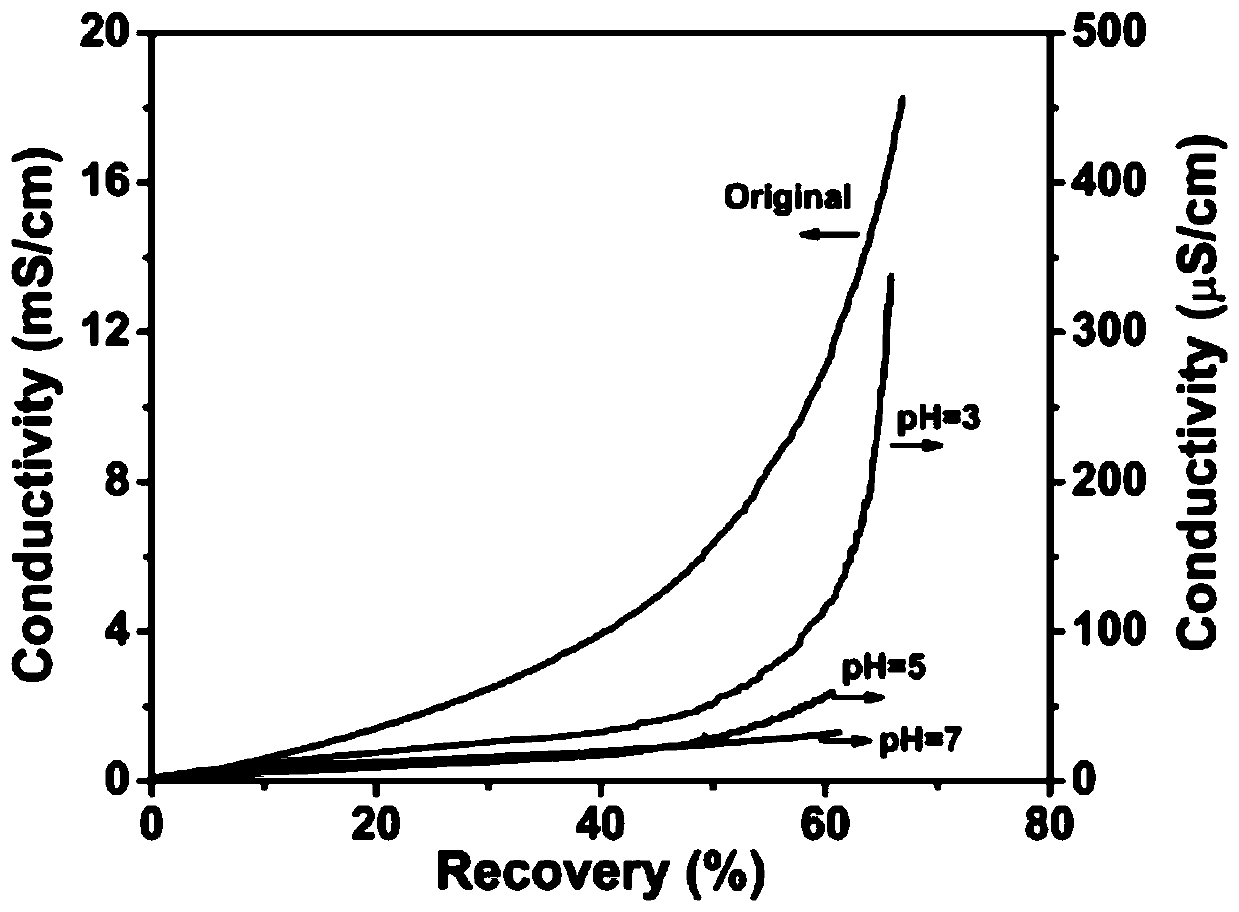

Method for treating spent catalyst noble metal recovery wastewater

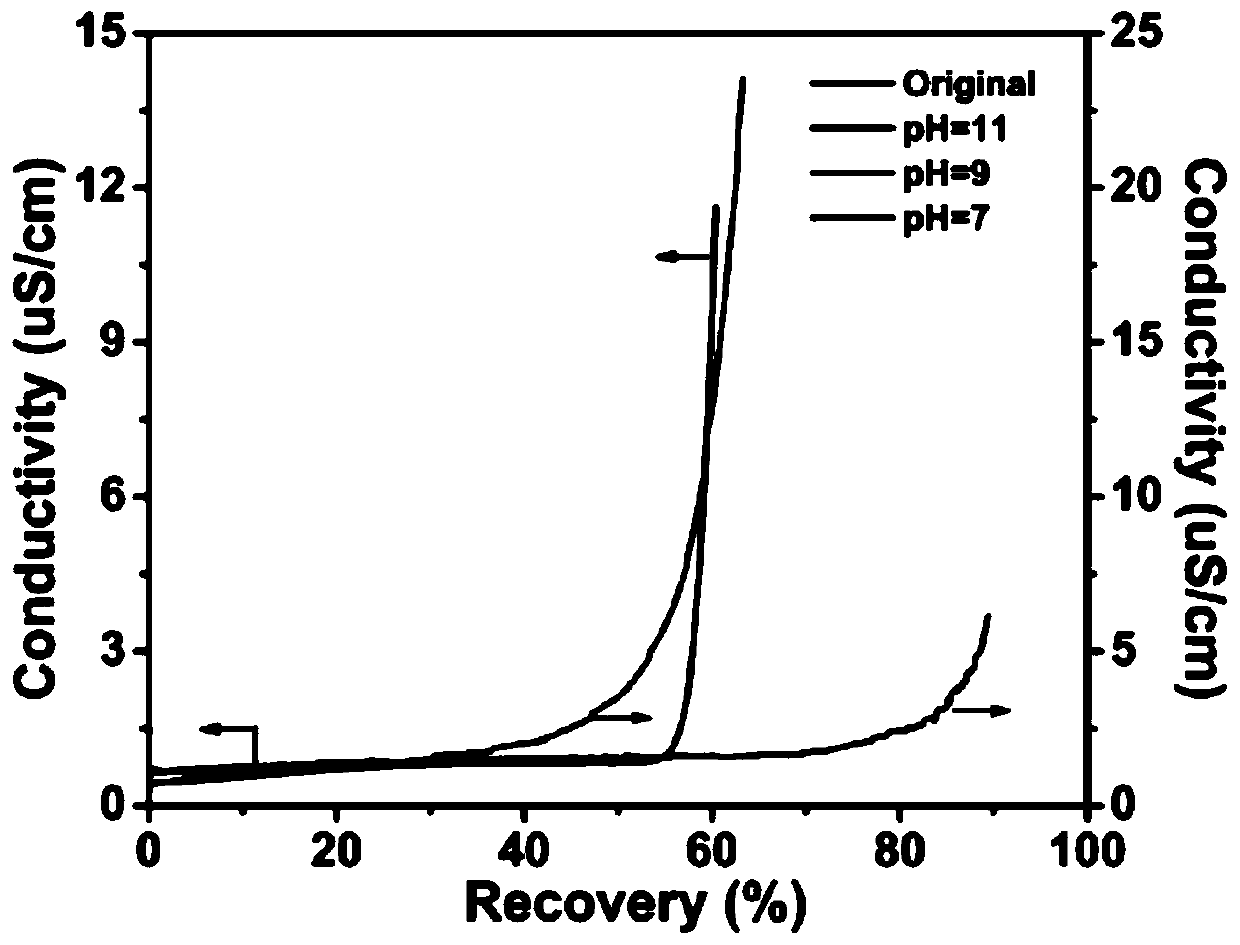

InactiveCN111547917AImprove qualityReduce conductivityTreatment involving filtrationWaste water treatment from metallurgical processPtru catalystPhysical chemistry

The invention relates to a method for treating spent catalyst precious metal recovery wastewater. The method comprises the following steps: treating wastewater with different pH values by adopting a membrane distillation process, hydroxide colloid is formed by utilizing the transformation of the form of coexisting metal ions in the wastewater; soluble silicon (SiO2) in wastewater is removed through mutual action of colloid with positive charges and silicate with negative charges in the wastewater, so that membrane pollution is reduced, high-quality hydrochloric acid HCl and low-conductivity high-quality wastewater can be obtained, and the volume of the wastewater can be greatly reduced. According to the method, resources can be recovered from the spent catalyst noble metal recovery wastewater, the wastewater volume can be greatly reduced, near-zero emission of the wastewater can be further realized, and strong acid or strong alkali high-salinity wastewater generated by spent catalyst noble metal recovery can be economically and effectively treated.

