Method for auxiliary preparation of biomass-based functional active carbon material by using concentrated seawater and application thereof

A technology of biomass materials and concentrated seawater, which is applied in the direction of chemical instruments and methods, carbon compounds, and other chemical processes, and can solve problems such as difficult seawater treatment and expensive activators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

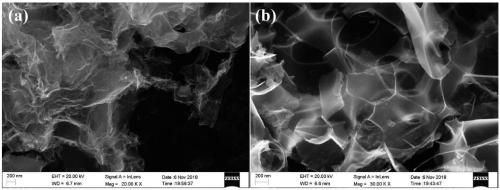

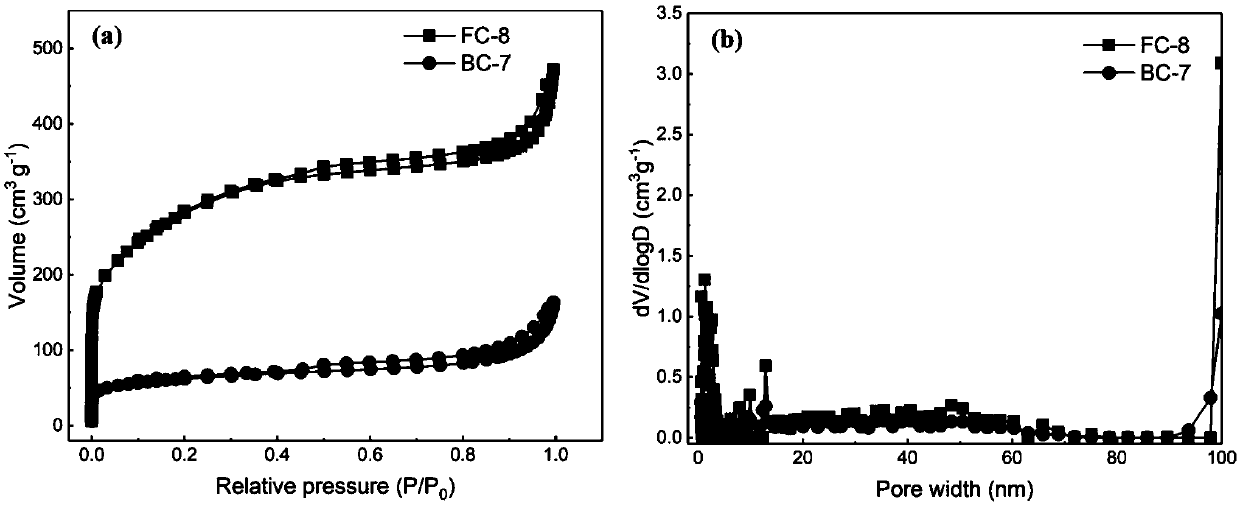

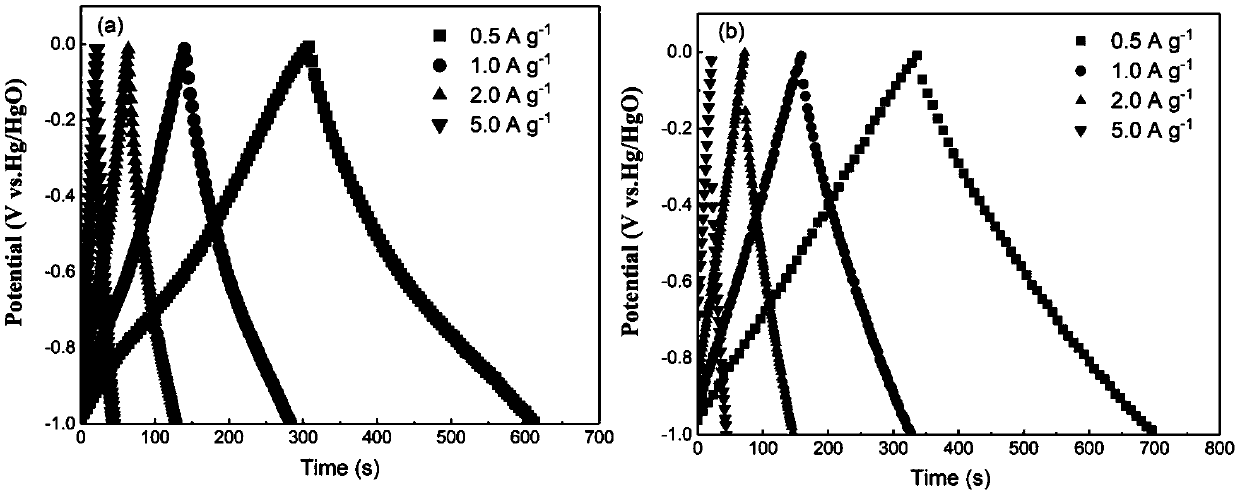

Image

Examples

Embodiment 1

[0061] A method of using concentrated seawater to assist in the preparation of biomass-based functional activated carbon materials in this embodiment specifically includes the following steps:

[0062] (1) Put the sycamore bark washed with distilled water several times in an oven at 60° C. to dry for 12 hours, and then use a ball mill at 350 rpm for 2 hours to be used for later use.

[0063] (2) Proportioning 100mL of 8 times concentrated seawater: add NaCl: 21.0g; MgCl 2 : 2.2g; MgSO 4 : 2.54g; CaCl 2 : 0.942g; KCl: 0.612g; NaHCO 3 : 0.159g; NaBr: 0.071g, then dilute to 100mL.

[0064] (3) Get 10g of the sycamore bark after ball milling in step (1) and 8 times concentrated seawater of step (2) 100mL to mix and stir overnight; add liquid nitrogen quickly after stirring, and place in a freeze dryer for freeze-drying for 48h; freeze The dried sample was placed in a tube furnace and heated up to 700°C at 4°C / min under an argon atmosphere of 100mL / min, kept at 700°C for 2 hour...

Embodiment 2

[0069] A method of using concentrated seawater to assist in the preparation of biomass-based functional activated carbon materials in this embodiment specifically includes the following steps:

