Method of treating aniline waste water through photo-catalytic oxidation

A photocatalytic oxidation and catalytic oxidation technology, which is applied in the treatment of aniline wastewater and the field of photocatalytic oxidation treatment of aniline wastewater, can solve the problems of complex process route, difficult recycling and reuse, long process route, etc., and achieve economical and efficient treatment process. , does not produce secondary pollution, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

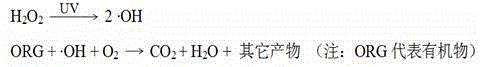

Method used

Image

Examples

Embodiment 1

[0015] (1) Photocatalytic oxidation reaction device

[0016] The device consists of two parts, the reaction pool and the ultraviolet light source. The size and volume of the reaction pool depends on the specific working conditions. The ultraviolet light source is provided by an ultraviolet lamp, and the wavelength of ultraviolet light emitted by it is 254~400nm, and the power can be arbitrarily selected within the range of 36W~320W. The ultraviolet lamp is connected with a voltage stabilizer, a ballast and a switch to ensure the stability of the light intensity. The lamp is covered with a quartz tube, and the quartz tube is fixed on the cover plate of the reaction pool. The number of ultraviolet lamps can be determined according to the volume of the reaction pool and specific working conditions.

[0017] (2) Treatment of aniline wastewater

[0018] Aniline wastewater: Aniline wastewater from a refinery, the concentration of aniline in the raw water is 10mg / L, the concentrat...

Embodiment 2

[0020] (1) Photocatalytic oxidation reaction device: same as Example 1;

[0021] (2) Treatment of aniline wastewater

[0022] Aniline wastewater: Aniline wastewater from a dye factory, the raw water aniline concentration is 20mg / L, the COD concentration is about 1570mg / L, and the chroma is about 10570 times. Pump the aniline wastewater into the reaction tank, according to H 2 o 2 Dosing H with aniline wastewater at a volume ratio of 1:100 2 o 2 , plus nitric acid to adjust the pH value of the wastewater to 3.0~4.0, and control the water temperature to normal temperature. Select an ultraviolet lamp with a power of 55W, turn on the power, turn on the ultraviolet lamp to start the photocatalytic oxidation reaction, and the reaction is completed after about 150 minutes. Sampling to determine the content of main pollutants such as aniline and nitrobenzene in water and the chromaticity of water. The aniline concentration of the final effluent is reduced to 0.56mg / L, the COD co...

Embodiment 3

[0024] (1) Photocatalytic oxidation reaction device: same as Example 1;

[0025] (2) Treatment of aniline wastewater

[0026] Aniline wastewater: Aniline wastewater from a chemical company, the concentration of aniline in the raw water is 40mg / L, the concentration of COD is about 1800mg / L, and the chroma is about 20200 times. Pump the aniline wastewater into the reaction tank, according to H 2 o 2 Dosing H with aniline wastewater at a volume ratio of 1:500 2 o 2 , plus nitric acid to adjust the pH value of the wastewater to 3.0~4.0, and control the water temperature to normal temperature. Select an ultraviolet lamp with a power of 55W, turn on the power, turn on the ultraviolet lamp to start the photocatalytic oxidation reaction, and the reaction is completed after about 180 minutes. Sampling to determine the content of main pollutants such as aniline and nitrobenzene in water and the chromaticity of water. The aniline concentration of the final effluent is reduced to 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com