Owner:DONGHUA UNIV +1

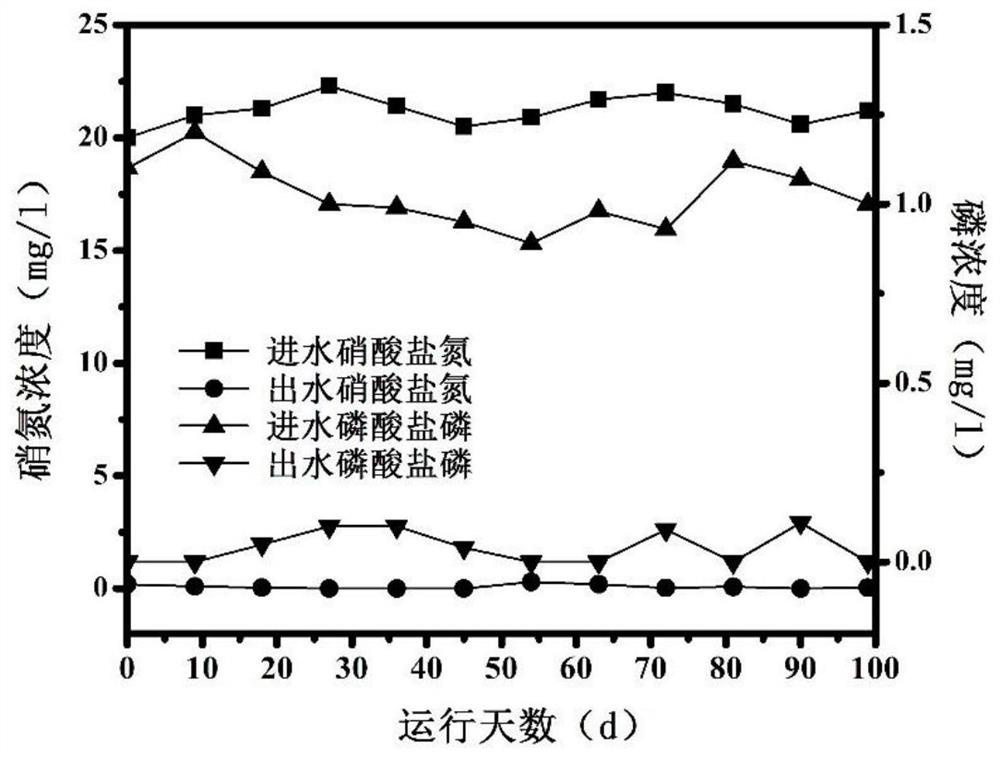

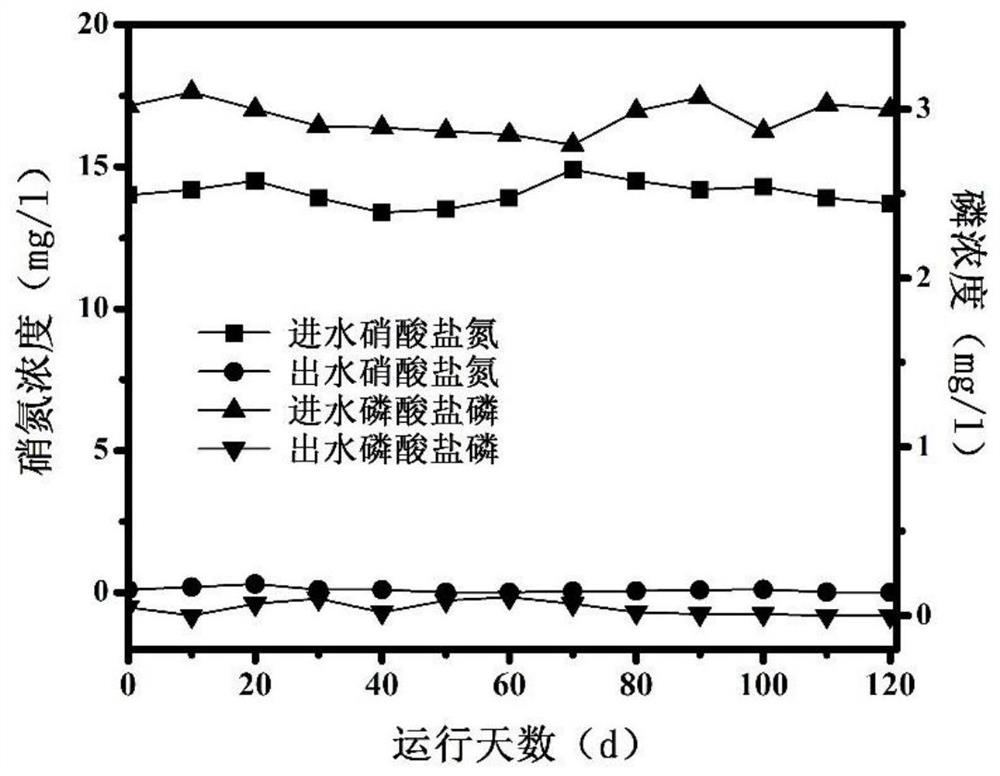

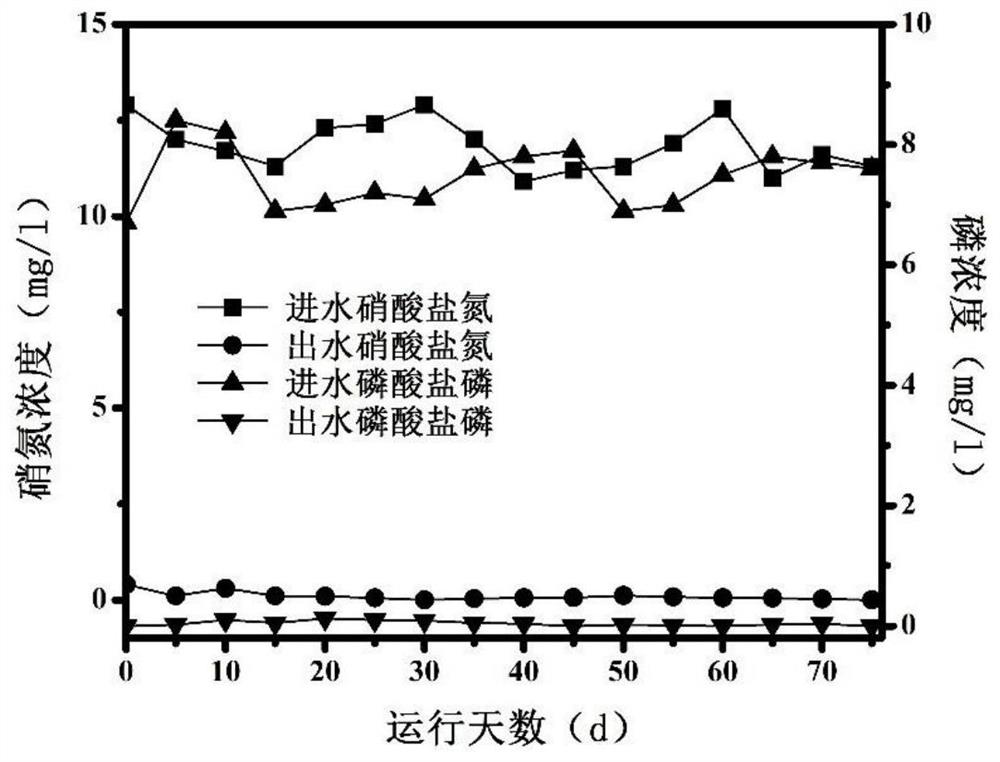

A coupling packing autotrophic denitrification biological filter and its application

ActiveCN109052641BDifficult to dissolveIncrease speedWater treatment compoundsTreatment with anaerobic digestion processesBiological filterPyritic sulfur

The invention discloses a coupling filler autotrophic denitrification biofilter and application and belongs to the technical field of sewage treatment. Pyrrhotite, sulfur and a carbon source are utilized to be mixed and coupled according to certain proportion; then the materials are put into a reactor, and the autotrophic denitrification biofilter can be formed after inoculating biofilm formation;sewage flows through the biofilter, and nitrogen and phosphorus in the water are removed. The biofilter disclosed by the invention has the advantages of simpleness, easiness, practicability and shortbiofilm formation time; when the biofilter is utilized to treat nitrogen and phosphorus containing sewage, hydraulic retention time is only 0.5 to 3 h, and yielding water can meet a requirement; furthermore, the biofilter has the advantages of excellent nitrogen and phosphorus removal effect, low cost and suitability for engineering application.