[0070] (1) Prepare 100mL of 8-fold concentrated seawater: add NaCl: 21.7g; MgCl 2 : 2g; MgSO 4 : 2.72g; CaCl 2 : 0.936g; KCl: 0.592g; NaHCO 3 : 0.168g; NaBr: 0.064g, then dilute to 100mL.

[0071](2) Mix 5 g of fish scales with 50 mL of 8-fold concentrated seawater prepared in step (1) and stir overnight. After the stirring is completed, quickly place it in a hydrothermal reaction kettle and keep it warm at 160° C. for 12 hours. Add liquid nitrogen to the obtained filtrate, place it in a freeze dryer and dry it for 24 hours; place the freeze-dried sample in a tube furnace and raise the temperature to 800°C at a rate of 5°C / min under an argon atmosphere of 100mL / min. Keep the temperature at 800°C for 2 hours, then cool down to room temperature naturally to obtain the carbonized prod...

Embodiment 3

[0076] A method of using concentrated seawater to assist in the preparation of biomass-based functional activated carbon materials in this embodiment specifically includes the following steps:

[0077] (1) Prepare 100mL of 8-fold concentrated seawater: add NaCl: 21.2g; MgCl 2 : 2.1g; MgSO 4 : 2.54g; CaCl 2 : 0.925g; KCl: 0.61g; NaHCO 3 : 0.172g; NaBr: 0.071g, then dilute to 100mL.

[0078] (2) Mix 3 g of tofu with 50 mL of 8-times concentrated seawater prepared in step (1) and stir overnight, and then quickly place it in a hydrothermal reaction kettle for 14 hours at 120° C. after stirring. Add liquid nitrogen to the obtained filtrate and place it in a freeze dryer to dry for 24 hours; place the freeze-dried sample in a tube furnace, raise the temperature to 900°C at 2°C / min under a nitrogen atmosphere of 100mL / min, and keep it at 900°C for 4 hours , and then naturally lowered to room temperature to obtain carbonized products. The obtained carbonized product was filtered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com