Owner:NANJING UNIV

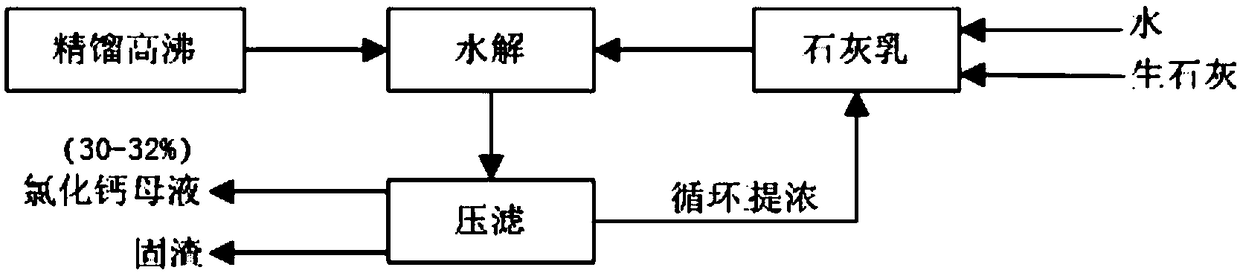

Process for preparing calcium chloride by utilizing high-boiling residues generated by silicon tetrachloride rectification via hydrolysis

PendingCN109133138AEnvironmental protectionEconomical and efficient processingCalcium/strontium/barium chloridesChlorideHydrogen chloride

The invention discloses a process for preparing calcium chloride by utilizing high-boiling residues generated by silicon tetrachloride rectification via hydrolysis. According to the process, quicklimeis made into lime milk, and the lime milk is reacted with hydrogen chloride (hydrochloric acid) generated by high-boiling residues via hydrolysis to prepare the calcium chloride. The process is greenand environmentally friendly, and is capable of economically and effectively treating the high-boiling residues generated by silicon tetrachloride rectification so as to provide a new way for the recycle of the high-boiling residues generated by silicon tetrachloride rectification.

Owner:浙江富士特硅材料有限公司

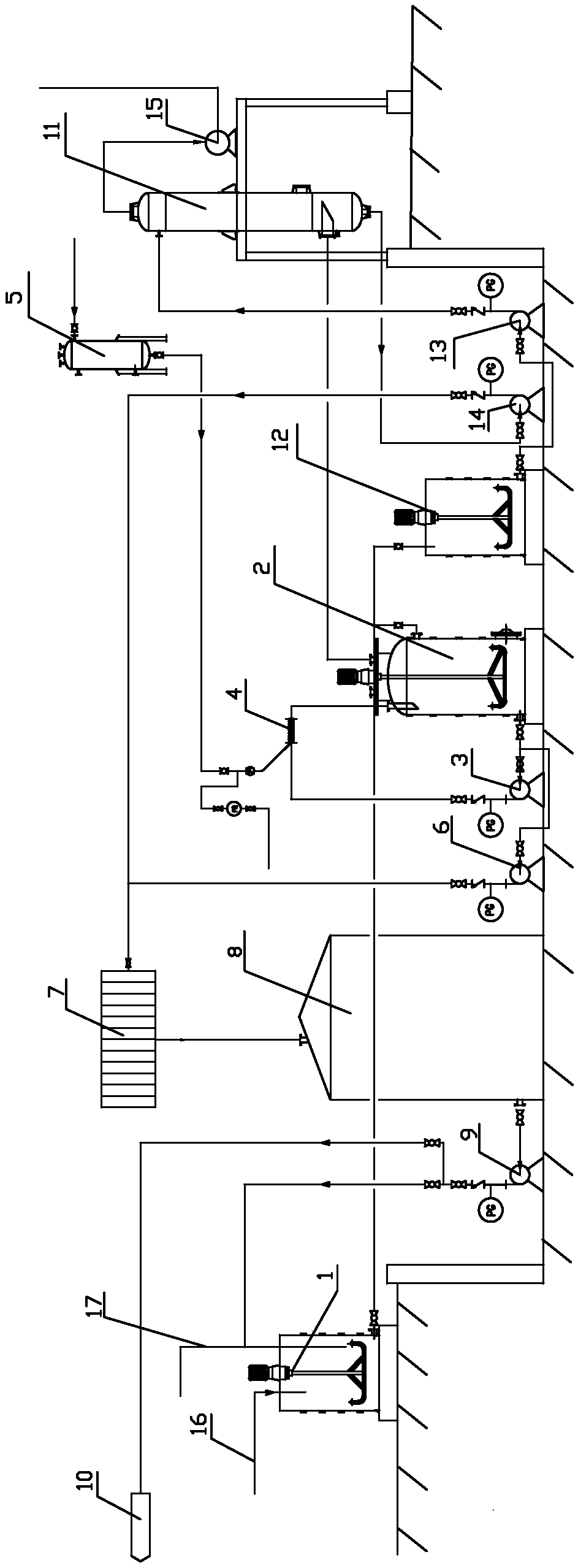

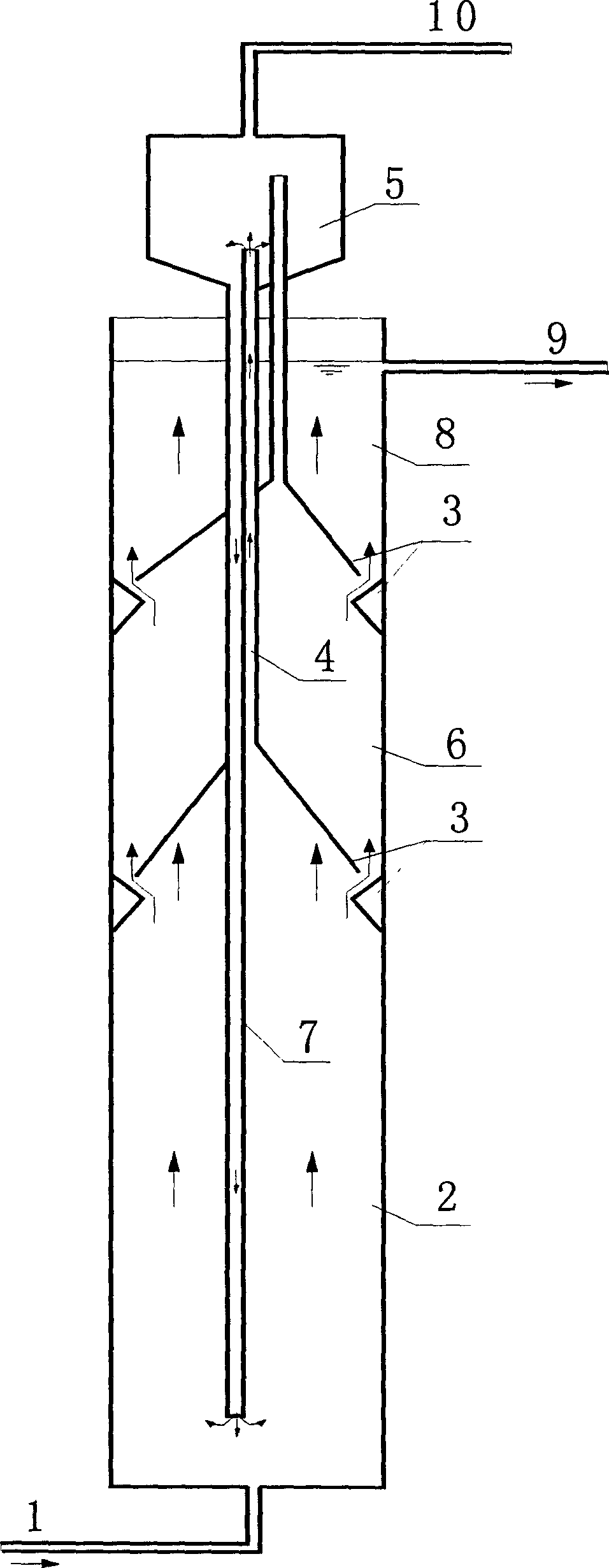

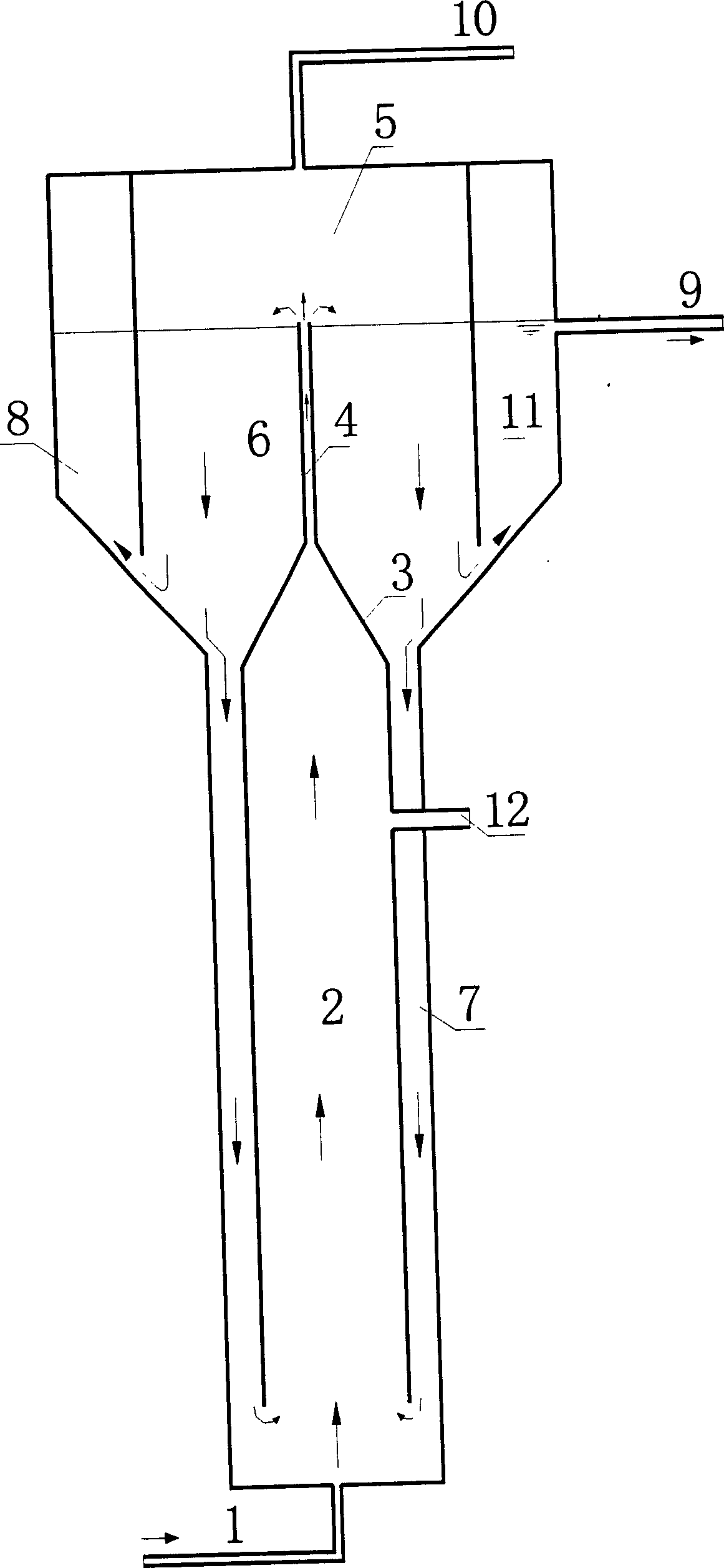

Anaerobic/aerobic dual purpose waste water treatment system

InactiveCN1226201CEconomical and efficient processingStart fastTreatment using aerobic processesWaste based fuelWater treatment systemGas compressor

A aerobic / anaerobic system for treating sewage has an anaerobic lifting flow reactor with inlet tube and aerating head connected via said inlet tube to gas compressor communicated via valve to the air, O2, or N2 cylinder, and the gas outlet tube of said reactor is connected to marsh gas cabnet communicated with compressor. Its advantages are both running modes, high stability, and high start speed.

Owner:TSINGHUA UNIV

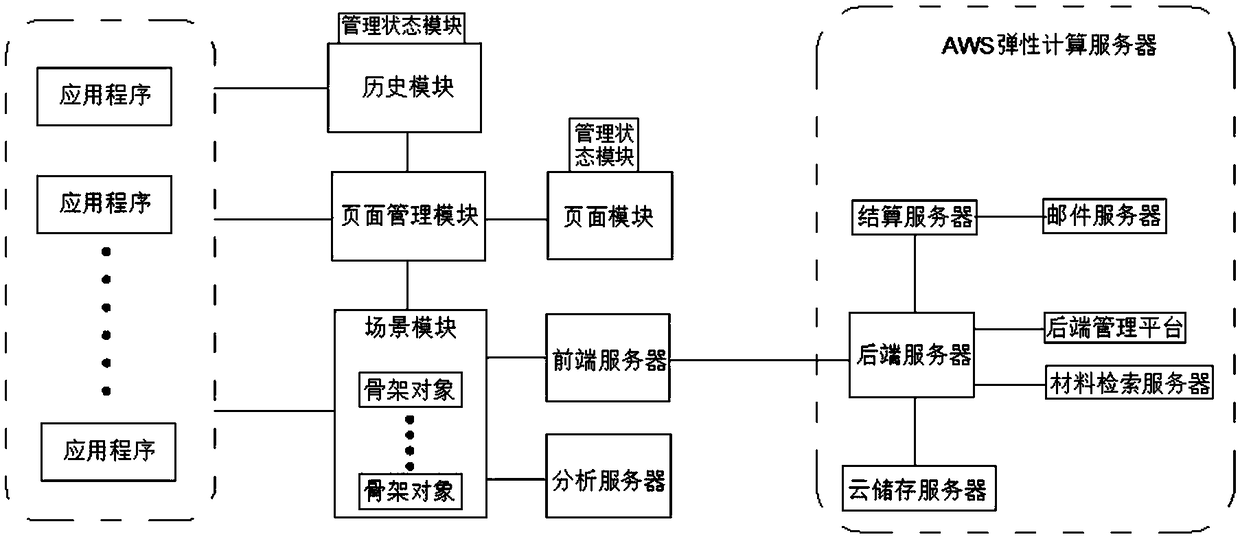

Internet of things-based remote platform monitoring system

ActiveCN108470047AEfficient constructionSolve the problem of difficult retrievalSoftware engineeringWebsite content managementEnd systemData source

The invention discloses an internet of things-based remote platform monitoring system. The system comprises a client, a front-end system and a rear-end system, wherein the front-end system and the rear-end system are used for supporting the client; the client comprises a plurality of independent application programs which are capable of displaying pages; the front-end system comprises a history module, a page management module and a scene module; the page management module is used for creating and managing a page module of the front-end system; the page module consists of a plurality of pages;the scene module is connected with a front-end server for providing a data source and an analysis server; the rear-end system comprises a rear-end server connected with the front-end server; and therear-end server is connected with a cloud storage server, a cargo information retrieval server, a rear-end management platform and a user settlement server. The system has the advantages of being convenient to retrieval cargo information, high in language processing and analysis efficiency and good in big data collection and processing.

Owner:谭亮

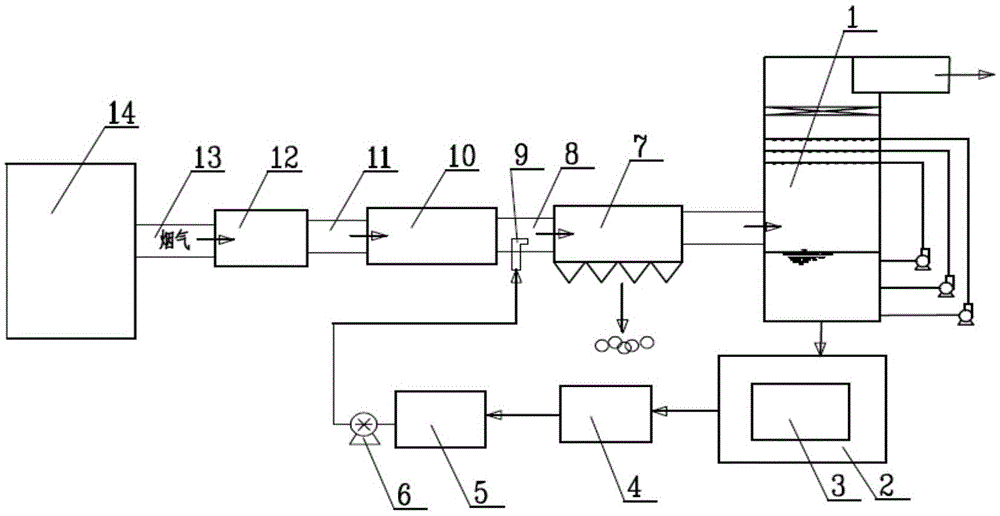

Desulfurization wastewater treatment process and treatment device thereof

PendingCN113896267AReduce the impact of safe operationsEconomical and efficient processingLighting and heating apparatusSpecific water treatment objectivesAtomizer nozzleFlue gas

The invention discloses a desulfurization wastewater treatment process which comprises the following steps: when hot flue gas generated by a boiler flows through an economizer, high-temperature heat of exhausted flue gas can be absorbed and recycled, and meanwhile, the exhaust gas temperature of the flue gas is reduced; according to the invention, the desulfurization wastewater is conveyed to the wastewater spray evaporator through the wastewater pump, the atomized desulfurization wastewater is sprayed into the flue by adopting the atomizing nozzle, the atomized desulfurization wastewater is quickly evaporated in the flue by utilizing the heat of the flue gas, and impurities in the wastewater enter the dust removal equipment together with fly ash in the form of solid substances along with the flue gas, so that compared with direct flue spray evaporation, bypass spray evaporation can greatly reduce the influence of spray on safe operation of a dust remover; and flue gas waste heat is used for evaporation drying, and desulfurization waste water can be economically and efficiently treated, so that the investment construction cost and the operation cost of a power plant waste water zero discharge system are greatly reduced; and the exhaust gas temperature is reduced through spray, and economic and stable operation of dust removal, a fan and desulfurization equipment is facilitated.

Owner:HUANENG CHAOHU POWER GENERATION

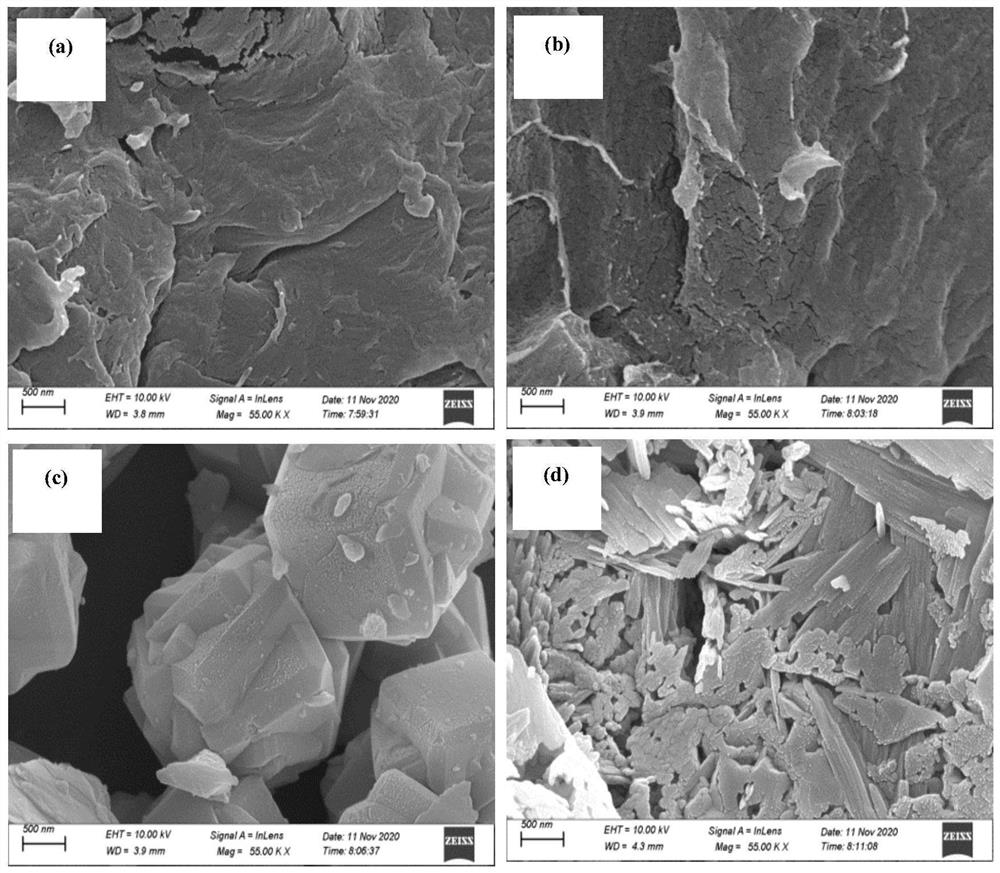

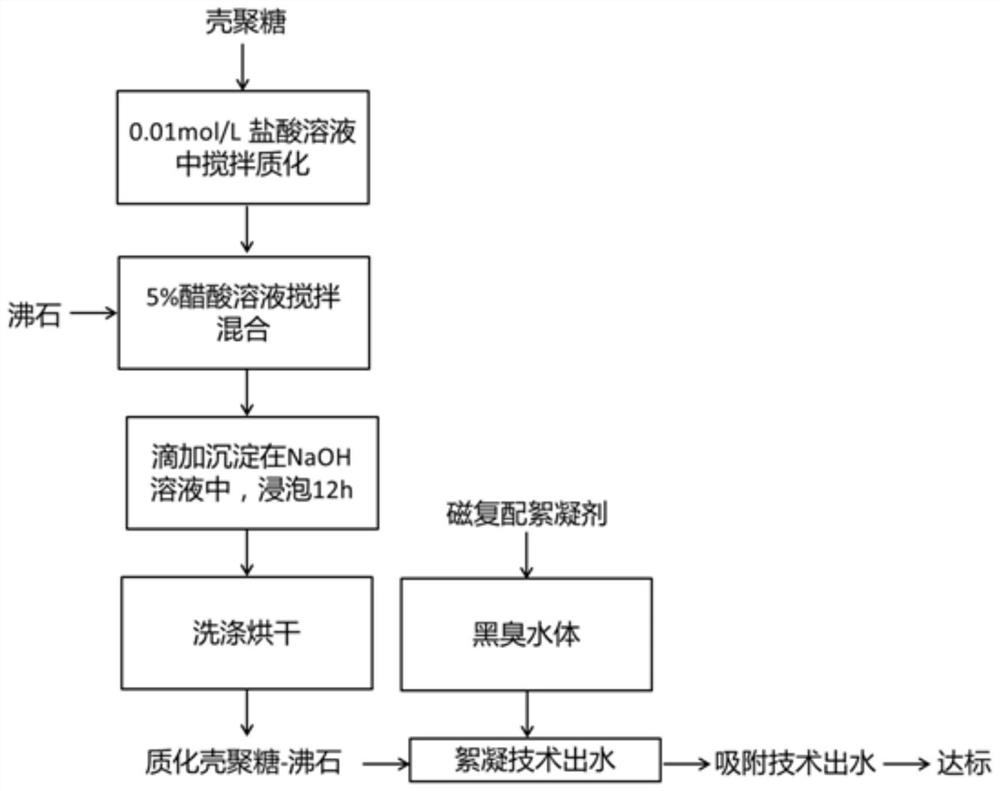

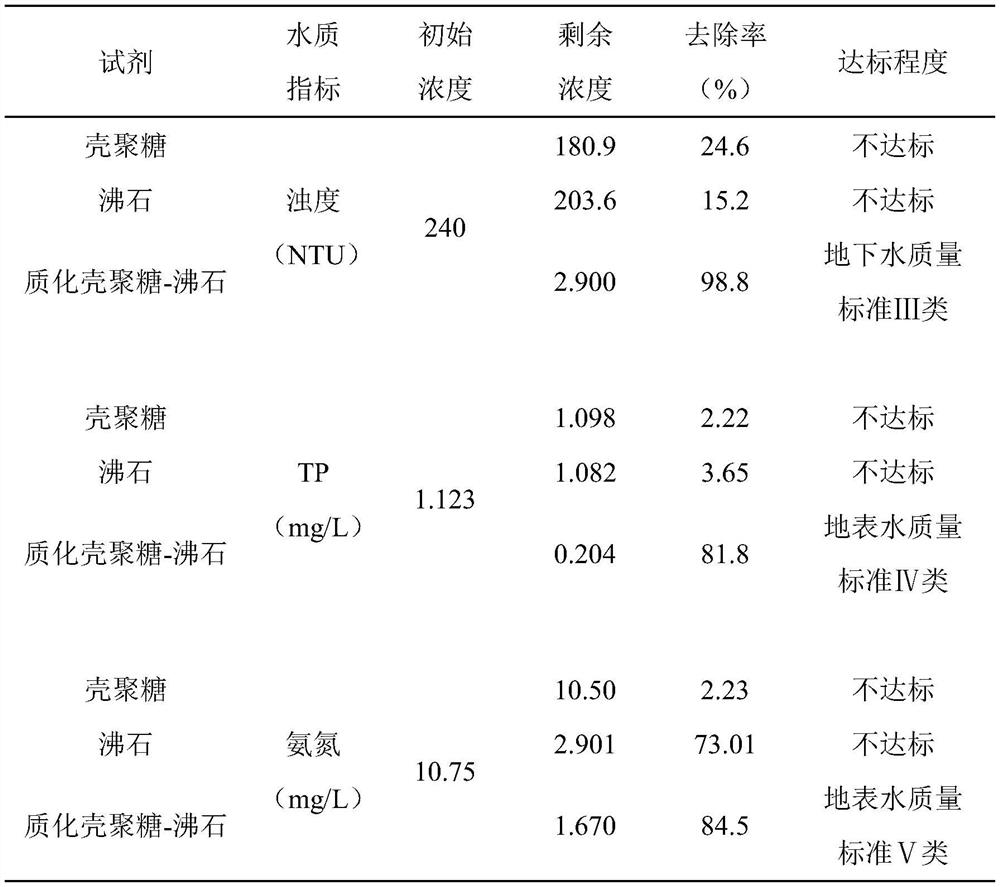

Flocculation-adsorption reagent and method for synchronously removing turbidity, ammonia nitrogen and TP in black and odorous water body

PendingCN112794416AAchieve recyclingExtension of timeWater treatment parameter controlOther chemical processesProtonationIron sulfate

The invention discloses a flocculation-adsorption reagent and method for synchronously removing turbidity, ammonia nitrogen and TP in a black and odorous water body. The flocculation-adsorption reagent comprises a magnetic compound flocculant and a modified chitosan-zeolite adsorbent; the magnetic compound flocculant is prepared from polyferric sulfate, polyacrylamide and magnetic powder; and the modified chitosan-zeolite adsorbent is formed by compounding protonated chitosan and zeolite. The flocculation-adsorption reagent is used for treating the black and odorous water, turbidity, ammonia nitrogen and TP in the black and odorous water can be efficiently removed at the same time, the turbidity and TP removal rate can reach the surface water environment quality IV standard, the ammonia nitrogen removal rate reaches the V standard, the flocculation sedimentation time is short, the dosing dosage is small, and the magnetic powder can be recycled. The flocculation-adsorption reagent is wide in raw material source, natural and non-toxic, and the preparation process is simple to operate, low in cost and suitable for industrial large-scale production.

Owner:XIANGTAN UNIV

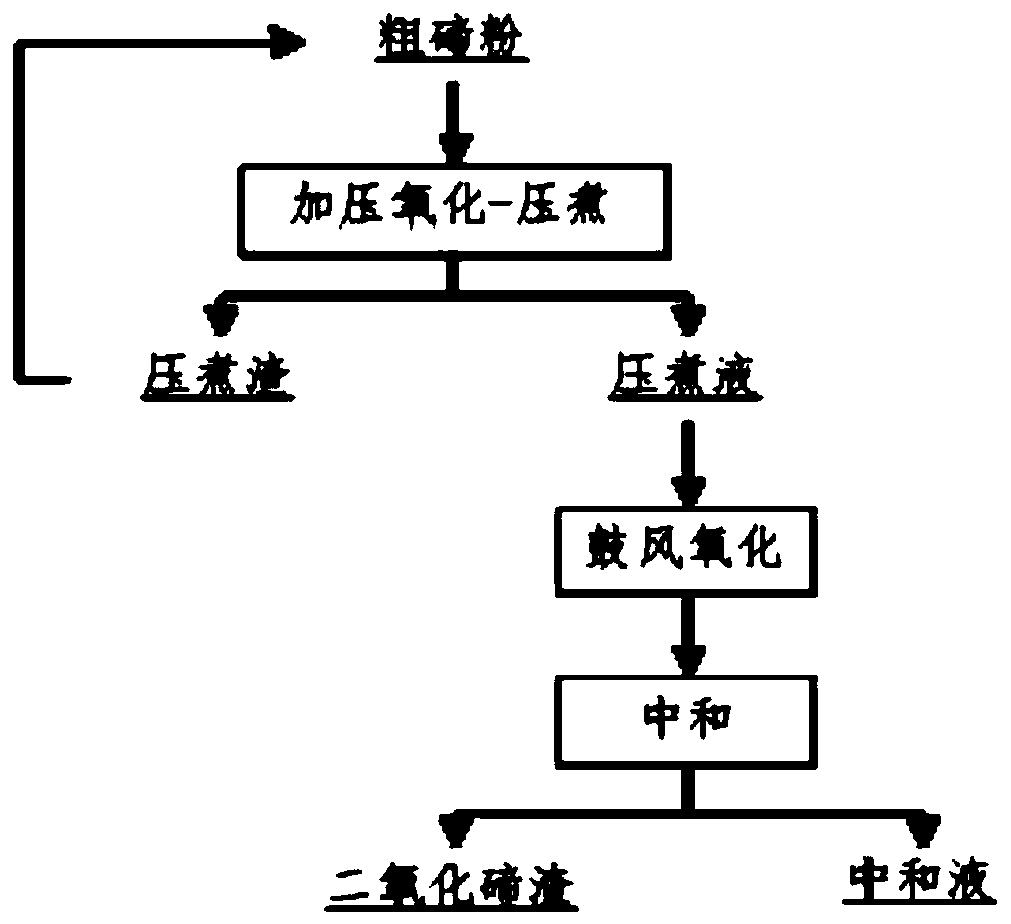

Method for producing tellurium dioxide by self-purification of crude tellurium powder

ActiveCN111268655ARealize self-purificationReduce contentProcess efficiency improvementSelenium/tellurium oxides/hydroxidesSlagNonferrous metal

The invention belongs to the technical field of nonferrous metallurgy. The invention relates to tellurium dioxide, in particular to a method for producing high-quality tellurium dioxide through self-purification of crude tellurium powder. The method comprises the following steps: carrying out pressurized oxidation-pressure boiling treatment on a material containing crude tellurium powder by utilizing a reaction container; after the reaction is finished, filtering a reaction product to obtain autoclaved liquid, and carrying out oxidation neutralization on the autoclaved liquid for selenium removal, thus preparing high-quality tellurium dioxide residue serving as a raw material for following production of 4N tellurium; according to the method, self-purification of impurities in the crude tellurium powder is achieved through oxidation neutralization after pressurized oxidation-pressure boiling treatment, the content of impurity elements in the produced tellurium dioxide can be remarkablyreduced, the quality of the tellurium dioxide is improved, and the subsequent refined tellurium production technological process is shortened. The method is short in process and low in cost, the effect of improving the quality of tellurium dioxide produced by taking crude tellurium powder as a raw material is obvious, and the obtained tellurium dioxide slag contains more than or equal to 70% of tellurium, less than 0.02% of arsenic, less than or equal to 0.01% of copper, less than or equal to 0.01% of selenium, less than 0.01% of lead and less than 0.03% of tin.

Owner:JIANGXI COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com